Adaptor Bolt: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for adaptor bolt

Navigating the complex landscape of the global market for adaptor bolts can be a daunting challenge for international B2B buyers. The need for reliable, high-quality components that bridge the gap between varying standards and specifications is crucial, particularly for industries spanning construction, manufacturing, and engineering. This guide aims to illuminate the diverse types of adaptor bolts available, their specific applications, and the critical factors to consider when sourcing these essential components.

Within these pages, you will find comprehensive insights into the various categories of adaptor bolts, from thread adapters to specialty kits designed for specific bolt diameters. We will also delve into supplier vetting processes, enabling you to make informed decisions that align with your operational needs and quality standards. Cost considerations will be examined to ensure that you not only find the right products but also at competitive prices that fit your budget.

This guide is tailored to empower B2B buyers from Africa, South America, the Middle East, and Europe—regions where sourcing quality components can often be a hurdle. By equipping you with the knowledge to navigate this market effectively, we aim to facilitate smoother procurement processes and enhance your operational efficiency. Join us as we explore the intricate world of adaptor bolts, ensuring your purchasing decisions are strategic, informed, and beneficial for your business growth.

Understanding adaptor bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Thread Adapters | Converts between different thread types (metric and imperial) | Machinery, automotive, electronics | Pros: Versatile, widely used; Cons: May require multiple types for various applications. |

| Bolt Fixing Adapter Kits | Includes multiple adapters for various bolt diameters | Construction, structural testing | Pros: Comprehensive, cost-effective; Cons: Initial investment may be high. |

| Anchor Bolt Adapters | Designed for securing structures, often with extended threads | Civil engineering, infrastructure projects | Pros: Robust, essential for stability; Cons: Limited to specific applications. |

| Screw Thread Adapters | Allows for internal and external threading conversions | Laboratory equipment, optical systems | Pros: Precision fit, customizable; Cons: Complexity in specifications may confuse buyers. |

| Specialty Adapters | Tailored for specific industries or unique applications | Aerospace, automotive racing | Pros: Optimized for performance; Cons: Higher cost, limited availability. |

What Are Thread Adapters and Their Applications?

Thread adapters are crucial for converting between different thread standards, such as metric and imperial sizes. They are commonly used in machinery, automotive applications, and electronics where diverse components must be integrated seamlessly. When purchasing thread adapters, B2B buyers should consider the specific thread types required for their projects, as well as the material quality to ensure durability and performance under stress.

How Do Bolt Fixing Adapter Kits Benefit B2B Buyers?

Bolt fixing adapter kits typically contain a variety of adapters designed to accommodate different bolt diameters, making them ideal for construction and structural testing. These kits streamline the procurement process by providing a comprehensive solution in one package, reducing the need for multiple purchases. Buyers should evaluate the range of adapters included and the compatibility with their existing tools to ensure they meet their operational needs effectively.

Why Are Anchor Bolt Adapters Essential for Construction?

Anchor bolt adapters are specifically designed for securing structures, often featuring extended threads to enhance stability. They are widely used in civil engineering and infrastructure projects, where the integrity of the structure is paramount. B2B buyers should assess the load-bearing capacity and material specifications of these adapters to ensure they align with project requirements and safety standards.

What Role Do Screw Thread Adapters Play in Laboratory Settings?

Screw thread adapters facilitate the connection of laboratory equipment by allowing for internal and external threading conversions. They are particularly valuable in optical systems and precision instrumentation, where exact measurements are critical. When selecting screw thread adapters, buyers should consider the precision of the fit and the materials used, as these factors can significantly impact the performance of sensitive equipment.

How Do Specialty Adapters Cater to Unique Industry Needs?

Specialty adapters are tailored for specific industries, such as aerospace or automotive racing, where performance and reliability are critical. These adapters often feature unique designs optimized for particular applications, providing B2B buyers with advanced solutions that standard products may not offer. However, buyers should be aware of the potentially higher costs and limited availability associated with these specialized components, making thorough market research essential.

Key Industrial Applications of adaptor bolt

| Industry/Sector | Specific Application of adaptor bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Use in anchoring systems for structural integrity | Enhances safety and durability of structures | Quality standards, load capacity, and corrosion resistance |

| Manufacturing | Integration in assembly lines for machinery | Improves efficiency and reduces downtime | Compatibility with existing systems, ease of installation |

| Automotive | Application in vehicle assembly and repairs | Ensures reliability and performance in vehicles | Material specifications, compliance with industry standards |

| Aerospace | Utilization in aircraft assembly and maintenance | Critical for safety and performance optimization | Certification requirements, high strength-to-weight ratio |

| Oil & Gas | Usage in pipeline and rig construction | Supports safe and efficient resource extraction | Resistance to harsh environments, sourcing from certified suppliers |

How are Adaptor Bolts Used in Construction Projects?

In the construction industry, adaptor bolts are essential for anchoring systems that require precise load distribution and structural integrity. They facilitate the connection of various components, such as steel beams and concrete foundations, ensuring that buildings withstand environmental stresses. International buyers must prioritize sourcing bolts that meet specific quality standards, including load capacity and corrosion resistance, to ensure safety and compliance with local regulations.

What Role Do Adaptor Bolts Play in Manufacturing Efficiency?

In manufacturing, adaptor bolts are crucial for integrating machinery and assembly lines. They enable seamless connections between different equipment, which enhances operational efficiency and minimizes downtime during production. Buyers in this sector should focus on compatibility with existing machinery and ease of installation, as these factors can significantly impact overall productivity and cost-effectiveness.

Why Are Adaptor Bolts Vital in the Automotive Industry?

The automotive sector relies heavily on adaptor bolts for both assembly and repair processes. These bolts ensure the reliability and performance of vehicles by securely fastening various components, from engines to chassis. For international buyers, it is essential to consider material specifications and compliance with industry standards to guarantee safety and durability in automotive applications.

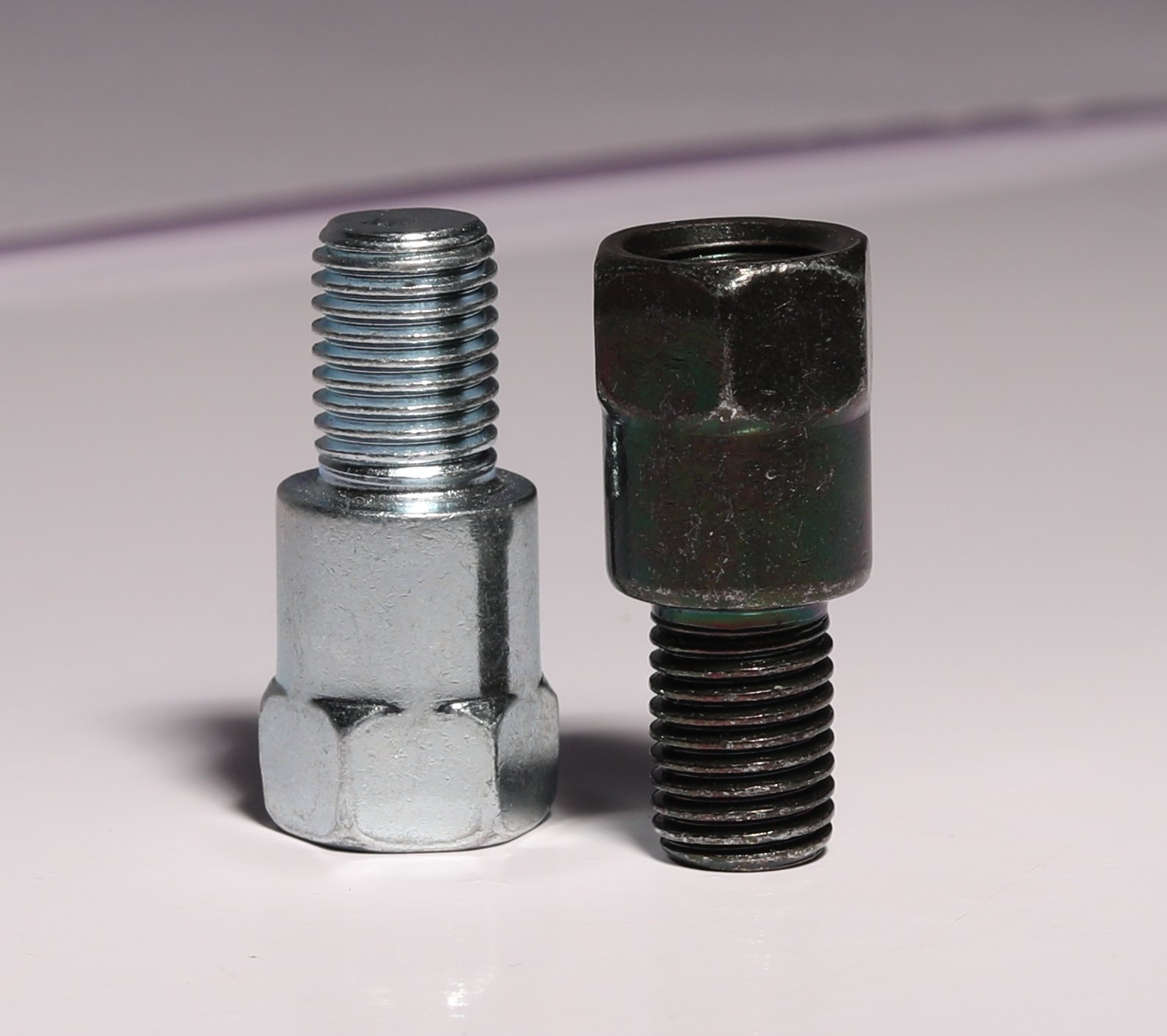

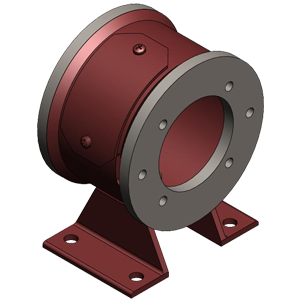

Illustrative image related to adaptor bolt

How Do Adaptor Bolts Contribute to Aerospace Safety?

In the aerospace industry, adaptor bolts are used in the assembly and maintenance of aircraft, where safety and performance are paramount. These bolts must meet stringent certification requirements and possess a high strength-to-weight ratio to withstand the extreme conditions faced during flight. Buyers should ensure that their suppliers are certified and can provide documentation of compliance with aerospace industry standards.

What Are the Key Considerations for Sourcing Adaptor Bolts in Oil & Gas?

The oil and gas industry utilizes adaptor bolts in pipeline and rig construction, where they play a vital role in maintaining safety and efficiency during resource extraction. Given the harsh environments these components operate in, sourcing bolts that offer resistance to corrosion and extreme temperatures is critical. Buyers should look for certified suppliers who can guarantee the reliability and performance of their products under challenging conditions.

3 Common User Pain Points for ‘adaptor bolt’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Adaptor Bolt Size

The Problem: B2B buyers often encounter a significant challenge when sourcing adaptor bolts that meet specific size and thread requirements. For example, a construction company in Brazil may require an adaptor bolt that seamlessly fits into existing machinery but finds that local suppliers only carry standard sizes. This mismatch can lead to costly delays in projects, increased downtime, and the frustration of having to re-engineer components to fit available products.

The Solution: To overcome this issue, it is crucial for buyers to develop a clear understanding of their specifications before sourcing adaptor bolts. This involves conducting a thorough inventory of existing equipment and its thread sizes. Buyers should then reach out to suppliers who specialize in custom solutions or have a wide range of products. Utilizing online platforms that aggregate multiple suppliers can also help identify manufacturers who offer the specific sizes needed. Finally, consider forming long-term relationships with suppliers who can provide ongoing support and a reliable supply of the necessary adaptor bolts.

Scenario 2: Compatibility Issues with Different Materials

The Problem: A common pain point for B2B buyers is the compatibility of adaptor bolts with various materials in their applications. For instance, a company in South Africa might need to connect steel structural components with aluminum fixtures. Using the wrong adaptor bolt can lead to galvanic corrosion, compromising the integrity of the assembly and leading to expensive repairs or replacements.

The Solution: To address material compatibility issues, buyers should prioritize sourcing adaptor bolts made from materials that are suitable for their specific applications. This involves consulting with manufacturers about the properties of different materials, such as stainless steel, brass, or titanium. Buyers should also inquire about protective coatings that can mitigate corrosion risks. Implementing a detailed material specification document for all components can assist in selecting the right adaptor bolts and prevent costly errors.

Scenario 3: Inadequate Technical Support and Documentation

The Problem: Many B2B buyers face challenges related to inadequate technical support and documentation when purchasing adaptor bolts. A buyer from a manufacturing plant in Europe may find that the technical specifications and installation guidelines provided with the adaptor bolts are insufficient, leading to improper installation and potential operational failures. This scenario can not only impact productivity but also create safety hazards.

The Solution: To mitigate this risk, buyers should prioritize suppliers that offer comprehensive technical support and detailed documentation. Before making a purchase, it’s beneficial to request product datasheets, installation manuals, and even training sessions for staff. Engaging with suppliers who have a strong customer support system can ensure that all questions are answered promptly. Additionally, participating in industry forums or user groups can provide valuable insights from other users who have navigated similar challenges, ultimately enhancing the buyer’s knowledge and confidence in using adaptor bolts effectively.

Strategic Material Selection Guide for adaptor bolt

What Are the Key Properties of Common Materials Used for Adaptor Bolts?

When selecting materials for adaptor bolts, it is essential to consider their properties as they directly affect performance in various applications. Here, we analyze four common materials: stainless steel, carbon steel, titanium, and aluminum. Each material has unique characteristics that cater to different operational requirements.

How Does Stainless Steel Perform in Adaptor Bolt Applications?

Stainless steel is renowned for its excellent corrosion resistance and strength, making it a popular choice for adaptor bolts. It can withstand high temperatures and pressures, which is critical in industrial applications. The most commonly used grades, such as 304 and 316, offer varying levels of resistance to corrosive environments, with 316 being preferable for marine or chemical applications.

Pros: Durable and resistant to rust and corrosion, stainless steel is easy to machine and can be finished to a high standard. It is suitable for a wide range of applications, including food processing and pharmaceuticals.

Cons: The higher cost compared to carbon steel can be a limiting factor for budget-sensitive projects. Additionally, while it is strong, it may not be as robust as titanium in extreme conditions.

Impact on Application: Stainless steel is compatible with various media, including water, oils, and chemicals, making it versatile for international buyers. Compliance with standards like ASTM A240 is crucial for ensuring quality.

What Advantages Does Carbon Steel Offer for Adaptor Bolts?

Carbon steel is another widely used material for adaptor bolts, especially in construction and heavy machinery. It is known for its high strength and toughness, making it suitable for applications that require load-bearing capabilities.

Pros: Carbon steel is generally more cost-effective than stainless steel and offers good durability. It can be treated with coatings to enhance corrosion resistance, making it adaptable for different environments.

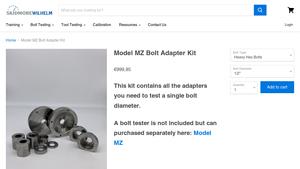

Illustrative image related to adaptor bolt

Cons: While it is strong, carbon steel is susceptible to rust and corrosion if not properly coated or maintained. This limitation can affect its longevity in harsh environments.

Impact on Application: Carbon steel is often preferred in regions where budget constraints are significant, such as in parts of Africa and South America. Buyers should ensure compliance with standards like ASTM A307 and be aware of the need for protective coatings.

Why Choose Titanium for Adaptor Bolts?

Titanium is a premium material known for its exceptional strength-to-weight ratio and corrosion resistance. It is particularly advantageous in aerospace and high-performance applications where weight savings are critical.

Pros: Titanium is lightweight yet incredibly strong, making it ideal for applications where reducing weight is essential. Its resistance to corrosion in harsh environments is superior to that of stainless steel.

Cons: The primary drawback of titanium is its high cost and manufacturing complexity. Machining titanium requires specialized tools and techniques, which can increase production time and costs.

Impact on Application: Titanium’s compatibility with aggressive media, such as saltwater and certain chemicals, makes it suitable for specialized applications in industries like aerospace and marine. International buyers must consider compliance with ASTM B348 and other relevant standards.

How Does Aluminum Compare for Adaptor Bolt Usage?

Aluminum is a lightweight and versatile material used in various applications, including automotive and consumer products. Its low density and good corrosion resistance make it a popular choice for applications where weight is a concern.

Pros: Aluminum is easy to machine and can be anodized for enhanced corrosion resistance. Its lightweight nature allows for cost savings in shipping and handling.

Cons: While aluminum is resistant to corrosion, it is not as strong as steel or titanium, limiting its use in high-load applications. It can also be more expensive than carbon steel.

Impact on Application: Aluminum is often favored in industries that prioritize weight reduction, such as automotive and aerospace. Compliance with standards like ASTM B211 is essential for ensuring quality and performance.

Summary Table of Material Selection for Adaptor Bolts

| Material | Typical Use Case for adaptor bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost than carbon steel | High |

| Carbon Steel | Construction, heavy machinery | Cost-effective and durable | Susceptible to rust without coatings | Low |

| Titanium | Aerospace, marine applications | Superior strength-to-weight ratio | High cost and complex machining | High |

| Aluminum | Automotive, consumer products | Lightweight and easy to machine | Lower strength compared to steel | Medium |

This strategic material selection guide provides insights into the properties, advantages, and limitations of various materials for adaptor bolts, aiding international B2B buyers in making informed decisions based on their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for adaptor bolt

What Are the Key Stages in the Manufacturing Process of Adaptor Bolts?

The manufacturing process of adaptor bolts involves several critical stages, each essential for ensuring the final product meets the necessary specifications and quality standards.

Illustrative image related to adaptor bolt

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage in the manufacturing of adaptor bolts is material preparation. Typically, high-grade metals such as stainless steel, carbon steel, or titanium are selected based on the intended application and required strength. The material is then cut into appropriate sizes using methods such as laser cutting or water jet cutting, ensuring precision and minimal waste. This stage may also include heat treatment processes to enhance the mechanical properties of the materials, such as hardness and tensile strength.

Forming: How Are Adaptor Bolts Shaped and Assembled?

Following material preparation, the forming stage shapes the raw materials into the desired configurations. This can involve several techniques, including:

- Machining: Using CNC (Computer Numerical Control) machines to achieve high precision in dimensions and tolerances.

- Forging: Applying compressive forces to shape the metal, which improves its grain structure and overall strength.

- Casting: Pouring molten metal into molds to create complex shapes that would be difficult to achieve with machining alone.

Once the individual components are formed, they are assembled into the final adaptor bolt configuration. This may involve threading, welding, or other joining techniques, depending on the design specifications.

Finishing: What Surface Treatments Are Applied to Ensure Quality?

The finishing stage is crucial for both aesthetic and functional purposes. Common finishing processes for adaptor bolts include:

- Plating: Applying a coating, such as zinc or nickel, to enhance corrosion resistance.

- Anodizing: Used mainly for aluminum components to increase surface durability.

- Polishing: Improving surface smoothness to reduce friction and enhance appearance.

These processes not only contribute to the longevity of the adaptor bolts but also ensure that they meet specific industry standards.

What Are the Quality Assurance Practices for Adaptor Bolts?

Quality assurance (QA) in the manufacturing of adaptor bolts is vital for ensuring that products meet the required specifications and standards.

What International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 are fundamental in ensuring consistent quality management systems across manufacturing processes. Additionally, industry-specific certifications like CE for European markets and API (American Petroleum Institute) standards for oil and gas applications are crucial for buyers to consider. These certifications indicate that the products have been manufactured in compliance with recognized quality benchmarks.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Inspecting raw materials for compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): Conducting inspections during various stages of manufacturing to identify and rectify issues early.

- Final Quality Control (FQC): Performing comprehensive tests on finished products to ensure they meet all specifications and standards.

Common testing methods include tensile testing, fatigue testing, and dimensional inspections, which are essential for verifying the mechanical properties and dimensions of the adaptor bolts.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial to ensure that they receive high-quality products.

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality assurance reports from suppliers, which outline the processes, methodologies, and results of their QC checks. Supplier audits, whether conducted by the buyer or third-party organizations, can provide insights into the supplier’s adherence to quality standards and their overall manufacturing capabilities.

How Can Third-Party Inspections Enhance Supplier Transparency?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct thorough inspections and testing, providing unbiased reports on product quality. This is particularly important for buyers who may not have the capacity to conduct on-site inspections themselves.

Illustrative image related to adaptor bolt

What Are the Specific Quality Control Nuances for International Buyers?

International buyers must be aware of specific quality control nuances that can impact the purchasing process. For example, variations in certification requirements between countries can affect the acceptance of products in different markets. Additionally, understanding local regulations regarding imports can help prevent compliance issues.

Furthermore, it’s essential for buyers to communicate their specific quality requirements clearly to suppliers to avoid misunderstandings and ensure that the final products meet all expectations.

Conclusion

Understanding the manufacturing processes and quality assurance practices for adaptor bolts is crucial for B2B buyers looking to procure high-quality products. By focusing on the various stages of manufacturing, relevant international standards, and effective verification methods, buyers can make informed decisions and establish successful partnerships with suppliers. As the global market continues to evolve, ensuring quality and compliance will remain paramount for businesses across all regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘adaptor bolt’

In the competitive world of B2B procurement, sourcing the right adaptor bolts is crucial for ensuring compatibility and functionality in various applications. This guide provides a step-by-step checklist to help international buyers navigate the procurement process effectively, ensuring they secure high-quality products that meet their specific needs.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the foundation of successful sourcing. Specify the type of adaptor bolt you need, including dimensions, thread types (metric or imperial), and material (such as stainless steel or titanium). This clarity will guide your search and help potential suppliers provide accurate quotes.

- Thread Compatibility: Identify the thread sizes you need to adapt to ensure that you can match the correct components.

- Load Requirements: Consider the load and stress the adaptor bolt will encounter in its application, which affects material choice.

Step 2: Research Potential Suppliers

A comprehensive supplier search can save time and prevent costly mistakes. Look for manufacturers or distributors with a solid reputation in the industry and expertise in producing adaptor bolts.

- Industry Experience: Prioritize suppliers who have experience in your specific industry, as they are more likely to understand your unique needs.

- Product Range: Ensure the supplier offers a variety of adaptor bolts to meet different specifications, which can be beneficial for future projects.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify that they meet relevant industry standards and certifications. This step is critical for ensuring product quality and compliance with safety regulations.

- ISO Certification: Check if the supplier holds ISO certifications, which indicate adherence to international quality management standards.

- Material Certifications: Request certificates for the materials used, especially if your application involves stringent safety requirements.

Step 4: Request Samples for Testing

Obtaining samples is a vital step to ensure that the adaptor bolts meet your technical specifications and quality standards. Testing samples can reveal potential issues before a larger order is placed.

- Fit and Functionality: Assess how well the samples fit with your existing components and whether they perform under expected loads.

- Quality Assessment: Inspect the finish, threading, and overall construction quality to ensure they meet your standards.

Step 5: Negotiate Pricing and Terms

Once you have identified a reliable supplier, engage in negotiations to secure favorable pricing and payment terms. Understanding the cost structure is essential for budget management.

- Bulk Discounts: Inquire about discounts for larger orders, which can lead to significant cost savings.

- Payment Terms: Discuss payment options, including deposits and credit terms, to ensure they align with your financial strategies.

Step 6: Confirm Shipping and Delivery Details

Clarifying shipping methods and delivery timelines is crucial to maintaining project schedules. Ensure that the supplier can meet your logistical requirements.

Illustrative image related to adaptor bolt

- Shipping Options: Evaluate the shipping methods offered, considering factors such as cost, speed, and reliability.

- Lead Times: Confirm lead times for production and delivery to avoid delays in your project timelines.

Step 7: Establish a Long-Term Relationship

Building a strong relationship with your supplier can lead to better collaboration and support in the future. Consider establishing a partnership that benefits both parties.

- Regular Communication: Maintain open lines of communication for ongoing support and to address any future needs.

- Feedback Loop: Provide feedback on product performance to help the supplier improve and tailor their offerings to better suit your requirements.

By following this checklist, B2B buyers can navigate the complexities of sourcing adaptor bolts, ensuring they make informed decisions that enhance their operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for adaptor bolt Sourcing

What Are the Key Cost Components in Adaptor Bolt Manufacturing?

When sourcing adaptor bolts, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly affects the cost. Common materials include stainless steel, titanium, and carbon steel. Stainless steel is favored for its corrosion resistance, while titanium offers superior strength-to-weight ratios. Prices can vary based on market fluctuations and material grades.

-

Labor: Labor costs encompass wages for skilled workers involved in production, assembly, and quality control. Higher labor costs may be associated with regions where skilled manufacturing labor is scarce or where labor laws impose higher wages.

-

Manufacturing Overhead: This includes indirect costs associated with the production process, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Custom tooling for specific adaptor designs can be a significant upfront cost. The complexity of the design will dictate the tooling investment required.

-

Quality Control (QC): Ensuring that each adaptor meets strict quality standards involves costs related to testing and inspection. This is particularly important for industries requiring certifications, such as aerospace and automotive.

-

Logistics: Shipping costs can vary significantly based on the distance from the manufacturer to the buyer, as well as the shipping method. Import duties and taxes should also be factored into the logistics cost.

-

Margin: Suppliers typically apply a markup to cover their costs and generate profit. Understanding the margin expectations of suppliers can aid in negotiating better pricing.

What Factors Influence Pricing of Adaptor Bolts?

Several factors play a critical role in determining the price of adaptor bolts:

-

Volume/MOQ: Bulk orders often attract lower per-unit prices due to economies of scale. Buyers should consider negotiating minimum order quantities (MOQs) that align with their needs.

-

Specifications and Customization: Custom-designed adaptors will generally be priced higher than standard products. Providing detailed specifications can help suppliers offer more accurate quotes.

-

Material Selection: The choice of materials not only impacts the cost but also the performance characteristics of the adaptor bolts. Higher-quality materials can lead to increased costs but may also reduce long-term maintenance expenses.

-

Quality and Certifications: Adaptor bolts used in critical applications often require certifications (e.g., ISO, ASTM). Products with these certifications may come at a premium, reflecting the additional testing and compliance processes.

-

Supplier Factors: Supplier reputation, production capabilities, and location can influence pricing. Established suppliers with proven track records may command higher prices due to their reliability and quality assurance.

-

Incoterms: The terms of shipping (Incoterms) can significantly affect the total cost. Understanding who is responsible for shipping, insurance, and duties can aid in calculating the total landed cost.

What Are Effective Negotiation and Cost-Efficiency Strategies for B2B Buyers?

For B2B buyers, particularly in diverse regions like Africa, South America, the Middle East, and Europe, strategic negotiation and cost efficiency are essential:

-

Leverage Volume Discounts: Whenever possible, consolidate orders to meet higher MOQ thresholds. This can lead to significant cost savings.

-

Assess Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes installation, maintenance, and potential downtime costs. Lower-priced adaptors might lead to higher long-term costs if they require frequent replacements.

-

Request Multiple Quotes: Engaging with several suppliers can provide valuable insights into market pricing and help identify competitive offers.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, delivery schedules, and other conditions that can provide more flexibility and potentially lower costs.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and access to exclusive products.

-

Stay Informed: Keep abreast of market trends, material costs, and industry standards to make informed decisions and negotiate effectively.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on specific supplier agreements, market conditions, and geographical factors. Always consult directly with suppliers for the most accurate and updated pricing information.

Alternatives Analysis: Comparing adaptor bolt With Other Solutions

Exploring Alternatives to Adaptor Bolts: What Are Your Options?

When it comes to securing components in machinery, construction, or various assembly applications, the adaptor bolt is a widely recognized solution. However, several alternatives exist that may suit specific needs or constraints better. In this section, we will compare the adaptor bolt against two viable alternatives: Threaded Inserts and Mechanical Fasteners. Each option has its unique advantages and disadvantages that can significantly affect performance and overall project outcomes.

Comparison Table

| Comparison Aspect | Adaptor Bolt | Threaded Inserts | Mechanical Fasteners |

|---|---|---|---|

| Performance | High tensile strength; versatile for various applications | Good for permanent fixtures but may weaken over time | Reliable for quick assembly; strength varies by type |

| Cost | Moderate initial cost; cost-effective for large-scale use | Low initial cost; may require specialized installation tools | Generally low-cost; can add up if multiple types are needed |

| Ease of Implementation | Simple installation; requires standard tools | Installation can be complex; may need additional tools | Easy to implement; requires minimal tools |

| Maintenance | Low maintenance; durable under various conditions | May require replacement if stripped or damaged | Generally low, but can require periodic checks |

| Best Use Case | Ideal for temporary or adjustable connections | Best for permanent installations in wood or composite materials | Suitable for quick assembly and disassembly in various applications |

Detailed Breakdown of Alternatives

What Are Threaded Inserts, and When Should You Use Them?

Threaded inserts are cylindrical metal or plastic inserts that provide a strong threaded hole in softer materials like wood or plastic. They are ideal for applications requiring permanent fixtures, such as furniture or cabinetry. While their installation may be complex, they offer excellent load-bearing capabilities. However, if the insert becomes stripped, it can necessitate replacement, potentially increasing long-term costs.

How Do Mechanical Fasteners Compare to Adaptor Bolts?

Mechanical fasteners, including screws, nuts, and bolts, are versatile and widely used in various applications. They excel in situations requiring quick assembly and disassembly. Mechanical fasteners are generally cost-effective; however, their strength can vary based on type and material. They are easy to implement but may require periodic checks to ensure tightness, especially in high-vibration environments.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right fastening solution depends on your specific application requirements, including load capacity, installation complexity, and maintenance considerations. Adaptor bolts are advantageous for their versatility and strength, making them suitable for various temporary or adjustable connections. In contrast, threaded inserts may be preferable for permanent installations, while mechanical fasteners are ideal for projects requiring rapid assembly. By evaluating these factors, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for adaptor bolt

What Are the Key Technical Properties of Adaptor Bolts?

When sourcing adaptor bolts, understanding their technical properties is essential for ensuring compatibility and performance in various applications. Here are some critical specifications to consider:

1. Material Grade

The material grade of an adaptor bolt indicates its strength and durability. Common materials include stainless steel, carbon steel, and titanium. Stainless steel is preferred for its corrosion resistance, making it suitable for outdoor or harsh environments, while carbon steel offers high strength at a lower cost. For specialized applications, titanium provides excellent strength-to-weight ratios. Selecting the appropriate material is crucial for meeting industry standards and ensuring longevity.

2. Thread Type and Size

Adaptor bolts come with different thread types (e.g., metric or imperial) and sizes (e.g., M6, M8, 1/4″-20). The thread specifications affect how well the bolt will fit into existing components. Ensuring the correct thread type and size is vital for avoiding mechanical failures and ensuring ease of installation. This is particularly important in industries like construction and manufacturing, where misfits can lead to costly delays.

3. Tolerance

Tolerance refers to the permissible limit of variation in the bolt’s dimensions, particularly in its diameter and length. Tight tolerances are critical in precision applications, such as in machinery or structural supports, where even minor deviations can impact performance. Understanding the required tolerance level helps in selecting the right adaptor bolt for specific applications, ensuring safety and reliability.

4. Load Capacity

The load capacity of an adaptor bolt indicates the maximum weight it can support without failure. This specification is crucial for applications involving heavy machinery or structural components. Knowing the load capacity helps buyers ensure that the selected adaptor bolts can handle the operational demands of their specific use cases, preventing accidents or equipment failures.

5. Coating and Finish

The coating and finish of an adaptor bolt affect its resistance to corrosion, wear, and environmental conditions. Common finishes include zinc plating, black oxide, and passivation. A suitable coating can enhance the lifespan of the bolt, particularly in harsh environments. Buyers should consider the operating conditions to select the appropriate finish that will protect their investment.

6. Length and Head Style

The length and head style of an adaptor bolt can influence its compatibility with various components. Different head styles (e.g., hex, socket) offer various installation methods and aesthetic considerations. Ensuring the right length and head style can facilitate easier assembly and maintenance, which is essential for operational efficiency.

What Are Common Trade Terms Related to Adaptor Bolts?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms related to adaptor bolts:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for buyers who need adaptor bolts that meet specific standards required by original equipment.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is significant for international buyers, as it can impact inventory costs and supply chain management. Buyers should inquire about MOQs to ensure they can meet their project needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific quantities and specifications of products. This term is critical for B2B buyers seeking competitive pricing and better negotiation terms on adaptor bolts.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping contracts. Understanding these terms is crucial for international buyers to ensure clarity on shipping costs, risk transfer, and delivery responsibilities.

5. Certification

Certification refers to the documentation that verifies a product meets specific industry standards or regulations. For adaptor bolts, certifications can include ISO standards or material certifications, which provide assurance of quality and compliance to buyers.

Illustrative image related to adaptor bolt

6. Lead Time

Lead time is the period between placing an order and receiving the products. This term is vital for planning and project timelines, especially for buyers in industries where timing is critical. Understanding lead times helps in managing inventory and ensuring projects remain on schedule.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing adaptor bolts, ultimately enhancing operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the adaptor bolt Sector

What Are the Key Market Trends Affecting the Adaptor Bolt Sector?

The adaptor bolt market is currently experiencing significant shifts driven by global demand for versatility in fastening solutions. As industries become increasingly interconnected, the need for adaptable components that can accommodate various specifications is paramount. This trend is particularly pronounced among international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, where infrastructure projects and industrial applications are on the rise. The integration of advanced manufacturing technologies, such as 3D printing and automation, is also reshaping sourcing strategies. Buyers are now looking for suppliers who can offer custom solutions with quick turnaround times, reflecting a move towards just-in-time inventory practices.

Moreover, sustainability is becoming a critical factor in procurement decisions. Many companies are prioritizing suppliers who demonstrate a commitment to environmentally friendly practices, including the use of recycled materials in production. This is especially relevant for industries focused on reducing their carbon footprint. The rise of digital platforms for sourcing is another noteworthy trend, enabling buyers to compare products and suppliers more efficiently, thus enhancing their purchasing decisions.

How Is Sustainability Impacting the Sourcing of Adaptor Bolts?

Sustainability and ethical sourcing are increasingly influencing the decision-making processes of B2B buyers in the adaptor bolt sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. As a result, companies are seeking suppliers who can provide eco-friendly alternatives, such as bolts made from recycled metals or those that meet stringent green certifications.

Incorporating sustainable practices not only benefits the environment but can also enhance a company’s brand reputation. Buyers are increasingly interested in transparency regarding the supply chain, favoring manufacturers who can trace their materials back to responsible sources. This trend is particularly relevant for industries operating under regulatory frameworks that demand accountability in sourcing. Furthermore, adopting sustainable materials can lead to cost savings in the long run, as they often reduce waste and energy consumption during production.

What Is the Historical Context of Adaptor Bolts in B2B Sourcing?

The evolution of adaptor bolts has been marked by advancements in engineering and manufacturing techniques. Initially, these components were relatively simple, designed primarily for specific applications. However, as industries expanded and diversified, the need for more versatile fastening solutions became apparent. The introduction of metric and imperial standards further complicated the landscape, leading to the development of various adaptor designs to accommodate differing specifications.

In the late 20th century, the growth of global supply chains transformed the adaptor bolt market. Manufacturers began to focus on producing a wider range of products to meet the demands of international buyers. This shift was accompanied by the rise of digital tools that facilitated better communication and logistics, allowing suppliers to cater to a broader audience. Today, the adaptor bolt sector continues to evolve, driven by technological advancements and a growing emphasis on sustainability and ethical sourcing practices.

Frequently Asked Questions (FAQs) for B2B Buyers of adaptor bolt

-

How do I choose the right adaptor bolt for my application?

Selecting the appropriate adaptor bolt involves understanding your specific application requirements, including the load capacity, environmental conditions, and the materials involved. Start by identifying the bolt diameter and thread type needed for your equipment. Consider the tensile strength and corrosion resistance of the adaptor bolt material, especially if it will be used in harsh environments. Consulting with suppliers who specialize in adaptor bolts can provide insights into the best options tailored to your needs. -

What is the best way to verify the quality of adaptor bolts from suppliers?

To ensure the quality of adaptor bolts, request certifications and test reports from suppliers, such as ISO 9001 or ASTM standards. Conducting a supplier audit can also be beneficial; this involves visiting the production facilities to evaluate their manufacturing processes and quality control measures. Additionally, consider sourcing samples for testing prior to bulk purchases to confirm that the products meet your specifications. -

What customization options are available for adaptor bolts?

Many manufacturers offer customization options for adaptor bolts, including specific thread sizes, lengths, materials, and coatings. When contacting suppliers, clearly outline your requirements and ask about their capabilities for customization. Some suppliers may also provide design assistance to ensure that the adaptor bolts are suitable for your unique applications. Be aware that customized orders may have longer lead times and higher minimum order quantities (MOQs). -

What are the typical minimum order quantities (MOQs) for adaptor bolts?

MOQs for adaptor bolts can vary significantly based on the supplier and the complexity of the product. Generally, standard items may have lower MOQs, while custom designs typically require larger orders. It’s advisable to discuss your needs with potential suppliers to understand their specific MOQs and see if they can accommodate smaller orders, especially if you are testing a new product or entering a new market. -

How do international shipping and logistics work for adaptor bolts?

When sourcing adaptor bolts internationally, it’s crucial to understand the shipping terms and logistics involved. Coordinate with suppliers to determine the best shipping methods, which can include air freight for faster delivery or sea freight for larger orders. Also, consider customs duties and regulations in your country, as these can impact costs and delivery times. Working with a logistics partner experienced in international trade can simplify the process and ensure compliance with all necessary regulations. -

What payment terms are typically offered for international B2B orders?

Payment terms for international B2B orders can vary widely. Common options include advance payment, letters of credit, and payment upon delivery. It’s essential to discuss and negotiate terms with your supplier before finalizing an order. Some suppliers may offer discounts for early payment or flexible terms based on your business relationship. Always ensure that the payment method chosen provides adequate security for both parties involved. -

How can I ensure timely delivery of adaptor bolts?

To ensure timely delivery of adaptor bolts, establish clear timelines with your supplier during the ordering process. Regularly communicate to confirm production schedules and shipping dates. Consider placing orders well in advance of your project deadlines to account for any unforeseen delays, such as customs clearance or production issues. Additionally, tracking shipments and maintaining an open line of communication with your logistics provider can help you stay informed throughout the delivery process. -

What are the best practices for supplier vetting when sourcing adaptor bolts?

When vetting suppliers for adaptor bolts, start by researching their reputation in the industry. Look for reviews and testimonials from other clients, and consider their experience in producing the specific type of adaptor bolt you need. Request references and follow up with them to gauge satisfaction levels. Additionally, assess the supplier’s financial stability and production capabilities to ensure they can meet your demands consistently. A thorough vetting process reduces risks and fosters a reliable business partnership.

Top 6 Adaptor Bolt Manufacturers & Suppliers List

1. McMaster – Bolt Adapters

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Bolt Adapters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Skidmore-Wilhelm – MZ Bolt Adapter Kit

Domain: skidmore-wilhelm.com

Registered: 2001 (24 years)

Introduction: Model: MZ Bolt Adapter Kit

Price: $1,160.00 (for various bolt sizes)

Available Bolt Sizes: 1/2″, 3/4″, 5/8″, 7/8″, 1″, 1 1/8″, 1 1/4″

Includes: All adapters needed to test a single bolt diameter

Note: Bolt tester not included, available for separate purchase.

3. Slingshot Sports – Hover Glide M6 Bolt Adaptor

Domain: slingshotsports.com

Registered: 2005 (20 years)

Introduction: {“name”:”Hover Glide M6 Bolt Adaptor (Set of 2)”,”sku”:”18711023″,”price”:”6.39″,”compare_at_price”:”8.88″,”save”:”2.49″,”weight”:”45 grams”,”package_includes”:”Set of 2 Titanium M6 Adapters”,”availability”:”In stock, ready to ship”}

4. NDT James – Bolt Fixing Adapter Kit

Domain: ndtjames.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “Bolt Fixing Adapter Kit”, “price”: “$455.00”, “product_code”: “P-C-7216”, “category”: “Accessory for Anchor Test System”, “related_categories”: [“Strength Testing > Pullqit Test”]}

5. Thorlabs – Screw Thread Adapters

Domain: thorlabs.com

Registered: 1995 (30 years)

Introduction: Screw Thread Adapters: Available in imperial, metric, and imperial-metric sizes. Thread sizes include M3, M4, M6, 4-40, 6-32, 8-32, and 1/4″-20. Types include internal-to-external, external-to-external, and internal-to-internal adapters. Counterbore adapters convert counterbores to threaded holes. Made from 303 stainless steel. Thread adapter kits available in both imperial and metric, packaged in…

6. All Fasteners – Step Bolt Adapter Assembly

Domain: allfasteners.com

Registered: 2002 (23 years)

Introduction: Step Bolt Adapter Assembly, SKU: 2RCNGM000.1A, Availability: In Stock, Price: $0.00 each, Size: M20 x 3/4 x 2-1/2, Patented Product #9683593, Made in the USA, High Grade Steel, 2H Nut used as Jam Nut, Magni Finish, Tested to Exceed 4-to-1 Safety Rating, Eliminates Welding on Step Bolts, Quick and Simple Installation Process for Tower Modifications.

Strategic Sourcing Conclusion and Outlook for adaptor bolt

What Are the Key Benefits of Strategic Sourcing for Adaptor Bolts?

In conclusion, the strategic sourcing of adaptor bolts presents a valuable opportunity for international B2B buyers to enhance their operations across diverse industries. By leveraging a global supply chain, businesses can access high-quality products tailored to their specific requirements, whether for construction, manufacturing, or specialized applications. Effective sourcing strategies not only streamline procurement processes but also foster strong supplier relationships, ultimately leading to cost savings and improved product availability.

How Can International Buyers Position Themselves for Future Growth?

As we look ahead, the demand for adaptable and versatile components like adaptor bolts will continue to rise, driven by innovation and the need for efficient assembly solutions. International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should actively engage with suppliers who demonstrate a commitment to quality, sustainability, and technological advancement. By staying informed about market trends and emerging technologies, businesses can ensure they remain competitive and responsive to changing customer needs.

What Steps Should You Take to Secure the Best Adaptor Bolt Solutions?

Investing in strategic sourcing now will equip your organization with the tools necessary to navigate future challenges effectively. Consider establishing partnerships with reliable manufacturers and exploring bulk purchasing options to maximize your procurement efficiency. By prioritizing strategic sourcing, you position your business not only to meet current demands but also to thrive in the evolving global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to adaptor bolt

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.