The Definitive Guide to Gd Shoes: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for gd shoes

In an increasingly competitive global market, sourcing high-quality gd shoes that cater to diverse consumer needs presents a significant challenge for B2B buyers. With an array of styles, functionalities, and price points available, decision-makers must navigate a landscape filled with options while ensuring they meet specific market demands. This comprehensive guide serves as a valuable resource, exploring various types of gd shoes—from athletic to orthotic designs—along with their applications across different industries.

Buyers will gain insights into essential aspects such as supplier vetting processes, cost considerations, and emerging trends, empowering them to make informed purchasing decisions. Whether you are a distributor looking to enter new markets in Africa, South America, the Middle East, or Europe, or a retailer aiming to expand your product offerings, understanding the nuances of the gd shoes market is crucial.

By leveraging this guide, international B2B buyers can enhance their sourcing strategies, align their product selections with customer preferences, and ultimately drive sales growth in their respective regions. As the demand for stylish yet functional footwear continues to rise, staying ahead of the curve in gd shoes will position your business for success in a dynamic marketplace.

Understanding gd shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Athletic Sneakers | Lightweight, breathable materials; shock-absorbing soles | Sports retailers, gyms, schools | Pros: High comfort, versatile use. Cons: Limited durability for heavy industrial use. |

| Casual Footwear | Stylish designs; often made with leather or synthetic materials | Fashion retailers, lifestyle brands | Pros: Trendy appeal, good for casual settings. Cons: May lack support for extensive walking. |

| Orthotic Shoes | Built-in arch support; designed for comfort and alignment | Healthcare providers, specialty stores | Pros: Alleviates foot pain, promotes health. Cons: Higher price point, niche market. |

| Custom Shoes | Handcrafted, unique designs; often made from premium materials | Luxury retailers, bespoke services | Pros: Exclusive designs, high quality. Cons: Longer lead times, potentially high costs. |

| Sandals and Slides | Open design for breathability; various styles for casual wear | Summer footwear retailers, beach resorts | Pros: Comfortable, easy to wear. Cons: Limited use in formal or rugged environments. |

What Are the Key Characteristics of Athletic Sneakers for B2B Buyers?

Athletic sneakers are designed primarily for performance, featuring lightweight construction and breathable materials that enhance comfort during physical activities. The shock-absorbing soles provide support, making them ideal for sports retailers, gyms, and schools looking to stock high-demand footwear. B2B buyers should consider the durability of these shoes, as they may not withstand heavy industrial use, despite their versatility and comfort for everyday wear.

How Do Casual Footwear Variants Appeal to B2B Markets?

Casual footwear combines style and comfort, often made from leather or synthetic materials that cater to fashion-conscious consumers. These shoes are suitable for lifestyle brands and fashion retailers aiming to attract customers seeking trendy options. While they offer a stylish appeal for casual settings, buyers must be aware that such footwear may lack the necessary support for extensive walking, making it less suitable for more demanding environments.

Why Are Orthotic Shoes Important in B2B Purchasing Decisions?

Orthotic shoes are specifically designed to provide built-in arch support and promote proper alignment, making them essential for healthcare providers and specialty stores. These shoes alleviate common foot pain and are ideal for individuals with specific health concerns. While they offer significant health benefits, B2B buyers should consider their higher price point and the niche market they serve, which may limit broader appeal.

What Makes Custom Shoes a Unique Offering for B2B Buyers?

Custom shoes are handcrafted and offer unique designs made from premium materials, appealing to luxury retailers and bespoke services. The exclusivity and high quality of these shoes cater to consumers looking for distinctive footwear. However, B2B buyers must be prepared for longer lead times and potentially higher costs, which can impact inventory management and pricing strategies.

How Do Sandals and Slides Fit into the B2B Footwear Market?

Sandals and slides are characterized by their open design, providing breathability and comfort, making them popular choices for summer footwear retailers and beach resorts. Their casual nature makes them easy to wear, but buyers should consider that they may not be suitable for formal or rugged environments, limiting their application in certain B2B contexts.

Key Industrial Applications of gd shoes

| Industry/Sector | Specific Application of gd shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Footwear for healthcare professionals | Enhanced comfort and support during long shifts | Need for ergonomic design and compliance with safety standards |

| Retail | Customizable fashion footwear for retail displays | Unique branding and customer engagement | Sourcing high-quality materials for durability and aesthetics |

| Hospitality | Stylish, comfortable shoes for staff in hotels and restaurants | Improved employee satisfaction and professional appearance | Focus on style, comfort, and ease of maintenance |

| Sports & Fitness | Performance-oriented shoes for athletic training | Enhanced performance and injury prevention for athletes | Collaboration with sports professionals for design specifications |

| Manufacturing & Warehousing | Durable footwear for factory and warehouse workers | Increased safety and productivity in high-risk environments | Compliance with industry safety regulations and comfort requirements |

How Are gd Shoes Used in Healthcare Settings?

In healthcare settings, gd shoes are particularly beneficial for professionals such as nurses and doctors who spend long hours on their feet. The ergonomic design and shock-absorbing features help alleviate foot pain and fatigue, promoting better overall health and productivity. International buyers from regions such as Africa and the Middle East may prioritize sourcing shoes that comply with local health and safety standards while ensuring high-quality materials that can withstand rigorous daily use.

What Role Do gd Shoes Play in the Retail Industry?

In the retail sector, gd shoes can be utilized as customizable fashion footwear that enhances brand identity. Retailers can offer unique designs that resonate with their target audience, driving customer engagement and loyalty. When sourcing, businesses should consider not only the aesthetic appeal but also the quality of materials to ensure longevity and customer satisfaction, particularly in competitive markets like South America and Europe.

Why Are gd Shoes Important for the Hospitality Sector?

For the hospitality industry, gd shoes provide a stylish yet comfortable option for staff in hotels and restaurants. These shoes enhance employee satisfaction by combining aesthetics with functionality, ensuring that staff can perform their duties without discomfort. When sourcing for this application, businesses should focus on both style and ease of maintenance, as footwear in this sector is often subject to spills and heavy use.

How Do gd Shoes Contribute to Sports and Fitness?

In the sports and fitness industry, gd shoes are designed to meet the performance needs of athletes. Features such as enhanced shock absorption and support help prevent injuries while improving athletic performance. For international B2B buyers, collaboration with sports professionals during the design phase can ensure that the shoes meet the specific needs of athletes, particularly in diverse markets like Brazil and Vietnam where sports culture varies significantly.

What Benefits Do gd Shoes Offer in Manufacturing and Warehousing?

In manufacturing and warehousing, gd shoes provide durable and comfortable footwear essential for worker safety. With features designed to reduce fatigue and improve stability, these shoes can enhance productivity in environments that pose risks such as heavy lifting and long hours of standing. Buyers in this sector should prioritize sourcing shoes that comply with industry safety regulations while ensuring comfort and durability to meet the demands of the workforce.

3 Common User Pain Points for ‘gd shoes’ & Their Solutions

Scenario 1: Sizing and Fit Challenges in Bulk Orders for GD Shoes

The Problem: One of the significant challenges faced by B2B buyers when ordering GD shoes in bulk is ensuring the correct sizing and fit for diverse customer demographics. Inconsistent sizing across different brands, along with varying regional foot shapes, can lead to high return rates and dissatisfied customers. This not only affects profitability but also complicates inventory management and customer satisfaction.

The Solution: To mitigate sizing issues, B2B buyers should utilize comprehensive size charts and fit guides provided by the GD shoes supplier. It is advisable to conduct a pre-order sample test where a selection of sizes is purchased and evaluated for fit before placing a larger order. Additionally, leveraging customer feedback on fit can provide valuable insights. Including a clear return policy that allows for exchanges or returns can also enhance buyer confidence and reduce the financial risk associated with sizing discrepancies.

Scenario 2: Navigating Customization Options for GD Shoes

The Problem: B2B buyers often grapple with the complexity of customization options available for GD shoes. While offering personalized designs can be a significant selling point, the myriad choices may overwhelm buyers, making it difficult to select the right options that align with their target market’s preferences. This indecision can lead to missed sales opportunities and unsold inventory if the wrong styles are chosen.

The Solution: To effectively navigate the customization process, B2B buyers should engage directly with GD shoes’ design consultants or customer service representatives. Establishing clear customer personas and understanding market trends can help guide customization decisions that resonate with target audiences. Utilizing data analytics to track sales of specific styles can further inform which designs are likely to succeed. Setting up a streamlined feedback loop with customers can also provide real-time insights into preferences, allowing for timely adjustments in product offerings.

Illustrative image related to gd shoes

Scenario 3: Managing Shipping and Delivery Timelines for GD Shoes

The Problem: Timely delivery is a critical concern for B2B buyers, particularly when dealing with GD shoes that may require extended production times due to their handcrafted nature. Delays in shipping can disrupt retail operations, leading to lost sales and strained customer relationships. Buyers may find it challenging to align their inventory needs with the production and shipping timelines provided by the manufacturer.

The Solution: To manage shipping and delivery effectively, B2B buyers should establish a clear communication channel with GD shoes regarding production timelines and shipping schedules. Planning orders well in advance and incorporating buffer periods into delivery schedules can help accommodate potential delays. Additionally, utilizing logistics tracking tools and establishing a relationship with reliable freight forwarders can ensure better visibility and control over the shipping process. Regular updates from the manufacturer about production status can also keep buyers informed, enabling them to proactively adjust their inventory plans as needed.

Strategic Material Selection Guide for gd shoes

When selecting materials for gd shoes, it is essential to consider various factors that influence performance, durability, and market acceptance. Below, we analyze four common materials used in the production of gd shoes, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Leather in gd Shoes?

Leather is a traditional material known for its durability and comfort. It offers excellent breathability, which is crucial for footwear, especially in warmer climates. Leather can withstand a range of temperatures and provides good resistance to wear and tear. However, it can be susceptible to water damage unless treated, and its maintenance requires regular conditioning.

Pros & Cons: Leather’s primary advantage is its longevity and ability to develop a unique patina over time, enhancing aesthetic appeal. However, it is generally more expensive than synthetic alternatives and can complicate manufacturing due to the need for skilled labor in tanning and finishing processes.

Impact on Application: Leather shoes are well-suited for formal and casual wear, making them versatile for various markets. Buyers in regions like Europe and the Middle East often prefer leather for its luxury appeal, while those in hotter climates may require additional features like moisture-wicking linings.

How Does Synthetic Material Enhance Performance in gd Shoes?

Synthetic materials, such as polyester or nylon, are increasingly popular in footwear manufacturing due to their lightweight properties and resistance to moisture. These materials can be engineered to provide specific performance characteristics, such as increased flexibility or enhanced breathability.

Pros & Cons: The primary advantage of synthetic materials is their cost-effectiveness and ease of manufacturing, allowing for mass production with less labor. However, they may not offer the same level of durability or comfort as leather, which could impact long-term wear.

Impact on Application: Synthetic shoes are ideal for athletic and casual footwear, appealing to younger demographics and markets in South America and Africa where affordability is a priority. Compliance with international standards for synthetic materials, such as REACH in Europe, is crucial for market entry.

What Are the Benefits of Rubber Soles in gd Shoes?

Rubber is commonly used for shoe soles due to its excellent grip and shock absorption capabilities. It performs well under various environmental conditions, making it suitable for both urban and outdoor settings.

Pros & Cons: Rubber soles provide durability and traction, which are essential for safety and comfort. However, they can add weight to the shoe and may be less environmentally friendly unless sourced from sustainable practices.

Impact on Application: In regions with varying terrains, such as Africa and South America, rubber soles are preferred for their performance in diverse conditions. Buyers should consider sourcing rubber that meets local and international environmental regulations.

How Does Foam Material Contribute to Comfort in gd Shoes?

Foam materials, particularly EVA (ethylene-vinyl acetate), are widely used in insoles and midsoles for their cushioning properties. They provide excellent energy return and are lightweight, enhancing overall comfort during wear.

Pros & Cons: The key advantage of foam is its ability to absorb shocks and reduce fatigue, making it ideal for shoes intended for extensive wear. However, foam can degrade over time and may not provide the same level of support as more rigid materials.

Impact on Application: Foam is particularly appealing in markets focused on health and wellness, such as Europe and the Middle East, where consumers are increasingly aware of the importance of comfort in footwear. Buyers should ensure that foam materials comply with safety standards, such as ASTM or ISO certifications.

Summary Table of Material Selection for gd Shoes

| Material | Typical Use Case for gd shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Formal and casual shoes | Durability and aesthetic appeal | Higher cost and maintenance needs | High |

| Synthetic | Athletic and casual footwear | Cost-effective and lightweight | Potentially less durable | Low |

| Rubber | Shoe soles for various terrains | Excellent grip and shock absorption | Can add weight and environmental concerns | Medium |

| Foam | Insoles and midsoles | Superior cushioning and comfort | Potential for degradation over time | Medium |

This strategic material selection guide provides B2B buyers with a comprehensive understanding of the materials used in gd shoes, enabling informed decisions that align with market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for gd shoes

What Are the Key Stages in the Manufacturing Process of GD Shoes?

The manufacturing process of GD shoes is a meticulous journey that emphasizes quality, craftsmanship, and innovation. This process can be broken down into several key stages: material preparation, forming, assembly, and finishing.

Material Preparation: How Are High-Quality Materials Selected?

The foundation of any great shoe lies in its materials. GD shoes primarily utilize premium Italian leather, renowned for its durability and aesthetic appeal. The selection process involves sourcing from reputable suppliers who adhere to stringent quality standards. Buyers should ensure that the leather is treated to withstand wear and tear while maintaining comfort. Additionally, other materials such as rubber for soles and various textile components are chosen based on their functional properties, like breathability and flexibility.

Forming: What Techniques Are Used to Shape GD Shoes?

Once materials are selected, the next step is forming. This stage involves cutting the leather and other materials into specific shapes that align with the shoe design. Advanced techniques, such as CAD (Computer-Aided Design), are employed to ensure precision in the cutting process. Following this, the upper parts of the shoes are shaped using molds that replicate the desired contours. This is where the fusion of design aesthetics and functional requirements begins, allowing for customization based on buyer specifications.

Assembly: How Are GD Shoes Assembled for Optimal Quality?

The assembly phase is critical in ensuring that all components come together seamlessly. Skilled artisans handcraft the shoes, stitching the upper parts to the soles with robust techniques that enhance durability. This process often includes reinforcing stress points, ensuring that the shoes can withstand the rigors of daily use. Quality control checkpoints are integrated into this stage, where each pair undergoes inspection to verify adherence to design specifications and quality standards.

Finishing: What Final Touches Are Applied to GD Shoes?

The finishing stage is where GD shoes receive their final touches, enhancing both aesthetics and performance. This includes polishing the leather to achieve a desirable sheen, applying protective coatings, and attaching any additional features such as laces or branding elements. Final inspections are conducted to ensure that each pair meets the established quality benchmarks before packaging. Buyers should look for detailed information on finishing techniques as they can significantly influence the product’s marketability.

What Quality Assurance Measures Are Implemented in GD Shoe Manufacturing?

Quality assurance is paramount in the manufacturing of GD shoes, ensuring that every pair meets international standards and buyer expectations. The quality assurance process encompasses several international standards and industry-specific certifications.

What International Standards Are Relevant for GD Shoes?

GD shoes adhere to several international quality standards, including ISO 9001, which focuses on effective quality management systems. Compliance with ISO standards ensures that manufacturing processes are continuously improved and that customer satisfaction is prioritized. Additionally, certifications like CE (Conformité Européenne) signify that the shoes meet European safety and health requirements, which is especially relevant for B2B buyers in Europe.

What Are the Key Quality Control Checkpoints in GD Shoe Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. These checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for compliance with quality standards before they enter the production line.

- In-Process Quality Control (IPQC): During assembly, random inspections are conducted to verify that manufacturing processes are being followed correctly and that the product meets defined specifications.

- Final Quality Control (FQC): Before packaging, each pair of shoes undergoes a thorough examination, checking for defects and ensuring that all quality standards are met.

B2B buyers should inquire about these QC checkpoints to assess the reliability of their suppliers.

What Common Testing Methods Are Used to Ensure GD Shoes’ Quality?

To ensure GD shoes meet quality and safety standards, various testing methods are employed, including:

Illustrative image related to gd shoes

- Durability Testing: Assessing the shoe’s ability to withstand wear and tear over time.

- Flexibility Testing: Evaluating how well the shoe adapts to different foot movements.

- Comfort Testing: Ensuring that the shoe provides the necessary support and comfort for prolonged use.

These tests not only guarantee product quality but also help in building a reputation for reliability among B2B buyers.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control measures of suppliers is essential for ensuring product reliability. Here are several strategies to consider:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is an effective way to assess the quality control processes in place. Buyers can request on-site visits to observe manufacturing practices firsthand, ensuring compliance with quality standards. During these audits, buyers should focus on examining the materials used, the production environment, and the final product inspection processes.

How Can Buyers Access Quality Control Reports?

Buyers should request detailed quality control reports from their suppliers. These documents should outline testing methods, results, and any corrective actions taken in response to identified issues. Transparency in reporting is a strong indicator of a supplier’s commitment to quality assurance.

What Role Do Third-Party Inspections Play in Quality Verification?

Engaging third-party inspection services can further enhance the verification process. These independent organizations specialize in quality assessments and can provide unbiased evaluations of the manufacturing processes. Buyers should consider incorporating third-party inspections as part of their procurement strategy, especially for international transactions where quality standards may vary.

What Are the Unique Quality Control Considerations for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Buyers should be aware of the following:

- Regulatory Compliance: Different regions may have specific regulations that products must meet. Familiarity with local laws and standards is essential to avoid compliance issues.

- Cultural Sensitivity: Quality expectations may differ across cultures. Engaging in open communication with suppliers about quality standards can help bridge these gaps.

- Logistical Challenges: International shipping can introduce risks such as damage or delays. Buyers should ensure that suppliers have robust packaging and shipping practices in place.

By understanding these aspects, B2B buyers can make informed decisions and establish strong partnerships with suppliers of GD shoes, ensuring they receive high-quality products that meet their expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gd shoes’

In the dynamic world of B2B sourcing, particularly for products like ‘gd shoes’, having a clear, actionable checklist is paramount. This guide will help international buyers streamline their procurement process, ensuring they find the right suppliers and products that meet their needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the ‘gd shoes’ you wish to procure. Consider factors such as material, design, size range, and intended use (e.g., casual, athletic, or formal). Clear specifications help suppliers understand your needs and reduce the likelihood of miscommunication.

- Material Quality: Specify if you require genuine leather, synthetic materials, or sustainable options.

- Design Preferences: Include any particular styles or branding elements that are essential.

Step 2: Conduct Market Research

Understanding the current market landscape is crucial for making informed purchasing decisions. Research trends in the footwear industry, particularly regarding ‘gd shoes’, to identify popular styles and features that appeal to your target market.

- Competitive Analysis: Look at what similar businesses are offering and how they position their products.

- Pricing Trends: Gather data on price ranges to ensure your budget aligns with market expectations.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step ensures you partner with reliable suppliers who can meet your quality and delivery expectations.

- Certifications and Compliance: Verify that suppliers comply with international standards for quality and safety.

- Production Capacity: Ensure they can meet your volume requirements without compromising quality.

Step 4: Request Samples for Quality Assessment

Always request samples before making a bulk order. This allows you to assess the quality of the ‘gd shoes’ firsthand, ensuring they meet your specifications and standards.

- Testing for Comfort and Durability: Evaluate the shoes for comfort, fit, and durability through real-world testing.

- Design Review: Confirm that the design aligns with your brand’s aesthetic and expectations.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier, it’s time to negotiate the terms of your purchase. This includes pricing, payment terms, delivery schedules, and return policies.

- Payment Flexibility: Discuss options such as deposits, payment on delivery, or credit terms that suit your cash flow.

- Delivery Timelines: Ensure that delivery schedules align with your inventory needs to avoid stockouts.

Step 6: Finalize the Purchase Order

After negotiating terms, draft a purchase order that clearly outlines all agreed-upon details. This formal document serves as a binding agreement between you and the supplier, minimizing the risk of misunderstandings.

- Include All Specifications: Ensure that the purchase order includes product specifications, quantities, and delivery dates.

- Review Cancellation Policies: Understand the implications of canceling or modifying orders to protect your investment.

Step 7: Establish Ongoing Communication

Maintain open lines of communication with your supplier throughout the procurement process and beyond. Regular check-ins can help address any issues promptly and foster a strong business relationship.

- Feedback Loop: Share feedback on the products and service quality to enhance future transactions.

- Collaboration Opportunities: Explore opportunities for collaboration on new designs or exclusive products that may benefit both parties.

By following this comprehensive checklist, B2B buyers can navigate the sourcing process for ‘gd shoes’ effectively, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for gd shoes Sourcing

What Are the Key Cost Components in Sourcing gd Shoes?

When sourcing gd shoes, understanding the comprehensive cost structure is crucial for B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality leathers, synthetic materials, and specialized components (like cushioning technology) can lead to higher prices but also enhance the product’s value. For instance, Italian leather is often considered a premium option, which can increase the unit cost.

-

Labor: Labor costs vary by region. Countries with a higher cost of living, such as Italy, may incur higher labor expenses compared to regions like Southeast Asia. Additionally, skilled labor for crafting custom shoes can further elevate costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient production processes can help minimize overhead, which is vital for maintaining competitive pricing.

-

Tooling: Custom designs may require specialized tooling and molds, which can add to upfront costs. These expenses should be factored into the total pricing, especially for small volume orders.

-

Quality Control (QC): Implementing robust QC measures ensures product reliability and compliance with international standards, which is particularly important for buyers in regulated markets. High-quality QC processes can add to the cost but ultimately protect your brand reputation.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, play a significant role in the total cost of sourcing gd shoes. International buyers should consider the implications of Incoterms, which define responsibilities for shipping and delivery.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. Understanding the expected margins within the industry can help buyers negotiate better pricing.

How Do Price Influencers Impact Sourcing Decisions?

Several factors influence the pricing of gd shoes, affecting how international buyers approach sourcing.

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Bulk orders usually result in lower per-unit costs, making it beneficial for buyers to consolidate orders when possible.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: The use of high-quality materials often comes with a premium. Additionally, certifications (like ISO or CE) can also affect pricing, as they typically require adherence to strict quality standards.

-

Supplier Factors: The reputation, reliability, and experience of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer competitive rates to gain market share.

-

Incoterms: Understanding Incoterms is vital for international shipping. They define who is responsible for shipping costs and risk at various stages, affecting the overall pricing structure.

What Are Essential Buyer Tips for Cost-Efficiency?

To optimize sourcing costs, buyers should consider the following strategies:

-

Negotiate Effectively: Building strong relationships with suppliers can lead to better pricing. Leverage volume orders and long-term contracts to negotiate discounts.

-

Focus on Total Cost of Ownership: Evaluate not just the purchase price but also shipping, handling, and potential returns. A lower upfront cost may lead to higher long-term expenses if quality issues arise.

-

Understand Pricing Nuances for International Transactions: Different regions may have varying pricing structures due to economic conditions, tariffs, and local market demands. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to identify the best sourcing options.

-

Consider Currency Fluctuations: Exchange rates can affect the final cost of sourcing shoes internationally. Buyers should factor this into their pricing strategy to avoid unexpected expenses.

Disclaimer

The prices and cost structures mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing gd shoes With Other Solutions

When considering footwear solutions for various business needs, it is essential to evaluate alternatives to ensure optimal performance, cost-effectiveness, and overall value. In this analysis, we will compare GD Shoes, which emphasizes comfort and custom craftsmanship, against two notable alternatives: G-Defy and JD Sports. This comparison will help B2B buyers identify the best footwear solution for their specific requirements.

| Comparison Aspect | GD Shoes | G-Defy | JD Sports |

|---|---|---|---|

| Performance | High-quality, handcrafted comfort | Advanced shock absorption technology | Trendy designs with decent comfort |

| Cost | Premium pricing for custom designs | Mid-range pricing | Affordable to mid-range options |

| Ease of Implementation | Longer lead time for custom orders | Ready-to-wear available | Widely available in stores and online |

| Maintenance | Low maintenance due to quality materials | Occasional replacement of orthotics | Standard care for sports footwear |

| Best Use Case | Luxury, custom footwear for branding | Everyday comfort for active lifestyles | Casual and sportswear for diverse needs |

What Are the Key Pros and Cons of G-Defy Shoes?

G-Defy shoes are designed specifically for comfort, featuring innovative technology such as VersoShock® for shock absorption. This makes them an excellent choice for individuals who spend long hours on their feet, like healthcare workers or retail staff. However, while G-Defy offers competitive pricing, the aesthetic appeal may not match the luxury branding that GD Shoes provides, which could be a drawback for companies looking to enhance their brand image.

How Does JD Sports Compare as an Alternative?

JD Sports offers a wide range of trendy footwear options, including popular brands like Nike and Adidas. Its affordability and accessibility make it an attractive option for businesses looking to outfit employees with stylish yet functional shoes. However, the focus is more on fashion than on specialized comfort features, which may not meet the needs of workers who require long-lasting comfort for extended wear. Additionally, the quality may vary compared to the handcrafted nature of GD Shoes.

Conclusion: How Can B2B Buyers Choose the Right Footwear Solution?

Selecting the right footwear solution involves assessing the specific needs of your workforce and brand identity. For companies prioritizing luxury and customization, GD Shoes stands out as a premium option. If comfort for active lifestyles is paramount, G-Defy may be the better choice. Conversely, for businesses seeking affordability and style, JD Sports offers a variety of options. Ultimately, understanding the unique requirements of your organization will guide you in making an informed decision that aligns with your operational goals and employee satisfaction.

Essential Technical Properties and Trade Terminology for gd shoes

What Are the Key Technical Properties of GD Shoes?

When sourcing GD shoes for your business, understanding the essential technical properties is vital for ensuring product quality and consumer satisfaction. Here are several critical specifications:

-

Material Grade: The quality of materials used in GD shoes, such as premium Italian leather or synthetic alternatives, directly impacts durability, comfort, and style. High-grade materials enhance the perceived value of the product, making them more appealing to buyers and end consumers alike.

-

Shock Absorption Technology: Many GD shoes incorporate advanced shock-absorbing features, such as VersoShock® Poly-Flex Spring technology. This property is crucial for reducing the impact on joints and providing comfort during prolonged wear, which is particularly important for customers in industries requiring long hours on their feet.

-

Fit and Sizing Tolerance: Accurate sizing and fit are essential to minimize returns and enhance customer satisfaction. GD shoes should adhere to specific sizing standards, ensuring that products meet the expectations of diverse markets across different regions, such as Europe, Africa, and South America.

-

Breathability: The breathability of materials used in GD shoes affects comfort and performance, especially in warmer climates. Shoes designed with breathable fabrics or ventilation systems can prevent overheating and moisture accumulation, making them more suitable for active consumers.

-

Customizability: Offering customization options can significantly increase market appeal. GD shoes often allow for personalization in design and fit, which can cater to unique consumer preferences, enhancing brand loyalty and repeat business.

-

Sustainability Standards: With growing awareness around environmental issues, the sustainability of materials and manufacturing processes is becoming increasingly important. GD shoes that meet eco-friendly standards can attract a broader audience, particularly among ethically conscious buyers.

What Are Common Trade Terms Used in the GD Shoes Industry?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are several key terms relevant to GD shoes:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce products that are marketed by another company under its brand name. For GD shoes, partnering with an OEM can streamline production and ensure high-quality manufacturing standards.

-

MOQ (Minimum Order Quantity): This is the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for inventory management and can impact pricing negotiations, especially when sourcing GD shoes in bulk.

-

RFQ (Request for Quotation): An RFQ is a document that buyers send to suppliers to request pricing information on specific products. When sourcing GD shoes, an RFQ helps clarify costs, delivery timelines, and terms, aiding in informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for GD shoes imports and exports, as they dictate who bears the risk and cost at various stages of shipping.

-

Lead Time: This refers to the amount of time it takes from placing an order to receiving the goods. For GD shoes, understanding lead times can help businesses manage inventory effectively and align with market demand.

-

B2B (Business to Business): This term describes transactions between businesses, as opposed to between businesses and consumers (B2C). Recognizing the B2B nature of GD shoes is essential for establishing appropriate marketing strategies and distribution channels.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions when sourcing GD shoes for your business, ultimately enhancing your competitive edge in the market.

Navigating Market Dynamics and Sourcing Trends in the gd shoes Sector

What Are the Key Market Trends Impacting the gd Shoes Sector?

The global market for gd shoes is experiencing significant transformation driven by several key trends. The increasing demand for athleisure and comfortable footwear is reshaping consumer preferences, particularly among younger demographics. This shift is evident across various regions, including Africa, South America, the Middle East, and Europe. Buyers are not only looking for stylish options but also prioritizing functionality and comfort, pushing manufacturers to innovate in materials and design.

Emerging technologies are also influencing sourcing strategies within the gd shoes sector. Digital platforms for supply chain management and e-commerce are becoming integral to how international buyers, especially from markets like Brazil and Vietnam, connect with manufacturers. Enhanced visibility through tech-driven solutions allows B2B buyers to track production timelines and inventory, ultimately streamlining their procurement processes.

Moreover, the rise of customization in footwear is notable. Brands are increasingly offering bespoke options that cater to individual customer preferences, which is appealing to B2B buyers looking to differentiate their product offerings. Companies that leverage data analytics to understand consumer behavior are gaining a competitive edge, aligning their products with market demand effectively.

How Is Sustainability Shaping B2B Sourcing in the gd Shoes Sector?

Sustainability is no longer a buzzword but a necessity in the gd shoes sector. The environmental impact of footwear production—ranging from water usage to carbon emissions—has prompted B2B buyers to seek suppliers that prioritize ethical sourcing practices. Transparent supply chains are becoming crucial, as buyers demand to know the origins of materials and the working conditions in factories.

Illustrative image related to gd shoes

Incorporating eco-friendly materials, such as recycled plastics and sustainably sourced leather, is gaining traction among manufacturers. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® are increasingly important for B2B buyers, as they assure that products meet stringent environmental and safety standards. These certifications can significantly influence purchasing decisions, especially in markets that are highly aware of sustainability issues, such as Europe.

Furthermore, ethical considerations extend beyond materials to include fair labor practices. Brands that commit to ethical labor standards are not only enhancing their brand reputation but also attracting conscientious buyers. For international buyers, aligning with manufacturers that embody these values can lead to long-term partnerships and customer loyalty.

What Is the Historical Context Behind the Evolution of gd Shoes?

The gd shoes sector has evolved significantly over the decades, transitioning from basic functional footwear to a dynamic segment characterized by innovation and style. Historically, shoes were primarily designed for utility; however, as lifestyle trends shifted towards wellness and fashion, the industry began to prioritize comfort and aesthetic appeal.

In recent years, advancements in technology have revolutionized manufacturing processes, allowing for greater customization and improved performance features. The rise of online shopping has further transformed the landscape, enabling brands to reach global markets more effectively. This evolution reflects broader societal changes, where consumers increasingly seek products that combine style, comfort, and sustainability.

As international B2B buyers navigate this evolving landscape, understanding the historical context of gd shoes can provide valuable insights into current market dynamics and future opportunities. By aligning their strategies with these trends, buyers can position themselves competitively in a crowded marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of gd shoes

-

How can I ensure the quality of GD shoes before purchasing?

To ensure the quality of GD shoes, consider requesting samples or visiting the manufacturing facility if possible. Look for certifications related to materials and craftsmanship, such as ISO standards. Additionally, review customer testimonials and case studies from other B2B buyers. Establishing a clear quality assurance process with the supplier, including inspections at various production stages, can also help maintain high standards. -

What customization options are available for GD shoes?

GD shoes offer a variety of customization options, including material selection, color choices, and design elements. Buyers can collaborate with the manufacturer to create unique styles tailored to their target market. It’s advisable to discuss specific customization requests upfront, including potential costs and lead times, to ensure that the final product aligns with your brand identity and customer preferences. -

What are the minimum order quantities (MOQ) for GD shoes?

The minimum order quantity for GD shoes typically varies based on the specific model and customization requirements. Generally, MOQs range from 50 to 200 pairs. It’s essential to communicate your needs with the supplier early in the negotiation process. This will allow you to assess whether the MOQ aligns with your business strategy, especially if you are targeting niche markets or launching new products. -

What payment terms should I expect when sourcing GD shoes?

Payment terms for sourcing GD shoes can vary by supplier but often include options such as a deposit upon order confirmation and the balance due before shipment. Some suppliers may offer net terms, allowing payment within 30 to 60 days after delivery. Always clarify payment methods accepted (bank transfer, credit card, etc.) and negotiate terms that protect your interests while fostering a strong supplier relationship. -

How can I vet potential suppliers for GD shoes effectively?

To vet potential GD shoe suppliers, conduct thorough research, including checking their business credentials, industry reputation, and customer reviews. Request references from other B2B clients, and consider visiting their facilities if feasible. Utilize platforms that verify supplier legitimacy, and assess their production capabilities and adherence to ethical practices. A well-defined vetting process mitigates risks and ensures a reliable partnership. -

What logistics considerations should I keep in mind when importing GD shoes?

When importing GD shoes, consider shipping methods, customs regulations, and potential tariffs. Work with a logistics provider experienced in footwear imports to navigate these complexities. Ensure that your supplier provides accurate documentation, including invoices and certificates of origin, to facilitate a smooth customs clearance process. Additionally, factor in lead times for production and shipping to align with your inventory needs. -

How do I handle returns and exchanges for GD shoes?

Establish a clear return and exchange policy with your supplier to manage any issues that arise after purchase. This should include guidelines on acceptable reasons for returns, timelines, and the process for handling defective or unsold merchandise. Many suppliers offer free returns, but it’s essential to confirm the details. Having a well-defined policy in place can enhance customer satisfaction and streamline your operations. -

What marketing strategies work best for selling GD shoes in international markets?

To effectively market GD shoes in international markets, tailor your strategies to local consumer preferences and cultural nuances. Utilize social media platforms popular in your target regions for brand awareness and engagement. Consider partnerships with local influencers or retailers to increase visibility. Additionally, investing in localized content and SEO strategies can improve your online presence, driving traffic and sales from diverse markets.

Top 6 Gd Shoes Manufacturers & Suppliers List

1. JD Sports – Sneakers, Shoes, and Apparel

Domain: jdsports.com

Registered: 1999 (26 years)

Introduction: JD Sports offers a wide range of products including sneakers, shoes, and apparel for men, women, and kids. Key brands featured include Nike, Jordan, adidas, ASICS, New Balance, HOKA, and The North Face. Notable collections include UGG favorites, metallic pieces, and Timberland classics. The site promotes a rewards program called STATUS, which offers a $10 reward for joining. Customers can shop by …

2. Gravity Defyer – Comfortable Orthotic Footwear

Domain: gravitydefyer.com

Registered: 2006 (19 years)

Introduction: Comfortable Orthotic & Supportive Footwear, G-defy, Pain-free returns & exchanges, 60-day guarantee, Specialty categories include Orthopedic, Medicare A5500, Diabetic Shoes, Wide Shoes, Slip-On, HSA/FSA, Activities include Walking, Running, Standing All Day, Hiking, Fitness, Casual, Everyday, Vacation, Comfort, Occupations include Healthcare, Anti-Slip, Retail, Restaurant, Warehouse, Education, De…

3. Nike – Key Product Details

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Key product details for G Dragon Nike items on eBay include:

– Product Lines: Nike Air Force, Nike Air, Nike Kwondo, Air Jordan, Nike Hyperdunk, Nike Zoom.

– Themes: Dragon, Air Force, Panda, Colorful, Retro, 90s, Athleisure, Sports.

– Sizes Available: US Shoe Sizes ranging from 8.5 to 13, including half sizes.

– Colors Available: Beige, Black, Blue, Brown, Gold, Green, Multicolor, Purple, Red, Wh…

4. G Dragon – Custom Shoes

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: G Dragon Shoes, Custom Shoes, Adidas, Nike, Casual Shoes, Urban Shoes, Nike Air Force, Nike Airmax 90, Nike Free Run, Sneakers, G Dragon Inspired Outfits, Peaceminusone, G Dragon Fashion, G Dragon Concert Outfit Ideas, G Dragon Custom Shoes, Bigbang, Ji Yong, G Dragon Style, Eboy Outfits, Vans, Chuck Taylor Sneakers, Handmade Diy, G Dragon Necklace, G Dragon Fashion Art, G Dragon Creative Instagra…

5. AliveShoes – GD by Aderinola Hi-Top Custom Shoes

Domain: aliveshoes.com

Registered: 2009 (16 years)

Introduction: GD by Aderinola is a custom shoe concept featuring a fashion strap hi-top design. The shoes are handcrafted in Italy from pristine Italian leather, ensuring high quality and uniqueness. Priced at $229, they come with zero tariffs on all US orders and free express shipping to Europe, the UK, Canada, and the USA. The shoes are available in various sizes for both males and females. Customers are guar…

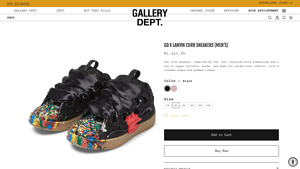

6. Gallery Dept – GD X LANVIN CURB SNEAKERS

Domain: gallerydept.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “GD X LANVIN CURB SNEAKERS (MEN’S)”, “color”: “BLACK”, “price”: “$1,420”, “size_options”: [39, 40, 41, 42, 46, 48], “description”: “The Curb sneaker, inspired by the ’90s, features bold dimensions and a mix of nappa calfskin, suede, and mesh for exceptional comfort, with a rounded shape and padded tongue.”, “materials”: [“Mesh”, “Calfskin”, “Nubuck”, “Rubber”], “care_instructions”…

Strategic Sourcing Conclusion and Outlook for gd shoes

In the evolving landscape of footwear, strategic sourcing for gd shoes offers international B2B buyers a unique opportunity to capitalize on quality craftsmanship and innovative designs. By leveraging partnerships with manufacturers that prioritize both style and functionality, businesses can meet the growing demand for diverse footwear options across various markets, including Africa, South America, the Middle East, and Europe.

As buyers consider their sourcing strategies, it is essential to evaluate factors such as material quality, production methods, and consumer preferences. The increasing emphasis on comfort, sustainability, and customization presents a significant competitive advantage for suppliers who can align their offerings with these trends. Investing in high-quality footwear that meets the ergonomic needs of customers not only enhances brand loyalty but also drives repeat business.

Looking ahead, the potential for growth in the global footwear market remains robust. By prioritizing strategic sourcing initiatives that focus on innovation and quality, B2B buyers can position themselves as leaders in their respective regions. Engage with suppliers who are committed to excellence, and explore the diverse possibilities that gd shoes can bring to your product line. Together, let’s step into a future of enhanced consumer satisfaction and thriving business partnerships.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.