Vibro Peen: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for vibro peen

The global market for vibro peen marking presents a unique challenge for international B2B buyers seeking reliable and effective part marking solutions. As industries evolve and expand, the demand for precise and durable marking systems has surged, particularly in regions such as Africa, South America, the Middle East, and Europe. This guide aims to navigate the complexities of sourcing vibro peen equipment and services, helping businesses understand the nuances of this advanced marking technology.

From exploring the different types of vibro peen systems to assessing their applications across various industries, this comprehensive resource will equip buyers with the knowledge needed to make informed purchasing decisions. Key topics include supplier vetting, cost considerations, and the advantages and limitations of vibro peen compared to other marking methods. By delving into these areas, businesses can better evaluate their options and select solutions that align with their operational needs and regulatory requirements.

This guide is designed to empower B2B buyers with actionable insights and strategies, enabling them to confidently engage with suppliers and enhance their production capabilities. Whether you’re in Brazil looking to streamline your manufacturing process or in Saudi Arabia aiming to meet stringent quality standards, understanding the global landscape of vibro peen marking is essential for success in today’s competitive market.

Understanding vibro peen Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pneumatic Vibro Peen | Uses compressed air for continuous marking; high-speed operation | Aerospace, automotive, and manufacturing | Pros: High speed, low-stress marking; Cons: Inconsistent depth and legibility. |

| Handheld Electric Vibro Peen | Portable design; suitable for on-site marking | Fieldwork, repair services, and maintenance | Pros: Versatile and easy to use; Cons: Limited to smaller tasks and less robust. |

| Bench-Top Vibro Peen | Stationary unit; designed for precision and detailed work | Quality control, lab environments | Pros: High accuracy and customizable settings; Cons: Requires dedicated workspace. |

| Integrated Production Line Vibro Peen | Embedded in assembly lines; automated marking process | Mass production environments | Pros: Streamlines workflow, reduces labor costs; Cons: High initial investment. |

| Custom Vibro Peen Solutions | Tailored machines with specific bevel and radius settings | Specialized manufacturing sectors | Pros: Precision tailored to specific needs; Cons: Potentially longer lead times. |

What are the Key Characteristics of Pneumatic Vibro Peen Machines?

Pneumatic Vibro Peen machines utilize compressed air to enable continuous marking, making them ideal for high-speed operations. They are widely used in industries like aerospace and automotive, where speed and efficiency are crucial. However, buyers should note that while these machines deliver quick results, they may struggle with depth consistency and legibility of the marks, which can be critical in applications requiring high precision.

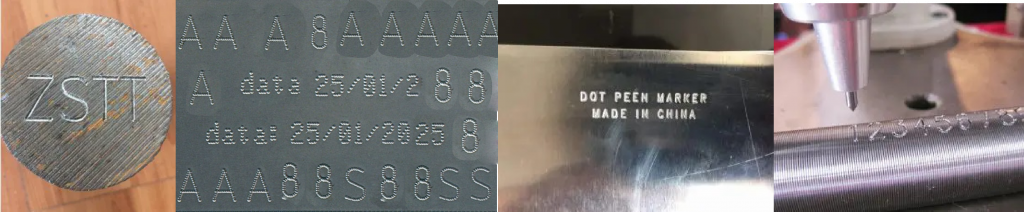

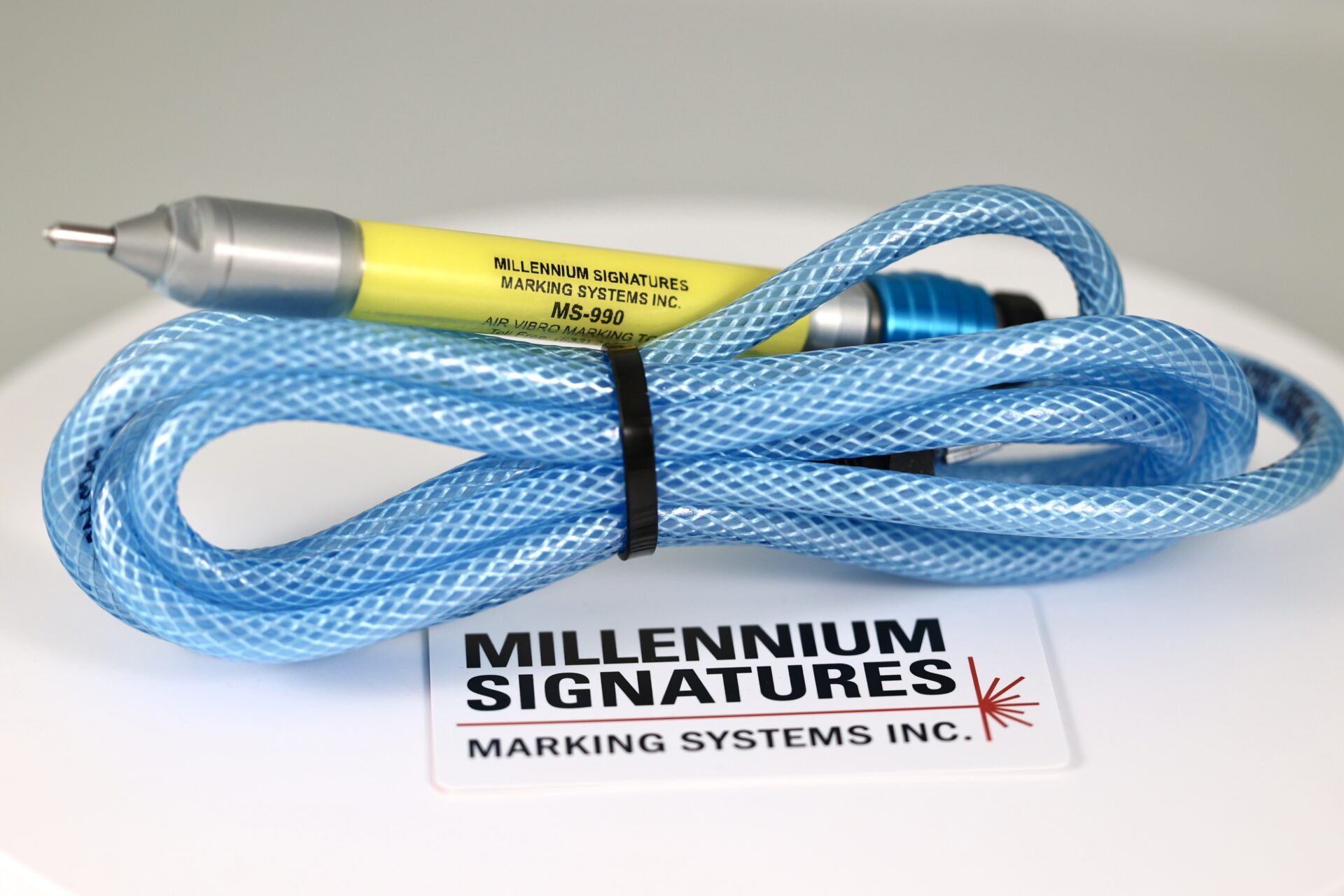

Illustrative image related to vibro peen

How Does Handheld Electric Vibro Peen Differ from Other Types?

The handheld electric Vibro Peen tool is designed for portability, allowing for on-site marking. This flexibility is particularly beneficial for fieldwork, repair services, and maintenance tasks. While easy to operate and versatile, it is best suited for smaller marking tasks and may not handle heavy-duty applications as effectively as larger, stationary models.

What Advantages Does the Bench-Top Vibro Peen Offer?

Bench-top Vibro Peen machines are stationary units that excel in precision marking. They are frequently employed in quality control and laboratory environments where detailed and accurate markings are essential. Buyers appreciate the customizable settings that allow for tight tolerances on marking depth and location. However, these units require dedicated workspace, which can be a limitation for some businesses.

Why Choose Integrated Production Line Vibro Peen Solutions?

Integrated production line Vibro Peen systems are designed to enhance automation in mass production environments. By embedding these machines into assembly lines, businesses can streamline their workflow and reduce labor costs. While the upfront investment may be significant, the long-term efficiency gains can justify the expense, making it a compelling option for manufacturers looking to optimize operations.

What Are the Benefits of Custom Vibro Peen Solutions?

Custom Vibro Peen solutions offer tailored machines that can meet specific manufacturing requirements. This includes adjustments to bevel and radius settings to accommodate unique marking needs. While these machines provide precise solutions, buyers should consider potential longer lead times for customization, which could affect project timelines and planning.

Key Industrial Applications of vibro peen

| Industry/Sector | Specific Application of vibro peen | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Marking of serial numbers and part codes | Ensures traceability and compliance with industry standards | Require machines that meet aviation specifications (e.g., MIL-STD-130) |

| Automotive | Component identification and marking | Enhances inventory management and quality control | Look for high-speed machines with precision marking capabilities |

| Medical Devices | Engraving of device identification codes | Facilitates regulatory compliance and patient safety | Sourcing machines that can handle varied materials and sizes |

| Heavy Machinery | Marking of manufacturing and assembly codes | Improves operational efficiency and product tracking | Need robust machines that can withstand harsh environments |

| Electronics | Marking of components and circuit boards | Supports product authenticity and reduces counterfeiting | Seek machines with fine marking capabilities for small parts |

How is Vibro Peen Used in Aerospace Applications?

In the aerospace sector, vibro peen is crucial for marking serial numbers and part codes on components. This process ensures that each part can be traced throughout its lifecycle, which is vital for compliance with stringent aviation regulations such as MIL-STD-130. International buyers must consider sourcing machines that are certified to meet these specifications, ensuring they can maintain quality and traceability in their operations.

Illustrative image related to vibro peen

What Role Does Vibro Peen Play in Automotive Manufacturing?

Within the automotive industry, vibro peen is utilized for marking various components, including engine parts and chassis identifiers. This identification process enhances inventory management and quality control, allowing manufacturers to track parts accurately through assembly lines. Buyers should prioritize high-speed machines capable of delivering precise marks to meet the fast-paced demands of automotive production.

Why is Vibro Peen Important for Medical Devices?

In the medical device sector, vibro peen is employed to engrave device identification codes, which are essential for regulatory compliance and patient safety. The durability of the marks ensures that they remain legible throughout the product’s lifespan. Buyers in this sector must source machines that can accommodate a variety of materials and sizes, as medical devices often require intricate and precise markings.

How Does Vibro Peen Enhance Heavy Machinery Operations?

For heavy machinery manufacturers, vibro peen is used to mark manufacturing and assembly codes on large components. This practice improves operational efficiency by enabling better tracking of parts during assembly and maintenance. Buyers should look for robust vibro peen machines designed to perform well in harsh environments, ensuring longevity and reliability in their applications.

What Advantages Does Vibro Peen Offer in Electronics?

In the electronics sector, vibro peen is crucial for marking small components and circuit boards, providing a means to authenticate products and reduce counterfeiting. The ability to create fine, precise markings is essential in this industry. Buyers should seek machines with the capability to handle small parts while maintaining high-quality standards, ensuring that their product integrity is upheld in a competitive market.

3 Common User Pain Points for ‘vibro peen’ & Their Solutions

Scenario 1: Inconsistent Marking Depth and Legibility

The Problem: Many B2B buyers encounter significant issues with the inconsistency in marking depth and legibility when using vibro peen marking systems. This can lead to confusion on the production floor, product recalls, and even regulatory compliance issues, especially in industries like aerospace and automotive where precise marking is essential. Clients may find that the marks vary in depth, causing some to be barely visible, while others are too deep and compromise the integrity of the part. This inconsistency often stems from inadequate machine calibration or operator error, which can be particularly frustrating for companies striving for high standards.

The Solution: To address this challenge, it’s vital to invest in high-quality vibro peen marking systems that allow for precise control over marking parameters. Regularly scheduled maintenance and calibration of the equipment should be a standard practice to ensure consistent performance. Buyers should also consider training sessions for operators that cover the best practices in machine setup and operation. This can include understanding the relationship between the machine’s speed, pressure, and the type of material being marked. Implementing a quality control process, such as using a microscope or measuring device to regularly check the depth and legibility of marks, can further enhance consistency. Furthermore, integrating an automated feedback loop can help adjust the machine’s settings in real-time to maintain optimal marking conditions.

Scenario 2: High Operational Costs Due to Inefficiencies

The Problem: Another common pain point is the high operational costs associated with vibro peen marking, often due to inefficient processes and machine downtime. Businesses that rely on continuous production lines may experience interruptions due to equipment failures, suboptimal settings, or the need for frequent manual adjustments. These inefficiencies not only increase labor costs but can also lead to delays in meeting customer demands, affecting overall profitability.

The Solution: To mitigate these costs, companies should conduct a thorough analysis of their current vibro peen marking processes to identify bottlenecks and areas for improvement. Investing in advanced vibro peen machines that feature programmable settings and automation can significantly reduce operational downtime. Buyers should also consider adopting predictive maintenance technologies that monitor machine performance and alert operators to potential issues before they lead to breakdowns. Additionally, streamlining workflows by integrating vibro peen marking systems with other production processes can enhance overall efficiency. By ensuring that the marking system is fully optimized for the materials and products being processed, companies can minimize waste and maximize productivity.

Scenario 3: Difficulty in Meeting Industry-Specific Marking Standards

The Problem: B2B buyers in specialized industries often face stringent marking standards and regulations, such as those dictated by aerospace or automotive specifications. Failure to comply with these standards can result in costly fines, legal issues, and loss of business reputation. Many companies struggle to understand and implement the required marking specifications for their products, leading to wasted resources and time.

The Solution: To effectively navigate these industry-specific challenges, buyers should prioritize partnering with suppliers who have expertise in the relevant marking standards. Engaging with manufacturers that can provide custom solutions tailored to meet specific regulatory requirements can alleviate compliance-related stress. Additionally, keeping abreast of the latest marking specifications through industry associations or regulatory bodies is crucial. Companies should also implement a robust documentation process that tracks compliance with marking standards, ensuring that all products are marked correctly before they reach the market. Regular audits and reviews of marking practices against industry standards can further help maintain compliance and improve overall operational integrity.

Illustrative image related to vibro peen

Strategic Material Selection Guide for vibro peen

What Materials Are Commonly Used for Vibro Peen Marking?

When selecting materials for vibro peen marking, understanding the properties and suitability of various substrates is essential for optimizing performance and ensuring compliance with international standards. Below, we analyze four common materials used in vibro peen applications, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Steel Perform in Vibro Peen Marking?

Key Properties: Steel is known for its high tensile strength and durability, making it suitable for various industrial applications. It typically has a temperature rating of up to 300°C and exhibits good corrosion resistance when treated with protective coatings.

Pros & Cons: The advantages of using steel include its robustness and ability to withstand high-stress applications. However, its susceptibility to rust and corrosion in harsh environments can be a drawback unless adequately treated. Additionally, steel can be more expensive to machine compared to softer metals.

Impact on Application: Steel is compatible with a wide range of media, including oils and chemicals, which makes it a versatile choice for many industries. However, its weight may be a consideration in applications where lighter materials are preferred.

Considerations for International Buyers: Compliance with standards such as ASTM A36 or DIN 17100 is crucial for steel products. Buyers from regions like Brazil and Saudi Arabia should ensure that their suppliers meet these specifications to avoid issues with quality and performance.

What About Aluminum for Vibro Peen Marking?

Key Properties: Aluminum is lightweight and has excellent corrosion resistance, making it ideal for applications where weight savings are critical. It can withstand temperatures up to 200°C and is often used in aerospace and automotive industries.

Pros & Cons: The primary advantage of aluminum is its low weight and resistance to oxidation, which enhances its durability. However, it is softer than steel, which may lead to less legible markings over time. Additionally, aluminum can be more expensive than other materials due to its processing requirements.

Impact on Application: Aluminum’s compatibility with various media, including water and certain chemicals, makes it suitable for diverse applications. However, its softness can be a limitation in high-wear environments.

Considerations for International Buyers: Buyers should be aware of compliance with standards like ASTM B221 and JIS H4000. In regions such as Europe, adherence to REACH regulations concerning chemical safety is also essential.

How Does Stainless Steel Compare in Vibro Peen Marking?

Key Properties: Stainless steel offers excellent corrosion resistance and strength, with temperature ratings often exceeding 500°C. Its composition includes chromium, which enhances its durability and resistance to oxidation.

Pros & Cons: The main advantage of stainless steel is its longevity and ability to maintain a clean appearance, which is vital for industries like food processing and pharmaceuticals. However, it can be more challenging to machine, leading to higher costs in manufacturing.

Impact on Application: Stainless steel is compatible with a wide range of media, including acids and bases, making it suitable for harsh environments. Its non-reactive nature is particularly beneficial in applications requiring hygiene.

Considerations for International Buyers: Compliance with standards such as ASTM A240 or DIN 1.4401 is critical for stainless steel products. Buyers from the Middle East and South America should ensure that their suppliers can meet these standards to guarantee product quality.

What Role Does Plastic Play in Vibro Peen Marking?

Key Properties: Plastic materials, such as polycarbonate and nylon, are lightweight and can be engineered for specific applications. They typically have lower temperature ratings, around 100-150°C, and varying degrees of chemical resistance.

Pros & Cons: The primary advantage of plastics is their versatility and low cost. They can be easily shaped and molded, making them suitable for custom applications. However, they may not provide the same level of durability as metals, leading to potential wear issues.

Impact on Application: Plastics are compatible with a limited range of media, often performing well in non-corrosive environments. However, their lower strength may limit their use in high-stress applications.

Considerations for International Buyers: Buyers should ensure that the plastic materials comply with relevant standards, such as ASTM D638 for tensile properties. In regions like Africa and South America, understanding local regulations regarding plastic use is also crucial.

Summary Table of Material Selection for Vibro Peen

| Material | Typical Use Case for vibro peen | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Aerospace and automotive parts | Lightweight and corrosion-resistant | Softer, less legible markings | High |

| Stainless Steel | Food processing equipment | Excellent corrosion resistance | Higher machining costs | High |

| Plastic | Custom housings and enclosures | Versatile and low-cost | Lower durability and strength | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in vibro peen marking. Understanding these factors will aid in making informed purchasing decisions that align with industry standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for vibro peen

What Are the Main Stages of the Vibro Peen Manufacturing Process?

The manufacturing process for vibro peen marking systems involves several critical stages, each designed to ensure high-quality output and adherence to industry standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Materials Are Used in Vibro Peen Systems?

The first step in the manufacturing process is material preparation, which involves sourcing high-quality materials. Typically, components like aluminum, stainless steel, and various alloys are utilized due to their durability and ability to withstand the marking process. Suppliers should ensure that materials meet specific international standards, such as ASTM or ISO certifications, to guarantee quality and compatibility with vibro peen applications.

2. Forming: How Is the Vibro Peen Equipment Shaped and Assembled?

Once materials are prepared, they undergo forming processes, including machining, cutting, and shaping. CNC (Computer Numerical Control) machines are often employed to ensure precision in creating components like the stylus and housing. This stage is crucial as it sets the foundation for the machine’s performance. Buyers should inquire about the machinery used and the experience of the operators to ensure high precision during this phase.

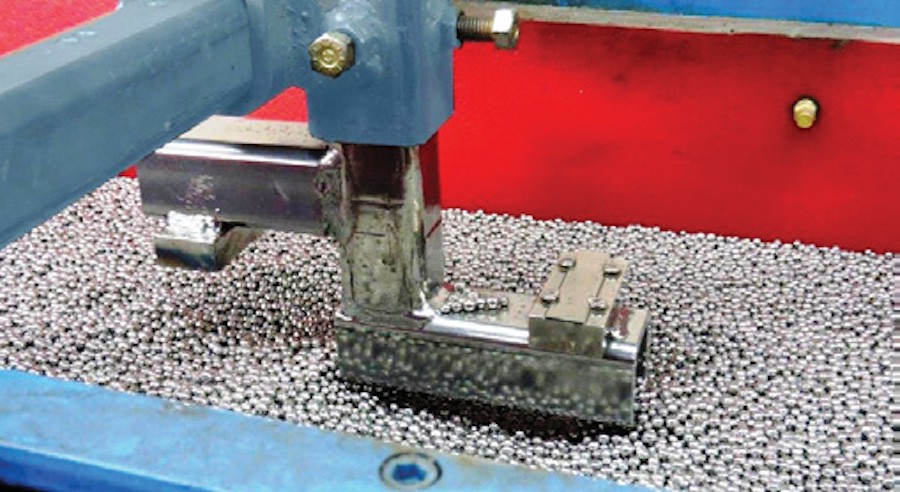

Illustrative image related to vibro peen

3. Assembly: What Are the Key Components of Vibro Peen Systems?

In the assembly stage, the components are brought together. This includes installing pneumatic actuators, stylus pins, and control systems. The assembly process should adhere to strict guidelines to prevent misalignment and ensure functional integrity. B2B buyers should look for suppliers who implement a systematic approach to assembly, including checklists and standardized operating procedures.

4. Finishing: How Are Vibro Peen Products Prepared for Market?

The finishing stage involves surface treatments, painting, or coating to enhance durability and aesthetics. This is also where final adjustments are made to ensure that the vibro peen marking systems meet the specified tolerances and performance standards. Buyers should verify that suppliers conduct thorough inspections during this phase to ensure that the final product is free from defects.

What Are the Key Quality Control Practices for Vibro Peen Systems?

Quality assurance is paramount in the manufacturing of vibro peen marking systems, ensuring that products meet international standards and customer specifications. Effective quality control (QC) practices help mitigate risks and enhance product reliability.

International Standards: Which Certifications Should Buyers Look For?

Vibro peen manufacturers should comply with international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE marking for European markets or API standards for the oil and gas sector can further validate the quality of the products. Buyers should request documentation proving compliance with these standards to ensure that they are partnering with reputable suppliers.

QC Checkpoints: What Are the Stages of Quality Inspection?

Quality control involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to verify that they meet specified criteria. Buyers should inquire about the procedures suppliers use for material inspections.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor adherence to specifications and detect any deviations early on. This includes checking the accuracy of machining and assembly.

-

Final Quality Control (FQC): Before shipment, a thorough inspection of the finished products is performed. This includes functionality tests and compliance checks against specifications. Buyers should confirm the criteria used for FQC to understand the reliability of the products they are purchasing.

What Common Testing Methods Are Used to Ensure Quality?

Various testing methods can be employed to ensure the quality of vibro peen marking systems:

-

Performance Testing: This assesses the marking quality, depth, and speed of the vibro peen systems under controlled conditions. Buyers can request performance test results to verify that the equipment meets their operational requirements.

-

Durability Testing: This involves subjecting the marking systems to conditions that simulate real-world usage. Tests may include exposure to environmental factors such as humidity and temperature fluctuations.

-

Dimensional Accuracy Testing: Using precision measuring instruments, suppliers can verify that the dimensions of components are within specified tolerances. This testing is crucial to ensure that parts fit and function correctly.

How Can B2B Buyers Verify Supplier Quality Control Measures?

Ensuring that a supplier’s quality control processes are robust is essential for B2B buyers. Here are several methods to verify QC measures:

1. Supplier Audits: What Should Buyers Look For?

Conducting on-site audits of suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. Buyers should look for evidence of compliance with international standards, documentation of quality control procedures, and records of past audits.

Illustrative image related to vibro peen

2. Quality Reports: How Can Documentation Help?

Requesting quality reports from suppliers can help buyers gauge the effectiveness of their QC processes. These reports should include data on defect rates, corrective actions taken, and results from performance testing. Regular reporting can indicate a supplier’s commitment to maintaining high-quality standards.

3. Third-Party Inspections: What Role Do External Auditors Play?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspections can verify compliance with international standards and assess the overall quality of the products being manufactured.

What Are the Specific Quality Control Nuances for International Buyers?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, may encounter unique quality control challenges. It’s important to consider:

-

Cultural Differences: Understand that suppliers from different regions may have varying approaches to quality control. Open communication about expectations is essential.

-

Regulatory Compliance: Buyers should familiarize themselves with local regulations and standards that may impact the quality of products. This is particularly relevant in regions with stringent import regulations.

-

Shipping and Handling: Quality can be affected during transit. Buyers should discuss packaging and handling protocols with suppliers to minimize the risk of damage.

By understanding the manufacturing processes and quality assurance practices involved in vibro peen marking systems, B2B buyers can make informed decisions and select suppliers that align with their quality expectations and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vibro peen’

Introduction

This guide is designed to assist international B2B buyers in sourcing vibro peen marking systems effectively. As the demand for precise part marking grows across industries, understanding the procurement process and evaluating suppliers is crucial for ensuring quality and reliability. This checklist provides actionable steps to streamline your sourcing journey.

Illustrative image related to vibro peen

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider the materials you will be marking, the required mark depth, and the speed of operation. Specific details like the type of characters (alphanumeric or continuous lines) and the environment in which the equipment will operate (e.g., manufacturing floor conditions) are critical.

- Marking Requirements: Determine if you need serial numbers, part numbers, or other identifiers.

- Material Compatibility: Ensure the vibro peen system is suitable for the specific materials you intend to mark.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers specializing in vibro peen systems. Utilize industry directories, trade shows, and online platforms to compile a list of candidates. This step is vital for ensuring a broad selection of quality options.

- Supplier Profiles: Look for suppliers with a strong reputation and proven track record in your industry.

- Market Presence: Consider suppliers that have experience in your geographical region, as they may better understand local regulations and market needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to assess the capabilities and reliability of potential suppliers. Request company profiles, product catalogs, and case studies that demonstrate their expertise in vibro peen marking.

- References and Reviews: Ask for references from other clients, especially those in similar industries or regions.

- Certifications: Verify any industry-specific certifications or quality assurance standards they comply with.

Step 4: Request and Compare Quotes

Once you have shortlisted potential suppliers, request detailed quotes. A comprehensive quote should include pricing, lead times, warranty information, and after-sales support.

Illustrative image related to vibro peen

- Cost Breakdown: Ensure that quotes provide a clear breakdown of costs, including any additional fees for customizations.

- Lead Times: Compare delivery times, as timely procurement is often critical to your operations.

Step 5: Assess Technical Support and Training

Understanding the level of technical support and training provided by suppliers is crucial for successful implementation. Ensure that the supplier offers adequate training for your team and ongoing support for troubleshooting.

- Training Programs: Inquire about the availability of training sessions, either on-site or online.

- Support Availability: Check if the supplier provides 24/7 technical support and maintenance services.

Step 6: Finalize the Contract and Terms

After evaluating all aspects, finalize your contract with the chosen supplier. Ensure that all terms, including payment schedules, delivery timelines, and warranty clauses, are clearly outlined.

- Legal Review: Consider having a legal expert review the contract to safeguard your interests.

- Payment Terms: Negotiate favorable payment terms that align with your cash flow requirements.

Step 7: Plan for Installation and Integration

Once the equipment is procured, plan for its installation and integration into your production line. Collaborate with the supplier for a smooth setup and ensure your team is prepared for operational changes.

- Installation Support: Confirm that the supplier provides installation assistance and any necessary adjustments.

- Integration Testing: Test the system thoroughly to ensure it meets your specifications and operational needs.

By following this checklist, B2B buyers can navigate the complexities of sourcing vibro peen marking systems effectively, ensuring they select the right equipment and supplier for their needs.

Comprehensive Cost and Pricing Analysis for vibro peen Sourcing

What Are the Key Cost Components in Vibro Peen Sourcing?

When sourcing vibro peen part marking systems, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The quality and type of materials used for vibro peen machines significantly affect pricing. High-grade steel and specialized components for pneumatic systems can lead to higher upfront costs but may result in better durability and performance over time.

-

Labor: Labor costs encompass assembly, calibration, and maintenance. Skilled technicians are often required to ensure that the machines are set up correctly and operate efficiently, impacting overall labor expenses.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help keep these costs low.

-

Tooling: Custom tooling may be necessary for specific applications or to meet unique marking requirements. This can add to the initial investment but may be essential for achieving precise results.

-

Quality Control (QC): Rigorous QC processes are vital for ensuring that machines meet specified standards. Investing in quality assurance can prevent costly errors and improve product reliability.

-

Logistics: Transporting heavy machinery can incur significant shipping costs, especially for international buyers. Understanding Incoterms can help in budgeting for these logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary widely based on market conditions, competition, and the specific value offered by the supplier.

What Influences Pricing for Vibro Peen Systems?

Several factors can influence the pricing of vibro peen systems:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Negotiating for bulk purchases can yield significant savings.

-

Specifications and Customization: Custom features or specific technical requirements can increase costs. Buyers should clearly define their needs to receive accurate quotes and avoid unexpected expenses.

-

Materials Quality and Certifications: Machines built with higher-quality materials or those that meet specific industry certifications (e.g., ISO, AS9100) may command higher prices but can provide better long-term value.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. For instance, opting for “FOB” (Free on Board) can shift the shipping costs to the buyer, impacting the overall cost analysis.

What Are the Best Buyer Tips for Cost-Efficiency?

-

Negotiation: Always negotiate prices and terms. Suppliers may have some flexibility, particularly for larger orders or long-term contracts. Emphasize your position as a repeat customer to leverage better terms.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate maintenance, operating costs, and potential downtime. A cheaper machine may incur higher TCO due to frequent repairs or lower efficiency.

-

Pricing Nuances for International Buyers: Be aware of potential tariffs, taxes, and currency exchange rates when importing from suppliers. Understanding the local market dynamics in your region can also guide negotiations and purchasing decisions.

-

Supplier Research: Investigate multiple suppliers to compare prices and offerings. Reviews, testimonials, and industry reputation can provide insights into the reliability and performance of their products.

-

Inquire About After-Sales Support: Strong after-sales support can save costs in the long run. Ensure that the supplier provides adequate training, spare parts availability, and technical support to minimize downtime.

Disclaimer for Indicative Prices

Prices for vibro peen systems can vary widely based on the aforementioned factors. It is advisable to request quotes from multiple suppliers and consider all cost components to ensure an informed purchasing decision.

Alternatives Analysis: Comparing vibro peen With Other Solutions

Introduction to Alternative Marking Solutions

In the realm of industrial part marking, vibro peen technology offers unique advantages, particularly in its ability to produce high-speed, low-stress markings. However, various alternatives exist that may better suit specific applications depending on factors such as performance requirements, cost constraints, and operational complexities. Understanding these alternatives is crucial for B2B buyers aiming to make informed decisions in their marking processes.

Comparison Table of Marking Technologies

| Comparison Aspect | Vibro Peen | Dot Peen Marking | Laser Marking |

|---|---|---|---|

| Performance | High-speed, continuous marking | Accurate, but slower than vibro peen | Extremely precise, high-quality marks |

| Cost | Moderate initial investment | Lower initial cost | Higher upfront costs |

| Ease of Implementation | Requires pneumatic setup | Easier to integrate into production | Requires specialized equipment |

| Maintenance | Moderate; requires periodic checks | Low; simple maintenance | High; requires skilled technicians |

| Best Use Case | Continuous line characters, large volumes | Serial numbers, part numbers | Detailed graphics, high-contrast markings |

Detailed Breakdown of Alternatives

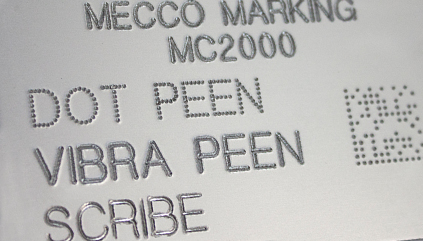

Dot Peen Marking

Dot peen marking is a prevalent alternative that uses a stylus to create individual dots on the surface of materials. While it is slower than vibro peen, it provides excellent accuracy and legibility. Dot peen systems are generally more cost-effective, making them appealing for small to medium-sized operations. However, they may not be as efficient for high-volume tasks where speed is critical. Maintenance is relatively low, but the system’s performance can be affected by wear over time, necessitating regular checks.

Illustrative image related to vibro peen

Laser Marking

Laser marking stands out for its exceptional precision and ability to create intricate designs on a variety of materials, including metals and plastics. This technology offers high-quality, permanent markings that are resistant to fading and wear. However, the initial investment for laser marking systems is typically higher than for vibro peen or dot peen systems. Additionally, implementation can be complex, requiring specialized knowledge for setup and maintenance. Laser marking is best suited for applications demanding high detail and contrast, such as branding and serialization in high-end manufacturing.

Conclusion: Choosing the Right Marking Solution

Selecting the appropriate marking technology hinges on evaluating specific operational needs, including production volume, material types, and budget constraints. Vibro peen marking is ideal for high-speed applications requiring continuous line characters, while dot peen marking offers a more cost-effective solution for precise, less frequent tasks. For applications demanding intricate designs and high durability, laser marking is unmatched despite its higher costs and complexity. By carefully assessing these factors, B2B buyers can make informed decisions that align with their production goals and operational requirements.

Essential Technical Properties and Trade Terminology for vibro peen

What Are the Key Technical Properties of Vibro Peen Marking Systems?

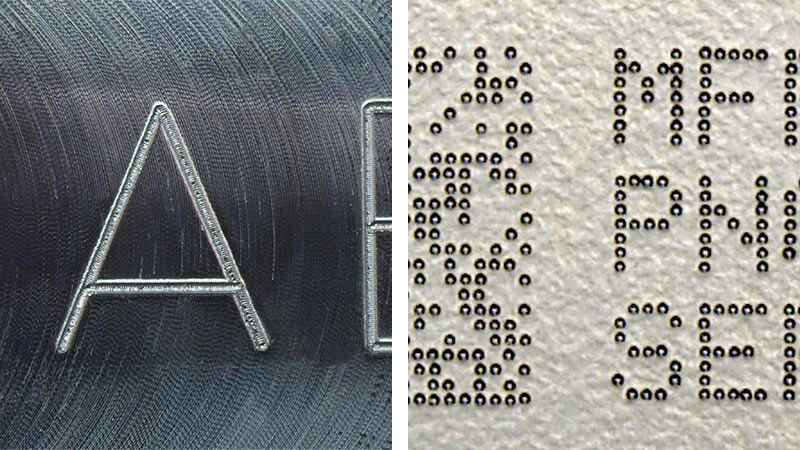

When considering vibro peen marking systems for your business, understanding the critical specifications is essential for ensuring the right fit for your operational needs. Below are some key properties that influence performance, efficiency, and cost-effectiveness.

1. Material Compatibility

Vibro peen marking systems are primarily used on metals, but their compatibility extends to various materials, including plastics and composites. The choice of material affects the marking depth and legibility. For industries such as aerospace and automotive, where material integrity is crucial, selecting a system that works with the intended substrates ensures durability and compliance with industry standards.

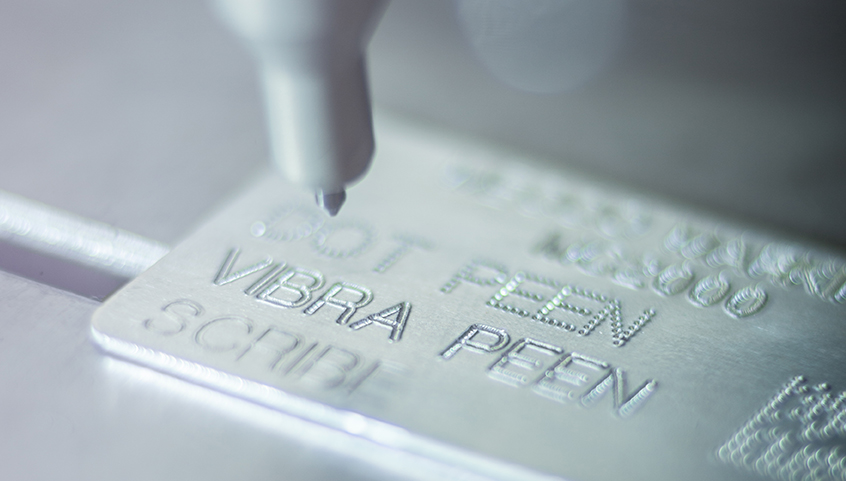

2. Marking Depth and Tolerance

The marking depth typically ranges from 0.001 to 0.005 inches, depending on the application. Tolerance levels can be as tight as ±0.001 inches. This precision is vital in industries that require strict adherence to specifications, such as medical device manufacturing and aerospace, where even minor deviations can lead to significant issues.

Illustrative image related to vibro peen

3. Speed of Operation

Vibro peen systems are designed for high-speed marking, capable of producing marks at rates of 300 characters per minute or more. This speed is essential for large production runs, reducing downtime and increasing throughput. Businesses looking to optimize their production efficiency will find this property particularly advantageous.

4. Operating Pressure

Most vibro peen machines operate within a specific air pressure range, typically between 80 and 100 psi. This operating pressure impacts the quality of the marking and the wear on the marking tool. Understanding the required pressure can help in selecting the right equipment and ensuring it fits within your existing production line’s capabilities.

5. Oscillation Frequency

The frequency of oscillation, usually adjustable, directly influences the quality and appearance of the mark. Higher frequencies can produce finer, more detailed marks, while lower frequencies may be suitable for deeper impressions. This flexibility allows businesses to tailor the marking process to meet specific branding or identification requirements.

6. Stylus Configuration

The stylus configuration, including tip radius and cone angle, can vary significantly. Customization options allow businesses to achieve specific marking styles, from sharp, clear characters to more rounded inscriptions. This adaptability is crucial for companies that require a diverse range of marking styles or have unique branding needs.

What Are Common Trade Terms Associated with Vibro Peen Marking?

Familiarity with industry jargon can enhance communication and negotiations with suppliers, ensuring clarity and efficiency in transactions. Here are some essential terms related to vibro peen marking:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in the manufacturing of another company’s products. Understanding OEM specifications is crucial when sourcing vibro peen marking machines, as it can affect compatibility and warranty issues.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for buyers to understand, especially when sourcing customized vibro peen marking solutions, as it can impact inventory management and cash flow.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. For businesses considering vibro peen systems, issuing an RFQ can help compare costs and features across different suppliers, aiding in informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps businesses understand shipping responsibilities, risk, and costs associated with vibro peen marking machinery, particularly when importing from overseas suppliers.

Illustrative image related to vibro peen

5. Lead Time

Lead time is the duration between placing an order and receiving the product. Understanding lead times for vibro peen marking systems is essential for production planning, ensuring that operations can proceed without delays.

6. Calibration

Calibration refers to the process of adjusting the precision of the marking system to meet specified standards. Regular calibration is necessary to maintain marking quality, making it a critical aspect of ongoing maintenance and operational efficiency.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when selecting vibro peen marking solutions, ultimately driving operational success and compliance in their industries.

Navigating Market Dynamics and Sourcing Trends in the vibro peen Sector

What Are the Key Market Drivers for Vibro Peen in International B2B Transactions?

The vibro peen marking sector is witnessing significant growth driven by several global factors. The increasing demand for permanent part identification in industries such as aerospace, automotive, and manufacturing is a primary catalyst. As regulatory requirements tighten, companies are compelled to adopt reliable marking solutions that ensure traceability and compliance. Moreover, the rise of automation in production lines enhances the adoption of vibro peen marking technologies, which can be seamlessly integrated into existing systems.

Emerging technologies are also reshaping the vibro peen landscape. Advancements in machine learning and AI are enabling more precise control over marking processes, improving efficiency and reducing waste. International buyers are increasingly looking for suppliers who offer smart, adaptable solutions that can meet their specific needs. Additionally, the trend toward customization is significant; businesses are seeking suppliers who can provide tailored marking solutions to accommodate unique branding or regulatory requirements.

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics is essential. Factors such as regional regulations, labor costs, and supply chain logistics can influence sourcing decisions. Buyers are encouraged to establish strong relationships with local suppliers who can offer insights into these dynamics while also ensuring consistent quality and support.

How Is Sustainability Influencing Sourcing Decisions in the Vibro Peen Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the vibro peen sector. With increasing awareness of environmental issues, B2B buyers are prioritizing suppliers who demonstrate a commitment to ethical practices and sustainable materials. The manufacturing process for vibro peen systems can have a considerable environmental impact, particularly in terms of energy consumption and waste generation. Therefore, companies are seeking equipment that minimizes these effects.

Adopting ‘green’ certifications and materials is critical for suppliers aiming to appeal to environmentally-conscious buyers. Certifications such as ISO 14001 for environmental management systems can enhance a supplier’s credibility. Moreover, the use of recyclable materials in equipment manufacturing can attract buyers who are looking to reduce their carbon footprint.

Ethical supply chains are equally important. Buyers are increasingly scrutinizing their suppliers’ practices, from sourcing raw materials to labor conditions. Transparency in these operations not only builds trust but can also enhance a company’s reputation in the marketplace. For B2B buyers, aligning with suppliers who uphold these values is not just a matter of compliance; it is a strategic move that can lead to long-term partnerships and a competitive edge.

What Is the Historical Context of Vibro Peen Marking Technology?

Vibro peen marking technology has evolved significantly since its inception. Initially developed as a solution for marking metal components, it has transitioned from rudimentary techniques to advanced pneumatic systems that offer high-speed and precision marking. The early methods relied heavily on manual operations, which were labor-intensive and inconsistent.

Over the decades, technological advancements have led to the automation of vibro peen marking, allowing for greater efficiency and accuracy. Innovations such as computer numerical control (CNC) have enabled the integration of vibro peen systems into larger manufacturing processes, making them indispensable in industries that require high-quality, permanent marking solutions. As the market continues to evolve, ongoing research and development are likely to further enhance the capabilities of vibro peen technologies, meeting the increasing demands of global industries.

Overall, the vibro peen sector stands at the intersection of tradition and innovation, making it a dynamic area for international B2B buyers to explore.

Frequently Asked Questions (FAQs) for B2B Buyers of vibro peen

-

How do I choose the right vibro peen marking machine for my application?

Selecting the right vibro peen marking machine involves assessing your specific marking needs, including the material type, desired mark depth, and character size. Consider factors such as the machine’s speed, ease of use, and whether it can integrate with existing production lines. Additionally, reviewing manufacturers’ specifications and seeking advice from industry experts can ensure that you choose a machine that meets your operational requirements and provides long-term reliability. -

What are the advantages of vibro peen marking over other methods?

Vibro peen marking offers several advantages, including high-speed marking and the ability to produce legible, engraved-like marks without exerting excessive pressure on the material. This method minimizes the risk of stress risers that could lead to material cracking. Additionally, vibro peen can maintain tight tolerances on marking location and depth, making it suitable for applications requiring precision and durability, such as aerospace and automotive industries. -

What customization options are available for vibro peen machines?

Many manufacturers offer customization options for vibro peen machines, including adjustable marking depths, different stylus configurations, and the ability to create bespoke marking patterns. You can also request modifications to accommodate unique part shapes or sizes. Engaging with suppliers about your specific needs can lead to tailored solutions that enhance efficiency and effectiveness in your marking processes. -

What are the typical minimum order quantities (MOQ) for vibro peen machines?

Minimum order quantities for vibro peen machines can vary significantly depending on the manufacturer and the complexity of the machine. Some suppliers may have a low MOQ for standard models, while custom machines may require a higher minimum. It’s advisable to communicate directly with suppliers to discuss your requirements and negotiate quantities that align with your production needs, especially if you’re a smaller business or start-up. -

What payment terms should I expect when sourcing vibro peen machines internationally?

Payment terms for international purchases of vibro peen machines can vary widely by supplier and region. Common terms may include a deposit upfront, followed by balance payment upon shipment or delivery. Some suppliers may offer flexible financing options or payment plans. It is crucial to clarify payment terms upfront and ensure that they align with your budgeting and cash flow management strategies. -

How do I vet suppliers for vibro peen machines effectively?

When vetting suppliers for vibro peen machines, consider their industry reputation, years of experience, and customer reviews. Request references and case studies from previous clients to assess their reliability and service quality. Additionally, evaluate their certifications, such as ISO standards, which indicate adherence to quality management practices. Engaging in direct communication and discussing technical support options can further ensure you select a trustworthy supplier. -

What logistics considerations should I keep in mind when importing vibro peen machines?

Logistics considerations for importing vibro peen machines include shipping methods, customs regulations, and potential import duties. It’s essential to choose a reliable freight forwarder who understands the complexities of international shipping and can navigate customs efficiently. Also, factor in lead times for production and shipping to ensure timely delivery to your facility, and consider local regulations that may affect the import process in your region. -

What quality assurance (QA) measures should I expect from vibro peen machine suppliers?

Reputable vibro peen machine suppliers will typically implement stringent quality assurance measures throughout the manufacturing process. Expect to see testing protocols that include performance checks, dimensional accuracy, and durability assessments. Suppliers may also provide warranties or guarantees on their machines. Inquire about their QA certifications and whether they conduct regular audits to maintain high standards, ensuring that the equipment meets your operational expectations.

Top 6 Vibro Peen Manufacturers & Suppliers List

1. McMaster – Vibro Pens and Electric Engravers

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Vibro Pens and Electric Engravers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Universal Marking – Vibro Peening Solutions

Domain: universalmarking.com

Registered: 1997 (28 years)

Introduction: Vibro Peening (or Dot Peening) is a metal engraving process that uses a rapidly vibrating carbide cutter to mark the surface of a part. The marks appear as a series of microscopic dots under magnification but look like a continuous line to the naked eye. Advantages include minimal pressure applied to the part, reducing the risk of stress risers that can lead to cracking, and producing a legible ‘E…

3. HeatSign – Vibrapeen Marking Solutions

Domain: heatsign.com

Registered: 2015 (10 years)

Introduction: Vibrapeen marking is a permanent marking/engraving solution for metals using a stylus or pin that strikes the surface to create dots. It includes various marking systems such as electromagnetic solenoid, pneumatic dot peen marking, and vibro peen marking. The vibro peen marking system is a pneumatic actuator-based technology that allows for continuous marking with a fixed frequency. It offers accu…

4. Telesis – Dot Peen Marking Machines

Domain: telesis.com

Registered: 1996 (29 years)

Introduction: A dot peen marking machine is used to imprint materials with a series of indentations to form permanent markings. It is commonly used in industrial manufacturing applications for marking products with customer-specific information like serial numbers, barcodes, and more. The machine creates human- and machine-readable patterns that are durable and resistant to wear. Dot peen marking machines can b…

5. Mecco – COUTH Standard Dot Peen Marking Machine

Domain: mecco.com

Registered: 1996 (29 years)

Introduction: This company, Mecco – COUTH Standard Dot Peen Marking Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Esslinger – Vibro-Graver Micro Hand Held Engraver

Domain: esslinger.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “Vibro-Graver Micro Hand Held Engraver”, “SKU”: “36.861”, “price”: “$39.99”, “features”: {“type”: “impact driven adjustable depth engraving tool”, “materials_supported”: [“metal”, “wood”, “more”], “design”: “comfortable to hold”, “stroke_depth_adjustment”: “dial from 1 to 5”, “common_uses”: [“marking property”, “personalized gifts”, “I.D. tags”, “engraved plates/plaques”, “custom …

Strategic Sourcing Conclusion and Outlook for vibro peen

As the demand for precision and efficiency in part marking continues to rise, vibro peen technology stands out as a robust solution for international B2B buyers. This method not only delivers high-speed marking with minimal stress on materials but also ensures legibility and tight tolerances, making it ideal for various industries, including aerospace, automotive, and manufacturing. Strategic sourcing of vibro peen marking systems can lead to enhanced operational efficiency and cost savings, particularly when partnering with suppliers who offer custom solutions tailored to specific needs.

In regions like Africa, South America, the Middle East, and Europe, the competitive landscape necessitates a forward-thinking approach to sourcing. By evaluating potential suppliers and investing in advanced vibro peen technologies, companies can secure a competitive edge in their markets.

Looking ahead, as industries evolve and the push for sustainable practices intensifies, vibro peen marking will likely play a pivotal role in ensuring compliance and traceability. We encourage international buyers to explore partnerships with leading vibro peen manufacturers and integrate these solutions into their operations for a future of innovation and growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to vibro peen