A B2B Buyer’s Guide to Solenoid Valve Vent: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for solenoid valve vent

In the rapidly evolving landscape of industrial automation, sourcing reliable solenoid valve vents can pose significant challenges for B2B buyers navigating the global market. With diverse applications ranging from fuel gas management to HVAC systems, understanding the intricacies of these components is crucial for operational efficiency. This comprehensive guide delves into the various types of solenoid valve vents, their specific applications, and the critical factors to consider when selecting a supplier.

International B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Saudi Arabia—will benefit from insights into supplier vetting processes, cost considerations, and quality assurance practices. By addressing common challenges, such as identifying reputable manufacturers and ensuring compliance with local regulations, this guide empowers businesses to make informed purchasing decisions.

Through expert analysis and actionable recommendations, readers will gain a deeper understanding of the market dynamics that affect solenoid valve vent procurement. Whether you are looking to enhance your supply chain efficiency or ensure compliance with international standards, this guide serves as a valuable resource to navigate the complexities of sourcing solenoid valve vents effectively. Prepare to transform your purchasing strategy with the knowledge and tools provided in this essential guide.

Understanding solenoid valve vent Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Normally Closed Solenoid Valve | Remains closed when de-energized; opens on power | Gas control in heating systems | Pros: Energy-efficient, safe in power outages. Cons: Slower response time. |

| Normally Open Solenoid Valve | Remains open when de-energized; closes on power | HVAC systems, cooling applications | Pros: Immediate flow, ideal for safety applications. Cons: May leak if power fails. |

| High-Flow Solenoid Valve | Designed for large volume gas applications | Industrial gas delivery systems | Pros: Handles high flow rates, durable. Cons: Higher upfront costs. |

| Low-Pressure Solenoid Valve | Operates effectively in low-pressure environments | Fuel systems in vehicles | Pros: Optimized for low pressure, compact design. Cons: Limited to specific applications. |

| Vent Valve for EVAP Systems | Controls vapor flow in automotive applications | Automotive emission control systems | Pros: Reduces emissions, essential for compliance. Cons: Prone to environmental wear. |

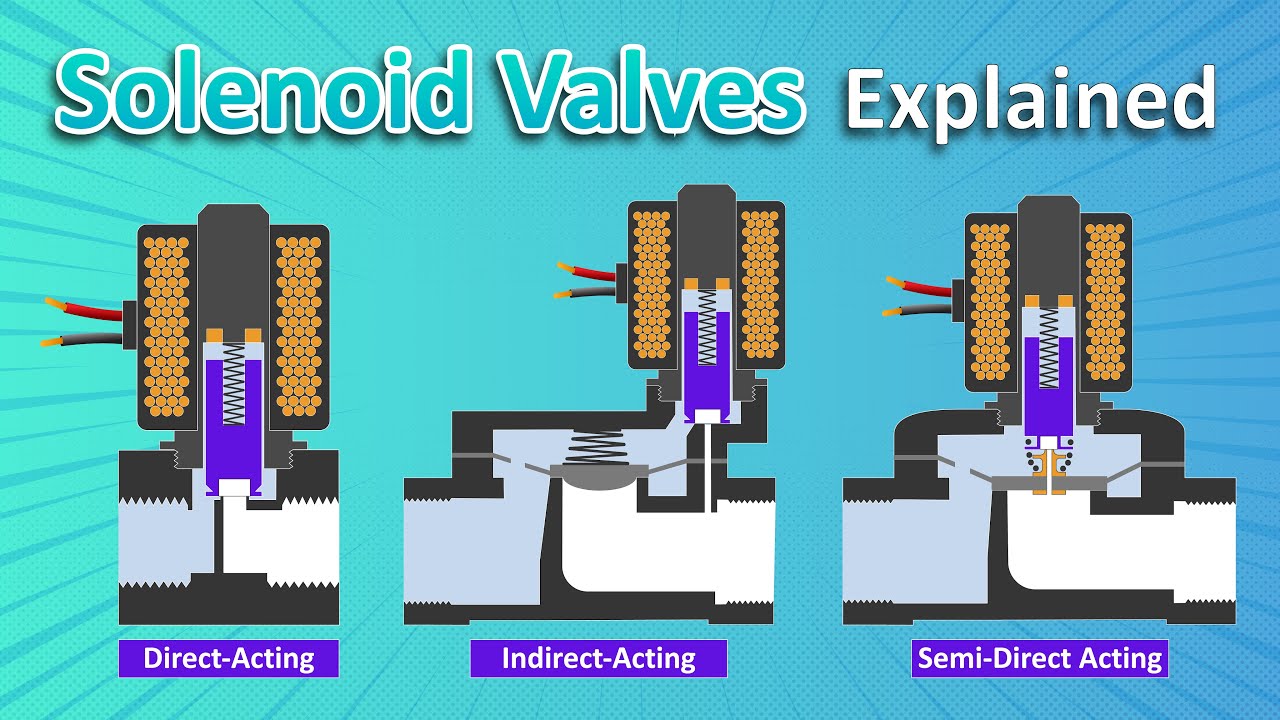

What are Normally Closed Solenoid Valves and Their Applications?

Normally closed solenoid valves are designed to remain shut when not energized, allowing for safe operation in applications where a failure to close could lead to hazardous situations. Commonly used in gas control systems for heating, these valves provide energy efficiency and safety during power outages. When purchasing, buyers should consider the valve’s response time and ensure it meets the specific pressure and flow requirements of their systems.

How Do Normally Open Solenoid Valves Function?

Normally open solenoid valves allow fluid flow when not energized, closing upon receiving power. This feature is particularly useful in HVAC systems and cooling applications, where immediate flow is essential for operational efficiency. Buyers should assess the potential for leaks in case of power failure and ensure compatibility with their system’s design and operational parameters.

What Makes High-Flow Solenoid Valves Ideal for Industrial Use?

High-flow solenoid valves are engineered to manage large volumes of gas, making them essential in industrial gas delivery systems. Their robust design and ability to handle high flow rates make them suitable for heavy-duty applications. While they come with a higher initial cost, their durability and efficiency can lead to long-term savings, making them a worthwhile investment for businesses requiring reliable gas control.

Why Choose Low-Pressure Solenoid Valves?

Low-pressure solenoid valves are specifically designed to operate effectively in environments with lower pressure ranges, such as fuel systems in vehicles. Their compact design is advantageous in space-constrained applications. Buyers should ensure these valves are suitable for their specific low-pressure requirements and consider the limited range of applications they can serve.

What Role Do Vent Valves Play in EVAP Systems?

Vent valves in evaporative emission control systems are crucial for managing vapor flow from fuel tanks, preventing harmful emissions. These valves are commonly used in the automotive industry to comply with environmental regulations. While they are essential for reducing emissions, buyers should be aware of their susceptibility to wear from environmental factors, necessitating regular maintenance and potential replacements.

Key Industrial Applications of solenoid valve vent

| Industry/Sector | Specific Application of solenoid valve vent | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Venting excess pressure from pipelines and tanks | Enhances safety by preventing overpressure scenarios | Ensure compliance with local regulations and safety standards |

| Manufacturing | Control of pneumatic systems in automated processes | Increases efficiency and reduces downtime in operations | Look for durability and reliability in harsh environments |

| Water Treatment | Regulating flow in wastewater treatment facilities | Improves operational efficiency and compliance with environmental standards | Consider corrosion resistance and compatibility with chemicals |

| HVAC Systems | Managing refrigerant gases in cooling systems | Improves energy efficiency and system longevity | Prioritize compatibility with specific refrigerants |

| Automotive | Emission control in fuel systems | Ensures compliance with environmental regulations | Focus on performance under varying temperatures and conditions |

How Are Solenoid Valve Vents Used in the Oil and Gas Industry?

In the oil and gas sector, solenoid valve vents are crucial for managing excess pressure in pipelines and storage tanks. These valves facilitate the safe release of gases during pressure fluctuations, thereby preventing hazardous overpressure situations that could lead to leaks or explosions. For international buyers, particularly in regions like the Middle East and Africa, it is essential to source valves that meet stringent safety regulations and are capable of withstanding harsh environmental conditions.

What Role Do Solenoid Valve Vents Play in Manufacturing?

In manufacturing, solenoid valve vents are integral to controlling pneumatic systems used in automated processes. These valves ensure that air pressure is regulated, which is vital for the operation of machinery and equipment. By maintaining optimal pressure, businesses can enhance operational efficiency and minimize downtime. Buyers should prioritize sourcing durable valves that can operate reliably in high-demand environments, especially in regions with varying climate conditions, such as South America and Europe.

Why Are Solenoid Valve Vents Important in Water Treatment?

In water treatment facilities, solenoid valve vents are employed to regulate the flow of water and treatment chemicals. They play a critical role in maintaining operational efficiency and ensuring compliance with environmental standards. The correct functioning of these valves prevents overflow and contamination, which is crucial for public health. For buyers in Africa and South America, it is vital to consider valves that offer corrosion resistance and compatibility with various treatment chemicals to ensure long-term reliability.

How Do Solenoid Valve Vents Enhance HVAC Systems?

Solenoid valve vents are essential in HVAC systems for managing refrigerant gases, particularly during the cooling process. By controlling the flow of refrigerants, these valves help improve energy efficiency and prolong system life. In international markets, particularly in Europe and the Middle East, buyers must ensure that the valves are compatible with specific refrigerants and can operate efficiently under varying temperature conditions, which is crucial for optimal HVAC performance.

What Is the Significance of Solenoid Valve Vents in Automotive Applications?

In the automotive industry, solenoid valve vents are critical for emission control systems, particularly in managing fuel vapor emissions. These valves help ensure that vehicles comply with environmental regulations by preventing harmful vapors from escaping into the atmosphere. For B2B buyers, particularly in regions like Brazil and Saudi Arabia, sourcing high-performance valves that can withstand varying temperatures and pressures is essential for maintaining vehicle compliance and reliability.

3 Common User Pain Points for ‘solenoid valve vent’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Solenoid Valve Vents

The Problem: Many B2B buyers face challenges in sourcing solenoid valve vents that meet specific operational requirements, especially in regions with varying standards and regulations. In markets across Africa, South America, the Middle East, and Europe, suppliers may not always provide clear information on product specifications, certifications, or compatibility with existing systems. This uncertainty can lead to procurement delays, increased costs, and operational inefficiencies.

The Solution: To effectively source solenoid valve vents, buyers should begin by conducting thorough research on potential suppliers. Utilize industry-specific platforms and trade shows to gather information on manufacturers that comply with international quality standards such as ISO 9001 or relevant regional certifications. Engage with suppliers who offer detailed product documentation, including technical specifications and compliance certificates. Additionally, consider establishing partnerships with local distributors who understand regional needs and can provide timely support and service. By verifying the credibility of suppliers and ensuring product compatibility, buyers can significantly reduce the risk of sourcing unsuitable valves.

Scenario 2: Frequent Failures of Solenoid Valve Vents

The Problem: Frequent failures of solenoid valve vents can lead to costly downtimes and maintenance disruptions, particularly in industries reliant on consistent gas flow, such as manufacturing and energy. Many buyers struggle with identifying the root causes of these failures, which can stem from improper installation, subpar product quality, or environmental factors such as corrosion or temperature fluctuations.

The Solution: To mitigate failures, buyers should prioritize the selection of high-quality solenoid valve vents designed for their specific applications. Implementing a rigorous quality assurance process during the procurement phase can help ensure that only reliable products are purchased. Additionally, provide comprehensive training for installation and maintenance personnel to ensure proper setup and handling. Regularly scheduled maintenance checks should also be established to identify wear and tear before they lead to failures. Buyers should work closely with manufacturers to understand the operating conditions of the vents and choose materials that are resistant to the environmental challenges they may face, such as corrosion-resistant coatings for valves exposed to harsh conditions.

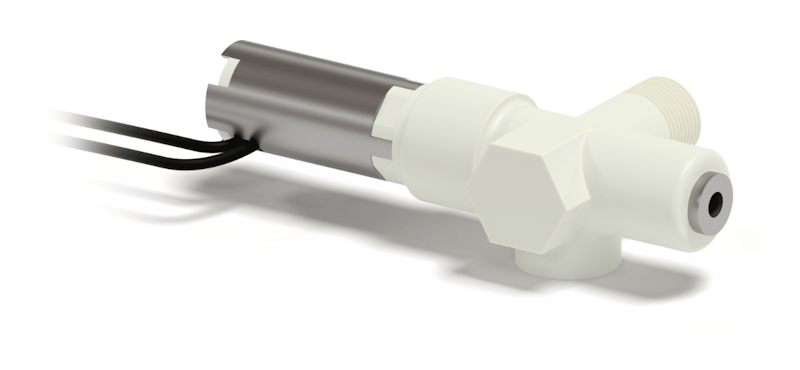

Illustrative image related to solenoid valve vent

Scenario 3: Lack of Technical Support and Guidance

The Problem: B2B buyers often encounter a lack of technical support when trying to integrate solenoid valve vents into their existing systems. This can lead to improper usage, resulting in inefficiencies or even operational failures. Buyers may feel overwhelmed by the technical complexities involved, especially if they do not have dedicated engineering teams.

The Solution: Buyers should seek suppliers that offer robust technical support services, including consultation during the design and integration phases. Requesting assistance with system specifications, installation guidance, and troubleshooting can help ensure that solenoid valve vents are implemented correctly. Additionally, consider investing in training programs provided by suppliers, which can empower staff with the knowledge needed to operate and maintain the systems effectively. Engaging with manufacturers that provide comprehensive after-sales support, including easy access to technical documentation and responsive customer service, will significantly enhance operational reliability and efficiency. By fostering a collaborative relationship with suppliers, buyers can ensure they have the necessary resources and support to successfully utilize solenoid valve vents in their operations.

Strategic Material Selection Guide for solenoid valve vent

When selecting materials for solenoid valve vents, it’s essential to consider the specific properties that will impact performance, durability, and suitability for various applications. Below is an analysis of four common materials used in solenoid valve vents, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Brass for Solenoid Valve Vents?

Brass is a popular choice for solenoid valve vents due to its excellent mechanical properties and corrosion resistance. It typically has a temperature rating of up to 200°C and can handle moderate pressure levels. Brass is also known for its good machinability, making it easier to manufacture into complex shapes.

Pros: Brass is durable and resistant to corrosion, which is crucial for applications involving gas and liquids. It also exhibits good thermal conductivity, enhancing its performance in temperature-sensitive environments.

Cons: The primary drawback of brass is its cost, which can be higher than other materials like plastic. Additionally, it may not be suitable for highly corrosive environments, such as those involving aggressive chemicals.

Impact on Application: Brass is compatible with a variety of media, including water, air, and non-corrosive gases, making it versatile for many industrial applications.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local standards like ASTM or JIS, as brass quality can vary significantly.

Why is Stainless Steel a Preferred Material for Solenoid Valve Vents?

Stainless steel is another common material for solenoid valve vents, known for its high corrosion resistance and strength. It can withstand temperatures up to 300°C and high-pressure applications, making it suitable for demanding environments.

Pros: Its durability and resistance to oxidation make stainless steel ideal for applications involving harsh chemicals or extreme temperatures. It also has a long lifespan, reducing the need for frequent replacements.

Cons: The primary disadvantage is its relatively high cost compared to materials like brass or plastic. Additionally, stainless steel can be more challenging to machine, leading to increased manufacturing complexity.

Impact on Application: Stainless steel is compatible with a broad range of media, including corrosive gases and liquids, making it a reliable choice for critical applications.

Considerations for International Buyers: Buyers should verify compliance with international standards such as DIN and ASTM, especially in regions like Europe and the Middle East, where regulations may be stringent.

How Does Plastic Compare for Solenoid Valve Vents?

Plastic, particularly materials like PVC or polypropylene, is often used in solenoid valve vents for applications where weight and cost are critical factors. These materials can typically handle temperatures up to 60°C and moderate pressures.

Pros: Plastic is lightweight and cost-effective, making it an attractive option for budget-conscious buyers. It also offers excellent chemical resistance, particularly against corrosive substances.

Cons: The primary limitation of plastic is its lower temperature and pressure ratings compared to metals, which may restrict its use in high-performance applications. Additionally, plastics can be more susceptible to UV degradation.

Impact on Application: Plastic materials are suitable for non-corrosive liquids and gases but may not be appropriate for high-temperature applications.

Considerations for International Buyers: Buyers should be aware of the specific chemical compatibility of the plastic used, especially in regions with diverse industrial applications like Brazil.

What Role Does Aluminum Play in Solenoid Valve Vent Applications?

Aluminum is increasingly being used in solenoid valve vents due to its lightweight nature and good corrosion resistance. It can handle temperatures up to 150°C and moderate pressures, making it suitable for various applications.

Pros: Aluminum is relatively inexpensive and easy to machine, allowing for complex designs without significant manufacturing costs. Its lightweight nature can lead to reduced shipping costs.

Cons: While aluminum is corrosion-resistant, it may not perform well in highly corrosive environments, particularly those involving strong acids or bases. Its lower strength compared to stainless steel may also be a concern in high-pressure applications.

Impact on Application: Aluminum is suitable for air and non-corrosive gas applications but may not be ideal for harsh chemical environments.

Illustrative image related to solenoid valve vent

Considerations for International Buyers: Buyers should consider the specific environmental conditions in their regions, such as humidity and chemical exposure, which can affect aluminum’s performance.

Summary Table of Material Selection for Solenoid Valve Vents

| Material | Typical Use Case for solenoid valve vent | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General industrial applications | Excellent corrosion resistance | Higher cost than plastic | Medium |

| Stainless Steel | Harsh chemical environments | High strength and durability | More expensive and complex to machine | High |

| Plastic | Lightweight, cost-sensitive applications | Cost-effective and lightweight | Lower temperature/pressure ratings | Low |

| Aluminum | Air and non-corrosive gas applications | Lightweight and easy to machine | Not suitable for harsh chemicals | Medium |

This guide provides a comprehensive overview of material options for solenoid valve vents, tailored for international B2B buyers, ensuring informed decision-making based on application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for solenoid valve vent

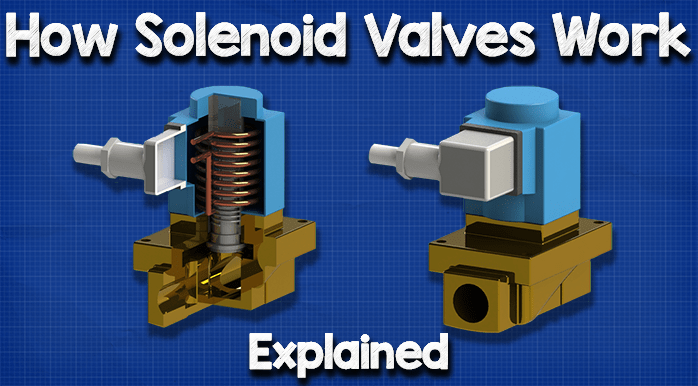

What Are the Main Stages of the Manufacturing Process for Solenoid Valve Vents?

Manufacturing solenoid valve vents involves several critical stages, each designed to ensure the final product meets stringent quality standards and performs reliably in various applications.

Material Preparation: What Materials Are Used and How Are They Prepared?

The first step in manufacturing solenoid valve vents is selecting appropriate materials. Common materials include brass, stainless steel, and plastic, chosen for their durability and resistance to corrosion.

Once materials are selected, they undergo preparation processes such as cutting, machining, and surface treatment. For instance, metal components may be machined to precise dimensions using CNC (Computer Numerical Control) machines, ensuring accuracy in the valve’s design. Surface treatments like anodizing or galvanizing are applied to enhance corrosion resistance, which is particularly vital for applications in harsh environments.

How Is the Forming Process Conducted for Solenoid Valve Vents?

The forming stage involves shaping the prepared materials into specific components. Techniques used can include die-casting, injection molding, or stamping, depending on the material and design requirements.

For metal components, die-casting allows for high-volume production with excellent dimensional accuracy, while injection molding is often used for plastic parts. This stage is crucial as it directly influences the valve’s performance and reliability. Rigorous adherence to specifications during forming helps prevent issues like leaks or operational failures.

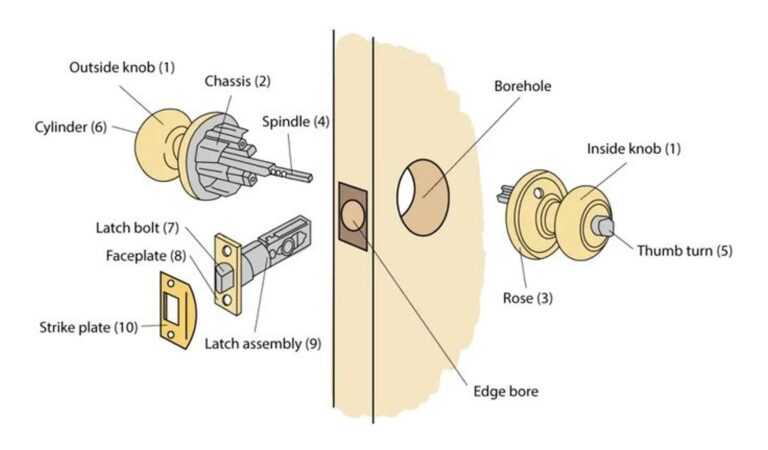

What Is Involved in the Assembly Stage of Solenoid Valve Vents?

During the assembly phase, various components of the solenoid valve vent are brought together. This may include the solenoid coil, valve body, and any electronic components.

Assembly is typically performed in a clean environment to minimize contamination. Automated assembly lines are increasingly common, allowing for efficient and precise assembly. Quality control checkpoints are integrated at this stage to catch any defects early on, ensuring that each unit meets the required specifications before moving on to the finishing stage.

How Is the Finishing Process Handled for Solenoid Valve Vents?

Finishing processes involve applying coatings, labels, and final inspections. Coatings may include paints or sealants that enhance durability and appearance. Labels are often affixed to provide essential information about the product, including safety warnings and specifications.

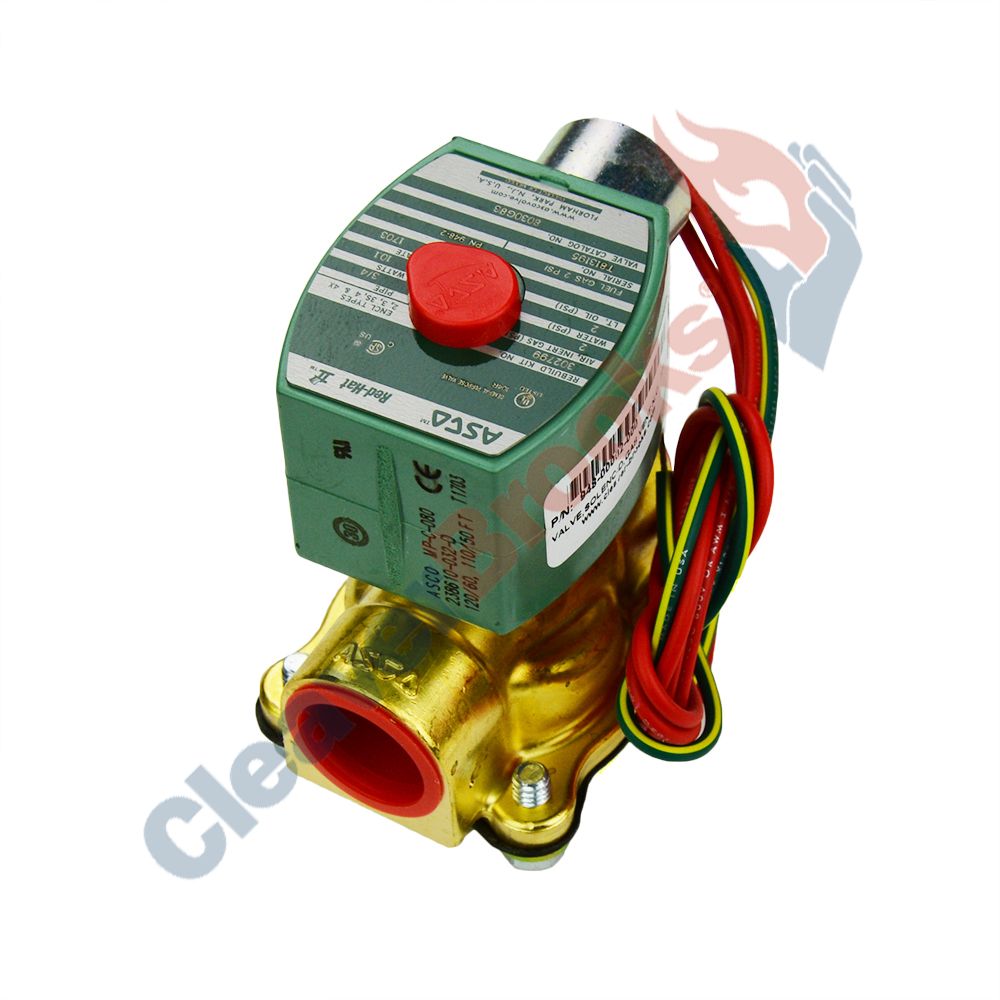

Illustrative image related to solenoid valve vent

Final inspection is a critical aspect of this stage, where each valve is checked against quality standards. This may involve visual inspections, dimensional checks, and functional testing to ensure that the valve operates correctly under simulated conditions.

What Quality Assurance Practices Are Important for Solenoid Valve Vents?

Quality assurance (QA) is vital in the manufacturing of solenoid valve vents to ensure reliability and safety. International standards such as ISO 9001 set the framework for quality management systems across various industries.

Which International Standards Are Relevant to Solenoid Valve Vent Manufacturing?

Compliance with international standards is crucial for B2B buyers. ISO 9001 focuses on consistent quality management practices, while industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are essential for products used in specific sectors, such as gas and oil.

CE marking indicates that the product complies with EU safety, health, and environmental protection standards, which is particularly significant for buyers in Europe. API certification is crucial for valves used in petroleum and natural gas industries, ensuring they meet rigorous safety and performance requirements.

Illustrative image related to solenoid valve vent

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is integrated at multiple stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor the production process and detect any deviations from established standards.

-

Final Quality Control (FQC): This stage includes thorough testing of the finished product to verify that it meets all design specifications and performance criteria.

Each checkpoint serves to identify and rectify issues early, reducing the risk of defects in the final product.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure they receive high-quality products.

What Methods Can Buyers Use to Assess Supplier Quality?

-

Supplier Audits: Conducting on-site audits provides a firsthand look at the supplier’s manufacturing processes, quality control measures, and compliance with industry standards. This can be a valuable opportunity to assess their commitment to quality.

-

Quality Assurance Reports: Requesting quality assurance documentation can give buyers insights into the supplier’s quality management practices. This should include information on certifications, testing procedures, and historical performance data.

-

Third-Party Inspections: Engaging a third-party inspection service can provide an unbiased assessment of the supplier’s quality control practices. These services can perform random inspections of production batches and verify compliance with relevant standards.

-

Traceability and Documentation: Buyers should ensure that suppliers maintain comprehensive documentation of their quality control processes. This includes records of material certifications, inspection results, and compliance with international standards, which can be crucial for accountability.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

For buyers in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

-

Cultural Differences: Different regions may have varying expectations regarding quality and compliance. Buyers should be aware of these differences to ensure effective communication and set realistic expectations.

-

Regulatory Requirements: Each region may have unique regulatory requirements that impact product certification and quality assurance practices. Familiarizing oneself with these regulations can help avoid potential compliance issues.

-

Logistics and Supply Chain Considerations: The logistics of international shipping can affect product quality. Buyers should work closely with suppliers to ensure that products are handled properly during transit, minimizing the risk of damage or contamination.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing solenoid valve vents, ultimately ensuring reliability and performance in their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solenoid valve vent’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure solenoid valve vents. Understanding the critical aspects of sourcing these components is vital to ensuring optimal performance and compliance with industry standards. By following this step-by-step checklist, buyers can make informed decisions that enhance operational efficiency and reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing solenoid valve vents. Consider factors such as pressure ratings, temperature ranges, and compatibility with your existing systems. These specifications will guide your selection process and ensure that the valves meet your operational requirements.

Step 2: Identify Application Requirements

Different applications may necessitate distinct types of solenoid valve vents. Determine the specific function the valve will serve, such as gas venting or fluid control, and assess the environment in which it will operate. This information will help narrow down the options and ensure you select a product suited to your needs.

Step 3: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in solenoid valve vents. Look for companies with a proven track record in your industry and positive customer feedback. Utilize industry directories, trade shows, and online marketplaces to compile a list of viable suppliers.

Step 4: Verify Supplier Certifications

Before proceeding with any supplier, it is crucial to verify their certifications and compliance with relevant standards. Check for ISO certifications, safety standards, and any industry-specific regulations that may apply. This step is essential to ensure the quality and reliability of the products you are sourcing.

Illustrative image related to solenoid valve vent

Step 5: Request Samples and Technical Documentation

Request samples of the solenoid valve vents you are considering, along with technical documentation such as installation guides and performance specifications. Evaluating samples allows you to assess the quality and functionality of the valves firsthand, while documentation provides critical insights into installation and maintenance.

Step 6: Assess Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare pricing and payment terms. Consider not only the unit price but also shipping costs and any bulk order discounts. Ensure that the payment terms align with your budget and cash flow requirements, facilitating a smooth procurement process.

Step 7: Evaluate After-Sales Support and Warranty

After confirming your supplier, evaluate their after-sales support and warranty policies. A reliable supplier should offer comprehensive technical support and a reasonable warranty period for their products. This support is vital for addressing any issues that may arise post-purchase and ensuring long-term satisfaction with your investment.

Illustrative image related to solenoid valve vent

By adhering to this checklist, B2B buyers can streamline their sourcing process for solenoid valve vents, ensuring they select the right products from reputable suppliers while maintaining compliance and quality standards.

Comprehensive Cost and Pricing Analysis for solenoid valve vent Sourcing

What Are the Key Cost Components in Sourcing Solenoid Valve Vents?

When sourcing solenoid valve vents, understanding the cost structure is critical for B2B buyers. The main components of cost include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for solenoid valves include brass, stainless steel, and various plastics. Higher-grade materials may enhance durability and performance but will also raise costs.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this could come at the expense of quality. It’s essential to balance labor expenses with the required skill level for manufacturing solenoid valves.

-

Manufacturing Overhead: This includes utilities, rent, and other indirect costs associated with production. Efficient manufacturing processes can help minimize overhead and should be a consideration when evaluating suppliers.

-

Tooling: The initial investment in tooling can be significant, particularly for custom valve designs. Buyers should consider whether the tooling costs are justified by the projected volume of orders.

-

Quality Control (QC): Implementing stringent QC processes ensures that the solenoid valves meet specified standards, which is crucial for applications in industries such as automotive, aerospace, and oil and gas. The costs associated with QC can vary based on the complexity of the product and the required certifications.

-

Logistics: Shipping and handling costs are vital, especially for international buyers. Factors such as distance, mode of transport, and customs duties can influence the total cost.

-

Margin: Suppliers will add a profit margin to cover their operational costs and generate profit. This margin varies by supplier and can be influenced by market demand and competition.

What Factors Influence Pricing for Solenoid Valve Vents?

Several key factors can influence the pricing of solenoid valve vents, particularly for international buyers:

Illustrative image related to solenoid valve vent

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing significantly. Larger orders often lead to volume discounts, making it more cost-effective for buyers.

-

Specifications and Customization: Customized valves that meet specific application requirements can incur higher costs. Buyers should assess whether the customization aligns with their operational needs.

-

Material Quality and Certifications: Valves that meet industry standards and certifications (such as ISO, CE, or API) may come at a premium. Buyers should consider the long-term benefits of investing in higher-quality, certified products.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding international shipping terms (Incoterms) is essential. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly impact the overall cost.

What Are Effective Buyer Tips for Cost-Efficiency in Sourcing?

To maximize cost-efficiency when sourcing solenoid valve vents, consider the following tips:

-

Negotiation: Always negotiate pricing with suppliers. Understanding the cost structure can provide leverage in discussions and potentially lead to better terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but the TCO, which includes maintenance, potential downtime, and replacement costs. Investing in higher-quality valves may reduce long-term expenses.

-

Research Pricing Nuances for International Markets: Different regions may have varying pricing structures due to local economic conditions, tariffs, and logistics costs. Understanding these nuances can help buyers make informed decisions.

-

Request Quotes from Multiple Suppliers: Gathering quotes from various suppliers allows for price comparisons and insight into market rates, helping to identify the best value.

-

Stay Informed on Market Trends: Keeping abreast of industry trends and pricing fluctuations can help buyers anticipate changes and adjust their sourcing strategies accordingly.

Disclaimer on Pricing

Prices for solenoid valve vents can vary widely based on the factors outlined above. Buyers should treat any indicative prices as starting points and seek detailed quotes from suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing solenoid valve vent With Other Solutions

When evaluating solutions for venting gases in industrial applications, understanding the alternatives to solenoid valve vents is crucial for informed decision-making. This section will explore various options available to B2B buyers, assessing their performance, costs, and suitability for specific applications.

| Comparison Aspect | Solenoid Valve Vent | Pneumatic Vent Valve | Mechanical Vent Valve |

|---|---|---|---|

| Performance | High accuracy, fast response time | Moderate accuracy, slower response | Variable accuracy, dependent on mechanical design |

| Cost | Moderate initial cost, potential for high long-term savings | Higher initial cost, lower operating costs | Low initial cost, variable maintenance costs |

| Ease of Implementation | Relatively easy installation, requires electrical connections | More complex installation, requires air supply | Simple installation, minimal requirements |

| Maintenance | Requires regular checks and potential replacement of electrical components | Requires periodic maintenance of air lines and valves | Low maintenance, but mechanical wear can occur |

| Best Use Case | Ideal for precise control in automated systems | Suitable for high-flow applications needing quick actuation | Best for simple, low-cost solutions in less critical applications |

What Are the Advantages and Disadvantages of Pneumatic Vent Valves?

Pneumatic vent valves utilize compressed air to open and close, making them a robust alternative to solenoid valve vents. Their high flow capacity and quick actuation are advantageous in applications requiring rapid venting. However, they often come with higher upfront costs and a more complex installation due to the need for an air supply. Maintenance can also be a concern, as leaks in the air supply can affect performance. Overall, pneumatic valves are best suited for industrial environments where speed and reliability are paramount.

How Do Mechanical Vent Valves Compare in Terms of Functionality?

Mechanical vent valves operate based on physical mechanisms, such as levers or springs, to control gas flow. They are generally lower in cost and easier to install than both solenoid and pneumatic options. Mechanical valves are ideal for applications where precision is less critical. However, they can suffer from wear and tear over time, which may lead to inconsistent performance. They are best utilized in simple systems where budget constraints are a priority and high precision is not required.

How to Choose the Right Venting Solution for Your Needs?

Selecting the appropriate venting solution involves understanding your specific operational requirements and constraints. If precise control and automation are crucial, solenoid valve vents may be the best choice. For applications requiring high flow rates and quick responses, pneumatic valves could be more suitable despite their higher costs. Mechanical valves provide a cost-effective solution for simpler applications where maintenance and precision are less of a concern. B2B buyers should assess their operational needs, budget, and maintenance capabilities to make an informed decision.

In conclusion, each venting solution offers unique advantages and potential drawbacks. By carefully evaluating performance, costs, installation complexities, and maintenance requirements, B2B buyers can select the most effective solution for their applications, ensuring efficiency and reliability in their operations.

Essential Technical Properties and Trade Terminology for solenoid valve vent

What Are the Essential Technical Properties of a Solenoid Valve Vent?

When sourcing solenoid valve vents, understanding their technical specifications is crucial for ensuring compatibility and performance in your applications. Below are several key properties that buyers should consider:

-

Material Grade

The materials used in solenoid valve vents, such as brass, stainless steel, or plastic, directly impact durability, corrosion resistance, and suitability for different gases or liquids. For instance, stainless steel is preferred for high-pressure applications due to its strength and resistance to rust, making it ideal for industries such as oil and gas. -

Operating Pressure

This specification indicates the maximum pressure at which the valve can operate safely. Knowing the operating pressure is essential for preventing system failures. Buyers should match the valve’s pressure rating with the requirements of their specific applications, as using a valve outside its rated pressure can lead to leaks or catastrophic failures. -

Flow Rate

The flow rate, often measured in liters per minute (LPM) or gallons per minute (GPM), defines how much fluid can pass through the valve in a given time. This is particularly important in systems requiring precise flow control, such as in manufacturing or chemical processing. Selecting a valve with the appropriate flow rate ensures operational efficiency and prevents bottlenecks. -

Temperature Range

The temperature range indicates the environmental limits within which the solenoid valve can function effectively. Different applications, especially in industries like food and beverage or HVAC, may expose valves to extreme temperatures. Understanding this range helps in selecting a valve that will operate reliably without degradation over time. -

Voltage Rating

Solenoid valves typically require a specific voltage to operate, which can vary based on the model (e.g., 12V, 24V, or 110V). Choosing a valve with the correct voltage rating is critical for ensuring proper operation within electrical systems. Mismatched voltage can lead to malfunction or damage to the valve or control system.

What Are Common Trade Terminology and Jargon Related to Solenoid Valve Vents?

Navigating the procurement process for solenoid valve vents requires familiarity with industry-specific terminology. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture parts or equipment that may be marketed by another company under its brand name. Understanding OEM specifications is vital for buyers looking for compatible components that meet their original equipment standards. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is particularly relevant for B2B buyers who must consider their inventory levels and budget constraints when negotiating orders. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests pricing and terms from suppliers. It is essential for obtaining competitive offers and ensuring that suppliers understand the specific requirements of the solenoid valve vents needed. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms helps buyers understand their shipping costs and liabilities, which is crucial for budget planning and risk management. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is essential for project planning and inventory management, allowing businesses to schedule their operations effectively. -

Certification Standards

Various industries may require solenoid valve vents to meet specific certification standards (e.g., ISO, CE, ATEX). These certifications ensure compliance with safety, quality, and environmental regulations, making it imperative for buyers to verify that their selected products meet these standards.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when selecting solenoid valve vents, ensuring they meet operational needs and compliance requirements.

Navigating Market Dynamics and Sourcing Trends in the solenoid valve vent Sector

What Are the Key Market Dynamics and Sourcing Trends in the Solenoid Valve Vent Sector?

The global solenoid valve vent market is undergoing significant transformation, driven by several key factors. Increasing automation across industries, coupled with a growing focus on energy efficiency and safety, is propelling demand for solenoid vent valves. In regions such as Africa and South America, industrial growth is fostering a rise in manufacturing and processing facilities, which require reliable vent solutions. Meanwhile, the Middle East and Europe are witnessing stringent regulations regarding emissions and energy consumption, prompting industries to adopt advanced technologies like solenoid valves that enhance operational efficiency.

Current B2B sourcing trends indicate a shift towards digital procurement platforms that facilitate easier access to global suppliers. International buyers are increasingly leveraging online marketplaces to compare products, prices, and supplier credentials, enabling them to make informed purchasing decisions. Additionally, manufacturers are investing in IoT-enabled solenoid valves that provide real-time monitoring and predictive maintenance capabilities, which are particularly appealing to buyers looking to enhance operational uptime and reduce maintenance costs.

Emerging technologies, such as AI and machine learning, are also reshaping the landscape by providing predictive analytics that help companies optimize their inventory and supply chain processes. This trend is especially relevant for buyers in Brazil and Saudi Arabia, where rapid urbanization and industrialization necessitate efficient sourcing strategies to keep pace with market demands.

How Can Sustainability and Ethical Sourcing Impact Your B2B Procurement of Solenoid Valve Vents?

Sustainability is becoming increasingly critical in B2B procurement, with buyers more frequently prioritizing suppliers who adhere to environmentally responsible practices. The production of solenoid valve vents often involves materials and processes that can have a significant environmental impact. Thus, understanding the environmental footprint of these products is essential for responsible sourcing.

Buyers should look for manufacturers that utilize eco-friendly materials and processes, such as recyclable metals and low-energy manufacturing techniques. Additionally, certifications such as ISO 14001 (Environmental Management) and Green Seal can serve as indicators of a supplier’s commitment to sustainability. These certifications assure B2B buyers that the products meet rigorous environmental standards, which is particularly relevant in Europe, where regulations are strict.

Moreover, ethical supply chains are increasingly important to international buyers, especially those in regions like Africa and South America, where labor practices and resource extraction can raise ethical concerns. Ensuring that suppliers adhere to fair labor practices and contribute positively to local communities not only enhances brand reputation but can also be a deciding factor for buyers when selecting vendors.

What Is the Evolution of Solenoid Valve Vents in the B2B Market?

The solenoid valve vent sector has evolved considerably over the last few decades. Initially, these valves were primarily mechanical devices, offering basic control over fluid and gas flow. However, advancements in technology have transformed them into sophisticated electronic components that are integral to modern automation systems.

The introduction of digital technologies has enabled solenoid valves to be integrated with control systems, allowing for precise operation and real-time monitoring. As industries across the globe strive for increased efficiency and reduced emissions, the role of solenoid valve vents has expanded from simple operational tools to essential components that contribute to energy management and environmental compliance.

Today, the focus is not just on functionality but also on sustainability and ethical sourcing, reflecting broader trends in the global market. As a result, buyers are now more informed and discerning, looking for products that not only meet their technical requirements but also align with their corporate values and sustainability goals.

Illustrative image related to solenoid valve vent

Frequently Asked Questions (FAQs) for B2B Buyers of solenoid valve vent

-

1. How do I solve issues with solenoid valve vent failures?

To address solenoid valve vent failures, first conduct a thorough inspection to identify any visible signs of damage, corrosion, or blockages. Ensure that the electrical connections are secure and that the solenoid is receiving the correct voltage. If the valve is sticking or leaking, it may need cleaning or replacement. Additionally, regularly scheduled maintenance can prevent future issues. Implementing a robust diagnostic procedure can help pinpoint problems early, reducing downtime and associated costs. -

2. What is the best solenoid valve vent for high-pressure applications?

For high-pressure applications, solenoid valves designed with robust materials and high flow rates are essential. Look for valves that can handle pressures exceeding your system’s requirements, typically rated for at least 150% of the maximum expected pressure. Brands like ASCO and Emerson offer high-flow models specifically engineered for demanding environments. Always consult the technical specifications and ensure compatibility with the fluids in use to optimize performance and safety. -

3. How can I vet suppliers for solenoid valve vents?

Vetting suppliers involves assessing their manufacturing standards, certifications, and customer reviews. Look for ISO certifications and compliance with international standards relevant to your region. Request samples to evaluate product quality firsthand and inquire about their production capacity, lead times, and after-sales support. Additionally, establish communication to gauge their responsiveness and willingness to address your specific needs, which can be crucial for long-term partnerships. -

4. Are customization options available for solenoid valve vents?

Many manufacturers offer customization for solenoid valve vents to meet specific operational needs. Customization may include modifications in size, material, or pressure ratings. When sourcing, inquire about the supplier’s capabilities to tailor products to your specifications and any associated costs or minimum order quantities. This can enhance compatibility with your systems and ensure optimal performance in your unique application. -

5. What are typical minimum order quantities (MOQ) for solenoid valve vents?

Minimum order quantities (MOQ) for solenoid valve vents can vary significantly by supplier, typically ranging from 50 to several hundred units. Some manufacturers may offer lower MOQs for specific models or during promotional periods. It’s advisable to communicate your requirements upfront to negotiate terms that align with your purchasing strategy. Consider establishing a relationship with suppliers who are flexible with MOQs, especially if you’re exploring new products. -

6. What payment terms should I expect when purchasing solenoid valve vents internationally?

Payment terms for international purchases of solenoid valve vents can vary widely. Common options include upfront payment, partial payment with a balance due upon delivery, or net payment terms (e.g., 30 or 60 days). Ensure to clarify these terms in advance and understand any additional fees related to currency exchange or international transactions. Utilizing secure payment methods and letters of credit can provide protection for both parties in the transaction. -

7. How do I ensure quality assurance for solenoid valve vents?

To ensure quality assurance, request detailed product specifications and certifications from the supplier. Conduct factory audits or third-party inspections to verify manufacturing practices and quality control measures. Establish a clear return policy for defective products and inquire about warranties offered. Implementing a quality inspection protocol upon receipt of goods can further safeguard against discrepancies and ensure compliance with your operational standards. -

8. What logistics considerations should I keep in mind for international shipping of solenoid valve vents?

When planning logistics for international shipping, consider factors such as shipping methods, lead times, and customs regulations in both the exporting and importing countries. Collaborate with suppliers who have experience in international shipping to navigate these complexities. Additionally, assess the packaging to prevent damage during transit and factor in potential tariffs and duties that may affect overall costs. Establishing a reliable logistics partner can streamline the process and ensure timely delivery.

Top 4 Solenoid Valve Vent Manufacturers & Suppliers List

1. Cleaver-Brooks – Solenoid Gas Vent Valve

Domain: parts.cleaverbrooks.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “Solenoid Gas Vent Valve”, “type”: “Normally Open”, “size”: “3/4\” NPT”, “weight”: “Not specified”, “price”: “Not Available”, “availability”: “Please contact your local Sales Representative for price and availability.”}

2. Emerson – ASCO™ Solenoid Vent Valves

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – ASCO™ Solenoid Vent Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Reddit – Purge Valve Functionality

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Purge Valve Functionality, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Samarins – EVAP Vent Valve

Domain: samarins.com

Registered: 2000 (25 years)

Introduction: The EVAP Vent Valve (solenoid) is a component of the Evaporative Emission Control (EVAP) system in modern cars, designed to prevent fuel vapors from escaping into the atmosphere. It controls the flow of outside air in and out of the charcoal canister, which is connected to the fuel tank. The vent valve is typically located near the charcoal canister, close to the fuel tank, and is controlled by th…

Strategic Sourcing Conclusion and Outlook for solenoid valve vent

In conclusion, the strategic sourcing of solenoid valve vents presents a significant opportunity for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. By prioritizing quality and reliability in procurement, businesses can ensure optimal performance and longevity of their systems, reducing downtime and maintenance costs. Understanding the diverse applications and specifications of solenoid valves is crucial for making informed purchasing decisions that align with operational needs.

Investing in strategic sourcing not only fosters stronger supplier relationships but also enhances supply chain resilience. Buyers should leverage digital platforms and industry networks to identify reputable manufacturers and suppliers, ensuring they access the latest innovations and competitive pricing.

Looking ahead, the demand for efficient and reliable solenoid valve solutions will continue to grow as industries evolve and regulatory standards tighten. International buyers are encouraged to stay proactive in their sourcing strategies, exploring new technologies and fostering partnerships that will drive sustainable growth. By doing so, they can position themselves at the forefront of industry advancements, unlocking new avenues for success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.