A B2B Buyer’s Guide to Alco Panel: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for alco panel

In an increasingly competitive global market, sourcing the right alco panel for your construction or design projects can be a daunting challenge. With a plethora of options available, international B2B buyers must navigate through varying quality standards, pricing structures, and supplier reliability. This guide serves as your comprehensive resource for understanding the diverse types of alco panels, their applications across multiple industries, and crucial supplier vetting strategies to ensure you make informed purchasing decisions.

We delve into the intricacies of different panel types, from fire-resistant variants to lightweight options ideal for architectural facades. Additionally, the guide outlines essential factors influencing cost, helping you budget effectively while maximizing value. As buyers from Africa, South America, the Middle East, and Europe (including Germany and Brazil) face unique market conditions and regulations, this guide is tailored to empower you with actionable insights and practical knowledge.

By equipping you with the necessary tools and information, we aim to streamline your sourcing process, enabling you to select the most suitable alco panels that align with your project requirements and business objectives. From understanding material specifications to exploring innovative design possibilities, this guide is your key to making strategic decisions in the global alco panel market.

Understanding alco panel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| ALCOPANEL FR | Fire-resistant core, non-toxic gas emission during fire | Exterior cladding, high-rise buildings | Pros: Enhanced safety, compliance with fire regulations. Cons: Higher initial cost compared to standard panels. |

| ALCOEMBO | Lightweight, flame-retardant aluminum triple-layer structure | Industrial applications, transport | Pros: Superior fire resistance, reduced weight. Cons: May require specialized installation techniques. |

| ALCOHIVE | Honeycomb core for lightweight strength, excellent structural integrity | Architecture, signage, furniture | Pros: Durable, aesthetic appeal. Cons: Limited color options compared to other panels. |

| ALCOPANEL A2 | Passed EN 13501-1:2018 Class A2 fire safety standards | High-end commercial projects | Pros: High fire safety rating, versatile applications. Cons: Potentially higher procurement time due to testing certifications. |

| ALCOPANEL SCP | High-strength GI material, lightweight, and high-density polyethylene core | Industrial, modular construction | Pros: Cost-effective, easy to install. Cons: Less aesthetic variety compared to aluminum panels. |

What Are the Characteristics of ALCOPANEL FR?

ALCOPANEL FR features a unique fire-resistant core designed to minimize the risk of fire hazards, making it an ideal choice for high-rise buildings and other structures where safety is paramount. Its non-toxic properties ensure that no harmful gases are released during a fire. When considering ALCOPANEL FR, B2B buyers should evaluate local fire safety regulations and building codes, as compliance can significantly impact project approval and insurance costs.

How Does ALCOEMBO Stand Out in the Market?

ALCOEMBO is known for its lightweight design and exceptional fire resistance, achieved through a specialized aluminum triple-layer structure. This makes it particularly suitable for industrial applications and transport vehicles where weight reduction is crucial. Buyers should assess the specific weight requirements of their projects, as ALCOEMBO can contribute to improved fuel efficiency and overall performance in transport applications.

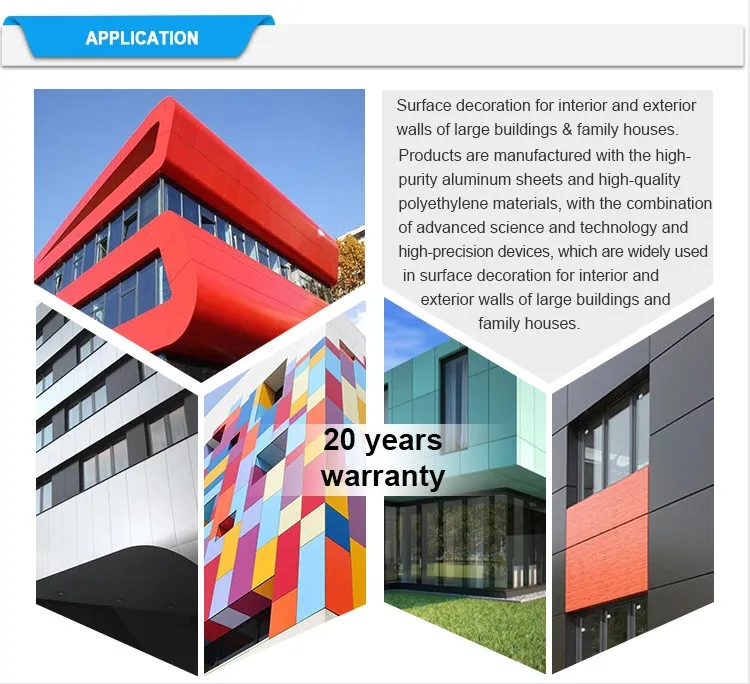

Illustrative image related to alco panel

Why Choose ALCOHIVE for Your Projects?

ALCOHIVE incorporates a honeycomb core that provides superior lightweight strength, making it a popular choice in architectural applications and signage. Its structural integrity allows for innovative design possibilities while maintaining durability. When selecting ALCOHIVE, businesses should consider the aesthetic preferences of their projects, as this panel offers a balance between functionality and visual appeal, although it may have fewer color options compared to other types.

What Makes ALCOPANEL A2 a Preferred Choice for High-End Projects?

ALCOPANEL A2 has successfully met the rigorous EN 13501-1:2018 Class A2 fire safety standards, making it an excellent option for high-end commercial projects. This panel combines advanced fire safety features with versatility, suitable for various applications. Buyers should consider the importance of fire safety ratings in their projects and the potential impact on brand reputation and customer trust, especially in regions with strict safety regulations.

How Does ALCOPANEL SCP Benefit Modular Construction?

ALCOPANEL SCP is made from high-strength galvanized iron (GI) material and features a lightweight polyethylene core, making it an economical choice for industrial and modular construction. Its ease of installation can lead to significant labor cost savings. When evaluating ALCOPANEL SCP, buyers should weigh the cost-effectiveness against aesthetic considerations, as this panel may not offer the same visual variety as aluminum counterparts but excels in functional applications.

Key Industrial Applications of alco panel

| Industry/Sector | Specific Application of alco panel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Exterior Cladding | Enhances aesthetic appeal and provides weather resistance | Compliance with local building codes and fire safety regulations |

| Transportation | Interior and Exterior Panels for Vehicles | Lightweight design improves fuel efficiency and durability | Need for customization to fit specific vehicle designs |

| Signage and Advertising | Advertising Boards and Signage | High-quality surface for printing, weather-resistant | Availability of various finishes and colors for branding |

| Furniture and Interiors | Modular Kitchen and Furniture Design | Stylish and modern appearance, easy to clean and maintain | Durability against wear and tear, design flexibility |

| Electronics | Protective Covers and Housing | Lightweight yet strong, enhances product longevity | Compatibility with electronic components and thermal management |

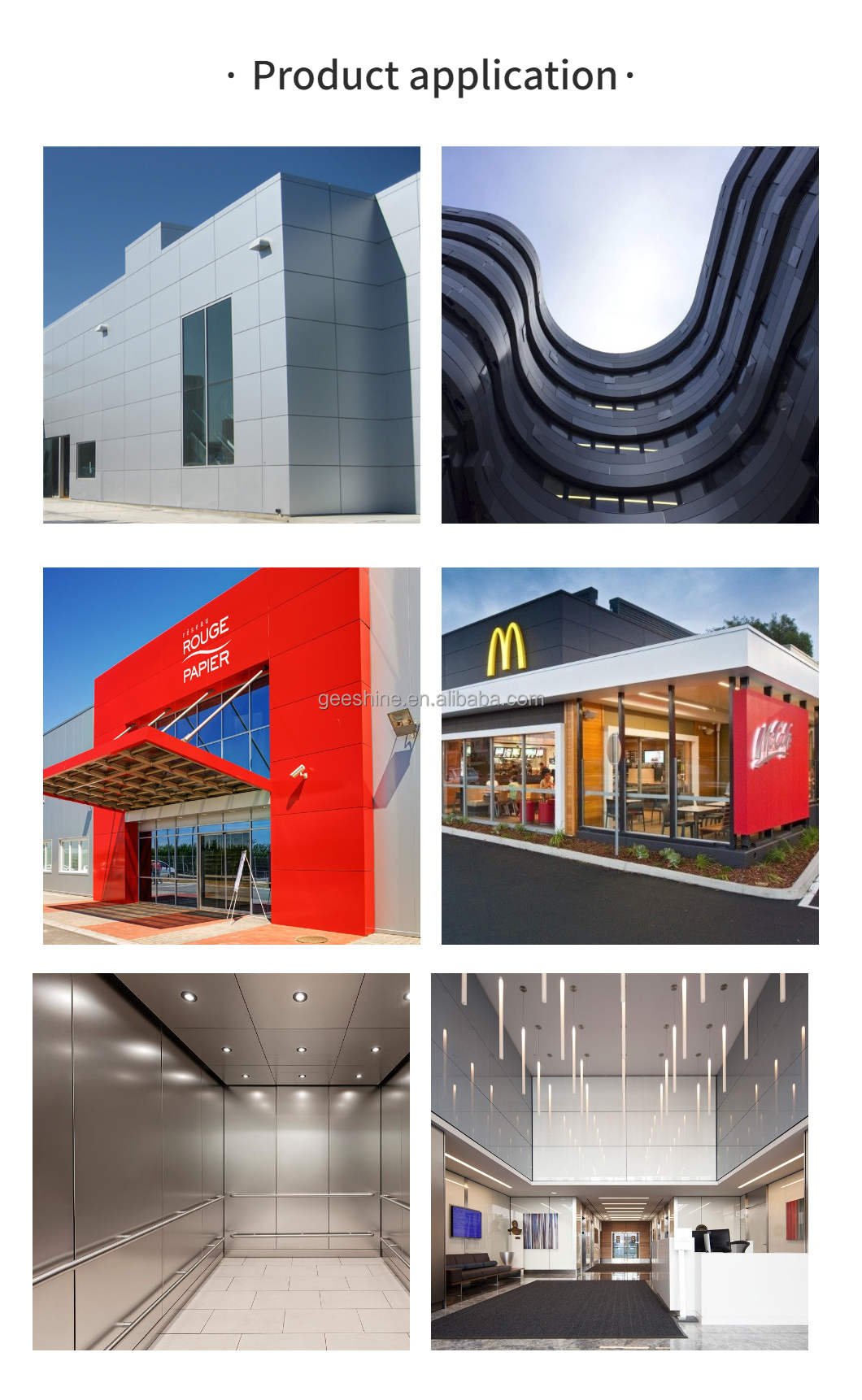

How is Alco Panel Used in Construction for Exterior Cladding?

In the construction industry, alco panels are predominantly used for exterior cladding due to their lightweight yet durable nature. These panels provide superior weather resistance, making them ideal for various climates, particularly in regions prone to extreme weather conditions like Africa and South America. They enhance the aesthetic appeal of buildings while ensuring compliance with local building codes, including fire safety standards. Buyers must consider the panel’s fire resistance ratings and available finishes to match architectural designs.

What Role Does Alco Panel Play in the Transportation Sector?

In the transportation sector, alco panels are utilized for both interior and exterior applications in vehicles. Their lightweight design contributes to improved fuel efficiency while maintaining structural integrity. This is particularly valuable for manufacturers in Europe and the Middle East, where fuel efficiency regulations are stringent. Buyers should focus on customization options to ensure panels meet specific design requirements and operational needs of various vehicle types.

How Are Alco Panels Used in Signage and Advertising?

Alco panels serve as an excellent choice for signage and advertising boards due to their smooth surface and durability. They withstand harsh environmental conditions, making them suitable for outdoor advertising in diverse regions such as Africa and Brazil. The ability to print high-quality graphics on these panels enhances brand visibility. When sourcing, businesses should prioritize the availability of various finishes and colors to align with their branding strategies.

What Are the Benefits of Alco Panels in Furniture and Interior Design?

In the realm of furniture and interior design, alco panels are increasingly popular for modular kitchens and contemporary furniture solutions. Their sleek appearance, combined with easy maintenance, appeals to consumers looking for modern aesthetics. Additionally, these panels offer durability against everyday wear and tear, making them a cost-effective choice for businesses in Europe and South America. Buyers should consider the design flexibility and finishes available to meet market trends.

How Do Alco Panels Enhance Electronic Products?

In the electronics industry, alco panels are often used for protective covers and housings. Their lightweight yet robust characteristics help enhance the longevity of electronic products while also contributing to thermal management. This is particularly relevant for manufacturers in high-temperature regions like the Middle East. When sourcing, companies should ensure compatibility with various electronic components and consider thermal properties to optimize performance.

3 Common User Pain Points for ‘alco panel’ & Their Solutions

Scenario 1: Navigating Fire Safety Regulations in Construction Projects

The Problem: B2B buyers in the construction industry often face stringent fire safety regulations when selecting materials for building projects. Non-compliance with these regulations can lead to significant financial losses, project delays, or even legal repercussions. For instance, a buyer might find themselves in a situation where the chosen materials do not meet the required fire resistance standards, thus jeopardizing the entire project and risking safety violations.

The Solution: To effectively navigate fire safety regulations, it is crucial for buyers to prioritize selecting fire-resistant variants of alco panels, such as ALCOPANEL FR or ALCOPANEL A2, which have been rigorously tested and certified to meet international standards like EN 13501-1:2018 Class A2. Buyers should engage with suppliers who can provide detailed documentation of compliance and test results. Additionally, it is advisable to collaborate with fire safety consultants during the material selection phase to ensure that the chosen panels not only meet but exceed regulatory requirements. This proactive approach minimizes risks associated with non-compliance and enhances the safety profile of the completed project.

Scenario 2: Balancing Aesthetic Appeal with Functional Requirements

The Problem: In the competitive landscape of architecture and construction, striking the right balance between aesthetic appeal and functional requirements can be a daunting challenge. Buyers may find that while certain alco panels offer visually stunning finishes, they may lack the durability or weather resistance needed for specific environments, particularly in regions with extreme weather conditions.

The Solution: To achieve both aesthetic and functional goals, buyers should leverage the diverse range of finishes and textures available with alco panels, such as metallic, wooden, or mirror effects. By conducting a thorough analysis of the project’s location and environmental factors, buyers can select panels that not only enhance the visual allure of the structure but also withstand harsh weather conditions. It is advisable to request samples and conduct real-world tests to assess the performance of the selected finishes in local climates. Collaborating with experienced architects and designers who understand the unique requirements of specific projects can also lead to innovative design solutions that meet both aesthetic and functional needs.

Scenario 3: Managing Installation Challenges and Labor Costs

The Problem: Installation of alco panels can be complex, particularly for large-scale projects, leading to increased labor costs and potential delays. Buyers often struggle with ensuring that installation teams are adequately trained and equipped to handle the specific characteristics of the panels, which can result in improper installation and subsequent issues such as warping or detachment.

The Solution: To mitigate installation challenges, buyers should prioritize sourcing alco panels from manufacturers that offer comprehensive installation guides and training resources. Engaging with suppliers who provide hands-on training for installation teams can significantly reduce the risk of errors. Additionally, it is beneficial to establish clear communication channels between the design and installation teams to ensure that all parties are aligned on project specifications and installation techniques. Buyers can also consider using prefabricated components or modular designs that simplify installation, thereby reducing labor costs and improving overall project timelines. Investing in these practices not only enhances installation efficiency but also ensures the long-term performance and durability of the panels used.

Strategic Material Selection Guide for alco panel

What Are the Key Materials Used in Alco Panels?

When selecting materials for alco panels, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Here, we analyze four common materials used in the production of alco panels, focusing on their performance characteristics and implications for international B2B buyers.

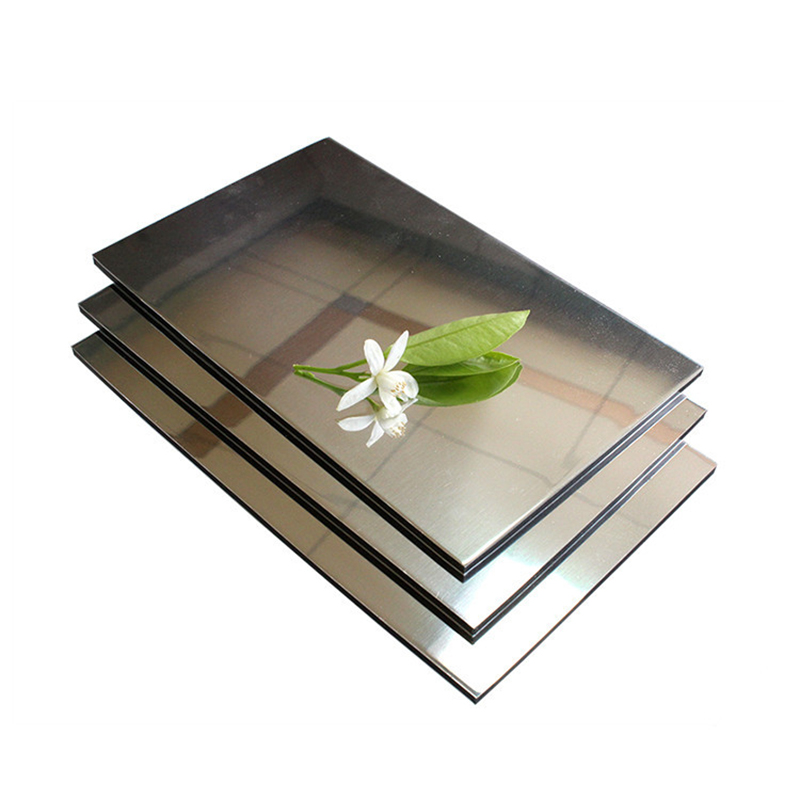

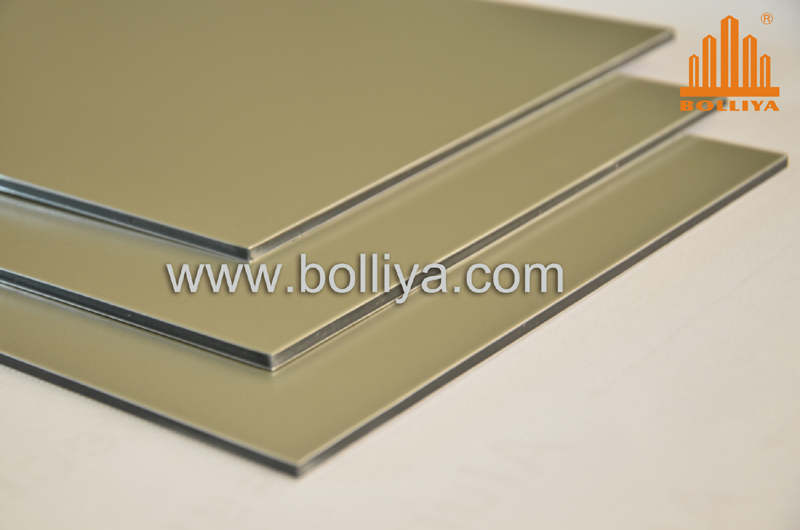

What Are the Key Properties of Aluminum Composite Panels?

Aluminum Composite Material (ACM) is a widely used option for alco panels, consisting of two thin layers of aluminum enclosing a non-aluminum core. This material is known for its lightweight nature and excellent durability. Key properties include high corrosion resistance, good thermal insulation, and fire resistance, particularly in variants like ALCOPANEL FR, which features a fire-retardant core.

Pros: ACM panels are cost-effective, easy to fabricate, and offer a wide range of aesthetic finishes. They are also relatively simple to install, which can reduce labor costs.

Cons: While durable, ACM panels can be susceptible to denting and scratching. Additionally, the initial investment may be higher than other materials, depending on the desired finish and specifications.

Impact on Application: ACM is suitable for both interior and exterior applications, providing a modern appearance while ensuring structural integrity. However, buyers must consider local fire safety regulations, as some regions may require specific fire ratings.

How Does Polyethylene Core Material Perform?

Polyethylene (PE) core panels are another common choice for alco panels. These panels are lightweight and provide good thermal insulation, making them ideal for various applications.

Pros: PE core panels are generally more affordable than their fire-resistant counterparts and are available in a variety of colors and finishes. Their lightweight nature allows for easy handling and installation.

Illustrative image related to alco panel

Cons: The primary drawback of PE core panels is their lower fire resistance, which may not meet stringent building codes in certain regions. Additionally, they may have limited durability compared to other materials.

Impact on Application: PE core panels are often used in non-combustible applications, such as signage and interior cladding. International buyers should ensure compliance with local building codes, especially in fire-sensitive areas.

What Are the Advantages of Fire-Retardant Core Materials?

Fire-Retardant (FR) core materials are designed to enhance the safety of alco panels. These materials are engineered to resist ignition and limit the spread of flames, making them suitable for high-risk environments.

Pros: FR core panels offer enhanced safety and compliance with international fire safety standards, making them a preferred choice for commercial and public buildings.

Cons: The manufacturing process for FR core panels can be more complex, leading to higher costs. Additionally, they may be heavier than standard polyethylene core panels, which can affect installation logistics.

Impact on Application: FR core panels are ideal for high-rise buildings, airports, and other structures where fire safety is paramount. B2B buyers must verify that the panels meet local and international standards such as EN 13501-1 and ASTM E84.

How Does Honeycomb Core Material Enhance Structural Integrity?

Honeycomb core panels, which feature a lightweight honeycomb structure sandwiched between aluminum skins, are known for their high strength-to-weight ratio.

Pros: These panels provide excellent structural integrity and rigidity while remaining lightweight. They are also highly resistant to bending and deformation, making them suitable for demanding applications.

Cons: The complexity of manufacturing honeycomb core panels can lead to higher costs. Additionally, they may require specialized installation techniques, which could increase labor expenses.

Impact on Application: Honeycomb core panels are often used in applications requiring high strength and low weight, such as transportation and aerospace. Buyers should consider the specific requirements of their projects and ensure compliance with relevant industry standards.

Summary Table of Material Properties for Alco Panels

| Material | Typical Use Case for alco panel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Composite Material | Exterior cladding, signage | Lightweight and durable | Susceptible to dents and scratches | Medium |

| Polyethylene Core | Interior cladding, signage | Cost-effective and easy to install | Lower fire resistance | Low |

| Fire-Retardant Core | High-rise buildings, public structures | Enhanced safety and compliance | Higher manufacturing complexity | High |

| Honeycomb Core | Transportation, aerospace applications | High strength-to-weight ratio | Higher costs and specialized installation | High |

This strategic material selection guide provides valuable insights for B2B buyers considering alco panels, ensuring informed decisions that align with their project requirements and regional standards.

Illustrative image related to alco panel

In-depth Look: Manufacturing Processes and Quality Assurance for alco panel

What Are the Main Stages in the Manufacturing Process of Alco Panels?

The manufacturing process of Alco panels, a type of aluminum composite panel (ACP), involves several critical stages that ensure the final product meets the high standards of quality and performance expected by B2B buyers.

1. Material Preparation

The first step in the manufacturing process is the careful selection and preparation of raw materials. Alco panels typically consist of two outer layers of aluminum sheets and a core material, which can vary depending on the required specifications (e.g., polyethylene, fire-resistant mineral core). The aluminum sheets are often pre-treated to enhance adhesion and corrosion resistance. This stage includes cutting the materials to appropriate sizes and applying coatings that can affect the panel’s final appearance and durability.

2. Forming

Once the materials are prepared, the forming stage involves shaping the aluminum sheets and core into the desired panel structure. This is typically done using advanced techniques such as:

- Roll Forming: This process involves feeding the aluminum sheets through rollers that shape them into the desired profiles.

- Hot Pressing: This technique applies heat and pressure to bond the aluminum layers to the core material, ensuring a strong and uniform panel.

- Die Cutting: Precise cutting tools are employed to create specific shapes and sizes, enhancing design flexibility.

3. Assembly

The assembly stage is crucial for ensuring the structural integrity of Alco panels. The core material is sandwiched between the aluminum sheets and bonded using adhesive or through heat and pressure in a single step. This stage also includes quality checks to verify that the bonding process has been successful and that no air pockets or defects are present.

4. Finishing

In the finishing stage, the panels undergo surface treatments to enhance their aesthetic appeal and performance characteristics. This may include:

- Coating: A variety of finishes can be applied, including anodized, painted, or fluoropolymer coatings, which provide additional durability and aesthetic options.

- Quality Inspection: Panels are inspected for surface defects, color consistency, and adherence to specifications.

What Quality Control Measures Are Implemented During Manufacturing?

Quality control (QC) is an integral part of the manufacturing process for Alco panels, ensuring that each product meets international standards and customer specifications.

Relevant International Standards for Quality Assurance

Alco panel manufacturers typically adhere to several international quality standards, including:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For panels used in specific industries, such as oil and gas, compliance with American Petroleum Institute standards may be necessary.

What Are the Key Quality Control Checkpoints?

Quality control involves several checkpoints throughout the manufacturing process to identify and rectify potential issues:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the manufacturing process. Suppliers must provide certifications and test reports to verify material compliance.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring ensures that processes are followed correctly. Operators perform routine checks on dimensions, bonding strength, and surface quality.

-

Final Quality Control (FQC): Once the panels are completed, a final inspection is conducted. This includes visual inspections, dimensional checks, and testing for fire resistance and weatherproofing.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial for ensuring product reliability. Here are actionable strategies:

Illustrative image related to alco panel

Conducting Supplier Audits

Regular audits of the manufacturing facility can provide insights into the quality control processes in place. This can be conducted by the buyer or through third-party inspection services. Audits should evaluate:

- Manufacturing capabilities

- Compliance with international standards

- Implementation of quality control checkpoints

Requesting Quality Reports

B2B buyers should request detailed quality reports from suppliers, including:

- Certificates of compliance with ISO and other relevant standards

- Results from testing performed during the manufacturing process

- Documentation of any quality issues encountered and corrective actions taken

Engaging Third-Party Inspection Services

Utilizing independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These services can perform:

- Pre-shipment inspections to ensure compliance with specifications

- Random sampling of products for quality testing

- Verification of certifications and standards compliance

What Are the Unique Quality Control Considerations for International Buyers?

International buyers often face unique challenges when sourcing Alco panels, particularly concerning quality assurance. Here are some considerations:

Illustrative image related to alco panel

-

Understanding Local Standards: Different regions may have varying standards for construction materials. Buyers should familiarize themselves with local regulations to ensure compliance.

-

Language Barriers: Miscommunication can lead to misunderstandings regarding quality expectations. Clear documentation and communication in a common language can mitigate this risk.

-

Cultural Differences in Quality Expectations: Buyers from different regions may have varying perceptions of quality. It is important for suppliers to understand these differences and adapt their quality control processes accordingly.

Conclusion

Understanding the manufacturing processes and quality assurance measures for Alco panels is essential for B2B buyers seeking reliable, high-quality products. By familiarizing themselves with the key stages of production, relevant quality standards, and effective verification methods, buyers can make informed decisions that align with their project requirements and ensure long-term satisfaction with their purchases.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alco panel’

To assist international B2B buyers in effectively procuring alco panels, this guide provides a clear, actionable checklist. Following these steps will ensure a smooth sourcing process, enabling you to select high-quality panels that meet your specific project requirements.

Step 1: Define Your Technical Specifications

Clearly outline your project’s requirements regarding the type, size, thickness, and finish of the alco panels you need. This step is crucial because it helps narrow down potential suppliers who can meet your specifications. Consider factors such as fire resistance, insulation properties, and aesthetic preferences.

- Key Considerations:

- Fire ratings (e.g., A2, FR)

- Weather resistance and durability

- Design finishes and colors

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for manufacturers with a strong track record in the composite panel industry, especially those who have experience in international markets like Africa, South America, the Middle East, and Europe.

- Where to Look:

- Industry trade shows and exhibitions

- Online platforms and directories

- Recommendations from industry peers

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that your potential suppliers hold relevant certifications and compliance with international standards. This step is vital for ensuring product quality and safety, especially for construction applications.

- Certifications to Check:

- ISO certifications

- Fire safety and environmental compliance (e.g., EN 13501-1)

- Product testing reports

Step 4: Request Product Samples

Request samples of the alco panels to assess their quality, appearance, and suitability for your project. This step allows you to evaluate the panels firsthand, ensuring they meet your aesthetic and functional requirements.

- What to Assess:

- Color accuracy and finish quality

- Weight and structural integrity

- Ease of installation and handling

Step 5: Analyze Pricing and Payment Terms

Gather detailed quotations from multiple suppliers, breaking down costs for materials, shipping, and any additional services. Understanding the pricing structure is essential for budgeting and ensuring you receive value for your investment.

- Important Aspects:

- Compare per-unit costs and bulk discounts

- Check for hidden fees (shipping, customs, etc.)

- Understand payment terms (e.g., deposits, credit terms)

Step 6: Confirm Lead Times and Availability

Discuss lead times and ensure that the supplier can meet your project timeline. Timeliness is critical in construction projects, and delays can lead to increased costs and project overruns.

- Questions to Ask:

- What is the typical production time?

- Are there any current supply chain issues?

- How do they handle urgent orders?

Step 7: Establish Communication and Support Channels

Ensure that the supplier provides clear communication channels for updates and support throughout the procurement process. Good communication is key to addressing any issues that may arise quickly.

- What to Look For:

- Responsiveness and clarity in communication

- Availability of technical support and after-sales service

- Design and installation assistance if needed

By following this checklist, B2B buyers can navigate the sourcing process for alco panels with confidence, ensuring they select the right products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for alco panel Sourcing

What Are the Key Cost Components in Alco Panel Sourcing?

When sourcing alco panels, understanding the cost structure is crucial for optimizing procurement strategies. The primary components include:

-

Materials: The core of any cost analysis, the materials used in alco panels can vary significantly based on quality and specifications. Common materials include aluminum sheets and non-aluminum cores, with costs fluctuating based on market demand and availability.

-

Labor: Labor costs encompass not only the workforce involved in manufacturing but also skilled labor for installation. In regions with high labor costs, such as Europe, these expenses can considerably impact the total cost.

-

Manufacturing Overhead: This includes expenses related to the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Custom panel designs may require specialized tooling, which can add to initial costs but is often justified through the production of high-quality, tailored products.

-

Quality Control (QC): Ensuring panels meet safety and performance standards involves dedicated QC processes. This is particularly important for international buyers who must adhere to local regulations and certifications.

-

Logistics: Transportation costs can vary widely based on distance, shipping method, and the choice of Incoterms. This is a critical area for cost efficiency, especially for international shipments.

-

Margin: Supplier margins can fluctuate based on competition and market conditions. Understanding the margin structure can help buyers negotiate better terms.

How Do Price Influencers Affect Alco Panel Costs?

Several factors can influence the pricing of alco panels:

-

Volume/MOQ: Bulk orders typically yield lower unit prices. Establishing a minimum order quantity (MOQ) can lead to significant savings, making it essential to align purchasing strategies with project needs.

-

Specifications and Customization: Customized panels tailored to specific project requirements can incur higher costs. Buyers should weigh the benefits of customization against budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., fire resistance) often come at a premium. Buyers must assess the importance of these features against their project specifications.

-

Supplier Factors: Supplier reputation and reliability can influence pricing. Established suppliers may command higher prices due to perceived value, while newer or lesser-known suppliers might offer competitive rates.

-

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. Buyers should clearly understand their obligations regarding shipping and insurance to avoid unexpected expenses.

What Tips Can Help Buyers Negotiate Better Pricing for Alco Panels?

Navigating the procurement landscape for alco panels requires strategic approaches to ensure cost-effectiveness:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Building a long-term relationship may provide leverage for better deals.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also installation, maintenance, and potential energy savings over the panel’s lifecycle. This comprehensive view can justify higher upfront costs for superior products.

-

Consider Regional Market Variations: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional market conditions that can influence pricing. Currency fluctuations, trade tariffs, and local competition can all affect costs.

-

Leverage Technology for Communication: Utilize digital platforms for inquiries and negotiations, which can streamline processes and reduce misunderstandings.

Disclaimer on Indicative Prices

Pricing for alco panels can vary widely based on the aforementioned factors. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions. Prices mentioned in any reference materials should be viewed as indicative and may not reflect the current market situation.

Alternatives Analysis: Comparing alco panel With Other Solutions

Understanding Alternatives in Composite Panel Solutions

In the competitive landscape of construction materials, particularly in the realm of architectural cladding, businesses often seek alternatives to established products like Alco Panel. This section explores viable alternatives that serve similar purposes but may vary in performance, cost, and applicability. Understanding these options can empower B2B buyers to make informed decisions tailored to their project requirements.

Illustrative image related to alco panel

| Comparison Aspect | Alco Panel | ALUCOBOND | Trespa Meteon |

|---|---|---|---|

| Performance | High durability, fire-resistant, lightweight | Excellent durability, variety of finishes | Weather-resistant, robust for exterior use |

| Cost | Competitive pricing with custom options | Premium pricing, value for aesthetics | Mid-range pricing, cost-effective for large projects |

| Ease of Implementation | Easy to install, flexible design options | Requires skilled labor for installation | Straightforward installation, but heavier |

| Maintenance | Low maintenance, easy to clean | Low maintenance, durable finishes | Moderate maintenance, susceptible to scratches |

| Best Use Case | Ideal for modern architecture, signage | Great for high-end commercial projects | Suitable for both residential and commercial exteriors |

In-Depth Look at Alternative Solutions

What are the Advantages and Disadvantages of ALUCOBOND?

ALUCOBOND is a well-established brand recognized for its premium aluminum composite panels. One of its primary advantages is the vast range of aesthetic options it offers, including numerous colors and finishes, which can enhance architectural designs. The durability of ALUCOBOND panels makes them suitable for high-end commercial projects where visual appeal is crucial. However, this premium comes at a higher cost, which may not be justifiable for budget-conscious projects. Additionally, the installation of ALUCOBOND often requires specialized skills, potentially increasing labor costs.

How Does Trespa Meteon Compare to Alco Panel?

Trespa Meteon panels are known for their robustness and weather resistance, making them an excellent choice for exterior cladding in various climates. They are particularly suited for applications that demand high durability and aesthetic appeal. The cost of Trespa Meteon panels is generally mid-range, making them a practical choice for larger projects where budget constraints are a consideration. However, these panels tend to be heavier, which can complicate the installation process and may require additional structural support.

Making the Right Choice: Which Solution is Best for Your Project?

When evaluating composite panel solutions, B2B buyers should consider specific project requirements, including budget constraints, aesthetic goals, and installation capabilities. Alco Panel offers a balanced mix of performance and cost-effectiveness, making it suitable for a wide range of applications. In contrast, ALUCOBOND is ideal for projects where visual impact and premium quality are paramount, while Trespa Meteon provides a durable option for those focusing on weather resistance and structural integrity.

Ultimately, the choice of panel will depend on the unique needs of the project, the desired outcomes, and the available budget. Careful consideration of these factors will lead to a more satisfactory investment in architectural materials.

Essential Technical Properties and Trade Terminology for alco panel

What Are the Key Technical Properties of Alco Panels?

Understanding the essential technical properties of Alco panels is crucial for B2B buyers looking for durable and versatile building materials. Here are some critical specifications:

1. Material Composition

Alco panels are primarily made of aluminum composite, consisting of two aluminum sheets enclosing a non-aluminum core, typically made of polyethylene or fire-resistant material. This combination provides a lightweight yet robust structure, making the panels ideal for various applications, from cladding to interior design. The material’s lightweight nature also reduces transportation costs and installation time, which is vital for project efficiency.

2. Fire Resistance Rating

Fire resistance is a critical specification for construction materials. Alco panels come with various fire ratings, including those meeting the EN 13501-1:2018 Class A2 standard. This rating indicates that the panels can withstand fire without contributing to its spread, providing an essential safety feature for buildings. For B2B buyers, especially in regions with stringent fire safety regulations, this property is a non-negotiable aspect when selecting materials for construction projects.

3. Weather and Corrosion Resistance

Alco panels are designed to withstand harsh weather conditions, making them suitable for both interior and exterior applications. They are resistant to UV rays, moisture, and extreme temperatures, ensuring longevity and maintaining aesthetic appeal over time. This property is particularly important for international buyers operating in diverse climates, as it reduces maintenance costs and prolongs the lifespan of the installation.

4. Thickness and Tolerance

The thickness of Alco panels typically ranges from 3mm to 6mm, with specific tolerances depending on the product line. The thickness affects the panel’s strength, insulation properties, and aesthetic finish. For B2B buyers, understanding the required thickness and tolerance is crucial for ensuring the panels meet the structural and design specifications of their projects.

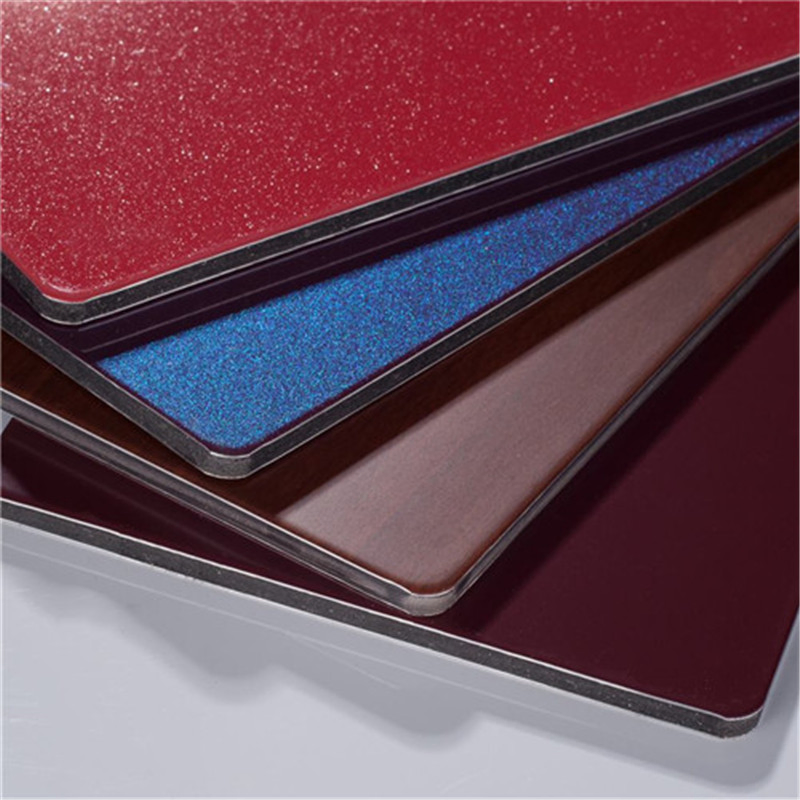

5. Surface Finish Options

Alco panels are available in a variety of finishes, including matte, gloss, metallic, and textured surfaces. This diversity allows architects and designers to choose finishes that align with their design vision. For buyers, the ability to customize finishes enhances branding opportunities and overall project aesthetics, making it a significant consideration in the purchasing process.

Which Trade Terms Are Essential for Alco Panel Transactions?

Familiarity with industry terminology is vital for effective communication and negotiation in B2B transactions. Here are some common terms associated with Alco panels:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of Alco panels, OEMs often provide custom solutions tailored to specific project needs. Understanding OEM relationships can help buyers negotiate better terms and ensure product compatibility.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For Alco panels, knowing the MOQ is essential for budgeting and project planning. Buyers must align their order quantities with their project requirements to avoid excess inventory or unmet needs.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price proposals from suppliers. When purchasing Alco panels, submitting an RFQ allows buyers to receive detailed pricing, delivery timelines, and terms from multiple vendors, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to determine shipping costs, risk allocation, and delivery responsibilities when importing Alco panels.

5. Lead Time

Lead time refers to the period between the initiation of an order and the delivery of the product. For Alco panels, lead times can vary based on customization and manufacturing processes. Awareness of lead times helps buyers plan their projects efficiently and avoid delays.

Conclusion

Equipped with knowledge of both the technical properties and trade terminology associated with Alco panels, B2B buyers can make informed decisions that align with their project requirements and market standards. Understanding these aspects is crucial for optimizing procurement processes and ensuring successful outcomes in construction and design projects.

Navigating Market Dynamics and Sourcing Trends in the alco panel Sector

What Are the Current Market Dynamics and Key Trends Impacting the Alco Panel Sector?

The global alco panel market is experiencing robust growth, driven by the escalating demand for lightweight, durable, and versatile building materials. Key markets in Africa, South America, the Middle East, and Europe are witnessing a surge in construction and renovation projects, fueled by urbanization and infrastructure development. For instance, countries like Brazil and Germany are investing heavily in modern architecture, which is increasing the adoption of aluminum composite panels (ACPs) for both aesthetic and functional applications.

Emerging B2B tech trends are reshaping sourcing strategies in the alco panel sector. Digital platforms are streamlining procurement processes, allowing buyers to compare products, prices, and suppliers more efficiently. Additionally, advancements in manufacturing technologies, such as automation and AI-driven quality control, are enhancing product consistency and reducing lead times. As a result, international buyers are increasingly seeking suppliers who can provide customized solutions and rapid delivery.

Illustrative image related to alco panel

Moreover, sustainability is becoming a critical consideration for B2B buyers. As regulations tighten globally, especially in Europe, companies are prioritizing eco-friendly materials and suppliers with sustainable practices. The integration of green technologies in manufacturing processes is not only meeting regulatory demands but also appealing to environmentally conscious consumers, thus driving market competitiveness.

How Is Sustainability and Ethical Sourcing Shaping the Alco Panel Industry?

Sustainability is at the forefront of the alco panel sector, with growing awareness of the environmental impact of construction materials. The manufacturing processes for alco panels are increasingly incorporating recycled materials and energy-efficient practices, significantly reducing the carbon footprint. B2B buyers are now more inclined to partner with suppliers who prioritize sustainable practices, such as the use of low-VOC paints and non-toxic adhesives.

Ethical sourcing is equally crucial, as it ensures that the materials used in alco panels are obtained responsibly. Buyers should look for suppliers with certifications like ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) for building projects. These certifications not only demonstrate a commitment to sustainability but also enhance the credibility of the supplier in the eyes of environmentally-conscious clients.

Illustrative image related to alco panel

In addition to certifications, transparency in the supply chain is vital. Buyers should inquire about the sourcing of raw materials and the labor practices of suppliers to ensure compliance with ethical standards. By prioritizing sustainability and ethical sourcing, B2B buyers can contribute to a greener construction industry while also meeting the growing demand for environmentally friendly products.

What Are the Historical Developments That Have Shaped the Alco Panel Market?

The alco panel sector has evolved significantly since its inception, with the first aluminum composite panels introduced in the early 1960s. Initially, these panels were primarily used in the aerospace industry due to their lightweight and durable properties. Over time, advancements in technology and manufacturing processes led to the adaptation of these panels for architectural and construction applications.

The establishment of companies like ALCOPANEL in the early 1990s marked a turning point, as they began to specialize in the production of high-quality composite panels for various industries, including construction and transportation. As urbanization and architectural innovation surged globally, the demand for versatile and aesthetically appealing materials led to the widespread adoption of alco panels in high-profile projects, from skyscrapers to shopping malls.

Today, the alco panel market is characterized by a diverse range of products that cater to different design needs and environmental standards, reflecting the industry’s response to both consumer preferences and regulatory pressures. This evolution underscores the importance of innovation and adaptability in maintaining market leadership in the competitive landscape of building materials.

Frequently Asked Questions (FAQs) for B2B Buyers of alco panel

1. How do I choose the right type of alco panel for my project?

Selecting the appropriate alco panel depends on several factors, including the intended application, environmental conditions, and aesthetic requirements. For exterior applications, consider panels with fire-resistant properties and weather resistance, such as ALCOPANEL FR or ALCOPANEL A2. If lightweight properties are essential, options like ALCOHIVE may be suitable. Evaluate the design flexibility and available finishes to ensure the panel aligns with your project’s visual goals. Consulting with a manufacturer or supplier can provide insights tailored to your specific needs.

Illustrative image related to alco panel

2. What are the minimum order quantities (MOQ) for alco panels?

Minimum order quantities for alco panels can vary significantly based on the supplier and the specific product line. Generally, MOQs can range from a few hundred to several thousand square meters. It’s advisable to discuss your project’s scale with potential suppliers to negotiate favorable terms. Smaller orders may incur higher per-unit costs, so planning ahead for larger quantities can lead to cost savings. Always confirm MOQs during the initial inquiry phase to ensure alignment with your procurement strategy.

3. How can I ensure the quality of alco panels before purchase?

To ensure the quality of alco panels, request product samples and certifications from suppliers. Look for panels that comply with international standards such as EN 13501-1 for fire safety. Additionally, inquire about the supplier’s quality assurance processes, including testing methods and material sourcing. Reviews and testimonials from previous clients can also provide insights into the supplier’s reliability and product performance. Consider conducting factory visits or audits if feasible, especially for larger projects.

4. What customization options are available for alco panels?

Most suppliers offer a range of customization options for alco panels, including color, finish, size, and panel thickness. Many manufacturers can accommodate specific design requests, enabling you to create unique solutions that fit your architectural vision. Discuss your requirements with the supplier to explore available options, such as custom colors or textures. Keep in mind that customizations may affect lead times and pricing, so plan accordingly in your project timeline.

Illustrative image related to alco panel

5. What payment terms should I expect when sourcing alco panels internationally?

Payment terms for international transactions can vary by supplier but typically include options such as advance payment, letter of credit, or payment on delivery. Expect to negotiate terms based on your relationship with the supplier and order size. It’s common for suppliers to require a deposit upfront, especially for custom orders. Always clarify payment methods, timelines, and any associated fees before finalizing the order to avoid surprises during the transaction process.

6. What logistics considerations should I take into account when importing alco panels?

When importing alco panels, consider shipping methods, costs, and delivery timelines. Determine whether air or sea freight is more suitable for your order size and urgency. Be aware of customs regulations and tariffs that may apply in your country. Collaborating with a logistics provider experienced in handling construction materials can streamline the import process. Additionally, ensure that your supplier provides necessary documentation, such as bills of lading and certificates of origin, to facilitate smooth customs clearance.

7. How do I vet suppliers for alco panels effectively?

Vetting suppliers for alco panels involves assessing their reputation, product quality, and operational capabilities. Start by researching potential suppliers online, checking reviews and ratings on industry platforms. Request references from previous clients and inquire about their experience with the supplier. Evaluate the supplier’s certifications and compliance with international standards. If possible, visit their manufacturing facilities to inspect production processes and quality controls. Building a relationship based on trust and transparency is essential for long-term partnerships.

8. What are the key applications of alco panels in various industries?

Alco panels are versatile materials used across multiple industries, including construction, transportation, and advertising. In construction, they serve as exterior cladding, offering durability and aesthetic appeal. In the transportation sector, alco panels are utilized in vehicle interiors and exteriors for their lightweight and resilient properties. Additionally, they are popular for signage due to their smooth finish, making them ideal for digital printing. Understanding these applications can help buyers identify opportunities for using alco panels in their projects.

Top 2 Alco Panel Manufacturers & Suppliers List

1. Sassignage – ALCO Panel 0.3mm Skin

Domain: sassignage.com.au

Introduction: ALCO Panel 0.3mm Skin, available in various sizes: 2440 x 1220mm, 2440 x 1250mm, 3050 x 1500mm, 3050 x 2000mm, 3660 x 1220mm, 4000 x 1500mm, 4000 x 2000mm. Thickness: 3mm. Features: polyester coating, UV stabilised, weather resistant finish. Colour options include: Brush Copper, Brush Gold, Brush Silver, Raw Aluminium, Gloss Black, Gloss White, High Gloss Black, Matte Black, High Gloss White, Matt…

2. Falken Acrylic – ACM Sign Panels

Domain: falkenacrylic.com

Registered: 2013 (12 years)

Introduction: [{‘name’: ‘ACM Sign Panel – Black Matte’, ‘thickness’: ‘1/8 inch’, ‘price’: ‘From $15.44’}, {‘name’: ‘ACM Sign Panel – Brushed Silver’, ‘thickness’: ‘1/8 inch’, ‘price’: ‘From $15.24’}, {‘name’: ‘ACM Sign Panel – White Matte’, ‘thickness’: ‘1/8 inch’, ‘price’: ‘From $15.15’}, {‘name’: ‘ACM Sign Panel – Brushed Gold’, ‘thickness’: ‘1/8 inch’, ‘price’: ‘From $15.44’}, {‘name’: ‘ACM Sign Panel – Blue…

Strategic Sourcing Conclusion and Outlook for alco panel

In the ever-evolving landscape of construction materials, strategic sourcing of ALCOPANEL products presents a significant opportunity for international buyers. The versatility and robust performance of ALCOPANEL’s aluminum composite panels make them a prime choice across various sectors, including construction, transportation, and industrial applications. By prioritizing high-quality materials that meet stringent safety standards, businesses can enhance the durability and aesthetic appeal of their projects while ensuring compliance with local regulations.

Investing in ALCOPANEL not only offers immediate benefits in terms of product reliability and visual impact but also contributes to long-term sustainability goals. As global demand for innovative building solutions continues to rise, sourcing from a reputable manufacturer like ALCOPANEL enables companies to stay competitive.

Looking ahead, international B2B buyers from Africa, South America, the Middle East, and Europe are encouraged to explore the extensive range of ALCOPANEL products. Engaging with ALCOPANEL’s expertise can lead to tailored solutions that meet specific project requirements. Seize the opportunity to elevate your construction projects by partnering with a leader in composite panel technology.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.