Chroma Spectruanalyzer: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for chroma spectruanalyzer

In today’s competitive landscape, sourcing a high-quality chroma spectruanalyzer presents a unique challenge for international B2B buyers. The demand for precision in color measurement and analysis has surged across various industries, from electronics manufacturing to life sciences. This comprehensive guide is designed to navigate the complexities of the global market for chroma spectruanalyzers, offering valuable insights into different types, applications, and the nuances of supplier vetting. By understanding the key factors influencing cost and performance, buyers can make informed decisions that align with their operational needs.

This guide delves into the diverse applications of chroma spectruanalyzers, highlighting their significance in ensuring product quality and consistency. It also outlines critical considerations for evaluating suppliers, including product specifications, customer service, and technical support. For B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Germany—this resource serves as a strategic tool. By equipping decision-makers with the knowledge to assess options effectively, the guide fosters confidence in purchasing decisions, ultimately enhancing operational efficiency and product excellence. As the global market continues to evolve, staying informed about the latest technologies and trends in chroma spectruanalyzers is essential for maintaining a competitive edge.

Understanding chroma spectruanalyzer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2D Color Analyzer | CIE-matched filters, automatic ROI, high-resolution sensors | Display technology testing | Pros: Accurate measurements, suitable for various displays. Cons: May require technical training for optimal use. |

| Small Size Measuring Probe | Compact design, low luminance measurement capability | Mobile devices, small displays | Pros: Portability, ideal for tight spaces. Cons: Limited measurement range compared to larger models. |

| High Accuracy Universal Probe | Supports flicker measurements, high precision in low luminance | LED and OLED display testing | Pros: High accuracy, versatile for different applications. Cons: Higher initial investment. |

| Display Color Analyzer | Wide luminance range, integrated flicker measurement | Consumer electronics, automotive displays | Pros: Comprehensive testing capabilities. Cons: Can be complex to integrate with existing systems. |

| Flicker Measuring Probe | Designed for integration with LCM ATS, specialized flicker measurement | Quality control in manufacturing | Pros: Enhances product quality assurance. Cons: Requires compatible systems for full functionality. |

What Are the Key Characteristics of a 2D Color Analyzer?

The 2D Color Analyzer is distinguished by its use of CIE-matched filters and high-resolution sensors, allowing it to deliver precise color measurements across various display technologies. This type of analyzer is particularly beneficial for B2B applications in display technology testing, ensuring that products meet strict color accuracy standards. When considering this option, buyers should evaluate the need for technical training, as the advanced features may require a deeper understanding to utilize effectively.

How Does a Small Size Measuring Probe Stand Out in the Market?

The Small Size Measuring Probe offers a compact design and is ideal for low luminance measurements, making it suitable for mobile devices and small displays. Its portability allows for easy integration into tight spaces, which is a significant advantage for manufacturers in the consumer electronics sector. However, potential buyers should be aware that while it is convenient, its measurement range may not be as extensive as larger models, which could limit its applications in more demanding environments.

What Makes the High Accuracy Universal Probe Ideal for Display Testing?

The High Accuracy Universal Probe is notable for its ability to support flicker measurements and provide high precision in low luminance conditions. This capability is essential for testing LED and OLED displays, where color consistency and brightness are critical. B2B buyers should consider the initial investment required, as this probe typically comes at a higher price point, but its accuracy and versatility can justify the cost in environments where quality is paramount.

What Are the Advantages of Using a Display Color Analyzer?

The Display Color Analyzer is recognized for its wide luminance range and integrated flicker measurement capabilities, making it a comprehensive solution for testing consumer electronics and automotive displays. Its advanced features allow for thorough testing, ensuring that products meet market demands for quality and performance. However, the complexity of integration with existing systems may pose a challenge for some buyers, necessitating careful consideration of their current setup and potential need for additional training.

How Does the Flicker Measuring Probe Enhance Quality Control?

The Flicker Measuring Probe is specifically designed for integration with LCM Automated Test Systems (ATS) and excels in specialized flicker measurement. This type of probe is crucial for manufacturers focused on quality control, as it helps ensure that products meet stringent performance standards. While it provides significant advantages in quality assurance, buyers must ensure compatibility with their existing systems to fully leverage its capabilities, which could require additional investment in infrastructure.

Key Industrial Applications of chroma spectruanalyzer

| Industry/Sector | Specific Application of chroma spectruanalyzer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Quality control of display screens | Ensures uniform color and brightness, enhancing product quality | Precision measurement capabilities, support for low luminance |

| Automotive | Color matching in automotive interiors | Increases customer satisfaction through consistent aesthetics | Robustness for varied environments, compliance with industry standards |

| Pharmaceutical | Analyzing colorimetric data in drug formulations | Improves accuracy in quality control and compliance | Calibration standards, compatibility with laboratory equipment |

| Aerospace | Spectral analysis for material testing | Enhances safety and reliability of components in harsh conditions | High precision, resistance to extreme conditions |

| Food & Beverage | Color consistency in product packaging | Builds brand trust and consumer appeal | Compliance with food safety regulations, accuracy in low-light conditions |

How is the Chroma Spectruanalyzer Used in Electronics Manufacturing?

In electronics manufacturing, the chroma spectruanalyzer is pivotal in ensuring the quality of display screens by measuring color accuracy and luminance. This device helps detect inconsistencies in color reproduction, which can lead to customer dissatisfaction. For international buyers, especially in regions like Europe and South America, the need for precise measurement capabilities is crucial, as it aligns with stringent quality assurance standards. Sourcing spectruanalyzers with advanced features such as low luminance measurement and high-resolution sensors is essential for maintaining product excellence.

What Role Does the Chroma Spectruanalyzer Play in Automotive Applications?

In the automotive sector, the chroma spectruanalyzer is utilized for color matching in interiors and exteriors, ensuring that all components meet aesthetic standards. Consistent color application is vital for customer satisfaction and brand integrity. Buyers in Africa and the Middle East should consider sourcing spectruanalyzers that can withstand various environmental conditions, as automotive components are often subjected to extreme temperatures and humidity. Additionally, compliance with automotive industry standards is a key consideration for ensuring reliability and safety.

How Does the Chroma Spectruanalyzer Enhance Pharmaceutical Quality Control?

Pharmaceutical companies use the chroma spectruanalyzer to analyze colorimetric data in drug formulations, which is essential for quality control and regulatory compliance. Accurate color measurement helps in detecting variations that may affect drug efficacy. Buyers from Europe and South America need to ensure that the spectruanalyzer meets calibration standards and is compatible with existing laboratory equipment to optimize workflow and maintain compliance with health regulations.

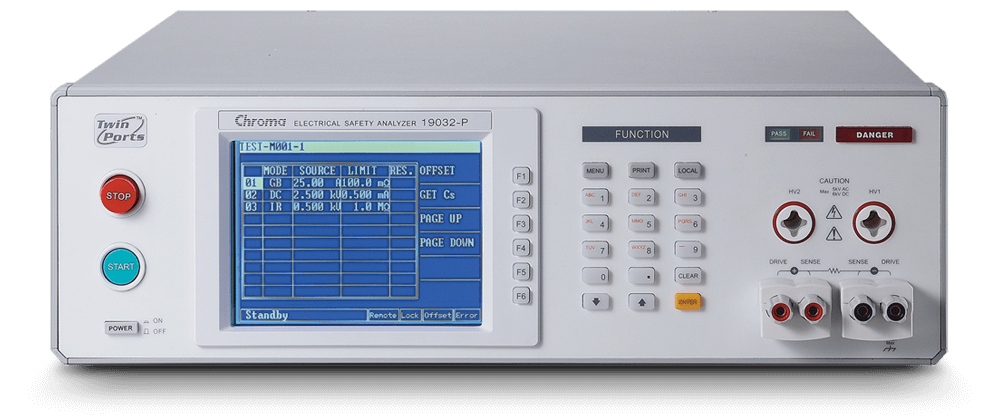

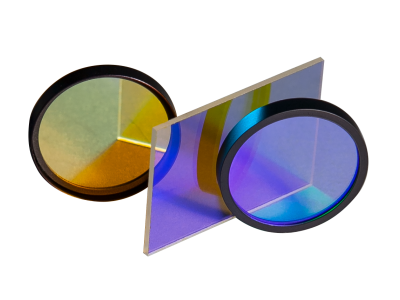

Illustrative image related to chroma spectruanalyzer

In What Ways is the Chroma Spectruanalyzer Beneficial for Aerospace Testing?

In aerospace applications, the chroma spectruanalyzer is employed for spectral analysis of materials, vital for testing components under extreme conditions. This analysis enhances the safety and reliability of aerospace products. Buyers in regions like Saudi Arabia and Germany should prioritize sourcing high-precision spectruanalyzers that can operate in harsh environments, ensuring that all components meet rigorous safety standards. The ability to provide consistent and accurate measurements is crucial for maintaining operational integrity in aerospace applications.

How is the Chroma Spectruanalyzer Used in the Food & Beverage Industry?

In the food and beverage sector, the chroma spectruanalyzer ensures color consistency in product packaging, which is essential for brand trust and consumer appeal. Accurate color measurement can influence purchasing decisions, making this tool vital for quality assurance. International buyers, particularly from Africa and Europe, should look for spectruanalyzers that comply with food safety regulations and can accurately measure colors under low-light conditions, ensuring that products meet consumer expectations and regulatory standards.

3 Common User Pain Points for ‘chroma spectruanalyzer’ & Their Solutions

Scenario 1: Difficulty in Accurate Color Measurement for Diverse Applications

The Problem: B2B buyers in industries like manufacturing or biomedical applications often face challenges with precise color measurements. Variations in lighting conditions, surface textures, or material compositions can lead to discrepancies in chromaticity and luminance readings. This inconsistency can result in defective products or inaccurate research data, causing costly rework or delays in product launches.

The Solution: To overcome this challenge, buyers should prioritize sourcing a chroma spectruanalyzer that includes features like automatic regions of interest (ROI) and high-resolution sensors. These features enhance measurement accuracy by minimizing the influence of external variables. Buyers should also invest in robust training for their team on optimal usage, including proper calibration techniques and understanding the impact of environmental conditions on measurements. Additionally, using standards such as CIE-matched filters will ensure consistency across different testing environments. Regular maintenance and recalibration of the spectruanalyzer will further enhance reliability and performance.

Scenario 2: Integration Challenges with Existing Systems

The Problem: Many B2B buyers operate within complex systems that require seamless integration of new tools, such as a chroma spectruanalyzer, with existing equipment and software. Buyers may encounter compatibility issues that lead to increased downtime and frustration among staff, hampering productivity and leading to potential financial losses.

Illustrative image related to chroma spectruanalyzer

The Solution: To mitigate integration challenges, buyers should conduct thorough compatibility assessments before purchasing. Engaging with suppliers who provide clear technical specifications and support for integration is crucial. It’s beneficial to choose a chroma spectruanalyzer that offers flexible connectivity options, such as USB or Ethernet, to facilitate easy integration into existing workflows. Additionally, buyers should inquire about the availability of APIs or software development kits (SDKs) that can assist in creating custom integrations. Collaborating with technical teams from the vendor during the installation phase can help ensure that all systems work harmoniously, minimizing disruptions.

Scenario 3: Limited Technical Support and Training Resources

The Problem: B2B buyers often struggle with the lack of adequate technical support and training when deploying sophisticated equipment like a chroma spectruanalyzer. This gap can lead to underutilization of the device’s capabilities, resulting in suboptimal performance and missed opportunities for more efficient operations.

The Solution: To address this pain point, buyers should prioritize vendors that offer comprehensive training programs and responsive technical support. Before making a purchase, it’s advisable to request detailed information about the training resources available, including online tutorials, manuals, and live support options. Establishing a direct line of communication with a technical representative can be invaluable for troubleshooting and optimizing the use of the spectruanalyzer. Additionally, organizing in-house training sessions for staff can empower them to leverage the full range of functionalities offered by the device. Buyers might also consider joining user communities or forums related to chroma spectruanalyzers, where they can share insights and solutions with other users, enhancing their overall expertise and confidence in using the technology effectively.

Strategic Material Selection Guide for chroma spectruanalyzer

When selecting materials for a chroma spectruanalyzer, several factors must be considered to ensure optimal performance and compatibility with various applications. Below is an analysis of four common materials used in the manufacturing of chroma spectruanalyzers, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Aluminum in Chroma Spectruanalyzers?

Aluminum is a lightweight yet robust material known for its excellent corrosion resistance and thermal conductivity. It typically has a temperature rating up to 150°C and can withstand moderate pressures. The material’s ability to be anodized enhances its durability and aesthetic appeal, making it suitable for various applications in spectrometry.

Pros & Cons:

Aluminum is relatively inexpensive and easy to machine, which simplifies manufacturing processes. However, it may not be suitable for high-pressure environments and can be less durable than other metals like stainless steel.

Impact on Application:

Aluminum’s compatibility with various media makes it a versatile choice for spectruanalyzers, especially in environments where weight is a concern, such as portable devices.

International Considerations:

Buyers from regions like Europe and the Middle East should ensure that the aluminum used meets standards such as ASTM B221 for structural applications.

How Does Stainless Steel Enhance the Performance of Chroma Spectruanalyzers?

Stainless steel is renowned for its strength and resistance to corrosion, making it an ideal choice for applications requiring durability and longevity. It can withstand temperatures up to 800°C and is suitable for high-pressure environments.

Pros & Cons:

The primary advantage of stainless steel is its exceptional durability, which can lead to lower maintenance costs over time. However, it is more expensive than aluminum and can be more challenging to machine, increasing manufacturing complexity.

Impact on Application:

Stainless steel is particularly beneficial in applications where chemical exposure is a concern, ensuring the integrity of the chroma spectruanalyzer over time.

International Considerations:

For buyers in regions like Germany, compliance with DIN EN 10088 standards for stainless steel is crucial.

What Role Does Glass Play in the Construction of Chroma Spectruanalyzers?

Glass is often used in optical components due to its transparency and ability to be treated for specific wavelengths. It can withstand moderate temperatures and is generally resistant to chemical corrosion.

Pros & Cons:

The primary advantage of glass is its optical clarity, which is essential for accurate measurements. However, it is fragile and can be prone to breakage, making it less suitable for rugged applications.

Impact on Application:

Glass is critical in applications requiring precise optical measurements, such as in laboratory settings.

International Considerations:

International buyers should ensure that the glass components meet relevant optical standards, such as ISO 10110 for optical elements.

How Does Plastic Contribute to the Functionality of Chroma Spectruanalyzers?

Plastics, particularly those engineered for optical applications, are increasingly used in spectruanalyzers due to their lightweight and versatile properties. They can be formulated to withstand a range of temperatures and pressures.

Pros & Cons:

Plastics are cost-effective and easy to mold into complex shapes, which can simplify manufacturing. However, they may not offer the same durability as metals or glass, particularly in high-temperature or chemically aggressive environments.

Impact on Application:

Plastics are suitable for non-critical components, such as housings or support structures, where weight reduction is essential.

International Considerations:

Buyers should verify that the plastics used comply with international safety standards, such as REACH in Europe, to ensure environmental compliance.

Summary Table of Material Selection for Chroma Spectruanalyzer

| Material | Typical Use Case for chroma spectruanalyzer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Less durable under high pressure | Low |

| Stainless Steel | Optical and structural components | High durability and corrosion resistance | Higher cost and machining complexity | High |

| Glass | Optical components | Excellent optical clarity | Fragile and prone to breakage | Medium |

| Plastic | Non-critical components | Cost-effective and easy to mold | Lower durability compared to metals | Low |

This guide provides a comprehensive overview of material selection for chroma spectruanalyzers, helping international B2B buyers make informed decisions based on performance, cost, and regulatory compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for chroma spectruanalyzer

What Are the Main Stages of Manufacturing a Chroma Spectruanalyzer?

The manufacturing process for a chroma spectruanalyzer involves several critical stages, each designed to ensure precision and quality. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial phase focuses on sourcing high-quality raw materials, such as optical components, electronic circuits, and casing materials. Suppliers must be vetted for their ability to provide materials that meet stringent quality specifications. For optical components, precision in manufacturing is paramount, as even minor defects can affect measurement accuracy.

-

Forming: In this stage, the prepared materials undergo shaping and fabrication. Techniques such as laser cutting, molding, and machining are commonly employed to create the spectruanalyzer’s components. For example, optical filters may be produced using advanced thin-film coating techniques to ensure they meet the required spectral characteristics.

-

Assembly: The assembly process integrates various components, including sensors, optics, and electronics. This stage often involves automated systems for precision placement and soldering, ensuring high reliability. Additionally, specialized fixtures may be used to align optical components accurately, which is crucial for maintaining measurement integrity.

-

Finishing: After assembly, the spectruanalyzer undergoes finishing processes, including surface treatment and calibration. Calibration is critical, as it ensures that the device provides accurate measurements across its operational range. This process might involve using reference standards and involves rigorous testing to verify that performance meets established specifications.

How Is Quality Assurance Implemented in Chroma Spectruanalyzer Manufacturing?

Quality assurance (QA) is integral to the manufacturing of chroma spectruanalyzers, ensuring that the final products meet international standards and specific customer requirements.

-

International Standards: Compliance with standards such as ISO 9001 is essential for manufacturers targeting the global market. This standard focuses on quality management systems and requires continuous improvement processes. Additionally, compliance with industry-specific standards like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for specific applications can enhance product credibility.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are established throughout the manufacturing process to detect defects early. These checkpoints typically include:

– Incoming Quality Control (IQC): Inspection of raw materials and components upon receipt to ensure they meet specified requirements.

– In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to monitor production quality and adherence to specifications.

– Final Quality Control (FQC): A comprehensive assessment of the finished product, which includes functional testing and performance validation against defined criteria. -

Common Testing Methods: Various testing methods are employed to verify the performance and accuracy of the spectruanalyzer. These may include:

– Spectral Response Testing: Evaluating how the device responds to different wavelengths.

– Calibration Tests: Ensuring that measurements align with established standards.

– Durability Testing: Assessing the device’s resilience to environmental factors such as temperature fluctuations and humidity.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial for ensuring product reliability and compliance. Here are several steps buyers can take:

-

Conduct Supplier Audits: Regular audits of suppliers can help buyers assess manufacturing practices, quality control measures, and compliance with international standards. These audits can be scheduled annually or bi-annually and should focus on both the manufacturing process and documentation practices.

-

Request Quality Assurance Documentation: Buyers should ask for detailed quality assurance documentation, including certificates of compliance with relevant standards (e.g., ISO, CE). This documentation should also include test reports and calibration certificates for the specific devices being purchased.

-

Utilize Third-Party Inspection Services: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These agencies can conduct inspections at various stages of the manufacturing process, ensuring that products meet specified standards before shipment.

-

Evaluate Past Performance and References: Buyers should request references from other customers who have previously sourced products from the supplier. This feedback can provide insights into the supplier’s reliability, quality, and responsiveness to issues.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate specific quality control nuances when sourcing chroma spectruanalyzers from different regions. Here are some considerations:

-

Understanding Regional Standards: Different markets may have varying standards and regulations. For example, products sold in the European Union must comply with CE marking requirements, while those in the United States may need to meet ANSI or ASTM standards. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Language and Cultural Barriers: Communication can sometimes be a barrier. Buyers should ensure that all quality control documentation is available in their preferred language and that they have a clear understanding of the supplier’s quality control processes.

-

Logistics and Transportation Factors: When sourcing internationally, logistics can impact product quality. Buyers should consider how transportation conditions (e.g., temperature fluctuations, humidity) might affect the spectruanalyzer during shipment and ensure that suppliers have measures in place to mitigate these risks.

-

Post-Purchase Support and Warranty: Understanding the supplier’s post-purchase support and warranty policies is crucial. Buyers should inquire about the terms of warranty and the procedures for handling defects or quality issues once the product is received.

By comprehensively evaluating the manufacturing processes and quality assurance measures for chroma spectruanalyzers, B2B buyers can make informed decisions, ensuring that they partner with reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chroma spectruanalyzer’

The procurement of a chroma spectruanalyzer is a critical investment for businesses looking to enhance their color measurement capabilities. This guide provides a structured approach to help B2B buyers navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring the chroma spectruanalyzer meets your operational needs. Consider the spectral range, resolution, and measurement accuracy required for your applications.

– Key considerations:

– Determine if you need features like flicker measurement or low luminance capabilities.

– Identify whether a compact probe or a larger system is more suitable for your workspace.

Step 2: Research Market Options

Conduct comprehensive research to identify potential suppliers and their offerings. Look for manufacturers with a strong reputation in the industry and a proven track record in delivering high-quality products.

– Focus on:

– Customer reviews and testimonials.

– Industry certifications and compliance with international standards.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– What to check:

– Supplier’s experience with chroma spectruanalyzers and related technologies.

– Availability of customer support and technical assistance.

Step 4: Assess Product Features and Capabilities

Examine the specific features of each chroma spectruanalyzer model. Ensure that the product aligns with your defined specifications and offers additional functionalities that could benefit your operations.

– Consider:

– The presence of automatic regions of interest (ROI) measurement capabilities.

– Compatibility with existing systems for seamless integration.

Illustrative image related to chroma spectruanalyzer

Step 5: Verify Supplier Certifications

Confirm that your chosen suppliers hold relevant industry certifications, which can be indicative of product quality and reliability. This step is essential for ensuring compliance with both local and international standards.

– Look for:

– ISO certifications that validate manufacturing processes.

– Compliance with safety and performance standards applicable to your region.

Step 6: Request Samples or Demonstrations

If possible, request samples or demonstrations of the chroma spectruanalyzer. This allows you to evaluate its performance in real-world conditions and assess its usability for your specific applications.

– Key actions:

– Arrange for on-site demos to see how the equipment operates.

– Test the product against your defined specifications to ensure it meets your expectations.

Step 7: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to finalize pricing, warranty, and after-sales support. Clear agreements on these aspects can prevent misunderstandings and ensure a smooth purchasing process.

– Important factors to discuss:

– Payment terms and delivery timelines.

– Service agreements for maintenance and technical support.

By following these steps, B2B buyers can make informed decisions when sourcing a chroma spectruanalyzer, ensuring that they invest in a solution that meets their needs and supports their business objectives.

Comprehensive Cost and Pricing Analysis for chroma spectruanalyzer Sourcing

When sourcing chroma spectruanalyzers, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis focuses on the various cost components, price influencers, and practical buyer tips, particularly for markets in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Chroma Spectruanalyzer Pricing?

The cost structure for chroma spectruanalyzers typically includes several essential components:

-

Materials: High-quality optical components, sensors, and electronic parts are fundamental to the performance of chroma spectruanalyzers. The choice of materials directly affects the device’s durability and measurement precision.

-

Labor: Skilled labor is required for assembly, calibration, and testing of the analyzers. The labor cost can vary significantly based on the manufacturing location and the expertise of the workforce.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: Custom tooling may be necessary for specific designs or configurations, impacting initial costs. However, investing in efficient tooling can lead to long-term savings through improved production efficiency.

-

Quality Control (QC): Rigorous QC processes are essential to ensure that the spectruanalyzers meet industry standards and customer specifications. This includes testing for accuracy, calibration, and certification, which can add to the overall cost.

-

Logistics: Shipping and handling costs are significant, especially for international buyers. Factors like distance, shipping methods, and customs duties can influence logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and provide a return on investment. Understanding typical margins in the industry can help buyers assess the fairness of pricing.

How Do Volume and Customization Affect Pricing?

The pricing of chroma spectruanalyzers is influenced by several key factors:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk can lead to significant cost reductions due to economies of scale. Suppliers often offer tiered pricing based on the volume ordered, making it essential for buyers to consider their needs carefully.

-

Specifications and Customization: Custom features or specific requirements can lead to higher costs. Buyers should clearly define their specifications to avoid unexpected expenses. Customization can also lead to longer lead times, which should be factored into procurement planning.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO standards) can increase costs but are often necessary for compliance and reliability, especially in regulated industries.

-

Supplier Factors: The reputation and location of suppliers can also affect pricing. Established suppliers with a track record of quality may charge a premium, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact total costs.

What Are the Best Negotiation Strategies for International Buyers?

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost-efficiency strategies are vital:

-

Research and Compare: Conduct thorough market research to understand the price range for chroma spectruanalyzers. Comparing multiple suppliers can provide leverage in negotiations.

-

Discuss Total Cost of Ownership: Rather than focusing solely on the purchase price, consider the Total Cost of Ownership (TCO), which includes maintenance, operation, and potential resale value. This broader view can justify higher initial costs if long-term savings are evident.

-

Be Transparent About Needs: Communicate your specific needs and constraints clearly. Suppliers appreciate transparency, which can foster trust and lead to better pricing terms.

-

Explore Payment Terms: Flexibility in payment terms can sometimes lead to discounts. Consider negotiating terms that align with your cash flow needs.

Conclusion

In conclusion, sourcing chroma spectruanalyzers involves navigating a complex landscape of costs and pricing factors. By understanding the cost components, price influencers, and employing effective negotiation strategies, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always keep in mind that prices may vary based on the specifics of each transaction, and it is prudent to request detailed quotes from suppliers to ensure clarity and transparency in pricing.

Alternatives Analysis: Comparing chroma spectruanalyzer With Other Solutions

When evaluating solutions for spectrometry and color analysis, it is essential to consider various alternatives to the Chroma Spectruanalyzer. Each option presents unique advantages and limitations, influencing the decision-making process for B2B buyers. This analysis will provide insights into how the Chroma Spectruanalyzer compares with alternative solutions, enabling informed purchasing decisions.

| Comparison Aspect | Chroma Spectruanalyzer | Color Analyzer (Chroma ATE) | Spectra Viewer (Chroma Technology) |

|---|---|---|---|

| Performance | High precision, supports multiple measurements | High accuracy, supports chromaticity and luminance | Interactive tool for spectral analysis |

| Cost | Premium pricing, tailored solutions | Moderate pricing, good value for features | Free tool with limited functionality |

| Ease of Implementation | Requires calibration and setup | User-friendly with quick setup | Simple to use, web-based access |

| Maintenance | Regular calibration needed | Low maintenance, robust design | No maintenance required for software |

| Best Use Case | Advanced applications needing detailed analysis | General color measurement and display testing | Educational and research purposes |

What Are the Advantages and Disadvantages of Using a Color Analyzer as an Alternative?

The Color Analyzer from Chroma ATE serves as a practical alternative to the Chroma Spectruanalyzer, particularly for organizations focusing on color measurement and display testing. It offers high accuracy in chromaticity and luminance measurements, making it suitable for industries such as electronics and display manufacturing. One of its key advantages is the moderate pricing, which provides a compelling value for the features offered. However, it may lack the depth of analysis that the Chroma Spectruanalyzer provides, which could be a limitation for specialized applications requiring comprehensive spectral data.

How Does the Spectra Viewer Compare to the Chroma Spectruanalyzer?

The Spectra Viewer from Chroma Technology is a free, interactive tool that enables users to visualize and analyze spectral data. Its simplicity and accessibility make it an excellent choice for educational and research purposes, allowing users to explore optical filters and their applications without significant investment. However, it does not provide the same level of precision or detailed analysis capabilities as the Chroma Spectruanalyzer. Therefore, while it can be beneficial for initial exploration and understanding of spectral data, it may not meet the rigorous demands of professional environments requiring advanced analysis.

Illustrative image related to chroma spectruanalyzer

How Should B2B Buyers Choose Between These Solutions?

Selecting the right solution for spectrometry and color analysis hinges on specific organizational needs and use cases. B2B buyers should assess factors such as the complexity of their applications, budget constraints, and required accuracy levels. For high-end applications that demand detailed spectral analysis, the Chroma Spectruanalyzer stands out despite its premium pricing. Conversely, for businesses needing efficient color measurement without extensive analysis, the Color Analyzer may provide a more cost-effective and user-friendly solution. Lastly, for educational or preliminary research purposes, the Spectra Viewer serves as an accessible entry point into the world of optical analysis without the burden of investment.

In conclusion, understanding the strengths and weaknesses of each alternative enables B2B buyers to make informed decisions aligned with their operational requirements and strategic objectives.

Essential Technical Properties and Trade Terminology for chroma spectruanalyzer

What Are the Key Technical Properties of a Chroma Spectruanalyzer?

Understanding the technical specifications of a chroma spectruanalyzer is vital for making informed purchasing decisions. Here are some critical properties to consider:

-

Spectral Range

The spectral range indicates the wavelengths the spectruanalyzer can measure, typically expressed in nanometers (nm). For example, a device that measures from 200 nm to 3000 nm provides versatility across various applications, from life sciences to industrial testing. In B2B contexts, selecting a spectruanalyzer with an appropriate spectral range ensures compatibility with the specific requirements of your industry, enhancing operational efficiency. -

Resolution

Resolution defines the smallest detectable difference in wavelength or color that the device can measure. Higher resolution is crucial for applications requiring precise color differentiation, such as in quality control for manufacturing. For B2B buyers, a high-resolution spectruanalyzer minimizes errors in measurements, leading to better product quality and compliance with industry standards. -

Accuracy and Precision

Accuracy refers to how close a measurement is to the true value, while precision indicates the reproducibility of measurements. For example, an accuracy of ±0.002 (greater than 0.1 cd/m²) in luminance measurements means reliable performance. Buyers should prioritize instruments with high accuracy and precision to avoid costly mistakes and ensure consistent product quality in their operations. -

Dynamic Range

The dynamic range indicates the range of luminance levels the device can accurately measure, from low to high. A spectruanalyzer with a wide dynamic range can handle various lighting conditions, making it suitable for diverse applications. For businesses, this flexibility can lead to improved adaptability in testing environments, ultimately saving time and resources. -

Measurement Modes

Many chroma spectruanalyzers offer various measurement modes such as chromaticity, luminance, and contrast. Each mode serves different analytical needs, allowing users to tailor their measurements based on specific requirements. In a B2B setting, understanding these modes can help businesses select a device that meets their precise testing needs, enhancing operational efficiency. -

Integration Capabilities

Modern spectruanalyzers often feature capabilities for integration with automated systems and software. This functionality can streamline workflows and improve data management. For B2B buyers, investing in equipment that supports integration can lead to significant long-term cost savings and enhanced productivity.

What Are Common Trade Terms Related to Chroma Spectruanalyzers?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B environment. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for businesses looking to source components or complete systems, as it can affect pricing and product support. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is important for B2B buyers as it can influence purchasing decisions, especially for small to mid-sized enterprises looking to manage inventory costs effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For businesses, a well-crafted RFQ can lead to competitive pricing and better negotiation outcomes. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and tariffs. Understanding these terms is vital for B2B buyers engaged in global trade, as they clarify the cost and risk distribution. -

Calibration

Calibration is the process of adjusting the spectruanalyzer to ensure accurate measurements. In a B2B context, regular calibration is essential for maintaining compliance with industry standards and ensuring product quality. -

Lead Time

Lead time refers to the time taken from placing an order to receiving it. For businesses, understanding lead times is crucial for inventory management and project planning, especially in sectors where timely delivery is critical.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right chroma spectruanalyzer for their specific needs while optimizing their purchasing processes.

Navigating Market Dynamics and Sourcing Trends in the chroma spectruanalyzer Sector

What Are the Current Market Dynamics and Key Trends in the Chroma Spectruanalyzer Sector?

The global market for chroma spectruanalyzers is experiencing dynamic growth, driven by several key factors. Firstly, the increasing demand for high-precision color measurement in industries such as automotive, electronics, and textiles is propelling the market forward. As companies in Africa, South America, the Middle East, and Europe seek to enhance product quality and customer satisfaction, the need for reliable color analysis tools becomes essential. Additionally, advancements in technology, including the integration of artificial intelligence and machine learning into color measurement systems, are enabling more accurate and efficient testing processes.

Emerging trends in sourcing for chroma spectruanalyzers include a shift towards modular and customizable solutions that cater to specific industry needs. International buyers are increasingly looking for suppliers that offer tailored products, which can adapt to various applications. Moreover, the rise of Industry 4.0 is prompting manufacturers to invest in smart systems that integrate seamlessly into automated production lines, thereby enhancing operational efficiency. As a result, B2B buyers are advised to engage with suppliers who not only provide robust products but also exhibit flexibility in meeting diverse requirements.

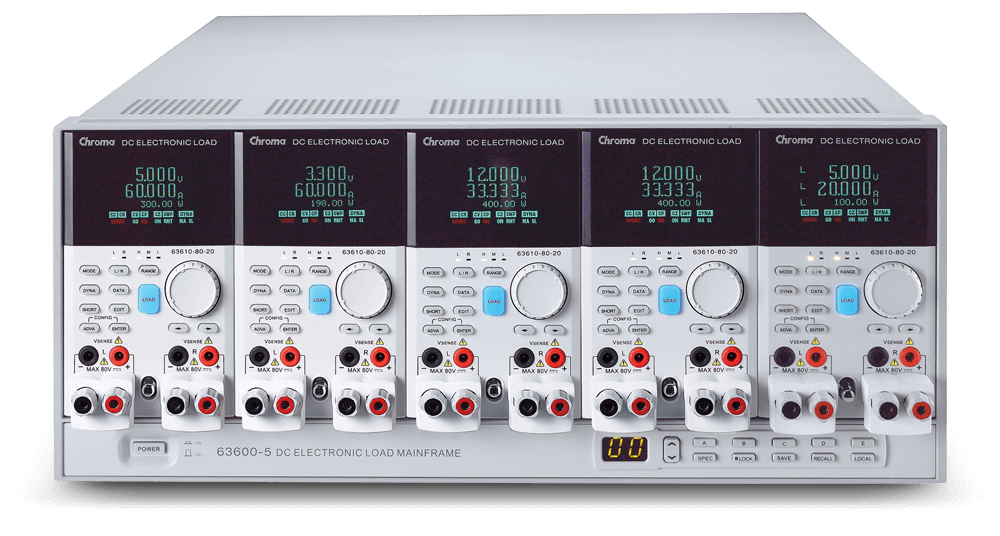

Illustrative image related to chroma spectruanalyzer

How Is Sustainability Shaping the Chroma Spectruanalyzer Supply Chain?

Sustainability has become a critical consideration in the sourcing of chroma spectruanalyzers, reflecting a broader industry shift towards environmentally responsible practices. The environmental impact of manufacturing processes, particularly in terms of waste generation and energy consumption, is under scrutiny. B2B buyers are increasingly favoring suppliers who demonstrate a commitment to sustainability through ethical sourcing practices and the use of eco-friendly materials.

The importance of ethical supply chains cannot be overstated, particularly as consumers and regulatory bodies demand greater transparency. Suppliers that adhere to ‘green’ certifications, such as ISO 14001 or RoHS compliance, not only contribute to environmental protection but also enhance their marketability. For international buyers, particularly in regions like Europe where sustainability regulations are stringent, partnering with manufacturers who prioritize green materials and processes can lead to competitive advantages. Ultimately, adopting sustainable sourcing practices can help companies mitigate risks and appeal to environmentally conscious customers.

How Has the Chroma Spectruanalyzer Sector Evolved Over Time?

The evolution of the chroma spectruanalyzer sector can be traced back to the early developments in optical measurement technology. Initially, color measurement was a labor-intensive process, relying heavily on subjective human interpretation. Over the years, technological advancements have transformed the landscape, leading to the introduction of sophisticated spectrometers and analyzers that provide objective, precise measurements.

Illustrative image related to chroma spectruanalyzer

The integration of digital technology and software solutions has further enhanced the capabilities of chroma spectruanalyzers, allowing for real-time data analysis and improved user interfaces. Today, these instruments are pivotal in a wide array of applications, from quality control in manufacturing to research and development in various scientific fields. As the market continues to innovate, it is essential for B2B buyers to stay informed about the latest technological advancements and their implications for sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of chroma spectruanalyzer

-

How do I ensure the accuracy of my chroma spectruanalyzer measurements?

To ensure accurate measurements with your chroma spectruanalyzer, regular calibration is essential. Work with a certified service provider to perform routine maintenance and calibration checks. Additionally, utilize reference standards and control samples to validate the performance of your instrument. Always follow the manufacturer’s guidelines for operation and maintenance, as well as environmental controls to mitigate any external factors that may affect readings. -

What is the best chroma spectruanalyzer for industrial applications?

The best chroma spectruanalyzer for industrial applications typically combines high precision with robust features tailored to specific needs. Look for models with high-resolution sensors, multiple measurement capabilities (like luminance and chromaticity), and low luminance measurement options. Additionally, consider units that offer automated testing and integration with existing systems for increased efficiency. Research user reviews and case studies from similar industries to make an informed decision. -

What customization options are available for chroma spectruanalyzers?

Many manufacturers offer customization options for chroma spectruanalyzers to meet specific customer needs. Customizations can include tailored measurement ranges, integration with existing systems, or modifications to the software interface. When sourcing, inquire about the manufacturer’s ability to provide bespoke solutions and the associated lead times. It’s beneficial to discuss your requirements in detail to ensure the final product aligns with your operational goals. -

What are typical minimum order quantities (MOQs) for chroma spectruanalyzers?

Minimum order quantities (MOQs) for chroma spectruanalyzers can vary significantly depending on the supplier and the specific product. Generally, MOQs may range from one unit for standard models to larger quantities for customized solutions. It’s advisable to communicate directly with suppliers about your needs and negotiate MOQs, especially if you are a small or medium-sized enterprise looking to enter the market. -

What payment terms should I expect when purchasing a chroma spectruanalyzer?

Payment terms for purchasing a chroma spectruanalyzer can vary widely among suppliers. Common terms include upfront payment, partial payment upon order confirmation, and the balance upon delivery. In international transactions, consider factors like currency fluctuations and bank fees. It’s crucial to clarify payment terms before finalizing an order and to ensure that they align with your company’s financial policies. -

How can I vet suppliers of chroma spectruanalyzers effectively?

To effectively vet suppliers, start by researching their reputation in the industry through reviews, testimonials, and case studies. Evaluate their certifications and quality assurance processes, such as ISO compliance. Request references from other B2B clients and inquire about after-sales support and warranty policies. Additionally, consider visiting their facilities if possible, or participating in virtual meetings to assess their capabilities. -

What logistics considerations should I keep in mind when importing chroma spectruanalyzers?

When importing chroma spectruanalyzers, consider factors such as shipping methods, customs regulations, and delivery timelines. Ensure that the supplier provides all necessary documentation, including certificates of conformity and shipping invoices. Additionally, calculate potential duties and taxes to avoid unexpected costs upon arrival. Collaborating with a reliable logistics partner can streamline the process and ensure compliance with international trade regulations. -

What quality assurance processes should I expect from manufacturers of chroma spectruanalyzers?

Reputable manufacturers of chroma spectruanalyzers should have stringent quality assurance processes in place. This typically includes rigorous testing of each unit before shipment, compliance with international standards, and offering warranties or guarantees on performance. Ask about their quality control measures, such as calibration standards and testing protocols, to ensure that you receive a product that meets your specifications and operational needs.

Top 5 Chroma Spectruanalyzer Manufacturers & Suppliers List

1. Chroma – Spectra Viewer

Domain: chroma.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Spectra Viewer”, “company”: “Chroma Technology Corp”, “filter_types”: [“Bandpass Filters”, “Longpass Filters”, “Multi-bandpass Filters”, “Shortpass Filters”, “Single Bandpass Filters”, “Beamsplitters”, “Multi-band Dichroic Beamsplitters”, “Fluorescence Dichroic Beamsplitters”, “Emission Filters”, “Excitation Filters”, “Neutral Density Filters”, “Notch Rejection Filters”, “Polariz…

2. Chromaate – Chroma Color Analyzer 71803 Series

Domain: chromaate.com

Registered: 1996 (29 years)

Introduction: Chroma Color Analyzer 2D Color Analyzer Model 71803 Series: CIE-matched filter and ND filters, 12-bit high-resolution sensor, Automatic regions of interest (ROI), measures Chromaticity, Luminance, Contrast, Uniformity, and Correlated Color Temperature. Small Size Measuring Probe Model 71242: Small measurement aperture for 10mm, measures brightness and chromaticity of color displays, low luminance …

3. Chroma – 7120 Color LCD Analyzer

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“item_name”: “Chroma7120 color LCD analyzer”, “quantity”: “1PCS”, “model”: “7120#LL”, “condition”: “Used”, “price”: “US $397.00 or Best Offer”, “shipping”: “Free Economy Shipping from Greater China to worldwide”, “returns”: “30 days returns, buyer pays for return shipping”, “seller_feedback”: “100% positive feedback”, “location”: “Shenzhen, China”}

4. Chroma – Spectra Analyzer

Domain: patchstorage.com

Registered: 2015 (10 years)

Introduction: Chroma Spectra is an eight band spectrum analyzer designed for the Empress Effects Zoia. It features an analyzer page, an expression input for controlling intensity, audio input/output, and a VCA. The filters on the third page feed into the visualization pixels on the first page. The product is categorized under Utility, with a revision of 1.0 and a license allowing public use. It has received 681…

5. Chroma – EMC Test Equipment

Domain: theemcshop.com

Registered: 2014 (11 years)

Introduction: Chroma Products – The EMC Shop offers a wide range of EMC test equipment including: Automotive/Electric Vehicle test systems, Transient Immunity Generators, Load Dump Generators, Battery Simulators, Artificial Mains Networks, Bulk Current Injection systems, ESD immunity test equipment, RF Power Amplifiers across various frequency ranges, EMC antennas, and various types of probes and clamps for tes…

Strategic Sourcing Conclusion and Outlook for chroma spectruanalyzer

In today’s competitive landscape, strategic sourcing of chroma spectruanalyzers presents a unique opportunity for international B2B buyers to enhance their operational capabilities. By investing in high-quality color analysis solutions, companies across Africa, South America, the Middle East, and Europe can achieve superior accuracy in product testing, leading to improved quality control and customer satisfaction. The advanced features of modern chroma spectruanalyzers, such as high-resolution sensors and automatic regions of interest, are critical for industries ranging from aerospace to life sciences, where precise measurements can significantly impact performance outcomes.

Furthermore, leveraging partnerships with reputable manufacturers ensures access to innovative technology and expert support, which can streamline procurement processes and reduce lead times. As the demand for precision measurement continues to rise, aligning your sourcing strategy with these advanced tools will not only optimize your operations but also position your business for future growth.

As you explore sourcing options, consider reaching out to leading suppliers and engaging in discussions about tailored solutions that meet your specific requirements. Embrace the future of color analysis with confidence, ensuring your business remains at the forefront of technological advancements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.