A B2B Buyer’s Guide to Metal Metallic Fidget Spinner: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for metal metallic fidget spinner

In an increasingly competitive global marketplace, sourcing high-quality metal metallic fidget spinners presents unique challenges for B2B buyers. As the demand for these innovative stress-relief tools rises, especially among diverse demographics across Africa, South America, the Middle East, and Europe, understanding the nuances of this market becomes essential. This guide offers a comprehensive exploration of the metal metallic fidget spinner landscape, covering various types, applications, supplier vetting processes, and cost considerations.

Navigating the complexities of this market requires more than just product knowledge; it demands a strategic approach to sourcing. Buyers must consider factors such as quality standards, supplier reliability, and market trends to make informed decisions that align with their business goals. This guide is designed to empower international B2B buyers by providing actionable insights that streamline the purchasing process. Whether you’re looking to enhance your product offerings in Nigeria or Germany, this resource equips you with the tools to identify reputable suppliers, evaluate product quality, and understand pricing structures.

By leveraging the information within this guide, you can navigate the global market for metal metallic fidget spinners with confidence, ensuring that your business remains competitive while meeting the evolving needs of your customers.

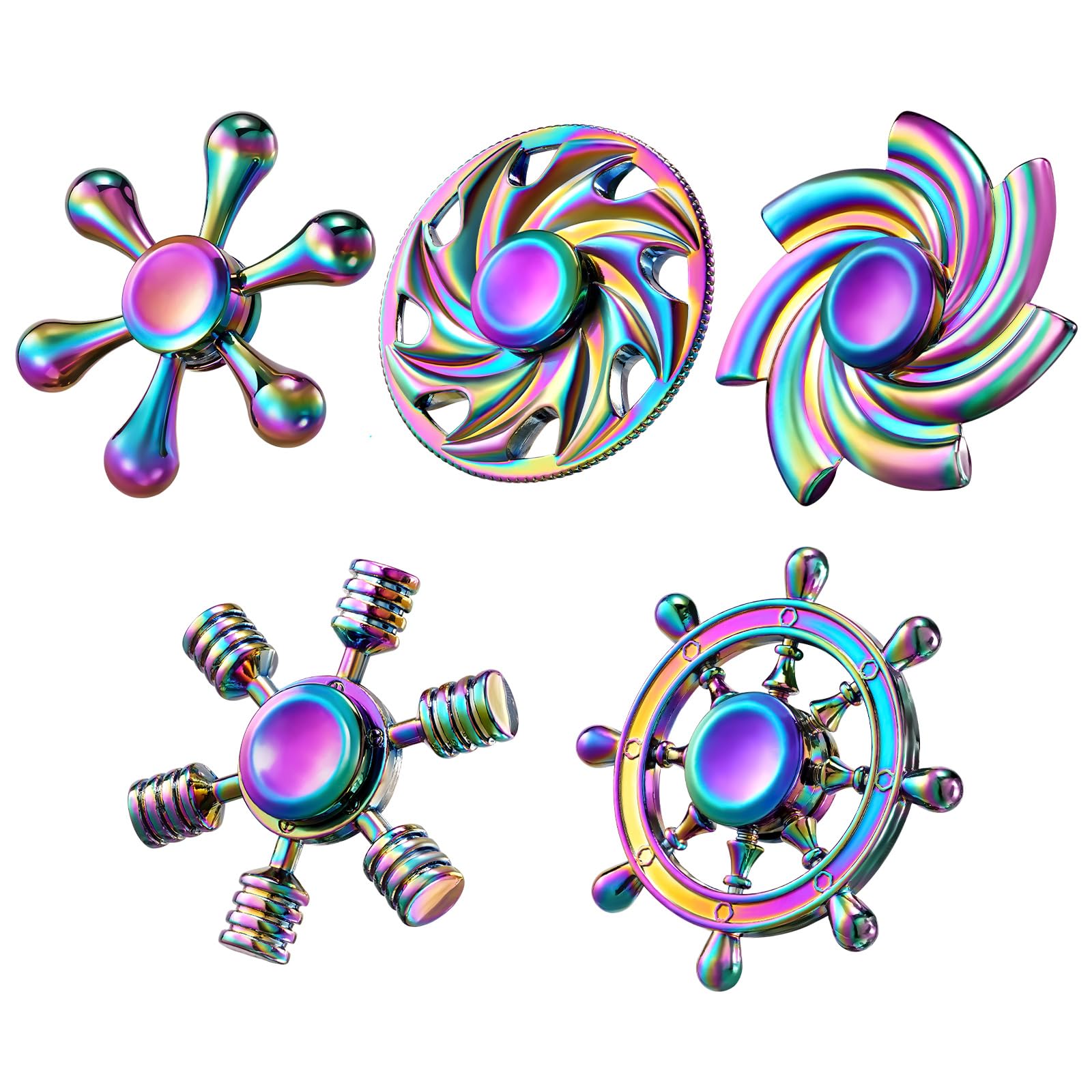

Understanding metal metallic fidget spinner Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Metal Spinner | Made from stainless steel or aluminum; smooth spinning | Retail, promotional products | Pros: Durable, affordable; Cons: Basic design may not appeal to all. |

| Premium Weighted Spinner | Heavier materials like brass or titanium; enhanced stability | Gifts, corporate branding | Pros: High-quality feel, better spin time; Cons: Higher price point. |

| Customizable Spinner | Options for engraving or unique colors; bespoke designs | Corporate gifts, events | Pros: Personalized touch, brand visibility; Cons: Longer lead times for production. |

| Multi-functional Spinner | Incorporates additional features (e.g., bottle opener) | Novelty items, promotional giveaways | Pros: Versatile, attracts diverse buyers; Cons: Potentially higher complexity in manufacturing. |

| Artistic Design Spinner | Unique shapes and artistic finishes; collectible appeal | Specialty retail, art-focused markets | Pros: Eye-catching, appeals to collectors; Cons: May not appeal to all demographics. |

What Are the Key Characteristics of Standard Metal Spinners?

Standard metal fidget spinners are typically crafted from stainless steel or aluminum, known for their durability and smooth spinning capabilities. These spinners are ideal for basic retail environments and promotional products due to their affordability. B2B buyers should consider the balance between cost and quality, as while they are economical, their simplistic design may not attract all customer segments.

Why Choose Premium Weighted Spinners for Corporate Branding?

Premium weighted spinners utilize heavier materials such as brass or titanium, providing enhanced stability and spin duration. They are particularly suitable for corporate branding and gifting, creating an impression of quality and sophistication. B2B buyers should weigh the benefits of investing in higher-priced items against the potential for improved customer satisfaction and brand loyalty.

How Do Customizable Spinners Enhance Brand Visibility?

Customizable spinners offer businesses the opportunity to engrave logos or select unique colors, making them ideal for corporate gifts and events. This personalization fosters brand visibility and a connection with clients. However, B2B buyers should be prepared for longer lead times due to the customization process, which may affect inventory management.

Illustrative image related to metal metallic fidget spinner

What Are the Advantages of Multi-functional Spinners?

Multi-functional spinners incorporate additional features, such as bottle openers, making them versatile promotional items. Their novelty appeal can attract a diverse range of buyers, particularly for giveaways and events. B2B buyers should consider the complexity of manufacturing these items, as it may lead to increased costs and production times.

Why Invest in Artistic Design Spinners for Specialty Markets?

Artistic design spinners feature unique shapes and finishes, appealing to collectors and art enthusiasts. They are well-suited for specialty retail environments where aesthetic appeal is paramount. B2B buyers must assess the potential market demand, as while these items can command higher prices, they may not resonate with all customer demographics.

Key Industrial Applications of metal metallic fidget spinner

| Industry/Sector | Specific Application of metal metallic fidget spinner | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Classroom stress relief tools | Enhances focus and reduces anxiety for students | Look for durable designs that can withstand frequent use; consider bulk purchasing for cost efficiency. |

| Mental Health Services | Therapeutic tools for stress management | Provides a calming effect for clients during therapy | Ensure compliance with health regulations; prioritize non-toxic materials and ergonomic designs. |

| Corporate Offices | Employee wellness initiatives | Promotes relaxation and mental clarity in the workplace | Source from reputable manufacturers; consider customization options for branding. |

| Retail and E-commerce | Novelty items for consumer engagement | Attracts customers seeking stress-relief solutions | Focus on trendy designs and colors; assess shipping logistics for international distribution. |

| Event Planning | Fidget spinners as promotional giveaways | Enhances brand visibility and creates a memorable experience | Evaluate cost per unit and potential for bulk discounts; ensure timely delivery for event dates. |

How Are Metal Metallic Fidget Spinners Utilized in Education?

In educational environments, metal metallic fidget spinners serve as effective tools for stress relief among students. They assist in enhancing focus, particularly for those with attention difficulties or anxiety. By providing an outlet for repetitive motion, these spinners can help students manage their stress and improve concentration during lessons. For B2B buyers in education, it is crucial to consider the durability of the spinners, as they will be subjected to frequent use. Bulk purchasing options can also lead to significant cost savings.

What Role Do Metal Metallic Fidget Spinners Play in Mental Health Services?

Within mental health services, metal metallic fidget spinners are used as therapeutic tools to aid clients in managing anxiety and stress. These spinners provide a tactile focus that can help ground individuals during therapy sessions. Buyers in this sector should prioritize sourcing spinners made from non-toxic materials to ensure safety for all clients. Additionally, ergonomic designs are essential for comfort during extended use, making it vital to assess product specifications closely.

How Can Corporate Offices Benefit from Metal Metallic Fidget Spinners?

In corporate settings, metal metallic fidget spinners are increasingly integrated into employee wellness programs. They promote relaxation and mental clarity, helping to alleviate workplace stress. Businesses looking to incorporate these spinners should focus on sourcing options that allow for customization, such as branding with company logos. This not only enhances the spinners’ appeal but also serves as a unique marketing tool. Reliable suppliers are essential to ensure consistent quality and timely delivery.

Why Are Metal Metallic Fidget Spinners Popular in Retail and E-commerce?

In the retail and e-commerce sectors, metal metallic fidget spinners are marketed as novelty items that cater to consumers seeking stress-relief solutions. Their popularity stems from their aesthetic appeal and the growing trend of fidget toys. Retailers should focus on sourcing trendy designs and vibrant colors to attract customers effectively. Additionally, understanding the logistics of international shipping is crucial for reaching markets in Africa, South America, and Europe, ensuring that products can be delivered efficiently.

How Are Metal Metallic Fidget Spinners Used as Promotional Items in Event Planning?

Metal metallic fidget spinners can be effectively utilized as promotional giveaways in event planning. They not only enhance brand visibility but also create memorable experiences for attendees. When sourcing these spinners for events, it is important to evaluate the cost per unit and explore potential discounts for bulk orders. Timely delivery is also critical to ensure that the items are available for distribution on the event day, making it essential to partner with reliable suppliers.

3 Common User Pain Points for ‘metal metallic fidget spinner’ & Their Solutions

Scenario 1: Sourcing Quality Metal Fidget Spinners for Diverse Markets

The Problem: B2B buyers often face significant challenges when sourcing high-quality metal fidget spinners that meet the diverse needs of their target markets. In regions like Africa and South America, buyers may struggle with limited access to reliable suppliers who offer products that not only comply with local regulations but also cater to cultural preferences. Furthermore, the inconsistency in product quality can lead to increased returns, customer dissatisfaction, and ultimately, a negative impact on brand reputation.

Illustrative image related to metal metallic fidget spinner

The Solution: To overcome these sourcing challenges, B2B buyers should conduct thorough market research to identify reputable manufacturers and suppliers. Utilize platforms such as Alibaba or Global Sources to vet suppliers, focusing on their production capabilities, quality certifications, and customer reviews. Request samples before placing bulk orders to ensure the product’s quality aligns with your standards. Additionally, consider establishing partnerships with local distributors who understand the cultural nuances of your target market, which can enhance the product’s appeal and ensure a smoother distribution process.

Scenario 2: Addressing Safety and Compliance Concerns with Metal Fidget Spinners

The Problem: Safety and compliance are paramount concerns for B2B buyers, particularly when dealing with products designed for children or individuals with sensory processing disorders. Metal fidget spinners can pose risks if they do not adhere to safety standards, potentially leading to injuries or legal repercussions. Buyers must navigate complex regulations that vary by region, making it crucial to ensure that their products meet all necessary safety requirements.

The Solution: To mitigate these risks, B2B buyers should prioritize sourcing metal fidget spinners that come with comprehensive safety certifications, such as EN71 (European Toy Safety) or ASTM F963 (US Toy Safety). When negotiating with suppliers, insist on transparency regarding materials used and the manufacturing process. Implement a rigorous quality assurance program that includes testing products for sharp edges, toxic materials, and durability to ensure they meet safety standards. Collaborating with compliance consultants can also provide valuable insights into navigating regional regulations, ensuring that your product line is safe and compliant.

Scenario 3: Managing Inventory and Seasonal Demand for Fidget Spinners

The Problem: Many B2B buyers encounter difficulties managing inventory levels of metal fidget spinners, especially during peak seasons such as back-to-school or holiday periods. Fluctuating demand can lead to overstocking or stockouts, both of which can severely impact cash flow and profitability. Additionally, buyers may struggle to predict trends, especially in diverse markets where consumer preferences can shift rapidly.

The Solution: To effectively manage inventory, B2B buyers should implement a robust demand forecasting system that analyzes historical sales data, market trends, and seasonality. Utilize inventory management software to automate tracking and reorder processes, ensuring optimal stock levels are maintained. Establish flexible agreements with suppliers that allow for smaller, more frequent shipments, reducing the risk of overstock. Engaging in collaborative planning with key customers can also enhance visibility into future demand, enabling more accurate inventory management and minimizing financial risk.

Strategic Material Selection Guide for metal metallic fidget spinner

What Are the Key Materials for Metal Metallic Fidget Spinners?

When selecting materials for metal metallic fidget spinners, several options stand out due to their unique properties and performance characteristics. Understanding these materials can help B2B buyers make informed decisions that align with their product specifications and market demands.

How Does Stainless Steel Perform in Fidget Spinner Applications?

Stainless steel is a popular choice for fidget spinners due to its excellent mechanical properties and aesthetic appeal. It boasts high corrosion resistance, making it suitable for various environments, including humid or saline conditions. The temperature rating for stainless steel can reach up to 870°C, ensuring durability under heat.

Pros: Stainless steel’s high durability and resistance to wear make it ideal for long-term use. Additionally, it offers a premium look and feel, appealing to consumers who prioritize quality.

Cons: The manufacturing process can be complex and costly, especially for intricate designs. Furthermore, stainless steel spinners may be heavier, which could affect the spinning experience.

Impact on Application: Stainless steel is compatible with a wide range of media, including water and oil, making it versatile for different user environments.

Illustrative image related to metal metallic fidget spinner

Considerations for International Buyers: Buyers from regions like Germany and Nigeria should ensure compliance with ASTM and DIN standards, which govern the quality of stainless steel products. The availability of high-grade stainless steel may vary by region, impacting sourcing decisions.

What Advantages Does Aluminum Offer for Fidget Spinners?

Aluminum is another common material used in the production of fidget spinners. It is lightweight, which enhances the spinning experience, and it can be anodized for improved surface durability and aesthetic variety.

Pros: The lightweight nature of aluminum allows for a more agile spinner, appealing to users who prefer a fast, responsive experience. Its cost-effectiveness makes it an attractive option for mass production.

Cons: While aluminum is resistant to corrosion, it is less durable than stainless steel and can dent or scratch more easily. This could affect the longevity of the product.

Impact on Application: Aluminum spinners are suitable for indoor use and casual environments but may not perform as well in harsh conditions.

Illustrative image related to metal metallic fidget spinner

Considerations for International Buyers: Buyers should consider the anodizing process, which can vary in quality. Compliance with local regulations regarding aluminum alloys is also crucial, particularly in markets like South America.

How Does Brass Compare as a Material Choice for Fidget Spinners?

Brass is often chosen for its unique aesthetic and weight. It offers a distinct look with a warm, golden hue, appealing to consumers looking for something different.

Pros: Brass is highly durable and resistant to corrosion, providing a good balance of weight and performance. Its density contributes to a satisfying spinning experience.

Cons: The cost of brass can be higher than aluminum and stainless steel, which may affect pricing strategies for B2B buyers. Additionally, brass can tarnish over time, requiring maintenance to keep it looking new.

Illustrative image related to metal metallic fidget spinner

Impact on Application: Brass is compatible with various media but may not be suitable for environments with high moisture or corrosive elements.

Considerations for International Buyers: Compliance with JIS standards is essential for brass products, particularly in regions like the Middle East. Buyers should also consider the availability of brass alloys in their local markets.

What Role Does Titanium Play in Fidget Spinner Manufacturing?

Titanium is increasingly being used in high-end fidget spinners due to its exceptional strength-to-weight ratio and corrosion resistance. It can withstand extreme temperatures and is highly durable.

Pros: Titanium spinners are lightweight yet incredibly strong, making them ideal for high-performance applications. They also have a unique aesthetic, appealing to niche markets.

Cons: The primary drawback is the cost; titanium is significantly more expensive than other materials, which may limit its appeal for mass-market products.

Impact on Application: Titanium is highly compatible with various environments, including extreme conditions, making it suitable for specialized applications.

Considerations for International Buyers: Buyers should be aware of the stringent manufacturing standards associated with titanium, including compliance with ASTM standards. The availability of titanium products may vary by region, particularly in Africa.

Summary Table of Material Selection

| Material | Typical Use Case for metal metallic fidget spinner | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-end, durable spinners | Excellent durability and corrosion resistance | Higher manufacturing complexity and cost | High |

| Aluminum | Lightweight, mass-produced spinners | Lightweight and cost-effective | Less durable, prone to scratches | Medium |

| Brass | Aesthetic, premium spinners | Unique look and good durability | Higher cost and potential tarnishing | Medium to High |

| Titanium | High-performance, niche market spinners | Exceptional strength-to-weight ratio | Very high cost | High |

This guide provides a comprehensive overview of material options for metal metallic fidget spinners, equipping B2B buyers with the insights needed to make strategic sourcing decisions.

Illustrative image related to metal metallic fidget spinner

In-depth Look: Manufacturing Processes and Quality Assurance for metal metallic fidget spinner

What Are the Main Stages of Manufacturing Metal Fidget Spinners?

The manufacturing process for metal fidget spinners typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the final product meets quality standards and customer expectations.

-

Material Preparation: The process begins with selecting high-quality metals, commonly aluminum, brass, or stainless steel, chosen for their durability and weight properties. The raw materials are sourced from reputable suppliers, and their specifications are verified to ensure they meet required standards. This may include checking for tensile strength, corrosion resistance, and finish quality.

-

Forming: The next stage involves shaping the metal into the desired design. Techniques such as CNC machining, die-casting, or metal stamping are commonly used. CNC machining offers precision and allows for complex designs, while die-casting is efficient for mass production of simple shapes. The choice of technique depends on the design complexity and production volume.

-

Assembly: After forming, individual components like the spinner arms and central bearing are assembled. This stage may involve manual labor or automated systems, depending on the scale of production. Attention is paid to the alignment and fit of parts to ensure smooth spinning motion.

-

Finishing: The final stage includes surface treatments such as polishing, anodizing, or powder coating. These processes enhance the aesthetic appeal and provide additional protection against wear and corrosion. Quality checks are conducted at various points to ensure consistency in finish and functionality.

How Is Quality Assurance Implemented in Metal Fidget Spinner Production?

Quality assurance (QA) is integral to the manufacturing process, ensuring that every fidget spinner meets international standards and customer expectations.

-

International Standards: Compliance with international standards such as ISO 9001 is essential for establishing a robust quality management system. ISO 9001 certification demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific standards like CE marking for safety and performance may apply, particularly when exporting to European markets.

-

Quality Checkpoints: Various checkpoints are established throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified criteria before processing.

– In-Process Quality Control (IPQC): Quality checks during production help identify and rectify issues early. This may include measurements of dimensions, weight, and spin quality.

– Final Quality Control (FQC): After assembly, the final product undergoes rigorous testing to verify functionality, balance, and aesthetic quality. -

Common Testing Methods: Testing methods may include:

– Spin Duration Tests: Measuring how long the spinner continues to spin under specified conditions.

– Load Testing: Assessing how much weight the spinner can handle without deforming.

– Durability Testing: Simulating prolonged use to evaluate performance over time.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

B2B buyers must take proactive steps to ensure that their suppliers maintain high-quality standards. Here are several actionable strategies:

-

Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality control measures, and compliance with relevant standards. This can include on-site visits to observe operations firsthand.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC reports. These documents should detail the methods used, results obtained, and any corrective actions taken for non-conformities.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can occur at various stages, from raw material sourcing to final product delivery.

-

Certifications Verification: Verify that suppliers hold relevant certifications such as ISO 9001, CE, or other industry-specific qualifications. Request copies of these certifications and check their validity through official channels.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, understanding regional quality control nuances is vital.

Illustrative image related to metal metallic fidget spinner

-

Cultural Considerations: Different regions may have varying expectations regarding quality and compliance. Buyers should be familiar with local regulations and standards that may impact product acceptance.

-

Logistical Challenges: International shipping may introduce additional quality risks. Buyers should ensure that suppliers have robust packaging and handling processes to minimize damage during transit.

-

Communication Barriers: Clear communication is essential to address quality concerns promptly. Buyers should establish reliable channels for discussing quality issues and expectations with suppliers.

-

Market-Specific Regulations: For example, European markets may have stricter safety and environmental regulations compared to other regions. Understanding these market-specific requirements can help buyers avoid compliance issues.

Conclusion

The manufacturing and quality assurance processes for metal fidget spinners are complex and require meticulous attention to detail at every stage. By understanding these processes and implementing robust verification strategies, B2B buyers can ensure that they partner with reliable suppliers who deliver high-quality products that meet international standards. This proactive approach not only safeguards investments but also enhances customer satisfaction and brand reputation in competitive markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal metallic fidget spinner’

In the competitive world of B2B procurement, sourcing high-quality metal metallic fidget spinners requires a systematic approach to ensure you partner with the right suppliers and products. This guide serves as a step-by-step checklist to streamline your sourcing process, enabling you to make informed decisions that align with your business needs.

Step 1: Identify Your Market Demand

Understanding your target market is crucial. Analyze trends in fidget spinner popularity across regions like Africa, South America, the Middle East, and Europe. Consider factors such as age demographics, customer preferences, and purchasing power to tailor your offerings effectively.

Illustrative image related to metal metallic fidget spinner

Step 2: Define Your Technical Specifications

Clearly outline the specifications for the metallic fidget spinners you wish to source. This includes:

– Materials: Determine if you prefer stainless steel, brass, or other metals.

– Design Features: Specify size, weight, and any unique design elements that appeal to your audience.

Having precise specifications helps in communicating your needs to suppliers and ensures that the products meet your quality standards.

Step 3: Conduct Supplier Research

Thoroughly investigate potential suppliers before making any commitments. Look for:

– Company Credentials: Verify their business registration, certifications, and years of experience.

– Product Range: Ensure they offer a variety of designs and materials to meet your specifications.

Using reputable sources and directories can assist in finding established suppliers with a proven track record.

Step 4: Request Samples

Before placing a bulk order, always request samples of the fidget spinners. This allows you to:

– Assess Quality: Evaluate the craftsmanship, weight, and spinning performance.

– Check Compliance: Ensure the product meets any regional safety standards or regulations.

Samples provide tangible proof of what you can expect, helping to avoid costly mistakes down the line.

Step 5: Verify Pricing and Terms

Engage in discussions about pricing structures and payment terms with shortlisted suppliers. Pay attention to:

– Bulk Pricing: Inquire about discounts for larger orders.

– Shipping Costs: Understand how shipping fees will impact your overall budget.

Establishing clear pricing and terms upfront prevents misunderstandings and can enhance your profit margins.

Step 6: Evaluate Supplier Reliability

Assess the reliability of suppliers by checking:

– Customer Reviews: Look for testimonials or case studies from other B2B clients.

– Delivery Times: Ensure they can meet your timelines for order fulfillment.

Reliable suppliers not only provide quality products but also maintain communication and fulfill commitments, which is essential for a smooth supply chain.

Illustrative image related to metal metallic fidget spinner

Step 7: Establish a Long-Term Relationship

Once you’ve selected a supplier, focus on building a lasting partnership. Consider:

– Regular Communication: Stay in touch to discuss future orders or product improvements.

– Feedback Mechanism: Provide constructive feedback to help them understand your needs better.

A strong supplier relationship can lead to better pricing, priority service, and collaborative opportunities for new products.

By following these steps, you can navigate the sourcing process more effectively and secure high-quality metal metallic fidget spinners that meet the demands of your business and customers.

Comprehensive Cost and Pricing Analysis for metal metallic fidget spinner Sourcing

What Are the Key Cost Components in Sourcing Metal Metallic Fidget Spinners?

When sourcing metal metallic fidget spinners, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of metal significantly impacts costs. Common materials for fidget spinners include stainless steel, aluminum, and brass. Higher-grade metals may offer better durability and aesthetics but will also elevate the cost.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Automated production lines can reduce labor costs but may require a higher initial investment.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient management of these costs can lead to competitive pricing.

-

Tooling: The creation of molds and dies for metal spinners requires upfront investment. This cost can be amortized over larger production runs, making it more manageable for bulk orders.

-

Quality Control (QC): Ensuring that the fidget spinners meet quality standards involves testing and inspection, which adds to the overall cost. Certifications for safety and quality can further influence pricing.

-

Logistics: Shipping costs can vary widely based on distance, mode of transportation, and the final destination. International shipping may also incur tariffs and customs duties.

-

Margin: Suppliers will add a profit margin on top of their total costs, which can vary based on market conditions and competition.

How Do Price Influencers Affect the Cost of Metal Metallic Fidget Spinners?

Several factors can influence pricing when sourcing fidget spinners:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often benefit from lower per-unit costs. Suppliers may have specific MOQs that can affect pricing flexibility.

-

Specifications and Customization: Custom designs or unique features can lead to higher costs. Buyers should evaluate whether the added value justifies the increased price.

-

Material Quality and Certifications: Higher quality materials and certifications will typically drive up costs. For markets that prioritize safety, such as in Europe, these factors can be critical.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers may command higher prices due to their track record of quality and service.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) is essential for calculating total costs. Incoterms dictate who is responsible for shipping costs and risks, which can significantly affect the final price.

What Tips Should Buyers Consider for Cost-Efficiency in Sourcing?

To maximize cost-efficiency when sourcing metal metallic fidget spinners, consider the following strategies:

-

Negotiate Terms: Always engage in negotiations to secure better pricing, especially for larger orders. Suppliers may have room for discounts based on volume.

-

Analyze Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider long-term factors such as durability, maintenance, and potential shipping costs to assess the overall value.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to local labor costs, material availability, and regulations. For instance, buyers in Africa may face higher logistics costs due to infrastructure challenges.

-

Research Supplier Reliability: Before committing, verify the supplier’s reliability through references or reviews. A lower price from an unreliable supplier can lead to increased costs due to delays or quality issues.

Disclaimer on Indicative Prices

Prices for metal metallic fidget spinners can vary widely based on the aforementioned factors. The prices observed in the market range from approximately $7 to $265, depending on materials, complexity, and supplier reputation. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing metal metallic fidget spinner With Other Solutions

Exploring Alternative Solutions to Metal Metallic Fidget Spinners

In the growing market for stress-relief and focus-enhancing products, metal metallic fidget spinners have gained considerable attention. However, several alternative solutions exist that also aim to alleviate stress and improve concentration. This section evaluates the metal metallic fidget spinner against other viable options, helping B2B buyers make informed decisions based on performance, cost, and application.

Comparison Table

| Comparison Aspect | Metal Metallic Fidget Spinner | Fidget Cube | Haptic Coin |

|---|---|---|---|

| Performance | High spin time and durability | Multi-functional, tactile feedback | Compact, engaging haptic response |

| Cost | Moderate ($15 – $60) | Low to Moderate ($10 – $30) | Moderate to High ($20 – $100) |

| Ease of Implementation | Ready-to-use | Simple design, intuitive use | Requires familiarization |

| Maintenance | Minimal (cleaning required) | Minimal (cleaning required) | Low (occasional care needed) |

| Best Use Case | Ideal for prolonged focus sessions | Suitable for quick stress relief | Great for tactile stimulation and anxiety management |

Detailed Breakdown of Alternatives

Fidget Cube

The fidget cube is a compact, multi-faceted tool designed to provide various tactile experiences. Each side of the cube features a different sensory activity, such as clicking buttons, rolling a ball, or gliding a switch. Its major advantage lies in its versatility; it caters to different fidgeting preferences and can be used discreetly in professional settings. However, the potential downside is that it might not deliver the same satisfying spinning experience as a metallic fidget spinner, which could limit its appeal to some users.

Haptic Coin

The haptic coin is a small, coin-like device that provides various tactile sensations through its design and mechanics. It is designed for users who enjoy engaging with their hands in a discreet manner. The primary benefit of haptic coins is their portability and the unique sensory feedback they offer, making them suitable for quick stress relief. However, they may not provide the same level of engagement as a fidget spinner, as the experience is more about tactile interaction than visual stimulation.

Conclusion: How to Choose the Right Fidget Solution

When deciding between a metal metallic fidget spinner and its alternatives, B2B buyers should consider their target market’s preferences and needs. If the focus is on visual stimulation and prolonged use, the metal metallic fidget spinner stands out as a superior choice. However, for businesses aiming to cater to diverse fidgeting styles, incorporating fidget cubes or haptic coins into their product offerings could enhance customer satisfaction. Ultimately, understanding the specific use cases and desired experiences of end-users will guide buyers in selecting the most suitable fidgeting solution for their clientele.

Essential Technical Properties and Trade Terminology for metal metallic fidget spinner

What Are the Key Technical Properties of Metal Metallic Fidget Spinners?

When sourcing metal metallic fidget spinners for B2B purposes, understanding the essential technical properties is crucial. Here are some critical specifications that buyers should consider:

-

Material Grade

Metal fidget spinners are often made from materials like stainless steel, aluminum, or brass. The material grade affects durability, weight, and the spinner’s overall feel. For instance, stainless steel is known for its strength and resistance to rust, making it ideal for long-term use. Buyers should ensure that the material meets industry standards for quality and performance. -

Weight

The weight of a fidget spinner significantly influences its spinning time and stability. Heavier spinners typically offer a longer spin duration, which can enhance the user experience. When negotiating with suppliers, it’s beneficial to specify a preferred weight range to ensure that the product meets your target audience’s preferences. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. For fidget spinners, tighter tolerances in manufacturing can lead to better balance and smoother operation. This specification is vital for ensuring that the products are consistent in quality and performance, which is especially important for bulk orders. -

Finish

The finish of a fidget spinner can include anodized, polished, or powder-coated surfaces. A high-quality finish not only enhances aesthetic appeal but also affects the spinner’s grip and durability. Buyers should specify the desired finish to maintain uniformity across their product line. -

Spin Time

Spin time is a measure of how long a fidget spinner can maintain momentum. This metric is often influenced by material, weight, and bearing quality. Providing detailed specifications on expected spin times can help align supplier capabilities with customer expectations. -

Bearing Quality

The type of bearing used in a fidget spinner directly impacts its performance. Common bearing types include ball bearings and ceramic bearings, each offering different levels of friction and spin efficiency. Choosing high-quality bearings can significantly enhance the user experience, making it an essential consideration for B2B buyers.

What Are Common Trade Terms Used in the Metal Fidget Spinner Industry?

Understanding industry jargon is vital for effective communication with suppliers and partners. Here are some common trade terms relevant to the metal metallic fidget spinner market:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of fidget spinners, buyers might work with OEMs to create custom designs or branding on existing products. This relationship can enhance brand identity and market reach. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of goods that a supplier is willing to sell. Understanding the MOQ is essential for budgeting and inventory management, especially for B2B buyers looking to minimize excess stock while meeting customer demand. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing information for specific products or services. Providing detailed specifications in an RFQ can help ensure accurate quotes and facilitate smoother negotiations. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand total landed costs and manage risk effectively. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for inventory planning and ensuring timely delivery to customers. -

Customs Clearance

This term refers to the process of passing goods through customs so they can enter or leave a country. Buyers should be aware of customs regulations and potential delays, particularly when importing fidget spinners from international suppliers.

Incorporating these technical properties and trade terms into your procurement process will enhance your understanding and effectiveness when dealing with suppliers in the metal metallic fidget spinner market.

Illustrative image related to metal metallic fidget spinner

Navigating Market Dynamics and Sourcing Trends in the metal metallic fidget spinner Sector

What Are the Key Market Trends Affecting Metal Metallic Fidget Spinners?

The global market for metal metallic fidget spinners is experiencing notable growth, driven by increasing awareness of mental health and the demand for stress-relief products. This trend is particularly evident in regions such as Africa, South America, the Middle East, and Europe, where consumers are seeking innovative ways to manage stress and enhance focus. For B2B buyers, understanding the nuances of regional preferences and cultural attitudes towards fidget spinners is crucial. For instance, in countries like Nigeria, the focus may be more on affordability and functionality, while European markets may prioritize design and premium materials.

Emerging sourcing trends highlight the rise of e-commerce platforms and direct-to-consumer models. This shift is prompting manufacturers to enhance their online presence, offering detailed product specifications and customer reviews to facilitate informed purchasing decisions. Additionally, the increasing availability of customizable options allows businesses to cater to specific customer preferences, further expanding market reach. The integration of advanced manufacturing technologies, such as 3D printing, is also reshaping the landscape, enabling quicker prototyping and reduced lead times for B2B buyers.

How Is Sustainability and Ethical Sourcing Influencing the Metal Metallic Fidget Spinner Market?

Sustainability and ethical sourcing are becoming paramount in the metal metallic fidget spinner sector. As consumers become more environmentally conscious, B2B buyers are increasingly seeking suppliers who prioritize eco-friendly practices. The environmental impact of metal extraction and processing cannot be overlooked, making it essential for manufacturers to adopt responsible sourcing methods. This includes utilizing recycled metals and ensuring that extraction processes minimize ecological harm.

Moreover, ethical supply chains are gaining traction, with buyers demanding transparency regarding labor practices and sourcing origins. Certifications such as Fair Trade and ISO 14001 can serve as indicators of a supplier’s commitment to ethical practices. B2B buyers should prioritize partnerships with manufacturers who align with these values, as this not only enhances brand reputation but also meets the growing consumer demand for responsible products. Utilizing ‘green’ materials and processes not only appeals to environmentally conscious buyers but also positions businesses favorably in an increasingly competitive market.

What Is the Brief Evolution of Metal Metallic Fidget Spinners in the Market?

The evolution of metal metallic fidget spinners can be traced back to their initial surge in popularity around 2017, when they became a mainstream toy and stress-relief tool. Initially designed for children and individuals with attention disorders, these devices quickly garnered attention from a broader audience, including adults seeking stress relief in various settings such as offices and schools.

As the market matured, manufacturers began to innovate with materials, leading to the introduction of metal variants that offered enhanced durability and aesthetic appeal. This shift not only improved the product’s performance but also attracted a new demographic of consumers who valued quality and design. Today, metal metallic fidget spinners are available in a variety of styles and finishes, catering to diverse tastes and preferences while continuing to serve their original purpose of providing sensory stimulation and stress relief.

By staying informed about these trends, B2B buyers can make strategic sourcing decisions that align with market demands and consumer preferences, ensuring a competitive edge in the evolving fidget spinner landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of metal metallic fidget spinner

-

1. How do I choose the right supplier for metal metallic fidget spinners?

When selecting a supplier, evaluate their experience in manufacturing fidget spinners and their reputation in the market. Request samples to assess product quality and ensure compliance with safety standards, especially for international markets. Additionally, verify their production capacity and lead times, and seek testimonials or references from previous clients. It’s also crucial to understand their supply chain practices, including sourcing materials and manufacturing processes, to ensure ethical and sustainable operations. -

2. What are the benefits of custom branding for fidget spinners?

Custom branding allows you to differentiate your products in a competitive market. By adding your logo or unique designs, you enhance brand visibility and create a memorable customer experience. Customization can also attract specific demographics, especially if the design aligns with your target audience’s interests. Moreover, branded products often command higher price points, increasing your profit margins. Engaging in custom branding can foster customer loyalty and encourage repeat business. -

3. What are typical minimum order quantities (MOQs) for fidget spinners?

MOQs can vary widely based on the supplier and the complexity of the product. Generally, for metal metallic fidget spinners, you may encounter MOQs ranging from 100 to 1,000 units. Larger orders can often result in better pricing and lower per-unit costs. It’s advisable to discuss your needs with suppliers to negotiate MOQs that align with your business strategy while ensuring they can meet your quality and delivery requirements. -

4. What payment terms should I expect when sourcing internationally?

Payment terms can differ significantly among suppliers. Common practices include upfront deposits (often 30-50%) with the balance due upon delivery or before shipment. Some suppliers may also offer Letter of Credit (LC) options for added security. Always clarify payment methods accepted, such as wire transfers or PayPal, and ensure that all terms are documented in your contract to avoid misunderstandings. It’s also wise to discuss currency fluctuations if dealing in different currencies. -

5. How can I ensure quality assurance (QA) for my fidget spinner orders?

Implementing a robust QA process is essential to ensure product consistency and safety. Request detailed product specifications and quality standards from your supplier. Conduct pre-production samples to assess quality before mass production begins. Consider hiring a third-party inspection service to perform quality checks during production and before shipment. This proactive approach can help identify issues early, reducing the risk of defects and ensuring customer satisfaction upon delivery. -

6. What logistics considerations should I be aware of when importing fidget spinners?

When importing, factor in shipping methods (air vs. sea), costs, and delivery times. Ensure you understand customs regulations in your country, including tariffs and import duties that may apply. Collaborate with a freight forwarder who can navigate logistics complexities and ensure compliance with international shipping laws. It’s also important to have a contingency plan for potential delays, especially during peak seasons or due to unforeseen circumstances. -

7. How do I handle returns and warranties for fidget spinners?

Establish a clear return policy in advance to manage customer expectations. Discuss warranty terms with your supplier, including coverage for manufacturing defects and the process for handling returns. Ensure that your return policy is clearly communicated to customers, including time frames and conditions for returns. Consider offering a satisfaction guarantee to enhance customer trust and encourage purchases, while also protecting your business from excessive returns. -

8. What are the trends in the fidget spinner market that I should be aware of?

Stay informed about emerging trends such as eco-friendly materials, innovative designs, and multifunctional features. The demand for customizable and unique fidget spinners is increasing, as consumers seek products that reflect their personal style. Additionally, fidget spinners are gaining popularity in corporate gifting and promotional merchandise. Keeping an eye on market trends will help you adapt your product offerings and marketing strategies to meet evolving customer preferences.

Top 4 Metal Metallic Fidget Spinner Manufacturers & Suppliers List

1. Etsy – Metal Fidget Spinners

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Metal Fidget Spinners, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. EDC Titan – Fidget Toys

Domain: edctitan.com

Registered: 2024 (1 years)

Introduction: Fidget toys are small handheld devices designed to relieve stress and improve focus through repetitive movements. Examples include fidget spinners and fidget cubes. They are portable, help reduce anxiety, and enhance concentration, making them popular for both kids and adults. Available products include: 1. Mystery Fidget Box – $45.00 2. Bumpy Buddy: Metal Fidget Haptic Slider – Regular price $125…

3. TRB Creation – Premium Metal Fidget Toys

Domain: trb-creation.com

Registered: 2024 (1 years)

Introduction: Metal Fidget Toys from TRB Creation are designed for adults to relieve stress and enhance concentration. They are made with premium materials, ensuring quality and durability. The toys offer a satisfying weight and smooth spinning experience, making them ideal for work, study, or relaxation. The collection includes various types such as Fidget Sliders, Fidget Spinners, Haptic Coins, Fidget Rings, …

4. Bruce Charles Design – Micro Stackable

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for high-quality metal fidget toys with solid weight and smooth mechanisms. Recommendations include: 1. Bruce Charles Design Micro Stackable – praised for its value and smooth feel. 2. Kuko – available on Etsy and has great sliders, currently moving their workshop. 3. Lautie, Muyi, GoBigger – noted as top brands, with Muyi offering multi-purpose toys. 4. MagnusX Sliders – known for quality…

Strategic Sourcing Conclusion and Outlook for metal metallic fidget spinner

The market for metal metallic fidget spinners presents a unique opportunity for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. As consumer demand for stress-relief products continues to rise, businesses that strategically source high-quality fidget spinners can differentiate themselves in a competitive landscape. Key takeaways include the importance of selecting suppliers who prioritize quality materials and innovative designs, which not only enhance the product’s appeal but also ensure customer satisfaction and loyalty.

Incorporating diverse styles and functionalities, such as ergonomic designs and unique aesthetic elements, can significantly boost marketability. Buyers should also consider suppliers that offer flexible shipping options and strong customer service to facilitate seamless transactions across international borders.

Illustrative image related to metal metallic fidget spinner

Looking ahead, the potential for growth in the fidget spinner market remains promising. By investing in strategic sourcing now, international B2B buyers can position themselves favorably to capitalize on emerging trends and consumer preferences. Engage with trusted suppliers to explore tailored solutions that meet your business needs and drive future success in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.