Unlocking Value: A Strategic Analysis of the Sterling Seal And Supply Market

Introduction: Navigating the Global Market for sterling seal and supply

In the fast-paced world of international manufacturing and industrial supply, sourcing high-quality sealing solutions like those offered by Sterling Seal & Supply can present significant challenges. B2B buyers often grapple with the complexities of ensuring product reliability, compliance with local regulations, and efficient logistics, particularly when importing from regions like the United States to markets in Africa, South America, the Middle East, and Europe. This guide aims to demystify the landscape of Sterling Seal & Supply, providing an in-depth analysis of various sealing products, including O-rings, custom molded rubber parts, and gaskets, as well as their applications across industries such as automotive, oil and energy, and machinery.

Within these pages, you’ll find actionable insights into supplier vetting processes, cost considerations, and best practices for procurement, tailored specifically for the unique needs of global buyers. By understanding the nuances of the Sterling Seal & Supply offerings and leveraging strategic sourcing techniques, decision-makers can mitigate risks and enhance operational efficiency. This guide empowers you to make informed purchasing decisions that align with your business goals, ensuring you secure the right sealing solutions that meet both performance and budgetary requirements. As you navigate the global market, let this comprehensive resource be your trusted ally in achieving success in your sealing supply endeavors.

Understanding sterling seal and supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| O-Rings | Precision-molded, available in various materials | Automotive, oil & energy, machinery | Pros: Versatile, reliable sealing. Cons: Size limitations may require custom orders. |

| Custom Molded Rubber Parts | Tailored designs to meet specific application needs | Aerospace, medical devices, industrial machinery | Pros: Perfect fit for unique applications. Cons: Longer lead times for production. |

| Teflon Seals | High resistance to chemicals and temperature extremes | Chemical processing, food & beverage | Pros: Durable, non-stick properties. Cons: Higher cost compared to rubber seals. |

| Bonded Seals | Combination of materials for enhanced performance | Pumps, valves, HVAC systems | Pros: Improved sealing capabilities. Cons: More complex design may increase cost. |

| O-Ring Kits | Assorted sizes and materials in one package | Maintenance and repair across industries | Pros: Convenient for quick repairs. Cons: May include sizes not needed for specific applications. |

What are the Characteristics of O-Rings and Their Suitability for B2B Applications?

O-Rings are one of the most common sealing solutions in various industries due to their simplicity and effectiveness. They are precision-molded to ensure a tight fit and can be manufactured from a variety of materials, including rubber and silicone. Their versatility makes them suitable for applications in automotive, oil and energy, and machinery sectors. Buyers should consider the specific size and material requirements, as custom orders may be necessary for non-standard applications.

How Do Custom Molded Rubber Parts Meet Specific Industry Needs?

Custom molded rubber parts are designed to meet the unique specifications of different applications. These parts can be tailored in terms of shape, size, and material composition, making them ideal for industries such as aerospace, medical devices, and industrial machinery. When purchasing these components, B2B buyers must consider lead times and potential costs associated with custom tooling and production. However, the advantage of a perfect fit can significantly enhance operational efficiency and reduce the risk of leaks.

What Advantages Do Teflon Seals Offer in Harsh Environments?

Teflon seals are known for their high chemical resistance and ability to withstand extreme temperatures, making them a preferred choice in industries like chemical processing and food and beverage. Their non-stick properties also reduce friction and wear, contributing to longer service life. B2B buyers should weigh the higher costs against the longevity and performance benefits, especially in demanding environments where failure is not an option.

Why Choose Bonded Seals for Enhanced Performance?

Bonded seals combine different materials to optimize sealing performance, particularly in applications involving pumps, valves, and HVAC systems. These seals can handle higher pressures and provide better resistance to environmental factors compared to standard O-Rings. Buyers should consider the complexity of the design and the potential for increased costs, but the enhanced sealing capabilities can justify the investment in high-performance applications.

How Do O-Ring Kits Simplify Maintenance for B2B Buyers?

O-Ring kits provide a convenient solution for maintenance and repair across various industries by offering assorted sizes and materials in one package. They are particularly useful for businesses that require quick access to sealing solutions for routine repairs. However, buyers should be mindful that these kits may include sizes that are not needed for specific applications, which could lead to unnecessary inventory costs. Overall, O-Ring kits can streamline operations and minimize downtime, making them a valuable asset for B2B buyers.

Key Industrial Applications of sterling seal and supply

| Industry/Sector | Specific Application of sterling seal and supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Sealing solutions for engine components | Enhances reliability, reduces maintenance costs | Quality certification, compatibility with OEM specs |

| Oil and Gas | Seals for drilling and extraction equipment | Prevents leaks, ensures safety in hazardous conditions | Temperature and pressure ratings, material durability |

| Food and Beverage | Gaskets and seals for processing equipment | Ensures hygiene, prevents contamination | Compliance with food safety standards, FDA approval |

| Manufacturing | Custom molded parts for machinery | Improves efficiency, reduces downtime | Customization capabilities, lead times |

| HVAC Systems | Seals for ductwork and HVAC units | Enhances energy efficiency, reduces operational costs | Material specifications, compatibility with existing systems |

How Does Sterling Seal and Supply Support the Automotive Industry?

In the automotive sector, sterling seal and supply provides essential sealing solutions for engine components, including O-rings and gaskets. These seals are critical in preventing oil and coolant leaks, thus enhancing the reliability of vehicles and reducing the frequency of maintenance. International B2B buyers should prioritize suppliers that offer quality certifications and ensure that their products meet OEM specifications to maintain compliance with stringent automotive standards.

What Role Does Sterling Seal and Supply Play in the Oil and Gas Sector?

In the oil and gas industry, sealing solutions from sterling seal and supply are utilized in drilling and extraction equipment to prevent leaks that could lead to environmental hazards. The materials used must withstand extreme temperatures and pressures, making it crucial for buyers to consider the durability and performance ratings of the seals. Ensuring that the seals meet industry-specific safety standards is vital for operational safety and efficiency.

Why Are Sterling Seal and Supply Products Essential in Food and Beverage Processing?

Sterling seal and supply offers gaskets and seals that are specifically designed for food and beverage processing equipment. These products are crucial in maintaining hygiene and preventing contamination during production. Buyers in this sector must ensure that all sealing solutions comply with food safety regulations, including FDA approvals, to guarantee the safety of their products and maintain consumer trust.

How Can Manufacturers Benefit from Custom Molded Parts by Sterling Seal and Supply?

In manufacturing, custom molded parts from sterling seal and supply can significantly improve machinery efficiency and reduce downtime. These parts are tailored to specific machinery requirements, ensuring a perfect fit and optimal performance. B2B buyers should assess the supplier’s customization capabilities and lead times to ensure that their unique needs are met without delays that could impact production schedules.

What Advantages Do HVAC Systems Gain from Sterling Seal and Supply Seals?

Sterling seal and supply provides high-quality seals for ductwork and HVAC units, which are essential for enhancing energy efficiency and reducing operational costs. Proper sealing minimizes air leaks, leading to better climate control and lower energy bills. Buyers should focus on material specifications that align with their existing systems to ensure compatibility and effective performance, especially in diverse climates across international markets.

3 Common User Pain Points for ‘sterling seal and supply’ & Their Solutions

Scenario 1: Difficulty Sourcing Specific O-Ring Sizes

The Problem: B2B buyers often encounter challenges when they need specific O-ring sizes or materials that are not available in standard catalogs. This issue is particularly prevalent in industries such as automotive and machinery, where precise specifications are critical to ensure the effectiveness of seals. The inability to find the right size can lead to delays in production, increased costs due to emergency sourcing, and potential equipment failures that could cause significant downtime.

Illustrative image related to sterling seal and supply

The Solution: To effectively source specific O-ring sizes from Sterling Seal & Supply, buyers should start by reviewing the company’s extensive catalog of standard sizes. If the required size is not listed, buyers can take advantage of Sterling Seal’s custom order capabilities. It’s advisable to prepare a detailed specification sheet that includes dimensions, material requirements, and application conditions. Engaging directly with Sterling Seal’s customer support can expedite the process; they can provide expert advice on material compatibility and performance expectations. Establishing a relationship with your sales representative can also facilitate quicker responses for future needs, ensuring that your supply chain remains uninterrupted.

Scenario 2: Quality Concerns with Imported Seals

The Problem: In many regions, especially in emerging markets across Africa and South America, B2B buyers often grapple with the quality of imported sealing solutions. Poor quality seals can lead to leaks, product failures, and ultimately, customer dissatisfaction. This concern is heightened when buyers are faced with multiple suppliers offering competitive prices but varying standards of quality assurance. The challenge is to ensure that the sealing solutions purchased will meet the rigorous demands of their applications.

The Solution: To address quality concerns, buyers should leverage Sterling Seal & Supply’s certifications and compliance information available on their website. It’s essential to inquire about the materials used and the manufacturing processes to ensure they meet international standards. Buyers can also request product samples or small test orders before committing to larger purchases. Additionally, engaging in discussions with Sterling Seal’s technical support team can provide insights into the durability and reliability of the seals. Establishing a quality assurance protocol that includes regular assessments of received products can further enhance confidence in the supply chain.

Scenario 3: Long Lead Times Impacting Production Schedules

The Problem: B2B buyers frequently face the issue of long lead times when ordering sealing solutions, which can disrupt production schedules and lead to financial losses. This is particularly problematic in industries where timely maintenance or replacement of seals is crucial, such as in the oil and gas sector or manufacturing. When orders are delayed, it can result in extended equipment downtime and increased operational costs.

The Solution: To mitigate lead time issues, buyers should take advantage of Sterling Seal & Supply’s robust inventory management. With a stock of over 200 million items across multiple locations, buyers are encouraged to explore the option of keeping a safety stock of critical components. Creating a forecast of seal usage based on historical data can help determine optimal reorder points. Additionally, buyers should communicate their production schedules and urgency levels to their Sterling Seal representatives to facilitate priority handling of urgent orders. Utilizing Sterling Seal’s expedited shipping options can also significantly reduce lead times and ensure that critical parts arrive on time, helping to maintain seamless operations.

Strategic Material Selection Guide for sterling seal and supply

What Are the Key Materials Used in Sterling Seal & Supply Products?

When selecting materials for sealing solutions, it is crucial to consider the specific requirements of the application and the operating environment. Sterling Seal & Supply offers a variety of materials, each with distinct properties and suitability for various industrial applications. Below are analyses of four common materials used in their products, focusing on key properties, advantages, disadvantages, and considerations for international B2B buyers.

How Do Different Rubber Compounds Affect Performance?

Rubber Compounds are widely used in O-rings and seals due to their flexibility and resilience. Common types include Nitrile (Buna-N), Neoprene, and EPDM.

- Key Properties: Rubber compounds generally exhibit excellent elasticity, good compression set resistance, and can handle moderate temperature ranges (typically -40°F to 250°F). They are also resistant to various chemicals, depending on the specific compound.

- Pros & Cons: The primary advantage of rubber is its cost-effectiveness and ease of manufacturing. However, rubber can degrade under extreme temperatures or in the presence of certain chemicals, limiting its application in harsh environments.

- Impact on Application: Rubber compounds are suitable for sealing applications in automotive, machinery, and plumbing. However, compatibility with specific media (e.g., oils, fuels) must be verified.

- International Considerations: Buyers from regions like Europe and Africa should ensure compliance with local standards (e.g., ASTM, DIN) and consider the climate’s impact on rubber performance.

What Advantages Do Teflon Products Offer in Sealing Solutions?

Teflon (PTFE) is another popular material known for its chemical resistance and high-temperature tolerance.

- Key Properties: Teflon can withstand temperatures from -450°F to 500°F and is highly resistant to corrosive chemicals, making it ideal for demanding applications.

- Pros & Cons: The main advantage of Teflon is its durability and resistance to chemical attack. However, it can be more expensive than rubber and may require specialized manufacturing processes, increasing lead times.

- Impact on Application: Teflon is often used in applications involving aggressive chemicals, such as in the oil and gas industry. Its low friction properties also make it suitable for dynamic seals.

- International Considerations: Buyers should check for compliance with international standards and certifications, particularly in industries like pharmaceuticals and food processing.

Why Are Metal Seals Important for Heavy-Duty Applications?

Metal Seals, such as those made from stainless steel or brass, are critical in high-pressure and high-temperature applications.

Illustrative image related to sterling seal and supply

- Key Properties: Metal seals can withstand extreme temperatures and pressures, often exceeding the limits of rubber or Teflon. They also offer excellent mechanical strength and durability.

- Pros & Cons: The advantage of metal seals is their robustness and longevity in harsh environments. However, they can be more expensive and require precise machining, which may complicate manufacturing.

- Impact on Application: Metal seals are commonly used in aerospace, automotive, and heavy machinery applications where reliability is paramount.

- International Considerations: Buyers should ensure that metal seals meet relevant international standards, especially in industries where safety and compliance are critical.

How Do Specialty Materials Enhance Sealing Solutions?

Specialty Materials like silicone and fluorocarbon elastomers are tailored for specific applications.

- Key Properties: Silicone can handle extreme temperatures (-100°F to 500°F) and offers excellent flexibility. Fluorocarbon elastomers provide superior chemical resistance and can operate in harsh environments.

- Pros & Cons: Specialty materials offer tailored properties for specific needs, enhancing performance. However, they often come with a higher price tag and may have limited availability.

- Impact on Application: These materials are ideal for applications in the food and beverage industry, pharmaceuticals, and other sensitive environments.

- International Considerations: Compliance with health and safety regulations is crucial for international buyers, particularly in sectors with stringent standards.

Summary Table of Material Selection for Sterling Seal & Supply

| Material | Typical Use Case for sterling seal and supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber Compounds | Automotive seals, plumbing applications | Cost-effective and flexible | Limited temperature and chemical resistance | Low |

| Teflon (PTFE) | Chemical processing, dynamic seals | High chemical resistance | Higher cost and complex manufacturing | High |

| Metal Seals | Aerospace, heavy machinery | Extreme durability and strength | Higher manufacturing complexity | High |

| Specialty Materials | Food and beverage, pharmaceuticals | Tailored properties for specific needs | Higher cost and limited availability | Med |

This guide provides valuable insights for international B2B buyers, helping them make informed decisions when selecting materials for sealing solutions from Sterling Seal & Supply.

In-depth Look: Manufacturing Processes and Quality Assurance for sterling seal and supply

What Are the Main Stages in the Manufacturing Process of Sterling Seal & Supply Products?

The manufacturing process for products at Sterling Seal & Supply is a structured and meticulous journey that ensures high-quality sealing solutions. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to sterling seal and supply

-

Material Preparation: The process begins with sourcing high-quality raw materials, primarily rubber and Teflon, which are essential for producing O-rings and seals. These materials are chosen based on their durability and resistance to various environmental factors such as temperature fluctuations and chemical exposure. Suppliers are vetted to meet international standards, ensuring that the materials used are of the highest quality.

-

Forming: Once the materials are prepared, they undergo a forming process. This typically involves precision molding techniques where the raw materials are heated and shaped into specific forms. For O-rings, this often includes the use of injection molding machines that ensure uniformity and precision in size and shape. The forming stage is crucial as it directly impacts the performance characteristics of the final product.

-

Assembly: After forming, the components may require assembly, especially for complex sealing solutions that integrate multiple parts. This stage might involve bonding different materials or adding additional features to enhance the sealing capability. Skilled technicians oversee this process to maintain the integrity and functionality of the products.

-

Finishing: The final stage involves finishing touches, which may include surface treatment, quality checks, and packaging. This stage ensures that the products not only meet functional specifications but are also visually appealing and ready for shipment. Proper finishing is vital for enhancing the durability and longevity of the products, which is particularly important in demanding industrial applications.

How Does Sterling Seal & Supply Ensure Quality Control Throughout the Manufacturing Process?

Quality control (QC) is integral to Sterling Seal & Supply’s commitment to excellence. The company adheres to several international and industry-specific standards that guide its QC practices.

-

International Standards Compliance: Sterling Seal & Supply is ISO 9001 certified, which signifies a robust quality management system. This certification ensures that the company’s processes consistently meet customer and regulatory requirements. Compliance with standards such as CE and API further demonstrates the commitment to quality, particularly in industries like oil and gas, where reliability is paramount.

-

Quality Checkpoints: The QC process includes several critical checkpoints:

– Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet the specified standards. Any materials that do not pass this inspection are rejected.

– In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to ensure that the production adheres to quality standards. This includes monitoring machinery settings, production conditions, and intermediate product inspections.

– Final Quality Control (FQC): The final stage of QC involves comprehensive testing of the finished products. This may include pressure tests, temperature tests, and leakage tests, ensuring that the products perform as expected in real-world conditions. -

Common Testing Methods: Testing methods employed include tensile strength testing, hardness testing, and chemical resistance testing. These tests are essential in verifying that the products will withstand the conditions they will face in the field.

What Are the Best Practices for B2B Buyers to Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial to mitigate risks and ensure product reliability.

-

Supplier Audits: Conducting on-site audits of potential suppliers is one of the most effective ways to assess their manufacturing processes and quality control measures. During these audits, buyers can evaluate the facilities, review quality management systems, and engage with the production team to understand their practices better.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline the QC processes, testing results, and any certifications the supplier holds. These documents can provide insights into the supplier’s commitment to quality and their ability to meet international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s operations and product quality. These inspections can be scheduled at various stages of the manufacturing process, offering peace of mind that the products will meet the required specifications before shipment.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must be aware of specific nuances regarding quality control and certifications that may affect their procurement processes.

-

Understanding Regional Standards: Different regions may have varying standards and certifications. For instance, while ISO 9001 is a recognized standard globally, certain industries may require additional certifications, such as API for oil and gas or CE marking for products sold in Europe. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Cultural Considerations: When engaging with suppliers from different regions, cultural differences may influence communication and expectations regarding quality control. Building strong relationships and understanding local business practices can help bridge these gaps.

-

Documentation and Customs Compliance: Buyers should ensure that all quality certifications and compliance documents are in order to facilitate smooth customs clearance. Proper documentation can prevent delays and additional costs associated with non-compliance.

In summary, the manufacturing processes and quality assurance practices at Sterling Seal & Supply are designed to meet the highest standards of reliability and performance. By understanding these processes and implementing best practices for supplier verification, international B2B buyers can confidently source high-quality sealing solutions that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sterling seal and supply’

To effectively source products from Sterling Seal and Supply, B2B buyers must navigate a systematic approach that ensures quality, reliability, and alignment with their specific needs. This checklist provides a structured pathway for making informed procurement decisions.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements of the seals or O-rings you need. This includes dimensions, materials, and application environments. Precise specifications help avoid costly errors and ensure that the products meet the operational demands of your machinery or systems.

- Material Requirements: Consider temperature and pressure conditions that the seals will be exposed to.

- Industry Standards: Identify any industry-specific certifications or standards that the products must comply with.

Step 2: Research Sterling Seal & Supply Product Offerings

Familiarize yourself with the range of products available from Sterling Seal & Supply. This includes O-rings, rubber seals, and custom molded parts. Understanding their catalog will help you identify which products best fit your needs.

- Standard vs. Custom Products: Determine if your requirements can be met with standard items or if custom solutions are necessary.

- Product Variability: Assess the available materials and coatings to ensure compatibility with your applications.

Step 3: Evaluate Supplier Certifications

Verify that Sterling Seal & Supply holds relevant certifications and complies with industry standards. This is crucial for ensuring the quality and reliability of the products.

- Certifications to Look For: ISO certifications, UL listings, and compliance with TAA/BAA regulations can indicate a commitment to quality.

- Production Standards: Ensure that the manufacturing processes meet your industry’s requirements to reduce the risk of product failures.

Step 4: Request Samples for Testing

Before placing a large order, request samples of the products you intend to purchase. Testing these samples in your specific application can provide valuable insights into their performance and compatibility.

- Performance Testing: Evaluate how the samples perform under actual operating conditions.

- Fit and Functionality: Ensure that the dimensions and materials meet your specifications.

Step 5: Assess Lead Times and Inventory Levels

Investigate the lead times for delivery and check the inventory levels for the products you need. This information is essential to ensure that your operations are not interrupted due to stock shortages.

- Shipping Times: Understand the expected delivery times based on your location and the supplier’s logistics capabilities.

- Stock Availability: Confirm that the supplier has sufficient inventory to meet your demand without delays.

Step 6: Review Pricing and Payment Terms

Analyze the pricing structures and payment terms offered by Sterling Seal & Supply. Ensure that the pricing aligns with your budget while considering the quality of the products.

- Bulk Purchase Discounts: Inquire about any discounts for large orders, which can significantly reduce costs.

- Payment Options: Ensure that the payment terms are flexible and conducive to your financial processes.

Step 7: Establish Communication Channels

Finally, establish effective communication channels with Sterling Seal & Supply. Clear communication can facilitate smoother transactions and faster resolution of any issues.

- Dedicated Account Manager: Request a point of contact who can assist you with inquiries and order management.

- Feedback Mechanism: Implement a system for providing feedback on product performance and service quality to foster a strong supplier relationship.

By following these steps, international B2B buyers can confidently source from Sterling Seal and Supply, ensuring they receive high-quality sealing solutions that meet their specific operational needs.

Comprehensive Cost and Pricing Analysis for sterling seal and supply Sourcing

What Are the Key Cost Components for Sourcing from Sterling Seal & Supply?

Understanding the cost structure when sourcing from Sterling Seal & Supply is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of materials significantly impacts the overall cost. Sterling Seal & Supply offers a variety of rubber compounds and Teflon products, with prices fluctuating based on the material’s quality and specifications. High-performance materials designed for specific applications, such as those resistant to extreme temperatures or chemicals, typically command higher prices.

-

Labor and Manufacturing Overhead: Labor costs depend on the production location and the complexity of manufacturing processes. For instance, precision-molded O-rings may require skilled labor and specialized machinery, leading to higher manufacturing overhead.

-

Tooling: Initial tooling costs can be substantial, especially for custom products. Buyers should consider these costs when requesting unique specifications that deviate from standard offerings.

-

Quality Control (QC): A robust QC process ensures that products meet industry standards and certifications. While this adds to the initial cost, it can lead to long-term savings by reducing the risk of product failures and associated downtimes.

-

Logistics: Shipping costs can vary significantly based on destination, volume, and chosen Incoterms. Buyers should account for potential tariffs and customs duties, particularly when importing to regions such as Africa or South America.

-

Margin: The margin added by Sterling Seal & Supply reflects their operational costs and market positioning. It’s essential to understand that margins can vary depending on the product line and competitive landscape.

How Do Price Influencers Impact Your Sourcing Decisions?

Several factors influence pricing for Sterling Seal & Supply products, and understanding these can help buyers optimize their sourcing strategies.

Illustrative image related to sterling seal and supply

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Buyers should inquire about MOQs and potential price breaks for larger orders, which can enhance cost-efficiency.

-

Specifications and Customization: Custom products generally incur additional costs for tooling and production. Buyers should weigh the benefits of customization against the associated expenses.

-

Materials and Quality Certifications: Products with specific certifications (e.g., UL Listed, ADA Compliant) often come at a premium. Buyers must assess whether these certifications are essential for their applications.

-

Supplier Factors: The reliability and reputation of Sterling Seal & Supply can influence pricing. Established suppliers may command higher prices due to perceived value, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the implications of different Incoterms is crucial for international transactions. These terms dictate responsibility for shipping, insurance, and tariffs, directly impacting the total landed cost of products.

What Are Effective Buyer Tips for Negotiating Costs?

For B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation and strategic purchasing can lead to considerable savings.

-

Negotiate Based on Volume: Leverage potential order quantities to negotiate better pricing. Suppliers are often willing to provide discounts for larger commitments.

-

Focus on Total Cost of Ownership (TCO): Consider not just the initial purchase price but also long-term costs associated with maintenance, downtime, and product lifecycle. High-quality products may have a higher upfront cost but can save money over time.

-

Be Aware of Pricing Nuances: Understand regional pricing variations and currency fluctuations. Buyers in Europe might face different pricing structures compared to those in Africa or South America due to shipping distances and local market conditions.

-

Request Detailed Quotes: Encourage suppliers to provide itemized pricing that breaks down costs associated with materials, labor, and logistics. This transparency can help identify potential areas for cost savings.

Conclusion

Sourcing from Sterling Seal & Supply requires a comprehensive understanding of cost structures and pricing influences. By considering the outlined components and strategies, B2B buyers can make informed purchasing decisions that align with their operational goals while optimizing their budget. It’s vital to remain aware that prices can vary, and seeking multiple quotes can provide a clearer picture of the market landscape.

Alternatives Analysis: Comparing sterling seal and supply With Other Solutions

Understanding Alternatives in Sealing Solutions for B2B Buyers

When it comes to sealing solutions, businesses often seek alternatives that can provide comparable or superior performance, cost-effectiveness, and ease of implementation. Sterling Seal & Supply is a prominent player in this market, specializing in O-rings and various sealing products. However, there are other viable alternatives that B2B buyers should consider. This analysis will compare Sterling Seal & Supply against two alternatives: Parker Hannifin and McMaster-Carr, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Sterling Seal And Supply | Parker Hannifin | McMaster-Carr |

|---|---|---|---|

| Performance | High-quality seals; wide range of materials | Exceptional durability; extensive product testing | Broad selection; reliable quality |

| Cost | Competitive pricing; value for bulk orders | Higher price point; premium offerings | Varies; generally affordable |

| Ease of Implementation | Custom solutions available; good support | Standard products; some customization | Easy online ordering; fast shipping |

| Maintenance | Low maintenance; long lifespan | Durable but may require specific maintenance | Minimal maintenance; user-friendly |

| Best Use Case | Industrial applications; custom sealing needs | Aerospace and automotive industries | General-purpose applications; quick repairs |

What Are the Advantages and Disadvantages of Parker Hannifin as an Alternative?

Parker Hannifin is known for its high-quality sealing solutions, particularly in industries that demand exceptional durability, such as aerospace and automotive. One of the significant advantages of Parker is its rigorous product testing, ensuring that their seals can withstand extreme conditions. However, this premium quality comes at a higher price point, which may not be suitable for all budgets. Additionally, while they offer standard products, customization options can be limited compared to Sterling Seal & Supply.

Why Consider McMaster-Carr as an Alternative to Sterling Seal & Supply?

McMaster-Carr provides a broad range of industrial supplies, including sealing solutions. The primary advantage of McMaster-Carr is its user-friendly online platform, which allows for quick ordering and fast shipping. This can be particularly beneficial for businesses needing immediate supplies or quick repairs. However, while their products are generally reliable, the quality can vary, and they may lack the specialized customization that Sterling Seal offers for unique sealing applications.

How Can B2B Buyers Make the Right Choice for Their Needs?

Choosing the right sealing solution requires an understanding of specific business needs and operational requirements. B2B buyers should evaluate the performance, cost, and maintenance aspects of each alternative against their use case. For industries requiring high durability and performance, Parker Hannifin might be the right choice, while McMaster-Carr is ideal for general applications that demand quick delivery and affordability. Sterling Seal & Supply stands out for businesses needing custom solutions with a focus on industrial applications. Ultimately, the best choice will depend on balancing budget constraints with performance requirements and the urgency of supply needs.

Essential Technical Properties and Trade Terminology for sterling seal and supply

What Are the Key Technical Properties of Sterling Seal and Supply Products?

When sourcing seals and sealing solutions from Sterling Seal & Supply, understanding the critical specifications of their products is essential. Here are some key properties that influence performance and application suitability:

-

Material Composition

The materials used in manufacturing O-rings and seals, such as rubber, Teflon, and elastomers, greatly impact their durability, flexibility, and resistance to various chemicals and temperatures. For instance, fluorocarbon (FKM) is known for its high-temperature resistance and chemical compatibility, making it ideal for automotive and industrial applications. Buyers should evaluate material properties to ensure compatibility with their specific operational conditions. -

Durometer Hardness

Measured on the Shore A scale, durometer hardness indicates the softness or hardness of a material. A lower durometer rating suggests a softer material that can create a tighter seal, while a higher rating indicates a firmer product that may be better suited for high-pressure applications. Understanding durometer ratings helps buyers select the right seal for their operational requirements, balancing flexibility and strength. -

Temperature Range

Each sealing material has a specified temperature range within which it can operate effectively without compromising performance. For instance, certain rubber compounds can withstand temperatures from -40°F to 250°F, while Teflon products may offer even broader ranges. It is crucial for buyers to choose seals that can endure the environmental conditions they will face, ensuring longevity and reducing maintenance costs. -

Tolerance Specifications

Tolerances refer to the allowable deviations in the dimensions of O-rings and seals. Precision molding processes ensure that products meet specific tolerances, which are critical for achieving a proper fit within machinery. Understanding these specifications helps buyers avoid installation issues and ensures that seals function as intended, preventing leaks and enhancing system reliability. -

Certifications and Compliance

Many products from Sterling Seal & Supply come with certifications such as UL listing, ADA compliance, and GSA approval. These certifications ensure that products meet industry standards for safety and performance. Buyers, particularly in regulated industries, should prioritize products with the necessary certifications to mitigate risks and ensure compliance with local regulations.

What Are Common Trade Terms Used in the Sterling Seal and Supply Industry?

Navigating the B2B landscape requires familiarity with specific industry jargon. Here are some commonly used terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of sealing solutions, sourcing from an OEM ensures that the components are specifically designed for particular machinery, thus guaranteeing compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it can influence inventory management and cost-effectiveness. For businesses looking to minimize costs, negotiating lower MOQs can be beneficial, especially for high-volume applications. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. This process helps buyers compare offers from multiple suppliers to secure the best deal. Crafting a detailed RFQ can lead to better responses and more favorable terms. -

Incoterms (International Commercial Terms)

These are international standards that define the responsibilities of buyers and sellers for the delivery of goods. Familiarity with Incoterms is vital for B2B transactions, particularly in international trade, as they clarify who bears costs and risks at various points in the shipping process. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For businesses, understanding lead times is essential for planning and ensuring that production schedules are not disrupted. Companies should communicate clearly with suppliers about expected lead times to manage their operations effectively.

By grasping these technical properties and industry terms, international B2B buyers can make informed decisions when sourcing sealing solutions from Sterling Seal & Supply, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the sterling seal and supply Sector

What Are the Key Market Dynamics and Trends in the Sterling Seal and Supply Sector?

The sterling seal and supply sector is experiencing significant transformations driven by globalization, technological advancement, and shifting buyer expectations. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality, customizable sealing solutions that can withstand diverse industrial applications. The rise of Industry 4.0 has introduced automation and digitalization into the procurement process, allowing for more efficient inventory management and supply chain optimization. Buyers are leveraging advanced analytics and e-procurement platforms to make informed purchasing decisions, ensuring they source the right products at competitive prices.

Moreover, the demand for specialized products, such as precision-molded O-rings and custom rubber seals, is on the rise as industries like automotive, oil and energy, and machinery continue to expand. There is a notable shift towards sourcing from suppliers who maintain substantial inventories and can offer quick turnaround times, reflecting a growing emphasis on minimizing downtime in production processes. Buyers are also increasingly interested in suppliers with robust logistical capabilities that can facilitate international shipping and compliance with local regulations.

How Is Sustainability and Ethical Sourcing Shaping the Sterling Seal and Supply Market?

Sustainability has become a critical factor in the decision-making process for international B2B buyers. The environmental impact of manufacturing processes, particularly in sectors like rubber and plastic production, has prompted a shift towards more sustainable practices. Buyers are actively seeking suppliers who prioritize ethical sourcing and offer ‘green’ certifications for their products. These certifications not only enhance brand reputation but also align with corporate social responsibility goals.

Illustrative image related to sterling seal and supply

In the sterling seal and supply sector, utilizing eco-friendly materials, such as recycled rubber compounds or bioplastics, is gaining traction. Additionally, suppliers are increasingly adopting practices that reduce waste and energy consumption throughout their manufacturing processes. For B2B buyers, partnering with suppliers who demonstrate a commitment to sustainability can provide a competitive edge, as end-users and consumers are increasingly prioritizing environmentally responsible products.

How Has the Sterling Seal and Supply Sector Evolved Over Time?

The evolution of the sterling seal and supply sector dates back to the establishment of Sterling Plastic & Rubber Products, Inc. in 1970, which laid the groundwork for the modern-day Sterling Seal & Supply. Over the decades, the company has expanded its product offerings and geographical reach, becoming a leader in the distribution of O-rings, rubber seals, and custom molded parts. The growth of industries such as automotive and energy has driven demand for reliable sealing solutions, prompting Sterling Seal to innovate continually.

Today, with strategic locations across the United States and an extensive product catalog, Sterling Seal & Supply stands out as a trusted partner for international B2B buyers. Their commitment to customer service, rapid fulfillment, and product quality has cemented their reputation in the market, making them a go-to supplier for sealing solutions worldwide. As the industry continues to evolve, Sterling Seal remains focused on adapting to changing market demands and technological advancements, ensuring they meet the diverse needs of their global clientele.

Frequently Asked Questions (FAQs) for B2B Buyers of sterling seal and supply

-

1. How do I solve issues related to leakage in machinery using O-rings?

To address leakage problems in machinery, ensure you select the correct O-ring size and material for your specific application. O-rings must match the diameter and cross-section of the seal groove precisely to function effectively. Consider the operating conditions, such as temperature and pressure, and choose materials that are compatible with the fluids involved. If standard sizes are insufficient, Sterling Seal & Supply offers customization options to meet unique specifications, ensuring a reliable, leak-proof seal. -

2. What is the best type of O-ring for high-pressure applications?

For high-pressure applications, consider using O-rings made from materials like Viton or Nitrile, which offer superior resistance to pressure, temperature, and chemical exposure. These materials maintain their elasticity and sealing properties under extreme conditions. Additionally, ensure the O-ring is designed with a suitable cross-section to handle the pressure requirements of your system. Sterling Seal & Supply provides a range of O-rings tailored for various industrial applications, allowing for effective sealing solutions. -

3. What are the advantages of sourcing O-rings from Sterling Seal & Supply?

Sourcing O-rings from Sterling Seal & Supply offers several advantages, including a vast inventory of over 200 million items, ensuring availability for urgent needs. Their commitment to quality means that products meet industry standards, enhancing reliability. Moreover, the company provides customization options, allowing you to tailor O-rings to specific applications. Their strategic locations across the U.S. facilitate efficient logistics and rapid delivery, minimizing downtime for your operations. -

4. How can I ensure the quality of O-rings before purchasing?

To ensure the quality of O-rings before purchase, request certifications and compliance documentation from the supplier. Look for suppliers like Sterling Seal & Supply that adhere to industry standards and have a reputation for quality. Additionally, inquire about their quality assurance processes, including material testing and inspection protocols. If possible, consider obtaining samples for evaluation to confirm that the O-rings meet your specific requirements in terms of size, material, and performance. -

5. What are the minimum order quantities (MOQ) for O-rings at Sterling Seal & Supply?

Minimum order quantities can vary based on the specific type of O-ring and the material requested. Sterling Seal & Supply typically accommodates both small and large orders, making it easier for businesses of all sizes to source their sealing solutions. For customized O-rings, MOQs may be higher due to the production process. It’s advisable to contact their sales team directly to discuss your needs and obtain precise MOQ information tailored to your order. -

6. What payment terms does Sterling Seal & Supply offer for international buyers?

Sterling Seal & Supply provides flexible payment terms for international buyers, which may include options such as wire transfers, credit cards, or letters of credit. It’s essential to clarify the payment terms during the negotiation phase, as they can vary based on the order size and buyer’s location. Additionally, inquire about any potential discounts for early payment or bulk orders. Clear communication regarding payment expectations can facilitate smoother transactions and build a strong business relationship. -

7. How does Sterling Seal & Supply handle logistics and shipping for international orders?

Sterling Seal & Supply has established logistics processes to manage international shipping efficiently. They collaborate with reputable freight carriers to ensure timely delivery of products to various global destinations. Buyers can expect transparent shipping costs and tracking information for their orders. It’s advisable to discuss specific shipping requirements, customs duties, and estimated delivery times at the time of order placement to avoid any surprises and ensure a smooth import process. -

8. Can I customize O-rings for specific applications through Sterling Seal & Supply?

Yes, Sterling Seal & Supply offers customization options for O-rings to meet specific application requirements. Customers can request tailored sizes, materials, and designs to ensure optimal performance in their unique environments. When seeking customization, provide detailed specifications, including dimensions, material preferences, and operational conditions. Their experienced team will assist you in developing the right sealing solution, helping to enhance efficiency and reliability in your operations.

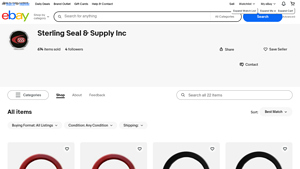

Top 4 Sterling Seal And Supply Manufacturers & Suppliers List

1. Sterling Seal – Sealing Solutions

Domain: sterlingseal.com

Registered: 2001 (24 years)

Introduction: Rubber Sheet, Belts, Packing, Braided Packing, SBS Stuffing Box, Sealant, Sealing Products, Bonded Seals, Kits, Rubber Balls, Static Seals, Standard O-rings, Cord, Rubber Quad Rings, Milspec O-rings, Parker O-rings, Backup rings, Encapsulated O-rings, FFKM/Kalrez, Square Rings, Rotary Seals, U-Cups, V-Rings, Wear Rings, Oil Seals, Springs, Ceramic Blankets, Fasteners, Safety Finger Saver Tools, Lu…

2. Sterling Seal & Supply – Precision-Molded O-Ring #12

Domain: hdsupplysolutions.com

Registered: 2006 (19 years)

Introduction: {“Product Name”: “Sterling Seal & Supply Precision-Molded O-Ring #12”, “Part Number”: “275149”, “Manufacturer Part Number”: “1-114”, “Brand”: “Sterling Seal & Supply”, “Price”: “$0.71”, “Country of Origin”: “China”, “UNSPSC”: “30181811”, “UPC”: “400654037887”, “Specifications”: {“Brand Compatibility”: “Sterling Seal & Supply”, “Color”: “White”, “Material”: “Brass”, “Package Quantity”: “1”}, “Certi…

3. Sterling Seal & Supply – 146-7470 PacFab O-Ring

Domain: poolwarehouse.com

Registered: 1998 (27 years)

Introduction: {“name”:”Sterling Seal & Supply 146-7470 PacFab O-Ring”,”price”:”$1.00″,”description”:”The Sterling Seal & Supply 146-7470 PacFab O-Ring is expertly crafted to ensure a tight, leak-proof seal for PacFab equipment, enhancing the longevity and efficiency of pool and filtration systems. Built from high-quality, durable materials, this O-ring is resistant to wear, pressure, and temperature fluctuation…

4. Kamlock™ – Encapsulated Gaskets and Air Filters

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 1″ Kamlock™ Encapsulated Viton Gasket, FEP, Black (Pack of 1) – $63.99

6″ Kamlock™ Encapsulated Silicone Gasket, FEP, Red (Pack of 1) – $112.99

16x25x1 Xtreme Plus Air Guard Pleated Filter Merv: 8, (3 Pack) – $36.00

6″ Kamlock™ Encapsulated Viton Gasket, FEP, Black (Pack of 1) – $161.99

4″ Kamlock™ Encapsulated Viton Gasket, FEP, Black (Pack of 1) – $122.99

2″ Kamlock™ Encapsulated Silicone Gasket…

Strategic Sourcing Conclusion and Outlook for sterling seal and supply

How Can Strategic Sourcing Enhance Your Procurement Process with Sterling Seal & Supply?

In conclusion, strategic sourcing with Sterling Seal & Supply offers international B2B buyers a robust pathway to optimize procurement efficiency and cost-effectiveness. By leveraging Sterling’s extensive inventory of high-quality sealing solutions, including O-rings and custom molded parts, businesses can ensure reliability and performance across various applications, from automotive to industrial machinery.

The commitment to customer success, coupled with a vast selection and rapid delivery options, positions Sterling Seal as a partner capable of meeting diverse sourcing needs. Buyers in Africa, South America, the Middle East, and Europe can particularly benefit from strategic sourcing, as it not only reduces lead times but also mitigates risks associated with supply chain disruptions.

Looking ahead, organizations are encouraged to explore the potential of developing long-term partnerships with Sterling Seal & Supply. By integrating these strategic sourcing practices, businesses can enhance their operational resilience and adapt to evolving market demands. Take the next step towards optimizing your procurement strategy—connect with Sterling Seal & Supply today to discover tailored solutions that drive growth and innovation in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.