Body Bolts: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for body bolts

In the ever-evolving landscape of automotive manufacturing and repair, sourcing high-quality body bolts has emerged as a critical challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe strive for efficiency and durability, the need for reliable fasteners that withstand diverse environmental conditions cannot be overstated. This guide serves as a comprehensive resource for buyers looking to navigate the complex global market for body bolts, covering essential aspects such as types, applications, supplier vetting processes, and cost considerations.

With a focus on the unique needs of buyers from regions like Vietnam and Nigeria, this guide empowers decision-makers to make informed purchasing choices. By exploring various categories of body bolts—including SEMS bolts, machine screws, and corrosion-resistant options—buyers will gain insights into the best products suited for their specific applications. Additionally, we delve into supplier evaluation criteria to ensure that partnerships are built on quality, reliability, and competitive pricing.

Armed with the knowledge from this guide, B2B buyers can confidently approach their sourcing strategies, reducing the risk of costly mistakes and enhancing overall operational efficiency. Whether you are involved in automotive assembly, restoration, or maintenance, understanding the global body bolt market is essential for achieving long-term success in your projects.

Understanding body bolts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hex Head Body Bolts | Hexagonal head for easy wrenching; various sizes | Automotive assembly, machinery construction | Pros: Easy installation, strong grip. Cons: Can corrode without proper coating. |

| SEMS Body Bolts | Integrated washer; provides a larger bearing surface | Automotive repairs, body panel assembly | Pros: Reduces assembly time, reliable hold. Cons: Limited to specific applications. |

| Flat Head Body Washers | Low-profile design; distributes load evenly | Panel fastening, lightweight structures | Pros: Aesthetic finish, prevents damage. Cons: Requires precise fit for effectiveness. |

| Long Body Bolts | Extended length for deep fastening needs | Heavy-duty applications, custom builds | Pros: Versatile for various applications. Cons: May require special tools for installation. |

| Body Bolt Kits | Assortments including bolts and clips | General automotive maintenance | Pros: Comprehensive solution, cost-effective. Cons: May include unnecessary components. |

What Are Hex Head Body Bolts and Their Applications?

Hex head body bolts feature a hexagonal head, allowing for easy tightening with a wrench. These bolts come in various sizes and materials, making them suitable for a wide range of applications, particularly in automotive assembly and machinery construction. When purchasing, buyers should consider the corrosion resistance of the material, as this can significantly impact longevity in harsh environments.

How Do SEMS Body Bolts Enhance Assembly Efficiency?

SEMS body bolts are characterized by their integrated washer design, which provides a larger bearing surface. This feature not only enhances the bolt’s hold but also simplifies the assembly process, making it ideal for automotive repairs and body panel installations. Buyers should evaluate the compatibility of these bolts with their specific applications, as they are often tailored for particular uses, ensuring optimal performance.

Why Choose Flat Head Body Washers for Fastening Panels?

Flat head body washers are designed to distribute load evenly across the surface, which is crucial for panel fastening and lightweight structures. Their low-profile design offers an aesthetic advantage while preventing damage to the material being fastened. When selecting flat head washers, buyers should ensure a precise fit to maximize effectiveness, as improper sizing can lead to inadequate load distribution.

What Advantages Do Long Body Bolts Offer for Heavy-Duty Applications?

Long body bolts are essential for applications requiring deep fastening, such as heavy-duty machinery and custom builds. Their extended length allows for versatility, accommodating various materials and thicknesses. Buyers should consider the need for specialized installation tools, as these bolts may require more effort to secure effectively, particularly in tight spaces.

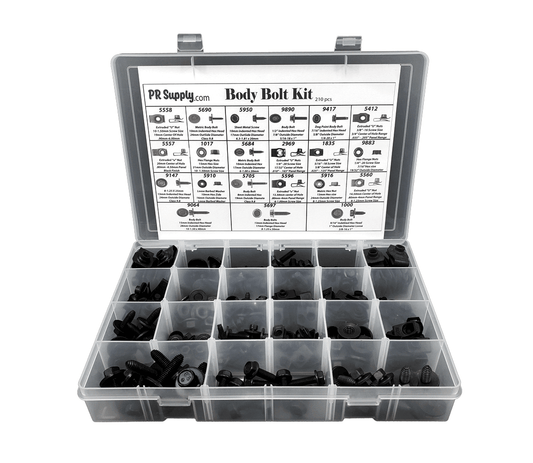

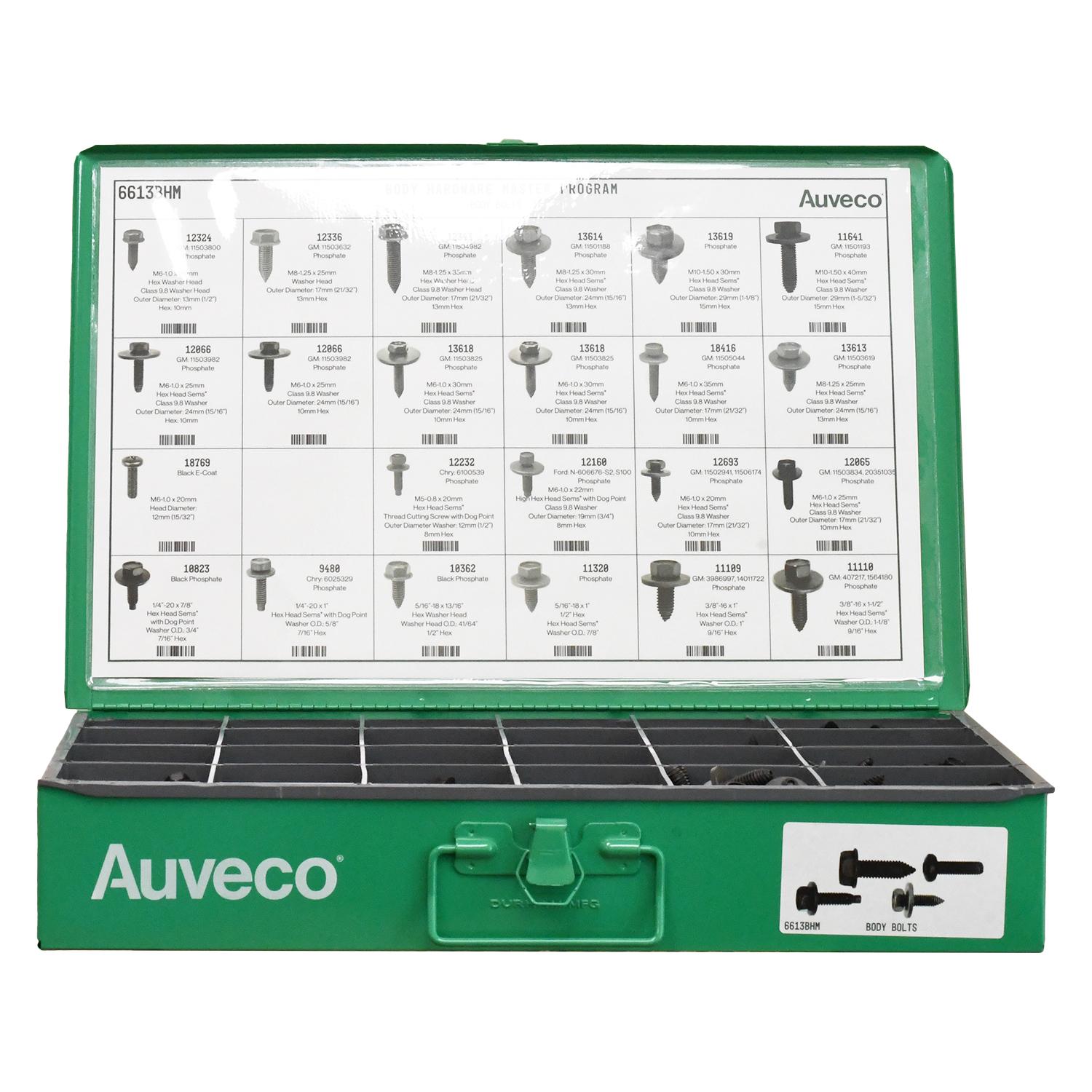

How Do Body Bolt Kits Provide Comprehensive Solutions?

Body bolt kits typically include a variety of bolts and clips, offering a comprehensive solution for general automotive maintenance. These kits can be cost-effective and convenient, allowing buyers to tackle multiple projects without needing to source individual components. However, it’s essential to review the contents carefully, as some kits may include items that aren’t necessary for every application, potentially leading to wasted resources.

Key Industrial Applications of body bolts

| Industry/Sector | Specific Application of body bolts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Assembly of vehicle body panels | Ensures structural integrity and safety compliance | Material quality, corrosion resistance, and compliance with automotive standards |

| Construction and Infrastructure | Securing structural components | Provides durability and stability in building projects | Load ratings, material specifications, and local regulations |

| Aerospace | Fastening aircraft body components | Critical for safety, weight reduction, and performance | Aerospace-grade materials, certifications, and traceability |

| Marine and Shipbuilding | Attaching hull and deck structures | Enhances vessel durability and resistance to harsh environments | Resistance to corrosion, material certifications, and weight considerations |

| Rail Transport | Securing train body and interior panels | Promotes safety and reliability in passenger and freight transport | Compliance with rail industry standards, material strength, and durability |

How Are Body Bolts Used in Automotive Manufacturing?

In the automotive manufacturing sector, body bolts are critical for assembling vehicle body panels. These bolts ensure the structural integrity of vehicles, which is essential for safety and compliance with industry regulations. Buyers in this sector must prioritize high-quality materials that resist corrosion and meet automotive standards. Additionally, they should consider the availability of different sizes and types to accommodate various vehicle designs, especially when sourcing from international suppliers in regions like Africa and South America.

What Role Do Body Bolts Play in Construction and Infrastructure?

Body bolts are widely used in construction and infrastructure projects to secure structural components such as beams and panels. Their ability to provide durability and stability is vital for the longevity of buildings and other structures. Businesses in this sector should focus on load ratings and material specifications to ensure compliance with local regulations. International buyers must also consider the logistical aspects of sourcing, such as shipping costs and lead times, particularly when importing from Europe or the Middle East.

Why Are Body Bolts Essential in Aerospace Applications?

In the aerospace industry, body bolts are used to fasten aircraft body components, playing a crucial role in ensuring safety and performance. These bolts must meet stringent aerospace standards, which often require specialized materials and certifications. Buyers need to prioritize suppliers that can provide traceability and documentation for the materials used. Additionally, given the global nature of the aerospace industry, sourcing from reliable manufacturers in different regions is essential for meeting production timelines and quality requirements.

How Are Body Bolts Utilized in Marine and Shipbuilding Industries?

Body bolts are essential in the marine and shipbuilding industries for attaching hull and deck structures. Their resistance to corrosion is particularly important due to the harsh marine environment. Businesses in this sector must ensure that the bolts they source can withstand exposure to saltwater and other corrosive elements. Key considerations include material certifications and the weight of the bolts, as these factors can significantly impact the overall performance and safety of the vessel.

What Is the Importance of Body Bolts in Rail Transport?

In rail transport, body bolts are used to secure train body and interior panels, contributing to the safety and reliability of passenger and freight transport. Buyers in this industry must ensure that the bolts comply with specific rail industry standards and are made from materials that can withstand the rigors of rail travel. Additionally, sourcing considerations should include material strength and durability, as well as the ability to meet tight production schedules, particularly when dealing with international suppliers.

3 Common User Pain Points for ‘body bolts’ & Their Solutions

Scenario 1: Sourcing Quality Body Bolts for Diverse Applications

The Problem: B2B buyers often struggle with sourcing body bolts that meet the diverse specifications required for different applications. This challenge is particularly pronounced in international markets where standards may vary widely, leading to compatibility issues. Buyers may find themselves receiving products that do not meet the necessary dimensions, material specifications, or corrosion resistance needed for their specific projects, leading to costly delays and rework.

The Solution: To effectively source quality body bolts, buyers should begin by conducting thorough research on suppliers that specialize in automotive fasteners. It’s crucial to specify the exact requirements, including dimensions, thread type, material grade, and finish, before placing an order. Utilize online catalogs and request samples to ensure that the product meets the desired specifications. Additionally, buyers can leverage relationships with local distributors who understand regional standards and can provide valuable insights. Implementing a quality assurance process—such as inspecting samples before bulk orders—can further mitigate risks associated with sourcing.

Scenario 2: Managing Inventory and Reducing Costs

The Problem: Many B2B buyers face difficulties in managing inventory levels of body bolts, leading to either excess stock or shortages. Over-ordering can tie up capital and increase storage costs, while under-ordering can halt production lines, causing significant delays. This balancing act becomes even more complex in international markets where lead times can fluctuate due to shipping and customs.

The Solution: Adopting a just-in-time (JIT) inventory management strategy can significantly alleviate these issues. This approach allows buyers to maintain minimal stock levels while ensuring that materials are available when needed. Implementing an inventory management system can provide real-time data on usage rates, helping to predict future needs accurately. Additionally, establishing a reliable supplier relationship with clear communication channels can facilitate quicker replenishment of stock, minimizing lead times and reducing the risks of production interruptions. Regularly reviewing inventory turnover rates can also help buyers optimize their purchasing strategies.

Scenario 3: Ensuring Proper Installation and Maintenance

The Problem: Another common pain point for B2B buyers is the improper installation and maintenance of body bolts, which can lead to mechanical failures and safety hazards. Lack of knowledge about the correct torque specifications and installation techniques can result in stripped threads or loose fasteners, affecting the integrity of the assembly.

The Solution: To ensure proper installation, buyers should provide comprehensive training for their teams on the correct procedures for installing body bolts. This could include workshops or training sessions led by experts in fastener installation. Additionally, creating detailed installation guides that outline torque specifications, recommended tools, and step-by-step procedures can serve as valuable references. Emphasizing the importance of regular maintenance checks on fasteners can also help prevent future issues. Implementing a routine inspection schedule can catch potential problems early and enhance overall safety and performance in the long run.

Strategic Material Selection Guide for body bolts

What are the Key Properties of Common Materials Used for Body Bolts?

When selecting body bolts for various applications, the choice of material is critical to ensure optimal performance and longevity. Here, we analyze four common materials used in body bolt manufacturing: steel, stainless steel, aluminum, and plastic composites.

How Does Steel Perform in Body Bolt Applications?

Steel is a widely used material for body bolts due to its high tensile strength and durability. It can withstand significant loads and is suitable for high-pressure applications. Steel bolts are often coated with zinc or other corrosion-resistant finishes to enhance their longevity, especially in environments prone to rust.

Pros: The primary advantage of steel body bolts is their strength and cost-effectiveness. They are readily available and can be produced in various grades, offering flexibility for different applications.

Cons: The main limitation of steel is its susceptibility to corrosion if not properly coated. Additionally, steel bolts can be heavier than alternatives, which may impact applications where weight is a concern.

Impact on Application: Steel bolts are ideal for automotive and heavy machinery applications where high strength is essential. However, they may not be suitable for environments with high humidity or exposure to corrosive substances without adequate protection.

What Advantages Does Stainless Steel Offer for Body Bolts?

Stainless steel is another popular choice for body bolts, particularly in applications where corrosion resistance is paramount. This material maintains its integrity in harsh environments, making it suitable for marine and outdoor applications.

Pros: The key advantage of stainless steel is its excellent corrosion resistance and aesthetic appeal. It is also relatively strong and can withstand high temperatures, making it versatile for various applications.

Cons: The downside is that stainless steel is generally more expensive than regular steel and may require more complex manufacturing processes, leading to higher costs.

Illustrative image related to body bolts

Impact on Application: Stainless steel bolts are ideal for automotive applications exposed to moisture and salt, such as coastal regions. Compliance with international standards like ASTM A193 or DIN 1.4401 is crucial for buyers in global markets.

In What Scenarios is Aluminum the Preferred Material for Body Bolts?

Aluminum body bolts are lightweight and resistant to corrosion, making them a suitable choice for applications where weight reduction is critical, such as in racing or aerospace industries.

Pros: The primary advantage of aluminum is its lightweight nature, which helps improve fuel efficiency in vehicles. Additionally, aluminum bolts can be anodized for added corrosion resistance and aesthetic appeal.

Cons: However, aluminum bolts are generally less strong than steel or stainless steel, which may limit their use in high-stress applications. They are also more expensive than standard steel options.

Illustrative image related to body bolts

Impact on Application: Aluminum body bolts are commonly used in high-performance automotive applications where weight savings are essential. International buyers should consider compliance with standards like ASTM B221 for aluminum products.

When Should Plastic Composites be Considered for Body Bolts?

Plastic composites are increasingly being used in body bolts, especially in applications where electrical insulation or weight reduction is desired. These materials are often used in non-structural applications.

Pros: The key advantages of plastic composites include their lightweight nature, resistance to corrosion, and non-conductive properties, making them ideal for specific applications.

Cons: The major limitation is that plastic bolts typically have lower tensile strength compared to metal options, which may restrict their use in high-load applications.

Impact on Application: Plastic composite bolts are suitable for automotive interiors and electronic housings where weight and electrical insulation are critical. Buyers should ensure that these materials meet relevant international standards for safety and performance.

Summary Table of Material Selection for Body Bolts

| Material | Typical Use Case for body bolts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive applications | High strength and cost-effective | Susceptible to corrosion without coating | Low |

| Stainless Steel | Marine and outdoor automotive applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Racing and aerospace applications | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Plastic Composites | Automotive interiors, electronic housings | Lightweight and non-conductive | Lower tensile strength | Medium |

This guide provides a comprehensive overview of materials used in body bolts, helping international B2B buyers make informed decisions based on application needs, environmental conditions, and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for body bolts

What Are the Key Stages in the Manufacturing Process of Body Bolts?

The manufacturing of body bolts involves several critical stages that ensure the final product meets the necessary specifications and quality standards. Understanding these stages can aid B2B buyers in making informed purchasing decisions.

1. Material Preparation

The first step in the manufacturing process is selecting and preparing the raw materials. Body bolts are typically made from various metals, including steel, stainless steel, and sometimes aluminum, depending on the application requirements. The chosen materials undergo rigorous inspection to ensure they meet specific mechanical and chemical properties. This may involve checking for impurities, tensile strength, and corrosion resistance.

Once the materials are approved, they are cut into specific lengths and widths, ready for the next stage. Advanced equipment, such as CNC machines, is often utilized to achieve precise dimensions, which are crucial for ensuring proper fit and function in automotive applications.

2. Forming Techniques: How Are Body Bolts Shaped?

After material preparation, the next step is forming. This process typically involves techniques like cold heading, forging, and machining.

Illustrative image related to body bolts

-

Cold Heading: In this technique, the metal is shaped at room temperature, which helps maintain the material’s integrity while producing the desired shape with minimal waste. Cold heading is often preferred for mass production due to its efficiency and cost-effectiveness.

-

Forging: This involves shaping the metal using compressive forces, which can enhance its strength and durability. Forged body bolts are often more resilient and capable of withstanding higher stresses.

-

Machining: Some body bolts require additional machining for features like threads or specific profiles. This is done using lathes or mills to achieve the necessary precision.

Each of these forming techniques plays a vital role in ensuring that the body bolts are not only functional but also reliable in demanding automotive environments.

3. Assembly and Finishing: What Enhancements Are Added?

Once the bolts are formed, they may undergo assembly processes, especially if they are part of a kit that includes washers or clips. This step ensures that all components fit seamlessly together and function as intended.

Following assembly, finishing processes are critical for enhancing the appearance and performance of body bolts. Common finishing techniques include:

-

Plating: Electroplating or hot-dip galvanizing are often employed to increase corrosion resistance. Zinc plating is a popular choice for automotive applications, as it protects against rust and wear.

-

Painting: Some bolts may be coated with paint for aesthetic reasons or additional corrosion protection.

-

Heat Treatment: This process is used to improve the mechanical properties of the bolts, enhancing their strength and toughness.

These finishing touches not only contribute to the longevity of the bolts but also ensure they meet industry standards for appearance and functionality.

What Are the Key Quality Assurance Practices for Body Bolts?

Quality assurance (QA) is paramount in the manufacturing of body bolts, especially for international B2B buyers who require consistency and reliability. Here are the main QA practices utilized in this industry.

Illustrative image related to body bolts

1. What International Standards Should B2B Buyers Be Aware Of?

Body bolts must comply with various international and industry-specific quality standards. The most relevant include:

-

ISO 9001: This standard focuses on quality management systems and is widely recognized across industries. Manufacturers that are ISO 9001 certified demonstrate their commitment to quality and customer satisfaction.

-

CE Marking: For products sold in the European Economic Area, CE marking signifies compliance with health, safety, and environmental protection standards.

-

API Standards: For bolts used in oil and gas applications, adherence to American Petroleum Institute (API) standards is crucial, ensuring that the products can withstand harsh operational environments.

Understanding these standards helps B2B buyers assess the credibility and reliability of their suppliers.

2. What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that any defects are identified and rectified early. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection verifies that raw materials meet predefined specifications before they enter the production line.

-

In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help identify issues in real-time, allowing for immediate corrective actions.

-

Final Quality Control (FQC): Before products are shipped, a comprehensive final inspection ensures that all specifications and standards have been met.

This multi-tiered QC approach minimizes the risk of defective products reaching the customer.

3. How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Here are practical steps to ensure compliance and quality:

-

Supplier Audits: Conducting on-site audits can provide insight into the supplier’s manufacturing processes, quality control measures, and adherence to international standards.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation demonstrating compliance with relevant standards, including test reports and certifications.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These organizations perform independent assessments of products and processes, ensuring unbiased evaluations.

By implementing these verification methods, buyers can significantly reduce the risk of receiving substandard products.

Illustrative image related to body bolts

What Testing Methods Are Commonly Used for Quality Assurance?

Testing methods are critical in ensuring that body bolts meet performance specifications and safety standards. Common methods include:

-

Tensile Testing: This assesses the strength of the bolts by measuring how much force they can withstand before breaking.

-

Corrosion Resistance Testing: Various methods, such as salt spray tests, evaluate how well the bolts resist corrosion, which is vital for longevity in automotive applications.

-

Dimensional Inspection: Precision measuring tools verify that the bolts meet specified dimensions and tolerances.

-

Functional Testing: This ensures that the bolts perform as intended in actual applications, often involving installation tests in real-world scenarios.

These testing methods not only confirm the quality of the bolts but also enhance buyer confidence in the products they are purchasing.

Conclusion: Navigating the Manufacturing and Quality Assurance Landscape

In conclusion, understanding the manufacturing processes and quality assurance practices for body bolts is essential for B2B buyers in international markets. By being informed about the production stages, quality standards, verification methods, and testing techniques, buyers can make educated decisions, ensuring they source high-quality body bolts that meet their operational needs. This knowledge not only protects their investment but also enhances overall project success in their respective industries.

Illustrative image related to body bolts

Practical Sourcing Guide: A Step-by-Step Checklist for ‘body bolts’

To effectively procure body bolts for your business needs, it is essential to follow a structured approach. This guide serves as a practical checklist to help international B2B buyers navigate the sourcing process, ensuring you make informed decisions that align with your operational requirements.

Step 1: Define Your Technical Specifications

Understanding the technical requirements of the body bolts you need is crucial. Consider factors such as size, thread type, material (e.g., stainless steel for corrosion resistance), and any specific standards your application may require. Clear specifications help narrow down potential suppliers and prevent costly mistakes.

Step 2: Identify Reliable Suppliers

Research potential suppliers by checking their industry reputation and customer reviews. Look for companies that specialize in automotive fasteners and have a proven track record in your target region. Reliable suppliers often provide detailed product catalogs, certifications, and customer support that can help you make informed purchasing decisions.

Step 3: Evaluate Supplier Certifications

Before finalizing your choice, verify that suppliers hold the necessary certifications. Look for ISO certifications or industry-specific standards that ensure quality control in their manufacturing processes. This step is vital to ensure that the body bolts meet international safety and quality standards, reducing the risk of failures in your applications.

Step 4: Request Samples for Testing

Always ask for product samples before placing a bulk order. Testing samples allows you to evaluate the quality, fit, and performance of the body bolts in real-world conditions. Pay attention to aspects such as tensile strength and resistance to environmental factors, which are critical for automotive applications.

Step 5: Compare Pricing and Terms

Collect quotes from multiple suppliers to compare pricing effectively. Be sure to consider the total cost of ownership, including shipping, taxes, and any potential customs fees. Understanding payment terms and return policies is also essential, as this can impact your budget and supply chain flexibility.

Step 6: Assess Supply Chain Capabilities

Evaluate the supplier’s logistics and delivery capabilities. Ensure they can meet your required lead times and can handle potential fluctuations in order volume. A dependable supply chain is essential for maintaining your production schedules, especially when working with international suppliers.

Illustrative image related to body bolts

Step 7: Establish Communication Channels

Maintain open lines of communication with your chosen supplier. Establishing clear contact points for inquiries, order tracking, and support will help facilitate smoother transactions. Regular updates on production status and shipping timelines can prevent misunderstandings and enhance collaboration.

By following this checklist, B2B buyers can confidently navigate the complexities of sourcing body bolts, ensuring they select the right products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for body bolts Sourcing

What Are the Key Cost Components in Body Bolt Sourcing?

Understanding the cost structure of body bolts is crucial for B2B buyers looking to optimize their procurement strategy. The primary cost components include:

Illustrative image related to body bolts

-

Materials: The choice of materials significantly impacts pricing. Common materials for body bolts include steel, stainless steel, and various alloys. The cost varies based on the material’s corrosion resistance, strength, and availability.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing, assembly, and quality control. Regions with lower labor costs may offer competitive pricing, but this must be balanced against the potential for quality variations.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient production processes can lower overhead, allowing for more competitive pricing.

-

Tooling: The initial investment in molds and machinery for producing specialized bolts can be substantial. This cost is amortized over production runs, influencing the final price per unit.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspection adds to the overall cost. Certifications (e.g., ISO) can further increase costs but are crucial for maintaining high standards.

-

Logistics: Shipping and handling costs vary based on distance, mode of transport, and volume. International shipping can be particularly complex and costly, influenced by customs duties and tariffs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This can vary widely based on market competition and perceived value.

How Do Volume and Customization Affect Body Bolt Pricing?

Pricing for body bolts is often influenced by volume and customization. Larger orders typically benefit from economies of scale, leading to lower per-unit costs. Minimum Order Quantities (MOQs) are common; buyers should be aware of these thresholds to maximize cost efficiency.

Customization, such as specific dimensions, coatings, or packaging, can increase costs. Buyers should weigh the benefits of customized products against standard options, considering long-term needs and potential inventory issues.

What Role Do Material Quality and Certifications Play in Pricing?

The quality of materials and any certifications can significantly influence pricing. High-quality materials, such as corrosion-resistant alloys, typically command higher prices. Certifications ensure compliance with industry standards, providing assurance of quality, but also add to the cost.

Buyers should conduct thorough research into suppliers’ certifications and material specifications, as these factors can affect the longevity and performance of body bolts.

How Do Supplier Factors and Incoterms Impact Sourcing Costs?

Supplier reputation, reliability, and location can all affect pricing. Suppliers with a strong track record may charge a premium for their products, reflecting their quality assurance and customer service.

Illustrative image related to body bolts

Incoterms, or International Commercial Terms, dictate the responsibilities of buyers and sellers regarding shipping and handling. Understanding these terms can help buyers avoid unexpected costs and clarify who bears the risk during transit.

What Negotiation Strategies Can B2B Buyers Use to Optimize Costs?

Effective negotiation can lead to better pricing and terms. Here are some strategies for B2B buyers:

- Volume Discounts: Leverage larger orders to negotiate better pricing.

- Long-Term Contracts: Consider establishing long-term relationships with suppliers for more favorable terms.

- Competitive Quotes: Obtain multiple quotes to understand market pricing and strengthen your negotiation position.

- Payment Terms: Negotiate favorable payment terms to improve cash flow while securing better prices.

What Are the Total Cost of Ownership Considerations for Body Bolts?

When sourcing body bolts, consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, replacement, and potential downtime costs. High-quality bolts may have a higher upfront cost but can result in lower maintenance and replacement expenses over time.

Conclusion: Understanding Pricing Nuances for International Buyers

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should remain aware of the nuances in pricing due to factors like currency fluctuations, import duties, and local regulations. These elements can significantly impact the final cost of sourcing body bolts. Prices can vary widely based on the discussed factors, so buyers should approach negotiations with a comprehensive understanding of their specific needs and market conditions. Always consult multiple suppliers and factor in all costs to make informed purchasing decisions.

Alternatives Analysis: Comparing body bolts With Other Solutions

When evaluating fastening solutions for automotive applications, it’s essential to consider various alternatives to body bolts. While body bolts are widely used for securing vehicle panels and components, other methods may offer distinct advantages depending on specific needs. This analysis will compare body bolts with two viable alternatives: Rivets and Adhesive Bonding.

| Comparison Aspect | Body Bolts | Rivets | Adhesive Bonding |

|---|---|---|---|

| Performance | High tensile strength; easy to replace | Excellent for permanent joints; good shear strength | Very high shear strength; flexible bonding |

| Cost | Moderate; bulk pricing available | Generally lower cost per unit | Potentially higher initial cost; varies by type |

| Ease of Implementation | Requires tools for installation; straightforward | Requires specialized tools; more complex installation | Needs surface preparation; curing time required |

| Maintenance | Easy to inspect and replace | Not easily removable; requires drilling out for replacement | Permanent; difficult to inspect or replace |

| Best Use Case | Ideal for applications requiring disassembly | Suitable for lightweight structures needing a permanent bond | Best for high-stress applications with minimal thermal expansion |

What Are the Advantages and Disadvantages of Rivets Compared to Body Bolts?

Rivets are a solid alternative to body bolts, particularly in applications where a permanent fastening solution is desired. Their installation often requires specialized tools like rivet guns, making them less user-friendly than body bolts. However, rivets excel in providing excellent shear strength, making them ideal for lightweight structures that may experience dynamic loads. On the downside, rivets can be challenging to remove; once installed, they require drilling out for disassembly, which can complicate maintenance.

How Does Adhesive Bonding Compare to Body Bolts?

Adhesive bonding offers a different approach, utilizing chemical adhesives to create strong bonds between surfaces. This method is advantageous for applications that require flexibility and resistance to thermal expansion, as adhesives can accommodate some movement without compromising strength. However, the initial costs of adhesive systems can be higher, and they often require thorough surface preparation for optimal performance. Additionally, the curing time can delay production processes, making them less suitable for scenarios demanding rapid assembly.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Choosing the right fastening solution depends on various factors, including application requirements, budget constraints, and maintenance considerations. Body bolts are ideal for applications requiring frequent disassembly and inspection, making them suitable for repair and maintenance-heavy environments. Rivets serve well in lightweight structures where permanent fastening is essential. Adhesive bonding is best suited for applications involving high-stress components that must withstand considerable loads.

In conclusion, B2B buyers should carefully assess their specific needs, including the nature of the materials being fastened, the environment in which the components will operate, and the necessity for future maintenance. By weighing the pros and cons of body bolts against rivets and adhesive bonding, buyers can make informed decisions that enhance the reliability and efficiency of their automotive applications.

Essential Technical Properties and Trade Terminology for body bolts

What Are the Key Technical Properties of Body Bolts That B2B Buyers Should Know?

When sourcing body bolts for automotive or industrial applications, understanding their technical specifications is crucial. Here are some essential properties to consider:

Illustrative image related to body bolts

1. Material Grade

Body bolts are typically made from materials such as carbon steel, stainless steel, or aluminum. Material grade indicates the strength and durability of the bolt. For example, Grade 8 bolts are made from a high-strength alloy and are suitable for heavy-duty applications. Buyers should choose the right material grade based on the environmental conditions and load requirements to ensure longevity and performance.

2. Thread Type

The thread type (e.g., coarse or fine) affects the bolt’s grip and holding power. Coarse threads provide better resistance to stripping, while fine threads can offer greater tension. Understanding the appropriate thread type is essential for ensuring compatibility with the corresponding nut or tapped hole in the assembly.

3. Tolerance

Tolerance refers to the allowable variation in dimensions of the bolt, including length, diameter, and thread pitch. Tight tolerances are often required in precision applications to ensure proper fit and function. B2B buyers should consider tolerance levels to avoid issues during assembly, which could lead to increased costs or operational delays.

4. Corrosion Resistance

Corrosion resistance is a critical property for body bolts exposed to harsh environments. Finishes such as zinc plating, chrome plating, or anodizing can enhance corrosion resistance. Selecting the right finish can significantly extend the lifespan of the bolts, making them more suitable for diverse applications, especially in humid or saline conditions.

5. Load Capacity

The load capacity indicates the maximum weight the bolt can support without failure. This property is particularly important in automotive applications, where structural integrity is crucial for safety. Buyers must assess load requirements based on specific use cases to avoid catastrophic failures.

6. Head Style

The head style of a bolt (e.g., hex, socket, or flat) impacts how the bolt is installed and removed. Different head styles are suited for various tools and applications. Understanding head styles will help buyers select bolts that align with their assembly processes and tool availability.

What Are Common Trade Terms Related to Body Bolts in B2B Transactions?

Navigating the world of body bolts involves familiarity with specific trade terminology. Here are some commonly used terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of body bolts, sourcing OEM parts ensures that the bolts meet the original specifications and quality standards set by the vehicle manufacturer.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory costs effectively and avoid over-commitment to a supplier, especially when testing new products.

Illustrative image related to body bolts

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain price quotes for specific quantities of body bolts. This document often includes technical specifications and delivery requirements, enabling buyers to compare offers and negotiate favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and duties. Familiarity with these terms helps B2B buyers understand their obligations and risks in cross-border purchases of body bolts.

5. Fastener Standards

Fastener standards refer to the specifications set by organizations like ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). These standards ensure that body bolts meet specific quality and safety criteria, which is crucial for regulatory compliance and performance reliability.

6. Lead Time

Lead time is the duration between placing an order and receiving the goods. Understanding lead time is essential for B2B buyers to plan their inventory and production schedules effectively, ensuring that they have the necessary components available when needed.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing body bolts, ensuring they meet their operational requirements and maintain product quality.

Illustrative image related to body bolts

Navigating Market Dynamics and Sourcing Trends in the body bolts Sector

What Are the Key Market Dynamics and Trends Affecting the Body Bolts Sector?

The body bolts market is currently experiencing significant growth driven by various global factors. Increasing automotive production, particularly in emerging markets like Africa, South America, and Southeast Asia, is a primary driver. The rise in vehicle ownership in these regions is pushing demand for automotive parts, including body bolts, which are critical for vehicle assembly and maintenance. Moreover, the shift towards electric vehicles (EVs) is generating new opportunities as manufacturers seek lightweight and durable fastening solutions.

In addition to traditional automotive applications, body bolts are increasingly being utilized in the aerospace and construction industries, further expanding their market potential. Digital transformation is influencing sourcing strategies, with B2B buyers leveraging e-commerce platforms for bulk purchasing. This trend is particularly relevant for international buyers from regions like Nigeria and Vietnam, who can access a global network of suppliers with ease. Key technologies such as automation and data analytics are also enhancing inventory management and supply chain efficiencies, enabling companies to respond swiftly to market demands.

How Is Sustainability and Ethical Sourcing Shaping the Body Bolts Industry?

Sustainability is becoming a cornerstone of sourcing strategies in the body bolts sector. The environmental impact of manufacturing processes and materials is under scrutiny, prompting buyers to seek suppliers committed to sustainable practices. This includes the use of recycled materials and eco-friendly coatings that minimize environmental harm.

Ethical sourcing is equally important, as buyers increasingly prioritize suppliers who adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and SA8000 for social accountability are becoming essential criteria for B2B partnerships. By aligning with suppliers that uphold these standards, companies can not only enhance their brand reputation but also meet the growing consumer demand for environmentally responsible products. This shift towards sustainability is particularly relevant for buyers in Europe, where regulations and consumer expectations regarding environmental impact are stringent.

What Is the Historical Context of Body Bolts and Their Evolution in the B2B Market?

The use of body bolts can be traced back to early automotive manufacturing, where fasteners played a crucial role in vehicle assembly. Initially made from basic steel, advancements in metallurgy led to the development of corrosion-resistant materials, enhancing durability and performance. Over the decades, the design of body bolts has evolved to accommodate various automotive innovations, including the integration of SEMS (screw and washer assemblies) that simplify installation and improve efficiency.

Today, the body bolts market is characterized by a diverse range of products tailored to meet specific industry standards and consumer needs. As technology continues to advance, innovations in fastening solutions are likely to drive further growth, catering to the evolving demands of various sectors, including automotive, aerospace, and construction. This historical context provides valuable insights into the ongoing trends and dynamics shaping the future of the body bolts sector in the B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of body bolts

-

How do I solve supply chain issues when sourcing body bolts internationally?

To address supply chain challenges, ensure you establish strong relationships with multiple suppliers across different regions. This diversification reduces dependency on a single source and mitigates risks associated with regional disruptions. Additionally, leverage logistics partners experienced in international trade to navigate customs and tariffs effectively. Regular communication and forecasting demand can also help suppliers manage inventory levels, ensuring timely delivery of body bolts. -

What is the best way to verify the quality of body bolts from suppliers?

To ensure the quality of body bolts, request samples before placing bulk orders. Conduct thorough inspections for material integrity, corrosion resistance, and compliance with industry standards. Certifications such as ISO or ASTM can also indicate reliability. Collaborating with third-party inspection agencies can provide unbiased evaluations of the products. Establishing a clear quality assurance agreement with your supplier is crucial to maintaining consistent standards. -

What are the most common materials used for body bolts, and which is best for my application?

Body bolts are typically made from stainless steel, carbon steel, and zinc-coated materials. Stainless steel offers excellent corrosion resistance, making it ideal for environments exposed to moisture. Carbon steel is often more cost-effective and suitable for indoor applications. Zinc-coated bolts provide a balance of affordability and corrosion resistance. The best choice depends on the specific environmental conditions and load requirements of your application. -

What is the minimum order quantity (MOQ) for body bolts from suppliers?

Minimum order quantities for body bolts can vary significantly among suppliers, often ranging from 100 to 1,000 units or more. It’s essential to discuss MOQ with potential suppliers during the negotiation phase. Some suppliers may offer flexibility on MOQ for larger orders or established business relationships. If your needs are smaller, consider suppliers that specialize in small-batch production or those willing to accommodate your requirements. -

What payment terms should I expect when sourcing body bolts internationally?

Payment terms can vary widely based on the supplier and the nature of the transaction. Common options include advance payment, letter of credit, or payment upon delivery. It’s advisable to negotiate terms that protect your interests, especially when dealing with new suppliers. Ensure clarity on currencies accepted, transaction fees, and payment timelines to avoid potential disputes. -

How can I customize body bolts to meet specific requirements?

Customization of body bolts is typically possible through suppliers that offer tailored manufacturing services. You can specify dimensions, thread types, coatings, and even packaging based on your needs. Discuss your requirements early in the sourcing process to allow for design adjustments and tooling. Be prepared to meet minimum order quantities for customized products, as they often require additional setup costs. -

What logistics considerations should I keep in mind when importing body bolts?

When importing body bolts, consider factors like shipping methods, customs clearance, and import duties. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Ensure you have all necessary documentation, including invoices and certificates of origin, to facilitate smooth customs clearance. Partnering with a logistics provider familiar with international shipping can streamline the process and reduce delays. -

How do I handle disputes with suppliers regarding body bolt quality or delivery?

In the event of disputes with suppliers over quality or delivery issues, maintain clear and documented communication. Address concerns immediately and provide evidence such as photos or inspection reports. Many suppliers have dispute resolution processes in place, so familiarize yourself with their policies. If the issue remains unresolved, consider mediation or arbitration services to find a mutually agreeable solution while preserving the business relationship.

Top 4 Body Bolts Manufacturers & Suppliers List

1. Hillco – 5/16-18 Hex Washer Head Spin Lock Bolt

Domain: hillcofasteners.com

Registered: 1998 (27 years)

Introduction: This company, Hillco – 5/16-18 Hex Washer Head Spin Lock Bolt, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Noonan Industries – Hex Head Body Washers

Domain: noonanindustriesllc.com

Registered: 2018 (7 years)

Introduction: {“products”:[{“name”:”Hex Head Body Washers”,”pack_size”:”Pack of 50″,”price”:”$33.00″},{“name”:”Long Body Bolts & Clips”,”pack_size”:”Pack of 50″,”price”:”$49.50″},{“name”:”Flat Head Body Washers”,”pack_size”:”Pack of 50″,”price”:”$45.00″}]}

3. Clips and Fasteners – M6 Torx Screws

Domain: clipsandfasteners.com

Registered: 2007 (18 years)

Introduction: [{‘size’: ‘M6-1.0 x 20mm’, ‘head_style’: ‘Torx’, ‘washer_point_type’: ‘CA’, ‘drive_type’: ‘Torx’, ‘washer_head_diameter’: ’18mm’, ‘package_quantity’: ’25’, ‘package_price’: ‘$5.97’}, {‘size’: ‘6-1.00 X 22mm’, ‘head_style’: ‘Indented Hex Head’, ‘washer_o_d’: ’19mm’, ‘finish’: ‘Black Phosphate’, ‘replaces’: ‘Ford: N606676-S2’, ‘package_quantity’: ’25’, ‘package_price’: ‘$5.99’}, {‘size’: ‘M6-1.0 X 2…

4. Allstar Performance – Body Bolt Kit w/ Clips 10pk Black

Domain: allstarperformance.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Body Bolt Kit w/ Clips 10pk Black”, “SKU”: “ALL18558”, “UPC”: “848238008968”, “MPN”: “ALL18558”, “Price”: {“Current”: “$12.49”, “Was”: “—”, “You Save”: “—”}, “Description”: “Kit allows the clip to stay fastened to body panel or angle bracing when removing body panels for maintenance or cleaning. 1/4′-20 thread bolts are 1-1/8′ UHL and have a built-in captured washer.”, “Package W…

Strategic Sourcing Conclusion and Outlook for body bolts

In the evolving landscape of body bolt procurement, strategic sourcing emerges as a cornerstone for enhancing operational efficiency and cost-effectiveness. B2B buyers are encouraged to leverage insights from the diverse offerings in the market, which range from standard body bolts to specialized fasteners designed for unique automotive applications. By understanding the variations in materials, sizes, and configurations, buyers can ensure they select the most suitable products that align with their specific needs.

Establishing strong relationships with suppliers is essential. Engaging with manufacturers who provide bulk ordering options and customizable solutions can lead to significant cost savings and improved supply chain reliability. Additionally, incorporating a variety of body bolt assortments into inventory can streamline operations, minimizing downtime during maintenance and repairs.

Looking ahead, the global demand for high-quality body bolts will continue to rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Buyers in these regions should proactively seek partnerships with reputable suppliers to secure competitive pricing and ensure access to innovative fastener solutions. By prioritizing strategic sourcing, businesses can enhance their operational resilience and position themselves for long-term success in a dynamic marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.