Everything You Need to Know About 2Jz Gte Engine For Sale Sourcing in 2025

Introduction: Navigating the Global Market for 2jz gte engine for sale

In an increasingly competitive landscape, sourcing the right 2JZ GTE engine for sale can be a daunting task for international B2B buyers. The 2JZ GTE, renowned for its reliability and power, particularly in high-performance applications like motorsports and vehicle modifications, presents unique challenges in sourcing. Buyers from regions such as Africa, South America, the Middle East, and Europe face hurdles such as fluctuating prices, varying quality standards, and the need for trustworthy suppliers. This guide aims to streamline the purchasing process, empowering buyers to make informed decisions.

Throughout this comprehensive resource, we will explore the diverse types of 2JZ GTE engines available, their applications across different industries, and essential strategies for vetting suppliers. Additionally, we will delve into cost considerations, highlighting how to balance quality with budget constraints. By providing actionable insights and best practices, this guide not only enhances your understanding of the global market but also equips you with the tools to negotiate effectively and secure the best deals.

Whether you are looking to enhance a vehicle’s performance or fulfill a specific project requirement, this guide will serve as your roadmap in navigating the complexities of acquiring a 2JZ GTE engine, ultimately leading to successful and satisfying procurement experiences.

Understanding 2jz gte engine for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| JDM 2JZ-GTE VVTI | Twin-turbo, inline-6, high horsepower (up to 320.5 HP) | Performance tuning, racing builds | Pros: High performance, reliability. Cons: Higher cost, requires compatible vehicle. |

| 2JZ-GTE Non-VVTI | Older variant, slightly lower power output (up to 276 HP) | Classic car restorations, drift cars | Pros: More affordable, easier to source. Cons: Lower performance, fewer features. |

| Rebuilt 2JZ-GTE | Remanufactured for reliability, often with upgraded components | Commercial fleet vehicles, tuning shops | Pros: Cost-effective, often comes with warranty. Cons: Potential for varied quality. |

| 2JZ-GTE Engine Swap Kits | Complete kits including engine, transmission, and accessories | Custom builds, performance upgrades | Pros: All-in-one solution, tailored performance. Cons: Requires installation expertise. |

| 2JZ-GTE with Aftermarket Parts | Customized with performance enhancements like turbos and ECUs | Racing teams, performance enthusiasts | Pros: Enhanced power and efficiency. Cons: Increased complexity and cost. |

What Are the Key Characteristics of JDM 2JZ-GTE VVTI Engines?

The JDM 2JZ-GTE VVTI engine is renowned for its robust construction and impressive performance metrics, including a maximum output of 320.5 HP. This version features variable valve timing (VVTi), which optimizes engine efficiency and power delivery. It is ideal for high-performance applications, such as racing and tuning, making it a popular choice among B2B buyers looking for engines to power competitive vehicles. When purchasing, consider the engine’s compatibility with your existing setup and the associated costs, as these engines typically come at a premium.

How Does the 2JZ-GTE Non-VVTI Differ from Its Counterparts?

The 2JZ-GTE Non-VVTI variant, while older, remains a staple in the automotive community, especially for those restoring classic cars or building drift machines. It offers a lower power output of around 276 HP but is often more affordable and easier to source than its VVTI counterpart. This engine is suitable for buyers looking for a balance between performance and cost. When considering a purchase, assess the engine’s condition and any required modifications to ensure it meets your performance goals.

What Advantages Do Rebuilt 2JZ-GTE Engines Offer?

Rebuilt 2JZ-GTE engines are an excellent option for B2B buyers seeking reliability at a lower cost. These engines are typically remanufactured with upgraded components, ensuring they meet or exceed original specifications. They are particularly appealing to commercial fleet operators or tuning shops looking for dependable engines without the higher price tag of new units. Buyers should inquire about warranty options and the reputation of the rebuilding company to ensure quality.

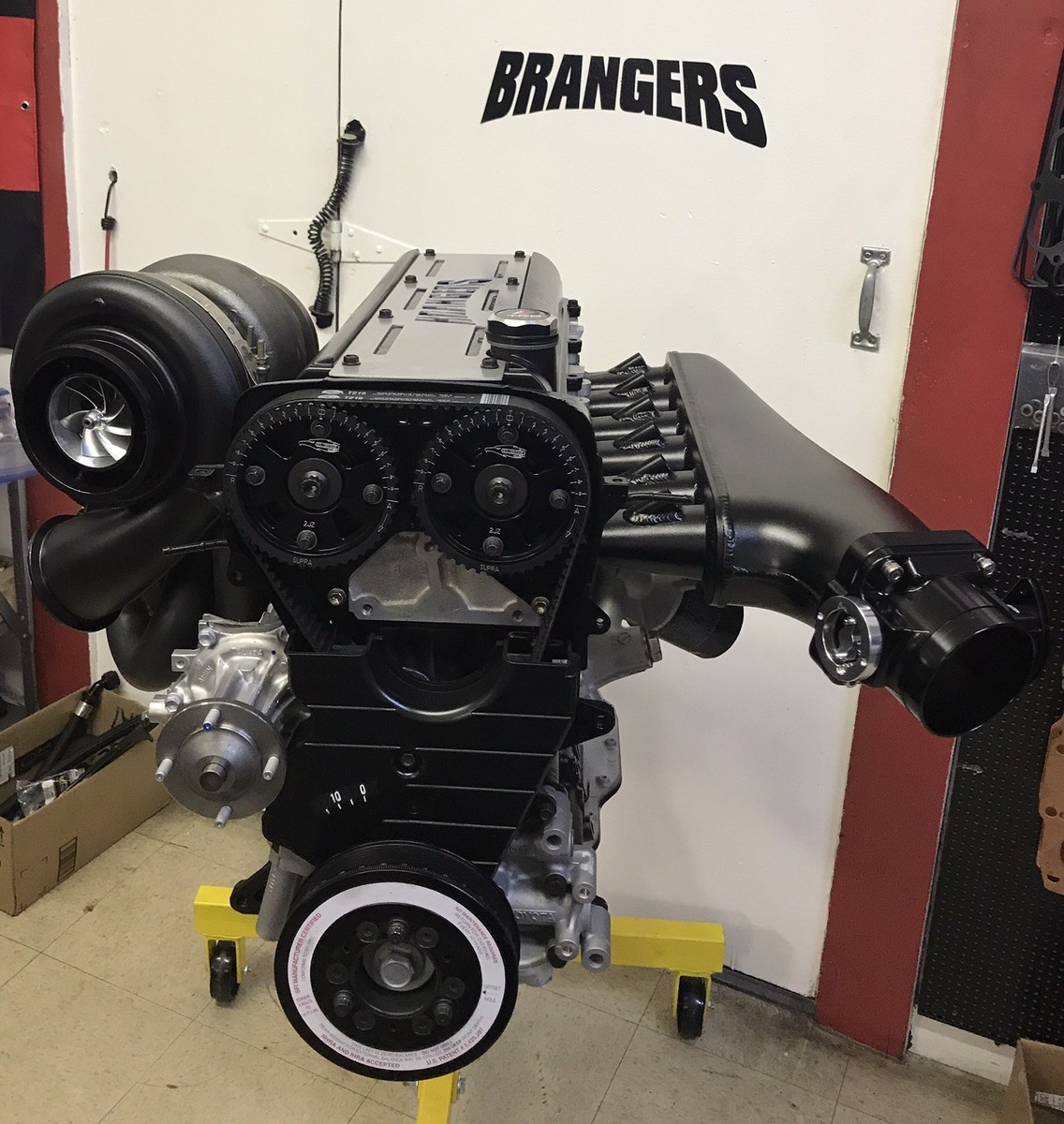

Illustrative image related to 2jz gte engine for sale

Why Consider 2JZ-GTE Engine Swap Kits?

Engine swap kits that include the 2JZ-GTE engine, along with transmission and necessary accessories, provide a comprehensive solution for custom builds. These kits are particularly beneficial for businesses engaged in performance upgrades or custom vehicle modifications. While they offer a straightforward installation process, buyers should ensure they have the technical expertise or support to execute the swap effectively. The investment in a complete kit can save time and effort, making it a worthwhile consideration for serious projects.

How Do Aftermarket Parts Enhance the 2JZ-GTE Engine?

For performance enthusiasts, 2JZ-GTE engines equipped with aftermarket parts can significantly boost power and efficiency. Upgrades may include enhanced turbochargers, improved ECUs, and performance exhaust systems. These enhancements cater to racing teams and performance shops looking to maximize their competitive edge. However, buyers should be cautious about the complexity and potential costs associated with these modifications, ensuring that they align with their performance objectives and budget.

Key Industrial Applications of 2jz gte engine for sale

| Industry/Sector | Specific Application of 2jz gte engine for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Performance | High-performance racing vehicles | Enhanced speed and power, attracting competitive edge | Engine specifications, compatibility with existing models, warranty options |

| Custom Builds | Modified street cars | Customization potential for unique designs | Availability of parts, ease of installation, support for aftermarket modifications |

| Motorsports | Drift and drag racing applications | Proven reliability under extreme conditions | Proven performance history, technical support, and tuning options |

| Export Markets | International vehicle restoration projects | Cost-effective sourcing for high-demand engines | Compliance with import regulations, shipping logistics, and customs considerations |

| Automotive Education | Training programs for mechanics | Hands-on experience with advanced engine technology | Availability of educational resources, training support, and documentation |

How is the 2JZ GTE Engine Used in Automotive Performance Applications?

In the automotive performance sector, the 2JZ GTE engine is renowned for its capability to deliver exceptional horsepower and torque, making it a favorite for high-performance racing vehicles. This engine’s robust design allows it to withstand the rigors of competitive racing, providing businesses with a significant advantage in speed and reliability. For international buyers, especially in regions like Africa and South America, sourcing this engine can elevate their racing teams’ performance, ensuring they remain competitive in local and international events.

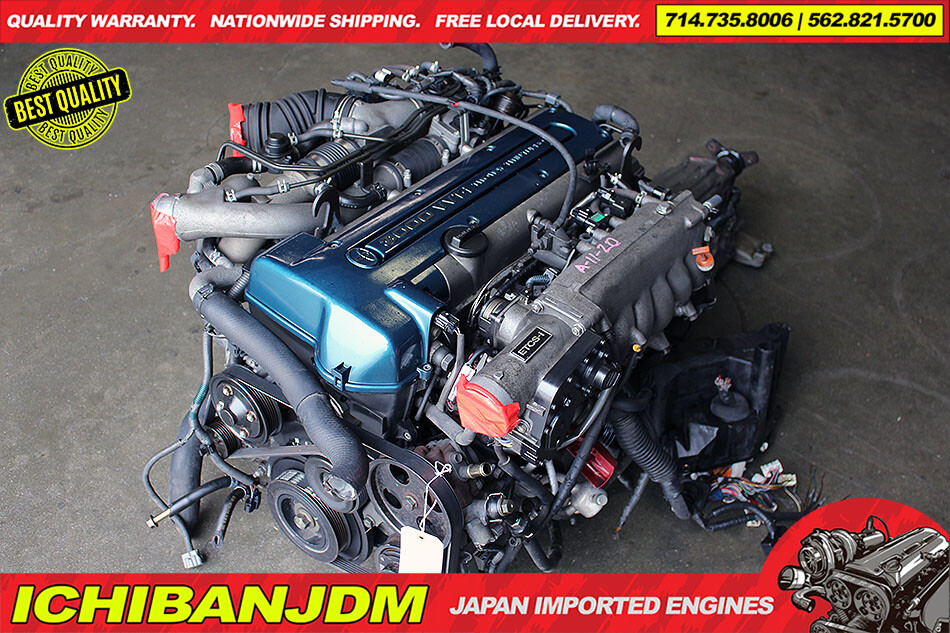

Illustrative image related to 2jz gte engine for sale

What Role Does the 2JZ GTE Engine Play in Custom Builds?

In the custom builds arena, the 2JZ GTE engine serves as a versatile power source for modified street cars. Its ability to be tailored to fit various chassis configurations allows builders to create unique vehicles that stand out in the market. For buyers in Europe and the Middle East, the appeal lies in the engine’s adaptability and the extensive aftermarket support available, enabling them to customize their builds to meet specific aesthetic and performance goals.

Why is the 2JZ GTE Engine Essential for Motorsports?

Motorsports applications, particularly in drift and drag racing, benefit significantly from the 2JZ GTE engine’s proven reliability and performance under extreme conditions. Its twin-turbo setup provides instant power delivery, crucial for competitive racing scenarios. Businesses involved in this sector can leverage the engine’s reputation to attract sponsorships and partnerships, especially in regions with a burgeoning motorsports culture, such as Brazil and Nigeria.

How Can the 2JZ GTE Engine Support Export Markets?

For businesses focused on export markets, the 2JZ GTE engine represents a cost-effective solution for vehicle restoration projects. Its popularity and availability make it a sought-after component for restoring classic vehicles, enhancing their resale value. Buyers must consider compliance with local import regulations and shipping logistics to ensure a smooth procurement process, particularly in regions where classic car restoration is gaining traction.

What is the Importance of the 2JZ GTE Engine in Automotive Education?

In automotive education, the 2JZ GTE engine provides an excellent platform for training aspiring mechanics. Its advanced technology and engineering design allow students to gain hands-on experience with a high-performance engine. Educational institutions and training programs must ensure they have adequate resources and support materials to maximize the learning experience for their students, making it an attractive option for international educational buyers looking to enhance their curriculum.

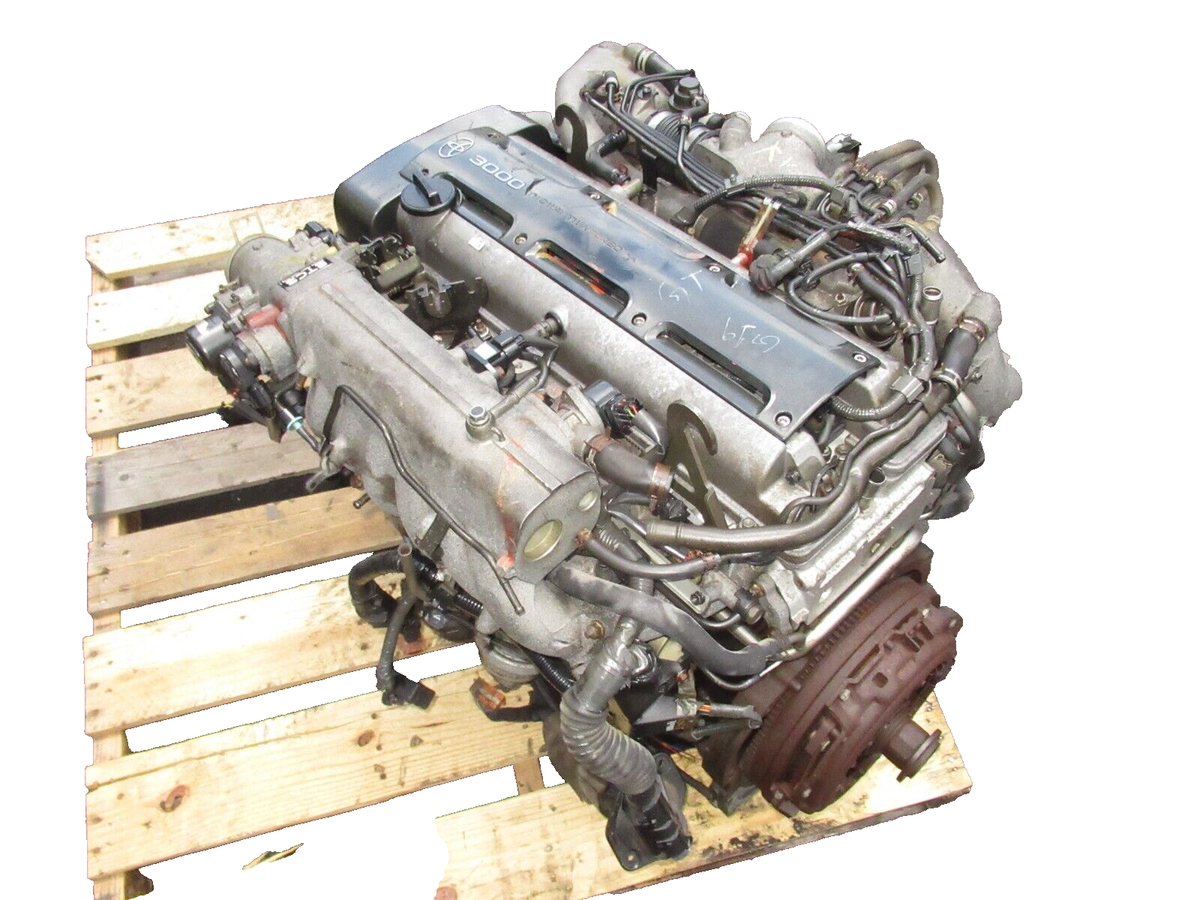

Illustrative image related to 2jz gte engine for sale

3 Common User Pain Points for ‘2jz gte engine for sale’ & Their Solutions

Scenario 1: Difficulty in Verifying Engine Authenticity and Condition

The Problem: Many B2B buyers face the challenge of ensuring that the 2JZ GTE engines they are purchasing are genuine and in good condition. Given the prevalence of counterfeit or subpar products in the market, especially in international transactions, buyers often worry about the risks associated with their investment. Concerns regarding engine mileage, previous usage, and overall reliability can lead to anxiety and hesitation in making a purchase.

The Solution: To mitigate these concerns, buyers should prioritize sourcing engines from reputable dealers who provide comprehensive documentation and warranties. Look for suppliers that offer detailed service history and inspection reports for their engines. Additionally, consider requesting a video demonstration or live inspection via video call to confirm the engine’s condition and functionality. Utilizing platforms that specialize in verified JDM (Japanese Domestic Market) engines can also enhance confidence. Establishing a direct line of communication with the supplier can facilitate transparency and build trust, ensuring that you are making a well-informed decision.

Scenario 2: Complications in International Shipping and Customs

The Problem: International B2B buyers often encounter logistical challenges when importing a 2JZ GTE engine. Issues can arise from complex customs regulations, unexpected shipping delays, and additional tariffs that can significantly increase the overall cost of the purchase. Furthermore, miscommunication regarding shipping terms can lead to misunderstandings and additional fees, which can sour the purchasing experience.

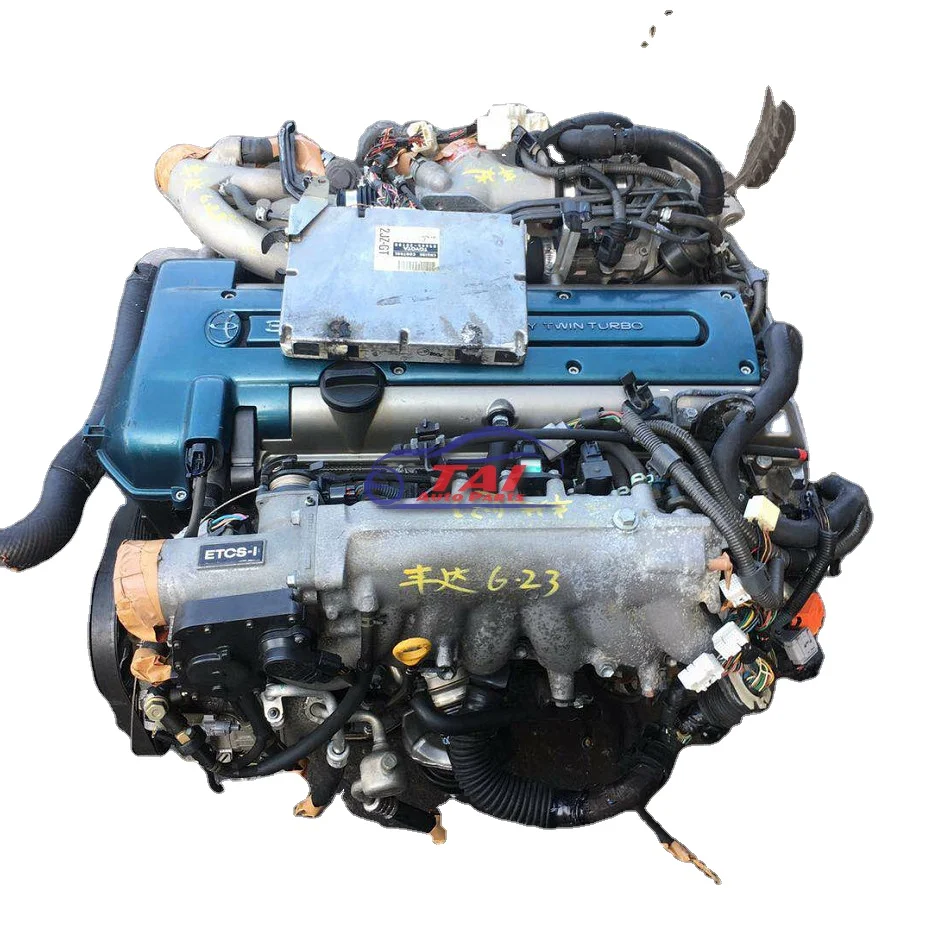

Illustrative image related to 2jz gte engine for sale

The Solution: To navigate these complexities, buyers should engage with shipping professionals who specialize in international automotive parts. They can provide insights into the best shipping methods and help you understand the customs requirements specific to your country. It’s crucial to clarify the Incoterms with your supplier to ensure both parties understand who is responsible for shipping costs, insurance, and customs duties. Additionally, consider leveraging a freight forwarder who can handle all logistics and paperwork, ensuring a smoother transaction. Researching your country’s import regulations ahead of time will also prepare you for potential hurdles.

Scenario 3: Uncertainty About Engine Compatibility and Installation

The Problem: A common pain point for B2B buyers is the uncertainty regarding whether the 2JZ GTE engine will be compatible with their existing vehicle models. Buyers often lack the technical knowledge to determine if additional modifications or parts are necessary for installation. This uncertainty can lead to increased costs and time delays, affecting project timelines and profitability.

The Solution: To avoid compatibility issues, buyers should conduct thorough research prior to purchase. This includes consulting with automotive specialists or mechanics familiar with the 2JZ GTE engine and its installation requirements. Utilizing online forums and communities focused on the Toyota JDM market can also provide valuable insights from experienced users. When negotiating with suppliers, ask for compatibility details specific to your vehicle model and inquire about any additional components that may be required for a successful installation. Additionally, consider sourcing from suppliers who offer installation support or guidance, ensuring that you can effectively integrate the engine into your existing setup without unforeseen complications.

Strategic Material Selection Guide for 2jz gte engine for sale

What Are the Key Materials Used in the 2JZ GTE Engine?

When considering the purchase of a 2JZ GTE engine, understanding the materials used in its construction is crucial for B2B buyers. Each material contributes to the engine’s performance, durability, and overall suitability for various applications. Below, we analyze four common materials used in the 2JZ GTE engine, highlighting their properties, advantages, disadvantages, and considerations for international buyers.

How Does Aluminum Contribute to Engine Performance?

Aluminum is a primary material used in the construction of the 2JZ GTE engine block and cylinder head.

Illustrative image related to 2jz gte engine for sale

- Key Properties: Aluminum offers excellent thermal conductivity, lightweight characteristics, and good corrosion resistance. It has a melting point of approximately 660°C and can withstand moderate pressure levels.

- Pros & Cons: The lightweight nature of aluminum enhances engine responsiveness and performance. However, it is less durable than iron and may require careful handling during manufacturing. Additionally, aluminum can be more expensive than traditional materials like cast iron.

- Impact on Application: Aluminum’s thermal properties allow for efficient heat dissipation, making it suitable for high-performance applications. However, its lower strength compared to steel may limit its use in extremely high-stress environments.

- Considerations for International Buyers: Compliance with international standards such as ASTM and JIS is essential. Buyers from regions like Africa and South America should ensure that suppliers provide materials that meet local regulations regarding emissions and performance.

Why Is Cast Iron a Popular Choice for Engine Components?

Cast iron is often used in the manufacturing of engine components such as the crankshaft and cylinder liners.

- Key Properties: Cast iron is known for its high wear resistance, excellent compressive strength, and ability to withstand high temperatures (up to 1200°C). It also has good vibration damping properties.

- Pros & Cons: The durability and strength of cast iron make it ideal for high-stress applications. However, it is heavier than aluminum, which can affect overall engine weight and performance. Additionally, cast iron can be prone to rust if not properly maintained.

- Impact on Application: Cast iron components are well-suited for high-torque applications, providing longevity and reliability. However, its weight can be a disadvantage in performance-focused scenarios.

- Considerations for International Buyers: Buyers should verify the quality of cast iron used, ensuring it meets ASTM standards. In regions with high humidity, such as parts of South America, corrosion resistance is a significant factor.

What Role Does Steel Play in Engine Construction?

Steel is commonly used in various engine components, including bolts, gears, and the crankshaft.

- Key Properties: Steel offers high tensile strength, excellent fatigue resistance, and can withstand high temperatures and pressures. Its melting point is around 1370°C, making it suitable for high-performance applications.

- Pros & Cons: The strength and durability of steel make it an ideal choice for critical engine components. However, it is heavier than aluminum and can be more expensive due to the manufacturing processes involved.

- Impact on Application: Steel components provide reliability and stability under high-stress conditions, which is crucial for performance engines. The weight factor may be a concern for buyers focused on weight reduction.

- Considerations for International Buyers: Buyers should ensure that steel components meet international standards for quality and performance. In regions like the Middle East, where extreme temperatures are common, selecting high-grade steel is essential for engine longevity.

How Does Composite Material Enhance Engine Efficiency?

Composite materials are increasingly used in engine applications, particularly for gaskets and seals.

- Key Properties: Composites can be engineered to provide excellent thermal stability, lightweight characteristics, and resistance to chemical degradation. They can operate effectively at temperatures up to 300°C.

- Pros & Cons: The lightweight nature of composites can enhance fuel efficiency and performance. However, they may not be as durable as metals and can be more expensive to manufacture.

- Impact on Application: Composites are ideal for applications where weight savings are critical, such as in racing or high-performance vehicles. However, their lower durability may limit their use in high-stress environments.

- Considerations for International Buyers: Buyers should check for compliance with international material standards and ensure that the composites used are suitable for the specific environmental conditions in their region.

Summary of Material Properties for 2JZ GTE Engine

| Material | Typical Use Case for 2JZ GTE Engine for Sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine block and cylinder head | Lightweight and excellent thermal conductivity | Less durable than cast iron | Medium |

| Cast Iron | Crankshaft and cylinder liners | High wear resistance and strength | Heavier and prone to rust | Medium |

| Steel | Bolts, gears, and crankshaft | High tensile strength and durability | Heavier and potentially more expensive | High |

| Composite | Gaskets and seals | Lightweight and thermal stability | Lower durability and higher cost | Medium |

This strategic material selection guide provides valuable insights for B2B buyers considering the purchase of a 2JZ GTE engine. Understanding the properties and implications of each material can aid in making informed decisions that align with performance needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 2jz gte engine for sale

What Are the Main Stages of Manufacturing a 2JZ GTE Engine?

Manufacturing a 2JZ GTE engine involves several critical stages, ensuring that each component meets stringent quality standards and performance specifications. The typical manufacturing process can be broken down into the following main stages:

Material Preparation

The first stage involves sourcing high-quality raw materials, primarily aluminum for the engine block and iron for the cylinder head. These materials undergo rigorous inspections to confirm their mechanical properties and chemical composition, ensuring they meet industry standards. Suppliers are typically selected based on their ability to provide materials that comply with international standards such as ISO 9001.

Forming

Once the materials are prepared, the forming stage begins. This involves machining processes like casting, forging, and CNC machining to shape the engine components. For the 2JZ GTE, precision is paramount; thus, advanced CNC machines are utilized to achieve the necessary tolerances. The components are then subjected to various treatments, such as heat treatment and surface hardening, to enhance durability and performance.

Assembly

The assembly stage is where the engine comes together. Technicians follow detailed assembly protocols to ensure each component is correctly fitted. This includes installing the crankshaft, pistons, and turbochargers, as well as integrating the ECU and wiring harnesses. Each assembly step is closely monitored and documented to maintain traceability and accountability.

Finishing

Finally, the finishing stage involves quality checks and surface treatments. Components are cleaned, and any necessary coatings are applied to prevent corrosion and wear. This stage also includes final inspections to verify that all specifications are met before the engine is packaged for shipment.

How Is Quality Assurance Implemented in the Manufacturing of 2JZ GTE Engines?

Quality assurance (QA) is a critical aspect of manufacturing, especially for high-performance engines like the 2JZ GTE. Various international and industry-specific standards guide the QA process.

Illustrative image related to 2jz gte engine for sale

What Are the Relevant International Standards for Quality Assurance?

For manufacturers targeting B2B buyers, adhering to international standards such as ISO 9001 is essential. This standard focuses on quality management systems and ensures that manufacturers have processes in place to consistently deliver quality products. In addition, certifications like CE mark and API standards may be relevant depending on the region and application of the engine.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival to ensure they meet specifications before they enter the production line.

-

In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process. Technicians perform regular checks on dimensions and tolerances to catch any deviations early.

-

Final Quality Control (FQC): Before the engines are shipped, a comprehensive final inspection is conducted. This includes functional testing and performance evaluations to ensure that the engine meets or exceeds manufacturer specifications.

What Common Testing Methods Are Used for Quality Assurance?

Various testing methods are employed to ensure the 2JZ GTE engine’s performance and reliability:

-

Dynamometer Testing: This method assesses engine performance, measuring power output and torque under various conditions.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection are used to detect internal flaws without damaging the components.

-

Leak Testing: Ensures that the engine’s cooling and lubrication systems are free from leaks, maintaining operational integrity.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance with local regulations.

What Steps Can Buyers Take to Audit and Verify Quality Control?

-

Supplier Audits: Buyers can request audits of the manufacturing facilities to assess the adherence to quality standards. This includes evaluating the manufacturing processes, equipment, and personnel qualifications.

-

Quality Reports: Requesting detailed QC reports can provide insight into the supplier’s testing methodologies, results, and any corrective actions taken in response to failures.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the manufacturing quality. This is particularly valuable for buyers who may not be able to conduct on-site audits.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers should be aware of specific nuances when it comes to quality control and certification:

-

Local Compliance: Different countries may have unique regulations regarding engine emissions and safety standards. Buyers should ensure that the engines comply with the relevant regulations in their markets.

-

Documentation: Proper documentation, including certificates of compliance and quality assurance, should accompany the product. This documentation is critical for customs clearance and legal compliance in the buyer’s country.

-

After-Sales Support: Understanding the supplier’s after-sales support and warranty policies is crucial, especially when dealing with high-performance engines. This can impact long-term satisfaction and operational reliability.

Conclusion

The manufacturing processes and quality assurance practices for the 2JZ GTE engine are designed to ensure that B2B buyers receive a reliable and high-performance product. By understanding the intricacies of manufacturing stages, quality control standards, and verification methods, international buyers can make informed purchasing decisions that align with their operational needs and regulatory requirements.

Illustrative image related to 2jz gte engine for sale

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2jz gte engine for sale’

This guide serves as a practical checklist for B2B buyers seeking to procure a 2JZ GTE engine. By following these steps, you can ensure a successful purchasing experience, minimizing risks and maximizing the value of your investment.

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline the technical specifications you need for the 2JZ GTE engine. Consider factors such as power output, compatibility with existing systems, and any additional components required for your project. This clarity will help you communicate effectively with suppliers and ensure you receive the right product.

- Power Requirements: Determine the horsepower and torque levels you need based on your application.

- Compatibility: Ensure the engine fits within your vehicle or project specifications, including dimensions and mounting points.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in JDM engines, particularly the 2JZ GTE. Look for companies with a strong online presence, positive customer reviews, and extensive experience in the industry.

- Supplier Reputation: Check online reviews and testimonials from previous buyers, especially those from your region.

- Product Range: Ensure the supplier offers a variety of options, including different conditions (new, rebuilt, or used).

Step 3: Evaluate Supplier Certifications

Before proceeding with a purchase, verify that the supplier holds necessary certifications and adheres to industry standards. This step is crucial for ensuring product quality and compliance with international shipping regulations.

- Quality Assurance: Look for ISO certifications or similar standards that indicate a commitment to quality.

- Regulatory Compliance: Ensure that the supplier complies with export regulations, particularly if you’re sourcing from overseas.

Step 4: Request Detailed Product Information

Once you have shortlisted potential suppliers, request detailed product information for the 2JZ GTE engines they offer. This information should include specifications, condition reports, and any warranties or guarantees.

- Documentation: Ensure you receive proper documentation such as engine history, mileage, and maintenance records.

- Warranty Terms: Understand the warranty coverage and what it includes, as this can vary significantly between suppliers.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your chosen supplier to secure the best price and payment terms. Be clear about your budget constraints and any additional costs, such as shipping or customs fees.

- Bulk Discounts: If you plan to purchase multiple engines, inquire about bulk pricing.

- Payment Options: Discuss acceptable payment methods and terms to ensure a smooth transaction.

Step 6: Confirm Shipping and Delivery Logistics

Before finalizing the purchase, clarify shipping arrangements and delivery timelines. Understanding the logistics will help you plan for any potential delays and ensure that you can receive and install the engine promptly.

Illustrative image related to 2jz gte engine for sale

- Shipping Method: Choose a reliable shipping method that balances cost and delivery speed.

- Tracking and Insurance: Ensure that the shipment is trackable and consider insuring the engine during transit.

Step 7: Establish Post-Purchase Support

After the engine is delivered, maintain communication with the supplier for any post-purchase support. This includes assistance with installation, troubleshooting, or warranty claims.

- Technical Support: Confirm that the supplier offers technical support for installation and operation.

- Return Policy: Understand the return policy in case the engine does not meet your expectations or has defects.

By following these steps, B2B buyers can navigate the complexities of sourcing a 2JZ GTE engine effectively, ensuring a smooth procurement process and a successful project outcome.

Comprehensive Cost and Pricing Analysis for 2jz gte engine for sale Sourcing

What Are the Key Cost Components of Sourcing a 2JZ GTE Engine?

When analyzing the cost structure for sourcing a 2JZ GTE engine, several critical components come into play. First, materials account for a significant portion of the total cost. The engine consists of high-quality components such as aluminum alloy for the block, steel for the crankshaft, and various alloy materials for pistons and valves, which can drive up prices depending on market fluctuations.

Next, labor costs are essential in determining the final price. This includes the wages of skilled workers who assemble the engines and perform necessary quality checks. In regions where labor is more expensive, such as Europe, the overall cost may be higher than in countries with lower labor costs.

Illustrative image related to 2jz gte engine for sale

Manufacturing overhead encompasses indirect costs such as utilities, rent, and administrative expenses that contribute to production. These costs can vary significantly between manufacturers, affecting the final pricing of the engine.

Tooling costs also play a role. Advanced machinery for precision manufacturing can be costly, and these expenses are typically factored into the engine price. Additionally, quality control (QC) processes ensure that each engine meets performance standards, which may add to the overall cost but is crucial for maintaining reliability and customer satisfaction.

Lastly, logistics must be considered, particularly for international buyers. Shipping costs, customs duties, and insurance can significantly impact the final price of the engine when sourced from overseas.

What Influences the Pricing of 2JZ GTE Engines for International Buyers?

Several factors influence the pricing of the 2JZ GTE engines, particularly for international B2B buyers. Volume and Minimum Order Quantity (MOQ) are crucial. Suppliers may offer better pricing tiers based on larger orders, encouraging buyers to purchase multiple units at a time.

Illustrative image related to 2jz gte engine for sale

Specifications and customization can also affect pricing. Engines tailored to specific performance requirements or those with additional features may incur higher costs. Buyers should assess whether the additional investment aligns with their project goals.

The quality of materials used, along with any certifications, can also impact pricing. Engines that meet higher quality standards or come with certifications may command a premium but often ensure better performance and reliability.

Supplier factors, including reputation and experience, influence pricing as well. Established suppliers with proven track records may charge more due to their reliability and customer service, while newer entrants might offer competitive rates to gain market share.

Incoterms are vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and duties, affecting the overall landed cost of the engine.

How Can Buyers Optimize Their Costs When Sourcing 2JZ GTE Engines?

International buyers should consider several strategies to enhance cost-efficiency when sourcing 2JZ GTE engines. Negotiation is key; engaging in discussions about pricing, payment terms, and delivery timelines can yield better deals. Buyers should be prepared with market research to substantiate their negotiation points.

Understanding the Total Cost of Ownership (TCO) is crucial. This includes not just the purchase price but also maintenance, fuel efficiency, and potential resale value. Evaluating TCO can guide buyers in making informed decisions that save money in the long run.

Buyers from regions such as Africa and South America should be aware of pricing nuances related to import tariffs and taxes, which can differ significantly based on country regulations. It’s advisable to work with local experts or logistics companies familiar with the import process to avoid unexpected costs.

Lastly, exploring alternative suppliers and comparing quotes can uncover competitive pricing options. Utilizing online marketplaces and platforms specializing in automotive parts can provide a broader view of available options, enhancing the chances of finding a favorable deal.

Disclaimer on Pricing

It is important to note that the prices mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult multiple sources and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing 2jz gte engine for sale With Other Solutions

Understanding Alternatives to the 2JZ GTE Engine

In the automotive industry, particularly for high-performance applications, buyers often seek alternatives that can deliver similar or enhanced capabilities compared to the widely acclaimed 2JZ GTE engine. This engine, known for its robustness and power, has a strong following among car enthusiasts and racers. However, as the market evolves, it’s essential for B2B buyers to explore other viable options that meet their specific needs, whether for performance builds, engine swaps, or replacements.

Comparison Table of Alternatives

| Comparison Aspect | 2JZ GTE Engine For Sale | LS V8 Engine | RB26DETT Engine |

|---|---|---|---|

| Performance | 276-320 HP, known for high tuning potential | 400-700 HP, excellent torque and tuning flexibility | 276 HP, strong aftermarket support |

| Cost | $3,350 average | $5,000 average (varies widely) | $4,000 average |

| Ease of Implementation | Moderate; requires specific mounts and wiring | Relatively easy; many kits available | Moderate; specific mounts needed |

| Maintenance | High; parts can be expensive | Moderate; widespread availability of parts | High; specialized components |

| Best Use Case | Performance tuning in JDM builds | Muscle cars, street performance | Drift and race applications |

In-Depth Analysis of Alternatives

What are the Pros and Cons of the LS V8 Engine?

The LS V8 engine has gained immense popularity due to its impressive performance and versatility. With horsepower ranging from 400 to over 700, it offers significant power and torque, making it a favorite for performance builds, especially in muscle cars. The cost of an LS engine is generally higher than that of a 2JZ GTE, averaging around $5,000, but the abundance of aftermarket parts and support simplifies maintenance. However, implementing an LS engine may require modifications to the vehicle’s structure and wiring, which can add complexity to the installation process.

How Does the RB26DETT Engine Compare to the 2JZ GTE?

The RB26DETT engine, originating from the Nissan Skyline, is another strong alternative to the 2JZ GTE. With similar performance figures (approximately 276 HP), it is a popular choice among enthusiasts for drift and race applications. The engine is renowned for its durability and has a robust aftermarket support system. However, like the 2JZ GTE, maintenance can be costly, and sourcing parts may be challenging in certain regions, particularly outside of Japan. The installation process requires specific mounts and adaptations, making it moderately easy to implement.

How Can B2B Buyers Choose the Right Engine Solution?

When selecting the right engine solution, B2B buyers should consider several factors, including performance requirements, budget constraints, ease of installation, and long-term maintenance costs. The 2JZ GTE remains an excellent choice for buyers focused on high-performance JDM builds, while the LS V8 engine may appeal to those looking for more power and availability of parts. The RB26DETT serves as a strong alternative for those seeking to replicate the performance of the 2JZ GTE while also enjoying the benefits of a different brand’s engineering. Ultimately, assessing the specific application and intended use will guide buyers in making an informed decision that aligns with their operational needs.

Illustrative image related to 2jz gte engine for sale

Essential Technical Properties and Trade Terminology for 2jz gte engine for sale

What Are the Key Technical Properties of the 2JZ GTE Engine?

When considering the purchase of a 2JZ GTE engine, understanding its technical specifications is crucial for making informed decisions. Here are some essential properties to be aware of:

-

Engine Code: 2JZ-GTE

– This is the specific identification for the engine, denoting its model and variant. For B2B buyers, knowing the engine code ensures compatibility with vehicles and helps in sourcing the correct parts. -

Displacement: 3.0 L (2,997 cm³)

– The engine’s displacement refers to the total volume of all the cylinders. Displacement affects the power output and efficiency of the engine. Buyers should consider displacement when evaluating performance needs and compliance with local regulations. -

Max Power Output:

– The 2JZ GTE engine produces approximately 276 HP (JDM) to 320.5 HP (North American and European markets) at 5,600 RPM. This parameter is critical for performance applications, and B2B buyers must match power output with their specific performance goals or vehicle requirements. -

Torque:

– The engine generates a maximum torque of up to 451 Nm (332.8 ft·lb) at 3,600 RPM. Torque is a key factor in determining an engine’s ability to accelerate and perform under load, making it vital for buyers focused on heavy-duty applications. -

Fuel System: Multi-Point Fuel Injection

– This type of fuel system optimizes fuel delivery for better performance and efficiency. Understanding the fuel system is essential for buyers looking to integrate the engine into specific setups or for tuning purposes. -

Weight: 230 kg (507 lbs)

– The weight of the engine impacts the vehicle’s handling and balance. Buyers should consider the weight in relation to the vehicle’s design and intended use, especially in performance or racing applications.

What Are the Common Trade Terms Related to the 2JZ GTE Engine?

Navigating the procurement process involves familiarizing oneself with industry-specific terminology. Here are some key trade terms relevant to the purchase of the 2JZ GTE engine:

-

OEM (Original Equipment Manufacturer)

– OEM refers to parts made by the manufacturer of the original product. For buyers, sourcing OEM parts ensures compatibility and quality, which is crucial for maintaining vehicle performance. -

MOQ (Minimum Order Quantity)

– MOQ defines the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to avoid overstocking or incurring higher per-unit costs. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is a vital step in the procurement process, helping buyers gather competitive pricing for the 2JZ GTE engine. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms is crucial for understanding shipping costs and responsibilities, especially for international transactions. -

Aftermarket

– This term refers to parts and accessories made by companies other than the original manufacturer. For buyers, aftermarket options can provide cost-effective alternatives for upgrades or repairs. -

Warranty Period

– This term defines the time frame during which the manufacturer guarantees the engine’s performance and condition. A robust warranty is a significant factor for buyers, providing assurance of quality and potential cost savings on repairs.

Understanding these technical properties and trade terms is essential for B2B buyers looking to procure the 2JZ GTE engine effectively. This knowledge not only aids in making informed decisions but also enhances negotiations and strengthens supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the 2jz gte engine for sale Sector

What Are the Current Market Dynamics and Key Trends Affecting the 2JZ GTE Engine for Sale Sector?

The global demand for the 2JZ GTE engine, particularly among international B2B buyers from regions like Africa, South America, the Middle East, and Europe, is driven by several key factors. Firstly, the engine’s reputation for reliability and performance has solidified its status as a sought-after component for high-performance vehicles, especially in motorsport and aftermarket modifications. As more automotive enthusiasts and businesses seek to enhance vehicle performance, the demand for the 2JZ GTE engine continues to rise.

Illustrative image related to 2jz gte engine for sale

Emerging trends in sourcing are also shaping the market landscape. The rise of digital platforms for engine sales has transformed how businesses connect with suppliers. Online marketplaces now facilitate easier comparisons of specifications, prices, and customer reviews, allowing buyers to make informed decisions quickly. Additionally, the integration of advanced technologies such as artificial intelligence and machine learning is improving supply chain efficiencies, enabling faster response times and better inventory management.

Furthermore, geopolitical factors and economic conditions in target markets influence sourcing dynamics. For instance, fluctuating currency rates and trade policies can affect pricing strategies and supply chain stability. Buyers from regions like Nigeria and Brazil may face unique challenges such as import tariffs and regulatory compliance, necessitating a thorough understanding of local market conditions to navigate these complexities effectively.

How Important Is Sustainability and Ethical Sourcing for the 2JZ GTE Engine Market?

Sustainability has become a focal point in the automotive industry, including the market for the 2JZ GTE engine. The environmental impact of sourcing and manufacturing practices is under scrutiny, prompting buyers to seek suppliers who prioritize ethical sourcing and sustainability. This shift is particularly relevant for B2B buyers in environmentally-conscious markets, where companies are increasingly held accountable for their supply chain practices.

The importance of ethical supply chains cannot be overstated. Buyers are encouraged to engage with suppliers who demonstrate a commitment to environmentally friendly practices, such as using recycled materials or ensuring minimal waste during production. Certifications such as ISO 14001 (Environmental Management) can serve as indicators of a supplier’s dedication to sustainability.

Moreover, the integration of ‘green’ technologies in engine manufacturing can enhance market competitiveness. Suppliers that invest in cleaner production methods or offer engines with improved fuel efficiency are likely to gain favor among buyers looking to align their purchases with sustainability goals. As the market evolves, understanding these trends will be crucial for international B2B buyers aiming to make responsible sourcing decisions.

What Is the Evolution and Historical Significance of the 2JZ GTE Engine in the B2B Context?

The 2JZ GTE engine has a rich history that dates back to its introduction in the early 1990s. Originally designed for the Toyota Supra, it quickly became renowned for its performance and tuning potential. This engine is part of the JZ family, which was developed to meet the demands of the Japanese Grand Touring Car Championship, showcasing Toyota’s commitment to innovation and performance.

Over the years, the 2JZ GTE has evolved from a niche engine for sports cars to a staple in the aftermarket tuning community. Its robust design, capable of handling high power outputs, has made it a favorite among performance enthusiasts and professional racers alike. This evolution has created a vibrant secondary market where B2B buyers can source engines for various applications, from racing to custom builds.

As the demand for high-performance components continues to grow, understanding the historical significance of the 2JZ GTE engine can provide valuable insights into current market dynamics and future trends. Buyers who appreciate the legacy of this engine are better positioned to leverage its reputation in their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of 2jz gte engine for sale

-

How do I ensure the quality of a 2JZ GTE engine before purchase?

To ensure the quality of a 2JZ GTE engine, request comprehensive documentation from the supplier, including service history, performance specifications, and warranty details. Ask for engine compression tests and visual inspections of critical components. Additionally, consider engaging third-party inspection services that specialize in automotive components to verify the engine’s condition before finalizing the purchase. -

What are the common uses for a 2JZ GTE engine in automotive applications?

The 2JZ GTE engine is highly sought after for performance builds, particularly in racing and high-performance street vehicles. Common applications include modifications for the Toyota Supra, as well as swaps into various other models for improved power output. Its robust design and tuning potential make it ideal for enthusiasts looking to enhance vehicle performance significantly. -

What should I consider when vetting suppliers for 2JZ GTE engines?

When vetting suppliers, consider their reputation, customer reviews, and years of experience in the industry. Check for certifications and compliance with international standards. It’s also beneficial to request samples or references from previous clients to assess their reliability and quality. Engaging in direct communication to gauge responsiveness and customer service can also provide valuable insights. -

Are there minimum order quantities (MOQ) for purchasing a 2JZ GTE engine?

Minimum order quantities can vary significantly between suppliers. Some may offer single units for individual buyers, while others may require bulk orders for wholesale pricing. Always clarify MOQ terms before negotiating pricing to ensure that your purchasing needs align with the supplier’s capabilities. -

What payment terms are typically accepted for international purchases of automotive engines?

Payment terms for international purchases usually vary by supplier but may include options such as bank transfers, letters of credit, and escrow services. Discussing payment terms upfront can help avoid misunderstandings. Some suppliers might offer installment payment plans for larger orders, which can be beneficial for managing cash flow. -

How can I handle logistics and shipping when purchasing a 2JZ GTE engine internationally?

When managing logistics, collaborate with your supplier to determine the most efficient shipping methods, whether by air or sea. Ensure that the supplier provides all necessary shipping documentation, including customs declarations. It’s wise to work with experienced freight forwarders familiar with automotive parts to facilitate smooth customs clearance and delivery. -

What warranty options should I look for when buying a 2JZ GTE engine?

Always inquire about warranty options before purchase. A reputable supplier should offer warranties covering defects in materials or workmanship, typically ranging from 30 days to several years, depending on the engine’s condition and whether it’s new or used. Understand the warranty terms, including coverage limits and procedures for filing claims, to protect your investment. -

Can I customize the 2JZ GTE engine to fit specific performance requirements?

Yes, many suppliers offer customization options for the 2JZ GTE engine to meet specific performance needs. Customizations can include modifications to the turbo setup, changes in fuel injectors, or adjustments to the ECU. Discuss your performance goals with the supplier to explore available modifications that align with your project requirements.

Top 5 2Jz Gte Engine For Sale Manufacturers & Suppliers List

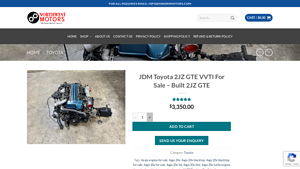

1. JDM Toyota – 2JZ GTE VVTI Engine

Domain: nwjdmmotors.com

Registered: 2022 (3 years)

Introduction: JDM Toyota 2JZ GTE VVTI For Sale – Built 2JZ GTE

Price: $3,350.00

Rating: 4.93 out of 5 based on 122 customer ratings

Mileage: 51,123 miles

Includes: 2JZ-GTE VVTi Twin Turbo motor, Complete ECU, Engine Harness and Accessories, Six-Speed Manual V160 Transmission with OEM Clutch, Flywheel, Slave Cylinder, and driveshaft, front and rear subframes, Turbo Brakes, Axles, Differential, Manifold, Intake M…

2. Supraforums – 2JZ-GTE Engine Insights

Domain: supraforums.com

Registered: 2000 (25 years)

Introduction: 2JZ-GTE VVTI engine; price range: $2,000 to $10,000; considerations for purchase include engine condition, specifications, and potential for modifications; advice to consider 2JZGE VVTI as a budget-friendly alternative; potential for high output (1000+ hp) with modifications; common issues and dealbreakers to look for before purchase.

3. 2JZGTE Parts – Buy Sell Trade Community

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, 2JZGTE Parts – Buy Sell Trade Community, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

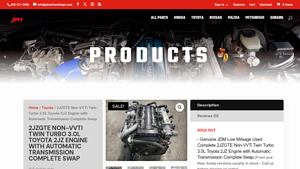

4. Toyota – 2JZGTE Non-VVTi Twin Turbo Engine Swap

Domain: jdmofsandiego.com

Registered: 2015 (10 years)

Introduction: {“name”:”2JZGTE Non-VVTi Twin Turbo 3.0L Toyota 2JZ Engine with Automatic Transmission Complete Swap”,”original_price”:”$7,000.00″,”current_price”:”$6,500.00″,”category”:”Toyota”,”tags”:[“Engines”],”availability”:”SOLD OUT”,”description”:”Genuine JDM Low Mileage Used Complete 2JZGTE Non-VVTi Twin Turbo 3.0L Toyota 2JZ Engine with Automatic Transmission Complete Swap. Hand Picked and Imported Direc…

5. GReddy – 2JZ VVTi Complete Crate Engine

Domain: greddy.com

Registered: 1996 (29 years)

Introduction: Product Name: GReddy 2JZ VVTi Complete Crate Engine (Long Block)

Sale Price: £38,948.00

Regular Price: £38,948.00

Engine Models Available:

– GReddy 2JZ VVTi Complete Crate Engine (Long Block)

– GReddy 2JZ (non-VVTi) Complete Crate Engine (Long Block)

Optional Components:

– Turbo Manifold Options:

– None

– Artec Cast SUS 2JZ-GTE 70mm V-band Std. Rotation Exh. Manifold

– Ar…

Strategic Sourcing Conclusion and Outlook for 2jz gte engine for sale

In navigating the global marketplace for the 2JZ GTE engine, B2B buyers can unlock significant opportunities by leveraging strategic sourcing practices. Understanding the engine’s specifications, performance capabilities, and the benefits of sourcing from trusted suppliers can streamline the procurement process. Key takeaways include the importance of verifying product quality, assessing supplier reliability, and being aware of regional market dynamics that influence pricing and availability.

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, the potential for high-performance automotive applications is substantial. The 2JZ GTE engine’s reputation for durability and power makes it a coveted choice for various automotive projects, from racing to performance tuning.

Looking ahead, fostering strong relationships with reputable suppliers and staying informed about market trends will be essential for securing favorable deals and ensuring product quality. We encourage buyers to engage proactively with suppliers, explore diverse sourcing options, and capitalize on the growing demand for high-performance engines like the 2JZ GTE. This strategic approach will not only enhance your procurement outcomes but also position your business for sustained success in the competitive automotive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to 2jz gte engine for sale