Is Your Cowl Bolts Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for cowl bolts

In today’s global marketplace, sourcing high-quality cowl bolts poses a significant challenge for international B2B buyers. These essential components are crucial for securing vehicle hoods, firewalls, and cowl areas in various automotive applications. However, navigating the complexities of sourcing cowl bolts—ranging from understanding specifications to identifying reliable suppliers—can be daunting, particularly for businesses operating in diverse regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Saudi Arabia.

This comprehensive guide aims to empower B2B buyers by providing detailed insights into the types of cowl bolts available, their specific applications, and the intricacies of supplier vetting. We will cover essential factors such as material quality, sizing standards, and industry compliance, enabling buyers to make informed decisions that align with their operational needs. Furthermore, the guide addresses cost considerations, shipping logistics, and best practices for ensuring product reliability and performance.

By equipping buyers with actionable knowledge and a clear understanding of the global cowl bolt market, this guide not only enhances purchasing strategies but also fosters long-term partnerships with suppliers. Whether you are a buyer in the automotive industry or a restoration enthusiast, understanding the nuances of cowl bolts can lead to improved product integrity and customer satisfaction.

Understanding cowl bolts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Bolts | Corrosion-resistant, strong, and durable | Automotive, marine, heavy machinery | Pros: Long lifespan; Cons: Higher cost compared to standard bolts. |

| Metric Cowl Bolts | Standardized sizes (e.g., M6, M8) for global compatibility | Automotive manufacturing, restoration | Pros: Easy to source internationally; Cons: May require specific tools for installation. |

| Security Bolts | Designed to prevent tampering, often with unique heads | High-security applications in automotive | Pros: Enhanced security; Cons: Limited availability and higher price. |

| Race Cowl Latches | Designed for high-performance applications, weather-resistant | Racing, marine applications | Pros: High durability under stress; Cons: Specific to racing contexts, may not suit general use. |

| Plastic Cowl Anchors | Lightweight, often used in non-load-bearing applications | Automotive assembly, lightweight structures | Pros: Cost-effective; Cons: Less durable than metal options. |

What are the Characteristics of Stainless Steel Cowl Bolts?

Stainless steel bolts are favored in various industries due to their resistance to corrosion and high tensile strength. These bolts are ideal for environments exposed to moisture, such as marine applications and automotive sectors. When purchasing stainless steel cowl bolts, buyers should consider the grade of stainless steel, as higher grades provide better resistance to rust and wear, ensuring longevity. However, they come at a premium price compared to standard bolts, which can impact overall project budgets.

How Do Metric Cowl Bolts Facilitate International Trade?

Metric cowl bolts, defined by standardized sizes like M6 and M8, are crucial for international B2B transactions. Their widespread use across different regions simplifies sourcing and inventory management for manufacturers and retailers. Buyers should ensure they have the appropriate tools for installation, as metric sizes may not be compatible with standard imperial tools. This compatibility can streamline production processes and reduce the risk of delays in assembly.

What Advantages Do Security Bolts Offer to Buyers?

Security bolts are engineered to deter tampering and unauthorized access, making them ideal for applications where safety and security are paramount. These bolts typically feature unique heads that require specialized tools for installation and removal. While they provide enhanced protection for automotive components, their higher cost and limited availability can be a drawback for some buyers. Companies must weigh the importance of security against budget constraints when considering these products.

In What Scenarios Are Race Cowl Latches Most Suitable?

Race cowl latches are specifically designed for high-performance environments, such as motorsports and marine racing. They are constructed to withstand extreme conditions, including high speeds and rough waters, and are often made from weather-resistant materials. Buyers in these sectors should focus on the latch’s ability to absorb vibrations and maintain a secure fit during rigorous activities. However, these latches may not be suitable for general automotive applications, limiting their market appeal.

Why Are Plastic Cowl Anchors Used in Lightweight Applications?

Plastic cowl anchors are a cost-effective solution for non-load-bearing applications, commonly found in automotive assembly and lightweight structural uses. Their lightweight nature makes them easy to handle and install, reducing labor costs. However, buyers should be cautious about their durability, as plastic anchors may not withstand heavy stress or environmental factors as well as metal alternatives. Companies must assess the specific requirements of their projects to determine if plastic options are viable.

Key Industrial Applications of cowl bolts

| Industry/Sector | Specific Application of cowl bolts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Securing hoods and firewalls in vehicle assembly | Ensures structural integrity and safety of vehicles | Material quality, corrosion resistance, and compliance with OEM standards |

| Marine Engineering | Attaching cowlings on racing outboard motors | Enhances performance and durability in harsh conditions | Weather resistance, vibration absorption, and availability of OEM-compatible parts |

| Aerospace | Fastening components in aircraft fuselage | Critical for safety and performance in aviation | Lightweight materials, high strength-to-weight ratio, and certification requirements |

| Heavy Machinery | Securing engine covers and protective panels | Protects sensitive machinery components from damage | Durability under heavy loads, resistance to environmental factors, and custom sizing options |

| Construction Equipment | Installing protective panels on machinery | Increases safety and operational efficiency | Availability of bulk orders, customization options, and compatibility with various equipment models |

In the automotive manufacturing sector, cowl bolts are essential for securing hoods and firewalls during vehicle assembly. Their reliability ensures the structural integrity of vehicles, which is paramount for safety. For international buyers, especially in regions like Africa and South America, sourcing high-quality, corrosion-resistant bolts that meet OEM specifications is critical to avoid costly recalls and repairs.

In marine engineering, cowl bolts are used to attach cowlings on racing outboard motors, enhancing both performance and durability. These bolts must be weather-resistant and capable of absorbing vibrations, which is crucial for motors operating in rough waters. B2B buyers in this sector should prioritize sourcing from suppliers that offer high-quality, OEM-compatible parts to ensure reliability during competition.

The aerospace industry utilizes cowl bolts to fasten components within the aircraft fuselage, where safety and performance are non-negotiable. Buyers in this sector must consider lightweight materials that also provide high strength, as well as compliance with stringent certification requirements. For international procurement, understanding regional regulations and certifications is essential to ensure smooth operations.

In heavy machinery, cowl bolts secure engine covers and protective panels, safeguarding sensitive machinery components from damage. The durability of these bolts under heavy loads is vital, and buyers should focus on sourcing high-quality materials that can withstand harsh operational environments. For buyers from regions with extreme weather conditions, resistance to environmental factors is a key consideration.

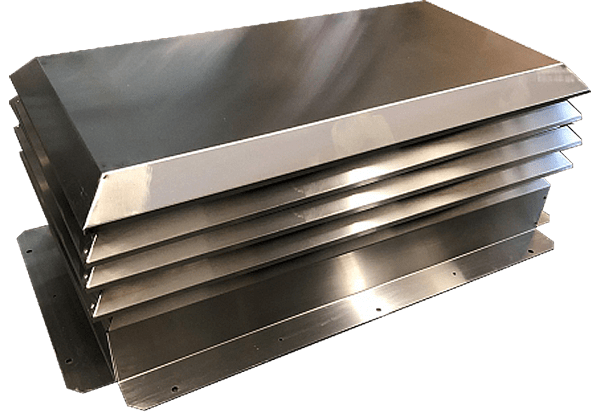

Illustrative image related to cowl bolts

Lastly, in the construction equipment sector, cowl bolts are used for installing protective panels on machinery to enhance safety and operational efficiency. B2B buyers should look for suppliers that can provide bulk orders and customization options, ensuring compatibility with various equipment models. For international buyers, establishing strong supplier relationships can lead to better pricing and availability of parts tailored to specific machinery needs.

3 Common User Pain Points for ‘cowl bolts’ & Their Solutions

Scenario 1: Inconsistent Sizing and Specifications of Cowl Bolts

The Problem: B2B buyers often encounter difficulties with inconsistent sizing and specifications of cowl bolts. This issue is particularly prevalent when sourcing from multiple suppliers, especially in international markets where standardization may vary. For instance, a buyer in Nigeria may order cowl bolts that are advertised as M6x1 but receive bolts that do not fit their specific applications due to differing thread pitches or lengths. This can lead to project delays and increased costs as teams may need to re-order parts or make modifications.

The Solution: To mitigate this issue, buyers should invest in a detailed specification document before making purchases. This document should include all necessary measurements, thread types, and material specifications. Establishing a close relationship with suppliers can also help ensure clarity around product specifications. Moreover, buyers should request samples to verify fitment before placing large orders. Utilizing standardized part numbers can streamline the ordering process across different suppliers, ensuring compatibility and reducing the risk of errors.

Scenario 2: Poor Quality Materials Leading to Premature Wear

The Problem: Another common pain point is the use of subpar materials in cowl bolts, which can lead to premature wear and failure. Buyers from regions with harsh environmental conditions, such as the Middle East or South America, may find that low-quality bolts corrode or break more quickly than anticipated. This not only affects the durability of the installation but can also lead to costly repairs and replacements, impacting overall project timelines.

The Solution: To address this challenge, buyers should prioritize sourcing cowl bolts made from high-quality materials, such as stainless steel or other corrosion-resistant alloys. It is advisable to conduct thorough research on potential suppliers, looking for those who provide detailed material certifications. Additionally, implementing a quality assurance process, such as third-party inspections or using a sample batch for testing, can help ensure that the products meet the required durability standards. By investing in quality upfront, companies can save on future repair costs and improve the reliability of their installations.

Scenario 3: Difficulty in Finding Compatible Cowl Bolt Kits

The Problem: B2B buyers often struggle to find comprehensive cowl bolt kits that are compatible with specific vehicle models or applications. This is particularly true in the restoration and aftermarket sectors, where unique cowl designs may require specialized bolt kits. For example, a buyer in Europe restoring a classic vehicle may find that standard kits do not include the necessary components, leading to frustrations and wasted time in searching for compatible parts.

The Solution: To streamline the sourcing process, buyers should utilize industry-specific databases or forums that specialize in automotive parts. Engaging with other professionals in restoration or aftermarket communities can provide insights into reliable sources for specialized cowl bolt kits. Furthermore, buyers can collaborate with manufacturers to create custom kits tailored to their specific needs, ensuring all necessary components are included. Establishing partnerships with trusted distributors who have a deep understanding of various vehicle models can also simplify the sourcing process and reduce the likelihood of compatibility issues.

Strategic Material Selection Guide for cowl bolts

What Are the Key Properties of Common Materials Used for Cowl Bolts?

When selecting cowl bolts, the choice of material is crucial for ensuring performance, durability, and compliance with international standards. Here, we analyze four common materials used for cowl bolts: stainless steel, carbon steel, aluminum, and plastic composites. Each material has unique properties and implications for various applications, especially for international buyers.

How Does Stainless Steel Perform in Cowl Bolt Applications?

Stainless steel is a popular choice for cowl bolts due to its excellent corrosion resistance and high strength. It can withstand a wide range of temperatures and pressures, making it suitable for various automotive and industrial applications. The most common grades, such as 304 and 316, offer different levels of resistance to corrosion, with 316 being more suitable for marine environments.

Pros: Stainless steel bolts are highly durable and resistant to rust, which is essential in humid or corrosive environments. They also have a polished finish, enhancing aesthetic appeal.

Cons: The primary drawback is cost; stainless steel is generally more expensive than other materials. Additionally, manufacturing complexity can increase due to the need for specialized tooling.

Impact on Application: Stainless steel bolts are compatible with a variety of media, including water and oil, making them versatile for automotive applications.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with ASTM or ISO standards, as these materials are often subject to stringent regulations.

What Advantages Does Carbon Steel Offer for Cowl Bolts?

Carbon steel is another common material used for cowl bolts, known for its strength and affordability. It is often treated with coatings to enhance corrosion resistance, making it suitable for various environments.

Pros: The primary advantage of carbon steel is its low cost and high tensile strength, making it a cost-effective choice for bulk orders.

Illustrative image related to cowl bolts

Cons: However, carbon steel is prone to rust and corrosion if not properly coated or maintained, which can limit its lifespan in harsh environments.

Impact on Application: Carbon steel bolts are generally suitable for dry environments but may not perform well in marine or high-humidity applications.

Considerations for International Buyers: Buyers should be aware of local corrosion resistance standards, especially in humid climates, to avoid premature failure.

How Does Aluminum Compare in Cowl Bolt Applications?

Aluminum is lightweight and resistant to corrosion, making it an attractive option for applications where weight savings are essential, such as in the automotive and aerospace industries.

Pros: Aluminum bolts are easy to install and provide excellent corrosion resistance without additional coatings. Their lightweight nature can enhance overall vehicle performance.

Cons: The main limitation is strength; aluminum bolts may not be suitable for high-stress applications and can be more expensive than carbon steel.

Impact on Application: Aluminum bolts are ideal for applications where weight is a critical factor, but they may not be suitable for high-temperature environments.

Illustrative image related to cowl bolts

Considerations for International Buyers: Compliance with international standards is essential, particularly in regions where aluminum alloys are commonly used in automotive applications.

What Role Do Plastic Composites Play in Cowl Bolt Applications?

Plastic composites are increasingly used in cowl bolt applications, especially in environments where corrosion resistance is paramount.

Pros: These materials are lightweight, resistant to corrosion, and do not conduct electricity, making them ideal for specific applications.

Cons: However, plastic composites may lack the tensile strength required for high-stress applications, limiting their use in structural components.

Impact on Application: They are suitable for applications where corrosion is a concern, but buyers should assess their mechanical properties for specific uses.

Illustrative image related to cowl bolts

Considerations for International Buyers: Buyers should ensure that plastic composites meet local regulations regarding materials used in automotive applications.

Summary Table of Material Properties for Cowl Bolts

| Material | Typical Use Case for cowl bolts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Automotive, marine applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | General automotive applications | High strength and low cost | Prone to rust without coatings | Low |

| Aluminum | Lightweight automotive parts | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Plastic Composites | Non-structural automotive parts | Corrosion resistance and lightweight | Limited mechanical strength | Medium |

This guide provides a comprehensive overview of the materials commonly used in cowl bolts, offering valuable insights for international B2B buyers looking to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for cowl bolts

What Are the Main Stages of Manufacturing Cowl Bolts?

The manufacturing process of cowl bolts involves several crucial stages, each critical to ensuring that the final product meets the required specifications and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Cowl Bolt Production?

Material selection is fundamental in the production of cowl bolts. Typically, high-grade stainless steel or carbon steel is chosen for its strength, corrosion resistance, and durability. The first step in material preparation involves sourcing raw materials that meet international quality standards, such as ASTM or ISO specifications. Once sourced, the materials undergo inspection to confirm their quality and suitability for manufacturing.

After inspection, the materials are cut to size using precision cutting methods. Techniques such as laser cutting or shearing ensure that the dimensions are accurate, which is critical for the subsequent forming process. This precision minimizes waste and ensures consistency in production, vital for maintaining inventory levels and meeting demand.

What Techniques Are Used in the Forming Process?

The forming stage is where the raw materials are transformed into cowl bolts. Common techniques include cold heading and forging. Cold heading is particularly effective for creating the bolt head, allowing for high production rates and minimal material waste. In this process, a cylindrical piece of metal is struck by a die, forming the head without heating the material, which maintains its structural integrity.

Forging, on the other hand, is often used for producing high-strength bolts. This technique involves heating the metal to a specific temperature and then shaping it using mechanical presses. The forging process enhances the material’s grain structure, resulting in improved mechanical properties.

How Are Cowl Bolts Assembled and Finished?

Following forming, the assembly stage involves attaching components such as washers and nuts. Automated assembly lines are commonly employed to ensure efficiency and consistency. This stage may also include the application of coatings or finishes to enhance corrosion resistance and aesthetic appeal. Common finishing techniques include electroplating, powder coating, or anodizing, depending on the specific requirements of the buyer.

Finally, the finished cowl bolts are packaged in sets and prepared for shipment. Packaging is crucial, especially for international shipments, as it protects the products during transit and provides essential information for buyers.

What Quality Assurance Measures Are Important for Cowl Bolts?

Quality assurance is a critical aspect of the manufacturing process for cowl bolts, ensuring that each product meets industry standards and buyer expectations. The quality assurance process can be broken down into several key components, including adherence to international standards, quality checkpoints, and testing methods.

Which International Standards Should Be Considered?

For B2B buyers, understanding the relevant international standards is crucial. ISO 9001 is a widely recognized standard for quality management systems, ensuring that manufacturers maintain consistent quality in their processes. Additionally, industry-specific certifications like CE for European markets or API for oil and gas applications may be applicable, depending on the intended use of the cowl bolts.

These standards provide a framework for manufacturers to follow, ensuring that their products are safe, reliable, and of high quality. Buyers should inquire about these certifications when evaluating potential suppliers.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential throughout the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): This is the initial inspection phase where raw materials are assessed for compliance with specifications.

- In-Process Quality Control (IPQC): During production, regular inspections are conducted to identify and rectify any defects immediately. This ensures that any issues are addressed before the final assembly stage.

- Final Quality Control (FQC): After assembly, the finished cowl bolts undergo a comprehensive inspection to verify that they meet all specifications and standards.

Implementing these checkpoints helps to minimize defects and maintain a high level of product quality.

What Common Testing Methods Are Used for Cowl Bolts?

Testing methods play a vital role in verifying the quality and durability of cowl bolts. Common testing techniques include:

- Tensile Testing: To measure the strength and ductility of the bolts.

- Corrosion Resistance Testing: To evaluate how well the bolts can withstand environmental factors that may lead to corrosion.

- Dimensional Inspection: Ensuring that the bolts meet specified dimensions and tolerances.

These tests help ensure that the bolts can perform as required in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several strategies to ensure that suppliers adhere to quality standards:

What Should Buyers Look for in Supplier Audits?

Conducting supplier audits is an effective way to assess compliance with quality standards. Buyers can request audits that evaluate the supplier’s manufacturing processes, quality control systems, and adherence to international standards. These audits can be performed by the buyers themselves or through third-party inspection agencies.

How Can Buyers Utilize Quality Reports?

Requesting quality control reports from suppliers can provide insights into their manufacturing practices. These reports should detail the results of various tests conducted on the cowl bolts, including any corrective actions taken in response to defects. Transparency in reporting is a sign of a reliable supplier.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can further validate a supplier’s quality assurance processes. These independent agencies can conduct comprehensive inspections and testing of the products before shipment, providing an additional layer of confidence for buyers.

What Are the Quality Control Nuances for International B2B Buyers?

For international transactions, understanding the nuances of quality control is essential. Different regions may have varying standards and expectations regarding product quality. For instance, buyers in Europe may prioritize CE certifications, while those in the Middle East may focus on compliance with local regulations.

Furthermore, language barriers and differing regulatory environments can pose challenges. Buyers should ensure that they have clear communication with suppliers regarding quality expectations and that all documentation is available in a language understood by both parties.

Conclusion

Understanding the manufacturing processes and quality assurance measures for cowl bolts is crucial for B2B buyers looking to make informed purchasing decisions. By considering the manufacturing stages, adhering to international standards, and verifying quality control practices, buyers can ensure they receive high-quality products that meet their specific needs. This comprehensive approach not only enhances product reliability but also fosters long-term relationships with suppliers across diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cowl bolts’

To assist international B2B buyers in sourcing cowl bolts effectively, this guide provides a structured checklist to streamline the procurement process. Cowl bolts play a critical role in securing various automotive components, making the selection of the right hardware essential for quality and performance.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the specifications needed for the cowl bolts. Consider factors such as size, material (e.g., stainless steel for corrosion resistance), thread type, and load-bearing capacity. Accurate specifications will help you avoid costly errors and ensure compatibility with your existing components.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers who specialize in cowl bolts. Utilize online marketplaces, industry directories, and trade shows to compile a list of candidates. Focus on suppliers with a proven track record in the automotive sector and those who understand the specific requirements of your regional market.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess relevant industry certifications, such as ISO 9001 or TS16949. These certifications indicate adherence to international quality management standards, ensuring that their products meet safety and performance benchmarks. Additionally, inquire about their manufacturing processes and quality control measures.

Step 4: Request Samples for Testing

Always request samples before placing a bulk order. Testing samples allows you to assess the quality, fit, and functionality of the cowl bolts in your specific application. Look for signs of durability and corrosion resistance, especially if your operations are in regions with harsh environmental conditions.

Step 5: Review Pricing and Payment Terms

Collect quotes from multiple suppliers to compare pricing structures. Pay attention to not only the unit price but also additional costs such as shipping, taxes, and potential customs fees. Negotiate payment terms that are favorable for your cash flow, ensuring that you understand the implications of any upfront costs or deposits.

Step 6: Understand Delivery Times and Logistics

Discuss delivery timelines and logistics with your chosen supplier. It’s crucial to understand their shipping capabilities, especially if you operate in regions with logistical challenges. Confirm lead times and ensure they can meet your project deadlines to avoid disruptions in your supply chain.

Step 7: Establish a Communication Plan

Once you select a supplier, establish clear lines of communication. Regular updates on order status, potential issues, and delivery confirmations are vital for maintaining a smooth workflow. Utilize tools like email, messaging apps, or dedicated project management platforms to facilitate ongoing communication.

By following this structured checklist, B2B buyers can make informed decisions when sourcing cowl bolts, ensuring that they obtain high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for cowl bolts Sourcing

What Are the Key Cost Components for Sourcing Cowl Bolts?

When sourcing cowl bolts, understanding the cost structure is essential for effective budgeting and decision-making. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts cost. Stainless steel, for instance, is often preferred for its durability and resistance to corrosion but comes at a higher price than standard steel. Buyers should assess whether the added cost aligns with the intended application and environmental conditions.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Regions with higher labor costs may produce better-quality products, which can justify the price difference.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Suppliers in regions with lower operational costs can offer more competitive pricing.

-

Tooling: Custom tooling for specialized cowl bolts can be a significant initial investment. Buyers should consider the long-term benefits of investing in custom tools versus purchasing standard products.

-

Quality Control: High-quality cowl bolts may require rigorous QC processes, adding to the cost. Certifications such as ISO can also impact pricing but assure buyers of product reliability.

-

Logistics: International shipping costs can vary widely based on distance, shipping method, and Incoterms. Buyers must factor in these costs when comparing supplier quotes.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the industry standard margins can aid buyers in assessing whether a quote is competitive.

How Do Volume and Customization Affect Cowl Bolt Pricing?

Pricing for cowl bolts is heavily influenced by order volume and customization requirements.

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer tiered pricing based on order volume. Higher quantities typically result in lower per-unit costs. Buyers should evaluate their needs and consider bulk purchasing to maximize savings.

-

Specifications and Customization: Specialized bolts, such as those requiring specific threading or coatings, can incur additional costs. Buyers should be clear about their requirements and obtain quotes from multiple suppliers to find the best balance between customization and cost.

What Factors Should Buyers Consider When Sourcing Cowl Bolts?

Several external factors can influence pricing and sourcing decisions for cowl bolts, especially for international buyers from regions like Africa, South America, the Middle East, and Europe.

-

Quality and Certifications: Products that meet international quality standards can command higher prices. Buyers should weigh the importance of certification against the cost, particularly for critical applications.

-

Supplier Reputation: Established suppliers may charge more due to their reliability and service history. Conducting due diligence on potential suppliers can help mitigate risks associated with sourcing.

-

Incoterms: Understanding shipping terms is crucial for managing logistics costs. Different Incoterms can affect pricing, delivery times, and responsibilities for duties and tariffs.

What Are Effective Negotiation Strategies for Cowl Bolt Purchases?

Negotiation plays a critical role in securing favorable pricing for cowl bolts. Here are a few strategies:

-

Leverage Volume: If planning to purchase in bulk, use this as leverage to negotiate lower prices or better payment terms.

-

Request Detailed Quotes: Ask suppliers for itemized quotes that break down costs. This transparency can help identify areas for negotiation.

-

Explore Alternative Suppliers: Don’t hesitate to seek multiple quotes from different suppliers. This practice can provide insight into market rates and strengthen your negotiating position.

How Can Buyers Optimize Total Cost of Ownership?

Understanding the Total Cost of Ownership (TCO) is vital for making informed purchasing decisions. This includes not just the purchase price but also costs associated with installation, maintenance, and potential replacement. High-quality cowl bolts might have a higher upfront cost but can offer savings over time through reduced maintenance needs and longer service life.

Disclaimer on Indicative Prices

Prices for cowl bolts can vary widely based on the factors mentioned above. The pricing information provided is indicative and may not reflect current market conditions. Buyers should conduct thorough research and engage with suppliers for accurate quotes tailored to their specific needs.

Alternatives Analysis: Comparing cowl bolts With Other Solutions

Exploring Viable Alternatives to Cowl Bolts for Secure Fastening

In the realm of automotive and machinery maintenance, securing components effectively is crucial. While cowl bolts are a popular choice for fastening, various alternatives can serve similar purposes. This analysis explores cowl bolts in comparison to two other fastening solutions: threaded inserts and adhesive bonding. Each alternative presents distinct advantages and drawbacks, making it essential for B2B buyers to understand which option best suits their specific applications.

| Comparison Aspect | Cowl Bolts | Threaded Inserts | Adhesive Bonding |

|---|---|---|---|

| Performance | High tensile strength; reliable fit | Strong load-bearing capacity | Excellent for non-structural joints |

| Cost | Moderate ($24.97 for a kit) | Moderate to high (varies by type) | Low to moderate (depends on volume) |

| Ease of Implementation | Simple installation with tools | Requires precise installation | Requires surface preparation |

| Maintenance | Minimal; occasional checks needed | Low; durable over time | Moderate; may degrade over time |

| Best Use Case | Automotive applications; easy access | Structural applications; metalwork | Non-load-bearing applications; plastics |

Detailed Breakdown of Alternatives

Threaded Inserts

Threaded inserts provide a robust fastening solution, particularly in applications where high load-bearing capacity is required. They are typically made from metal and can be installed into various materials, including plastics and wood. The primary advantage of threaded inserts is their ability to create a strong, reusable thread that can withstand repeated assembly and disassembly. However, they require precise installation, which can increase labor costs and complexity. For B2B buyers in industries like manufacturing or automotive repair, threaded inserts are ideal for projects where strength and durability are paramount.

Illustrative image related to cowl bolts

Adhesive Bonding

Adhesive bonding has gained popularity as a fastening method, particularly in applications where traditional fasteners may not be suitable. This method involves using high-strength adhesives to bond materials together. One of the main advantages of adhesive bonding is its ability to distribute stress evenly across the bonded surfaces, reducing the risk of failure. Additionally, it can be used on a variety of materials, including metals, plastics, and composites. However, it may not be suitable for load-bearing applications and often requires careful surface preparation for optimal performance. B2B buyers looking for versatile and efficient solutions may find adhesive bonding a compelling option, especially in non-structural applications.

Conclusion: Choosing the Right Fastening Solution for Your Needs

When deciding between cowl bolts and alternative fastening methods like threaded inserts and adhesive bonding, B2B buyers should consider several factors. The specific application, material compatibility, and load requirements play critical roles in this decision-making process. Cowl bolts offer a straightforward, reliable fastening solution for automotive needs, while threaded inserts provide enhanced strength for structural applications. On the other hand, adhesive bonding presents a flexible option for non-load-bearing joints. By carefully evaluating these alternatives, businesses can select the most effective fastening solution tailored to their operational requirements.

Essential Technical Properties and Trade Terminology for cowl bolts

What Are the Key Technical Properties of Cowl Bolts?

Understanding the technical properties of cowl bolts is essential for B2B buyers, particularly when sourcing components for automotive applications. Here are some critical specifications to consider:

-

Material Grade

– Cowl bolts are typically manufactured from stainless steel or carbon steel. Stainless steel provides excellent corrosion resistance, making it ideal for vehicles exposed to various weather conditions. For high-performance applications, selecting bolts with a higher material grade (like A2 or A4 for stainless steel) ensures better durability and resistance to environmental factors. -

Thread Size and Pitch

– Thread specifications, such as M6x1 or M8x1.25, are vital for compatibility with existing hardware. Buyers must ensure that the thread size matches the specifications of the vehicle or component to avoid issues during installation. Accurate thread sizing is crucial for maintaining structural integrity and preventing failures. -

Length and Diameter

– The length and diameter of cowl bolts affect their strength and application suitability. A longer bolt may be required for thicker materials, while the diameter influences load distribution. It’s essential for buyers to verify that the dimensions align with the intended use to ensure optimal performance and safety. -

Tolerance

– Tolerance levels indicate how much variation is acceptable in the dimensions of the bolts. Tight tolerances are critical for applications requiring precision, such as in high-performance racing environments. Understanding tolerance specifications can help buyers select the right bolts that meet the quality standards of their projects. -

Coating and Finish

– Coatings, such as zinc plating or anodizing, enhance corrosion resistance and aesthetic appeal. Buyers should consider the environmental conditions in which the cowl bolts will be used to choose appropriate coatings that provide longevity and maintain performance. -

Load Rating

– The load rating indicates the maximum load that a bolt can safely support. This specification is crucial for applications where structural integrity is paramount. Buyers must ensure that the load rating of the cowl bolts matches or exceeds the requirements of their specific application to prevent failures.

What Are Common Trade Terms Related to Cowl Bolts?

Familiarity with trade terminology can significantly enhance communication and efficiency in sourcing cowl bolts. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts that are used in the manufacturing of vehicles. For buyers, sourcing OEM cowl bolts ensures compatibility and quality, as these parts are designed to meet the specifications of the original vehicle manufacturer. -

MOQ (Minimum Order Quantity)

– MOQ represents the smallest quantity of product that a supplier is willing to sell. Understanding MOQ is vital for buyers, especially in international markets where purchasing in bulk may be necessary to achieve cost efficiency. -

RFQ (Request for Quotation)

– An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. Including detailed specifications for cowl bolts in an RFQ helps suppliers provide accurate quotes and improves the procurement process. -

Incoterms (International Commercial Terms)

– These terms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand their obligations and mitigate risks associated with international transactions. -

Lead Time

– Lead time refers to the time it takes from placing an order to receiving the product. For cowl bolts, understanding lead time is crucial for project planning, especially in industries where timing is critical. -

Certification Standards

– Certifications, such as ISO or ASTM, indicate that products meet specific quality and safety standards. Buyers should consider certification when sourcing cowl bolts to ensure compliance with industry regulations and enhance product reliability.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing cowl bolts, ultimately leading to enhanced project success and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the cowl bolts Sector

What Are the Current Market Dynamics and Key Trends in the Cowl Bolts Sector?

The global cowl bolts market is witnessing significant growth driven by increased demand for automotive components, especially in the restoration and performance enhancement sectors. As vehicles age, the need for replacement parts such as cowl bolts becomes crucial for maintaining functionality and safety. Key trends include a shift towards lightweight materials, such as aluminum and advanced composites, which offer durability while reducing overall vehicle weight. Additionally, the rise of electric vehicles (EVs) and the subsequent changes in design requirements are influencing the specifications and sourcing of cowl bolts.

Emerging B2B technologies are reshaping the procurement landscape. Digital platforms are facilitating easier access to suppliers, enabling international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, to source high-quality products efficiently. E-commerce solutions are becoming more prevalent, allowing for streamlined ordering and inventory management, which is particularly beneficial for B2B transactions where bulk purchases are common.

Moreover, buyers are increasingly seeking out suppliers who can provide detailed product specifications and certifications, ensuring compatibility with various vehicle models. Global supply chain disruptions have also prompted businesses to consider local sourcing options, which can mitigate risks associated with long lead times and transportation costs. This trend is especially relevant for buyers in regions like Nigeria and Saudi Arabia, where local manufacturing capabilities are expanding.

How Important Is Sustainability and Ethical Sourcing in the Cowl Bolts Market?

Sustainability is becoming an essential consideration in the sourcing of cowl bolts. The environmental impact of manufacturing processes, including resource extraction and waste generation, is prompting buyers to seek out suppliers who adhere to sustainable practices. Ethical sourcing not only enhances brand reputation but also aligns with growing consumer expectations for corporate responsibility.

Buyers should look for cowl bolts made from recycled materials or those that have certifications such as ISO 14001, which indicate adherence to environmental management standards. Additionally, suppliers who are transparent about their supply chain practices and demonstrate a commitment to reducing their carbon footprint are becoming increasingly attractive to B2B buyers.

Incorporating ‘green’ materials into product offerings is also gaining traction. For instance, using stainless steel with a lower environmental impact or adopting eco-friendly coatings can appeal to environmentally conscious buyers. As companies in Africa, South America, the Middle East, and Europe prioritize sustainable procurement, they are likely to favor suppliers who can provide these certifications and demonstrate ethical sourcing practices.

What Is the Historical Context of Cowl Bolts in the Automotive Industry?

The evolution of cowl bolts can be traced back to the early days of automotive manufacturing when vehicles were constructed with a focus on functionality and durability. Initially, cowl bolts were made from basic steel, but as automotive technology advanced, so did the materials and manufacturing techniques.

The introduction of stainless steel and advanced alloys has significantly improved the performance and longevity of cowl bolts, making them more resistant to corrosion and wear. Over the years, the design of vehicles has also changed, leading to the development of specialized cowl bolts that cater to varying vehicle models and types. This historical context is crucial for B2B buyers, as understanding the evolution of these components can aid in making informed purchasing decisions that align with modern automotive standards.

In conclusion, navigating the cowl bolts market requires an understanding of the dynamic trends influencing sourcing decisions, the growing importance of sustainability, and the historical context that shapes current product offerings. B2B buyers must be proactive in seeking suppliers that align with their operational needs and ethical standards to ensure long-term success in this sector.

Frequently Asked Questions (FAQs) for B2B Buyers of cowl bolts

-

How do I solve issues with missing or broken cowl bolts?

To address missing or broken cowl bolts, first assess the specific requirements for your vehicle model, as compatibility is crucial. Look for comprehensive cowl hardware kits that include bolts, washers, and jack nuts, which can replace factory screws and anchors. Always verify the specifications (such as size and thread pitch) before purchasing. If you’re sourcing internationally, ensure the supplier provides accurate product descriptions and installation guides to avoid further complications. -

What is the best material for cowl bolts?

The best material for cowl bolts typically includes stainless steel due to its corrosion resistance and durability. This is particularly important in regions with extreme weather conditions, such as high humidity or salinity. Stainless steel bolts not only withstand rust but also maintain structural integrity over time, making them ideal for automotive applications. When sourcing, inquire about the grade of stainless steel used, as higher grades will offer better performance and longevity. -

How can I verify the quality of cowl bolts from a supplier?

To verify the quality of cowl bolts from a supplier, request detailed product specifications, including material certifications and testing reports. Look for suppliers with a proven track record and positive reviews from other international buyers. It’s also beneficial to ask for samples before making a bulk purchase to assess the quality firsthand. Inquire about their quality assurance processes and any warranties they offer to ensure you receive reliable products. -

What are the typical minimum order quantities (MOQ) for cowl bolts?

Minimum order quantities (MOQ) for cowl bolts can vary significantly depending on the supplier and the specific product. Generally, MOQs can range from as low as 100 pieces to several thousand. When negotiating with suppliers, consider your inventory needs and discuss the possibility of lower MOQs for initial orders or trial runs. Additionally, some suppliers may offer flexible terms for repeat customers or larger contracts. -

What payment terms should I expect when sourcing cowl bolts internationally?

When sourcing cowl bolts internationally, payment terms can vary widely among suppliers. Common terms include a deposit upfront (typically 30% to 50%) with the balance due upon shipping or delivery. Some suppliers may also accept letters of credit or payment through escrow services for added security. Always clarify payment terms in advance and ensure they align with your cash flow management strategy. -

How do I handle logistics for international shipping of cowl bolts?

Handling logistics for international shipping of cowl bolts involves several key steps. First, confirm the shipping options available, such as air freight for speed or sea freight for cost-effectiveness. Ensure that your supplier provides clear shipping terms and estimated delivery times. It’s essential to understand customs regulations in your country to avoid delays. Working with a freight forwarder can help streamline the process, ensuring compliance and efficient delivery. -

What customization options are available for cowl bolts?

Many suppliers offer customization options for cowl bolts, including size, threading, and finishes. If you require specific dimensions or features, communicate your needs during the sourcing process. Custom orders may involve additional costs and longer lead times, so it’s important to plan accordingly. Always ask for prototypes or samples of customized bolts to ensure they meet your specifications before placing a larger order. -

How can I ensure compliance with international standards for cowl bolts?

To ensure compliance with international standards for cowl bolts, research relevant industry standards applicable to your market, such as ISO or ASTM specifications. Request documentation from your supplier that verifies their products meet these standards, including certifications and test reports. Establishing a clear quality control process during procurement can help mitigate risks associated with non-compliance, ensuring that the bolts perform reliably in your applications.

Top 7 Cowl Bolts Manufacturers & Suppliers List

1. Hush Performance – EF Cowl Hardware

Domain: hushperformance.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “EF COWL HARDWARE”, “price”: “$24.97”, “description”: “Sharp new way to secure your cowl. Our cowl hardware replaces factory screws, screw caps and plastic anchors that are sometimes found missing or broken.”, “kit_contents”: {“total_pieces”: 21, “components”: {“bolts”: 7, “washers”: 7, “jack_nuts”: 7, “lower_plastic_plugs”: 7}}, “note”: “Does not fit OEM hood seal”, “shipping_tim…

2. The Stop Shop – Cowl Induction Hood Flapper Valve Frame Bolts Set

Domain: thestopshop.com

Registered: 2008 (17 years)

Introduction: Cowl Induction Hood Flapper Valve Frame Bolts Set – Regular price: $8.31 – Six piece set for classic cars – Correct size, shape & markings as originals – Mounts cowl induction flapper frame to the hood – Fits: 1969 Camaro, 1970-1972 Chevelle – Part Number: AIR-56

3. Mutton Hollow Chevys – Classic Chevy Cowl Kits

Domain: muttonhollowchevys.com

Registered: 2004 (21 years)

Introduction: Mutton Hollow Chevys offers cowl kits for attaching firewalls, grille, and hood areas, specifically for classic Chevy vehicles (1955, 1956, 1957). The product range includes: 1. 1955 1956 Chevy Hood Hinge Hardware Kit – Stainless Steel – $30.49 (Out of Stock) 2. 1957 Chevy Hood Hinge Hardware Kit – Stainless Steel – $30.49 (Out of Stock) 3. 1957 Chevy Hood Hinge To Fender Bracket And Bolts – $19.9…

4. Honda – Cowl Replacement Bolt for Rebel Windshield

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Replacement bolt for the cowl of a Honda Rebel motorcycle, specifically for the windshield part. Users suggested checking online retailers like Amazon, Partzilla, and local hardware or auto parts stores for a match.

5. Wrangler – Cowl Screw Replacement Kit

Domain: wranglertjforum.com

Registered: 2015 (10 years)

Introduction: Replacement cowl screw kit including u-clips and push-in nylon nuts. Suggested vendors include Jeep Hardware and jeepbolts.com. Discussion highlights the need for stainless clips and black stainless screw sets for the cowl. Users express interest in a complete hardware kit due to issues with rust and mismatched screws.

6. Jalopy Journal – Model A Cowl Bolts

Domain: jalopyjournal.com

Registered: 1997 (28 years)

Introduction: Model A Cowl bolts; Stock thread diameter and pitch: 12-24 for 30/31 A’s; Part # A80046 for machine bolts to fasten cowl to gas tank; Recommended sizes for replacement: 1/4-20 or 1/4-28; Fine threads (UNF) are suggested for better tightening; Stainless steel recommended with anti-seize.

7. Hush Performance – EF Cowl Bolts

Strategic Sourcing Conclusion and Outlook for cowl bolts

In today’s competitive automotive landscape, effective strategic sourcing of cowl bolts is crucial for ensuring product quality and operational efficiency. By focusing on high-quality materials—such as stainless steel—and sourcing from reputable suppliers, businesses can enhance the durability and reliability of their offerings. This not only fulfills customer expectations but also mitigates long-term costs associated with replacements and repairs.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize suppliers who understand local market needs and can provide customized solutions. Engaging with manufacturers that offer comprehensive support, including installation guidance and product guarantees, will further streamline operations and build trust in partnerships.

Looking ahead, the demand for high-performance cowl bolts is expected to grow, driven by trends in automotive restoration and customization. It is imperative for buyers to stay informed about evolving specifications and emerging technologies in the cowl hardware sector. By leveraging strategic sourcing practices, businesses can position themselves for success in this dynamic market. Engage with trusted suppliers today to ensure your inventory meets the highest standards and aligns with future industry demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.