Choosing Your Brass Aluminum Forging: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for brass aluminum forging

In today’s competitive landscape, international B2B buyers are increasingly challenged by the complexities of sourcing high-quality brass aluminum forgings. With applications spanning industries such as aerospace, automotive, and medical, the demand for precision-engineered components is on the rise. However, navigating the global market can be daunting, given the varied supplier capabilities, quality standards, and cost considerations. This guide aims to demystify the brass aluminum forging sector by providing a thorough exploration of its types, applications, and critical factors influencing procurement.

Throughout this comprehensive resource, readers will gain insights into the various forging techniques—such as hot, warm, and cold forging—and their specific applications across different industries. We will also delve into supplier vetting processes, ensuring that buyers can identify reliable manufacturers who meet their stringent quality requirements. Additionally, this guide will address cost factors, helping businesses optimize their purchasing strategies while maintaining high standards.

Designed specifically for international B2B buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—this guide empowers decision-makers to make informed choices. By leveraging the actionable insights and expert recommendations contained within, businesses can confidently navigate the complexities of sourcing brass aluminum forgings, ultimately enhancing their operational efficiency and product offerings.

Understanding brass aluminum forging Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hot Forging | Involves shaping metal at high temperatures, improving ductility and reducing brittleness. | Aerospace, Automotive, Military | Pros: High strength, better material flow. Cons: Higher energy costs, potential oxidation. |

| Cold Forging | Conducted at room temperature, resulting in improved surface finish and dimensional accuracy. | Electronics, Medical Devices, Small Components | Pros: Enhanced mechanical properties, lower energy consumption. Cons: Limited to softer metals. |

| Warm Forging | Performed at intermediate temperatures, combining benefits of both hot and cold forging. | Automotive, Industrial Machinery | Pros: Improved strength and toughness, reduced tool wear. Cons: Requires precise temperature control. |

| Drop Forging | Utilizes a hammer to shape the metal, suitable for larger components. | Heavy Equipment, Construction | Pros: Cost-effective for large quantities, excellent grain structure. Cons: Limited design flexibility. |

| Precision Forging | Focuses on tight tolerances and intricate designs, often requiring advanced tooling. | Aerospace, Defense, High-Performance Applications | Pros: High precision, reduced machining requirements. Cons: Higher upfront tooling costs. |

What Are the Characteristics of Hot Forging in Brass Aluminum Forging?

Hot forging is characterized by the shaping of brass and aluminum alloys at elevated temperatures, which enhances the material’s ductility and reduces the likelihood of brittleness. This method is highly suitable for applications in demanding industries such as aerospace and military, where strength and reliability are paramount. When considering hot forging, B2B buyers should evaluate the energy costs associated with the heating process and the potential for oxidation, which can affect the final product’s quality.

How Does Cold Forging Differ and What Are Its Key Benefits?

Cold forging is performed at room temperature, leading to improved surface finishes and tighter tolerances. This process is particularly advantageous for manufacturing smaller components used in electronics and medical devices, where precision is critical. Buyers should consider the mechanical properties that cold forging imparts to the final product, as well as the energy efficiency of the process. However, it is important to note that cold forging is typically limited to softer metals, which may restrict material options.

What Advantages Does Warm Forging Offer for B2B Buyers?

Warm forging operates at intermediate temperatures, providing a balance between the benefits of hot and cold forging. This technique is favored in automotive and industrial machinery applications, where both strength and formability are required. B2B buyers should assess the process’s ability to reduce tool wear and enhance strength, while also recognizing the need for precise temperature control to achieve optimal results.

What Are the Key Features of Drop Forging in Brass Aluminum Forging?

Drop forging involves the use of a hammer or a die to shape the metal, making it suitable for larger components typically found in heavy equipment and construction. This method is cost-effective for mass production due to its efficiency and the resulting superior grain structure. Buyers should weigh the benefits of reduced production costs against the limitations in design flexibility that drop forging may impose.

How Does Precision Forging Meet Specialized Needs in B2B Markets?

Precision forging is designed for applications that require tight tolerances and complex geometries, making it ideal for sectors like aerospace and defense. This process minimizes the need for additional machining, thus saving time and costs in production. However, B2B buyers must consider the higher initial tooling costs associated with precision forging, as well as the long-term benefits of enhanced product performance and durability.

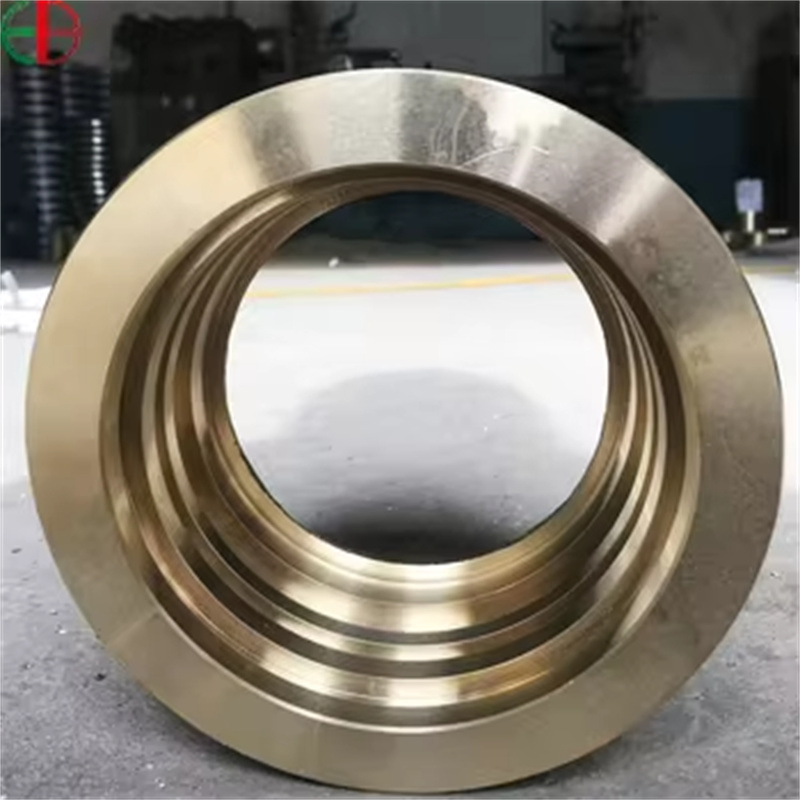

Illustrative image related to brass aluminum forging

Key Industrial Applications of brass aluminum forging

| Industry/Sector | Specific Application of brass aluminum forging | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft components such as brackets and fittings | High strength-to-weight ratio, essential for safety | Certifications (e.g., AS9100), compliance with international standards |

| Automotive | Engine components and transmission parts | Enhanced durability and performance under high stress | Precision tolerances, batch sizes, and lead times |

| Defense/Military | Firearm components, including receivers and triggers | Reliability and precision critical for operational success | Material certifications, traceability, and adherence to military specifications |

| Medical | Surgical instruments and implants | Biocompatibility and precision in critical applications | FDA compliance, quality assurance processes, and customization needs |

| Power Generation | Components for turbines and generators | Ability to withstand extreme conditions and corrosion | Material properties, environmental resistance, and longevity |

How is Brass Aluminum Forging Used in Aerospace Applications?

In the aerospace sector, brass aluminum forging is pivotal for producing components like brackets, fittings, and structural parts. These components require a high strength-to-weight ratio to ensure safety and performance during flight. Buyers from international markets, especially in Europe and the Middle East, must prioritize suppliers with AS9100 certification and adherence to stringent aerospace standards. This guarantees that the parts not only meet performance criteria but also comply with safety regulations mandated by aviation authorities.

What Role Does Brass Aluminum Forging Play in Automotive Manufacturing?

Brass aluminum forging is extensively utilized in the automotive industry for creating engine components and transmission parts. The forging process enhances the durability and performance of these parts under high stress, leading to improved vehicle reliability. B2B buyers from regions like South America and Africa should focus on suppliers that can provide precision tolerances and accommodate various batch sizes. Lead times are also crucial, as they directly impact production schedules and inventory management.

Why is Brass Aluminum Forging Critical for Defense and Military Applications?

In the defense sector, brass aluminum forging is essential for manufacturing firearm components, including receivers and triggers. The reliability and precision of these parts are critical for operational success in various military applications. International buyers, particularly from Africa and Europe, need to ensure that their suppliers can provide material certifications and traceability to meet military specifications. This focus on compliance helps mitigate risks associated with performance and safety in the field.

How is Brass Aluminum Forging Beneficial in Medical Devices?

In the medical industry, brass aluminum forging is used to produce surgical instruments and implants that require high precision and biocompatibility. These components are crucial in critical applications where safety and effectiveness are paramount. Buyers should seek suppliers with FDA compliance and robust quality assurance processes to ensure that the instruments meet stringent medical standards. Customization capabilities are also essential, as medical applications often require tailored solutions to meet specific procedural needs.

What Advantages Does Brass Aluminum Forging Offer in Power Generation?

Brass aluminum forging is vital for creating components used in turbines and generators within the power generation sector. These components must withstand extreme conditions and resist corrosion to ensure long-term reliability and efficiency. B2B buyers should evaluate the material properties and environmental resistance of the forgings they source. Additionally, understanding the longevity and performance characteristics of the components is key to making informed purchasing decisions that align with operational goals.

3 Common User Pain Points for ‘brass aluminum forging’ & Their Solutions

Scenario 1: Inconsistent Quality in Forged Components

The Problem: A common challenge faced by B2B buyers in industries such as aerospace, automotive, and medical is the inconsistency in quality of forged components. When sourcing brass aluminum forgings, discrepancies in specifications, materials, and manufacturing processes can lead to parts that do not meet critical performance standards. This can result in costly rework, production delays, and even safety hazards in end applications. Buyers may find themselves questioning the reliability of their suppliers, especially when products arrive with defects or do not meet the required tolerances.

The Solution: To mitigate quality inconsistencies, B2B buyers should prioritize sourcing from certified manufacturers who adhere to industry standards such as ISO 9001 and AS9100. Request comprehensive quality assurance documentation and inspect the supplier’s manufacturing processes. Establishing a collaborative relationship with the forging partner can also lead to better outcomes. Engage in pre-production reviews to verify specifications and materials, and consider implementing a quality audit process. Additionally, investing in advanced quality control technologies, such as automated inspection systems, can help ensure that every batch meets the required standards before delivery.

Scenario 2: Long Lead Times Impacting Production Schedules

The Problem: International buyers often face lengthy lead times when ordering brass aluminum forgings, especially when working with overseas suppliers. Such delays can disrupt production schedules, leading to lost revenue and strained relationships with clients. The challenge is exacerbated by time zone differences and communication barriers, making it difficult to obtain updates on order status or address any issues that may arise during the manufacturing process.

The Solution: To address lead time issues, buyers should consider establishing partnerships with suppliers who have a strong local presence or regional manufacturing facilities. This can significantly reduce shipping times and enhance communication. Furthermore, implementing a Just-In-Time (JIT) inventory strategy can streamline the supply chain and minimize the need for large inventory holdings. Buyers should also communicate their production timelines clearly and negotiate expedited shipping options in advance. Lastly, utilizing project management tools to track orders and maintain open lines of communication with suppliers can help anticipate delays and adjust schedules accordingly.

Scenario 3: Difficulty in Customization for Specialized Applications

The Problem: In many cases, B2B buyers require custom forged components to fit specific applications, whether in military, medical, or automotive sectors. However, they often encounter challenges in conveying their unique specifications to manufacturers. Miscommunication can lead to parts that do not function as intended, resulting in wasted resources and potential project setbacks.

Illustrative image related to brass aluminum forging

The Solution: To ensure successful customization, buyers should provide detailed technical drawings and specifications, including tolerances, materials, and finishing requirements. Engaging in initial consultations with potential suppliers can help clarify capabilities and expectations. It may also be beneficial to request prototypes before committing to larger production runs, allowing for adjustments and refinements based on real-world testing. Building a collaborative approach with engineers from the forging company can lead to innovative solutions that meet specific needs. Additionally, incorporating feedback loops during the design and production phases can enhance the final product’s alignment with buyer expectations.

Strategic Material Selection Guide for brass aluminum forging

What Are the Key Properties of Brass in Forging Applications?

Brass is an alloy primarily composed of copper and zinc, known for its excellent machinability and corrosion resistance. It typically exhibits good strength and ductility, making it suitable for various forging applications. Brass can withstand moderate temperatures and pressures, making it ideal for components in the automotive and aerospace sectors. Its resistance to corrosion, particularly in marine environments, enhances its longevity in applications like plumbing fittings and electrical connectors.

Pros and Cons of Brass Forging

The advantages of using brass in forging include its durability and ease of machining, which can reduce manufacturing complexity and costs. However, brass can be more expensive than other materials, and its mechanical properties may not be suitable for high-stress applications. Additionally, brass’s susceptibility to dezincification in certain environments can limit its use in specific applications.

How Does Aluminum Perform in Forging Processes?

Aluminum, particularly in its alloyed forms, is lightweight and exhibits excellent strength-to-weight ratios. It has good thermal and electrical conductivity, making it a popular choice for industries such as automotive and aerospace. Aluminum forgings can withstand high temperatures and pressures, and they are often treated with anodizing to enhance corrosion resistance.

Illustrative image related to brass aluminum forging

Pros and Cons of Aluminum Forging

The primary advantage of aluminum is its lightweight nature, which can lead to significant fuel savings in transportation applications. However, aluminum forgings can be more complex to manufacture due to the need for precise temperature control during the forging process. Additionally, while aluminum is generally less expensive than brass, the cost can vary significantly based on alloy composition and market conditions.

What Are the Benefits of Copper in Forging Applications?

Copper is renowned for its excellent electrical and thermal conductivity, making it indispensable in electrical applications. It also has good corrosion resistance and can be easily forged into intricate shapes. Copper forgings can perform well under high temperatures and pressures, making them suitable for applications in the electrical and plumbing industries.

Pros and Cons of Copper Forging

The key advantage of copper is its superior conductivity, which is essential for electrical components. However, copper is heavier than aluminum and brass, which can be a disadvantage in applications where weight is a critical factor. The cost of copper is typically higher than that of aluminum and brass, which may impact budget considerations for large-scale projects.

What Should International Buyers Consider for Brass Aluminum Forging?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must consider compliance with local standards and regulations. Common standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards) can influence material selection. Additionally, buyers should be aware of the local market conditions, including material availability and cost fluctuations, which can impact project timelines and budgets.

Summary Table of Material Selection for Brass Aluminum Forging

| Material | Typical Use Case for brass aluminum forging | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Plumbing fittings, electrical connectors | Excellent corrosion resistance | More expensive than alternatives | Medium |

| Aluminum | Automotive components, aerospace parts | Lightweight with high strength-to-weight ratio | Complex manufacturing process | Medium |

| Copper | Electrical wiring, plumbing applications | Superior electrical and thermal conductivity | Heavier and more expensive | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to make informed decisions in the brass aluminum forging market. Understanding the properties, advantages, and limitations of each material will aid in selecting the most suitable option for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for brass aluminum forging

What Are the Key Stages in the Manufacturing Process of Brass Aluminum Forging?

The manufacturing process for brass aluminum forging is a detailed and precise operation that typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the quality and performance of the final product.

1. Material Preparation: How Are Raw Materials Processed?

The initial step in the manufacturing process involves the careful selection and preparation of raw materials, primarily brass and aluminum alloys. The selection criteria include mechanical properties, corrosion resistance, and thermal conductivity, which are crucial for the intended application.

Once the materials are chosen, they are subjected to thorough cleaning to remove any contaminants or oxides. This is often done through chemical cleaning or shot blasting. The cleaned materials are then cut into appropriate sizes, typically in the form of billets or bars, which are subsequently heated to the desired temperature to enhance malleability.

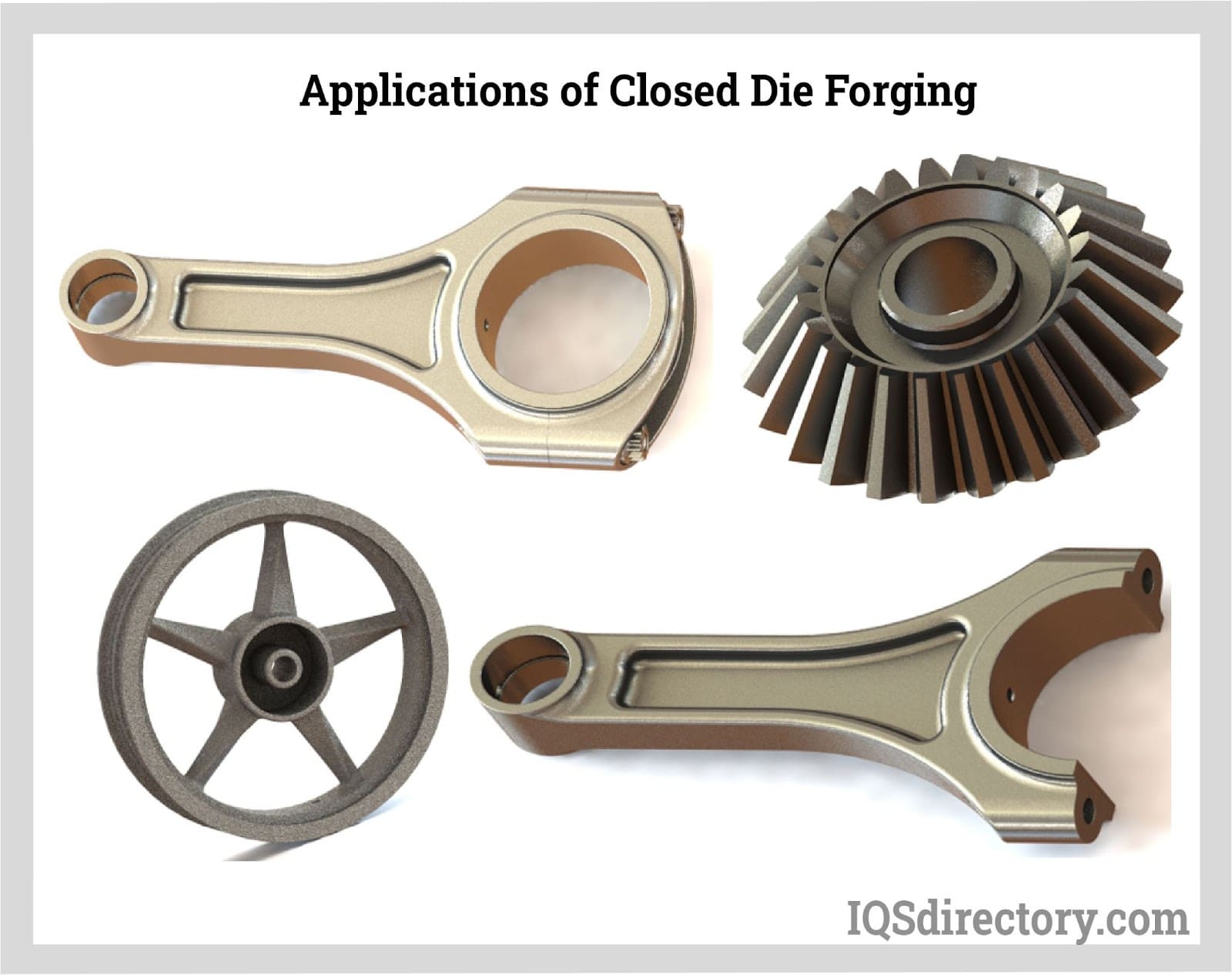

2. Forming: What Techniques Are Used to Shape the Forgings?

The forming stage is where the actual forging takes place. There are several techniques employed, including hot forging, warm forging, and cold forging. Hot forging is the most common method for brass and aluminum, as it allows for easier shaping at elevated temperatures, resulting in better mechanical properties.

During hot forging, the heated billet is placed into a die and subjected to high pressure, which deforms the material to take on the shape of the die. This process can be performed using various machinery, such as hammers or hydraulic presses. Warm forging operates at a lower temperature than hot forging but still enhances the material’s ductility. Cold forging, on the other hand, is performed at room temperature and is used for applications requiring high dimensional accuracy and surface finish.

Illustrative image related to brass aluminum forging

3. Assembly: How Are Components Joined or Integrated?

In some cases, especially for complex assemblies, multiple forged components may need to be joined. This can be accomplished through welding, riveting, or mechanical fastening methods. Each method has its own advantages and is chosen based on the specific requirements of the application, such as load-bearing capacity and resistance to environmental factors.

The assembly process is typically followed by an inspection to ensure that all components fit together correctly and meet the design specifications.

4. Finishing: What Post-Processing Techniques Enhance Product Quality?

Finishing is a crucial stage that enhances both the aesthetics and functionality of the forged parts. Common finishing techniques include machining, heat treating, anodizing, and surface treatment.

- Machining is used to achieve tighter tolerances and smoother surfaces.

- Heat treating enhances material strength and toughness, while also relieving any internal stresses from the forging process.

- Anodizing is particularly important for aluminum components, as it improves corrosion resistance and surface hardness.

- Surface treatments such as shot peening can also be applied to improve fatigue resistance.

How Is Quality Assurance Implemented in Brass Aluminum Forging?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that products meet international and industry-specific standards. Effective QA involves a series of checkpoints throughout the manufacturing cycle.

1. What International Standards Govern Quality in Brass Aluminum Forging?

For brass aluminum forging, adherence to international standards such as ISO 9001 is essential. This standard outlines requirements for a quality management system, ensuring that organizations consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications like AS9100 for aerospace components or API standards for oil and gas applications may also apply.

2. What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) is typically divided into three main checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to verify compliance with specifications. Materials not meeting standards are rejected or reprocessed.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checks are conducted to monitor parameters like temperature, pressure, and dimensional accuracy. This ensures that any deviations are corrected in real-time, minimizing defects.

-

Final Quality Control (FQC): After manufacturing, products undergo a comprehensive inspection that includes dimensional checks, visual inspections, and functional tests. This final checkpoint is critical for confirming that the products meet all specified requirements before shipment.

3. How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to verify a supplier’s quality control processes should consider several approaches:

-

Audits: Conducting on-site audits of suppliers can provide insights into their manufacturing capabilities and QA processes. This can include reviewing documentation, inspecting facilities, and observing manufacturing practices.

-

Quality Reports: Requesting detailed quality reports can help buyers assess the supplier’s performance history, including defect rates and compliance with industry standards.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the supplier’s quality processes and product compliance. These inspectors can perform random checks or complete audits based on the buyer’s requirements.

What Nuances Should International B2B Buyers Consider Regarding QC?

When dealing with international suppliers, B2B buyers from regions such as Africa, South America, the Middle East, and Europe should consider the following:

Illustrative image related to brass aluminum forging

-

Cultural Differences: Communication styles and business practices may vary significantly across cultures, which can impact quality expectations and delivery timelines. Establishing clear communication protocols is essential.

-

Regulatory Compliance: Different countries have varying regulations regarding product quality and safety. Buyers must ensure that suppliers comply with both local regulations and international standards.

-

Supply Chain Logistics: Understanding the logistics of shipping and customs regulations can help mitigate risks related to delays and compliance issues.

In summary, the manufacturing processes and quality assurance practices in brass aluminum forging are complex and critical to ensuring the production of high-quality components. By understanding these processes, B2B buyers can make informed decisions when sourcing from international suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brass aluminum forging’

To effectively procure brass aluminum forgings, an organized approach ensures that you meet your project specifications while maintaining quality and budgetary constraints. The following checklist outlines crucial steps for B2B buyers to streamline their sourcing process.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes dimensions, tolerances, material grades, and any specific finishes or coatings needed. Precise specifications help potential suppliers understand your needs and provide accurate quotes, minimizing the risk of miscommunication later in the process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in brass aluminum forgings. Look for companies with extensive experience in your industry, as well as positive customer reviews and case studies that demonstrate their capabilities. Utilize industry associations and trade shows to gather insights and recommendations.

Step 3: Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications, such as ISO 9001 and AS9100, which indicate adherence to international quality management standards. Certification validates a supplier’s commitment to quality and safety, reducing the likelihood of defects in your forgings. Additionally, inquire about their compliance with industry-specific regulations, especially if your application involves aerospace or military components.

Step 4: Request Samples and Prototypes

Prior to making a bulk order, request samples or prototypes of the forgings you require. Evaluating samples allows you to assess the quality of materials, craftsmanship, and adherence to your specifications. This step is crucial for establishing a reliable relationship with your supplier and ensuring that the final products will meet your expectations.

Step 5: Discuss Production Capabilities and Lead Times

Engage with suppliers to understand their production capabilities and lead times. Ask about their manufacturing processes, equipment, and capacity to handle your order volume. Understanding lead times is essential for project planning, especially if your production schedule is tight.

Step 6: Evaluate Quality Control Measures

Inquire about the quality control measures implemented by your suppliers. Look for details on inspection processes, testing protocols, and how they handle defects or discrepancies. A robust quality assurance program is vital to ensuring consistent product quality and minimizing the risk of costly errors.

Illustrative image related to brass aluminum forging

Step 7: Review Terms and Conditions

Before finalizing your order, carefully review the terms and conditions proposed by the supplier. Pay close attention to payment terms, warranty policies, and return procedures. Understanding these elements helps mitigate risks and ensures that both parties are aligned on expectations.

By following this checklist, B2B buyers can navigate the complexities of sourcing brass aluminum forgings more effectively, ensuring they select the right suppliers and achieve optimal results for their projects.

Comprehensive Cost and Pricing Analysis for brass aluminum forging Sourcing

What Are the Key Cost Components in Brass Aluminum Forging?

When sourcing brass aluminum forgings, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The cost of raw materials is a significant factor, particularly for non-ferrous metals like brass and aluminum. Prices fluctuate based on market conditions, alloy specifications, and global demand. For buyers, it’s essential to stay informed about commodity prices and consider the potential for price volatility.

-

Labor: Labor costs encompass skilled workforce wages, which can vary significantly based on the region and the complexity of the forging process. For instance, labor costs in Europe may be higher compared to those in Africa or South America. Additionally, labor costs can be influenced by the level of automation in the manufacturing process.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, facility costs, and administrative expenses. Efficient operations can lower overhead costs, which may be passed on to buyers.

-

Tooling: Tooling costs are particularly relevant for custom or complex forgings. The initial investment in dies and molds can be substantial, and these costs are often amortized over large production runs. Buyers should inquire about tooling costs when negotiating pricing, especially for low-volume orders.

-

Quality Control (QC): Rigorous quality assurance processes are essential in the forging industry to meet international standards. QC costs can include testing, inspection, and certification fees, which should be factored into the overall pricing.

-

Logistics: Shipping and handling costs can vary widely based on distance, mode of transport, and delivery terms. International buyers must consider these costs, which can significantly affect the total price of sourced products.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition, supplier reputation, and the complexity of the product.

How Do Price Influencers Impact Sourcing Decisions?

Several factors influence the pricing of brass aluminum forgings, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their production needs to optimize pricing.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Material Quality and Certifications: The presence of certifications such as ISO or AS9100 can add to the cost but also provide assurance of quality. Buyers should weigh the benefits of certified products against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more for their products but could offer better quality and service.

-

Incoterms: Understanding Incoterms is vital for international transactions. They dictate who bears the cost and risk during shipping, which can influence the overall cost structure.

What Are the Best Buyer Tips for Cost-Efficiency?

To enhance cost-efficiency in sourcing brass aluminum forgings, consider the following strategies:

-

Negotiate Effectively: Engaging in open discussions with suppliers about pricing can lead to better deals. Highlighting your long-term potential as a customer can incentivize suppliers to offer competitive rates.

-

Assess Total Cost of Ownership (TCO): Look beyond initial pricing. Consider long-term factors like durability, maintenance, and logistics that can impact the overall cost.

-

Stay Informed on Market Trends: Keeping an eye on metal prices and global market trends can provide leverage in negotiations. Understanding seasonal fluctuations can also help in timing purchases.

-

Evaluate Multiple Suppliers: Obtaining quotes from several suppliers can provide insight into market pricing and help in identifying the best value.

-

Customize Wisely: While customization can enhance product performance, it often comes at a premium. Evaluate if standard solutions can meet your needs without incurring additional costs.

Conclusion

While sourcing brass aluminum forgings involves various cost components and pricing influencers, informed decision-making can lead to significant savings. By understanding the cost structure, negotiating effectively, and considering the total cost of ownership, B2B buyers can optimize their sourcing strategies for better outcomes. Always remember that indicative prices can fluctuate, so continuous market monitoring is essential for maintaining cost efficiency.

Alternatives Analysis: Comparing brass aluminum forging With Other Solutions

When considering manufacturing processes for components in various industries, B2B buyers often evaluate multiple solutions to determine the most effective method. Brass aluminum forging, known for its strength and versatility, is just one option among several alternatives, each with its unique advantages and limitations. This analysis compares brass aluminum forging with two viable alternatives: CNC Machining and Die Casting.

Comparison Table

| Comparison Aspect | Brass Aluminum Forging | CNC Machining | Die Casting |

|---|---|---|---|

| Performance | High strength and durability; excellent for complex shapes | High precision; ideal for intricate designs | Good surface finish; suitable for large volumes |

| Cost | Moderate to high; tooling can be expensive | High initial setup costs, but economical for large runs | Lower cost per unit at high volumes, higher initial investment |

| Ease of Implementation | Requires specialized equipment and skilled labor | Requires CNC machinery and skilled operators | Requires specific molds and machinery setup |

| Maintenance | Low; durable end products | Moderate; wear on tools and machinery | Moderate; molds may require regular maintenance |

| Best Use Case | Aerospace, automotive, and defense applications needing high strength | Custom parts, prototypes, and intricate designs | High-volume production of non-ferrous parts |

Detailed Breakdown of Alternatives

CNC Machining

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses programmed software to control machining tools. One of the primary advantages of CNC machining is its ability to produce highly intricate components with tight tolerances. This method is particularly beneficial for custom parts and prototypes. However, the initial setup costs can be high due to the need for advanced machinery and skilled operators. While it offers flexibility in design, the per-unit cost can become expensive if production volumes are low.

Die Casting

Die casting is a manufacturing process that involves forcing molten metal into a mold under high pressure. This method is especially well-suited for mass production, providing good dimensional accuracy and surface finish. The main advantage of die casting is its cost-effectiveness at high volumes, as the cost per unit decreases significantly with increased production. However, the initial investment in molds and machinery can be substantial, and die casting is typically limited to non-ferrous metals. Additionally, the process may not be as suitable for highly complex shapes compared to forging.

Conclusion

When choosing the right manufacturing solution, B2B buyers should carefully evaluate their specific needs, including performance requirements, budget constraints, and production volumes. Brass aluminum forging excels in applications requiring high strength and durability, making it ideal for industries such as aerospace and defense. CNC machining offers flexibility and precision for custom parts, while die casting is an excellent choice for high-volume production with cost-efficiency. By assessing these factors, buyers can make informed decisions that align with their operational goals and product specifications.

Essential Technical Properties and Trade Terminology for brass aluminum forging

When navigating the brass aluminum forging landscape, understanding critical technical properties and industry terminology is essential for effective decision-making. This section outlines key specifications and common jargon that B2B buyers should be familiar with.

What Are the Essential Technical Properties in Brass Aluminum Forging?

1. Material Grade

Material grades, such as ASTM B455 or UNS C36000, specify the chemical composition and mechanical properties of brass and aluminum alloys. Each grade has distinct characteristics, influencing strength, corrosion resistance, and machinability. For B2B buyers, selecting the right material grade is crucial for ensuring that the forged components meet performance requirements in applications like aerospace or automotive manufacturing.

2. Tolerance

Tolerance refers to the permissible limit of variation in a manufactured component’s dimensions. In brass aluminum forging, tight tolerances (e.g., ±0.005 inches) are often required for precision parts. Understanding tolerance specifications is vital for buyers, as deviations can lead to assembly issues or functional failures in end products.

3. Yield Strength

Yield strength indicates the maximum stress a material can withstand before it begins to deform permanently. For brass and aluminum forgings, higher yield strength translates to greater durability and load-bearing capacity. This property is particularly significant for industries like aerospace and automotive, where safety and reliability are paramount.

4. Surface Finish

Surface finish describes the texture and quality of a forged part’s surface, often specified in terms of Ra (roughness average). A superior surface finish can enhance corrosion resistance and aesthetics, which are critical in consumer-facing applications. For B2B buyers, understanding surface finish requirements can impact overall product quality and longevity.

Illustrative image related to brass aluminum forging

5. Heat Treatment

Heat treatment processes, such as annealing or aging, alter the mechanical properties of brass and aluminum forgings. This process can enhance strength, ductility, and toughness. Buyers should consider the implications of heat treatment on performance and cost, as it may influence production timelines and pricing.

What Are Common Trade Terms in Brass Aluminum Forging?

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are sold under another company’s brand name. In the context of brass aluminum forging, OEMs often outsource their forging needs to specialized manufacturers. Understanding OEM relationships is crucial for buyers looking to establish long-term partnerships for consistent quality and supply.

2. MOQ (Minimum Order Quantity)

MOQ represents the minimum number of units a supplier is willing to produce or sell. This term is significant for B2B buyers, as it can affect inventory management and cost efficiency. Knowing the MOQ helps buyers assess whether a supplier can meet their production needs without incurring excessive costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For brass aluminum forging, submitting an RFQ allows buyers to compare offers from multiple manufacturers, ensuring they secure competitive pricing and favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international shipping to define the responsibilities of buyers and sellers. Understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for B2B buyers engaged in cross-border transactions, as they clarify cost allocation and risk during transport.

Illustrative image related to brass aluminum forging

5. CAD (Computer-Aided Design)

CAD refers to software used to create precise drawings and technical illustrations for manufacturing. In brass aluminum forging, CAD files are often shared between buyers and manufacturers to ensure accurate production of complex designs. Familiarity with CAD can streamline communication and enhance collaboration between parties.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions that align with their production goals and market demands. Understanding these elements fosters effective communication with suppliers and enhances the overall procurement process.

Navigating Market Dynamics and Sourcing Trends in the brass aluminum forging Sector

What are the Current Market Trends in Brass Aluminum Forging?

The brass aluminum forging sector is witnessing significant growth, driven by the increasing demand for lightweight and high-strength materials across various industries. Key markets include aerospace, automotive, medical, and defense, where the need for precision components is paramount. In particular, the automotive sector is transitioning towards electric vehicles (EVs), which require advanced materials to enhance performance and efficiency. This trend is encouraging manufacturers to adopt innovative forging technologies, such as warm and cold forging, to produce components that meet stricter weight and strength specifications.

Illustrative image related to brass aluminum forging

International buyers from regions like Africa, South America, the Middle East, and Europe are also increasingly leveraging digital tools for sourcing. Platforms that facilitate direct communication with manufacturers and streamline procurement processes are becoming essential. Additionally, data analytics and AI-driven insights are helping buyers identify the best suppliers, manage risks, and optimize inventory, thus reducing lead times and costs. Emerging technologies, such as additive manufacturing and automated machining, are also influencing sourcing decisions, allowing for customization and rapid prototyping.

How Does Sustainability Impact Sourcing in Brass Aluminum Forging?

Sustainability has become a critical concern in the brass aluminum forging industry, significantly impacting sourcing decisions. The environmental impact of metal forging, particularly in terms of energy consumption and waste generation, has prompted companies to seek greener practices. Ethical sourcing is not only a regulatory requirement in many regions but also a consumer expectation. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management).

Incorporating recycled materials into the forging process is one effective way to enhance sustainability. Many manufacturers are now sourcing brass and aluminum alloys that contain recycled content, thereby reducing the carbon footprint associated with raw material extraction and processing. Additionally, investing in energy-efficient equipment and exploring renewable energy sources are becoming common practices among industry leaders. These initiatives not only contribute to environmental conservation but also enhance brand reputation, making them attractive to a growing segment of environmentally conscious consumers and businesses.

How Has the Brass Aluminum Forging Sector Evolved Over Time?

The brass aluminum forging industry has evolved significantly since its inception, transitioning from traditional manual techniques to advanced automated processes. Established in the early 20th century, companies like Brass Aluminum Forging Enterprises have played a crucial role in this evolution, setting standards for quality and precision. Over the decades, technological advancements such as computer numerical control (CNC) machining and automation have revolutionized production capabilities, allowing for higher precision and lower production costs.

The industry’s focus has shifted towards meeting the demands of modern applications, particularly in high-performance sectors like aerospace and automotive. This evolution is characterized by a greater emphasis on research and development, leading to innovative forging techniques that enhance material properties and component design. As global markets continue to expand, the brass aluminum forging sector is positioned to capitalize on emerging trends, ensuring its relevance and competitiveness in the international landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of brass aluminum forging

-

How do I ensure the quality of brass aluminum forgings from international suppliers?

To ensure the quality of brass aluminum forgings, verify that the supplier adheres to recognized quality standards, such as ISO 9001 or AS9100 certifications. Request documentation of their quality assurance processes, including material certifications and inspection reports. It’s also beneficial to seek samples for preliminary evaluation before placing a bulk order. Establishing a clear communication channel for ongoing quality checks throughout production can help mitigate risks. Additionally, consider third-party inspections to provide an unbiased assessment of the products. -

What factors should I consider when choosing a supplier for brass aluminum forgings?

When selecting a supplier, consider their experience in the industry, production capabilities, and specialization in the specific type of forging you require. Assess their reputation by checking client testimonials and case studies. It’s also important to evaluate their ability to provide custom solutions, lead times, and flexibility with minimum order quantities (MOQs). Furthermore, ensure they have robust logistics systems in place for timely delivery to your location, particularly if you are sourcing from different continents. -

What customization options are typically available for brass aluminum forgings?

Many suppliers offer a range of customization options, including size, shape, and material specifications. You can request specific tolerances, surface treatments, and finishes to meet your application requirements. Discuss your design specifications with the supplier’s engineering team, who can provide insights into manufacturability and material suitability. Be clear about your needs, as early collaboration can lead to better outcomes and cost efficiency in the production process. -

What is the typical minimum order quantity (MOQ) for brass aluminum forgings?

The minimum order quantity for brass aluminum forgings can vary significantly depending on the supplier and the complexity of the part. Generally, MOQs can range from a few hundred to several thousand units. Suppliers often set MOQs based on production costs and economies of scale. If you have a smaller requirement, some suppliers may accommodate you by charging a premium or offering a prototype service, allowing you to test designs without committing to larger orders. -

What payment terms are standard in international B2B transactions for forgings?

Standard payment terms can include options such as net 30, net 60, or advance payment for new customers. Many suppliers require a deposit upon order confirmation, with the balance due upon completion or prior to shipment. It is crucial to establish clear payment terms upfront to avoid misunderstandings. Additionally, consider using secure payment methods or escrow services to protect your financial interests, especially when dealing with new suppliers. -

How can I manage logistics for sourcing brass aluminum forgings from overseas?

Managing logistics involves several key steps: selecting a reliable freight forwarder familiar with international shipping regulations, determining the most cost-effective shipping method (air or sea), and ensuring compliance with customs requirements. Communicate closely with your supplier regarding packaging and labeling to prevent delays. Additionally, consider the lead times for production and shipping to align with your inventory needs. Tracking shipments and having contingency plans for potential delays can also enhance your logistics management. -

What industries commonly use brass aluminum forgings, and how can this impact my sourcing decisions?

Brass aluminum forgings are widely used in industries such as aerospace, automotive, medical, and military applications. Understanding the specific requirements of these industries can guide your sourcing decisions, as certain sectors may demand higher quality standards or specific certifications. Align your sourcing strategy with industry trends, as demand fluctuations in these sectors can affect lead times and pricing. It’s also beneficial to work with suppliers who specialize in your industry to leverage their expertise. -

What are the common challenges in international sourcing of brass aluminum forgings, and how can I overcome them?

Common challenges include language barriers, differing quality standards, and logistical complications. To overcome these, establish clear communication channels and consider hiring a local representative or translator. Conduct thorough research on suppliers’ quality certifications and production capabilities to ensure they align with your standards. Additionally, build strong relationships with suppliers to foster trust and open dialogue, which can help address issues proactively. Utilizing technology for real-time tracking and communication can also enhance the efficiency of your sourcing process.

Top 5 Brass Aluminum Forging Manufacturers & Suppliers List

1. BA Forging Enterprises – Non-Ferrous Closed Die Forgings

Domain: baforging.com

Registered: 1999 (26 years)

Introduction: BA Forging Enterprises specializes in the production of brass, copper, and aluminum forgings. They offer non-ferrous closed die forgings and have experience in various fields since 1934. Their major markets served include Military/Firearms, Automotive/Motor Sports, Aerospace, Medical, Power Generation, and Mining. Specialty services include Heat Treating/Hardening, Shot Peening/Blasting, Vibratory…

2. BAFE – Aluminum Forgings for AR-15 Upper Receivers

Domain: ar15.com

Registered: 1997 (28 years)

Introduction: Brass Aluminum Forging Enterprises (BAFE) produces aluminum forgings used by various manufacturers for AR-15 upper receivers. Notable brands that utilize BAFE products include Bravo Company, Daniel Defense, Colt, Rock River, and CMMG. The company is located in Ferndale, MI, and is known for its square forge mark labeled “Military Components.” The discussion also mentions potential compatibility is…

3. Brass Aluminum Forging Enterprises – Precision Aluminum and Brass Forgings

Domain: forgingcompanies.com

Registered: 2025 (0 years)

Introduction: Brass Aluminum Forging Enterprises is a leading manufacturer of precision aluminum and brass forgings for various industries, including aerospace, defense, medical, and automotive. Established in 1934, they offer hot forging, warm forging, and cold forging capabilities. Their products range from small intricate parts to large complex forgings, with production quantities from small prototype runs t…

4. Indeed – Employee Experience Insights

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, Indeed – Employee Experience Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. QC Forge – Brass Forging Components

Domain: qcforge.com

Registered: 1995 (30 years)

Introduction: Brass forging is a precision manufacturing process that creates strong, reliable parts with superior strength, corrosion resistance, and cost-efficiency compared to other manufacturing techniques. Common forged brass components include valves, pipe fittings, hose ends, and more. Brass is an alloy primarily made of copper and zinc, known for its excellent working properties, hardness, and lower mel…

Strategic Sourcing Conclusion and Outlook for brass aluminum forging

In the dynamic landscape of brass aluminum forging, strategic sourcing emerges as a cornerstone for B2B buyers aiming to enhance operational efficiency and product quality. By partnering with reputable manufacturers like Brass Aluminum Forging Enterprises, businesses can leverage advanced forging techniques and extensive expertise across diverse sectors, including aerospace, automotive, and medical applications. The emphasis on quality assurance through certifications such as AS9100 and ISO 9001 ensures that international buyers receive products that meet stringent standards.

As industries evolve, the demand for high-strength, lightweight materials continues to rise. This presents an opportunity for companies in Africa, South America, the Middle East, and Europe to capitalize on innovations in forging technology. Engaging with established suppliers not only facilitates access to cutting-edge solutions but also supports sustainable practices that are becoming increasingly vital in global markets.

Looking ahead, B2B buyers should prioritize strategic sourcing in their procurement strategies. By fostering strong relationships with key suppliers, businesses can ensure they remain competitive in a rapidly changing environment. Take the next step in your sourcing journey—explore partnerships that align with your goals and drive your business forward in the brass aluminum forging sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.