Electric Transformers Types: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for electric transformers types

In the ever-evolving landscape of global commerce, sourcing the right electric transformers types poses a significant challenge for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. The complexity of selecting transformers tailored to specific applications—be it liquid-filled, dry-type, or specialized designs—can be daunting. This comprehensive guide aims to demystify the various types of electric transformers, their applications, and the critical considerations for sourcing these essential components.

Throughout this guide, we will explore the distinct categories of transformers, including padmount, substation, pole mount, and submersible options, alongside their respective benefits and ideal use cases. Buyers will gain insights into supplier vetting processes, cost factors, and best practices for ensuring quality and compliance with international standards. By understanding the nuances of each transformer type, B2B buyers will be better equipped to make informed purchasing decisions that align with their operational needs and budget constraints.

Whether you’re navigating the complexities of energy distribution in a burgeoning market or seeking reliable power solutions for industrial applications, this guide serves as a vital resource. Our goal is to empower you with the knowledge necessary to confidently engage with suppliers and optimize your investment in electric transformers, ultimately facilitating sustainable growth and operational efficiency in your business endeavors.

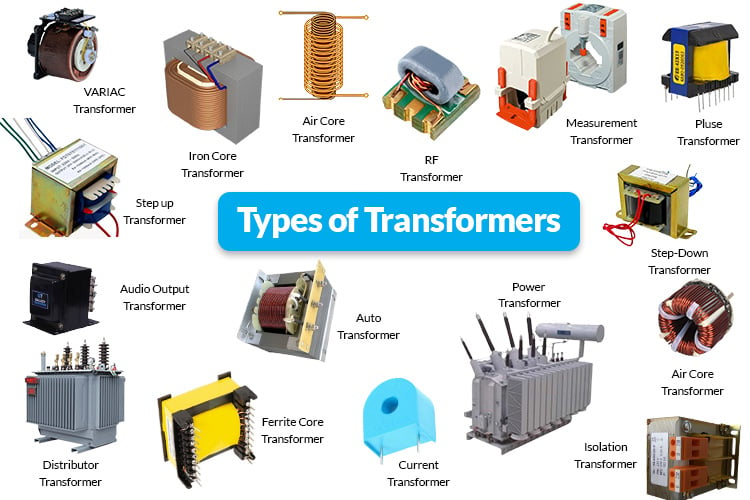

Understanding electric transformers types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Liquid-Filled Transformer | Contains dielectric fluid for cooling and insulation | Outdoor applications, substations | Pros: Excellent heat dissipation, robust design. Cons: Requires containment, higher maintenance. |

| Dry-Type Transformer | Air-cooled, no fluid, designed for indoor use | Commercial buildings, industrial facilities | Pros: No risk of fluid leaks, lower maintenance. Cons: Less effective in overload situations. |

| Padmount Transformer | Tamper-proof, low-profile design, often green in color | Public areas like campuses, airports | Pros: Cost-effective, easy installation. Cons: Limited to specific applications, outdoor use only. |

| Substation Transformer | Rugged design, external cooling systems | Heavy industrial areas, power distribution | Pros: Handles high loads, durable. Cons: Requires significant space, expensive. |

| Autotransformer | Single coil design, compact and cost-effective | Voltage adjustments in various applications | Pros: Smaller size, lower cost. Cons: Not suitable for isolation applications. |

What are the key characteristics of Liquid-Filled Transformers?

Liquid-filled transformers utilize a dielectric fluid for cooling and insulation, making them ideal for outdoor installations. Their sealed design enhances durability and heat dissipation, allowing them to handle overload situations effectively. B2B buyers should consider their application environment, as these transformers are well-suited for substations and other outdoor settings. However, they require containment to manage potential leaks, which can increase maintenance costs.

How do Dry-Type Transformers differ in application?

Dry-type transformers are primarily designed for indoor use and rely on air for cooling. Their construction avoids the use of any fluids, thus eliminating the risk of leaks. They are commonly used in commercial buildings and industrial facilities. Buyers should evaluate their heat dissipation needs, as dry-type transformers may not perform as well under overload conditions compared to liquid-filled options. However, their lower maintenance requirements can make them an attractive choice for many businesses.

What makes Padmount Transformers suitable for public applications?

Padmount transformers feature a tamper-proof, low-profile design, typically in a green color that blends with outdoor environments. They are ideal for public areas such as campuses and airports. Their compact nature allows for easy installation and cost-effectiveness, making them a preferred choice for many B2B applications. However, they are limited to specific uses and may not be suitable for all environments, particularly those requiring higher voltage capacities.

Why choose Substation Transformers for industrial use?

Substation transformers are built with rugged designs and often include external cooling systems to accommodate high load capacities. They are typically used in heavy industrial areas and are integral to power distribution networks. Buyers should be aware that these transformers require significant space and can be more costly than other options. However, their durability and ability to handle substantial loads make them essential for large-scale operations.

What advantages do Autotransformers offer for voltage adjustments?

Autotransformers utilize a single coil design, making them compact and cost-effective solutions for applications requiring voltage adjustments. They are particularly effective when only a small voltage change is necessary. B2B buyers should consider their operational needs, as these transformers are not suitable for applications requiring isolation between primary and secondary circuits. Their smaller size and lower cost can provide significant savings in many projects, but the lack of isolation may limit their use in certain scenarios.

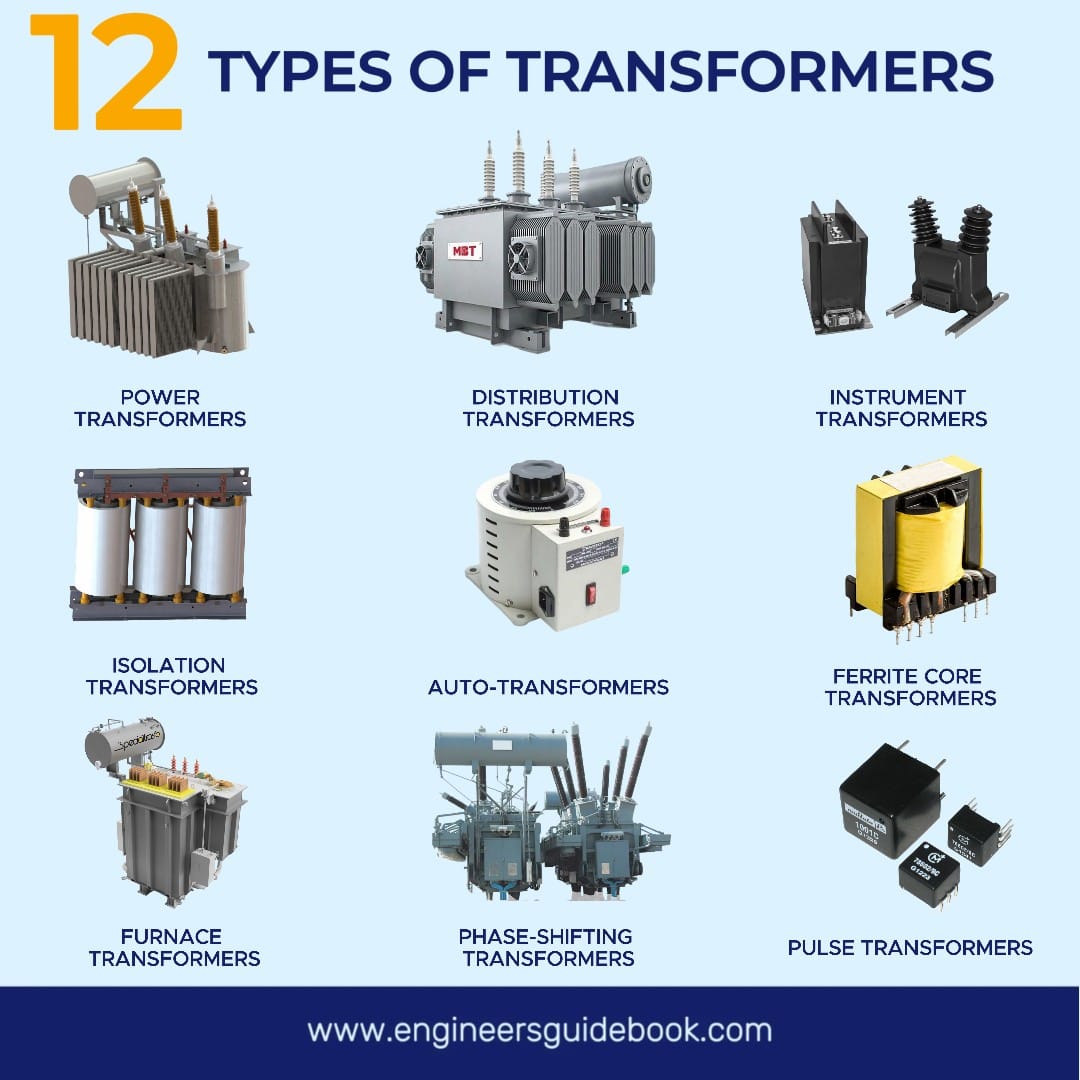

Key Industrial Applications of electric transformers types

| Industry/Sector | Specific Application of Electric Transformers Types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Energy & Utilities | Substation Transformers for Power Distribution | Reliable voltage regulation for large grids | Compliance with local regulations and environmental standards |

| Manufacturing | Dry-Type Transformers in Production Facilities | Enhanced safety and reduced fire risk indoors | Availability of specific voltage ratings and configurations |

| Transportation | Padmount Transformers for Rail Systems | Space-efficient power distribution in urban areas | Tamper-proof designs and ease of maintenance |

| Construction & Real Estate | Submersible Transformers for Urban Developments | Reliable power supply in densely populated areas | Design considerations for flooding and space constraints |

| Telecommunications | Autotransformers for Signal Boosting | Improved signal quality and reduced losses | Compatibility with existing infrastructure and load requirements |

How Are Electric Transformers Used in Energy & Utilities?

In the energy and utilities sector, substation transformers play a crucial role in stepping down high voltages for safe distribution across power grids. These transformers ensure reliable voltage regulation, which is essential for maintaining grid stability. International buyers must consider local regulations and environmental standards when sourcing these transformers, particularly in regions with stringent compliance requirements, such as Europe and the Middle East.

What Role Do Electric Transformers Play in Manufacturing?

In manufacturing, dry-type transformers are commonly employed to power machinery and equipment. Their design minimizes fire risks, making them ideal for indoor applications. They allow for the conversion of service voltage to suitable levels for specific machinery. Buyers should prioritize availability of various voltage ratings and configurations to match their operational needs, especially in regions with diverse industrial requirements like South America and Africa.

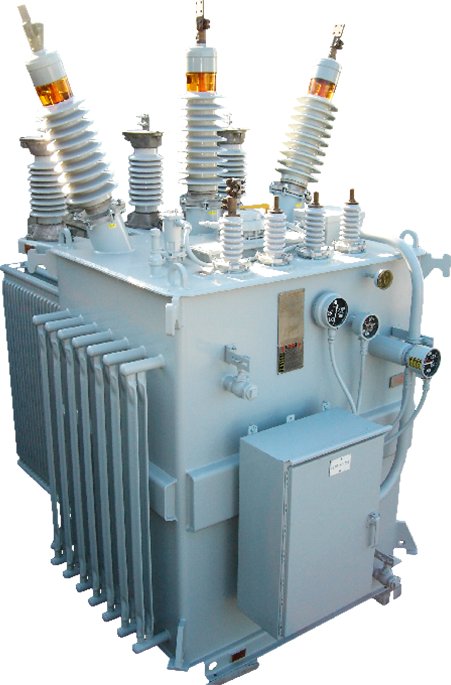

Illustrative image related to electric transformers types

How Are Electric Transformers Beneficial in Transportation?

For the transportation industry, padmount transformers are essential for rail systems and urban transit networks. Their compact, tamper-proof design allows for effective power distribution in space-constrained urban environments. The ability to maintain reliable power supply while minimizing visual and physical footprint makes them attractive for city planners and transportation authorities. Key considerations for sourcing include maintenance ease and compliance with urban infrastructure standards.

Why Are Submersible Transformers Important in Construction & Real Estate?

Submersible transformers are pivotal in urban developments, particularly in densely populated areas where flooding can be a concern. They are designed to operate effectively below ground, providing reliable power to residential and commercial buildings. Buyers should focus on design features that accommodate space constraints and environmental challenges, especially in regions prone to heavy rains or flooding, such as parts of Africa and South America.

How Do Autotransformers Enhance Telecommunications?

In telecommunications, autotransformers are utilized to boost signal quality by stepping up voltages with minimal losses. They are particularly effective in applications requiring slight voltage adjustments, making them a cost-effective solution for telecom infrastructure. Buyers need to ensure compatibility with existing systems and consider the load requirements to avoid performance issues. This is particularly critical in fast-growing markets like Brazil and Vietnam, where network demands are rapidly evolving.

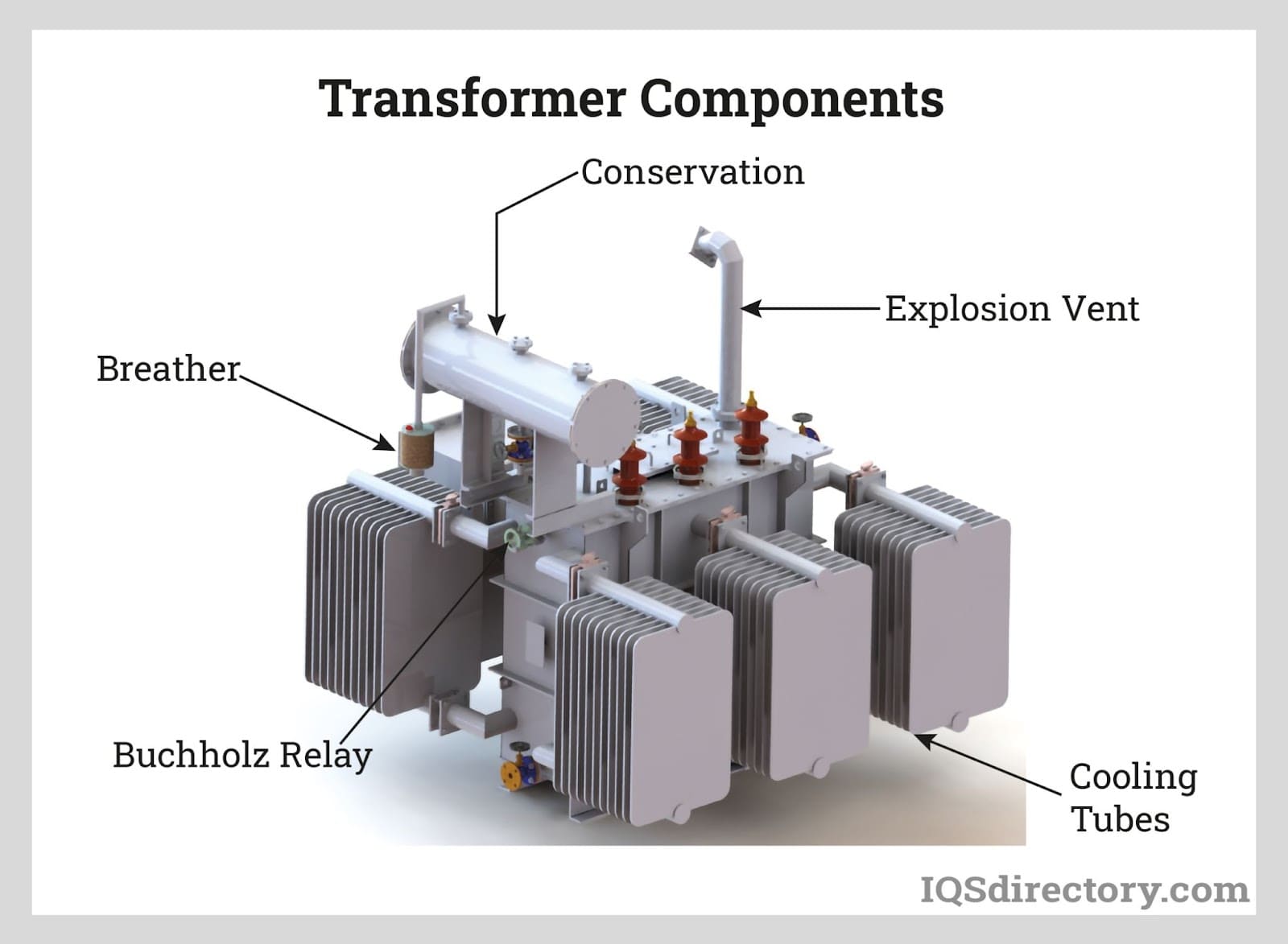

Illustrative image related to electric transformers types

3 Common User Pain Points for ‘electric transformers types’ & Their Solutions

Scenario 1: Inadequate Transformer Selection for Specific Applications

The Problem: Many B2B buyers struggle with selecting the right type of electric transformer for their specific applications. For instance, a manufacturing company in Brazil might need a transformer that can handle high load capacities while ensuring safety and efficiency. However, the buyer may not fully understand the differences between liquid-filled and dry-type transformers, leading to the selection of a suboptimal model. This misalignment can result in frequent outages, increased maintenance costs, and potential damage to sensitive equipment.

The Solution: To avoid this pitfall, buyers should conduct a thorough needs assessment before purchasing. Start by evaluating the specific requirements of your application, including load capacity, environmental conditions, and space constraints. For outdoor applications with high load demands, consider liquid-filled transformers, which provide better heat dissipation and overload protection. Conversely, for indoor installations, dry-type transformers may be more suitable due to their compact design and lower maintenance needs. Collaborating with suppliers who can provide detailed specifications and consultative support can also ensure the selection of the most appropriate transformer type.

Scenario 2: High Operational Costs Due to Inefficient Transformer Use

The Problem: A common issue faced by B2B buyers is the high operational costs associated with inefficient transformer use. For instance, a company in the Middle East might be using an older transformer model that consumes excessive energy and requires frequent maintenance. This inefficiency not only inflates operational costs but can also lead to unscheduled downtimes that disrupt production schedules.

Illustrative image related to electric transformers types

The Solution: To mitigate these costs, businesses should consider investing in modern, energy-efficient transformer technologies. For example, opting for cast resin transformers can enhance performance in harsh environments while reducing energy losses. Additionally, implementing regular maintenance schedules can help identify inefficiencies early and prolong the lifespan of existing transformers. It’s advisable to partner with manufacturers who offer energy audits and efficiency assessments to help identify areas for improvement and tailor solutions to specific operational needs.

Scenario 3: Challenges with Installation and Compliance

The Problem: International buyers often face challenges with the installation and compliance of electric transformers, especially in regions with varying regulatory standards. A power distribution company in Africa might find it difficult to navigate local regulations while ensuring that the transformer installation meets safety and environmental standards. This can lead to delays, increased costs, and potential fines, affecting project timelines and budgets.

The Solution: To address these challenges, it’s crucial for buyers to engage with local experts and transformer manufacturers who understand the regulatory landscape. Before installation, conduct a comprehensive review of local codes and standards related to transformer installations. This includes environmental regulations, safety protocols, and installation guidelines. Additionally, consider hiring local contractors with experience in transformer installation to ensure compliance with all regulations. Building a relationship with a transformer supplier who can offer ongoing support and guidance throughout the installation process will also help mitigate these risks and ensure a smooth project execution.

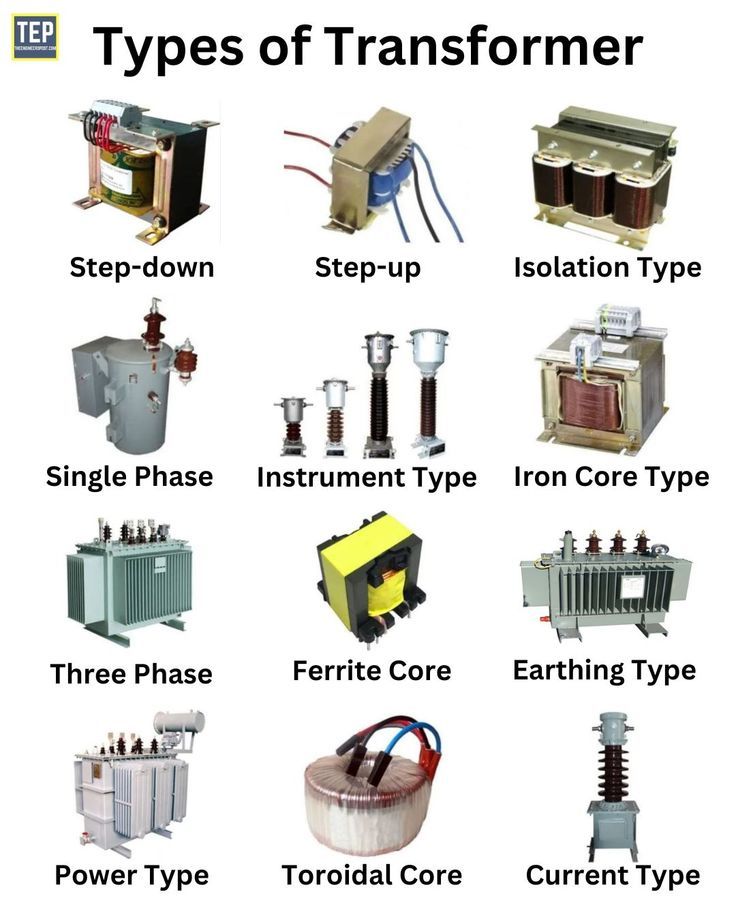

Strategic Material Selection Guide for electric transformers types

When selecting materials for electric transformers, it is crucial to understand the properties, advantages, and limitations of each material type. This knowledge allows B2B buyers to make informed decisions based on performance, cost, and application compatibility. Below, we analyze four common materials used in electric transformers: copper, aluminum, silicon steel, and epoxy resin.

What Are the Key Properties of Copper in Electric Transformers?

Copper is widely recognized for its excellent electrical conductivity, which significantly enhances the efficiency of transformers. It has a high melting point (around 1,085°C) and excellent thermal conductivity, making it suitable for high-performance applications. Additionally, copper’s corrosion resistance is beneficial in varying environmental conditions, ensuring longevity.

Illustrative image related to electric transformers types

Pros and Cons of Using Copper

The primary advantage of copper is its superior conductivity, which leads to lower energy losses. However, it is more expensive than aluminum, which may impact the overall cost of transformer production. The manufacturing complexity is relatively moderate, but the weight of copper can be a disadvantage in applications where weight is a critical factor.

How Does Aluminum Compare as a Transformer Material?

Aluminum is another common material used in transformer windings. It has a lower density than copper, making it lighter and easier to handle. Although its electrical conductivity is about 60% that of copper, it is often used in applications where weight savings are essential.

Pros and Cons of Using Aluminum

The key advantage of aluminum is its cost-effectiveness, making it a popular choice for budget-sensitive projects. However, its lower conductivity can lead to higher energy losses, especially in larger transformers. Additionally, aluminum is prone to oxidation, which can affect its performance if not properly treated.

Why Is Silicon Steel Important for Transformer Cores?

Silicon steel is primarily used for transformer cores due to its magnetic properties. The addition of silicon enhances the electrical resistivity of the steel, reducing energy losses due to eddy currents. Silicon steel can withstand high temperatures and has a good mechanical strength, making it suitable for various transformer designs.

Pros and Cons of Using Silicon Steel

The main advantage of silicon steel is its efficiency in reducing energy losses, which is critical for transformer performance. However, it can be more expensive than standard steel and may require more complex manufacturing processes. Additionally, silicon steel can be brittle, which necessitates careful handling during installation.

What Role Does Epoxy Resin Play in Transformer Insulation?

Epoxy resin is often used for insulation in dry-type transformers. It provides excellent dielectric strength, thermal stability, and moisture resistance, making it suitable for harsh environments. Epoxy resin can be cast around windings, offering robust protection against environmental factors.

Pros and Cons of Using Epoxy Resin

The primary advantage of epoxy resin is its durability and resistance to moisture and chemicals, which extends the lifespan of transformers. However, the cost of epoxy resin can be high, and the manufacturing process may be complex. Additionally, it may not perform well in extremely high-temperature applications compared to traditional insulation materials.

Summary of Material Selection for Electric Transformers

| Material | Typical Use Case for electric transformers types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings in high-efficiency transformers | Superior electrical conductivity | Higher cost and weight | High |

| Aluminum | Windings in cost-sensitive transformers | Lightweight and cost-effective | Lower conductivity and oxidation risk | Medium |

| Silicon Steel | Transformer cores for energy efficiency | Reduced energy losses | Higher cost and brittleness | Medium |

| Epoxy Resin | Insulation in dry-type transformers | Excellent moisture and chemical resistance | High cost and complex manufacturing | High |

In summary, the choice of materials for electric transformers significantly impacts performance, durability, and cost. B2B buyers should consider these factors, along with regional compliance standards, to ensure they select the most suitable materials for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for electric transformers types

Electric transformers are critical components in electrical distribution systems, and their manufacturing processes and quality assurance protocols play a significant role in their performance and longevity. For B2B buyers, understanding these processes can aid in making informed procurement decisions, especially when considering suppliers from diverse regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to electric transformers types

What Are the Main Stages of Manufacturing Electric Transformers?

The manufacturing of electric transformers involves several key stages, each integral to ensuring the final product meets the necessary specifications and quality standards.

How is Material Preparation Conducted in Transformer Manufacturing?

Material preparation is the initial stage where the primary components are sourced and prepared. This includes:

- Selection of Raw Materials: Manufacturers typically use high-grade electrical steel for the core and copper or aluminum for the windings. The selection is based on the required conductivity and mechanical properties.

- Quality Inspection of Materials: Incoming materials undergo rigorous quality checks to ensure they meet international standards (e.g., ISO 9001) and specific industry certifications (e.g., CE for European markets). This is crucial as the quality of raw materials directly affects transformer performance.

What Techniques Are Used in Forming Transformer Components?

Once the materials are prepared, the next step is forming the components:

- Core Manufacturing: The core is assembled from thin sheets of electrical steel, which are coated to reduce eddy currents. This process involves precision cutting, stacking, and bonding to achieve the desired magnetic properties.

- Winding Process: The copper or aluminum wires are wound around the core using automated machines. This step is critical, as the number of turns and the winding technique (e.g., layer winding) significantly influence the transformer’s efficiency.

How is the Assembly of Transformers Managed?

The assembly phase integrates all components into a cohesive unit:

- Insulation and Assembly: The windings are insulated with high-quality dielectric materials to prevent short circuits. The core and windings are then assembled in a tank, which may be filled with oil or left dry, depending on the transformer type.

- Installation of Cooling Systems: For liquid-filled transformers, cooling systems are installed to manage heat dissipation effectively. This can include radiators or cooling fans for larger substation transformers.

What Finishing Processes are Critical in Transformer Manufacturing?

The finishing stage ensures that the transformer is ready for operation:

- Sealing and Painting: For liquid-filled transformers, the tank is sealed to prevent leaks, and protective paint is applied to guard against corrosion.

- Final Assembly and Testing: All external components, including bushings and terminals, are installed. This stage also includes a thorough inspection to ensure compliance with design specifications.

What Quality Assurance Measures Are Implemented in Transformer Manufacturing?

Quality assurance is paramount in transformer manufacturing, as it guarantees the reliability and safety of the product.

What International Standards Should B2B Buyers Consider?

Manufacturers often adhere to various international and industry-specific standards:

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring consistent quality and continuous improvement in manufacturing processes.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: In specific applications, particularly in oil and gas sectors, adherence to API standards is critical for transformers designed for harsh environments.

How Are Quality Control Checkpoints Established?

Quality control in transformer manufacturing typically involves several checkpoints:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications before processing.

- In-Process Quality Control (IPQC): Regular inspections are conducted during manufacturing to catch any defects early in the process.

- Final Quality Control (FQC): The finished transformer undergoes comprehensive testing, including electrical and thermal performance tests, to ensure it meets all operational standards.

What Common Testing Methods Are Used for Electric Transformers?

Testing is a vital component of the quality assurance process:

- Routine Testing: This includes insulation resistance testing, power factor testing, and transformer turns ratio testing to verify electrical characteristics.

- Type Testing: Conducted on sample transformers to establish performance under various conditions. This may include short-circuit tests and temperature rise tests.

- Special Testing: For transformers used in critical applications, additional tests such as seismic tests may be conducted to ensure reliability under extreme conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers adhere to robust quality control practices, B2B buyers should consider the following strategies:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality control measures, and adherence to international standards.

- Quality Reports: Request detailed quality reports that outline the testing processes and results for the transformers being procured.

- Third-Party Inspections: Engage third-party inspection agencies to validate the quality of transformers before shipment, especially for international purchases where compliance with local regulations may vary.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various regulatory landscapes when procuring transformers:

- Understanding Local Regulations: Different regions may have specific compliance requirements, such as safety and environmental standards, that must be met.

- Logistics and Supply Chain Considerations: Ensure that the chosen supplier can manage shipping and logistics efficiently, especially in regions with infrastructural challenges.

- Cultural and Communication Barriers: Establish clear communication channels to address any quality concerns promptly, considering potential language barriers.

Conclusion

The manufacturing processes and quality assurance practices for electric transformers are complex but essential for ensuring reliable performance. B2B buyers must be diligent in assessing suppliers based on their adherence to international standards, quality control measures, and testing protocols. By prioritizing these aspects, businesses can secure high-quality transformers that meet their operational needs, particularly when sourcing from diverse global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric transformers types’

Introduction

When sourcing electric transformers, especially in diverse markets like Africa, South America, the Middle East, and Europe, it is essential to navigate the complexities involved in selecting the right type. This practical checklist will guide B2B buyers through the critical steps necessary to procure electric transformers effectively. By following these steps, buyers can ensure they choose transformers that meet their operational needs, comply with local regulations, and are sourced from reliable suppliers.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your transformer, including voltage ratings, power capacity, and application-specific needs. Understanding whether you need a liquid-filled or dry-type transformer is crucial, as this decision will impact performance, cooling requirements, and installation conditions. Be specific about environmental factors, such as humidity or temperature extremes, that may affect the transformer’s operation.

Step 2: Research Transformer Types and Their Applications

Familiarize yourself with various transformer types—such as padmount, substation, and pole mount—and their specific applications. Each type is designed for different environments and uses, so knowing their strengths will help you match a transformer to your operational needs. For instance, substation transformers are ideal for heavy industrial areas, while padmount transformers are suitable for public spaces.

Illustrative image related to electric transformers types

Step 3: Evaluate Potential Suppliers

Before making a purchase, conduct thorough research on potential suppliers. Look for established companies with a solid reputation in the transformer market and check their certifications and industry standards compliance. Request company profiles, case studies, and references from other buyers in similar industries or regions to gauge their reliability and service quality.

Step 4: Verify Quality and Performance Standards

Ensure that the transformers meet relevant quality and performance standards, such as ISO certifications or compliance with local electrical codes. High-quality transformers not only ensure reliability but also minimize the risk of operational failures and safety hazards. Ask for test reports and performance data to assess the quality of the transformers offered.

Step 5: Assess After-Sales Support and Warranty Terms

Inquire about after-sales support and warranty terms provided by the supplier. A strong after-sales service can significantly reduce downtime and maintenance costs. Look for suppliers that offer comprehensive warranties and have a responsive support team to assist with any issues that may arise post-installation.

Step 6: Understand the Total Cost of Ownership

Consider not just the initial purchase price but the total cost of ownership, which includes installation, maintenance, and operational costs over the transformer’s lifespan. Analyze energy efficiency ratings and maintenance requirements to ensure that the transformer you choose is economically viable in the long run. This holistic view will help you make a more informed decision.

Step 7: Finalize the Purchase and Review Contracts

Once you have selected a supplier and transformer type, carefully review the purchase agreement and contracts. Ensure that all specifications, terms of delivery, and payment conditions are clearly stated to avoid misunderstandings later. It’s advisable to have a legal professional review the contract to ensure your interests are protected.

By following this comprehensive checklist, B2B buyers can effectively navigate the complexities of sourcing electric transformers, ensuring that their procurement decisions align with both technical and operational needs.

Comprehensive Cost and Pricing Analysis for electric transformers types Sourcing

What Are the Key Cost Components in Electric Transformers?

Understanding the cost structure of electric transformers is crucial for international B2B buyers. The main components that contribute to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly affects transformer pricing. For example, copper windings are generally more expensive than aluminum but offer better conductivity and efficiency. The dielectric fluids used in liquid-filled transformers also vary in cost based on quality and specifications.

-

Labor: Skilled labor is essential for manufacturing transformers, especially for custom designs. Labor costs can differ significantly across regions, impacting the final pricing. For buyers in Africa or South America, local labor costs might be lower, but this could be offset by the need for specialized training or expertise.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and maintenance of machinery. Companies that invest in modern manufacturing technologies may have higher overhead costs, which can lead to more competitive pricing due to efficiency gains.

-

Tooling: Custom transformers often require specialized tooling, which can add to the initial cost. Buyers should consider whether the tooling costs can be amortized over larger production runs to achieve better pricing.

-

Quality Control (QC): Rigorous QC processes ensure reliability and compliance with international standards. While this might increase upfront costs, it can save buyers money in the long run by reducing failures and maintenance expenses.

-

Logistics: Shipping transformers can be a significant cost, especially for international buyers. Factors such as distance, shipping method, and customs duties can all influence overall costs. Buyers should evaluate Incoterms to understand who bears the responsibility for shipping and associated costs.

-

Margin: Suppliers generally apply a profit margin that varies based on market conditions, competition, and demand. Understanding this margin can help buyers negotiate better pricing.

How Do Price Influencers Affect Transformer Sourcing?

Several factors can influence transformer pricing beyond the basic cost components:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for bulk purchases. Buyers should assess their needs carefully to negotiate better terms based on anticipated future demand.

-

Specifications and Customization: Custom-designed transformers will inherently cost more than standard models. Buyers should clearly outline their specifications to avoid unnecessary costs and ensure they receive the right product.

-

Material Quality and Certifications: Transformers that meet higher quality standards or certifications (e.g., ISO, IEC) may come at a premium. However, these investments often translate into better performance and lower maintenance costs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer better warranties and support, which could justify higher prices.

-

Incoterms: Understanding the terms of shipping is vital. Different Incoterms can shift costs and responsibilities between buyer and seller, affecting the overall price.

What Are the Best Negotiation Tips for International B2B Buyers?

When negotiating prices, especially in diverse markets like Africa, South America, the Middle East, and Europe, consider these strategies:

-

Total Cost of Ownership (TCO): Focus on the long-term costs associated with the transformer, including maintenance, energy efficiency, and reliability. A higher initial cost might be justified by lower operational costs.

-

Research and Benchmarking: Analyze market prices and trends to have a solid basis for negotiation. Being informed about competitor pricing can strengthen your negotiating position.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Consider long-term partnerships rather than one-off purchases.

-

Explore Local Options: Investigate local manufacturers or suppliers in your region. They may offer competitive pricing and reduced shipping costs, which can be beneficial for both parties.

-

Be Open to Alternatives: If a particular type or brand of transformer is too costly, explore alternatives that may meet your needs at a lower price point without compromising quality.

Disclaimer on Pricing

Prices can vary widely based on specifications, market conditions, and geographic factors. It’s essential for buyers to conduct thorough research and consider all influencing factors before making procurement decisions.

Illustrative image related to electric transformers types

Alternatives Analysis: Comparing electric transformers types With Other Solutions

Introduction: Understanding Alternatives to Electric Transformers

In the realm of electrical power distribution, electric transformers play a pivotal role in stepping voltage levels up or down to meet varying application needs. However, there are alternatives that may suit specific operational requirements or project constraints. This analysis explores how electric transformer types compare with other viable solutions, helping B2B buyers make informed decisions based on performance, cost, and application.

Comparison Table

| Comparison Aspect | Electric Transformers Types | Static Frequency Converters | Voltage Regulators |

|---|---|---|---|

| Performance | High efficiency and reliability; widely used for voltage transformation in various settings. | Good for converting AC to DC and vice versa; efficient for specific frequency applications. | Provides stable voltage output; effective in managing voltage fluctuations. |

| Cost | Initial investment can be high, but long-term savings through energy efficiency. | Generally lower initial cost, but may incur higher operational costs. | Moderate cost; often less expensive than transformers for specific voltage needs. |

| Ease of Implementation | Installation can be complex, requiring skilled labor; space considerations for larger units. | Easier to implement in some configurations; compact designs available. | Simple installation; often requires minimal space and can be integrated easily. |

| Maintenance | Regular maintenance is required; can be costly depending on type (liquid-filled vs. dry-type). | Minimal maintenance needed; generally robust and reliable. | Low maintenance; mostly involves periodic checks for operational integrity. |

| Best Use Case | Ideal for large-scale power distribution in industrial and commercial settings. | Best suited for applications needing frequency conversion, such as renewable energy systems. | Effective in residential areas or where voltage regulation is critical. |

Detailed Breakdown of Alternatives

Static Frequency Converters

Static frequency converters are electronic devices that convert electrical power from one frequency to another, making them particularly useful in applications where AC and DC power need to be interchanged, such as in renewable energy systems. The primary advantage of static frequency converters is their efficiency and compact size, allowing for easier integration into existing electrical systems. However, they may not be suitable for all applications, particularly where high voltage transformation is required, and can lead to higher operational costs due to energy losses over time.

Voltage Regulators

Voltage regulators are devices designed to maintain a constant voltage level in electrical systems, providing stability against fluctuations. They are particularly beneficial in environments where voltage consistency is critical, such as residential areas or sensitive industrial operations. The main advantage of voltage regulators lies in their ease of installation and low maintenance requirements. However, they may not be as effective for large-scale power distribution needs, where transformers are typically more suitable due to their ability to handle higher loads and voltage changes.

Conclusion: How to Choose the Right Solution

When evaluating the best solution for electrical power management, B2B buyers should consider several factors, including the scale of their operations, budget constraints, and specific technical requirements. Electric transformers remain the gold standard for high-capacity voltage management, particularly in industrial settings. However, for applications focused on frequency conversion or voltage regulation, alternatives like static frequency converters and voltage regulators may provide more tailored solutions. Ultimately, the choice should align with the operational goals and infrastructure capabilities of the organization, ensuring both efficiency and reliability in electrical distribution.

Illustrative image related to electric transformers types

Essential Technical Properties and Trade Terminology for electric transformers types

What Are the Key Technical Properties of Electric Transformers?

Understanding the technical specifications of electric transformers is crucial for B2B buyers, especially when making purchasing decisions. Below are several critical specifications that define transformer performance and reliability.

1. Material Grade

The material grade of transformer components, particularly the core and windings, significantly impacts efficiency and durability. Common materials include silicon steel for cores and copper or aluminum for windings. High-grade materials reduce losses and improve thermal performance, essential for long-term reliability in demanding environments. For buyers, selecting transformers with superior materials can lead to lower operating costs and reduced maintenance.

2. Voltage Rating

Voltage rating indicates the maximum voltage a transformer can handle safely. It is vital for determining compatibility with existing electrical systems. Transformers are classified into low voltage (up to 1,000 volts), medium voltage (1,000 to 35,000 volts), and high voltage (above 35,000 volts). Understanding these ratings helps buyers ensure that the transformer will meet their operational needs without risking equipment damage or failure.

3. Efficiency

Efficiency, typically expressed as a percentage, represents the ratio of output power to input power. Higher efficiency ratings mean less energy is wasted as heat, translating to lower electricity costs and a smaller carbon footprint. For B2B buyers, investing in high-efficiency transformers can result in significant long-term savings, especially for large-scale operations.

4. Insulation Class

The insulation class indicates the maximum temperature a transformer can withstand without degrading. Classes range from A (105°C) to H (180°C). Selecting the appropriate insulation class is crucial for ensuring reliable operation in specific environmental conditions, such as high ambient temperatures or humidity. Buyers must consider the operational environment to avoid premature transformer failure.

5. Cooling Method

Transformers can be air-cooled or liquid-cooled, impacting their performance and installation requirements. Liquid-filled transformers are generally more efficient in heat dissipation, making them suitable for outdoor installations. In contrast, dry-type transformers are often used indoors due to their simplicity and lower maintenance. Understanding cooling methods helps buyers select the right transformer for their applications.

What Are Common Trade Terms Associated with Electric Transformers?

Familiarity with industry jargon can facilitate better communication and negotiation in the procurement process. Here are some essential trade terms relevant to electric transformers.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of transformers, working with an OEM ensures that the components meet specific quality standards and compatibility requirements. Buyers often prefer OEM products for reliability and warranty support.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory costs and assess feasibility for their projects. It can also affect pricing, as larger orders often yield discounts.

Illustrative image related to electric transformers types

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price proposals for specific products or services. For B2B buyers, issuing an RFQ can help compare costs and terms from multiple suppliers, ensuring they get the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, used in international trade. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms can help buyers navigate the complexities of international procurement effectively.

5. K-Rating

K-Rating is a measure of a transformer’s ability to handle harmonic distortion in electrical systems. Higher K-Ratings indicate a transformer’s capability to manage increased heat and stress from harmonic currents, which is essential for operations involving variable frequency drives (VFDs). Buyers in industries with high harmonic content should prioritize transformers with appropriate K-Ratings to ensure longevity and performance.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and financial goals.

Navigating Market Dynamics and Sourcing Trends in the electric transformers types Sector

What Are the Key Market Trends Influencing Electric Transformers?

The electric transformers market is experiencing significant growth driven by the global transition toward renewable energy sources and the modernization of aging electrical infrastructure. As countries in Africa, South America, the Middle East, and Europe strive to enhance their energy efficiency and reliability, the demand for various transformer types, including liquid-filled and dry-type transformers, is increasing. Emerging technologies such as smart grids and IoT-enabled transformers are reshaping the sourcing landscape, allowing for better monitoring, management, and maintenance of electrical systems.

International buyers are particularly focused on transformers that can adapt to diverse environments and operational demands. For instance, in regions like Africa and Brazil, where energy access is still a challenge, transformers that facilitate off-grid solutions and integrate with renewable energy sources, such as solar and wind, are gaining traction. Additionally, the trend toward modular and scalable transformer solutions is appealing to industries looking for flexibility in their energy management systems.

Furthermore, the market is also witnessing a shift toward increased localization of supply chains. Buyers are increasingly seeking regional suppliers who can offer rapid response times and tailored solutions, thereby reducing lead times and enhancing reliability.

How Can Sustainability and Ethical Sourcing Impact Electric Transformer Purchases?

Sustainability is becoming an essential consideration for B2B buyers in the electric transformers sector. The environmental impact of manufacturing and disposing of transformers is significant, with concerns about greenhouse gas emissions and the use of hazardous materials. As a result, many companies are prioritizing ethical sourcing practices and looking for suppliers who adhere to stringent environmental regulations.

Buyers are encouraged to seek transformers that incorporate sustainable materials and processes, such as those that are recyclable or use non-toxic insulation fluids. Certifications such as ISO 14001 (Environmental Management Systems) and IEC 60076-14 (which addresses eco-design requirements for transformers) are increasingly important in the decision-making process. These certifications not only demonstrate a commitment to sustainability but also help mitigate risks associated with regulatory compliance and environmental liability.

Moreover, suppliers that offer “green” transformers—those designed for energy efficiency and reduced carbon footprints—are becoming more attractive to conscious buyers. This trend aligns with global initiatives aimed at reducing energy consumption and promoting cleaner energy sources, providing a competitive advantage for companies that align with these values.

What Is the Historical Context of Electric Transformers in the B2B Sector?

The evolution of electric transformers dates back to the late 19th century, with the invention of the first practical transformer by William Stanley in 1885. Over the decades, transformers have undergone significant technological advancements, transitioning from simple designs to complex systems capable of handling varied voltage levels and applications.

Illustrative image related to electric transformers types

The introduction of liquid-filled transformers in the early 20th century marked a significant development, as they provided enhanced cooling capabilities and greater efficiency for high-voltage applications. Similarly, the rise of dry-type transformers in the mid-20th century offered safe and environmentally friendly options for indoor installations.

Today, the industry continues to innovate with the integration of smart technology, which enhances monitoring and control capabilities, thereby providing B2B buyers with greater operational efficiency and reliability. Understanding this historical context can help buyers appreciate the advancements that have shaped the current market and anticipate future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of electric transformers types

-

1. How do I determine the right type of transformer for my application?

Choosing the appropriate transformer depends on various factors, including voltage requirements, installation environment, and application type. For outdoor use, liquid-filled transformers, like padmount or substation transformers, are ideal due to their robust design. Conversely, dry-type transformers are preferable for indoor applications where space and safety are concerns. Assessing your specific needs, such as load capacity and environmental conditions, will help narrow down the options. Consulting with a transformer expert can also provide insights tailored to your project’s requirements. -

2. What is the best transformer type for urban areas?

In urban settings, submersible transformers are often the best choice due to their compact design and ability to withstand flooding and space constraints. These transformers are designed for underground installations, making them suitable for densely populated areas. If overhead installations are preferred, padmount transformers can be utilized for their tamper-proof features and low-profile design. Evaluate your urban infrastructure and consider transformer types that align with local regulations and safety standards. -

3. How can I ensure the quality of transformers from international suppliers?

To ensure quality when sourcing transformers internationally, conduct thorough supplier vetting. Request certifications such as ISO 9001 for quality management systems and relevant product standards specific to your region, like IEC or ANSI. Consider visiting manufacturing facilities or relying on third-party inspection services. It’s also beneficial to review customer testimonials and case studies to gauge a supplier’s reliability and performance. Establishing a clear quality assurance process in your contract can further safeguard your investment. -

4. What are the typical minimum order quantities (MOQs) for transformers?

Minimum order quantities for transformers can vary significantly based on the type, specifications, and supplier policies. Generally, larger manufacturers might have higher MOQs due to production costs, while smaller suppliers may offer flexibility. It’s essential to communicate your requirements upfront and negotiate MOQs that align with your project needs. Additionally, consider the potential for bulk purchasing discounts, which can offset initial costs when sourcing multiple units. -

5. What payment terms should I expect when purchasing transformers internationally?

Payment terms can vary widely among international suppliers. Common practices include advance payment, letters of credit, or staggered payments based on shipment milestones. It’s crucial to establish clear terms before finalizing the agreement, including currency, payment method, and timelines. Some suppliers may offer financing options, while others might require full payment upfront. Understanding your supplier’s payment policies can help mitigate risks and ensure smooth transactions. -

6. How do I handle logistics and shipping for transformers?

Logistics for shipping transformers involve coordinating with freight forwarders and understanding shipping regulations specific to your destination country. Factors to consider include the size and weight of the transformer, transportation methods (sea, air, or land), and potential customs duties. Ensure that your supplier provides proper packaging and documentation to facilitate smooth transit. Engaging a logistics partner with experience in handling heavy equipment can streamline the process and reduce the risk of delays or damages during transport. -

7. Can transformers be customized to meet specific project requirements?

Yes, many manufacturers offer customization options for transformers to suit specific project needs. Customization can include alterations in voltage ratings, enclosure types, cooling methods, and additional features such as built-in monitoring systems. When discussing your requirements with suppliers, be clear about your operational needs and any environmental considerations. Keep in mind that custom units may have longer lead times and higher costs, so plan accordingly in your project timeline. -

8. What certifications should I look for in electric transformers?

When sourcing electric transformers, look for certifications that ensure compliance with international standards. Key certifications include ISO 9001 for quality management, IEC 60076 for power transformers, and ANSI/IEEE standards for safety and performance. These certifications indicate that the manufacturer adheres to rigorous testing and quality assurance processes. Additionally, region-specific certifications may be necessary depending on your local regulations. Verifying these certifications can help ensure that the transformers meet the reliability and safety standards required for your applications.

Top 4 Electric Transformers Types Manufacturers & Suppliers List

1. Maddox – Types of Transformers

Domain: maddox.com

Registered: 1997 (28 years)

Introduction: Types of Transformers: 1. Padmount Transformers: a. 3-Ph Padmount Transformer b. 1-Ph Padmount Transformer c. Polemount Transformers 2. Substation Transformers 3. Dry-Type Transformers: a. Low Voltage Dry-Type Transformers b. Medium Voltage Dry-Type Transformers c. Cast Coil Transformers 4. Mini Power Centers 5. Switchgear: a. Metal-Enclosed Switchgear b. Pad-Mounted Switchgear

2. Meta Power Solutions – Transformers

Domain: metapowersolutions.com

Registered: 2021 (4 years)

Introduction: Types of Transformers: 1. Single Phase Pad Mount Transformers: 25 kVA, 50 kVA, 75 kVA, 100 kVA, 125 kVA, 150 kVA. 2. Three Phase Pad Mount Transformers: 50 kVA, 80 kVA, 100 kVA, 160 kVA, 200 kVA, 250 kVA, 315 kVA, 500 kVA, 630 kVA, 800 kVA, 1000 kVA, 1500 kVA, 2000 kVA, 2500 kVA, 3000 kVA, 3750 kVA, 5000 kVA. 3. Substation Transformers: 76 MVA, 1000 kVA, 1500 kVA, 2000 kVA, 2500 kVA, 3000 kVA, 375…

3. Monolithic Power – Distribution Transformers

Domain: monolithicpower.com

Registered: 1998 (27 years)

Introduction: Distribution transformers play a crucial role in electrical power distribution, carrying out the final voltage transformation stage before delivering electrical energy to the end user. They reduce high voltage electrical power transferred over long distances to lower voltage levels suitable for commercial, industrial, and residential settings. Characteristics include operation at lower voltage lev…

4. UTB Transformers – Step Up & Step Down Transformers

Domain: utbtransformers.com

Registered: 2020 (5 years)

Introduction: 1. Step Up Transformers: Converts low-voltage, high-current power to high-voltage, low-current power; used at power generation sources. 2. Step Down Transformers: Converts high-voltage, low-current power to lower-voltage, higher-current power; used in various applications, including substation and distribution transformers. 3. Substation Transformers: Large units that convert power from 46k to 161…

Strategic Sourcing Conclusion and Outlook for electric transformers types

In conclusion, navigating the diverse landscape of electric transformer types is essential for international B2B buyers aiming to optimize their sourcing strategies. Understanding the distinctions between liquid-filled and dry-type transformers, along with their specific applications, empowers businesses to make informed decisions tailored to their operational needs. For instance, selecting padmount transformers for public installations or opting for substation transformers in industrial settings can significantly enhance efficiency and safety.

Strategic sourcing plays a pivotal role in ensuring that organizations not only procure the right transformers but also secure competitive pricing and reliable supply chains. As demand for sustainable and efficient energy solutions grows, buyers in regions such as Africa, South America, the Middle East, and Europe must prioritize partnerships with reputable manufacturers and suppliers who can deliver innovative solutions.

Looking ahead, the electric transformer market is poised for growth, driven by advancements in technology and increasing energy demands. B2B buyers are encouraged to stay ahead of trends and leverage comprehensive resources to identify the best transformer solutions for their projects. Engage with trusted suppliers today to power your future effectively and sustainably.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.