Top 6 Toroidal Ferrite Suppliers (And How to Choose)

Introduction: Navigating the Global Market for toroidal ferrite

Navigating the global market for toroidal ferrite can present unique challenges for international B2B buyers seeking reliable suppliers and quality products. With the increasing demand for efficient magnetic components in industries ranging from telecommunications to renewable energy, understanding the nuances of toroidal ferrite sourcing is crucial. This guide aims to demystify the complexities of the market by exploring various types of toroidal ferrite cores, their applications, and essential considerations for supplier vetting.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Brazil, will benefit from insights into cost structures, quality standards, and compliance requirements that influence purchasing decisions. By equipping stakeholders with knowledge on the performance characteristics and advantages of different ferrite materials, this guide empowers them to make informed choices that enhance operational efficiency and product reliability.

Ultimately, navigating the toroidal ferrite market does not have to be daunting. With a comprehensive understanding of the available options and strategic insights into supplier relationships, buyers can confidently invest in products that meet their specific needs and drive their businesses forward.

Understanding toroidal ferrite Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| MnZn Ferrite Toroids | High magnetic permeability, low losses at high frequencies | Power transformers, inductors | Pros: High efficiency, compact size. Cons: Limited frequency range compared to other types. |

| NiZn Ferrite Toroids | Higher frequency operation, lower saturation magnetization | RF applications, telecommunications | Pros: Excellent for high-frequency applications. Cons: Higher losses at lower frequencies. |

| Amorphous Toroids | Non-crystalline structure, excellent magnetic properties | High-frequency transformers, energy storage | Pros: Low core losses, high efficiency. Cons: More expensive than traditional ferrites. |

| Nanocrystalline Toroids | Fine-grained structure, superior magnetic characteristics | Advanced inductors, high-performance devices | Pros: Excellent performance in high-frequency applications. Cons: Complex manufacturing process, higher costs. |

| Iron Powder Toroids | Made from iron powder, good for low-frequency applications | Audio transformers, chokes | Pros: Cost-effective, good for low frequencies. Cons: Bulkier and less efficient at high frequencies. |

What Are the Characteristics of MnZn Ferrite Toroids?

MnZn ferrite toroids are characterized by their high magnetic permeability and low core losses, making them ideal for power transformers and inductors. They operate efficiently at low to medium frequencies, which is critical for many industrial applications. When sourcing these toroids, buyers should consider the specific frequency requirements of their applications, as well as the operational temperature range to ensure optimal performance.

How Do NiZn Ferrite Toroids Differ from Other Types?

NiZn ferrite toroids excel in high-frequency applications due to their lower saturation magnetization. This makes them suitable for telecommunications and RF applications where efficiency at elevated frequencies is paramount. Buyers should evaluate the trade-off between higher losses at lower frequencies and the benefits of reduced electromagnetic interference in their specific use cases.

What Advantages Do Amorphous Toroids Offer?

Amorphous toroidal cores are notable for their non-crystalline structure, which leads to exceptionally low core losses and high efficiency. These properties make them particularly advantageous in high-frequency transformers and energy storage systems. However, buyers must be prepared for a higher price point, which reflects the advanced materials and manufacturing processes involved.

Why Consider Nanocrystalline Toroids?

Nanocrystalline toroids feature a fine-grained structure that provides superior magnetic performance, especially in high-frequency applications. They are ideal for advanced inductors and high-performance devices. When purchasing, buyers should assess the complexity of manufacturing and the associated costs, as these factors can impact overall project budgets.

What Are the Best Uses for Iron Powder Toroids?

Iron powder toroids are primarily used in low-frequency applications like audio transformers and chokes. They are cost-effective and suitable for a range of applications where size and weight are less critical. Buyers should consider their specific frequency requirements and the trade-offs in efficiency when selecting this type of toroidal core.

Key Industrial Applications of toroidal ferrite

| Industry/Sector | Specific Application of toroidal ferrite | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Electronics | Transformer cores in power supplies | High efficiency and low heat generation improve device longevity | Quality certifications (ISO, RoHS) and material specifications |

| Telecommunications | Inductors in RF and microwave applications | Enhanced signal integrity and reduced interference | Frequency range compatibility and form factor |

| Renewable Energy | Components in solar inverters | Increased energy conversion efficiency and reliability | Environmental compliance and thermal performance |

| Automotive | Noise suppression in electric vehicle systems | Improved performance and user experience through reduced EMI | Adherence to automotive industry standards and testing protocols |

| Consumer Electronics | Filters for audio and video devices | Higher sound quality and reduced distortion | Customization options and lead times for production |

How is Toroidal Ferrite Used in Power Electronics?

In power electronics, toroidal ferrite is primarily utilized in transformer cores for power supplies. These transformers benefit from the high magnetic efficiency of toroidal cores, which minimizes energy losses and reduces heat generation. For international buyers, especially in regions like Africa and South America, sourcing high-quality toroidal ferrite is crucial. They must consider certifications such as ISO and RoHS to ensure compliance with international standards, which can directly impact the reliability and longevity of their power devices.

What Role Does Toroidal Ferrite Play in Telecommunications?

In the telecommunications sector, toroidal ferrite is essential for inductors used in RF and microwave applications. These inductors help maintain signal integrity while reducing electromagnetic interference (EMI), which is critical for communication systems. Buyers from the Middle East and Europe should pay close attention to the frequency range compatibility of the ferrite materials, as well as the form factor, to ensure they meet specific application requirements. These considerations can greatly affect the performance of telecommunications equipment.

How is Toroidal Ferrite Applied in Renewable Energy?

Within the renewable energy sector, particularly in solar inverters, toroidal ferrite components are used to enhance energy conversion efficiency. The unique properties of ferrite cores allow for better handling of high-frequency signals, which leads to improved reliability and performance of solar energy systems. Buyers should prioritize sourcing materials that comply with environmental regulations and demonstrate excellent thermal performance, especially in regions with extreme temperatures.

Why is Toroidal Ferrite Important in Automotive Applications?

In the automotive industry, toroidal ferrite is utilized for noise suppression in electric vehicle systems. This application is crucial for enhancing the overall performance and user experience by minimizing EMI, which can interfere with sensitive electronics. Buyers in this sector, particularly in Europe and Saudi Arabia, need to ensure that the ferrite materials sourced adhere to stringent automotive standards and testing protocols to guarantee safety and reliability in their vehicles.

How is Toroidal Ferrite Beneficial for Consumer Electronics?

In consumer electronics, toroidal ferrite is commonly used in filters for audio and video devices. The high magnetic efficiency of these ferrite components contributes to improved sound quality and reduced distortion, making them essential for high-fidelity audio systems. Buyers should look for customization options to meet specific design requirements and be aware of lead times for production to ensure timely delivery and integration into their products.

3 Common User Pain Points for ‘toroidal ferrite’ & Their Solutions

Scenario 1: Inconsistent Quality in Toroidal Ferrite Supplies

The Problem: Many B2B buyers face the challenge of inconsistent quality when sourcing toroidal ferrite from various suppliers. This inconsistency can lead to unreliable performance in their applications, such as transformers and inductors. Buyers may experience fluctuations in magnetic properties, dimensions, and overall durability, resulting in increased operational risks and potential financial losses. The lack of standardized quality assurance processes among suppliers can exacerbate this issue, leaving buyers uncertain about the reliability of their components.

The Solution: To address this problem, B2B buyers should prioritize sourcing toroidal ferrite from manufacturers with robust quality assurance protocols and industry certifications. Conducting thorough supplier evaluations and requesting detailed specifications can help ensure that the materials meet necessary performance criteria. Establishing long-term partnerships with reputable suppliers who have proven track records can also mitigate quality risks. Additionally, buyers can implement incoming inspection processes to verify the magnetic properties and physical dimensions of the ferrite cores before use, ensuring that any discrepancies are identified and addressed promptly.

Scenario 2: Difficulty in Selecting the Right Toroidal Ferrite Material

The Problem: Selecting the appropriate toroidal ferrite material for specific applications can be a daunting task for B2B buyers. With various types of ferrite mixes available—each exhibiting unique magnetic properties and frequency responses—buyers may struggle to determine which material best suits their operational needs. This can lead to suboptimal performance, increased costs, and potential project delays as buyers may need to iterate their designs based on improper material selection.

The Solution: To streamline the selection process, buyers should invest time in understanding the specific requirements of their applications, such as operating frequency, temperature range, and the desired level of electromagnetic interference (EMI) suppression. Engaging with suppliers who offer expert consultation services can provide valuable insights into the most suitable ferrite materials. Additionally, buyers can leverage application notes and technical datasheets provided by manufacturers to compare the properties of different ferrite mixes. Conducting small-scale prototype testing with various materials can also help in making informed decisions before committing to large-scale orders.

Scenario 3: High Costs Associated with Toroidal Ferrite Components

The Problem: High costs of toroidal ferrite components can be a significant pain point for B2B buyers, especially in regions where import tariffs and shipping fees add to the overall expense. This can limit the ability of companies to source high-quality components within budget constraints, ultimately affecting their competitiveness in the market. Buyers may find themselves compromising on quality or seeking cheaper alternatives that do not meet performance standards.

The Solution: To mitigate high costs, buyers should explore bulk purchasing options or long-term contracts with suppliers to secure better pricing. Engaging in negotiations and leveraging their purchasing volume can lead to significant cost savings. Additionally, buyers can consider sourcing from local or regional manufacturers, which may reduce shipping costs and lead times. Implementing a total cost of ownership (TCO) analysis can also help buyers assess the long-term value of their investments in toroidal ferrite components, allowing them to make more informed purchasing decisions that balance cost with quality and performance.

Strategic Material Selection Guide for toroidal ferrite

What Are the Key Materials for Toroidal Ferrite?

When selecting materials for toroidal ferrite cores, several common options stand out due to their unique properties and applications. Understanding these materials is crucial for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, where specific compliance and performance standards can vary.

What Are the Key Properties of MnZn Ferrite Toroids?

MnZn (Manganese-Zinc) ferrite is one of the most commonly used materials for toroidal cores. It exhibits excellent magnetic properties, particularly at lower frequencies, making it suitable for power transformers and inductors.

Key Properties: MnZn ferrites have high permeability and low core loss, allowing them to operate efficiently at frequencies up to 1 MHz. They also have a temperature rating of around 100°C, making them suitable for various applications.

Pros & Cons: The primary advantage of MnZn ferrites is their high magnetic efficiency, which translates to better performance in transformers. However, they can be sensitive to temperature fluctuations and may require careful thermal management. Additionally, while they are generally cost-effective, the manufacturing process can be complex due to the need for precise material formulations.

Impact on Application: MnZn ferrites are ideal for applications involving AC signals and power supplies. However, they may not perform well in high-frequency applications beyond their rated limits.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN. In regions like Saudi Arabia and Brazil, local regulations may also dictate specific material properties and certifications.

How Does NiZn Ferrite Compare in Performance?

NiZn (Nickel-Zinc) ferrite is another popular choice for toroidal cores, particularly in high-frequency applications.

Key Properties: NiZn ferrites have lower permeability compared to MnZn ferrites but excel in high-frequency scenarios, operating effectively up to 400 MHz. They typically have a temperature rating similar to MnZn ferrites but offer better performance in RF applications.

Pros & Cons: The key advantage of NiZn ferrites is their low core loss at high frequencies, making them suitable for RF transformers and inductors. However, they are generally more expensive than MnZn ferrites and may not be as efficient in low-frequency applications.

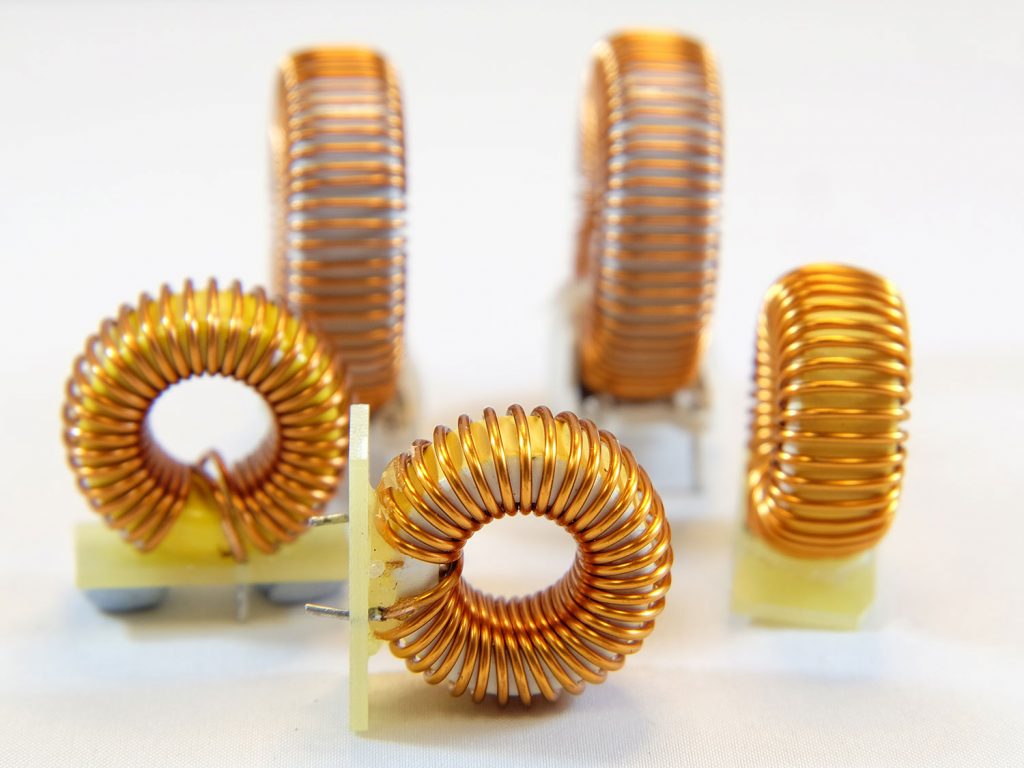

Illustrative image related to toroidal ferrite

Impact on Application: NiZn ferrites are ideal for applications involving RF signals, such as telecommunications and high-speed data transmission. Their performance in these areas can significantly enhance signal integrity.

Considerations for International Buyers: Compliance with standards like JIS and ISO is crucial, especially in regions with stringent electronic manufacturing regulations. Buyers in Europe and the Middle East should also consider local sourcing options to reduce lead times.

What Are the Advantages of Amorphous Ferrite?

Amorphous ferrite cores are a newer material option that offers unique advantages for specific applications.

Illustrative image related to toroidal ferrite

Key Properties: These cores have a non-crystalline structure, which allows for very low core loss and high saturation magnetization. They can operate efficiently at frequencies above 1 MHz and have a temperature rating that can exceed 150°C.

Pros & Cons: The primary advantage of amorphous ferrites is their superior energy efficiency, making them ideal for applications requiring minimal energy loss. However, they tend to be more expensive and may require specialized manufacturing techniques.

Impact on Application: Amorphous ferrites are particularly suitable for high-efficiency transformers and inductors, especially in renewable energy applications like solar inverters.

Considerations for International Buyers: Buyers should be aware of the higher costs associated with these materials and ensure that they meet local and international compliance standards.

How Do Iron Powder Toroids Fit into the Picture?

Iron powder toroids are often used in applications where cost and simplicity are key considerations.

Key Properties: These cores provide decent magnetic properties at lower frequencies and are generally less expensive than ferrite cores. They can handle temperatures up to 120°C.

Pros & Cons: The main advantage of iron powder toroids is their affordability and ease of manufacturing. However, they have higher core losses compared to ferrite materials, which can limit their efficiency in certain applications.

Impact on Application: Iron powder toroids are suitable for applications involving low-frequency signals, such as audio transformers and power supplies.

Considerations for International Buyers: Buyers should evaluate the cost-benefit ratio of using iron powder versus ferrite materials, especially in regions where performance standards are critical.

Summary Table of Material Selection for Toroidal Ferrite

| Material | Typical Use Case for toroidal ferrite | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| MnZn Ferrite | Power transformers and inductors | High magnetic efficiency | Sensitive to temperature changes | Medium |

| NiZn Ferrite | RF transformers and inductors | Low core loss at high frequencies | More expensive than MnZn ferrite | High |

| Amorphous Ferrite | High-efficiency transformers | Superior energy efficiency | Higher cost and complex manufacturing | High |

| Iron Powder Toroids | Audio transformers and power supplies | Affordable and easy to manufacture | Higher core losses | Low |

This strategic material selection guide provides a comprehensive overview of the key materials used in toroidal ferrite applications. Understanding these materials will help international B2B buyers make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for toroidal ferrite

What Are the Main Stages in the Manufacturing Process of Toroidal Ferrite?

The manufacturing process of toroidal ferrite cores involves several key stages, each critical to ensuring the final product meets the required specifications for quality and performance. The main stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality raw materials, primarily ferrite powder. This powder is often a mix of manganese, zinc, and nickel oxides, which are blended in precise ratios to achieve desired magnetic properties. The mixing process may also include additives to enhance specific characteristics, such as temperature stability and magnetic permeability. Quality control begins here, as the consistency and purity of the raw materials significantly affect the performance of the final product.

-

Forming: Once the materials are prepared, they undergo a shaping process. The ferrite powder is typically compacted into toroidal shapes using a die-pressing technique. This method allows manufacturers to achieve the precise dimensions needed for various applications, such as transformers and inductors. During this stage, it’s crucial to maintain uniform density and avoid air pockets, which can lead to performance inconsistencies.

-

Assembly: After forming, the toroidal cores may undergo additional processes, such as sintering, where they are heated in a controlled atmosphere to achieve the desired hardness and magnetic properties. This stage is essential for enhancing the structural integrity of the cores. The sintering temperature and duration are carefully controlled to avoid over-sintering, which can degrade magnetic performance.

-

Finishing: The final stage involves surface treatment and coating to improve the cores’ electrical insulation and protect them from environmental factors. Techniques such as epoxy coating or other insulating materials may be applied. This not only enhances durability but also minimizes electromagnetic interference (EMI), making the cores suitable for sensitive applications.

How Is Quality Assurance Integrated Into the Manufacturing of Toroidal Ferrite?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that the final product adheres to international standards and meets customer expectations. Various quality control measures are employed throughout the manufacturing stages.

-

International Standards and Certifications: Many manufacturers adhere to international quality standards such as ISO 9001, which focuses on maintaining a quality management system. Additional certifications like CE for European markets or API for specific applications may also be relevant. These certifications demonstrate a commitment to quality and can significantly enhance a supplier’s credibility in international markets.

-

Quality Control Checkpoints: Quality control is typically structured around several key checkpoints:

– Incoming Quality Control (IQC): This phase involves inspecting raw materials upon receipt to ensure they meet predefined specifications. Any deviations are addressed before production begins.

– In-Process Quality Control (IPQC): During the manufacturing process, various parameters such as temperature, pressure, and density are monitored. This real-time monitoring helps identify any issues early on, preventing defective products from advancing to the next stage.

– Final Quality Control (FQC): Once the toroidal ferrites are completed, they undergo rigorous testing to verify performance characteristics such as permeability, saturation magnetization, and electrical insulation. This stage often includes electrical and mechanical testing to ensure the cores meet the required standards. -

Common Testing Methods: Various testing methods are employed to validate the quality of toroidal ferrite cores. These may include:

– Magnetic Testing: Evaluating magnetic properties such as permeability and loss factors.

– Electrical Insulation Testing: Ensuring that the insulation meets voltage and dielectric strength requirements.

– Dimensional Inspection: Using precision measuring tools to confirm that the dimensions conform to specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in diverse international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is paramount. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and adherence to standards in real-time. During these audits, buyers can evaluate the effectiveness of the supplier’s QA protocols and gain insights into their operational efficiency.

-

Quality Reports and Documentation: Requesting detailed quality reports from suppliers can provide transparency regarding their quality assurance processes. This documentation should include results from IQC, IPQC, and FQC stages, along with any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging independent third-party inspection services can help validate the quality claims made by suppliers. These organizations can perform comprehensive assessments and provide objective reports on the quality of the manufacturing processes and final products.

-

Understanding Regional Compliance Nuances: Different regions may have specific compliance requirements that must be met. For instance, products destined for the European market must adhere to CE marking, while those in the Middle East may need to comply with local regulations. Buyers should familiarize themselves with these requirements to ensure that their suppliers can meet them.

-

Supplier Performance History: Evaluating a supplier’s performance history, including customer feedback and incident reports, can provide valuable insights into their reliability and quality standards. Engaging with other businesses in the industry can also yield recommendations on reputable suppliers.

What Are the Common Quality Control Challenges Faced by Manufacturers of Toroidal Ferrite?

Manufacturers of toroidal ferrite often encounter several quality control challenges that can impact product performance and customer satisfaction. Understanding these challenges can help B2B buyers make informed decisions.

-

Material Variability: Variations in raw material quality can lead to inconsistencies in the final product. Manufacturers must ensure stringent sourcing and testing protocols to minimize this risk.

-

Process Control: Maintaining consistent process parameters during manufacturing is crucial. Variations in temperature, pressure, or compaction can lead to defects. Continuous monitoring and adjustments are essential to maintain quality.

-

Regulatory Compliance: Navigating the complexities of international regulatory requirements can pose challenges. Manufacturers must stay updated on changes in standards and ensure compliance across different markets.

-

Cost Constraints: Balancing quality with cost-efficiency can be a challenge for manufacturers. Implementing high-quality processes may increase costs, but it’s vital to communicate the long-term benefits to buyers, such as reduced failure rates and enhanced performance.

By understanding the manufacturing processes and quality assurance measures related to toroidal ferrite, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific application needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘toroidal ferrite’

To successfully procure toroidal ferrite, a systematic approach is essential. This guide outlines a step-by-step checklist tailored for B2B buyers, ensuring a streamlined sourcing process that meets technical requirements and supplier standards.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your application is crucial. Determine the size, material composition, and electrical characteristics of the toroidal ferrite you need, as these factors will influence performance. For instance, consider:

– Frequency Range: Identify the operational frequency to select the appropriate ferrite mix.

– Size and Shape: Ensure the dimensions fit within your product design.

Step 2: Research Potential Suppliers

A thorough search for reputable suppliers is necessary to ensure quality. Look for manufacturers with a proven track record in producing toroidal ferrite. Key aspects to consider include:

– Industry Experience: Suppliers with extensive experience often have better quality control processes.

– Client Testimonials: Seek reviews from other B2B clients, especially in your industry or region.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that potential suppliers meet industry standards. Look for certifications such as ISO 9001, which indicates adherence to quality management principles. Additionally, consider:

– Compliance with RoHS: Ensure that the materials used are compliant with environmental regulations.

– Quality Assurance Procedures: Inquire about the supplier’s quality control measures to ensure consistency and reliability.

Step 4: Request Product Samples

Obtaining samples is a critical step in evaluating the quality of toroidal ferrite. Testing samples allows you to assess performance in your specific application. Focus on:

– Performance Testing: Evaluate the samples under your operational conditions to verify efficiency and effectiveness.

– Physical Inspection: Check for any defects or inconsistencies that could affect performance.

Step 5: Compare Pricing and Terms

Once you have shortlisted suppliers, compare their pricing structures and terms of service. Cost is an important factor, but it should not compromise quality. Pay attention to:

– Bulk Pricing Options: Inquire about discounts for larger orders, which can significantly affect your budget.

– Payment Terms: Understand the payment schedules and conditions to manage cash flow effectively.

Step 6: Conduct a Site Visit (If Possible)

If feasible, visiting the supplier’s facility can provide valuable insights into their operations. Observing the manufacturing process and quality control measures firsthand can confirm their capability to meet your requirements. Consider:

– Production Capacity: Ensure the supplier can handle your volume needs.

– Technology and Equipment: Assess whether their technology aligns with industry standards.

Step 7: Finalize Contractual Agreements

Once you have selected a supplier, ensure that all agreements are documented clearly. This should include pricing, delivery timelines, and quality expectations. Essential considerations include:

– Warranties and Guarantees: Specify any warranties on product performance to safeguard your investment.

– Dispute Resolution Procedures: Establish protocols for handling any potential disagreements to maintain a good business relationship.

By following this checklist, B2B buyers can confidently navigate the sourcing process for toroidal ferrite, ensuring that they select the best suppliers and products for their needs.

Comprehensive Cost and Pricing Analysis for toroidal ferrite Sourcing

What Are the Key Cost Components for Toroidal Ferrite Sourcing?

When sourcing toroidal ferrite, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

Illustrative image related to toroidal ferrite

-

Materials: The type of ferrite material used (MnZn or NiZn) significantly impacts costs. Higher-grade materials may be more expensive but offer better performance and efficiency.

-

Labor: Skilled labor is required for the manufacturing process, especially for precision tasks such as winding and assembly. Labor costs can vary widely based on the region, with lower costs in developing markets and higher wages in developed nations.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, such as utilities, maintenance, and facility expenses. Efficient manufacturing processes can help minimize overhead.

-

Tooling: The initial investment in tooling for custom shapes and sizes can be substantial. This cost is often amortized over large production runs, making it critical to consider order volume.

-

Quality Control (QC): Ensuring the quality of toroidal ferrites is vital, particularly for applications in sensitive electronic devices. QC processes may add to the overall cost but are essential for compliance with international standards.

-

Logistics: Transportation costs can vary based on the shipping method and distance. Incoterms also play a role in determining who bears these costs, impacting the total price.

-

Margin: Suppliers typically add a margin to cover their operating costs and profit. This margin can vary by supplier and market conditions.

What Influences the Pricing of Toroidal Ferrite Products?

Several factors influence the pricing of toroidal ferrite, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to ensure they are not overcommitting to inventory.

-

Specifications and Customization: Custom specifications can increase costs. Buyers should weigh the benefits of customization against the potential for higher prices.

-

Material Quality and Certifications: Higher quality materials and necessary certifications (like ISO or RoHS compliance) can drive up costs but are crucial for reliability and performance.

-

Supplier Factors: Supplier reputation, reliability, and location can affect pricing. Established suppliers may command higher prices due to their quality assurance processes.

-

Incoterms: The terms of shipping affect pricing significantly. Understanding who is responsible for shipping, insurance, and tariffs is essential for calculating total costs.

What Are Effective Buyer Tips for Negotiating Toroidal Ferrite Prices?

B2B buyers should adopt strategic approaches when negotiating prices for toroidal ferrites:

-

Leverage Volume Discounts: When possible, consolidate orders to achieve better pricing. Discuss volume commitments with suppliers to negotiate discounts.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the purchase price but also shipping, handling, and potential failure costs. A cheaper product may end up being more expensive in the long run due to higher failure rates or logistics issues.

-

Be Aware of Pricing Nuances for International Buyers: Different regions may have varying pricing structures based on local demand, tariffs, and market conditions. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand regional pricing dynamics.

-

Negotiate Payment Terms: Favorable payment terms can improve cash flow and reduce financial risk. Explore options for installment payments or extended payment terms.

-

Request Samples: Before committing to larger orders, request samples to evaluate quality. This can also serve as a negotiating tool to justify pricing adjustments.

Disclaimer for Indicative Prices

Prices for toroidal ferrites can vary widely based on the factors discussed above. It is essential for buyers to obtain quotes from multiple suppliers and consider all variables before making a purchasing decision. Prices mentioned in this analysis are indicative and subject to change based on market conditions and supplier terms.

Alternatives Analysis: Comparing toroidal ferrite With Other Solutions

When evaluating magnetic core solutions, it’s essential to consider various alternatives to toroidal ferrite. Each option offers unique advantages and trade-offs that can impact performance, cost, and application suitability. Below, we analyze toroidal ferrite against two other viable solutions: laminated silicon steel and iron powder cores.

| Comparison Aspect | Toroidal Ferrite | Laminated Silicon Steel | Iron Powder Cores |

|---|---|---|---|

| Performance | High magnetic efficiency; low core losses at high frequencies | Good performance at low frequencies; higher core losses at high frequencies | Moderate performance; suitable for low-frequency applications |

| Cost | Moderate to high | Generally lower | Low to moderate |

| Ease of Implementation | Requires careful winding techniques | Easier to assemble; widely available | Simple to manufacture; can be molded |

| Maintenance | Low maintenance | Low maintenance | Moderate; can degrade over time |

| Best Use Case | High-frequency transformers and inductors | Power transformers, motors | Low-frequency applications like chokes |

What Are the Advantages and Disadvantages of Laminated Silicon Steel?

Laminated silicon steel is commonly used in transformers and electrical motors due to its cost-effectiveness and ease of assembly. It features thin sheets of steel insulated from each other, which reduces eddy current losses. However, it is less effective at high frequencies compared to toroidal ferrite, making it unsuitable for applications requiring high efficiency at elevated frequencies. Additionally, while its lower initial cost is appealing, the potential for higher operational losses at high frequencies can lead to increased long-term costs.

Illustrative image related to toroidal ferrite

How Do Iron Powder Cores Compare to Toroidal Ferrite?

Iron powder cores are another alternative that can be used for inductors and transformers, especially in low-frequency applications. They are made from compressed iron powder and provide reasonable performance at a lower cost. However, they tend to have higher core losses compared to toroidal ferrite, particularly at higher frequencies. Their construction allows for flexibility in design, but they may require more maintenance over time as they can degrade and lose magnetic properties.

Conclusion: How to Choose the Right Magnetic Core Solution?

When selecting the right magnetic core solution, B2B buyers should carefully evaluate their specific application requirements, including operational frequency, efficiency, and budget constraints. Toroidal ferrite excels in high-frequency applications with its superior performance and low core losses, making it ideal for modern power supplies and transformers. On the other hand, laminated silicon steel and iron powder cores can be more cost-effective solutions for low-frequency applications. Ultimately, understanding the unique characteristics and limitations of each option will enable buyers to make informed decisions that align with their operational needs and financial objectives.

Essential Technical Properties and Trade Terminology for toroidal ferrite

What Are the Key Technical Properties of Toroidal Ferrite?

When sourcing toroidal ferrite cores, understanding their technical properties is crucial for ensuring compatibility with your specific applications. Here are some essential specifications to consider:

1. Material Grade

The material grade of a toroidal ferrite core is a critical factor that influences its magnetic properties. Common material grades include MnZn (Manganese-Zinc) and NiZn (Nickel-Zinc). MnZn ferrites are generally used for low-frequency applications (up to 1 MHz), while NiZn ferrites are better suited for higher frequencies (above 1 MHz). Selecting the appropriate material grade ensures optimal performance in your inductors and transformers, impacting efficiency and overall circuit design.

2. Inductance Value

Inductance value, measured in henries (H), indicates the core’s ability to store electrical energy in a magnetic field. This property is vital when designing inductors for power supplies or transformers. A higher inductance value typically results in better performance, but it must align with the operational frequency of your application. Understanding this value helps buyers assess whether a specific toroidal core meets their electrical requirements.

3. Core Losses

Core losses, including hysteresis and eddy current losses, are critical metrics that reflect the energy wasted as heat when the core is magnetized. Lower core losses translate to higher efficiency and better thermal management in electronic devices. For B2B buyers, selecting cores with minimal losses is essential for maintaining energy efficiency and prolonging equipment lifespan.

4. Temperature Coefficient

The temperature coefficient indicates how the inductance value changes with temperature variations. This property is important for applications exposed to varying environmental conditions. A stable temperature coefficient ensures that the performance of the toroidal ferrite remains consistent, which is vital for applications in automotive, telecommunications, and industrial electronics.

Illustrative image related to toroidal ferrite

5. Tolerance

Tolerance specifies the acceptable variance in the core’s dimensions and inductance value. Understanding tolerance is critical when precise specifications are required for high-performance applications. A tighter tolerance often means higher manufacturing costs but may be necessary for achieving desired performance levels in sensitive electronic circuits.

What Are Common Trade Terms Related to Toroidal Ferrite?

Familiarity with industry jargon can streamline communication and negotiations with suppliers. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of toroidal ferrites, OEMs typically supply components for use in larger electronic systems, highlighting the importance of quality and compatibility with existing products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to plan inventory and budget effectively. Often, higher MOQs can lead to better pricing, but they require careful consideration of demand forecasts.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers for specific products. Sending an RFQ for toroidal ferrites allows buyers to compare options and negotiate better deals, ensuring they get the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. Understanding these terms is crucial for B2B transactions, as they clarify who is responsible for shipping, insurance, and tariffs, thus minimizing potential disputes.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For manufacturers, understanding lead times for toroidal ferrites is vital for production scheduling and meeting customer demands. Longer lead times can affect inventory management and project timelines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing toroidal ferrite cores, ensuring they select the right products for their applications while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the toroidal ferrite Sector

What Are the Key Market Trends in the Toroidal Ferrite Sector?

The toroidal ferrite market is experiencing significant growth driven by advancements in technology and increasing demand across various industries. Key global drivers include the proliferation of electric vehicles (EVs), renewable energy solutions, and the rising need for efficient power management in electronic devices. As industries strive for higher energy efficiency, toroidal ferrites, known for their minimal electromagnetic interference and compact design, are becoming a preferred choice for transformers and inductors.

In emerging markets, particularly in Africa and South America, there is a notable shift towards local manufacturing capabilities. This trend is influenced by government initiatives aimed at fostering domestic industries and reducing dependency on imports. For international B2B buyers, this presents opportunities to engage with local suppliers who can offer competitive pricing and shorter lead times. In the Middle East and Europe, regulatory frameworks increasingly prioritize energy efficiency and sustainable practices, further propelling the demand for high-quality toroidal ferrite products.

Another trend is the integration of smart technologies within the manufacturing processes of toroidal ferrites. Automation and digitalization are leading to improved quality control, customization, and scalability, allowing suppliers to meet the specific needs of B2B clients. Additionally, the rise of e-commerce platforms is transforming how businesses source toroidal ferrites, enabling buyers to access a wider range of suppliers and compare products more effectively.

How Is Sustainability Impacting the Sourcing of Toroidal Ferrite Products?

Sustainability is becoming a cornerstone of sourcing strategies for B2B buyers in the toroidal ferrite sector. The environmental impact of manufacturing processes is under increasing scrutiny, prompting companies to adopt greener practices. Manufacturers are now focusing on minimizing waste, optimizing energy use, and utilizing sustainable materials in the production of toroidal ferrites. For instance, sourcing from suppliers who use recycled or eco-friendly materials not only reduces environmental footprints but also aligns with corporate social responsibility (CSR) goals.

Ethical sourcing has gained prominence, with buyers prioritizing suppliers that adhere to responsible labor practices and transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are becoming essential for suppliers looking to attract international buyers. These certifications assure buyers that the products they are sourcing meet stringent environmental standards.

Moreover, the demand for ‘green’ ferrite materials, which exhibit low environmental impact during both production and end-of-life disposal, is on the rise. Buyers are encouraged to seek out suppliers who provide detailed information on the sustainability of their products, enabling them to make informed decisions that contribute to a more sustainable future.

How Has the Toroidal Ferrite Market Evolved Over Time?

The evolution of the toroidal ferrite market can be traced back to the mid-20th century when the increasing demand for efficient electrical components led to the development of ferrite materials. Initially, toroidal ferrites were primarily used in radio frequency applications due to their superior magnetic properties. As technology advanced, their applications expanded into power electronics, telecommunications, and consumer electronics.

The introduction of nanocrystalline and amorphous core technologies further enhanced the performance of toroidal ferrites, making them indispensable in high-frequency applications. Over the years, the market has transitioned from traditional manufacturing techniques to more sophisticated, automated processes, ensuring consistent quality and performance.

Today, the toroidal ferrite sector stands at the intersection of innovation and sustainability, with ongoing research aimed at enhancing the properties of ferrite materials while minimizing their environmental impact. This evolution presents both challenges and opportunities for international B2B buyers, who must navigate a complex landscape to source high-quality, sustainable products that meet their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of toroidal ferrite

-

How do I solve electromagnetic interference (EMI) issues in my applications using toroidal ferrite?

To address EMI issues, incorporating toroidal ferrite cores into your circuit design is highly effective. Their unique shape allows for efficient magnetic field containment, minimizing EMI emissions. Ensure you select the appropriate mix of ferrite material based on your application’s frequency range. Testing with various core sizes and configurations can help optimize performance. Consulting with your supplier about the specific characteristics and ratings of different ferrite materials can also enhance your solution against EMI. -

What is the best toroidal ferrite material for power supply applications?

For power supply applications, MnZn (manganese-zinc) ferrite materials are typically the best choice due to their high permeability and low losses at high frequencies. Specifically, Mix 31 and Mix 43 materials are popular for their efficiency in the 1-300 MHz range. When sourcing, confirm that the ferrite cores meet the specifications for your voltage and current levels to ensure optimal performance and reliability in your power supply systems. -

How can I ensure the quality of toroidal ferrite I am sourcing from international suppliers?

To ensure quality, request certifications such as ISO 9001 from your suppliers, as this indicates adherence to quality management standards. Additionally, ask for test reports that validate the magnetic properties and dimensions of the ferrite cores. Conducting audits or site visits can further establish confidence in the supplier’s manufacturing processes. Lastly, consider using third-party testing services to verify compliance with industry standards. -

What are the typical minimum order quantities (MOQs) for toroidal ferrite cores?

Minimum order quantities for toroidal ferrite cores can vary significantly based on the supplier and material type. Generally, MOQs can range from 100 to 1,000 units. If you require a smaller quantity, some suppliers may offer flexibility, especially if they have stock items. Always clarify MOQs during negotiations to find a supplier that aligns with your purchasing capabilities and project timelines. -

What payment terms should I expect when sourcing toroidal ferrite internationally?

Payment terms for international transactions often vary by supplier and region. Common terms include 30% upfront payment with the remaining balance due before shipment. Some suppliers may offer net 30 or net 60 terms, especially for established relationships. Be sure to negotiate terms that suit your cash flow and consider using secure payment methods like letters of credit or escrow services to mitigate risk. -

How do I customize toroidal ferrite cores for my specific application?

Customization can involve altering the size, material mix, or coating of the ferrite cores to meet specific application requirements. Engage directly with your supplier’s engineering team to discuss your needs. They may provide design assistance and suggest suitable materials based on your frequency and environmental conditions. Ensure you provide detailed specifications to facilitate a smooth customization process. -

What logistics considerations should I keep in mind when importing toroidal ferrite?

When importing toroidal ferrite, consider shipping costs, delivery times, and customs regulations in your country. Choose a reliable freight forwarder who understands international trade regulations to help navigate customs clearance. Additionally, factor in lead times for manufacturing and delivery to avoid project delays. Monitoring logistics closely can help ensure that you receive your ferrite cores on time and in good condition. -

What applications benefit most from using toroidal ferrite cores?

Toroidal ferrite cores are widely used in applications such as transformers, inductors, and filters due to their high efficiency and low EMI emissions. They are particularly beneficial in power electronics, telecommunications, and audio equipment, where minimizing losses and maximizing performance is critical. Understanding your specific application requirements will help you determine the best ferrite core configurations for optimal results.

Top 6 Toroidal Ferrite Manufacturers & Suppliers List

1. MAG Inc – Ferrite Toroids

Domain: mag-inc.com

Registered: 1996 (29 years)

Introduction: Ferrite Toroids offer high magnetic efficiency with no air gap and uniform cross-sectional area. Available sizes range from 2mm to 140mm in outside diameter. Permeability options include 750µ to 15,000µ. Coatings can be applied to enhance winding ease and improve voltage breakdown. Hardware such as toroid mounts and headers is also available. Key characteristics include: Composition – Mn, Zn, Fe; …

2. Amidon Corp – Ferrite Toroids

Domain: amidoncorp.com

Registered: 1996 (29 years)

Introduction: Ferrite Toroids available in various materials including 31, 43, 4A3, 52, 61, 67, 68, 75, 77, F, H, J, K, and W. Prices range from $0.60 to $44.50. Specific products include FT-140A-FC ($8.00), FT-400-31 ($44.50), FT-62-WC ($2.00), FT-193B-JC ($25.00), FT-87-FC ($3.50), FT-240-31 ($11.00), FT-23A-43C ($1.00), FT-23-43B ($0.60), FT-22-43 ($0.60), FT-19-43 ($0.80), FT-14A-43C ($1.00), FT-23-HC ($3.0…

3. Palomar Engineers® – FT Mix 31

Domain: palomar-engineers.com

Registered: 1998 (27 years)

Introduction: All Ferrite Ring Toroid Cores – Ferrite Toroid/Ring Cores – Palomar Engineers®

Key Products:

1. FT Mix 31 – RFI Range: 1-300 MHz

2. FT Mix 43 – RFI Range: 25-200 MHz

3. Mix 52 – RFI Range: 200-1000 MHz

4. FT Mix 61 – RFI Range: 200-2000 MHz

5. FT Mix 75 – RFI Range: .15-10 MHz

6. AC Cable Noise Filter for Large Plugs – 3″ ID for Generator, Dryer (SKU: ACCF-3) – Price: $39.95

7. AC Cable Noise Fil…

4. CosmoFerrites – Toroidal Cores

Domain: cosmoferrites.com

Registered: 1999 (26 years)

Introduction: Toroidal Cores (Rings) are a type of soft ferrite product used in various applications including lighting, electric vehicles, automotive, solar energy, induction heating, and telecommunications. They are known for their advantages such as reduced electromagnetic interference (EMI) and enhanced efficiency in power conditioning. The cores come in various sizes and can be customized for specific appl…

5. Mouser – Ferrite Toroids & Rings

Domain: mouser.com

Registered: 1995 (30 years)

Introduction: This company, Mouser – Ferrite Toroids & Rings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Ferrite Shop – FT240-77 Ferrite Toroid

Domain: ferrite-shop.com

Registered: 2018 (7 years)

Introduction: {‘name’: ‘FT240-77 Ferrite Toroid’, ‘price’: ‘€14.00’, ‘bulk_discount’: {‘3-9_units’: ‘€12.60′, ’10_plus_units’: ‘€11.90’}, ‘applications’: [‘common mode choke’, ‘impedance transformer’, ‘balun’], ‘dimensions’: {‘A’: {‘mm’: 61, ‘tolerance’: ‘±1.3’, ‘inch’: 2.4}, ‘B’: {‘mm’: 35.55, ‘tolerance’: ‘±0.85’, ‘inch’: 1.4}, ‘C’: {‘mm’: 12.7, ‘tolerance’: ‘±0.5’, ‘inch’: 0.5}}, ‘material_properties’: {‘ini…

Strategic Sourcing Conclusion and Outlook for toroidal ferrite

As the demand for efficient and compact magnetic solutions rises globally, the strategic sourcing of toroidal ferrite presents significant opportunities for international B2B buyers. Key takeaways highlight the advantages of toroidal ferrites, such as their high magnetic efficiency, reduced electromagnetic interference, and suitability for diverse applications, including transformers and inductors. By partnering with reputable manufacturers who prioritize quality assurance and compliance, businesses can secure a reliable supply of these essential components.

The value of strategic sourcing cannot be overstated; it not only reduces costs but also enhances product performance and operational efficiency. In regions like Africa, South America, the Middle East, and Europe, where technological advancement is accelerating, sourcing high-quality toroidal ferrite can provide a competitive edge.

Looking ahead, international buyers are encouraged to stay informed about market trends and innovations in ferrite technology. Engaging with suppliers who understand regional needs and can offer tailored solutions will be crucial in optimizing supply chains. Embrace the potential of toroidal ferrite and position your business for success in an increasingly interconnected global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to toroidal ferrite