How to Source Co Packers In Nj Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for co packers in nj

The quest for reliable co-packers in New Jersey presents a unique challenge for international B2B buyers looking to enter or expand in the U.S. market. As global demand for diverse food and beverage products continues to rise, sourcing co-packers that align with specific quality standards, production capabilities, and regulatory requirements can be daunting. This comprehensive guide is designed to demystify the process by exploring various types of co-packers available in New Jersey, their applications, and the critical factors to consider when vetting suppliers.

From small-scale boutique bottling facilities catering to niche markets to large manufacturers capable of handling high-volume production, New Jersey is home to a diverse range of co-packing solutions. This guide will also delve into essential aspects such as cost considerations, timelines, and compliance with international food safety standards, all tailored to meet the needs of buyers from Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Brazil.

By equipping international buyers with actionable insights and a clear understanding of the landscape, this guide empowers them to make informed purchasing decisions that enhance their operational efficiency and market competitiveness. With the right knowledge, navigating the global co-packing market can transform challenges into opportunities for growth and innovation.

Understanding co packers in nj Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Food Co-Packers | Specialize in food products, often certified organic or kosher. | Private label, food service, retail distribution. | Pros: High compliance with safety standards. Cons: May have minimum order quantities. |

| Beverage Co-Packers | Focus on bottling and packaging beverages in various formats. | Soft drinks, juices, alcoholic beverages. | Pros: Expertise in beverage formulations. Cons: Limited to liquid products. |

| Cosmetic & Non-Food Co-Packers | Handle packaging for cosmetics and industrial products. | Personal care, cleaning products, industrial goods. | Pros: Specialized facilities prevent cross-contamination. Cons: Less focus on food safety. |

| Contract Manufacturing Co-Packers | Provide comprehensive manufacturing services from formulation to packaging. | Custom products, small batch runs, product development. | Pros: Flexibility in production scale. Cons: Potentially higher costs for low-volume orders. |

| Single-Serve Packaging Co-Packers | Specialize in single-serve formats, innovative packaging solutions. | Snacks, beverages, convenience foods. | Pros: Quick turnaround and market entry. Cons: May require specific design input from clients. |

What Are the Characteristics of Food Co-Packers in New Jersey?

Food co-packers in New Jersey are primarily focused on the production and packaging of edible products. They often possess certifications such as organic or kosher, ensuring compliance with stringent food safety standards. These co-packers are ideal for businesses looking to launch private label products or supply food service industries. When considering a food co-packer, B2B buyers should evaluate their certifications, minimum order quantities, and capability to handle specialized dietary requirements.

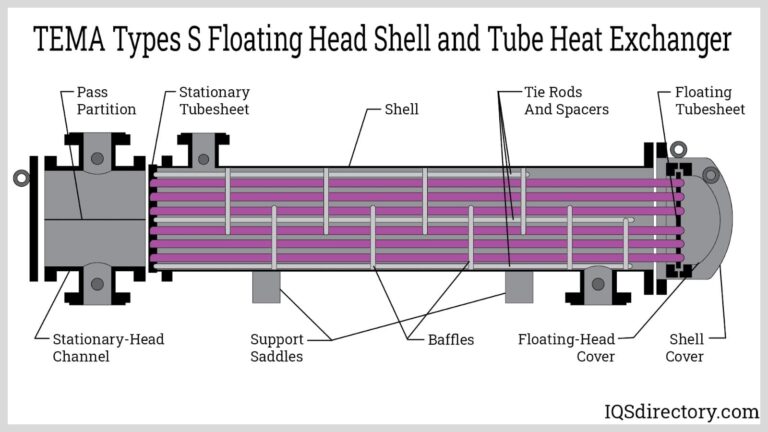

How Do Beverage Co-Packers Operate?

Beverage co-packers are specialized facilities that cater to the production and packaging of various liquid products, including soft drinks, juices, and alcoholic beverages. They are equipped with advanced bottling lines and can handle both hot fill and cold fill processes. These co-packers are particularly suitable for brands looking to scale production without investing in their own bottling infrastructure. Buyers should assess the co-packer’s experience with their specific beverage type, production capacity, and flexibility in packaging formats.

Illustrative image related to co packers in nj

What Should Buyers Know About Cosmetic & Non-Food Co-Packers?

Cosmetic and non-food co-packers focus on packaging products outside the food industry, including personal care items and industrial goods. These facilities are designed to prevent cross-contamination, ensuring product integrity. They are suitable for businesses needing specialized packaging solutions for non-food items. Buyers should consider the co-packer’s compliance with relevant regulations, the types of products they can handle, and their ability to scale production as needed.

Why Choose Contract Manufacturing Co-Packers?

Contract manufacturing co-packers offer a comprehensive range of services that go beyond simple packaging. They assist in product formulation, manufacturing, and packaging, making them an excellent choice for businesses launching new products or needing small batch runs. These co-packers provide flexibility in production and can adapt to unique requirements. However, buyers should be mindful of the potential costs associated with lower-volume orders and the need for clear communication regarding specifications.

What Are the Benefits of Single-Serve Packaging Co-Packers?

Single-serve packaging co-packers specialize in creating innovative, convenient packaging formats, such as stick packs and pouches. These co-packers are particularly advantageous for brands looking to enter the market quickly with ready-to-consume products. They often work closely with clients during the product development phase to ensure quality and efficiency. B2B buyers should consider the co-packer’s expertise in single-serve formats, turnaround times, and the potential for customization in design.

Key Industrial Applications of co packers in nj

| Industry/Sector | Specific Application of co packers in nj | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Co-packing of sauces and dressings | Enables rapid market entry with diverse product lines | Certifications (SQF, Organic), ingredient sourcing, scalability |

| Personal Care | Packaging of cosmetics and skincare products | Streamlined production and compliance with regulations | Quality control standards, packaging material options, flexibility in design |

| Beverage | Bottling and canning of ready-to-drink beverages | Cost-effective solutions for small to large batches | Equipment capabilities, temperature controls, storage options |

| Industrial Products | Packaging of powders and chemicals | Ensures safety and compliance in packaging processes | Material safety data sheets, cross-contamination prevention, labeling requirements |

| Private Label | Development and packaging of private label products | Custom branding opportunities and competitive pricing | Market research, design capabilities, minimum order quantities |

How Are Co-Packers in NJ Used in the Food and Beverage Sector?

Co-packers in New Jersey specialize in the production and packaging of sauces, dressings, and condiments. By leveraging their expertise, businesses can rapidly launch diverse product lines without the overhead of establishing their own manufacturing facilities. This is particularly beneficial for international buyers looking to meet local tastes and preferences. Key considerations include ensuring that the co-packer holds necessary certifications such as SQF and organic, as well as sourcing high-quality ingredients to maintain product integrity.

What Role Do Co-Packers Play in the Personal Care Industry?

In the personal care sector, co-packers provide essential services for the packaging of cosmetics and skincare products. They streamline production processes while ensuring compliance with stringent regulations. This is crucial for international brands entering markets with varying standards. Buyers should prioritize co-packers with proven quality control systems and flexible packaging design options to cater to specific branding needs.

How Can Co-Packers Support Beverage Production?

Co-packers in NJ offer bottling and canning services for ready-to-drink beverages, accommodating both small and large production runs. This flexibility allows brands to test new products without significant financial risk. International businesses must consider the co-packer’s equipment capabilities, especially for hot and cold fill processes, as well as their storage and distribution options to ensure timely delivery.

What Are the Benefits of Co-Packing Industrial Products?

For industrial sectors, co-packers handle the packaging of powders and chemicals, ensuring that safety and compliance are prioritized. This is vital for companies looking to maintain product integrity while adhering to regulatory requirements. When sourcing co-packers for industrial applications, businesses should evaluate material safety data sheets and measures in place to prevent cross-contamination, as well as labeling requirements for international shipping.

How Do Co-Packers Facilitate Private Label Opportunities?

Co-packers are instrumental in developing and packaging private label products, allowing brands to create custom offerings without investing in full-scale manufacturing. This approach provides competitive pricing and unique branding opportunities in diverse markets. International buyers should focus on co-packers that offer robust market research, design capabilities, and flexibility in minimum order quantities to effectively meet their specific needs.

Illustrative image related to co packers in nj

3 Common User Pain Points for ‘co packers in nj’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Co-Packing Partnerships

The Problem: International B2B buyers often face significant concerns regarding the quality and safety standards maintained by co-packers in New Jersey. With varying regulations across countries, buyers may worry about the integrity of their products, especially when it comes to food safety and compliance with international standards. The risk of subpar quality can lead to costly recalls, damaged reputations, and loss of customer trust.

The Solution: To address these concerns, it is crucial to thoroughly vet potential co-packers before entering into a partnership. Buyers should prioritize co-packers that hold relevant certifications, such as SQF, USDA Organic, and FDA compliance. Request detailed documentation of their quality assurance processes and facility audits. Additionally, visiting the facility in person can provide insights into their operations and adherence to safety protocols. Engaging in open communication about quality expectations and conducting regular checks throughout the production process can also help ensure that the products meet the necessary standards, reducing the risk of compliance issues.

Scenario 2: Scaling Production Amidst Supply Chain Challenges

The Problem: For companies looking to scale their production, especially those launching new products, the challenge often lies in the ability of co-packers to meet fluctuating demand and supply chain disruptions. International buyers, in particular, may experience delays due to customs issues or changes in ingredient availability, jeopardizing their timelines and market entry.

The Solution: To mitigate these risks, buyers should choose co-packers with a robust supply chain management system in place. It’s beneficial to inquire about their relationships with suppliers and their contingency plans for ingredient sourcing. Buyers can also collaborate with co-packers to establish flexible production schedules that can adapt to changing demands. Maintaining a buffer stock of key ingredients can also help prevent production delays. Building strong relationships with co-packers allows for better communication and quicker adjustments when challenges arise, ensuring a smoother scaling process.

Illustrative image related to co packers in nj

Scenario 3: Customization and Flexibility in Product Development

The Problem: International buyers often seek co-packers that can accommodate specific product formulations or packaging requirements tailored to their target markets. However, many co-packers may have rigid processes that do not allow for customization, making it difficult for buyers to differentiate their products in competitive markets.

The Solution: When seeking a co-packer, buyers should prioritize those that emphasize flexibility and innovation in their services. Engaging with co-packers that have a strong track record of product development and customization is essential. Buyers should communicate their unique requirements clearly and explore co-packers that offer R&D support, allowing for joint recipe development or packaging design. Additionally, negotiating terms that allow for small batch runs can enable buyers to test new products without a significant upfront investment, fostering a collaborative approach that enhances product differentiation in the marketplace.

Strategic Material Selection Guide for co packers in nj

What Are the Key Materials Used by Co-Packers in NJ?

When selecting materials for co-packing operations in New Jersey, international B2B buyers should consider various factors, including the properties of the materials, their suitability for specific applications, and compliance with international standards. Below, we analyze four common materials used by co-packers in NJ: glass, plastic, metal, and cardboard.

How Does Glass Perform as a Co-Packing Material?

Glass is a popular choice for co-packers, particularly in the beverage and food sectors. Its key properties include excellent barrier protection against moisture, gases, and UV light, making it ideal for preserving the quality of perishable products. Glass can withstand high temperatures, which is beneficial for hot-filling processes.

Pros: Glass is highly durable, recyclable, and provides a premium feel that can enhance brand perception. However, it is relatively heavy and fragile, which can lead to increased shipping costs and breakage during handling.

Illustrative image related to co packers in nj

Cons: The primary limitations of glass include its higher production costs and the complexity of manufacturing processes, which may require specialized equipment.

Impact on Application: Glass is suitable for products that require long shelf life and high-quality presentation, such as sauces, beverages, and specialty foods. International buyers should be aware of compliance with regulations like FDA standards and European food safety directives.

What Are the Advantages of Using Plastic in Co-Packing?

Plastic is widely used in co-packing due to its versatility and cost-effectiveness. Key properties include lightweight, corrosion resistance, and the ability to be molded into various shapes and sizes. Different types of plastics, such as PET and HDPE, offer specific benefits depending on the application.

Pros: Plastic is generally less expensive than glass and can be produced quickly, making it suitable for high-volume runs. It is also less prone to breakage, reducing the risk of product loss during transit.

Cons: The main drawbacks include environmental concerns related to plastic waste and potential leaching of chemicals into food products if not properly managed.

Impact on Application: Plastic containers are ideal for a wide range of products, from beverages to condiments. Buyers from regions like Africa and South America should consider local regulations regarding plastic use and recycling practices.

How Does Metal Compare as a Co-Packing Material?

Metal, particularly aluminum and tin, is commonly used for packaging beverages and food products. Its key properties include high strength, excellent barrier protection, and the ability to withstand high-pressure environments.

Pros: Metal packaging offers durability and is highly recyclable, appealing to environmentally conscious consumers. It also provides a long shelf life for products.

Cons: The limitations include higher production costs compared to plastic and the potential for corrosion if not properly coated.

Impact on Application: Metal is suitable for carbonated beverages and canned foods. International buyers should ensure compliance with standards such as ASTM for metal packaging and be aware of specific import regulations in their countries.

What Role Does Cardboard Play in Co-Packing?

Cardboard is frequently used for secondary packaging and shipping. Its key properties include lightweight, ease of customization, and recyclability. Cardboard can be treated for moisture resistance, making it suitable for various applications.

Illustrative image related to co packers in nj

Pros: Cardboard is cost-effective and can be easily printed on, allowing for brand promotion and product information. It is also biodegradable, which appeals to environmentally conscious consumers.

Cons: The main limitation is its lower durability compared to other materials, making it less suitable for products requiring high protection.

Impact on Application: Cardboard is ideal for packaging dry goods and secondary packaging for bulk shipments. Buyers should consider local recycling capabilities and regulations regarding cardboard use.

Summary Table of Material Selection for Co-Packers in NJ

| Material | Typical Use Case for Co-Packers in NJ | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Bottled sauces, beverages | Excellent barrier protection | Heavy and fragile | High |

| Plastic | Condiments, beverages | Lightweight and cost-effective | Environmental concerns | Medium |

| Metal | Canned foods, carbonated drinks | Durable and recyclable | Higher production costs | Medium |

| Cardboard | Secondary packaging, shipping | Cost-effective and customizable | Lower durability | Low |

This guide provides a comprehensive overview of material options for co-packers in NJ, helping international B2B buyers make informed decisions based on their product requirements and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for co packers in nj

What Are the Main Stages of Manufacturing Processes for Co-Packers in New Jersey?

Co-packers in New Jersey offer a variety of services that cater to diverse manufacturing needs, particularly for international B2B buyers. The manufacturing process typically involves several main stages: material preparation, forming, assembly, and finishing.

Illustrative image related to co packers in nj

Material Preparation is the first step, where raw ingredients are sourced and prepared for production. Co-packers like Chelten House emphasize the importance of using high-quality, freshly sourced ingredients. This stage may involve washing, cutting, or mixing raw materials to ensure they meet the required specifications.

Forming follows, where the prepared materials are shaped or processed into the desired format. For liquid products, this could mean filling containers, while for dry goods, it might involve packing into bags or boxes. Advanced technologies, such as precision computerized batching systems, are often employed to ensure consistency and quality across large production runs.

Assembly is where the product begins to take its final form. This stage can include labeling, capping, and packaging. Co-packers like ActionPak offer comprehensive assembly services that can be tailored to a client’s specific needs, ensuring that all components come together seamlessly.

Illustrative image related to co packers in nj

Finally, Finishing involves quality checks and packaging for distribution. This may include secondary packaging, such as shrink-wrapping or boxing, and is crucial for protecting the product during transport. Co-packers often utilize automated systems to streamline this process, ensuring efficiency and reducing labor costs.

How Do Quality Assurance Processes Work in Co-Packing Facilities?

Quality assurance (QA) is a critical component of co-packing operations, particularly for international clients who may have stringent quality requirements. New Jersey co-packers adhere to both international and industry-specific standards, such as ISO 9001, which lays out a framework for quality management systems.

In a typical QA process, several checkpoints are established, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

IQC involves inspecting raw materials upon arrival to ensure they meet specified standards before they enter production. This step is vital for maintaining the integrity of the final product.

-

IPQC occurs during the manufacturing process, where operators monitor critical parameters such as temperature, time, and ingredient ratios to ensure consistency. For example, co-packers like Hillside Beverage Packing maintain strict controls over their bottling processes to guarantee product quality.

-

FQC is the final checkpoint, where the finished products undergo rigorous testing before packaging and shipping. This may include taste tests, visual inspections, and laboratory analyses to confirm compliance with safety and quality standards.

What International Standards Should B2B Buyers Be Aware of When Working with Co-Packers?

When engaging with co-packers, particularly for exports to regions such as Africa, South America, the Middle East, and Europe, it’s essential to understand the relevant international standards that govern food safety and quality. Standards such as ISO 22000 (Food Safety Management) and HACCP (Hazard Analysis and Critical Control Points) are crucial for ensuring that food products are safe for consumption.

Co-packers in New Jersey often pursue certifications such as SQF (Safe Quality Food) and USDA Organic to assure clients of their commitment to quality and safety. For instance, ActionPak holds multiple certifications, including FDA and Organic certifications, which can be critical for international buyers looking for compliance with local regulations.

Illustrative image related to co packers in nj

How Can B2B Buyers Verify Supplier Quality Control Measures?

To ensure that a co-packer meets your quality standards, it’s important to conduct due diligence before entering into a partnership. Here are several strategies for verifying supplier quality control measures:

-

Audits: Conducting site visits and audits can provide firsthand insight into a co-packer’s operations and quality control systems. This allows you to assess their adherence to industry standards and internal protocols.

-

Quality Reports: Requesting detailed quality reports can help you understand the co-packer’s performance metrics and history. Look for documentation that outlines their QA processes, testing results, and compliance with relevant standards.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the co-packer’s facilities and processes. This can be particularly useful for international buyers who may not have the resources to perform audits themselves.

-

Certifications and Accreditations: Verify that the co-packer holds relevant certifications that align with your quality expectations. Certifications from recognized bodies can serve as a strong indicator of a facility’s commitment to quality.

What Are Common Testing Methods Used in Quality Assurance?

Quality assurance in co-packing facilities involves a variety of testing methods to ensure compliance with safety and quality standards. Some common methods include:

-

Microbiological Testing: This testing identifies any harmful bacteria or pathogens that could compromise product safety. It’s especially critical for food products, ensuring they are safe for consumption.

-

Chemical Testing: Ensures that products do not contain harmful levels of contaminants or allergens. This testing is vital for maintaining compliance with health regulations.

-

Physical Testing: Involves assessing the physical properties of the product, such as viscosity, pH, and texture. This helps ensure that products meet the intended specifications and quality standards.

-

Sensory Testing: Often used for food products, this involves taste tests to ensure flavor and aroma meet consumer expectations. It’s an important step for maintaining brand integrity.

Conclusion

Understanding the manufacturing processes and quality assurance measures employed by co-packers in New Jersey is crucial for international B2B buyers. By familiarizing themselves with the stages of production, relevant quality standards, and verification methods, buyers can make informed decisions when selecting a co-packing partner. With the right approach, companies can ensure that their products not only meet but exceed market expectations, paving the way for successful international business ventures.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘co packers in nj’

To assist B2B buyers in sourcing co-packers in New Jersey effectively, this practical guide outlines essential steps to ensure a successful partnership. By following this checklist, you can streamline your procurement process and make informed decisions.

Illustrative image related to co packers in nj

Step 1: Define Your Technical Specifications

Clearly outline your product requirements, including volume, packaging types, and any specific formulations. This step is critical as it helps you communicate effectively with potential co-packers about your needs and expectations. Make a detailed list of your product’s attributes, such as:

– Ingredient requirements: Organic, non-GMO, or specific allergens.

– Packaging formats: Bottles, pouches, or bulk containers.

Step 2: Research and Identify Potential Co-Packers

Conduct thorough research to compile a list of co-packers in New Jersey that align with your product specifications. Utilize industry directories, trade shows, and online platforms to find suitable candidates. Look for:

– Specialization: Focus on co-packers that have experience in your product category.

– Location: Proximity to your distribution centers can reduce shipping costs and lead times.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; instead:

– Visit facilities if possible: This allows you to assess their operations and quality control processes firsthand.

– Request samples: Evaluate the quality of their work and ensure it meets your standards.

Step 4: Verify Supplier Certifications

Confirm that potential co-packers possess relevant certifications that demonstrate compliance with industry standards, such as SQF, FDA, or organic certifications. This step is vital for ensuring product safety and quality. Check for:

– Food safety programs: Ensure they follow HACCP guidelines.

– Quality assurance processes: Look for documented procedures that guarantee consistency.

Step 5: Discuss Pricing and Contract Terms

Engage in discussions about pricing structures and contract terms to ensure transparency and avoid hidden costs. This includes understanding:

– Minimum order quantities: Clarify what is feasible for your production needs.

– Payment terms: Establish clear payment schedules and conditions.

Step 6: Assess Communication and Customer Service

Evaluate the responsiveness and support provided by potential co-packers during the initial discussions. Good communication is essential for a successful partnership. Consider:

– Availability of key contacts: Ensure you can reach decision-makers easily.

– Flexibility in addressing your concerns: A co-packer should be willing to adapt to your needs.

Step 7: Finalize the Partnership and Monitor Performance

Once you’ve selected a co-packer, finalize the agreement and establish a plan for monitoring performance. Regular evaluations can help maintain quality and efficiency. Focus on:

– Setting KPIs: Determine metrics to measure success, such as lead times and defect rates.

– Regular check-ins: Schedule meetings to discuss ongoing projects and address any issues that arise.

By following this checklist, B2B buyers can navigate the complexities of sourcing co-packers in New Jersey, ensuring a successful and productive collaboration.

Comprehensive Cost and Pricing Analysis for co packers in nj Sourcing

What Are the Key Cost Components for Co-Packers in NJ?

Understanding the cost structure of co-packers in New Jersey involves breaking down several key components. The primary cost drivers include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials is one of the largest expenditures for co-packers. Prices can fluctuate based on market demand and seasonality. Sourcing high-quality ingredients can also incur higher costs, especially if organic or specialized materials are required.

-

Labor: Labor costs vary depending on the complexity of the manufacturing process and the skill level required. Co-packers often employ skilled workers to ensure quality and efficiency, which can drive up labor expenses.

-

Manufacturing Overhead: This includes fixed costs such as utilities, facility maintenance, and equipment depreciation. Efficient operations can help minimize these costs, but they still contribute significantly to the overall pricing structure.

-

Tooling: If a project requires specialized tools or molds, these costs must be factored in. Tooling expenses can be significant, especially for unique product specifications or custom packaging designs.

-

Quality Control (QC): Ensuring products meet safety and quality standards involves rigorous testing and compliance with certifications (e.g., SQF, Organic). The costs associated with QC processes are essential for maintaining product integrity and brand reputation.

-

Logistics: Transportation and storage costs must be considered, especially for international shipments. Factors such as distance, shipment size, and mode of transport will influence overall logistics costs.

-

Margin: Co-packers typically add a profit margin to cover their expenses and ensure sustainability. Margins can vary widely based on the service level provided and market competition.

How Do Price Influencers Affect Co-Packing Costs in NJ?

Several factors influence the pricing of co-packing services, particularly for international buyers.

-

Volume and Minimum Order Quantity (MOQ): Co-packers often provide better pricing for larger orders. Understanding the MOQ can help buyers negotiate better terms and reduce unit costs.

-

Specifications and Customization: Custom packaging or formulation can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials or specific certifications (e.g., organic, kosher) can lead to increased costs. Buyers should evaluate whether the benefits align with their target market’s preferences.

-

Supplier Factors: The reputation and reliability of the co-packer can impact pricing. Established co-packers with a strong track record may charge a premium but offer greater assurance of quality and service.

-

Incoterms: The terms of shipment can significantly affect overall costs. Buyers should understand whether costs include shipping, insurance, and tariffs to accurately assess total expenses.

What Tips Can Help Buyers Negotiate Better Co-Packing Prices?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, can leverage several strategies to ensure cost-efficiency in co-packing agreements:

-

Negotiate Terms: Engage in discussions regarding pricing, payment terms, and delivery schedules. A collaborative approach can often yield favorable outcomes.

-

Consider Total Cost of Ownership (TCO): Evaluate the complete cost associated with a co-packing partnership, including hidden costs like logistics and quality assurance. This holistic view can lead to more informed decisions.

-

Understand Pricing Nuances: Be aware that international buyers may face additional fees related to customs, tariffs, or currency exchange. These can significantly affect the final costs, so it’s crucial to factor them into the overall budget.

-

Build Relationships: Establishing a good rapport with co-packers can lead to better pricing and service. Long-term partnerships often result in more favorable terms and conditions.

Conclusion

In summary, the cost structure and pricing of co-packers in New Jersey involve multiple components that vary based on specific project requirements and market conditions. By understanding these elements and leveraging negotiation strategies, international buyers can optimize their sourcing decisions and ensure a successful partnership with co-packers. Always consult with multiple suppliers to gather indicative pricing and explore options that best meet your business needs.

Alternatives Analysis: Comparing co packers in nj With Other Solutions

Understanding Alternatives to Co Packers in NJ for International B2B Buyers

When considering solutions for food production and packaging, co packers in New Jersey present unique advantages, particularly in terms of scalability and quality control. However, international buyers may also explore alternative methods to meet their specific needs. This section compares co packers in NJ with other viable options, enabling businesses to make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Co Packers In NJ | Private Label Manufacturing | In-House Production |

|---|---|---|---|

| Performance | High-quality, scalable production | Moderate to high, depending on partner | Varies widely, dependent on equipment |

| Cost | Higher initial setup costs, lower per-unit costs | Variable, often higher per unit | High initial investment, but lower ongoing costs |

| Ease of Implementation | Quick setup with established processes | Requires partner selection and agreements | Complex setup, requiring time and training |

| Maintenance | Minimal, handled by co packer | Moderate, shared responsibilities | High, requires skilled labor and equipment maintenance |

| Best Use Case | Large-scale, varied product offerings | Niche markets with specific branding needs | Custom, unique products with total control |

Analyzing Private Label Manufacturing as an Alternative

Private label manufacturing offers brands the opportunity to sell products under their own label while outsourcing production. This method is particularly appealing for companies looking to establish a unique identity in the market. One of the key advantages is the ability to leverage the expertise and resources of established manufacturers, which can provide high-quality products without the need for significant capital investment. However, the downside includes potentially higher costs per unit and the necessity to find and vet a reliable manufacturing partner, which can be time-consuming.

Evaluating In-House Production as an Alternative

In-house production allows companies full control over their manufacturing processes, from ingredient sourcing to quality control. This method is ideal for businesses that prioritize customization and wish to maintain a distinct competitive advantage through unique product offerings. While in-house production can lead to lower per-unit costs in the long term, it often requires substantial upfront investment in equipment and facility setup, as well as ongoing maintenance costs. Additionally, companies must invest in workforce training and management, which can complicate operations.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right production and packaging solution depends on various factors including budget, desired level of control, and specific product requirements. For businesses aiming for high scalability and consistent quality, co packers in NJ provide a compelling option. Conversely, if brand identity and product uniqueness are paramount, private label manufacturing or in-house production may be more suitable. Buyers should carefully assess their operational capabilities, market demands, and financial resources before making a decision, ensuring that their choice aligns with their long-term business objectives.

Illustrative image related to co packers in nj

Essential Technical Properties and Trade Terminology for co packers in nj

What Are the Key Technical Properties of Co-Packers in NJ?

When navigating the co-packing landscape in New Jersey, understanding critical technical properties is essential for international B2B buyers. Here are some key specifications that can influence your partnership with co-packers:

-

Material Grade

This refers to the quality and type of materials used in packaging and production. Material grades can affect product shelf life, safety, and compliance with international standards. For example, food-grade materials must meet stringent regulations to ensure consumer safety. Buyers should prioritize suppliers that utilize high-grade materials, especially when dealing with consumables. -

Tolerance Levels

Tolerance refers to the allowable variations in dimensions or characteristics of the products being packaged. In co-packing, maintaining specific tolerances is crucial for consistency and quality assurance. For instance, a beverage’s fill level must adhere to specified tolerances to avoid underfilling or overfilling, which could result in product loss or consumer complaints. -

Production Capacity

This specification indicates the maximum volume of product a co-packer can handle within a given timeframe. Understanding a co-packer’s production capacity is vital for meeting your business demands, especially during peak seasons. Companies should ensure that potential partners can scale operations to accommodate growth without compromising quality. -

Certifications and Compliance Standards

Certifications such as SQF (Safe Quality Food), FDA compliance, and organic certifications are critical indicators of a co-packer’s commitment to quality and safety. These certifications not only assure buyers of adherence to safety standards but also enhance product credibility in international markets. Ensure your co-packer holds relevant certifications that align with your product requirements. -

Lead Times

This refers to the time required to process an order from placement to delivery. Shorter lead times can significantly impact your supply chain efficiency and market responsiveness. When selecting a co-packer, inquire about their average lead times and their ability to handle urgent requests, especially if you are targeting dynamic markets. -

Quality Control Processes

A robust quality control process ensures that products meet the defined specifications consistently. This includes checks at various production stages, from ingredient sourcing to final packaging. Understanding the quality control measures in place will help mitigate risks associated with product recalls and compliance failures.

What Are Common Trade Terms Used in Co-Packing?

To facilitate effective communication and negotiations, familiarity with industry jargon is critical. Here are some common terms you might encounter:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products or components that are sold under another company’s brand. In co-packing, an OEM might create packaging solutions tailored to a client’s specifications, emphasizing the importance of branding in product presentation. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, particularly for international buyers who may have limited initial orders. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. This process helps buyers compare offers and negotiate better deals, ensuring they get the best value for their investment. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms is crucial for understanding shipping costs, risk, and insurance responsibilities, especially when sourcing from overseas. -

Bottleneck

In the context of production, a bottleneck refers to a point in the manufacturing process where the flow of operations slows down, limiting overall output. Identifying potential bottlenecks in co-packing operations can help buyers ensure smoother production timelines. -

Turnkey Solutions

This term refers to a complete service offering where the co-packer manages all aspects of production, packaging, and distribution. Turnkey solutions can simplify the supply chain for buyers, allowing them to focus on marketing and sales.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when selecting co-packers in New Jersey, ultimately enhancing their product offerings in competitive international markets.

Navigating Market Dynamics and Sourcing Trends in the co packers in nj Sector

What are the Key Market Dynamics and Trends Impacting Co-Packers in NJ?

The co-packing sector in New Jersey is experiencing significant growth driven by globalization, e-commerce expansion, and changing consumer preferences. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking reliable partners that can accommodate diverse product lines and rapid turnaround times. The demand for customized solutions, particularly in food and beverage packaging, is rising, with companies looking for co-packers that can support unique formulations and private-label products. The emergence of advanced manufacturing technologies, such as automation and precision batching systems, is enhancing efficiency and consistency in production, making it easier for brands to scale operations quickly.

Moreover, the trend toward health-conscious and organic products is reshaping the offerings of co-packers. Buyers are increasingly interested in sourcing organic and ethically produced goods, aligning with the global movement towards sustainability. As a result, co-packers in NJ are investing in certifications like SQF and Organic to meet the stringent requirements of international markets. The ability to provide innovative packaging solutions, such as single-serve formats and eco-friendly materials, has become a significant differentiator in attracting B2B clients looking to stand out in competitive markets.

How are Sustainability and Ethical Sourcing Shaping the Co-Packing Landscape?

Sustainability has emerged as a core value in the co-packing industry, influencing buyer decisions and supplier partnerships. The environmental impact of packaging materials and production processes is under increasing scrutiny, with B2B buyers prioritizing co-packers who demonstrate a commitment to eco-friendly practices. This includes the use of sustainable materials, waste reduction strategies, and energy-efficient manufacturing processes. Buyers are encouraged to seek out co-packers that have received certifications for environmental standards, such as ISO 14001, which can serve as a benchmark for sustainable practices.

Ethical sourcing is equally important, as consumers become more aware of the social implications of their purchases. Co-packers that prioritize ethical labor practices and transparency in their supply chains are more likely to attract international clients. This trend is particularly relevant for buyers from regions like Europe and North America, where ethical consumerism is prevalent. By aligning with co-packers that uphold these values, international buyers can enhance their brand reputation and meet the expectations of socially conscious consumers.

What is the Historical Context of the Co-Packing Industry in NJ?

The co-packing industry in New Jersey has evolved significantly over the past few decades, driven by the state’s strategic location and robust transportation infrastructure. Initially focused on traditional food products, the sector has expanded to accommodate a diverse range of goods, including personal care items and industrial products. The rise of private label brands in the 1990s and 2000s prompted many manufacturers to turn to co-packers for flexible production solutions. As global trade expanded, New Jersey co-packers adapted to meet the needs of international buyers, establishing themselves as key players in the global supply chain. This evolution has positioned New Jersey as a hub for innovation and efficiency in the co-packing landscape, making it an attractive option for B2B buyers seeking reliable partners.

Frequently Asked Questions (FAQs) for B2B Buyers of co packers in nj

-

How do I find reliable co-packers in New Jersey for my product?

To find reliable co-packers in New Jersey, begin by researching companies with a strong reputation in your industry. Look for certifications such as SQF, FDA compliance, and organic certifications, as these indicate a commitment to quality and safety. Attend industry trade shows, engage in networking, and utilize online directories to identify potential partners. Additionally, request case studies or references from past clients to gauge their experience and reliability. Finally, arrange site visits to assess their facilities and operational capabilities firsthand. -

What are the key factors to consider when vetting co-packers in NJ?

When vetting co-packers in New Jersey, consider their certifications, production capacity, and experience with your specific product type. Assess their quality assurance processes, including adherence to safety standards and consistency in production. Evaluate their flexibility in terms of customization options and Minimum Order Quantities (MOQs). It’s also crucial to review their logistics capabilities for shipping and storage, as well as their responsiveness to communication. Lastly, inquire about their pricing structure and payment terms to ensure alignment with your budget. -

What customization options do co-packers in NJ typically offer?

Co-packers in New Jersey often provide a range of customization options, including formulation development, packaging design, and labeling. Many facilities work closely with clients to create unique recipes that reflect specific market preferences. They may also offer various packaging types, such as pouches, jars, and bottles, and can accommodate different sizes and volumes. Be sure to discuss your specific needs early in the process to ensure the co-packer can meet your requirements effectively. -

What are the typical Minimum Order Quantities (MOQs) for co-packing in NJ?

Minimum Order Quantities (MOQs) for co-packing can vary significantly based on the product type, packaging, and specific co-packer capabilities. Generally, MOQs can range from a few hundred to several thousand units. High-volume production runs usually result in lower per-unit costs, while smaller batches may incur higher rates. When sourcing a co-packer, it’s essential to discuss MOQs upfront to ensure they align with your production plans and budget. -

What payment terms should I expect when working with co-packers in NJ?

Payment terms with co-packers in New Jersey can vary widely depending on the company and the scope of the project. Common arrangements include upfront payments, deposits, or payment upon delivery. Some co-packers may offer net payment terms (e.g., net 30 or net 60 days) based on established trust and relationship. Always clarify payment terms before signing contracts to avoid any misunderstandings later, and consider negotiating terms that work best for your cash flow needs. -

How do co-packers ensure quality assurance in their processes?

Co-packers in NJ typically implement stringent quality assurance (QA) protocols to maintain product integrity. This includes regular inspections of raw materials, monitoring production processes, and conducting finished product testing. Many facilities adhere to HACCP (Hazard Analysis Critical Control Point) guidelines and may hold certifications like SQF or ISO. Additionally, they often maintain detailed records of quality checks to ensure compliance with safety standards and client specifications. -

What logistics support can co-packers in NJ provide for international shipping?

Most co-packers in New Jersey offer logistics support that includes warehousing, inventory management, and assistance with international shipping. They can help navigate customs regulations, documentation, and freight forwarding to ensure smooth delivery to your target markets. Discuss your shipping needs and timelines with potential co-packers to determine their capabilities in handling international logistics effectively. It’s also beneficial to inquire about their partnerships with shipping companies for competitive rates. -

How can I ensure timely delivery of my products with a co-packer in NJ?

To ensure timely delivery of your products, establish clear communication with your chosen co-packer from the outset. Provide detailed production schedules and deadlines, and regularly check in on progress. Discuss their capacity to handle your order volume and any potential bottlenecks in their production process. It’s also wise to build in buffer time for unforeseen delays and confirm their logistics capabilities for shipping. A solid partnership based on transparency and proactive communication will significantly enhance your chances of meeting delivery timelines.

Top 5 Co Packers In Nj Manufacturers & Suppliers List

1. Hillside Beverage – Carbonated Bottling Solutions

Domain: hillsidebev.com

Registered: 2012 (13 years)

Introduction: Hillside Beverage Packing is a boutique bottling facility located in Hillside, NJ, 15 miles from NYC. They have been operating since 2009 and specialize in producing carbonated beverages in glass, PET, and aluminum bottles. They cater to both emerging and established brands that require smaller production quantities than those offered by large contract packing facilities.

2. Chelten House – Co-Manufacturing Services

Domain: cheltenhouse.com

Registered: 1999 (26 years)

Introduction: Co-Manufacturing services with 8 full-scale production lines in New Jersey, over 400,000 square feet of manufacturing and distribution space, precision computerized batching system, SQF 2000 – Level 3 Certified Facilities, Organic and Kosher Certified, H.A.C.C.P. based program for food quality and safety. Products include Salad Dressings, Pasta Sauces, Pizza Sauces, Salsas, BBQ Sauces, Ketchup, Ma…

3. ActionPak – Comprehensive Packaging Solutions

Domain: actionpakinc.com

Registered: 1997 (28 years)

Introduction: ActionPak offers a range of packaging services including:

– Contract Manufacturing

– Co-Packing

– Product Assembly

– Design and Material Sourcing

– Liquid Filling Services

– Powder Filling Services

– Stick Packs

– Vitamin & Tablet Packing

– Club & Multi-Packaging

– Display Assembly Services

– Fulfillment Services

– Labeling

– Poly Bundling Services

– Shrink Sleeving Services

– Shrin…

4. T.H.E.M. – Stick Pack Solutions

Domain: them.net

Registered: 1998 (27 years)

Introduction: T.H.E.M. is a leading co-packing packaging manufacturer specializing in single-serve packaging solutions. They introduced the stick pack to North America in 1996 and have extensive experience in stick pack production. T.H.E.M. emphasizes a scientific and entrepreneurial approach to projects, ensuring quality, innovation, and efficiency in packaging. They focus on speed-to-market, working closely w…

5. Trans-Packers – Contract Food Packaging Services

Domain: transpackers.com

Registered: 1998 (27 years)

Introduction: Trans-Packers-Services Corp. offers contract food packaging, blending, and manufacturing services. Established in 1969, the company operates from a 100,000-square-foot, state-of-the-art facility in Piscataway, New Jersey. They have over 60 unique machine lines for packaging, blending, and manufacturing needs. The facility is USDA dairy certified and specializes in food pouching, bottling, and cann…

Strategic Sourcing Conclusion and Outlook for co packers in nj

In today’s competitive global market, strategic sourcing from co-packers in New Jersey offers international B2B buyers a unique advantage. With a diverse range of services from private label production to innovative culinary solutions, these co-packers are equipped to meet the needs of various industries, including food and beverage, cosmetics, and industrial goods. The state’s robust infrastructure and proximity to major shipping routes facilitate efficient distribution, ensuring timely delivery to international markets.

Moreover, New Jersey co-packers adhere to stringent quality control standards, such as SQF and organic certifications, which are crucial for maintaining product integrity and meeting regulatory requirements. By partnering with these experienced manufacturers, buyers can leverage their expertise in product development, packaging, and compliance to enhance their own supply chain capabilities.

As you consider your sourcing strategy, now is the time to explore the opportunities presented by New Jersey co-packers. Engaging with these industry leaders can not only streamline your operations but also help you innovate and expand your product offerings. Reach out to potential partners today to discover how they can support your growth in diverse markets across Africa, South America, the Middle East, and Europe.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to co packers in nj

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.