120V Power Cord: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for 120v power cord

In the ever-evolving landscape of global commerce, sourcing a reliable 120v power cord can present significant challenges for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. With varying standards, specifications, and supplier reliability, the process can become overwhelming. This comprehensive guide aims to demystify the complexities surrounding 120v power cords by covering essential aspects such as types, applications, supplier vetting processes, and cost considerations.

International buyers will benefit from a thorough understanding of the diverse power cord options available, including heavy-duty, medium-duty, and specialized cords tailored for specific applications. Additionally, the guide will delve into key factors to assess when evaluating potential suppliers, ensuring that your procurement decisions are informed and strategic.

By equipping B2B buyers with actionable insights, this guide empowers organizations to make confident purchasing decisions that meet their operational needs while navigating the intricacies of the global market. Whether you are looking to support manufacturing processes, enhance infrastructure, or improve energy efficiency, understanding the nuances of 120v power cords is crucial for driving business success in today’s interconnected world.

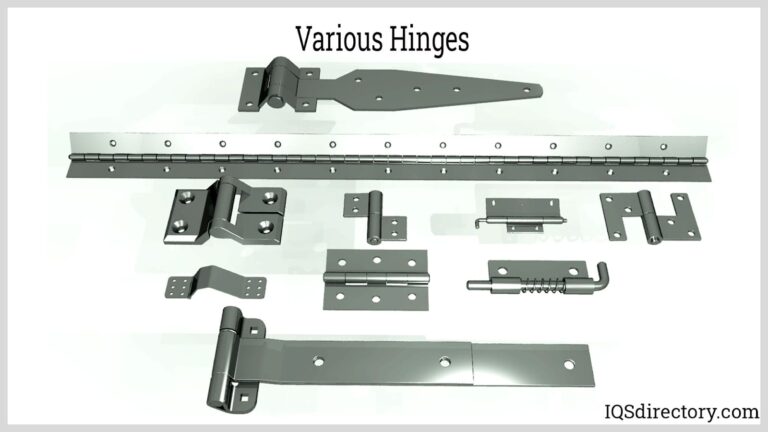

Understanding 120v power cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Power Cords | NEMA 5-15 plug, 15A capacity, typically 6-10 feet long | Appliances, electronics, general use | Pros: Versatile, widely available. Cons: Limited to lower amperage. |

| Heavy-Duty Extension Cords | 12-10 gauge wire, 15-30A capacity, often weather-resistant | Construction sites, outdoor equipment | Pros: High durability, suitable for demanding tasks. Cons: Bulkier and more expensive. |

| GFCI Power Cords | Ground Fault Circuit Interrupter, safety features | Wet locations, outdoor use, kitchens | Pros: Enhanced safety, prevents electrical shocks. Cons: Higher cost and complexity. |

| Appliance-Specific Cords | Designed for specific appliances, often with custom plugs | HVAC units, kitchen appliances | Pros: Tailored for specific needs, reliable. Cons: Limited compatibility with other devices. |

| Generator Power Cords | NEMA L14-30 or L5-30 plugs, heavy gauge, high amperage | Emergency power supply, construction sites | Pros: Supports high power demands, ideal for temporary setups. Cons: Requires careful handling and storage. |

What Are the Characteristics of Standard Power Cords?

Standard power cords are the most commonly used type of 120V power cord, featuring a NEMA 5-15 plug and typically designed to handle up to 15 amps. These cords are usually 6 to 10 feet long, making them suitable for general use in offices, homes, and light industrial applications. B2B buyers should consider the versatility and availability of these cords, as they can be used with a wide range of appliances and electronic devices. However, their lower amperage capacity may limit their use in more demanding applications.

Why Choose Heavy-Duty Extension Cords for Your Business Needs?

Heavy-duty extension cords are constructed with thicker gauge wires (12-10 AWG) and can handle higher amperage, ranging from 15 to 30 amps. These cords are often weather-resistant, making them ideal for construction sites and outdoor equipment. Businesses that require robust electrical solutions will find heavy-duty extension cords essential for powering tools and machinery safely. While they offer greater durability and performance, buyers should be prepared for a higher cost and bulkier design compared to standard cords.

How Do GFCI Power Cords Enhance Safety in Electrical Applications?

Ground Fault Circuit Interrupter (GFCI) power cords are designed to prevent electrical shocks by interrupting the current when a fault is detected. These cords are especially useful in wet locations, such as kitchens and outdoor settings. B2B buyers in industries where safety is paramount will appreciate the added protection that GFCI cords provide. However, the increased safety features come at a higher price point, which should be factored into budget considerations.

What Are the Benefits of Appliance-Specific Cords?

Appliance-specific power cords are custom-made for certain devices, often featuring unique plugs that fit specific appliances like HVAC units or kitchen equipment. These cords ensure optimal performance and safety for the designated appliances. B2B buyers should consider these cords when purchasing or installing new equipment, as they can enhance reliability and efficiency. However, the limited compatibility with other devices may necessitate additional purchases.

Why Are Generator Power Cords Important for Emergency Power Supply?

Generator power cords, such as those with NEMA L14-30 or L5-30 plugs, are designed for high-amperage applications, making them essential for connecting generators to various equipment during power outages or on construction sites. These cords typically support high power demands, which is crucial for businesses relying on temporary power solutions. While they offer significant utility, users must handle them carefully to avoid hazards, and proper storage is essential to maintain their integrity.

Key Industrial Applications of 120v power cord

| Industry/Sector | Specific Application of 120v power cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering assembly line tools and equipment | Enhances operational efficiency and reduces downtime | Ensure compatibility with equipment voltage requirements and amperage ratings. |

| Construction | Connecting temporary lighting and power tools | Improves site safety and productivity | Look for heavy-duty options that withstand outdoor conditions. |

| Hospitality | Providing power for kitchen appliances and electronic devices | Supports seamless service and guest satisfaction | Consider cord length and flexibility for various appliance placements. |

| Agriculture | Operating irrigation systems and greenhouse equipment | Increases crop yield through reliable power supply | Verify weather resistance and durability for outdoor applications. |

| Event Management | Powering audio/visual equipment at events | Ensures high-quality presentations and entertainment | Focus on portable and easy-to-install options for quick setups. |

How is the 120v Power Cord Used in Manufacturing?

In the manufacturing sector, 120v power cords are crucial for connecting assembly line tools and machinery. These cords ensure a steady power supply to equipment like drills, saws, and conveyor belts, thereby enhancing operational efficiency. For international buyers, especially in regions like Africa and South America, sourcing cords that meet local safety standards and voltage requirements is vital. Additionally, businesses should consider the cords’ durability to withstand industrial environments.

What Role Does the 120v Power Cord Play in Construction?

In construction, 120v power cords are essential for powering temporary lighting and various power tools on job sites. These cords help improve site safety by providing adequate illumination and ensuring that tools operate effectively. Buyers from the Middle East and Europe should prioritize heavy-duty options that can endure harsh outdoor conditions, as well as cords with GFCI protection to prevent electrical hazards in wet environments.

Why is the 120v Power Cord Important for Hospitality?

In the hospitality industry, 120v power cords are used extensively to power kitchen appliances, electronic devices, and lighting fixtures. Reliable power supply is essential for maintaining seamless service and enhancing guest satisfaction. For B2B buyers in Europe, it’s important to consider cord length and flexibility to accommodate various appliance placements and ensure compliance with local electrical standards.

How Do 120v Power Cords Benefit Agriculture?

Agricultural applications often require 120v power cords to operate irrigation systems and greenhouse equipment. A consistent power supply can significantly increase crop yield and support efficient farming operations. Buyers in Africa and South America should verify that the cords are weather-resistant and durable, ensuring they can withstand outdoor conditions and provide reliable service throughout the growing season.

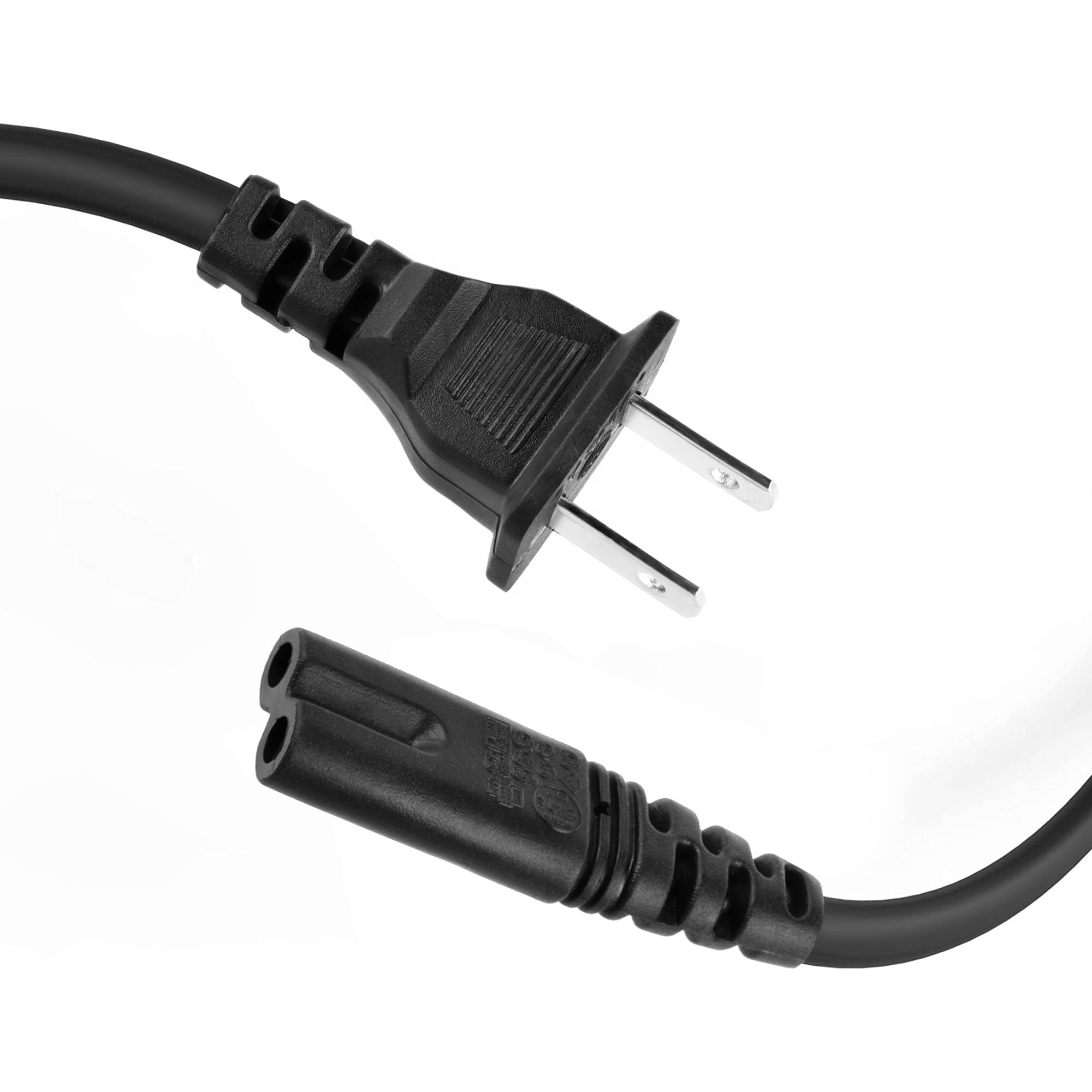

Illustrative image related to 120v power cord

What is the Significance of 120v Power Cords in Event Management?

In event management, 120v power cords are critical for powering audio/visual equipment, lighting, and other essential devices at events. These cords help ensure high-quality presentations and entertainment, which are vital for client satisfaction. For international buyers, focusing on portable and easy-to-install options can facilitate quick setups and enhance overall event execution.

3 Common User Pain Points for ‘120v power cord’ & Their Solutions

Scenario 1: Inconsistent Power Supply for Equipment

The Problem: Many B2B buyers in manufacturing and construction industries face challenges with equipment that requires a reliable power source. Inconsistent power supply can lead to equipment malfunctions, downtime, and ultimately financial losses. For instance, a construction site may rely on multiple tools powered by 120V power cords, and if these cords are subpar or incorrectly rated, it can lead to outages or even damage to sensitive machinery.

The Solution: To mitigate the risks associated with power inconsistencies, it is essential to source high-quality, heavy-duty 120V power cords specifically designed for industrial applications. Look for cords with appropriate amperage ratings that can handle the maximum load of your tools. Additionally, consider cords with features like GFCI (Ground Fault Circuit Interrupter) protection to safeguard against electrical faults. Regularly inspect cords for wear and replace any that show signs of damage. Implementing a routine maintenance schedule for power cords can also help ensure that all equipment operates smoothly and efficiently.

Scenario 2: Difficulty in Finding Compatible Power Cords

The Problem: International B2B buyers often struggle to find compatible power cords for their specific equipment, particularly when dealing with different regional standards. For example, a company in Saudi Arabia might require a 120V power cord for imported machinery that was originally equipped with a different type of cord. This lack of standardization can lead to delays in operations and increased costs due to incompatible accessories.

The Solution: To overcome compatibility issues, establish relationships with reputable suppliers who offer a wide range of 120V power cords tailored to various international standards. Provide your suppliers with detailed specifications of your equipment, including the required amperage, plug type, and length of the cord. This proactive approach can streamline your procurement process and reduce the likelihood of delays. Additionally, consider bulk purchasing to ensure you have a stock of the necessary cords on hand, which can help maintain operational continuity.

Scenario 3: Safety Concerns with Improper Cord Usage

The Problem: Safety is a paramount concern when using 120V power cords, especially in environments such as warehouses and construction sites. Many B2B buyers may inadvertently choose cords that do not meet safety standards or fail to follow proper usage protocols. This can lead to electrical hazards, including shocks, fires, or equipment damage, posing serious risks to personnel and property.

Illustrative image related to 120v power cord

The Solution: To enhance safety, it is crucial to prioritize the selection of cords that are compliant with international safety standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne) certifications. Provide training for employees on the proper usage and handling of power cords, including guidelines on not overloading circuits and regularly inspecting cords for frays or damage. Implementing a safety audit system can help ensure that all equipment is used correctly and that safety practices are consistently followed. By fostering a culture of safety, companies can significantly reduce risks associated with electrical equipment.

Strategic Material Selection Guide for 120v power cord

What Are the Common Materials Used in 120V Power Cords?

In the production of 120V power cords, several materials are commonly utilized, each with distinct properties that affect performance, durability, and cost. Understanding these materials is crucial for international B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe.

How Does PVC (Polyvinyl Chloride) Perform in 120V Power Cords?

PVC is one of the most widely used materials for insulation in power cords due to its excellent electrical properties and cost-effectiveness. It can withstand temperatures ranging from -10°C to 70°C, making it suitable for various indoor and outdoor applications. PVC is also resistant to moisture and chemicals, which enhances its durability in harsh environments.

Pros: PVC is relatively inexpensive and easy to manufacture, allowing for mass production. Its flexibility makes it suitable for various applications, including residential and commercial use.

Cons: While PVC is durable, it can become brittle over time, especially when exposed to UV light or extreme temperatures. This can lead to cracking and potential safety hazards.

Illustrative image related to 120v power cord

International Considerations: Buyers should ensure that PVC materials comply with local regulations, such as RoHS in Europe, which restricts hazardous substances. Understanding the specific standards in countries like Germany and Saudi Arabia is essential for compliance.

What Role Does Rubber Play in 120V Power Cord Manufacturing?

Rubber, particularly synthetic rubber, is another common material for power cords. It offers superior flexibility and resilience, making it ideal for heavy-duty applications. Rubber can handle temperatures from -40°C to 90°C, providing excellent performance in extreme conditions.

Pros: The high tensile strength and flexibility of rubber make it suitable for environments where cords may be subject to bending or twisting. It is also resistant to abrasion and tearing.

Cons: Rubber can be more expensive than PVC and may require more complex manufacturing processes. Additionally, it can degrade over time when exposed to certain chemicals or oils.

International Considerations: Buyers should verify that rubber materials meet international standards such as ASTM D-2000 for rubber products. This is particularly relevant in regions with stringent quality control, such as Europe.

How Does Thermoplastic Elastomer (TPE) Compare in 120V Power Cord Applications?

Thermoplastic elastomers (TPE) combine the properties of rubber and plastic, making them an attractive option for power cords. TPE can withstand temperatures ranging from -40°C to 120°C and exhibits excellent resistance to UV light, ozone, and chemicals.

Pros: TPE is lightweight, flexible, and provides a high degree of durability. It is also recyclable, aligning with sustainability trends in manufacturing.

Cons: TPE can be more costly than both PVC and rubber, which may impact overall production costs. The manufacturing process can also be more complex, requiring specialized equipment.

Illustrative image related to 120v power cord

International Considerations: Buyers should be aware of the environmental regulations in their respective markets, particularly regarding the recyclability of materials. Compliance with standards like ISO 14001 for environmental management can be beneficial.

What Is the Impact of Polypropylene (PP) on Power Cord Applications?

Polypropylene (PP) is less common but is used in specific applications for its excellent chemical resistance and lightweight properties. It can handle temperatures up to 100°C, making it suitable for applications where heat resistance is necessary.

Pros: PP is highly resistant to chemicals and moisture, making it ideal for outdoor applications. It is also lightweight, which can reduce shipping costs.

Cons: While it offers good performance, PP is less flexible than rubber or PVC, which may limit its use in applications requiring bending or twisting.

International Considerations: Buyers should ensure that PP complies with relevant standards, such as ASTM D-4101, which governs the specifications for polypropylene materials. Understanding regional preferences can also guide material selection.

Illustrative image related to 120v power cord

Summary of Material Selection for 120V Power Cords

| Material | Typical Use Case for 120v power cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General indoor and outdoor use | Cost-effective and widely available | Can become brittle over time | Low |

| Rubber | Heavy-duty applications | High flexibility and durability | More expensive and complex to manufacture | Med |

| TPE | Flexible and environmentally-friendly | Lightweight and recyclable | Higher cost and complex manufacturing | High |

| Polypropylene | Outdoor applications | Excellent chemical resistance | Less flexible than other materials | Med |

This strategic material selection guide provides valuable insights for international B2B buyers looking to make informed decisions about 120V power cord materials. Understanding the properties, advantages, and limitations of each material will help ensure compliance with local standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for 120v power cord

What Are the Key Stages in the Manufacturing Process of 120V Power Cords?

The manufacturing process of 120V power cords involves several critical stages, each designed to ensure the final product meets safety and performance standards. Understanding these stages is essential for B2B buyers looking for reliable suppliers.

1. Material Preparation

The manufacturing process begins with the selection and preparation of raw materials. The primary components include copper wire for conductivity, insulation materials (typically PVC or rubber), and connectors such as NEMA plugs. Quality of these materials is paramount, as they directly affect the cord’s performance and safety. B2B buyers should inquire about the sourcing of these materials, ensuring they meet international standards for electrical components.

Illustrative image related to 120v power cord

2. Forming

Once materials are prepared, the next stage involves the forming of the cord. This includes the processes of wire drawing, insulation extrusion, and stranding. Wire drawing reduces the diameter of copper wire, while insulation extrusion involves covering the wire with protective materials. Stranding combines multiple strands of wire to enhance flexibility and conductivity. Advanced machinery is often used in these processes, which can vary in precision and efficiency.

3. Assembly

After forming, the assembly process takes place. This involves connecting the insulated wires to the terminals and plugs. Automated assembly lines may be employed to enhance accuracy and speed, reducing the chances of human error. Each connection is crucial as it impacts the electrical performance and safety of the power cord. B2B buyers should assess the level of automation used by the supplier, as higher automation typically leads to better consistency and quality.

4. Finishing

The finishing stage includes several processes such as testing, labeling, and packaging. Each cord undergoes various tests to ensure it meets electrical and safety specifications. Proper labeling is essential for compliance with international standards. Additionally, packaging must protect the cords during transport while providing necessary information to end-users.

How Is Quality Assurance Implemented in Power Cord Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for 120V power cords. Ensuring that products meet rigorous standards is essential for maintaining customer trust and regulatory compliance.

Relevant International Standards for Quality Assurance

Manufacturers of power cords must adhere to various international standards, such as ISO 9001, which outlines requirements for a quality management system. Other industry-specific certifications may include CE marking for compliance with European safety standards and UL certification for North American markets. B2B buyers should verify that their suppliers have the necessary certifications, which often require periodic audits.

What Are the Key QC Checkpoints in Power Cord Production?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure that the final product meets all quality standards:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Suppliers should conduct tests for electrical conductivity, insulation resistance, and physical integrity to prevent substandard materials from entering the production line.

-

In-Process Quality Control (IPQC): During the manufacturing stages, in-process inspections are conducted to monitor the forming and assembly processes. This ensures that any deviations from standard procedures are caught early.

-

Final Quality Control (FQC): The final stage of QC involves comprehensive testing of the finished product. This includes electrical testing (e.g., voltage drop, insulation resistance), mechanical testing (e.g., pull tests on connections), and visual inspections for any defects.

What Testing Methods Are Commonly Used for 120V Power Cords?

Testing methods are crucial for ensuring that power cords perform reliably and safely. Various testing techniques are employed throughout the manufacturing process:

-

Electrical Testing: This includes tests for insulation resistance, dielectric strength, and continuity to ensure that the cord can safely carry the intended voltage without risk of failure.

-

Mechanical Testing: Mechanical tests assess the physical durability of the cords, including flex testing, tensile strength, and abrasion resistance.

-

Environmental Testing: Some manufacturers conduct environmental tests to assess how cords perform under extreme conditions, such as high temperatures or humidity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of potential suppliers to mitigate risks associated with substandard products.

Conducting Supplier Audits

One effective method is to conduct supplier audits. These audits can provide insights into the manufacturing processes, QC checkpoints, and adherence to international standards. Buyers should prepare a checklist of key areas to assess, including equipment quality, personnel training, and compliance documentation.

Requesting Quality Reports

Buyers should also request detailed quality reports from suppliers. These reports should include results from IQC, IPQC, and FQC stages, demonstrating the supplier’s commitment to maintaining high standards.

Third-Party Inspections

Engaging third-party inspection services can provide an additional layer of assurance. These independent entities can conduct random checks and assessments, offering unbiased verification of a supplier’s quality control measures.

What Are the Unique QC Considerations for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific QC nuances that may impact their purchasing decisions.

Compliance with Local Regulations

Different regions may have unique regulatory requirements for electrical products. Buyers should ensure that suppliers understand and comply with local regulations, such as those enforced by the European Union or specific Middle Eastern countries.

Cultural and Logistical Challenges

Cultural differences may affect communication regarding quality expectations. Buyers should establish clear lines of communication and set explicit quality criteria to mitigate misunderstandings. Additionally, logistical challenges, such as shipping times and customs regulations, can affect product availability and quality upon arrival.

Currency and Payment Considerations

Finally, currency fluctuations and payment terms can impact the cost of products and the supplier’s ability to maintain quality standards. Buyers should discuss payment options and currency risks upfront to avoid complications later.

In conclusion, understanding the manufacturing processes and quality assurance protocols for 120V power cords is essential for B2B buyers. By focusing on material preparation, assembly techniques, and stringent quality control measures, buyers can ensure they partner with reliable suppliers who meet their quality standards and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘120v power cord’

Introduction

This practical sourcing guide is designed to assist B2B buyers in efficiently procuring 120V power cords. Whether you are sourcing for industrial applications, consumer electronics, or any other sector, this checklist will help ensure that you make informed decisions that meet your specific needs while adhering to quality and safety standards.

Step 1: Define Your Technical Specifications

Start by outlining the technical requirements for the 120V power cord you need. This includes factors such as amperage, length, gauge, and insulation type. Understanding these specifications will ensure compatibility with your devices and compliance with relevant safety standards.

- Amperage: Ensure the cord can handle the required load (e.g., 15A or 20A).

- Length: Determine the distance the cord needs to cover to avoid voltage drop issues.

Step 2: Research Applicable Standards and Certifications

Familiarize yourself with the necessary safety standards and certifications for power cords in your target market. Compliance with international and local regulations is crucial for ensuring product safety and reliability.

- UL and CE Certifications: Look for cords that are certified by recognized organizations to ensure they meet industry standards.

- RoHS Compliance: Ensure that the cord adheres to regulations regarding hazardous substances, especially if you are sourcing for the EU market.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your technical and quality requirements. A reliable supplier will not only provide the product but also support and service.

- Request Documentation: Ask for company profiles, certifications, and case studies from similar businesses.

- Check References: Speak with previous clients to assess their experiences regarding product quality and delivery reliability.

Step 4: Compare Pricing and Payment Terms

Once you have identified potential suppliers, compare pricing structures and payment terms. Understanding the total cost, including shipping and duties, will help you make an informed decision.

- Bulk Discounts: Inquire about pricing tiers for larger orders to maximize cost savings.

- Payment Flexibility: Evaluate payment terms to ensure they align with your budget and cash flow.

Step 5: Assess Delivery and Lead Times

Delivery timelines can significantly impact your project schedules. Ensure that suppliers can meet your required lead times without compromising quality.

- Shipping Methods: Confirm shipping options and estimated delivery dates to avoid delays.

- Production Capacity: Verify the supplier’s ability to meet your order volume within the specified timeframe.

Step 6: Confirm Warranty and Return Policies

Understanding the warranty and return policies is essential for mitigating risks associated with defective products. A solid warranty will protect your investment.

Illustrative image related to 120v power cord

- Warranty Duration: Look for cords that offer a warranty period that reflects their quality and reliability.

- Return Process: Ensure the supplier has a clear and reasonable return process in case of defects or issues.

Step 7: Finalize and Document Your Order

Before finalizing your order, document all agreed terms, including specifications, pricing, and delivery details. This will serve as a reference point for both parties and help prevent misunderstandings.

- Order Confirmation: Request written confirmation of the order details to avoid discrepancies.

- Maintain Communication: Keep lines of communication open with the supplier for any future inquiries or adjustments.

By following this checklist, you will be well-equipped to source 120V power cords that meet your business needs while ensuring quality and compliance with industry standards.

Comprehensive Cost and Pricing Analysis for 120v power cord Sourcing

What Are the Key Cost Components in Sourcing 120V Power Cords?

When considering the sourcing of 120V power cords, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The choice of materials significantly affects costs. High-quality copper conductors, durable insulation, and robust connectors typically lead to higher prices but improve performance and safety. Buyers should assess the balance between cost and quality to ensure value.

-

Labor: Labor costs vary by region and can be influenced by the level of automation in manufacturing processes. In countries with higher wage standards, such as Germany, labor costs may comprise a larger portion of the overall expense compared to regions with lower labor costs.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, which is beneficial for maintaining competitive pricing.

-

Tooling: Custom tooling for specific designs or features can lead to higher initial costs. However, if a buyer anticipates large volumes, investing in custom tooling can yield long-term savings.

-

Quality Control (QC): Implementing rigorous QC processes can increase costs but is essential for ensuring product safety and reliability, particularly for markets with stringent regulations, such as the EU.

-

Logistics: Shipping and handling costs can vary significantly based on the distance from the supplier, shipping methods, and any tariffs or import duties applicable in the buyer’s country. These factors should be carefully considered in the total cost analysis.

-

Margin: Suppliers will typically apply a margin to cover their costs and profit. Understanding the typical margins in different regions can help buyers negotiate better prices.

How Do Price Influencers Impact 120V Power Cord Costs?

Several factors influence the pricing of 120V power cords in the B2B market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs. Suppliers may offer better pricing for bulk purchases, making it beneficial for businesses to consolidate orders.

-

Specifications and Customization: Custom specifications, such as length, gauge, and additional features (e.g., GFCI protection), can affect pricing. Buyers should define their requirements clearly to avoid unexpected costs.

-

Material Quality and Certifications: Products that meet specific safety and quality certifications (such as UL, CE, or RoHS) may carry a premium price. However, investing in certified products can mitigate risks and enhance brand reputation.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers with a proven track record may charge more but often provide higher quality and better service.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can influence total costs, including shipping and insurance. Buyers should understand these terms to negotiate favorable shipping arrangements.

What Are Some Effective Buyer Tips for Cost-Efficiency?

-

Negotiation Strategies: Effective negotiation can lead to significant savings. Engage suppliers in discussions about pricing, especially when placing large orders or establishing long-term partnerships.

-

Understanding Total Cost of Ownership (TCO): Consider not just the upfront costs but also the long-term costs associated with maintenance, reliability, and potential downtimes. A lower-priced cord may result in higher TCO if it fails prematurely.

-

Pricing Nuances for International Buyers: B2B buyers from regions such as Africa and South America should be aware of currency fluctuations and international shipping costs. Establishing contracts in stable currencies can mitigate risks.

-

Conducting Market Research: Regularly evaluate market trends and competitor pricing to ensure that you are sourcing at competitive rates. Leverage market intelligence to make informed sourcing decisions.

-

Building Supplier Relationships: Long-term relationships with suppliers can lead to preferential pricing and priority service. Consider establishing strategic partnerships to enhance supply chain reliability.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on several factors, including market conditions, supplier negotiations, and changes in material costs. Buyers are encouraged to conduct thorough research and engage directly with suppliers for accurate quotations tailored to their specific needs.

Alternatives Analysis: Comparing 120v power cord With Other Solutions

Exploring Alternatives to the 120V Power Cord

In the realm of electrical solutions, the 120V power cord is a widely used option for powering devices in various environments. However, there are alternative solutions that may better suit specific applications or requirements. This section explores different technologies that provide similar functions as the 120V power cord, allowing B2B buyers to make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to 120v power cord

| Comparison Aspect | 120V Power Cord | Heavy-Duty Extension Cord | Generator Power Cord |

|---|---|---|---|

| Performance | Standard power delivery for household appliances and light equipment | Higher amperage support for power tools and heavy appliances | Provides power during outages, flexible for various devices |

| Cost | Generally low cost, around $10-$30 | Moderate cost, typically $20-$100 | Higher upfront cost, $50-$200 depending on capacity |

| Ease of Implementation | Simple plug-and-play use | Requires careful handling due to higher power | Requires setup and safety measures for proper usage |

| Maintenance | Minimal; check for wear and tear | Moderate; inspect regularly for damage | Regular maintenance needed for generators, including fuel checks |

| Best Use Case | Ideal for home appliances and small devices | Best for construction sites and outdoor use | Suitable for emergency power supply during outages |

What Are the Advantages and Disadvantages of a Heavy-Duty Extension Cord?

Heavy-duty extension cords are designed for high-performance applications, capable of supporting higher amperage than standard 120V power cords. They are ideal for powering tools and equipment on construction sites or in workshops. While they offer robust performance, they can be more expensive and require careful handling to prevent hazards. Additionally, their bulkiness may limit portability, making them less suitable for casual home use.

How Does a Generator Power Cord Compare?

Generator power cords are specialized for connecting devices to generators, providing flexibility during power outages. They often come with weather-resistant features, making them suitable for outdoor use. However, they tend to be more expensive and require additional setup compared to standard power cords. Regular maintenance of the generator itself is necessary to ensure safety and reliability, which can add to operational costs over time.

Making the Right Choice for Your B2B Needs

When selecting the best power solution for your specific needs, consider the intended application, budget constraints, and the environment in which the equipment will be used. The 120V power cord is an excellent choice for general household use and light equipment, while heavy-duty extension cords and generator power cords cater to more demanding scenarios. By evaluating performance requirements, cost implications, and maintenance needs, B2B buyers can choose the most effective solution that aligns with their operational goals and enhances overall productivity.

Essential Technical Properties and Trade Terminology for 120v power cord

What Are the Key Technical Properties of a 120V Power Cord?

Understanding the essential technical properties of a 120V power cord is crucial for international B2B buyers, especially those in regions with diverse electrical standards and applications. Here are some key specifications that are vital for selecting the right power cord for your business needs:

-

Voltage Rating (V)

The voltage rating indicates the maximum voltage the power cord can safely carry. For 120V power cords, this rating is essential for ensuring compatibility with devices designed to operate at this voltage. Selecting a cord with the correct voltage rating prevents electrical failures and potential hazards, which is especially critical for industries like manufacturing and construction. -

Amperage Rating (A)

This specification refers to the maximum current a power cord can handle without overheating. For instance, a 15A rating is common for standard household appliances, while heavy-duty applications may require cords rated for 20A or more. B2B buyers must choose cords with appropriate amperage ratings to ensure safety and efficiency in their operations. -

Wire Gauge (AWG)

The American Wire Gauge (AWG) measures the thickness of the wire within the cord. A lower AWG number indicates a thicker wire, which can carry more current. For example, a 12 AWG wire is suitable for heavy-duty applications, while a 16 AWG wire may suffice for lighter use. Understanding wire gauge is essential for ensuring that the power cord meets the specific power demands of your equipment. -

Material Composition

The materials used in a power cord can affect its durability, flexibility, and resistance to environmental factors. Common materials include PVC and rubber for insulation, while copper is often used for the conductors. Selecting high-quality materials is crucial for minimizing wear and tear, ensuring longevity, and maintaining performance in various conditions, particularly in outdoor or industrial settings. -

Cord Length

Cord length can significantly impact the usability of a power cord. Longer cords provide flexibility in positioning equipment but can lead to voltage drop issues if too long for the application. B2B buyers should assess their spatial requirements and the implications of cord length on electrical performance.

What Common Trade Terms Should B2B Buyers Know When Sourcing 120V Power Cords?

Familiarity with industry terminology can streamline communication and negotiations in B2B transactions. Here are several key terms relevant to sourcing 120V power cords:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers source high-quality, compatible power cords tailored to specific equipment needs. -

MOQ (Minimum Order Quantity)

The MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers assess the feasibility of purchasing in bulk, which can lead to cost savings, especially for businesses requiring large quantities of power cords. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for a specific quantity of products. Utilizing RFQs can help B2B buyers compare offers and negotiate better terms, ensuring they receive the best value for their procurement needs. -

Incoterms (International Commercial Terms)

These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risk transfer, and cost implications, which are crucial when importing power cords from different regions. -

NEMA (National Electrical Manufacturers Association) Rating

NEMA ratings specify the standards for electrical connectors and plugs. Understanding NEMA configurations, such as NEMA 5-15 for standard 120V plugs, is vital for ensuring compatibility with devices and adherence to safety regulations.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing 120V power cords, ensuring they meet their operational needs while adhering to safety and regulatory standards.

Navigating Market Dynamics and Sourcing Trends in the 120v power cord Sector

What Are the Key Trends and Dynamics in the Global 120V Power Cord Market?

The global 120V power cord market is experiencing significant growth, driven by rising demand for electrical appliances and equipment across various sectors, including home improvement, manufacturing, and renewable energy. As urbanization accelerates in regions like Africa and South America, the need for reliable and safe power solutions becomes more critical. Key trends influencing the market include the shift towards smart technology integration in power cords, such as cords with built-in surge protection and smart plugs that allow for remote operation and monitoring.

Illustrative image related to 120v power cord

Moreover, international buyers are increasingly focused on sourcing from manufacturers that leverage automation and advanced manufacturing techniques, which enhance product quality and reduce lead times. The emergence of e-commerce platforms has also transformed how businesses source these products, providing more options and competitive pricing. For B2B buyers in Europe, the Middle East, and Africa, understanding local regulations and standards is vital. Countries like Germany have stringent safety and quality certifications that suppliers must meet, while Middle Eastern markets may prioritize durability and weather resistance due to varying environmental conditions.

How Does Sustainability Influence Sourcing Decisions for 120V Power Cords?

Sustainability has become a crucial factor in the sourcing of 120V power cords. B2B buyers are increasingly aware of the environmental impact of their purchasing decisions, pushing suppliers to adopt more sustainable practices. This includes the use of recyclable materials, reduction of plastic usage, and the implementation of energy-efficient manufacturing processes.

Ethical sourcing is also gaining traction, with buyers preferring suppliers who can demonstrate compliance with environmental regulations and social responsibility standards. Certifications such as RoHS (Restriction of Hazardous Substances) and Energy Star can enhance a product’s appeal, ensuring that it meets both environmental and efficiency criteria. For international buyers, particularly those in Europe, aligning with suppliers who prioritize sustainable practices not only mitigates environmental impact but also enhances corporate reputation and compliance with increasingly strict regulations.

What Historical Factors Have Shaped the 120V Power Cord Market?

The 120V power cord market has evolved significantly over the decades, shaped by technological advancements and changing consumer preferences. Initially, power cords were basic, often lacking safety features. However, as electrical standards were established and safety concerns rose, the industry saw the introduction of features such as grounding, insulation improvements, and standardized plug designs.

Illustrative image related to 120v power cord

The rise of consumer electronics in the late 20th century further propelled the market, as more devices required specialized power cords. In recent years, the focus has shifted towards smart technology and eco-friendly materials, reflecting broader societal trends towards sustainability and energy efficiency. As a result, today’s power cords not only serve a functional purpose but also align with the growing demand for smarter and greener solutions in the electrical landscape.

In conclusion, understanding these dynamics, sustainability considerations, and the historical context of the 120V power cord market can empower B2B buyers to make informed sourcing decisions that align with their operational needs and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of 120v power cord

-

1. How do I solve compatibility issues with 120V power cords in different regions?

To address compatibility issues with 120V power cords, it’s crucial to understand the voltage and plug type specific to the region where the product will be used. For instance, while the 120V standard is widely accepted in North America, other countries may have different configurations. Ensure that the power cords meet international standards and are compatible with local electrical systems. Additionally, consider sourcing cords that come with interchangeable plug types or offer adapters for regional compatibility to avoid operational disruptions. -

2. What is the best power cord for high-demand appliances?

For high-demand appliances, a heavy-duty 120V power cord is recommended. Look for cords with a higher amperage rating, typically around 15A or more, which can handle the electrical load without overheating. Furthermore, opt for cords with durable insulation and additional features like GFCI (Ground Fault Circuit Interrupter) protection. Brands that offer cords with reinforced connectors and water-resistant properties are ideal for ensuring safety and longevity, especially in industrial or outdoor settings. -

3. What are the minimum order quantities (MOQs) for purchasing 120V power cords?

Minimum order quantities (MOQs) for 120V power cords can vary significantly among suppliers. Generally, MOQs may range from 100 to 1,000 units, depending on the manufacturer and product specifications. It is advisable to discuss MOQs with potential suppliers during the negotiation phase, especially if you require customization. Some suppliers may offer lower MOQs for standard products, while customized solutions might necessitate higher quantities to justify production costs. -

4. How can I vet suppliers for 120V power cords?

When vetting suppliers for 120V power cords, assess their industry experience, certifications, and product quality. Request samples to evaluate the durability and performance of their cords. Check for compliance with international standards like IEC, UL, or CE certifications, ensuring the products meet safety requirements. Additionally, consider supplier reviews, case studies, and their capacity to provide timely delivery and customer service. Engaging in direct communication can also help establish trust and clarify any doubts about their capabilities. -

5. What payment terms should I expect when sourcing 120V power cords internationally?

Payment terms for sourcing 120V power cords can vary based on supplier policies and the nature of the transaction. Common terms include advance payment, a deposit followed by the balance upon delivery, or net payment terms (e.g., net 30 or net 60 days). It’s essential to clarify these terms before finalizing the order and consider using secure payment methods like letters of credit or escrow services to mitigate risks. Ensure that both parties agree on the payment schedule to avoid misunderstandings. -

6. What quality assurance measures should I implement for 120V power cords?

Implementing quality assurance measures for 120V power cords involves setting clear specifications and conducting regular inspections during production. Request certifications and test reports from suppliers to confirm compliance with safety standards. Consider establishing a quality control team to perform random checks on batches upon arrival. Additionally, maintaining open communication with suppliers regarding production processes can help address any potential quality issues proactively. -

7. How can I ensure timely logistics and shipping for 120V power cords?

To ensure timely logistics and shipping for 120V power cords, work closely with suppliers to establish clear timelines and shipping methods. Opt for suppliers with experience in international shipping and a reliable logistics network. Discuss the use of expedited shipping options if time-sensitive. Additionally, consider customs clearance processes and work with freight forwarders who can assist in navigating regulations to prevent delays at borders. -

8. Are there customization options available for 120V power cords?

Yes, many manufacturers offer customization options for 120V power cords, including variations in length, gauge, plug types, and insulation materials. Customization allows businesses to tailor cords to specific applications and requirements. When discussing customization with suppliers, provide detailed specifications and inquire about minimum order quantities for custom products. Additionally, be prepared for potential price variations based on the complexity and volume of the customization requested.

Top 3 120V Power Cord Manufacturers & Suppliers List

1. EG4 Electronics – EG4 Chargeverter GC Power Cord – 120V

Domain: signaturesolar.com

Registered: 2010 (15 years)

Introduction: {“Product Name”: “EG4 Chargeverter GC Power Cord – 120V”, “Brand”: “EG4 Electronics”, “SKU”: “1511083”, “Price”: “$17.99”, “Input Voltage”: “120 V”, “Current Rating”: “15 A”, “Charging Power”: “Up to 1.8kW (31.5A @ 57V DC)”, “Plug Type”: “15A NEMA 5-15 Plug”, “Features”: [“Easy Setup: Directly plugs into the Chargeverter GC.”, “No Need for Modifications: Allows hassle-free operation without alteri…

2. Grainger – 120V AC Power Cords

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – 120V AC Power Cords, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Smartest House – 120 V AC 2 Prong Plug-in Power Cord

Domain: thesmartesthouse.com

Registered: 2013 (12 years)

Introduction: {‘name’: ‘120 V AC 2 Prong Plug-in Power Cord’, ‘price’: ‘$2.95’, ‘description’: “120 VAC plug-in cord cable with line and neutral pigtails. Perfect for Qubino or Fibaro 120 V relays and switches where 120 VAC is not readily available (don’t use this power supply for low-voltage relays!)”, ‘warranty’: ‘1-year warranty’, ‘specifications’: {‘input’: ‘120 VAC’, ‘output’: ‘120 VAC (line and neutral pi…

Strategic Sourcing Conclusion and Outlook for 120v power cord

In conclusion, the strategic sourcing of 120V power cords is essential for international B2B buyers seeking reliable, cost-effective solutions. By understanding the diverse product offerings—including various lengths, amperages, and specialized features—businesses can make informed procurement decisions that align with their operational needs. Leveraging trusted suppliers and manufacturers ensures access to high-quality cords that comply with safety standards, particularly in regions like Africa, South America, the Middle East, and Europe.

As market demands evolve, the emphasis on sustainable and innovative sourcing practices will only grow. Buyers are encouraged to explore partnerships that prioritize not just cost but also quality and reliability, fostering long-term relationships with manufacturers who can adapt to changing market dynamics.

Looking ahead, the ongoing development of smart and energy-efficient technologies presents an opportunity for businesses to enhance their electrical infrastructure. We invite you to engage with suppliers who are at the forefront of these advancements, ensuring your operations remain competitive and efficient. Your proactive approach to sourcing can pave the way for future success in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.