Is Your Bubble Stickers Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for bubble stickers

Navigating the dynamic landscape of the global market for bubble stickers presents unique challenges for B2B buyers, particularly when sourcing quality products that meet diverse regional preferences. As businesses from Africa, South America, the Middle East, and Europe—such as those in Saudi Arabia and Nigeria—seek to enhance their branding and marketing strategies, understanding the nuances of bubble stickers becomes essential. This comprehensive guide covers everything from the various types of bubble stickers available, such as dome stickers and vinyl decals, to their multifaceted applications across different industries, including retail, promotional events, and product packaging.

Moreover, it provides critical insights into supplier vetting processes, ensuring that buyers can identify reliable manufacturers who deliver quality products on time. Cost considerations, including bulk pricing and shipping logistics, are also addressed to help businesses make informed purchasing decisions. With actionable strategies and expert recommendations, this guide empowers international B2B buyers to navigate the complexities of the bubble sticker market confidently. By equipping themselves with the right knowledge, businesses can leverage these customizable marketing tools to enhance visibility and engage their target audiences effectively.

Understanding bubble stickers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dome (3D) Stickers | Raised, glossy finish; adds depth and texture | Branding, product labels, promotional items | Pros: Eye-catching, enhances brand visibility. Cons: Higher production costs, limited design options. |

| Vinyl Stickers | Durable, weather-resistant; available in various finishes | Outdoor advertising, packaging, giveaways | Pros: Long-lasting, versatile. Cons: May require specific adhesives for certain surfaces. |

| Holographic Stickers | Iridescent finish that changes color with light | Event promotions, special editions | Pros: Unique aesthetic appeal. Cons: Can be more expensive than standard stickers. |

| Custom Die-Cut Stickers | Tailored shapes and sizes; high-quality printing options | Custom branding, event giveaways | Pros: Fully customizable, enhances brand identity. Cons: Longer production times, may have higher MOQs. |

| Bubble Tea Stickers | Fun, thematic designs often related to pop culture | Niche marketing, youth-oriented products | Pros: Engages younger demographics, trendy. Cons: Limited appeal for more formal brands. |

What Are Dome (3D) Stickers and Their B2B Applications?

Dome (3D) stickers have a raised, glossy finish that adds depth and texture, making them visually striking. This type of sticker is particularly effective in branding, product labeling, and promotional items, as their three-dimensional appearance attracts attention. When considering B2B purchases, it’s essential to evaluate the costs associated with production, as they can be higher than standard flat stickers. However, their unique look can significantly enhance brand visibility, making them a worthwhile investment for businesses aiming to stand out.

How Do Vinyl Stickers Stand Out in the Market?

Vinyl stickers are known for their durability and weather resistance, making them suitable for both indoor and outdoor applications. These stickers can be used for outdoor advertising, packaging, and giveaways, providing a versatile solution for various marketing strategies. When purchasing vinyl stickers, businesses should consider the adhesive quality, as some surfaces may require specific types for optimal adhesion. The longevity and versatility of vinyl stickers often justify their investment, especially for brands looking to maintain a consistent presence.

What Makes Holographic Stickers Unique for B2B Buyers?

Holographic stickers feature an iridescent finish that changes color depending on the angle of light, offering a visually captivating experience. They are often used for event promotions and limited-edition products, appealing to brands looking to create a sense of exclusivity. While these stickers can command a higher price point due to their unique aesthetic, they can effectively differentiate a product in a crowded market. B2B buyers should weigh the potential ROI against the increased costs when considering holographic options.

Why Choose Custom Die-Cut Stickers for Branding?

Custom die-cut stickers allow businesses to create stickers in tailored shapes and sizes, offering high-quality printing options. This customization enhances brand identity and is ideal for event giveaways and unique branding initiatives. However, buyers should be aware that custom orders may involve longer production times and higher minimum order quantities (MOQs). The ability to fully customize these stickers can significantly impact brand recognition and marketing effectiveness, making them a valuable option for businesses focused on differentiation.

How Can Bubble Tea Stickers Engage Target Audiences?

Bubble tea stickers often feature fun and thematic designs that resonate with younger demographics and niche markets. These stickers can be used in youth-oriented products and marketing campaigns, making them an effective tool for engaging specific audiences. While they may not appeal to more traditional or formal brands, their trendy designs can boost visibility among target groups. Businesses should consider their overall branding strategy when incorporating bubble tea stickers, ensuring that they align with their marketing goals.

Key Industrial Applications of bubble stickers

| Industry/Sector | Specific Application of bubble stickers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Product labeling and branding | Enhances brand visibility and consumer engagement | Quality of adhesive, custom designs, and durability |

| Logistics and Shipping | Package sealing and identification | Provides tamper evidence and improves package tracking | Resistance to environmental factors and visibility options |

| Education | Promotional materials for events and campaigns | Increases awareness and participation in educational initiatives | Customization options and durability for long-term use |

| Food and Beverage | Branding for packaging and promotional giveaways | Attracts customers and promotes brand loyalty | Compliance with food safety standards and material quality |

| Automotive | Custom decals for vehicle branding | Enhances brand recognition and creates a unique vehicle identity | Resistance to weather conditions and longevity of print |

How Are Bubble Stickers Used in Retail for Product Labeling and Branding?

In the retail sector, bubble stickers serve as an effective tool for product labeling and branding. They can be customized to include logos, product information, and promotional messages, thus enhancing visibility on shelves. This application addresses the challenge of standing out in crowded marketplaces, especially for international buyers seeking to penetrate diverse markets in Africa, South America, the Middle East, and Europe. Buyers should prioritize high-quality adhesive properties and vibrant printing options to ensure the stickers withstand various environmental conditions.

What Role Do Bubble Stickers Play in Logistics and Shipping?

In logistics and shipping, bubble stickers are utilized for package sealing and identification. They provide a tamper-evident solution that not only secures packages but also offers a way to track shipments visually. This application is critical for businesses operating across borders, where compliance with international shipping standards is vital. Buyers should consider the stickers’ resistance to moisture and temperature fluctuations, ensuring they maintain visibility and integrity throughout the shipping process.

How Are Bubble Stickers Beneficial in Education?

Educational institutions often leverage bubble stickers for promotional materials during events and campaigns. These stickers can be distributed to promote activities, engage students, and increase participation in educational initiatives. This application helps address the challenge of attracting attention in a competitive educational landscape. International buyers should look for customization options that reflect cultural relevance and durability to withstand various usage scenarios, such as outdoor events.

In What Ways Do Bubble Stickers Enhance Food and Beverage Branding?

In the food and beverage industry, bubble stickers are frequently used for branding packaging and promotional giveaways. They help attract customers and foster brand loyalty by providing eye-catching visuals and essential product information. This application is particularly important for businesses looking to establish a strong market presence in diverse regions. Buyers should ensure that the materials used are compliant with food safety standards and possess high-quality printing to withstand refrigeration or exposure to moisture.

How Are Bubble Stickers Used for Custom Vehicle Branding in the Automotive Sector?

In the automotive industry, bubble stickers are often applied as custom decals for vehicle branding. They serve to enhance brand recognition and create a unique identity for vehicles, which is especially beneficial for companies involved in logistics or delivery services. This application addresses the need for effective advertising on the move. Buyers should consider the stickers’ resistance to weather conditions, ensuring they remain intact and visually appealing over time.

3 Common User Pain Points for ‘bubble stickers’ & Their Solutions

Scenario 1: The Challenge of Adhesive Quality in Diverse Environments

The Problem: B2B buyers often face difficulties with the adhesive quality of bubble stickers, especially when using them in varying climates and surfaces. For example, stickers intended for outdoor use in humid climates, such as parts of Nigeria or the Middle East, may peel off or fail to adhere properly if not made with high-quality adhesives. This not only leads to wasted resources but can also damage a brand’s reputation if the stickers fail in their intended applications.

The Solution: To ensure that bubble stickers perform well across different environments, buyers should prioritize sourcing stickers that utilize high-grade, weather-resistant adhesives. When placing orders, request detailed specifications about the adhesive used, such as its temperature and humidity resistance. Additionally, consider samples from suppliers before committing to larger orders to test their durability in your specific conditions. Opting for manufacturers that offer stickers with 3M adhesives or similar high-performance options can significantly enhance longevity and effectiveness. Always conduct a surface preparation protocol before application, ensuring the area is clean and dry to maximize adhesion.

Scenario 2: Navigating Custom Design and Production Times

The Problem: For businesses requiring custom bubble stickers, the process of design approval and production can become a bottleneck. Companies in regions like Europe or South America may experience extended lead times due to complex design requirements or miscommunication with suppliers. This can result in delays that hinder marketing campaigns or product launches, impacting overall business performance.

The Solution: To streamline the custom sticker production process, establish clear communication protocols with suppliers. Create a comprehensive design brief that includes dimensions, colors, and intended usage, and share examples to minimize misunderstandings. It’s also beneficial to collaborate with suppliers who have a fast turnaround time and can accommodate rush orders when necessary. Additionally, consider using online design tools provided by sticker manufacturers to facilitate quicker approvals. Engaging suppliers who specialize in on-demand production can also help meet urgent needs without compromising on quality.

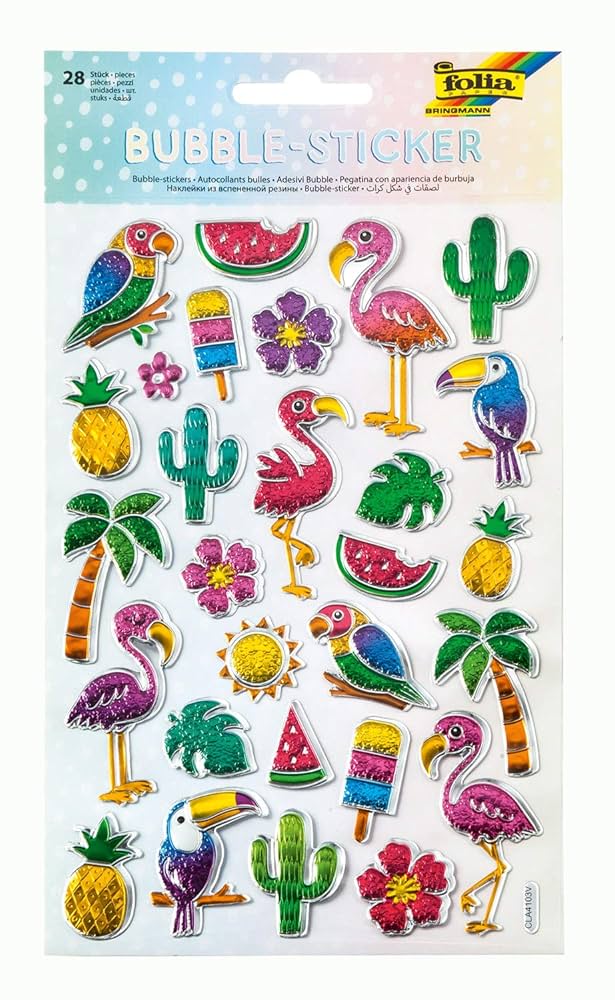

Illustrative image related to bubble stickers

Scenario 3: Managing Inventory and Waste Concerns

The Problem: B2B buyers often struggle with managing inventory levels of bubble stickers, leading to overproduction and waste, particularly in regions where demand fluctuates. For instance, companies in Saudi Arabia may order large quantities for events, only to find themselves with excess stock that could deteriorate or become outdated, increasing costs and impacting sustainability efforts.

The Solution: To address inventory management challenges, implement a just-in-time (JIT) ordering system that aligns production with actual demand. Engage with suppliers who offer flexible order quantities and shorter production runs, allowing you to adjust your inventory according to current needs. Additionally, consider eco-friendly options that use sustainable materials and inks, which can appeal to environmentally conscious consumers and help mitigate waste. Regularly review your sales data to forecast demand accurately and adjust your ordering strategy accordingly, ensuring you maintain an optimal inventory level without incurring unnecessary costs.

Strategic Material Selection Guide for bubble stickers

What Are the Key Materials Used for Bubble Stickers in B2B Applications?

When selecting materials for bubble stickers, it’s essential to consider the properties, advantages, and limitations of each option. This guide highlights four common materials used in bubble sticker production: vinyl, paper, polyester, and polypropylene. Each material has unique characteristics that can influence performance, durability, and suitability for various applications.

How Does Vinyl Perform as a Material for Bubble Stickers?

Vinyl is one of the most popular materials for bubble stickers due to its durability and versatility. It offers excellent resistance to water, UV light, and temperature fluctuations, making it suitable for both indoor and outdoor applications. Vinyl stickers can withstand a range of environmental conditions without fading or peeling.

Pros: Vinyl is highly durable, offering a long lifespan and resistance to wear and tear. It is also available in a variety of finishes, including glossy and matte, which can enhance visual appeal.

Cons: The cost of vinyl can be higher compared to other materials, and its manufacturing process may involve more complexity, particularly for custom designs.

Impact on Application: Vinyl stickers adhere well to various surfaces, including metal, plastic, and glass, making them ideal for promotional materials and product labeling.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial, especially for markets in Europe and the Middle East. Buyers should also consider local preferences for finishes and adhesive strength.

What Are the Advantages of Using Paper for Bubble Stickers?

Paper is a cost-effective option for bubble stickers, especially for short-term use. It is lightweight and easy to print on, allowing for vibrant colors and intricate designs.

Pros: Paper stickers are generally less expensive to produce and can be printed quickly, making them ideal for promotional campaigns with tight deadlines.

Cons: They lack the durability of vinyl and are not water-resistant, which limits their use in outdoor applications. Paper stickers may also not adhere well to certain surfaces.

Illustrative image related to bubble stickers

Impact on Application: Paper stickers are best suited for indoor use, such as labeling products or for temporary promotions.

Considerations for International Buyers: Buyers should ensure that paper stickers meet local environmental regulations, particularly in regions like Europe where sustainability is a priority.

How Does Polyester Enhance Bubble Sticker Performance?

Polyester is known for its strength and durability, making it a suitable choice for bubble stickers that require a robust material. It offers excellent resistance to tearing, chemicals, and UV exposure.

Pros: Polyester stickers can withstand harsh conditions, making them ideal for outdoor applications. They also have a high-quality appearance, often used for premium branding.

Cons: The cost of polyester can be higher than vinyl and paper, and the manufacturing process can be more complex, particularly for custom shapes and sizes.

Illustrative image related to bubble stickers

Impact on Application: Polyester is compatible with various printing technologies, allowing for high-quality graphics and designs.

Considerations for International Buyers: Compliance with industry standards is essential, especially in regions with stringent regulations like the EU. Buyers should also consider the environmental impact of polyester production.

What Role Does Polypropylene Play in Bubble Sticker Production?

Polypropylene is a versatile plastic material that is gaining popularity for bubble stickers due to its lightweight and water-resistant properties. It is often used for labels and stickers that need to endure moisture.

Pros: Polypropylene stickers are resistant to water and chemicals, making them suitable for a variety of applications, including food packaging.

Cons: While polypropylene is durable, it may not have the same level of adhesion as vinyl, which can affect performance on certain surfaces.

Impact on Application: Polypropylene is ideal for applications requiring moisture resistance, such as in kitchens or bathrooms.

Considerations for International Buyers: Buyers should verify that polypropylene stickers meet local safety regulations, especially for food-related applications in regions like South America and Africa.

Illustrative image related to bubble stickers

Summary Table of Material Selection for Bubble Stickers

| Material | Typical Use Case for bubble stickers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vinyl | Outdoor advertising and product labels | High durability and weather resistance | Higher cost and manufacturing complexity | High |

| Paper | Indoor promotions and temporary labels | Cost-effective and easy to print | Not water-resistant and less durable | Low |

| Polyester | Premium branding and outdoor stickers | Excellent tear and UV resistance | Higher cost and complex manufacturing | High |

| Polypropylene | Food packaging and moisture-prone areas | Lightweight and water-resistant | May have lower adhesion on some surfaces | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and considerations for various materials used in bubble stickers, facilitating informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for bubble stickers

What Are the Key Stages in the Manufacturing Process of Bubble Stickers?

The manufacturing of bubble stickers involves several critical stages, each contributing to the final product’s quality and functionality. Understanding these stages can help B2B buyers ensure they partner with manufacturers who adhere to high standards.

Material Preparation: What Materials Are Used for Bubble Stickers?

The first step in the manufacturing process is material preparation. Bubble stickers are typically made from vinyl or polypropylene, chosen for their durability and ability to retain vibrant colors. The selected materials are cut into sheets, which are then printed with high-resolution graphics using advanced digital printing techniques. This step is crucial as the quality of the raw materials directly impacts the final sticker’s appearance and performance.

Forming: How Are Bubble Stickers Shaped?

Once the materials are printed, they undergo a forming process. This involves cutting the stickers into their desired shapes, which can range from simple circles to intricate custom designs. Techniques such as die-cutting or kiss-cutting are employed during this stage. Die-cutting is often used for more complex shapes, while kiss-cutting allows for easier peeling from the backing. This precision is essential for ensuring that the stickers can be easily applied without damaging the design.

Illustrative image related to bubble stickers

Assembly: What Happens During the Assembly Stage?

In the assembly phase, the stickers are prepared for packaging. This can include stacking, sorting, and sometimes even adding protective layers to ensure they reach the buyer in pristine condition. For bubble stickers, it’s common to include a protective laminate layer that adds durability and water resistance, enhancing their usability in various environments.

Finishing: What Final Touches Are Applied to Bubble Stickers?

The finishing stage includes applying any additional coatings or treatments to enhance the stickers’ appearance and longevity. Common finishes include gloss or matte lamination, which not only improves aesthetics but also provides protection against scratches and UV light. This stage is vital for B2B buyers who require products that maintain their quality over time, especially in outdoor applications.

How Is Quality Assurance Integrated into Bubble Sticker Manufacturing?

Quality assurance (QA) is an essential aspect of the manufacturing process, ensuring that the final products meet international standards and customer expectations. For B2B buyers, understanding the QA processes can facilitate better supplier relationships and product consistency.

Illustrative image related to bubble stickers

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are critical in the bubble sticker manufacturing industry. ISO 9001 focuses on quality management systems and emphasizes continual improvement, ensuring that manufacturers consistently produce high-quality products. Additionally, certifications like CE mark may be relevant, especially for markets in Europe, indicating that products meet health, safety, and environmental protection standards.

What Are the Key QC Checkpoints in Bubble Sticker Production?

Quality control (QC) checkpoints are integral throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This checkpoint assesses raw materials before production begins, ensuring they meet predefined quality standards.

- In-Process Quality Control (IPQC): Conducted during the manufacturing stages, IPQC monitors processes to identify and rectify any issues early on. This can include checks on printing quality, cutting precision, and adhesive application.

- Final Quality Control (FQC): The final stage of QC, FQC ensures that the finished products are free from defects and meet all specifications before they are shipped to customers.

What Testing Methods Are Commonly Used for Bubble Stickers?

Testing methods play a significant role in verifying the quality of bubble stickers. Common tests include:

- Adhesive Testing: Evaluating the strength and durability of the adhesive under various conditions.

- Durability Testing: Subjecting stickers to abrasion, water exposure, and UV light to assess their longevity.

- Visual Inspection: A thorough check for any defects in printing, cutting, or application.

These tests ensure that the bubble stickers can withstand real-world usage, which is crucial for B2B buyers looking for reliable products.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance with international standards. Here are several strategies:

- Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality control measures in place. This firsthand observation can help identify potential issues or areas for improvement.

- Quality Reports: Requesting detailed quality reports from suppliers can offer transparency regarding their manufacturing practices and adherence to standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an objective assessment of the manufacturing process and product quality before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, may face unique challenges regarding quality control. Understanding local regulations, import standards, and cultural expectations can help mitigate these challenges.

Illustrative image related to bubble stickers

- Cultural Sensitivity: Different regions may have varying expectations regarding product quality and compliance. Understanding these nuances can facilitate smoother negotiations and partnerships.

- Regulatory Compliance: Familiarizing oneself with local and international regulations (e.g., CE in Europe, or specific import regulations in African countries) can help avoid compliance issues that could delay product delivery or incur additional costs.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing bubble stickers, ensuring that they select suppliers that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bubble stickers’

To assist B2B buyers in procuring bubble stickers effectively, this guide provides a structured checklist. It covers essential steps to ensure that you choose the right products and suppliers for your business needs.

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for the bubble stickers you need. Consider factors such as size, shape, material, and finish (e.g., matte vs. glossy). This step is crucial to ensure that the final product aligns with your branding and application needs.

Illustrative image related to bubble stickers

- Size and Shape: Determine the dimensions and whether you require standard shapes or custom die-cuts.

- Material: Decide on the type of vinyl (e.g., durable, waterproof) to ensure longevity and appropriate usage.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in bubble stickers. Look for companies with a strong reputation and positive reviews from previous clients. This foundational step helps minimize risks associated with quality and reliability.

- Supplier Experience: Focus on suppliers with proven experience in producing bubble stickers.

- Customer Feedback: Investigate reviews and testimonials to gauge the supplier’s service quality and product satisfaction.

Step 3: Evaluate Product Quality

Request samples from potential suppliers to assess the quality of their bubble stickers. This is essential to verify the durability, print quality, and adherence properties of the stickers before making a bulk order.

- Durability Tests: Check how well the stickers resist wear, fading, and water exposure.

- Application Ease: Ensure the stickers are easy to apply without air bubbles, which can affect the aesthetic appeal.

Step 4: Verify Supplier Certifications

Confirm that your chosen suppliers have the necessary certifications and quality assurance processes in place. This step is vital for ensuring compliance with international standards, especially if you’re sourcing from different regions.

- Certifications: Look for ISO certifications or other relevant industry standards.

- Quality Control Processes: Inquire about their quality assurance protocols to ensure consistent product standards.

Step 5: Discuss Minimum Order Quantities (MOQs)

Engage with suppliers to understand their minimum order quantities. This is particularly important for budgeting and aligning your needs with the supplier’s capabilities.

- Flexibility in Orders: Check if suppliers offer flexibility in MOQs, especially for first-time orders or trial runs.

- Bulk Discounts: Negotiate pricing based on order volume to achieve cost savings.

Step 6: Understand Pricing Structures

Before finalizing any agreements, ensure you have a clear understanding of the pricing structure. This includes base costs, potential additional fees for customization, and shipping costs.

- Transparent Pricing: Seek suppliers that provide a detailed breakdown of costs to avoid hidden fees.

- Negotiation Opportunities: Don’t hesitate to negotiate prices, especially for larger orders.

Step 7: Establish Communication Channels

Effective communication is key to a successful sourcing process. Establish clear lines of communication with your suppliers for updates and queries throughout the procurement process.

- Dedicated Contacts: Ensure you have a primary contact person to facilitate smooth communication.

- Response Times: Assess how quickly suppliers respond to inquiries, as this reflects their customer service standards.

By following this checklist, B2B buyers can streamline their sourcing process for bubble stickers, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for bubble stickers Sourcing

What Are the Key Cost Components for Sourcing Bubble Stickers?

When sourcing bubble stickers, understanding the cost structure is critical for effective budgeting and pricing strategies. The primary cost components include:

Illustrative image related to bubble stickers

-

Materials: The choice of materials significantly impacts costs. High-quality vinyl or specialized adhesive materials may raise expenses, but they enhance durability and appearance. For instance, options like transparent or holographic films can command a premium.

-

Labor: Labor costs can vary based on the region of production. Countries with lower labor costs may offer competitive pricing, but it is essential to consider the quality of craftsmanship and expertise in sticker production.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient production processes can lower overheads, allowing for more competitive pricing.

-

Tooling: Custom tooling for unique shapes or designs adds to initial costs but can lead to significant savings in the long run if large volumes are produced.

-

Quality Control (QC): Implementing stringent QC processes ensures that the final products meet quality standards. While this incurs additional costs, it protects buyers from returns and reputational damage due to poor-quality products.

-

Logistics: Shipping costs can fluctuate based on distance, volume, and chosen shipping methods. International shipments may involve customs duties and taxes, which must be factored into the total cost.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on market competition and buyer negotiation power.

How Do Price Influencers Impact the Cost of Bubble Stickers?

Several factors influence the pricing of bubble stickers, particularly for international B2B buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can vary significantly between suppliers. Larger orders often qualify for volume discounts, reducing the cost per unit.

-

Specifications and Customization: Custom designs, sizes, and colors can increase costs. Providing suppliers with clear specifications can help avoid unexpected expenses during production.

-

Material Choices: Premium materials like eco-friendly vinyl or specialty adhesives may incur higher costs but can appeal to environmentally conscious consumers, thus enhancing brand value.

-

Quality and Certifications: Certifications related to material safety or environmental impact can influence pricing. Products that meet specific standards may command higher prices but offer assurance of quality.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may offer better quality assurance but at a premium.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate shipping responsibilities and costs. Understanding these terms can help buyers avoid unexpected charges.

What Are Effective Buyer Tips for Cost-Efficiency in Bubble Stickers Sourcing?

B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiate with Suppliers: Leverage volume purchases or long-term contracts to negotiate better pricing. Suppliers are often willing to offer discounts for guaranteed business.

-

Assess Total Cost of Ownership (TCO): TCO encompasses not just the purchase price but also shipping, handling, and potential returns. A lower upfront cost may lead to higher overall expenses if quality is compromised.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations and regional market trends that may impact pricing. Consider establishing contracts in stable currencies to mitigate risks.

-

Evaluate Supplier Locations: Sourcing from nearby suppliers can reduce logistics costs and lead times. However, balancing cost with quality and reliability is crucial.

-

Stay Informed on Market Trends: Keeping abreast of changes in material costs and manufacturing technologies can provide insights into future pricing. This knowledge enables better negotiation and planning strategies.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on specific supplier conditions, market fluctuations, and negotiation outcomes. Always consult with multiple suppliers to ensure competitive pricing and terms tailored to your business needs.

Alternatives Analysis: Comparing bubble stickers With Other Solutions

When evaluating the best branding and promotional tools, it’s crucial to consider not only bubble stickers but also other viable alternatives. This analysis compares bubble stickers with dome stickers and vinyl decals, both of which serve similar marketing and decorative purposes. Understanding their respective advantages and disadvantages will help B2B buyers make informed decisions based on their unique needs.

Illustrative image related to bubble stickers

| Comparison Aspect | Bubble Stickers | Dome Stickers | Vinyl Decals |

|---|---|---|---|

| Performance | Durable, water-resistant, versatile | 3D appearance, visually striking | Long-lasting, weather-resistant |

| Cost | Generally low cost (from $1.79) | Moderate cost (from $0.39) | Variable cost (from $0.38) |

| Ease of Implementation | Easy to apply, no special tools needed | Requires careful placement | Requires surface preparation |

| Maintenance | Minimal, easy to clean | Durable, but can peel over time | Low maintenance, easy to replace |

| Best Use Case | Casual branding, personal use | High-impact advertising | Professional branding, signage |

What Are the Advantages and Disadvantages of Dome Stickers?

Dome stickers, also known as 3D stickers, provide a distinctive tactile feel and visual impact that can elevate brand presence. The dome effect enhances colors and makes designs more vibrant, capturing attention effectively. However, they may come at a higher price point and can require more careful application to avoid air bubbles. Dome stickers are ideal for high-stakes marketing campaigns or products that demand a premium feel, making them suitable for luxury brands.

How Do Vinyl Decals Compare to Bubble Stickers?

Vinyl decals are another popular alternative, known for their durability and long-lasting nature. These decals can withstand various weather conditions, making them perfect for outdoor applications such as vehicle branding or storefront displays. Their application process might require surface preparation, and while they offer a professional finish, they can be less customizable than bubble stickers in terms of shape and size. Vinyl decals work best for businesses aiming for a polished look in their branding efforts.

Conclusion: Which Solution Should B2B Buyers Choose?

Choosing the right promotional tool depends on the specific goals and context of your business. If budget and versatility are key considerations, bubble stickers provide an excellent, cost-effective option for casual branding and personal use. For companies looking to make a bold statement, dome stickers can offer a unique visual appeal that stands out. Conversely, businesses needing durability and professional aesthetics may find vinyl decals to be the most suitable choice. Ultimately, evaluating the performance, cost, and application needs will guide B2B buyers in selecting the optimal solution for their branding strategies.

Essential Technical Properties and Trade Terminology for bubble stickers

What Are the Key Technical Properties of Bubble Stickers?

When sourcing bubble stickers for commercial use, understanding the technical properties is crucial for ensuring product quality and performance. Here are some essential specifications to consider:

-

Material Grade

– Bubble stickers are typically made from vinyl or polyester. Vinyl offers durability and resistance to moisture, making it ideal for outdoor applications. Polyester can provide superior clarity and scratch resistance, which is essential for high-quality graphics. Choosing the right material impacts the longevity and visual appeal of the stickers, which is vital for branding efforts. -

Adhesive Type

– The adhesive used in bubble stickers can vary widely. Options include permanent, removable, and repositionable adhesives. Permanent adhesives are ideal for long-term applications, while removable adhesives allow for easy repositioning without leaving residue. Understanding adhesive properties ensures that the stickers perform as intended on various surfaces and in different environments. -

Thickness and Density

– The thickness of bubble stickers typically ranges from 50µ to 100µ. A higher density indicates a more robust sticker that can withstand wear and tear. This specification is important for buyers looking for stickers that will last, especially in high-traffic areas or outdoor settings. -

Finish Type

– Bubble stickers come in various finishes, such as matte, gloss, and holographic. The finish affects not only the aesthetic appeal but also the sticker’s performance in terms of light reflection and durability. Selecting the right finish can enhance brand visibility and consumer engagement. -

Printing Technology

– The method of printing (e.g., digital, screen printing, or offset printing) significantly influences the quality and vibrancy of the colors. Digital printing is often favored for small runs due to its flexibility, while screen printing is ideal for larger batches with consistent quality. Understanding these options helps businesses align their production needs with expected outcomes.

Which Trade Terms Should You Know When Purchasing Bubble Stickers?

Familiarity with industry jargon can facilitate smoother negotiations and purchasing processes. Here are some key terms relevant to bubble stickers:

-

OEM (Original Equipment Manufacturer)

– OEM refers to a company that produces parts or products that are used in another company’s end products. In the context of bubble stickers, buyers may seek OEM partnerships to create custom designs that fit their branding needs without managing the manufacturing process themselves. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for budget management and inventory planning. For bubble stickers, MOQs can vary based on material, printing method, and customization levels, influencing how businesses plan their orders. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and other details about products. When seeking bubble stickers, an RFQ can help businesses compare costs and terms, ensuring they receive competitive pricing and quality assurance. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for ensuring clarity in shipping, insurance, and delivery obligations when sourcing bubble stickers from global suppliers. -

Customs Duties and Tariffs

– These are taxes imposed on goods when they are transported across international borders. Buyers must be aware of potential customs duties and tariffs when importing bubble stickers, as these costs can significantly affect the overall expense of the order. -

Lead Time

– Lead time refers to the period between placing an order and receiving the product. For bubble stickers, this can be influenced by production schedules, shipping methods, and supplier capabilities. Being aware of lead times is essential for effective inventory management and meeting marketing timelines.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing bubble stickers, ensuring they meet their specific business needs while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the bubble stickers Sector

What Are the Key Drivers and Trends in the Global Bubble Stickers Market?

The bubble stickers market is experiencing significant growth, driven by a combination of consumer demand for personalization and the rise of digital marketing strategies. Globally, the trend towards customization is reshaping how brands engage with their audiences, particularly in regions like Africa, South America, the Middle East, and Europe. Businesses are increasingly using bubble stickers for promotional purposes, leveraging their eye-catching designs to enhance brand visibility. In these markets, digital printing technologies are emerging as a game-changer, enabling rapid production and high-quality outputs that cater to specific customer requirements.

Moreover, the popularity of e-commerce platforms has made it easier for international buyers to source bubble stickers from various suppliers, fostering a competitive environment that encourages innovation and cost-effectiveness. Emerging trends in the sector include the use of eco-friendly materials and advanced adhesive technologies, which not only improve the functionality of the stickers but also cater to the growing demand for sustainable products. This evolution aligns with a broader shift towards digital marketing strategies that focus on impactful visual content, making bubble stickers an integral part of modern branding efforts.

Illustrative image related to bubble stickers

How Is Sustainability Influencing the Sourcing of Bubble Stickers?

Sustainability is becoming a critical factor in the sourcing of bubble stickers, reflecting a growing awareness of environmental impacts among consumers and businesses alike. Many B2B buyers are now prioritizing suppliers who demonstrate a commitment to ethical practices and sustainable materials. This shift is particularly pronounced in regions where regulatory frameworks are evolving to encourage environmentally friendly manufacturing processes.

Bubble stickers made from biodegradable or recycled materials are gaining traction, as they meet the demand for products that minimize ecological footprints. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 (Environmental Management) are becoming essential for suppliers to showcase their commitment to sustainability. Additionally, the use of low-VOC (volatile organic compounds) inks and adhesives is increasingly preferred, as these options reduce harmful emissions during production. For international buyers, integrating sustainability into sourcing strategies not only aligns with corporate social responsibility goals but also enhances brand reputation in a market that increasingly values ethical consumption.

What Is the Historical Context of Bubble Stickers in the B2B Space?

The evolution of bubble stickers has been marked by significant technological advancements and changing consumer preferences. Initially, stickers served simple decorative purposes, primarily in the retail sector. However, with the advent of digital printing in the late 20th century, the bubble sticker market underwent a transformation. This technology allowed for mass customization, enabling businesses to create unique designs tailored to specific marketing campaigns.

The rise of social media and digital marketing further propelled the use of bubble stickers as branding tools, particularly among younger demographics. Today, these stickers are not only a form of expression but also a strategic asset for businesses aiming to enhance customer engagement. As the market continues to evolve, understanding this historical context can provide valuable insights for B2B buyers looking to leverage bubble stickers effectively within their marketing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of bubble stickers

-

How can I ensure the quality of bubble stickers from suppliers?

To ensure quality, conduct thorough supplier vetting by requesting samples before placing large orders. Look for suppliers who provide certifications, such as ISO or product safety standards. Additionally, inquire about their production processes and materials used. Establishing clear quality assurance protocols, including visual inspections and testing for durability, can further help you maintain high standards. -

What customization options are available for bubble stickers?

Customization options can vary widely among suppliers. Common choices include size, shape, color, and design elements. Many suppliers offer the ability to print logos or bespoke artwork, while some may provide different finishes, such as matte or gloss. When discussing customization, clearly outline your requirements and ask for mock-ups to ensure the final product meets your expectations. -

What is the typical minimum order quantity (MOQ) for bubble stickers?

MOQs for bubble stickers can differ significantly based on the supplier and the complexity of your order. Generally, you may find MOQs ranging from 50 to several thousand units. It’s advisable to communicate your needs upfront, as some suppliers may accommodate smaller orders for a higher price per unit or offer bulk discounts for larger quantities. -

What payment terms should I expect when sourcing bubble stickers internationally?

Payment terms can vary by supplier and region. Common practices include payment in advance, partial payment upfront with the balance due on delivery, or payment upon receipt of goods. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify the payment terms in your contract to avoid misunderstandings. -

How can I efficiently manage logistics when importing bubble stickers?

Efficient logistics management involves selecting reliable shipping partners and understanding import regulations in your country. Work with suppliers who offer comprehensive shipping options, including express and standard delivery. It’s also crucial to stay informed about customs duties and taxes applicable to your order. Establishing clear communication with your supplier and freight forwarder can help streamline the process. -

What are the most important factors to consider when vetting bubble sticker suppliers?

When vetting suppliers, prioritize factors such as their production capabilities, reputation, and customer reviews. Ensure they have experience in international trade and understand the specific needs of your market. Verify their compliance with industry standards and regulations. Establishing a strong relationship and open communication channels can also facilitate smoother transactions and better service. -

How do I handle quality assurance for bulk orders of bubble stickers?

Implement a quality assurance plan that includes setting clear specifications and standards for the stickers. Prior to mass production, request a pre-production sample to evaluate color accuracy and material quality. During production, consider arranging for third-party inspections to monitor quality and adherence to your requirements. After receiving the shipment, conduct a random inspection to ensure that the delivered products meet your standards. -

What are the best practices for placing an order for bubble stickers internationally?

Start by researching and identifying potential suppliers that align with your needs. Request quotes and compare pricing, lead times, and customization options. Once you select a supplier, clarify all terms, including payment, shipping, and delivery timelines, in a formal contract. Maintain regular communication throughout the process to address any issues promptly and ensure a successful transaction.

Top 6 Bubble Stickers Manufacturers & Suppliers List

1. Fast Printing – Dome Stickers

Domain: fastprinting.com

Registered: 1999 (26 years)

Introduction: Dome (3D) Stickers, also known as 3D stickers, have a dynamic three-dimensional or bubble-like appearance. They are popular for use on machinery, car windows, and special products, providing a unique tactile quality. Suitable for both indoor and outdoor use, they are favored by brands like Westfield and David Jones. Small quantity printing is available. Options for outdoor use include stronger adh…

2. Redbubble – Bubble Stickers

Domain: redbubble.com

Registered: 2004 (21 years)

Introduction: Bubble Stickers for Sale | Redbubble

– Types of Stickers: Holographic, Funny, Car, Bumper, Water Bottle, Cool, Anime, Laptop, Custom

– Price Range: From $1.72 to $3.59

– Key Features: Kiss-cut, vinyl or holographic film, removable without ripping or leaving residue, water-resistant

– Sizes: 4 sizes available

– Color Options: White, transparent, or holographic

– Usage: Suitable for phone cases, lap…

3. The Paper Studio – Iridescent Bubble Stickers

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {‘name’: ‘Iridescent Bubble Stickers’, ‘brand’: ‘The Paper Studio’, ‘SKU’: ‘1987437’, ‘discounted_price’: ‘$1.49’, ‘original_price’: ‘$2.49’, ‘discount’: ‘40% Off’, ‘color’: ‘Clear & AB’, ‘dimensions’: ‘3.94″ x 3.94″‘, ‘smallest_diameter’: ‘5.7mm’, ‘largest_diameter’: ‘9.7mm’, ‘material’: ‘Plastic’, ‘quantity’: ‘1 Sheet (54 Stickers)’, ‘warning’: ‘CHOKING HAZARD: Small Parts. Not for children unde…

4. Target – Bubble Stickers

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Bubble Stickers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Flaticon – Speech Bubble Stickers

Domain: flaticon.com

Registered: 2013 (12 years)

Introduction: Free Speech bubble Stickers, + 450 stickers (SVG, PNG)

6. Etsy – Bubble Stickers

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Bubble Stickers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for bubble stickers

In today’s competitive market, the strategic sourcing of bubble stickers is essential for businesses aiming to enhance brand visibility and customer engagement. By leveraging high-quality materials and innovative designs, companies can differentiate their products and create lasting impressions. Key takeaways include understanding the diverse applications of bubble stickers—from promotional tools to decorative elements—and recognizing the importance of selecting reliable suppliers who can meet specific regional demands.

International buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize partnerships with manufacturers that offer customization options and sustainable practices. As consumer preferences shift towards eco-friendly products, sourcing from vendors who adhere to these principles can not only align with market trends but also enhance brand reputation.

Looking ahead, the bubble sticker market is poised for growth, driven by the increasing demand for personalized and unique branding solutions. Now is the time to explore strategic sourcing opportunities that can provide your business with a competitive edge. Engage with suppliers who understand your local market needs and can deliver innovative solutions tailored to your brand’s vision. Take the next step in elevating your brand identity through strategic sourcing of bubble stickers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to bubble stickers

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.