Is Your Placa Madre Para Iphone 14 Pro Max Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for placa madre para iphone 14 pro max

In today’s fast-paced technology market, sourcing high-quality ‘placa madre para iPhone 14 Pro Max’ presents a significant challenge for B2B buyers. With a surge in demand for repairs and replacements, especially in regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of this global supply chain is crucial. Buyers face a multitude of options, but the key lies in navigating the complexities of supplier credibility, product authenticity, and competitive pricing.

This comprehensive guide delves into the essential aspects of the placa madre market, offering insights into different types, applications, and the critical process of supplier vetting. By addressing factors such as cost considerations and market trends, we equip international buyers with the knowledge needed to make informed purchasing decisions. Our goal is to streamline your sourcing process, enabling you to identify reliable suppliers who can meet your specific needs.

As you explore the landscape of placa madre for the iPhone 14 Pro Max, this guide serves as a valuable resource, providing actionable insights that empower your business to thrive in a competitive market. Whether you are looking to enhance your product offerings or ensure customer satisfaction through quality repairs, understanding these dynamics will position you for success in the global marketplace.

Understanding placa madre para iphone 14 pro max Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Placa Madre | Original equipment manufacturer specifications | Retail and repair shops | Pros: Guaranteed quality; Cons: Higher cost. |

| Refurbished Placa Madre | Tested and restored to original condition | Cost-effective repairs | Pros: Lower price; Cons: Potential reliability issues. |

| Aftermarket Placa Madre | Third-party components with varying quality standards | Bulk purchase for repair businesses | Pros: Competitive pricing; Cons: Uncertain quality. |

| Unlocked Placa Madre | Compatible with multiple carrier networks | International markets | Pros: Flexibility in use; Cons: May lack warranty. |

| Custom Placa Madre | Tailored features for specific applications or markets | Specialized repair services | Pros: Meets specific needs; Cons: Longer lead times. |

What Are the Key Characteristics of OEM Placa Madre for iPhone 14 Pro Max?

OEM (Original Equipment Manufacturer) placas madre are produced by Apple or authorized manufacturers, ensuring they meet the exact specifications required for the iPhone 14 Pro Max. These motherboards are ideal for businesses focused on high-quality repairs, as they provide reliability and compatibility. B2B buyers should consider the higher cost associated with OEM parts, which can be justified by the assurance of quality and performance, making them a preferred choice for retail and repair shops.

How Do Refurbished Placa Madre Options Differ from OEM Choices?

Refurbished placas madre are previously used components that have undergone testing and repairs to restore them to their original functionality. These are suitable for businesses looking to reduce costs while still offering reliable repair services. While refurbished options can provide significant savings, buyers must weigh the potential risks of reliability and warranty limitations. This type of motherboard is particularly attractive for cost-sensitive markets where budget constraints are a primary concern.

What Should B2B Buyers Know About Aftermarket Placa Madre?

Aftermarket placas madre are produced by third-party manufacturers and can vary widely in quality. These components are often much cheaper than OEM or refurbished options, making them appealing for bulk purchases in repair businesses. However, the inconsistent quality can lead to higher return rates and customer dissatisfaction. B2B buyers should thoroughly vet suppliers and consider warranty options to mitigate risks associated with aftermarket products.

What Are the Advantages of Unlocked Placa Madre?

Unlocked placas madre offer compatibility with various carrier networks, making them especially valuable in international markets. This flexibility allows businesses to cater to diverse customer needs, particularly in regions with multiple service providers. However, buyers should be cautious, as unlocked options may not come with a manufacturer warranty, which can pose a risk in terms of quality assurance. This type of motherboard is ideal for businesses that focus on international sales or repairs.

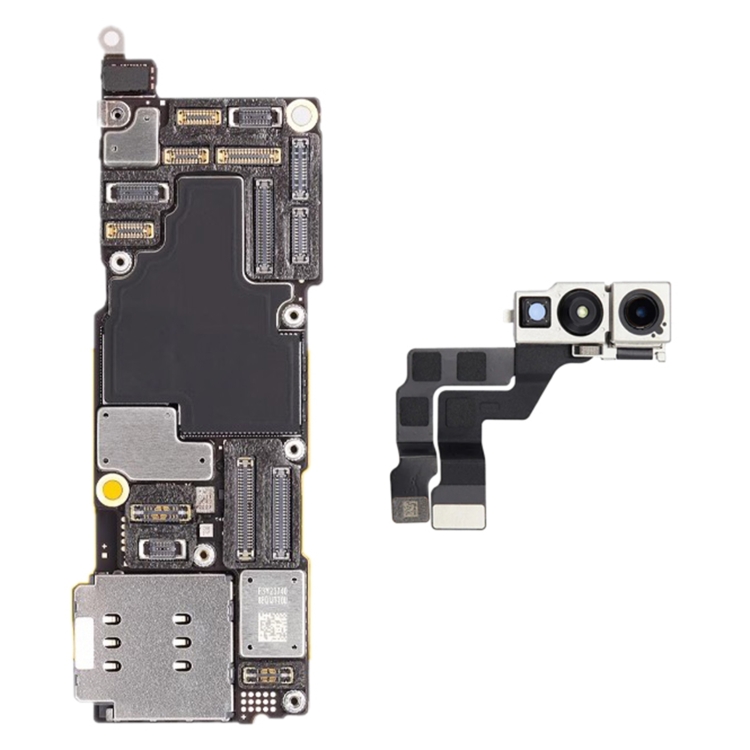

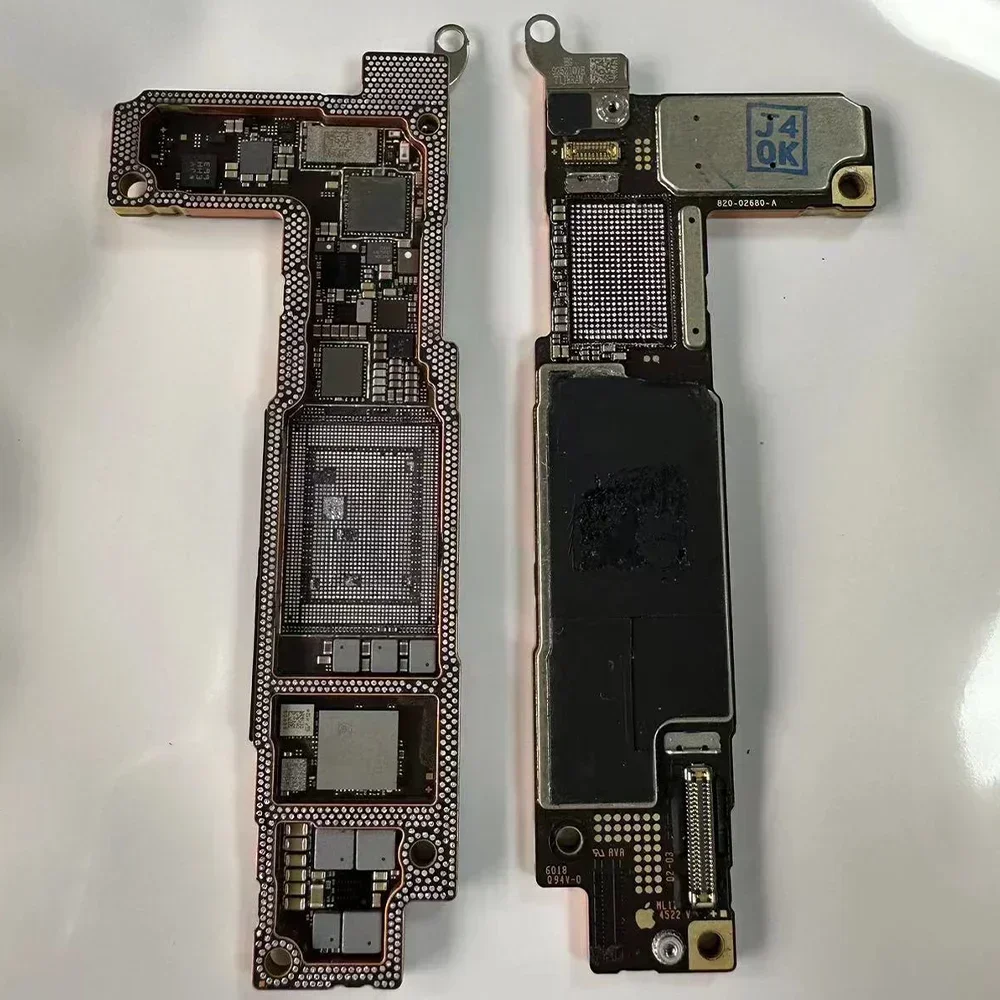

Illustrative image related to placa madre para iphone 14 pro max

How Can Custom Placa Madre Benefit Specialized Repair Services?

Custom placas madre are designed to meet specific requirements for unique applications or market segments. These motherboards can be tailored with additional features or specifications that cater to niche markets, providing a distinct competitive advantage. However, the production time for custom options can be longer, which may affect inventory management for businesses. B2B buyers should assess the demand for such specialized products in their target markets to justify the investment in custom solutions.

Key Industrial Applications of placa madre para iphone 14 pro max

| Industry/Sector | Specific Application of placa madre para iphone 14 pro max | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mobile Repair Services | Replacement in damaged iPhones | Enhances service offerings, customer satisfaction | Quality assurance, warranty, and compatibility checks |

| Electronics Manufacturing | Component for refurbished devices | Reduces costs, increases product lifecycle | Bulk purchasing options, supplier reliability |

| E-commerce | Resale of refurbished or repaired iPhones | Expands inventory, attracts budget-conscious buyers | Shipping logistics, import regulations |

| Telecommunications | Integration into rental or leasing programs | Increases device availability, customer retention | Supply chain efficiency, pricing strategies |

| Educational Institutions | Use in training programs for electronics repair | Prepares students for the workforce, hands-on experience | Quality of components, training resources |

How is the placa madre para iphone 14 pro max used in Mobile Repair Services?

In mobile repair services, the placa madre para iphone 14 pro max is essential for replacing damaged motherboards in iPhones. When a device suffers from water damage or a critical failure, technicians often need to replace the motherboard to restore functionality. This application not only enhances service offerings but also significantly boosts customer satisfaction by providing a reliable repair option. For international buyers, particularly from regions like Africa and South America, sourcing high-quality motherboards is crucial to maintaining service standards and ensuring customer loyalty.

What role does the placa madre para iphone 14 pro max play in Electronics Manufacturing?

In the electronics manufacturing sector, the placa madre for the iPhone 14 Pro Max is pivotal for creating refurbished devices. Manufacturers can reduce costs and enhance sustainability by sourcing these components to replace faulty ones, thus extending the product lifecycle. For businesses in Europe and the Middle East, the focus should be on ensuring that the components meet stringent quality standards and compatibility requirements to avoid production delays and maintain market competitiveness.

How do E-commerce platforms utilize the placa madre para iphone 14 pro max?

E-commerce businesses leverage the placa madre para iphone 14 pro max to sell refurbished or repaired iPhones. This strategy allows them to expand their inventory and attract budget-conscious consumers looking for reliable devices at lower prices. Key considerations for B2B buyers in this sector include establishing efficient shipping logistics and understanding import regulations to ensure compliance and timely delivery, especially when sourcing from international suppliers.

Illustrative image related to placa madre para iphone 14 pro max

Why is the placa madre para iphone 14 pro max important for Telecommunications?

In the telecommunications industry, the placa madre para iphone 14 pro max is integral to rental or leasing programs for smartphones. By integrating these components into their offerings, companies can increase device availability and enhance customer retention. International buyers must consider supply chain efficiency and pricing strategies to remain competitive in a market where rapid technological advancements often dictate customer preferences.

How can Educational Institutions benefit from the placa madre para iphone 14 pro max?

Educational institutions utilize the placa madre para iphone 14 pro max in training programs focused on electronics repair. This hands-on experience prepares students for careers in technology and repair services. For buyers in this sector, the quality of components and the availability of training resources are critical to ensuring that students receive effective, real-world training that meets industry standards.

3 Common User Pain Points for ‘placa madre para iphone 14 pro max’ & Their Solutions

Scenario 1: Difficulty in Identifying Genuine Components

The Problem: One of the most pressing challenges B2B buyers face when sourcing ‘placa madre para iphone 14 pro max’ is distinguishing genuine parts from counterfeit ones. This issue is particularly acute in regions where market regulation is lax, leading to an influx of low-quality components that can cause further damage to devices. Buyers often worry that purchasing a motherboard that looks identical to the original will ultimately compromise their reputation, lead to increased warranty claims, and cause dissatisfaction among their customers.

Illustrative image related to placa madre para iphone 14 pro max

The Solution: To effectively mitigate the risk of acquiring counterfeit motherboards, B2B buyers should establish strong relationships with reputable suppliers who can provide proof of authenticity, such as certificates of compliance or detailed product specifications. Implementing a thorough vetting process for suppliers, including checking reviews, certifications, and previous customer experiences, can help buyers make informed decisions. Additionally, utilizing advanced technology for tracking and verifying components, such as blockchain solutions, can add another layer of security and transparency to the supply chain, ensuring that only authentic products are procured.

Scenario 2: High Costs Associated with Repairs and Replacements

The Problem: Another significant concern for B2B buyers is the high cost involved in repairing or replacing damaged motherboards. In many cases, the price of a new ‘placa madre para iphone 14 pro max’ can significantly cut into profit margins, especially for small to medium-sized enterprises. This financial strain is compounded when devices must be sent to third-party repair centers, leading to longer turnaround times and potential loss of business from dissatisfied customers.

The Solution: To address cost concerns, buyers should consider bulk purchasing agreements with suppliers. By negotiating better prices for larger orders, businesses can reduce their costs significantly. Additionally, investing in training for in-house technicians can minimize reliance on external repair services. This approach not only cuts costs but also allows for quicker repairs, keeping customer satisfaction high. Buyers should also explore aftermarket solutions or refurbished motherboards as cost-effective alternatives, provided they meet quality and reliability standards.

Scenario 3: Limited Availability and Long Lead Times

The Problem: B2B buyers often face the issue of limited availability and long lead times for the ‘placa madre para iphone 14 pro max’. This can be particularly frustrating in regions that experience fluctuating demand or supply chain disruptions. Delays in receiving components can halt operations and lead to missed sales opportunities, as businesses struggle to fulfill customer needs promptly.

The Solution: To combat availability issues, B2B buyers should diversify their sourcing strategies. This includes establishing relationships with multiple suppliers across different regions to mitigate risks associated with single-source dependencies. Implementing just-in-time inventory practices can help manage stock levels more efficiently, ensuring that components are available when needed without overcommitting capital. Additionally, buyers should stay informed about market trends and forecasts to anticipate demand surges and plan their orders accordingly, ensuring they remain competitive in the marketplace.

Strategic Material Selection Guide for placa madre para iphone 14 pro max

What Are the Key Materials Used in the Placa Madre for iPhone 14 Pro Max?

When selecting materials for the placa madre (motherboard) of the iPhone 14 Pro Max, several factors influence performance, durability, and overall suitability for international markets. Below, we analyze four common materials used in this application: FR-4, copper, aluminum, and polyimide. Each material has unique properties that can impact the performance and compliance of the final product.

How Does FR-4 Perform in the Manufacturing of Placa Madre?

FR-4 is a widely used composite material made from woven fiberglass cloth and epoxy resin. It is known for its excellent electrical insulation properties and mechanical strength, making it suitable for high-density interconnect (HDI) applications.

Key Properties: FR-4 can withstand temperatures up to 130°C and offers good resistance to moisture and chemicals.

Pros & Cons: The durability of FR-4 is notable; however, it can be more expensive than other options. Its manufacturing complexity is moderate, and it is compatible with most soldering processes. However, it may not perform optimally in extremely high-temperature environments.

Impact on Application: FR-4 is ideal for electronic components that require stable performance under varying conditions.

Illustrative image related to placa madre para iphone 14 pro max

Considerations for International Buyers: Compliance with standards such as ASTM and IPC is crucial. Buyers should ensure that the FR-4 used meets the necessary certifications for their respective regions, especially in markets like Europe and South America, where regulations can be stringent.

What Role Does Copper Play in the Placa Madre?

Copper is a fundamental material in the construction of the placa madre due to its excellent electrical conductivity.

Key Properties: Copper has a high thermal and electrical conductivity rating, making it essential for signal integrity and heat dissipation.

Illustrative image related to placa madre para iphone 14 pro max

Pros & Cons: The primary advantage of copper is its performance in electrical applications; however, it is susceptible to corrosion if not properly coated. The cost of copper can vary based on market conditions, and its manufacturing complexity is relatively low, given its widespread use.

Impact on Application: Copper is crucial for pathways and connections within the motherboard, ensuring efficient operation of the device.

Considerations for International Buyers: Buyers should be aware of the fluctuating costs of copper and potential tariffs in different regions. Compliance with environmental regulations regarding copper usage is also important, particularly in Europe.

Why Is Aluminum Used in the Placa Madre Construction?

Aluminum is often used in the casing and heat sinks of electronic devices, including the placa madre.

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which contributes to the overall portability of the device. However, it may not provide the same level of electrical conductivity as copper. Manufacturing complexity is low, making it a cost-effective choice.

Illustrative image related to placa madre para iphone 14 pro max

Impact on Application: Aluminum’s thermal properties help manage heat dissipation, which is critical for maintaining device performance.

Considerations for International Buyers: Aluminum must comply with various international standards, and buyers should ensure that suppliers meet these requirements, especially in the Middle East and Africa, where material sourcing can be challenging.

How Does Polyimide Contribute to the Placa Madre?

Polyimide is a high-performance polymer that is increasingly used in flexible circuit boards and insulation layers.

Illustrative image related to placa madre para iphone 14 pro max

Key Properties: Polyimide can withstand high temperatures (up to 260°C) and offers excellent chemical resistance.

Pros & Cons: The flexibility of polyimide allows for innovative designs, but it can be more costly than traditional materials. Its manufacturing complexity is higher due to specialized processing requirements.

Impact on Application: Polyimide is particularly suitable for applications requiring flexibility and high thermal stability.

Considerations for International Buyers: Buyers should ensure that polyimide materials comply with international standards such as JIS and DIN, especially in regions like Asia and Europe where compliance is critical.

Illustrative image related to placa madre para iphone 14 pro max

Summary Table of Material Selection for Placa Madre

| Material | Typical Use Case for placa madre para iphone 14 pro max | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| FR-4 | Circuit boards and insulation layers | Excellent electrical insulation | Higher cost compared to alternatives | Medium |

| Copper | Conductive pathways and connections | High electrical and thermal conductivity | Susceptible to corrosion | Medium |

| Aluminum | Casing and heat sinks | Lightweight and corrosion-resistant | Lower conductivity than copper | Low |

| Polyimide | Flexible circuit boards | High thermal stability and flexibility | Higher manufacturing complexity | High |

This strategic material selection guide provides B2B buyers with critical insights into the properties, advantages, and considerations of materials used in the placa madre for the iPhone 14 Pro Max, facilitating informed purchasing decisions that align with regional compliance and market dynamics.

In-depth Look: Manufacturing Processes and Quality Assurance for placa madre para iphone 14 pro max

What Are the Key Stages in the Manufacturing Process of the iPhone 14 Pro Max Motherboard?

The manufacturing process of the iPhone 14 Pro Max motherboard (placa madre) is a complex and meticulous undertaking that involves several key stages. Each stage is crucial in ensuring the final product meets the high-performance standards set by Apple.

Material Preparation: Sourcing and Quality Control

The first stage involves sourcing high-quality materials, including various metals, semiconductors, and composite materials. Suppliers must adhere to strict specifications to ensure compatibility and performance. This stage often includes rigorous testing of raw materials to ensure they meet international standards such as ISO 9001, which focuses on quality management systems. B2B buyers should verify the traceability of materials and insist on documentation that confirms compliance with these standards.

Forming: Precision Manufacturing Techniques

Once materials are sourced, they undergo forming processes such as etching and layering. Photolithography is commonly used to create intricate circuit patterns on semiconductor materials. This technique ensures precision at a microscopic level, which is essential for the high-density circuits found in modern smartphones. Advanced manufacturing technologies, such as 3D printing and laser cutting, may also be employed to create specific components of the motherboard. Buyers should inquire about the technologies used by suppliers to ensure they utilize the latest innovations that enhance efficiency and quality.

Assembly: Integrating Components with Care

During the assembly phase, various components, including chips, capacitors, and connectors, are meticulously integrated into the motherboard. Automated assembly lines are often used to enhance speed and consistency, but skilled technicians are also involved to manage quality control at this stage. Manufacturers may utilize surface mount technology (SMT) to place components accurately and efficiently. B2B buyers should assess the supplier’s assembly capabilities, including the technology used and the level of human oversight, to gauge the quality of the final product.

Finishing: Ensuring Durability and Functionality

The final stage involves finishing processes such as soldering, coating, and testing. Protective coatings are applied to enhance durability and resist environmental factors. This stage also includes functional testing to ensure that the motherboard operates correctly under various conditions. Common tests include thermal cycling, vibration tests, and electrical performance assessments. Buyers can request detailed reports on these tests to ensure the motherboard meets their specific requirements.

How is Quality Assurance Implemented in Motherboard Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of the iPhone 14 Pro Max motherboard. It encompasses various checkpoints and standards that ensure each unit meets the required performance specifications.

Illustrative image related to placa madre para iphone 14 pro max

What Are the International Quality Standards Relevant to Motherboard Manufacturing?

International standards such as ISO 9001 provide a framework for quality management, while industry-specific standards like CE certification and API (Application Programming Interface) compliance ensure that the products meet specific safety and performance criteria. For B2B buyers, understanding these certifications is crucial, as they signify that the manufacturer adheres to global quality norms.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is typically implemented at multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the facility. Ensuring these materials meet the required specifications is vital for the overall quality of the final product.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves continuous monitoring of processes and components. This includes real-time inspections and testing, allowing manufacturers to identify and rectify issues immediately.

-

Final Quality Control (FQC): After assembly and finishing, the final products undergo rigorous testing to verify their functionality, durability, and compliance with international standards. This is the last line of defense against defects before products are shipped.

What Common Testing Methods Are Used in Motherboard Quality Control?

Manufacturers employ several testing methods to ensure the quality of the motherboards:

- Functional Testing: This involves running the motherboard through a series of operational tests to confirm that all components function as intended.

- Burn-In Testing: This test subjects the motherboard to extended periods of operation at elevated temperatures to identify potential failures early.

- Electrical Testing: Ensures that the electrical signals are transmitted correctly and that there are no short circuits or other electrical issues.

B2B buyers should inquire about the specific testing methods used by suppliers and request access to test reports to verify compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control measures is paramount. Here are actionable steps:

-

Conduct Supplier Audits: Schedule on-site audits to evaluate the manufacturer’s processes, equipment, and adherence to quality standards. This provides firsthand insight into their operations.

-

Request Quality Reports: Ask for documentation of previous quality control tests, including IQC, IPQC, and FQC results. These reports should detail the testing methods and outcomes.

-

Utilize Third-Party Inspections: Engage third-party inspection agencies to conduct independent assessments of the manufacturing processes and final products. This adds an additional layer of verification.

-

Understand Regional Compliance Nuances: Be aware of specific regulatory requirements in your region that may affect the quality of the product. For instance, buyers in the EU must ensure compliance with CE marking requirements, while those in South America may need to consider local certifications.

Conclusion: The Importance of Rigorous Manufacturing and Quality Control for B2B Buyers

The manufacturing processes and quality assurance measures for the iPhone 14 Pro Max motherboard are designed to uphold the highest standards of performance and reliability. For B2B buyers, understanding these processes and implementing thorough verification measures is essential for ensuring that they procure high-quality products that meet their specific needs. By prioritizing suppliers who demonstrate robust quality control practices, buyers can secure a reliable supply chain and maintain their competitive edge in the market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘placa madre para iphone 14 pro max’

This practical sourcing guide aims to assist B2B buyers in navigating the procurement process for the ‘placa madre para iPhone 14 Pro Max’. By following this checklist, you will ensure that you make informed decisions, minimize risks, and secure high-quality components for your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify the technical specifications required for the placa madre. This includes understanding the compatibility with iPhone 14 Pro Max, performance requirements, and any special features needed for your application. Documenting these specifications helps streamline communication with suppliers and ensures that you receive products that meet your exact needs.

Step 2: Conduct Market Research

Research the market landscape to identify potential suppliers and manufacturers. Utilize online platforms, trade shows, and industry publications to gather information about reputable vendors. Pay attention to reviews and feedback from other businesses to gauge the reliability and quality of the suppliers you are considering.

Step 3: Evaluate Potential Suppliers

Before making any commitments, thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and case studies to assess their experience and capabilities. It’s also wise to seek references from other clients in similar industries or regions to validate their reliability and service quality.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications and quality assurances. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, check for compliance with international regulations relevant to electronic components to avoid legal issues down the line.

Step 5: Request Samples

Before placing a bulk order, request samples of the placa madre to evaluate their quality firsthand. This step is crucial in assessing whether the product meets your specifications and performance criteria. Testing samples can reveal potential issues that may not be apparent from product descriptions alone.

Illustrative image related to placa madre para iphone 14 pro max

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery timelines. Ensure that you discuss warranties and return policies as well. A transparent negotiation process can lead to better terms and help establish a strong, long-term relationship with the supplier.

Step 7: Establish a Quality Control Process

After finalizing your order, implement a quality control process to monitor the incoming shipments. Define criteria for inspection that align with your specifications and establish a protocol for addressing any discrepancies. This proactive approach helps maintain product quality and reduces the risk of defective components impacting your business operations.

By following this checklist, B2B buyers can confidently navigate the sourcing process for the placa madre for iPhone 14 Pro Max, ensuring that they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for placa madre para iphone 14 pro max Sourcing

What Are the Key Cost Components for Sourcing Placa Madre para iPhone 14 Pro Max?

When sourcing a placa madre for the iPhone 14 Pro Max, it’s crucial to understand the various cost components involved. These typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the profit margin.

-

Materials: The primary costs arise from the raw materials used in the production of the placa madre. High-quality components, such as semiconductors and circuit boards, can significantly impact the overall price. Additionally, sourcing these materials from reputable suppliers ensures durability and performance, which is vital for end-user satisfaction.

-

Labor: Labor costs can vary widely based on the region of manufacture. Countries with lower labor costs may offer competitive pricing, but this can sometimes lead to compromises in quality. Evaluating the skill level and expertise of the workforce is essential, especially when dealing with complex electronics like a motherboard.

-

Manufacturing Overhead: This includes costs associated with factory maintenance, utilities, and administrative expenses. Efficient production processes can lower overhead costs, which can be a critical factor in pricing.

-

Tooling: The initial investment in tooling is significant. Depending on the complexity of the placa madre design, custom tooling may be required, which can increase upfront costs. However, once established, this cost can be amortized over larger production runs.

-

Quality Control (QC): Implementing stringent QC measures is necessary to ensure that each placa madre meets quality standards. While this adds to the cost, it is a worthwhile investment to avoid costly returns and warranty claims later.

-

Logistics: Shipping costs can vary based on the geographical distance between the supplier and the buyer, as well as the chosen Incoterms. Understanding these logistics can help buyers better estimate total costs.

-

Margin: Suppliers typically add a margin to cover their risks and profits. This can vary widely based on market demand, competition, and the supplier’s positioning strategy.

How Do Price Influencers Affect the Cost of Placa Madre para iPhone 14 Pro Max?

Several factors influence the pricing of placa madre, and understanding these can lead to better procurement strategies.

-

Volume/MOQ: Minimum Order Quantities (MOQ) can affect pricing significantly. Suppliers often provide discounts for larger orders, which can lead to cost savings for B2B buyers.

-

Specifications and Customization: Custom specifications may lead to increased costs due to the need for specialized materials or manufacturing processes. It’s essential to balance the need for custom features with budget constraints.

-

Materials and Quality Certifications: The choice of materials plays a crucial role in pricing. Suppliers offering certified components may charge higher prices, but these certifications can enhance product reliability and marketability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality and service may command higher prices, but they also reduce the risk associated with sourcing.

-

Incoterms: Understanding Incoterms is essential for international buyers, as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This knowledge can help in negotiating better terms and controlling costs.

What Buyer Tips Can Help Achieve Cost-Efficiency in Sourcing Placa Madre?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency.

-

Negotiate Terms: Always engage in negotiation, especially regarding pricing, payment terms, and delivery schedules. Building a strong relationship with suppliers can lead to better deals.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider long-term costs related to quality, warranty claims, and potential failures. A slightly higher upfront cost for a high-quality placa madre may result in lower TCO.

-

Stay Informed on Pricing Nuances: Prices can fluctuate based on market demand, currency exchange rates, and geopolitical factors. Keeping abreast of these changes can help buyers make informed purchasing decisions.

-

Leverage Local Insights: Understanding local market conditions in target sourcing countries can provide a competitive advantage. Networking with local distributors or industry contacts can yield valuable insights into pricing trends and supplier reliability.

By comprehensively analyzing these factors, B2B buyers can make informed decisions when sourcing placa madre for the iPhone 14 Pro Max, ultimately leading to enhanced profitability and market competitiveness.

Alternatives Analysis: Comparing placa madre para iphone 14 pro max With Other Solutions

Exploring Alternatives to Placa Madre Para iPhone 14 Pro Max

In the rapidly evolving landscape of mobile technology, finding the right solutions for device repair and enhancement is critical for businesses. The ‘placa madre para iPhone 14 Pro Max’ serves as a core component for functionality, but there are alternative methods and solutions that can also meet the needs of B2B buyers. This analysis presents a comparison of the placa madre with other viable alternatives, aiding businesses in making informed decisions.

Illustrative image related to placa madre para iphone 14 pro max

| Comparison Aspect | Placa Madre Para iPhone 14 Pro Max | Refurbished iPhone 14 Pro Max | Third-Party Repair Solutions |

|---|---|---|---|

| Performance | High performance, original quality | Similar performance, potential variability | Varies based on parts used |

| Cost | Higher initial investment | Moderate, often more affordable | Variable, can be budget-friendly |

| Ease of Implementation | Requires skilled technicians | Plug-and-play, easy to set up | Depends on complexity of repair |

| Maintenance | Typically low maintenance | Standard upkeep needed | Maintenance varies by provider |

| Best Use Case | Best for long-term use and reliability | Quick replacement for urgent needs | Cost-effective repairs on a budget |

What are the Pros and Cons of Refurbished iPhone 14 Pro Max?

Refurbished iPhones present a compelling alternative for businesses looking for a balance between cost and performance. These devices are often restored to like-new condition and come with a warranty, making them a reliable choice for urgent replacements. However, the performance can vary based on the refurbishing process, and they may not always include the latest software updates. This option is ideal for businesses that need a quick solution without the budget for new devices.

How Do Third-Party Repair Solutions Compare?

Third-party repair solutions offer a flexible and often more affordable way to address issues with iPhone devices, including the motherboard. Businesses can benefit from lower costs and faster service times, especially in regions where official service centers may be scarce. However, the quality of parts and expertise can differ significantly among providers, which may affect device longevity and performance. This route is best suited for companies that prioritize cost savings and can accept some variability in service quality.

Conclusion: Which Solution is Right for Your Business?

Choosing between the placa madre para iPhone 14 Pro Max and its alternatives hinges on specific business needs. If reliability and long-term performance are paramount, investing in the original motherboard is advisable. Conversely, for businesses with tighter budgets or urgent needs, refurbished devices or third-party repairs can provide adequate solutions. Evaluating the trade-offs in performance, cost, and maintenance will empower B2B buyers to select the option that aligns best with their operational goals.

Essential Technical Properties and Trade Terminology for placa madre para iphone 14 pro max

What Are the Critical Technical Properties of the Placa Madre para iPhone 14 Pro Max?

Understanding the essential technical properties of the placa madre (motherboard) for the iPhone 14 Pro Max is crucial for B2B buyers looking to source quality components. Here are some key specifications to consider:

Illustrative image related to placa madre para iphone 14 pro max

-

Material Composition

The motherboard is typically made from high-grade materials such as FR-4 (a type of fiberglass epoxy laminate) and copper for circuitry. The quality of these materials directly impacts durability and performance. For B2B buyers, sourcing motherboards made from superior materials ensures longevity and reliability in end products. -

Layer Count

The complexity of the motherboard is often indicated by its layer count, which can range from 4 to 12 or more layers in high-end devices. A higher layer count allows for more complex circuitry, enabling better performance and power efficiency. Buyers should consider this property, as it can affect the functionality of devices, particularly in high-demand applications. -

Tolerance Levels

Tolerance refers to the permissible variation in dimensions and electrical characteristics of the motherboard. Tight tolerances are crucial for ensuring compatibility with other components and overall device performance. For B2B buyers, understanding tolerance levels can help in selecting reliable suppliers and reducing the risk of defects in production. -

Thermal Management

Effective thermal management features, such as heat sinks or thermal pads, are essential for maintaining optimal operating temperatures. Overheating can lead to performance degradation or failure. Buyers should prioritize motherboards with proven thermal management capabilities to ensure product reliability and customer satisfaction. -

Connector Types and Compatibility

The motherboard will have various connectors for components such as the battery, camera, and display. Compatibility with existing hardware and ease of integration are vital factors. B2B buyers must assess these specifications to ensure seamless assembly and functionality in their final products. -

Firmware Compatibility

The firmware embedded within the motherboard plays a critical role in device functionality. It affects how the device interacts with its hardware and software ecosystems. Buyers should inquire about firmware updates and compatibility to ensure longevity and adaptability in a rapidly changing tech landscape.

Which Trade Terms Are Important for Sourcing Placas Madre?

Familiarity with trade terminology is essential for smooth transactions and effective communication in B2B environments. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of placas madre, working with an OEM can ensure that you receive high-quality, authentic products designed specifically for the iPhone 14 Pro Max. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQ is vital for managing inventory and cash flow. Buyers should negotiate MOQs to align with their purchasing strategy and ensure they are not overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for a specific quantity of goods. Submitting an RFQ is a critical step in the procurement process, allowing buyers to compare offers and negotiate better deals. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps mitigate risks related to shipping, insurance, and delivery. Buyers should ensure clarity on which Incoterms apply to their orders to avoid unexpected costs. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. It is a crucial factor in supply chain management. Buyers must consider lead times when planning production schedules to maintain efficiency and meet market demands. -

Warranty and Return Policy

Warranty terms and return policies are essential for risk management. A robust warranty can provide peace of mind regarding product quality, while a clear return policy allows for easier handling of defective units. Buyers should always review these terms before finalizing purchases.

By understanding both the technical properties and trade terminology associated with the placa madre para iPhone 14 Pro Max, B2B buyers can make informed decisions that enhance their procurement processes and overall business success.

Navigating Market Dynamics and Sourcing Trends in the placa madre para iphone 14 pro max Sector

What Are the Key Trends Shaping the Global Placa Madre para iPhone 14 Pro Max Market?

The market for the placa madre para iPhone 14 Pro Max is influenced by several global drivers that shape sourcing strategies for international B2B buyers. A significant trend is the increasing demand for high-quality, durable components as smartphones continue to evolve. Buyers are particularly focused on sourcing products that not only meet performance standards but also align with the latest technological advancements, such as 5G capabilities and enhanced processing power.

Emerging markets in Africa, South America, the Middle East, and Europe are witnessing a surge in smartphone usage, which directly impacts the demand for replacement parts like motherboards. Countries like Brazil and Vietnam are experiencing rapid digital transformation, leading to an increase in smartphone penetration and subsequently, the need for reliable replacement parts. Additionally, the rise of e-commerce platforms facilitates easier access to these components, enabling buyers to source globally while comparing prices and quality.

Another notable trend is the shift towards localized sourcing. This approach minimizes supply chain disruptions and reduces lead times, which is critical for businesses operating in regions with varying logistics capabilities. Furthermore, the impact of geopolitical tensions and trade regulations has prompted buyers to rethink their sourcing strategies, favoring suppliers that can offer transparency and compliance with international standards.

How Can Sustainability and Ethical Sourcing Impact the Placa Madre para iPhone 14 Pro Max Supply Chain?

The importance of sustainability and ethical sourcing in the placa madre para iPhone 14 Pro Max sector cannot be overstated. As environmental concerns grow, B2B buyers are increasingly prioritizing suppliers that adhere to sustainable practices. This includes the use of recycled materials and adherence to eco-friendly manufacturing processes, which not only reduce the environmental impact but also appeal to a socially conscious consumer base.

Buyers should look for suppliers that possess certifications such as ISO 14001, which demonstrates a commitment to environmental management, and other ‘green’ certifications that validate sustainable sourcing practices. Implementing these standards not only enhances a company’s brand reputation but also aligns with regulatory requirements that are becoming more stringent across various regions.

Moreover, ethical supply chains are crucial in mitigating risks associated with labor practices and sourcing materials from conflict zones. By choosing suppliers that prioritize ethical labor practices, companies can avoid reputational damage and potential legal issues. This commitment to ethical sourcing is increasingly becoming a differentiator in the competitive landscape, especially in regions where consumers are more informed and concerned about the origins of their products.

What Is the Brief Evolution of the Placa Madre para iPhone 14 Pro Max Sector?

The evolution of the placa madre para iPhone 14 Pro Max sector is closely tied to the advancements in smartphone technology. Initially, motherboards were relatively simple components, but as smartphones have integrated more features—such as advanced graphics, enhanced connectivity, and improved processing capabilities—the complexity of these components has increased significantly.

In recent years, the demand for high-performance motherboards has risen sharply, driven by consumer expectations for faster and more reliable devices. This has led manufacturers to innovate continuously, incorporating new materials and technologies to enhance the durability and functionality of motherboards. As a result, the supply chain has also evolved, with a greater emphasis on quality assurance and the establishment of robust partnerships between manufacturers and suppliers.

Today, B2B buyers are not only seeking out high-performance components but are also focused on securing sustainable and ethically sourced products, reflecting a broader shift in consumer behavior and industry standards. This evolution highlights the need for international buyers to stay informed about market dynamics and emerging trends to make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of placa madre para iphone 14 pro max

-

1. How do I identify a reliable supplier for placa madre para iphone 14 pro max?

To identify a reliable supplier, start by researching their reputation through online reviews and industry forums. Verify their business credentials, including registration and certifications. Request references from previous clients and check their response times and customer service quality. It’s also beneficial to conduct a factory visit if possible, or utilize third-party inspection services to ensure they meet quality standards. -

2. What is the best way to negotiate payment terms with suppliers?

Negotiating payment terms effectively involves understanding your cash flow and the supplier’s needs. Propose terms that balance your financial capabilities with the supplier’s requirements, such as 30% upfront and 70% upon delivery. Be open to discussing alternatives like letter of credit or escrow services for larger orders. Ensure all terms are documented clearly in the contract to avoid disputes later. -

3. What are the common minimum order quantities (MOQ) for placa madre?

Minimum order quantities can vary significantly based on the supplier and your negotiation leverage. Typically, MOQs for placa madre can range from 10 to 100 units. It’s advisable to discuss your specific needs with suppliers upfront, as some may be flexible on MOQs for first-time buyers or larger future orders. -

4. How can I ensure the quality of the placa madre before purchasing?

To ensure quality, request detailed specifications and certifications from the supplier. Conduct pre-production samples and quality assurance (QA) tests before full-scale production. Consider implementing a third-party inspection process to verify quality standards during manufacturing. Reviewing customer feedback on the supplier’s previous products can also provide insights into their reliability. -

5. What logistics considerations should I keep in mind when importing placa madre?

When importing, consider shipping methods, customs duties, and potential delays. Select a reliable freight forwarder experienced in electronics to navigate international shipping regulations. Ensure you have all necessary documentation, including invoices and certificates of origin, to facilitate smooth customs clearance. Additionally, factor in lead times for both production and shipping to plan your inventory effectively. -

6. What customization options are available for placa madre para iphone 14 pro max?

Many suppliers offer customization options such as branding, specific configurations, or additional features based on your requirements. Discuss your needs directly with the supplier, and inquire about the costs and timelines for customization. Ensure that any changes do not compromise the quality and compatibility of the placa madre with existing components. -

7. How can I handle post-purchase support and warranty issues?

Establish clear post-purchase support terms before finalizing the deal. Ensure the supplier provides a warranty that covers defects and offers a reasonable timeframe for claims. Familiarize yourself with the process for handling returns or exchanges, and document all communication for reference. Having a dedicated contact at the supplier can facilitate quicker resolutions for any issues. -

8. What are the key regulations to consider when importing placa madre into my region?

Regulations vary by country, so it’s essential to research the specific import laws applicable to electronic components in your region. Check for restrictions on materials, safety standards, and labeling requirements. Engaging a customs broker can help navigate these regulations efficiently, ensuring compliance and minimizing delays or penalties during the import process.

A Look at Placa Madre Para Iphone 14 Pro Max Manufacturers & Suppliers

Could not verify enough suppliers for placa madre para iphone 14 pro max to create a list at this time.

Strategic Sourcing Conclusion and Outlook for placa madre para iphone 14 pro max

In conclusion, effective strategic sourcing for the placa madre para iPhone 14 Pro Max is essential for B2B buyers navigating the competitive landscape of electronics. By prioritizing relationships with reliable suppliers, companies can secure high-quality components while optimizing costs. Understanding the regional market dynamics—especially in Africa, South America, the Middle East, and Europe—enables businesses to tailor their sourcing strategies to meet local demands and regulatory requirements.

The value of strategic sourcing goes beyond mere procurement; it fosters innovation, enhances supply chain resilience, and drives long-term partnerships. By leveraging data analytics and market insights, companies can anticipate trends and make informed decisions that align with their growth objectives.

Illustrative image related to placa madre para iphone 14 pro max

As international buyers, now is the time to engage with trusted suppliers and enhance your sourcing strategies. Embrace the opportunities presented by emerging markets and technological advancements to ensure your business remains competitive. By doing so, you will not only secure the best placa madre solutions but also position your company for sustained success in the evolving global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.