Unlocking Value: A Strategic Analysis of the Black Caster Wheels Market

Introduction: Navigating the Global Market for black caster wheels

In today’s fast-paced global market, sourcing high-quality black caster wheels can pose significant challenges for international B2B buyers. With diverse applications ranging from industrial machinery to office furniture, the need for durable, reliable, and aesthetically pleasing options is paramount. This guide addresses the complexities of selecting the right black caster wheels by exploring various types, their applications, and the key considerations for supplier vetting.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including Brazil and Germany—will find invaluable insights into pricing strategies and cost-effective solutions tailored to their unique market needs. The comprehensive scope of this guide not only highlights the features and benefits of different caster wheel types but also provides actionable tips for evaluating suppliers, ensuring that you make informed purchasing decisions that align with your business goals.

By understanding the nuances of the black caster wheels market, you will be empowered to select products that enhance operational efficiency and meet aesthetic standards. This guide serves as your roadmap to navigating the global landscape, equipping you with the knowledge necessary to make strategic investments in your business’s infrastructure.

Understanding black caster wheels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plate Casters | Fixed mounting plate; available in swivel and rigid types | Industrial equipment, carts, furniture | Pros: High load capacity, versatile; Cons: May require more space for installation. |

| Stem Casters | Mounting stem for direct attachment to furniture or equipment | Office chairs, mobile workstations | Pros: Easy installation, various stem types; Cons: Limited load capacity compared to plate casters. |

| Vintage Casters | Retro design, often made of cast iron with modern wheel materials | Antique furniture restoration, display units | Pros: Aesthetic appeal, durable; Cons: May not support heavy loads as effectively. |

| Low Profile Casters | Compact design for limited space applications | Medical equipment, low furniture | Pros: Space-saving, suitable for low clearance; Cons: Limited load capacity. |

| High Capacity Casters | Designed for heavy loads, often featuring reinforced wheels | Warehousing, heavy machinery | Pros: Can support significant weight, robust design; Cons: Higher cost, bulkier design. |

What are the characteristics of Plate Casters?

Plate casters are characterized by their fixed mounting plate, which provides a stable base for both swivel and rigid types. These casters are ideal for industrial applications where heavy equipment and carts are frequently used. When considering plate casters, B2B buyers should assess the load capacity and compatibility with existing equipment. Their versatility makes them a popular choice across various sectors, but they may require additional space for installation.

How do Stem Casters differ from other types?

Stem casters feature a mounting stem that allows for direct attachment to furniture or equipment, making them a practical option for office chairs and mobile workstations. They come in various styles, including coarse threaded and grip ring stems, catering to different installation needs. Buyers should consider the load capacity and the specific stem type required for their application. While they are easy to install, stem casters may not support as much weight as plate casters.

Illustrative image related to black caster wheels

Why choose Vintage Casters for specific applications?

Vintage casters combine a retro aesthetic with modern wheel materials, making them suitable for antique furniture restoration and display units. Their unique design adds character to products, appealing to businesses focused on aesthetics. However, B2B buyers should be cautious about the load-bearing limitations of vintage casters, as they may not be suitable for heavy-duty applications. Their durability and style can enhance product offerings but may come at a premium price.

What advantages do Low Profile Casters offer?

Low profile casters are designed for applications with limited space, such as medical equipment and low furniture. Their compact design allows for easy maneuverability in tight areas, making them ideal for environments where height is a constraint. Buyers should evaluate the load capacity and the specific requirements of their equipment before purchasing. While low profile casters are excellent for space-saving solutions, they typically have a reduced load capacity compared to standard casters.

What makes High Capacity Casters essential for heavy-duty applications?

High capacity casters are engineered to support significant loads, often featuring reinforced wheels and robust construction. They are crucial in warehousing and heavy machinery applications where durability and strength are paramount. B2B buyers should focus on the specific weight requirements of their equipment and consider the overall cost versus the benefits of enhanced load-bearing capabilities. While they may come with a higher price tag and bulkier design, the investment can lead to long-term savings and efficiency in operations.

Key Industrial Applications of black caster wheels

| Industry/Sector | Specific Application of black caster wheels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Material handling carts | Enhanced mobility and efficiency in transporting materials | Load capacity, wheel material durability, and compatibility with existing equipment |

| Healthcare | Hospital beds and medical equipment | Improved patient mobility and safety | Hygiene standards, noise reduction, and ease of cleaning |

| Retail | Display stands and shopping carts | Increased customer accessibility and product visibility | Aesthetic design, weight capacity, and maneuverability in tight spaces |

| Food and Beverage | Food service carts | Streamlined service and improved workflow | Resistance to spills, ease of cleaning, and temperature tolerance |

| Warehousing and Logistics | Pallet jacks and shelving units | Optimized storage solutions and reduced labor costs | Load ratings, wheel size for uneven surfaces, and material resilience |

How Are Black Caster Wheels Used in the Manufacturing Sector?

In manufacturing, black caster wheels are integral to material handling carts that transport raw materials and finished products throughout production facilities. Their robust construction ensures they can handle heavy loads, while the black finish offers an aesthetic advantage by concealing dirt and wear. Buyers in this sector should prioritize load capacity and wheel material durability to withstand industrial environments, especially in regions like Africa and South America where operational conditions may vary significantly.

What Role Do Black Caster Wheels Play in Healthcare Settings?

In healthcare, black caster wheels are commonly found on hospital beds and medical equipment, facilitating easy movement and repositioning. Their design minimizes noise, which is crucial in patient care environments, while the black finish aids in maintaining a clean appearance. Buyers must consider hygiene standards and the ability to easily clean these wheels, especially in Middle Eastern and European hospitals where sanitation protocols are stringent.

Illustrative image related to black caster wheels

How Do Retail Businesses Benefit from Black Caster Wheels?

Retail environments utilize black caster wheels in display stands and shopping carts, enhancing customer accessibility and product visibility. The sleek black finish aligns with modern retail aesthetics, while the wheels’ design allows for smooth maneuvering in crowded spaces. Sourcing considerations for retailers include aesthetic design and weight capacity to ensure that carts can support various products without compromising stability, particularly in bustling markets like Brazil and Germany.

Why Are Black Caster Wheels Essential in the Food and Beverage Industry?

In the food and beverage sector, black caster wheels are essential for food service carts that transport meals and supplies. Their ability to withstand spills and easy cleaning capabilities contribute to streamlined service and improved workflow. Buyers should focus on wheels that resist moisture and are easy to sanitize, meeting the high hygiene standards required in food service operations across diverse regions.

How Do Black Caster Wheels Improve Operations in Warehousing and Logistics?

In warehousing and logistics, black caster wheels are utilized in pallet jacks and shelving units, optimizing storage solutions and reducing labor costs. Their ability to navigate uneven surfaces and support heavy loads is critical in maintaining operational efficiency. Buyers should assess load ratings and wheel size to ensure compatibility with their existing infrastructure, especially in regions where warehouse layouts may differ significantly.

Illustrative image related to black caster wheels

3 Common User Pain Points for ‘black caster wheels’ & Their Solutions

Scenario 1: Difficulty in Load Capacity Specification

The Problem: A common challenge for B2B buyers is accurately determining the load capacity required for their applications. Black caster wheels come in various materials and designs, each with different load ratings. Buyers often face confusion over whether the specified load capacity accounts for factors such as surface conditions, frequency of use, and potential abuse. This lack of clarity can lead to purchasing wheels that either underperform or exceed necessary specifications, resulting in increased costs or equipment failure.

The Solution: To effectively source black caster wheels, buyers should conduct a thorough assessment of their operational needs. This includes understanding the weight of the items being transported, the type of flooring, and the environment in which the casters will be used (e.g., indoor vs. outdoor, temperature variations). When sourcing, request detailed specifications from suppliers that not only list the maximum load capacity but also provide insights into performance under real-world conditions. Additionally, consider opting for casters with a higher load capacity than the estimated requirement to account for unforeseen circumstances. Implementing a trial period for new casters can also ensure they meet the operational demands before committing to larger orders.

Scenario 2: Aesthetic Concerns in Professional Settings

The Problem: In many industries, especially in retail and hospitality, the aesthetic appeal of equipment is paramount. B2B buyers often struggle with finding black caster wheels that not only perform well but also complement the overall design and branding of their spaces. Casters that clash with interior design or appear low-quality can detract from the professional image a business strives to maintain.

Illustrative image related to black caster wheels

The Solution: To address aesthetic concerns, buyers should focus on sourcing black caster wheels that are designed with modern aesthetics in mind, such as those with sleek finishes or innovative designs that blend seamlessly with furniture or display units. Engaging with suppliers who specialize in custom solutions can also be beneficial. Consider requesting samples to evaluate both performance and appearance before making bulk purchases. Additionally, look for casters that offer optional features like decorative covers or integrated brakes that enhance functionality without compromising style. This approach ensures that the wheels not only serve a practical purpose but also contribute positively to the overall visual appeal of the workspace.

Scenario 3: Maintenance and Durability Issues

The Problem: Durability and maintenance are significant concerns for B2B buyers, particularly in heavy-use environments such as warehouses or manufacturing plants. Buyers often report that black caster wheels wear down quickly, leading to increased maintenance costs and downtime. Poor-quality wheels can fail under heavy loads or in harsh conditions, leading to potential safety hazards and operational disruptions.

The Solution: To mitigate these issues, buyers should prioritize sourcing black caster wheels made from high-quality materials such as polyurethane or rubber, which are known for their durability and resistance to wear and tear. It’s essential to inquire about the specific material properties and whether they are suited for the intended environment, such as exposure to chemicals or extreme temperatures. Additionally, establish a regular maintenance schedule that includes inspecting and lubricating casters to prolong their lifespan. Working closely with suppliers who can provide maintenance tips and recommendations for the best care practices can further enhance the durability of the wheels, ensuring a safer and more efficient operation. Investing in higher-quality casters initially can lead to significant long-term savings by reducing replacement frequency and maintenance costs.

Illustrative image related to black caster wheels

Strategic Material Selection Guide for black caster wheels

What Are the Key Materials Used for Black Caster Wheels?

When selecting black caster wheels for various applications, the choice of material is critical to ensuring optimal performance and durability. Here, we analyze four common materials used in black caster wheels: Polyurethane, Polyolefin, Rubber, and Steel. Each material has distinct properties, advantages, and limitations that can significantly impact their suitability for specific applications.

How Does Polyurethane Impact Caster Wheel Performance?

Polyurethane is a popular choice for black caster wheels due to its excellent wear resistance and shock-absorbing properties. It can typically withstand a temperature range of -30°F to 180°F (-34°C to 82°C) and offers good resistance to chemicals and oils. The primary advantage of polyurethane wheels is their ability to provide a smooth ride while minimizing floor damage, making them suitable for both industrial and commercial environments.

However, polyurethane can be more expensive than other materials, and its manufacturing process can be complex, potentially leading to longer lead times. For international buyers, especially in regions like Europe, compliance with standards such as DIN EN 12529 for load-bearing capacity is essential. Polyurethane wheels are often preferred in sectors where noise reduction and floor protection are priorities.

What Are the Benefits of Polyolefin for Caster Wheels?

Polyolefin is another widely used material for black caster wheels, particularly in applications requiring moderate load-bearing capabilities. These wheels typically handle loads up to 300 lbs and are resistant to moisture, making them suitable for environments like warehouses and food processing facilities. Polyolefin wheels can operate effectively in temperatures ranging from -20°F to 180°F (-29°C to 82°C).

The cost-effectiveness of polyolefin wheels is a significant advantage, making them an attractive option for budget-conscious buyers. However, they may not perform as well under heavy loads or extreme temperatures compared to polyurethane. Buyers from regions like Africa and South America should consider local climate conditions when selecting polyolefin wheels, as prolonged exposure to high temperatures can affect their longevity.

Illustrative image related to black caster wheels

How Does Rubber Compare for Caster Wheel Applications?

Rubber caster wheels are known for their excellent grip and shock-absorbing qualities, making them ideal for applications involving frequent movement over uneven surfaces. They typically perform well in temperature ranges of -20°F to 180°F (-29°C to 82°C) and are resistant to abrasion. The primary advantage of rubber wheels is their ability to protect floors from scratches and damage, making them suitable for use in retail and healthcare environments.

On the downside, rubber wheels may degrade faster when exposed to harsh chemicals or extreme temperatures, which can limit their application in industrial settings. For buyers in the Middle East, where high temperatures and sand exposure are common, selecting rubber wheels designed for such conditions is crucial to ensure durability.

What Role Does Steel Play in Caster Wheel Construction?

Steel is often used in the construction of caster wheel frames and supports due to its strength and durability. Steel wheels can handle heavy loads, often exceeding 1,200 lbs, and are suitable for industrial applications where high load capacity is essential. They are typically resistant to deformation and wear, providing longevity in demanding environments.

However, steel wheels are heavier and may not provide the same level of floor protection as softer materials like rubber or polyurethane. They are also prone to rusting if not properly coated, which can be a concern in humid environments. International buyers should ensure that steel wheels comply with relevant standards, such as ASTM A36 for structural steel, to guarantee quality and safety.

Summary Table of Material Selection for Black Caster Wheels

| Material | Typical Use Case for black caster wheels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Industrial and commercial environments | Excellent wear resistance | Higher cost and complex manufacturing | High |

| Polyolefin | Warehouses and food processing facilities | Cost-effective and moisture-resistant | Limited performance under heavy loads | Medium |

| Rubber | Retail and healthcare applications | Great grip and floor protection | Degrades faster in harsh conditions | Medium |

| Steel | Heavy-duty industrial applications | High load capacity and durability | Heavier and prone to rust | Medium to High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions when sourcing black caster wheels for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for black caster wheels

What Are the Main Stages of Manufacturing Black Caster Wheels?

The manufacturing process for black caster wheels typically consists of several key stages: material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers identify reliable suppliers who adhere to best practices and quality standards.

-

Material Preparation: The initial stage involves sourcing high-quality raw materials, such as polyolefin, rubber, or polyurethane for the wheels, and steel or aluminum for the frames. Suppliers often select materials based on load capacity, durability, and resistance to wear and environmental factors. Advanced suppliers may also conduct tests to ensure the materials meet required specifications before moving to the forming stage.

-

Forming: During the forming phase, the raw materials are shaped into components of the caster wheels. This process may involve injection molding for the wheels and stamping or machining for the metal parts. Modern manufacturers use computer numerical control (CNC) machines to achieve precise dimensions, ensuring that all components fit perfectly during assembly.

-

Assembly: Once the individual components are produced, they are assembled into complete caster wheels. This stage may include attaching the wheels to the axle, adding brakes, and installing any additional features, such as swivel mechanisms or threaded stems. Assembly lines are often organized for efficiency, with workers or machines performing specific tasks to ensure a streamlined process.

-

Finishing: The final stage involves surface treatments that enhance durability and aesthetics. For black caster wheels, common finishing techniques include e-coating, powder coating, or painting. These processes provide a protective layer against corrosion and wear while ensuring a uniform black finish. Quality control measures are implemented during this stage to verify that the finish meets the expected standards.

How Is Quality Assurance Implemented in Black Caster Wheel Production?

Quality assurance (QA) is a critical aspect of the manufacturing process for black caster wheels, ensuring that products meet both international and industry-specific standards. A robust QA program typically includes several checkpoints and testing methods.

-

Relevant International Standards: Many manufacturers adhere to ISO 9001, which focuses on quality management systems. This standard ensures that organizations consistently provide products that meet customer and regulatory requirements. Additionally, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be applicable, depending on the specific use cases of the caster wheels.

-

QC Checkpoints: Quality control is often structured around several key checkpoints:

– Incoming Quality Control (IQC): This step involves inspecting raw materials upon receipt to ensure they meet specified criteria before production begins.

– In-Process Quality Control (IPQC): During manufacturing, various checkpoints assess the quality of components and processes. This includes monitoring machinery, dimensions, and assembly accuracy.

– Final Quality Control (FQC): Once the caster wheels are assembled, FQC ensures that finished products meet the required specifications and performance standards through rigorous testing. -

Common Testing Methods: Various tests are employed to evaluate the performance and durability of black caster wheels. This may include load testing, rolling resistance testing, and brake effectiveness assessments. Manufacturers may also perform environmental testing to evaluate performance under extreme conditions, ensuring the wheels can withstand real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must conduct due diligence when selecting suppliers for black caster wheels. Several strategies can help verify the effectiveness of a supplier’s quality control processes.

-

Supplier Audits: Regular audits of manufacturing facilities can provide insights into a supplier’s operations, adherence to standards, and overall quality culture. Buyers should request audit reports and certifications to assess compliance with international standards.

-

Quality Reports: Requesting detailed quality reports can help buyers understand a supplier’s quality metrics, such as defect rates, return rates, and corrective actions taken for non-conformities. This data can provide transparency into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can offer an unbiased evaluation of a supplier’s quality assurance practices. These inspections can be conducted at various stages of production, ensuring that products meet the required specifications before shipment.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For B2B buyers operating across international borders, understanding the nuances of quality control and certification is crucial. Each region may have different standards and regulations that can impact the sourcing of black caster wheels.

-

Regional Standards: Buyers from Africa, South America, the Middle East, and Europe should be aware of specific regional standards that may apply. For example, European buyers may prioritize CE marking, while buyers in the Middle East might look for compliance with Gulf Standards Organization (GSO) guidelines.

-

Cultural and Regulatory Considerations: Cultural differences may influence business practices, including quality expectations. Buyers should familiarize themselves with local regulations and standards to ensure compliance and avoid potential issues during importation.

-

Supply Chain Transparency: Establishing a transparent supply chain can significantly enhance trust between buyers and suppliers. This may involve sharing information about sourcing, production methods, and quality assurance processes, fostering a collaborative approach to quality management.

Conclusion

In summary, a thorough understanding of the manufacturing processes and quality assurance measures for black caster wheels is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control practices, buyers can make informed decisions and ensure they partner with reliable suppliers. Taking proactive steps to verify quality control processes and understanding regional nuances will further enhance the buyer’s ability to source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘black caster wheels’

In the realm of industrial and commercial operations, sourcing the right black caster wheels is crucial for ensuring efficiency, safety, and aesthetics. This guide provides a step-by-step checklist to aid B2B buyers in making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for your black caster wheels is the first step in the sourcing process. Consider factors such as load capacity, wheel diameter, and material composition. For example, if your application involves heavy equipment, opt for casters with a higher load capacity and durable materials like polyurethane or rubber.

Step 2: Identify Application Requirements

Understanding the environment in which the casters will be used is critical. Will they be used on smooth floors, rough terrain, or in temperature-sensitive areas? Assess specific needs such as:

– Wheel Type: Swivel vs. rigid casters based on maneuverability requirements.

– Brake Options: Determine if brakes are necessary for stability in specific applications.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product catalogs, and customer references. Look for suppliers with:

– Industry Experience: Companies with a proven track record in your specific sector.

– Quality Assurance: Certifications that demonstrate adherence to industry standards, such as ISO or ASTM.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the black caster wheels for testing. This step allows you to assess:

– Performance: Test the wheels under actual operating conditions to evaluate their load-bearing capacity and maneuverability.

– Durability: Check for wear and tear, especially if the casters will be subjected to continuous use in demanding environments.

Step 5: Analyze Cost vs. Value

While budget considerations are important, focus on the overall value rather than just the initial cost. Analyze factors such as:

– Longevity: Higher-quality casters may have a higher upfront cost but can result in lower replacement and maintenance costs over time.

– Warranty and Support: Evaluate the warranty terms and post-purchase support offered by suppliers, which can significantly affect long-term satisfaction.

Step 6: Confirm Compliance and Safety Standards

Ensure that the black caster wheels meet necessary compliance and safety standards relevant to your industry. This may include:

– Material Safety: Verify that materials used are suitable for your application, especially if they interact with sensitive environments such as food processing or healthcare.

– Load Ratings: Be wary of load ratings that may not reflect real-world conditions; always confirm with the supplier the expected performance under typical usage scenarios.

Illustrative image related to black caster wheels

Step 7: Finalize the Purchase Agreement

Before finalizing your order, review the purchase agreement thoroughly. Ensure that all terms, including delivery timelines, payment terms, and return policies, are clearly outlined. This step is vital to prevent misunderstandings and ensure a smooth transaction.

By following this checklist, B2B buyers can navigate the complexities of sourcing black caster wheels, ensuring they select the right products for their operational needs while optimizing value and performance.

Comprehensive Cost and Pricing Analysis for black caster wheels Sourcing

What Are the Key Cost Components for Black Caster Wheels?

When sourcing black caster wheels, understanding the cost structure is crucial for informed decision-making. The primary cost components include:

-

Materials: The type of materials used, such as polyolefin, rubber, or polyurethane, significantly affects pricing. Higher-quality materials that offer durability and performance can lead to increased costs but may reduce long-term replacement needs.

-

Labor: Labor costs vary by region and can influence the overall pricing. Countries with lower labor costs may offer more competitive pricing, but this can sometimes come at the expense of quality.

-

Manufacturing Overhead: This includes expenses related to production facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help lower overhead costs, which can be passed on to buyers.

-

Tooling: Custom tooling for specific caster designs can incur significant upfront costs. However, these costs can be amortized over larger production runs, making it beneficial for buyers who anticipate high volume orders.

-

Quality Control (QC): Implementing stringent QC measures ensures that the casters meet specified standards. While this can increase manufacturing costs, it is essential for maintaining product reliability and minimizing returns.

-

Logistics: Transportation costs play a vital role in the overall pricing structure. Factors like distance, shipping methods, and whether the supplier offers FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms can all influence logistics expenses.

-

Margin: Suppliers will typically apply a margin on top of their costs, which can vary widely depending on the competitive landscape and the supplier’s positioning in the market.

What Influences Pricing for Black Caster Wheels?

Several factors can impact the pricing of black caster wheels, including:

-

Volume/MOQ: Minimum order quantities (MOQ) can greatly affect pricing. Larger orders often lead to volume discounts, making it more cost-effective for buyers to source in bulk.

-

Specifications and Customization: Customized casters that meet specific application requirements may incur additional costs. Buyers should evaluate whether customization is essential or if standard options suffice.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (like ISO or ANSI) can command higher prices. Buyers should consider the long-term value of investing in certified products versus cheaper alternatives.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: Understanding shipping terms is crucial for pricing. Incoterms define the responsibilities of buyers and sellers in international transactions, affecting overall costs and risks.

What Are the Best Negotiation Strategies for B2B Buyers?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings. Here are some tips:

Illustrative image related to black caster wheels

-

Leverage Volume Orders: Use large order quantities to negotiate better pricing. Suppliers are often willing to offer discounts for bulk purchases.

-

Seek Total Cost of Ownership (TCO): Evaluate the total cost of ownership rather than just the upfront price. Consider maintenance, durability, and replacement costs over time to make a more informed decision.

-

Request Multiple Quotes: Obtain quotes from various suppliers to compare prices and services. This can provide leverage during negotiations and help identify the best value.

-

Understand Local Market Dynamics: Being aware of market conditions in the supplier’s country can aid in negotiations. For example, understanding local labor costs can help assess the fairness of the pricing.

-

Be Flexible on Specifications: If possible, be open to slightly altering specifications to align with existing inventory or production capabilities of the supplier. This can lead to cost reductions.

Conclusion

While indicative prices for black caster wheels can range widely based on the aforementioned factors, it’s essential for buyers to conduct thorough due diligence. This includes understanding cost components, pricing influencers, and effective negotiation strategies to ensure they achieve the best possible outcomes in their sourcing efforts.

Alternatives Analysis: Comparing black caster wheels With Other Solutions

Introduction: Exploring Alternatives to Black Caster Wheels

In the realm of logistics and manufacturing, mobility solutions play a crucial role in efficiency and productivity. Black caster wheels, known for their durability and aesthetic appeal, are commonly used in various applications. However, depending on specific operational requirements, buyers may consider alternative solutions that can offer unique advantages. This analysis will compare black caster wheels with two viable alternatives: heavy-duty rubber wheels and pneumatic wheels.

Comparison Table

| Comparison Aspect | Black Caster Wheels | Heavy-Duty Rubber Wheels | Pneumatic Wheels |

|---|---|---|---|

| Performance | Excellent for hard surfaces; durable | Good on various surfaces; less noise | Superior shock absorption; versatile |

| Cost | Moderate price point | Generally lower cost | Higher initial investment |

| Ease of Implementation | Simple installation | Easy to install | Requires more setup and maintenance |

| Maintenance | Low maintenance | Low maintenance | Higher maintenance due to air pressure |

| Best Use Case | Industrial settings, furniture | Warehouses, retail spaces | Outdoor applications, uneven terrain |

Detailed Breakdown of Alternatives

Heavy-Duty Rubber Wheels

Heavy-duty rubber wheels are a popular alternative to black caster wheels, particularly in environments where noise reduction and surface protection are priorities. These wheels are designed to withstand heavy loads and provide good traction on a variety of surfaces. They are cost-effective, making them an attractive option for budget-conscious buyers. However, while they excel in durability, they may not perform as well on very rough terrains compared to pneumatic wheels.

Pneumatic Wheels

Pneumatic wheels offer a unique advantage due to their air-filled structure, which provides superior shock absorption. This makes them ideal for transporting items over uneven surfaces, such as outdoor terrains or construction sites. They can handle significant weight and are perfect for applications requiring mobility over rough paths. However, pneumatic wheels tend to come with a higher initial cost and require regular maintenance to check air pressure and ensure optimal performance.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between black caster wheels and their alternatives, B2B buyers should consider several factors, including performance requirements, cost constraints, and the specific environment in which the wheels will be used. Black caster wheels are well-suited for industrial applications, whereas heavy-duty rubber wheels might be better for noise-sensitive environments. Pneumatic wheels, while more expensive, are invaluable for operations involving rough terrains. By evaluating these aspects, businesses can make informed decisions that align with their operational needs and budget considerations.

Essential Technical Properties and Trade Terminology for black caster wheels

What Are the Key Technical Properties of Black Caster Wheels?

When selecting black caster wheels for industrial or commercial applications, understanding their technical properties is crucial for ensuring they meet performance and durability requirements. Here are several essential specifications:

-

Material Composition

The material used in manufacturing caster wheels, such as polyolefin, polyurethane, or rubber, significantly impacts their performance. Polyolefin wheels are known for their durability and resistance to moisture, making them ideal for outdoor or humid environments. Polyurethane wheels provide excellent floor protection and can handle heavier loads without damaging surfaces. Choosing the right material ensures longevity and optimal functionality for specific applications. -

Load Capacity

Each caster wheel comes with a specified load capacity, indicating the maximum weight it can safely support. It is critical to consider both the total load of the equipment and any dynamic forces that may occur during movement. Selecting casters with a capacity that exceeds the expected load helps mitigate risks of failure and enhances safety in the workplace. -

Wheel Diameter

The diameter of the wheel affects maneuverability and the type of surface it can traverse. Larger wheels roll more easily over obstacles and rough surfaces, while smaller wheels are more suited for tight spaces. Understanding the application environment will help in selecting the appropriate wheel size to ensure efficiency in operation. -

Swivel vs. Rigid Design

Casters can be classified into swivel and rigid types. Swivel casters allow for greater maneuverability and are ideal for navigating tight corners, while rigid casters provide stability and are better suited for straight-line movement. Depending on the layout of the workspace and the intended use, choosing the right design will enhance operational efficiency. -

Braking Mechanism

The type of brake mechanism, whether it’s a total lock or directional lock, plays a vital role in safety and control. A total lock brake immobilizes both the wheel and swivel, providing maximum stability, while a directional lock allows the wheel to roll in one direction while preventing swivel movement. Evaluating the braking needs based on the application environment is essential for effective usage.

What Are Common Trade Terms Used in the Caster Wheel Industry?

Understanding industry terminology can facilitate smoother communications and transactions with suppliers and manufacturers. Here are some common terms:

Illustrative image related to black caster wheels

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the caster wheel industry, this might involve sourcing custom wheels designed specifically for a particular brand or application. Knowing OEM specifications can enhance product compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest amount of a product that a supplier is willing to sell. This term is essential for B2B buyers as it affects purchasing decisions and inventory management. Understanding MOQ can help in negotiating terms and ensuring sufficient stock levels. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. This is particularly useful in B2B transactions to ensure competitive pricing and clarify specifications. Providing detailed RFQs can lead to better responses and tailored offers from suppliers. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight) is vital for B2B transactions to ensure clarity in shipping costs and risk management. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is crucial for inventory planning and ensuring that production schedules are met without delays. This factor can significantly influence project timelines and operational efficiency.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when procuring black caster wheels, ensuring they select the right products for their specific applications and operational needs.

Navigating Market Dynamics and Sourcing Trends in the black caster wheels Sector

What Are the Current Market Dynamics and Key Trends Influencing Black Caster Wheels?

The black caster wheels market is experiencing notable growth, driven by several global factors. The increasing demand for industrial mobility solutions across various sectors, including manufacturing, healthcare, and logistics, is a primary driver. With the rise of e-commerce and the need for efficient supply chain management, businesses are seeking durable and efficient mobility solutions like black caster wheels. Furthermore, the trend towards customization has gained traction, with buyers looking for specific designs, load capacities, and materials to meet their operational needs.

Emerging B2B technologies are also reshaping the sourcing landscape. The integration of automation and IoT in production processes has led to improved quality control and reduced lead times. International buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, are leveraging digital platforms for sourcing, allowing them to connect directly with manufacturers and suppliers. This shift towards online procurement facilitates better pricing, faster shipping, and broader product selection.

Illustrative image related to black caster wheels

Additionally, sustainability is becoming increasingly important in sourcing decisions. Buyers are now prioritizing suppliers who adhere to environmentally friendly practices and offer products made from recyclable or sustainable materials. This trend is particularly pronounced in Europe, where regulatory frameworks and consumer preferences are pushing companies towards greener alternatives.

How Is Sustainability and Ethical Sourcing Shaping the Black Caster Wheels Industry?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the black caster wheels sector. The environmental impact of manufacturing processes, including energy consumption and waste production, has prompted many companies to seek suppliers with sustainable practices. This includes the use of recycled materials in the production of caster wheels, as well as energy-efficient manufacturing processes.

Furthermore, the importance of ethical supply chains cannot be overstated. International buyers are increasingly aware of labor practices and the overall social responsibility of their suppliers. Certifications such as ISO 14001 for environmental management and Fair Trade standards are becoming essential in evaluating suppliers. By choosing partners who prioritize ethical sourcing, companies can enhance their brand reputation and meet the growing demand for responsible business practices.

The move towards sustainability is also reflected in product innovation. Many manufacturers are developing black caster wheels using eco-friendly materials, such as polyurethane or recycled rubber, which not only reduce environmental impact but also provide enhanced performance characteristics. Buyers are encouraged to inquire about the sustainability credentials of their suppliers to ensure alignment with their corporate social responsibility goals.

How Has the Black Caster Wheels Market Evolved Over Time?

The black caster wheels market has evolved significantly over the past few decades. Initially, caster wheels were primarily functional, designed to enhance mobility for a variety of applications. However, as industries have advanced, so too have the materials and technologies used in caster wheel production.

The introduction of new materials, such as high-performance plastics and advanced composites, has improved the durability and load-bearing capacity of black caster wheels. This evolution has led to the development of specialized products tailored for specific industries, such as healthcare and manufacturing, where safety and reliability are paramount.

Additionally, the design and aesthetic aspects of caster wheels have gained importance. The all-black finish not only serves a functional purpose by hiding wear and tear but also aligns with modern design trends in industrial and commercial spaces. As businesses continue to prioritize both functionality and aesthetics, the demand for innovative black caster wheels is expected to grow, shaping the future of this market.

Frequently Asked Questions (FAQs) for B2B Buyers of black caster wheels

-

How do I select the right black caster wheels for my application?

Choosing the appropriate black caster wheels involves assessing the specific requirements of your application, such as load capacity, wheel diameter, and material. Consider the surface type where the wheels will be used—hard or soft flooring—and the environment—indoor or outdoor. Additionally, evaluate whether you need swivel or rigid casters based on maneuverability needs. Consulting with suppliers for recommendations based on your operational conditions can also help ensure optimal performance and durability. -

What are the most common materials used for black caster wheels?

Black caster wheels are typically made from materials such as polyolefin, polyurethane, rubber, or metal. Polyolefin wheels are known for their resistance to wear and impact, making them suitable for heavy-duty applications. Polyurethane wheels provide a smooth ride and are ideal for sensitive flooring. Rubber wheels are great for shock absorption, while metal wheels are preferred for extremely heavy loads. Your choice should align with the specific demands of your operations and environmental conditions. -

What customization options are available for black caster wheels?

Many manufacturers offer customization options for black caster wheels, including specific wheel sizes, load capacities, and mounting styles. You can also request features like brakes, swivel locks, or specific finishes to meet aesthetic or functional requirements. Discuss your needs with suppliers to explore available options, as custom solutions may enhance performance and ensure better integration with your equipment. -

What is the minimum order quantity (MOQ) for black caster wheels?

The minimum order quantity for black caster wheels varies by supplier and product line. Some manufacturers may have a low MOQ for standard items, while custom designs typically require larger quantities. When sourcing, inquire directly with suppliers about their MOQ policies, as this can impact your procurement strategy and overall costs. Planning your purchase volume accordingly can also lead to better pricing and availability. -

What payment terms should I expect when purchasing black caster wheels internationally?

Payment terms for international purchases of black caster wheels can vary significantly between suppliers. Common practices include advance payments, letters of credit, or net payment terms (e.g., net 30 or net 60 days). It’s essential to negotiate terms that align with your cash flow and risk management strategies. Always clarify currency, payment methods, and any additional fees that may apply to avoid misunderstandings during transactions. -

How do I ensure quality assurance for black caster wheels?

To ensure quality assurance when sourcing black caster wheels, request certifications and quality control processes from suppliers. Look for industry standards such as ISO certifications, which indicate a commitment to quality. Conducting product samples and inspections before bulk orders can also help verify the quality. Additionally, consider suppliers with a solid reputation and positive reviews from previous clients to mitigate risks associated with quality issues. -

What logistics considerations should I keep in mind when importing black caster wheels?

When importing black caster wheels, consider shipping costs, delivery timelines, and customs regulations in your country. It’s crucial to work with logistics partners familiar with international trade to navigate import duties and tariffs effectively. Ensure that your supplier provides accurate documentation for customs clearance, and plan for possible delays, particularly in peak shipping seasons. Proper logistics management can help streamline the import process and reduce unexpected costs. -

How can I vet suppliers for black caster wheels to ensure reliability?

Vetting suppliers for black caster wheels involves several steps. Start by researching their business history, including years in operation and customer reviews. Request references from previous clients to gauge reliability and service quality. Additionally, evaluate their manufacturing capabilities, compliance with international standards, and responsiveness to inquiries. Attending trade shows or industry events can also provide insights into potential suppliers and help establish direct relationships.

Top 4 Black Caster Wheels Manufacturers & Suppliers List

1. Caster City – Heavy Duty Black Finish Casters

Domain: castercity.com

Registered: 2002 (23 years)

Introduction: Black Finish / All Black E-coat Casters, Lead Time is Everything, Call for Expedited Service: 800-501-3808, Capacity Ranges: Up to 350 lbs, Up to 1,200 lbs, Up to 2,500 lbs, Up to 7,000 lbs, Up to 15,000 lbs, Up to 20,000 lbs, Up to 40,000 lbs, Dual Wheel Heavy Duty Plate Casters, Total Locking Brake Casters, Suitable for industrial, commercial, and institutional settings, Available in various whe…

2. Access Casters – Heavy Duty & Light Duty Casters

Domain: accesscasters.com

Registered: 2003 (22 years)

Introduction: This company, Access Casters – Heavy Duty & Light Duty Casters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

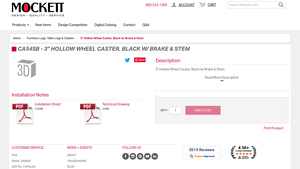

3. Mockett – 3 Hollow Wheel Caster

Domain: mockett.com

Registered: 1996 (29 years)

Introduction: {“name”:”3″ Hollow Wheel Caster, Black w/ Brake & Stem”,”model”:”CA54SB”,”designer”:”Gabriele and Davide Adriano – Sant’Angelo Lodigiano, Italy”,”dimensions”:{“height”:”76mm (3″)”,”wheel_diameter”:”65.8mm (2 19/32″)”,”thread”:”10mm-1.5″},”tire_material”:”Rubber”,”weight_capacity”:”70 lbs. per caster”,”usage”:”Indoor use only”,”base_finish”:”Black”,”tire_color”:”Black”,”assembly”:”Ships unassembled…

4. Electriduct – Heavy Duty Swivel Plate Caster Wheels

Domain: electriduct.com

Registered: 2003 (22 years)

Introduction: {“part_number”:”QWM-ED-CW-101-2PK”,”description”:”2″ Heavy Duty Swivel Plate Caster Wheels”,”color”:”Black”,”quantity_options”:[2, 4],”price”:”$14.99″,”features”:[“360 degree ball bearing swivel head for quick direction changes”,”Smooth and low noise rolling”,”Prevents floor damage”,”Supports over 100 pounds per caster”,”Total support of over 400 pounds with 4 casters installed properly”],”applica…

Strategic Sourcing Conclusion and Outlook for black caster wheels

In conclusion, the strategic sourcing of black caster wheels presents significant opportunities for B2B buyers across various international markets. By prioritizing quality, load capacity, and material durability, organizations can enhance operational efficiency and reduce maintenance costs. Understanding the nuances of different caster types—whether swivel, rigid, or specialized options—enables buyers to make informed decisions tailored to their specific applications.

Furthermore, the versatility of black caster wheels makes them suitable for diverse environments, from industrial settings to office spaces. As global supply chains evolve, the ability to source these products from reliable manufacturers will be crucial in maintaining competitive advantage.

International buyers, especially those in Africa, South America, the Middle East, and Europe, should actively engage with suppliers to explore customized solutions that align with their operational needs. Investing in high-quality casters not only improves mobility but also enhances overall product aesthetics and functionality.

As you consider your sourcing strategies, remember that the right choice in black caster wheels can drive significant value for your business. Embrace the future of procurement by establishing strategic partnerships with trusted suppliers and unlocking the full potential of your logistics operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to black caster wheels