Diagram Of A Ball Valve: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for diagram of a ball valve

In today’s competitive landscape, sourcing the right components for industrial applications can be a daunting challenge for B2B buyers, especially when it comes to complex products like the diagram of a ball valve. These valves play a critical role in controlling the flow of liquids and gases across various sectors, from oil and gas to food processing. Understanding the intricacies of ball valve designs, types, and applications is essential for making informed purchasing decisions that align with operational needs and regulatory standards.

This comprehensive guide delves into the various types of ball valves, including two-way and multi-port options, as well as their specific applications in different industries. We will explore critical aspects such as supplier vetting processes, cost considerations, and maintenance tips. By equipping international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe like Nigeria and Germany—with actionable insights, this guide aims to empower you to navigate the global market effectively.

Whether you are looking to streamline procurement processes or enhance your technical knowledge of ball valves, our insights will help you make educated decisions that support your business objectives and ensure operational efficiency.

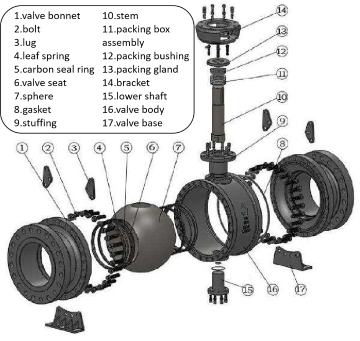

Understanding diagram of a ball valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2-Way Ball Valve | Two ports for on/off control; simple design | Oil & Gas, Water Treatment, HVAC | Pros: Cost-effective, straightforward installation. Cons: Limited to basic flow control. |

| 3-Way Ball Valve | Three ports for diverting flow; versatile | Chemical Processing, Food & Beverage, HVAC | Pros: Flexible flow direction, suitable for mixing. Cons: More complex design may increase costs. |

| Trunnion Ball Valve | Fixed ball design with lower operating torque | High-Pressure Systems, Oil & Gas, Water Treatment | Pros: Stable under high pressure, reduced wear. Cons: Typically higher initial investment. |

| Floating Ball Valve | Ball is supported by seats; common design | General Manufacturing, Automotive, Plumbing | Pros: Simple design, effective sealing. Cons: May require more torque for larger sizes. |

| Electric Actuated Valve | Automated control with electric actuators | Automated Systems, Remote Operations, HVAC | Pros: Precision control, reduces manual labor. Cons: Dependence on power supply, higher maintenance. |

What Are the Characteristics of a 2-Way Ball Valve?

The 2-way ball valve is the most basic type, featuring two ports that allow for simple on/off control of flow. This design is particularly suitable for applications requiring straightforward flow regulation, such as in oil and gas or water treatment facilities. B2B buyers should consider factors like the valve’s pressure rating and material compatibility, as these will affect performance and longevity in various operational environments.

How Does a 3-Way Ball Valve Work in Different Applications?

3-way ball valves have three ports, allowing them to either mix or divert flow. This versatility makes them ideal for industries like chemical processing and food and beverage, where precise control of media flow is crucial. When purchasing, buyers should evaluate the valve’s configuration—L-port or T-port—based on their specific application needs, as this will influence flow direction and mixing capabilities.

What Are the Benefits of Using Trunnion Ball Valves?

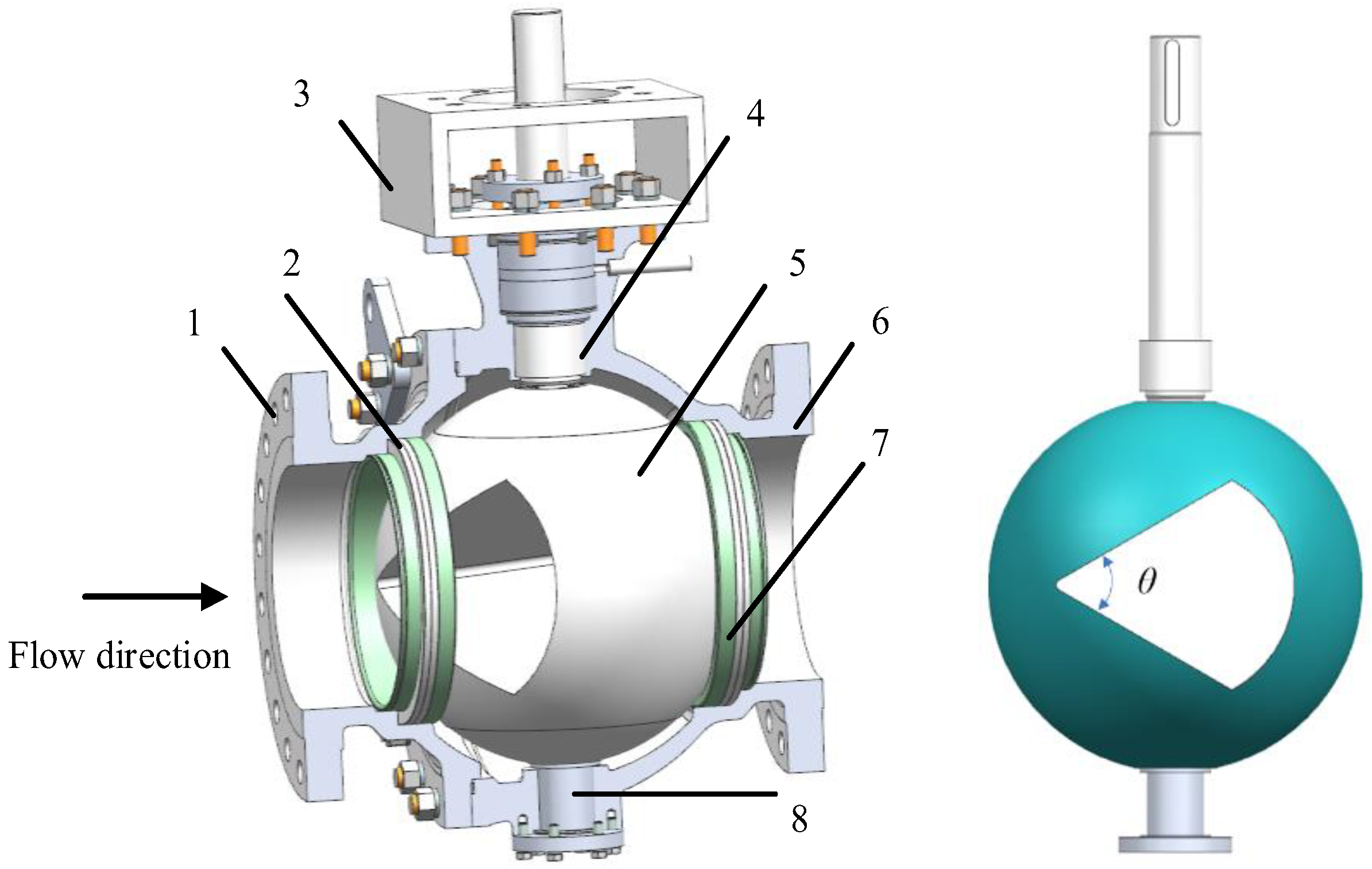

Trunnion ball valves feature a fixed ball design, which provides stability under high pressure, making them suitable for demanding applications like oil and gas and water treatment. Their lower operating torque also results in less wear and tear over time. Buyers should consider the initial investment costs against the potential for reduced maintenance and longer life cycle in high-pressure environments.

Why Choose Floating Ball Valves for General Manufacturing?

Floating ball valves are characterized by a ball that is supported by seats, making them a common choice for general manufacturing and plumbing applications. Their straightforward design allows for effective sealing and ease of operation. B2B buyers should assess the torque requirements and size of the valve, as larger floating ball valves may need more force to operate efficiently.

What Advantages Do Electric Actuated Ball Valves Offer?

Electric actuated valves allow for automated control, making them ideal for systems that require precision and remote operation, such as HVAC and other automated systems. While they offer the benefit of reducing manual labor and improving efficiency, buyers must consider the dependency on electrical power and the potential for higher maintenance costs, especially in environments where power supply may be inconsistent.

Key Industrial Applications of diagram of a ball valve

| Industry/Sector | Specific Application of diagram of a ball valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Control of flow in pipelines and refineries | Enhanced safety and efficiency in high-pressure environments | Material durability, compatibility with corrosive media, automation options |

| Food & Beverage | Regulation of liquid flow in processing systems | Compliance with hygiene standards and process efficiency | Certification standards (e.g., FDA), ease of cleaning, material safety |

| Water Treatment | Flow control in filtration and treatment processes | Improved water quality and operational reliability | Resistance to chemicals, maintenance requirements, local regulations |

| Pharmaceutical | Precise dosing and mixing of chemicals | High accuracy in formulation and compliance with regulations | Certification for pharmaceutical use, sealing performance, actuation options |

| Automotive | Fluid control in manufacturing and assembly lines | Increased production efficiency and reduced downtime | Compatibility with various fluids, size and fitting specifications, automation capabilities |

How Is the Diagram of a Ball Valve Used in the Oil & Gas Industry?

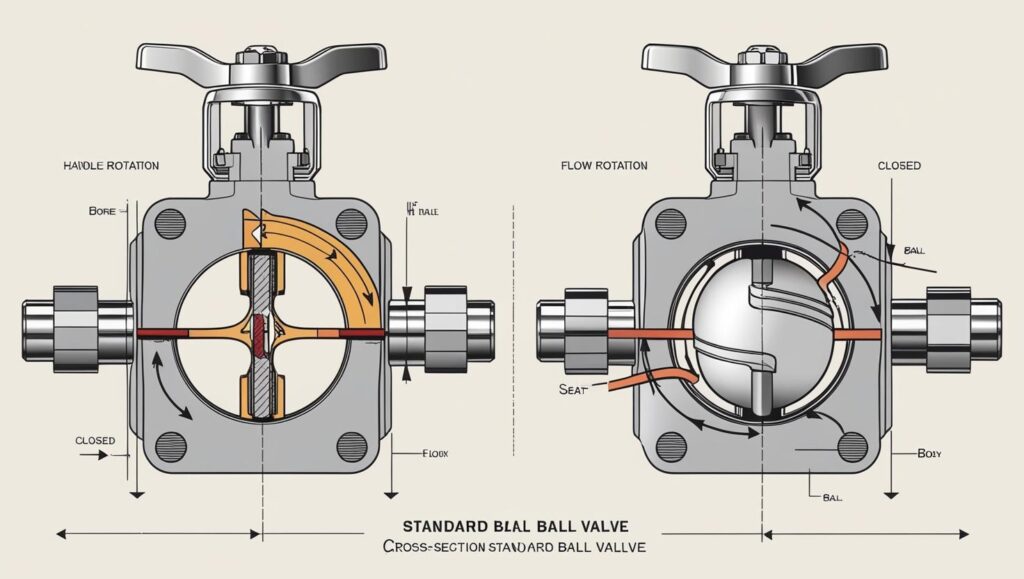

In the oil and gas sector, ball valves are critical for controlling the flow of hydrocarbons through pipelines and refineries. The diagram of a ball valve illustrates its operational mechanism, showcasing how the pivoting ball regulates flow. This application ensures safety in high-pressure environments while allowing for rapid shut-off capabilities. Buyers in this sector must consider the valve’s material durability, especially against corrosive substances, and the availability of automated actuation options for remote operations.

What Role Does a Ball Valve Play in Food & Beverage Processing?

In food and beverage production, ball valves are utilized to manage the flow of liquids in processing systems, ensuring that hygiene standards are met. The diagram highlights the valve’s construction, which is essential for maintaining cleanliness and preventing contamination. This application supports compliance with stringent food safety regulations, enhancing overall process efficiency. B2B buyers should prioritize valves with FDA certification, easy cleaning features, and materials that ensure safety in food contact.

How Are Ball Valves Applied in Water Treatment Facilities?

Water treatment plants rely on ball valves to control the flow of water through filtration and treatment processes. The diagram of a ball valve is vital for understanding its role in maintaining the quality of treated water. Effective flow control contributes to operational reliability and enhances water quality outcomes. Buyers must evaluate the valve’s resistance to various chemicals used in treatment processes and ensure compliance with local regulations regarding water safety.

What Is the Importance of Ball Valves in the Pharmaceutical Industry?

In pharmaceuticals, ball valves are crucial for precise dosing and mixing of chemicals during drug formulation. The diagram provides insight into how these valves function to ensure accuracy and compliance with industry regulations. This application is vital for maintaining product integrity and safety. Buyers in this sector should focus on valves that meet pharmaceutical certification standards, exhibit excellent sealing performance, and offer suitable actuation options for automated processes.

How Do Ball Valves Enhance Efficiency in Automotive Manufacturing?

Ball valves are used in automotive manufacturing for fluid control in various processes, including assembly lines. The diagram illustrates their design, which supports increased production efficiency and reduced downtime. This application allows for quick adjustments in fluid flow, essential for maintaining operational continuity. Buyers should ensure compatibility with diverse fluids, adhere to size and fitting specifications, and consider the benefits of automation to streamline their manufacturing processes.

3 Common User Pain Points for ‘diagram of a ball valve’ & Their Solutions

Scenario 1: Inconsistent Flow Regulation in High-Pressure Systems

The Problem: B2B buyers often encounter challenges with inconsistent flow regulation when using ball valves in high-pressure applications. This inconsistency can lead to inefficient operations, increased costs, and potential safety hazards. For example, in industries such as oil and gas or chemical processing, an improperly specified ball valve can result in fluctuating flow rates, making it difficult to maintain optimal pressure levels. This not only disrupts production but may also require costly downtime for adjustments or replacements.

The Solution: To address this issue, buyers should prioritize selecting ball valves that are specifically rated for the intended pressure and temperature conditions. Reviewing the valve specifications in detail is essential. Buyers should look for options like trunnion-mounted ball valves, which offer better flow control under high pressure due to their design. Additionally, conducting a thorough analysis of the piping and instrumentation diagram (P&ID) will help in understanding the specific flow requirements and ensuring the chosen ball valve aligns with those needs. Engaging with manufacturers or suppliers who offer technical support can also provide insights into the best practices for installation and operation, reducing the risk of flow inconsistencies.

Scenario 2: Difficulty in Understanding P&ID Symbols for Ball Valves

The Problem: International buyers, particularly those new to the industry, often struggle with interpreting piping and instrumentation diagrams (P&IDs) that include ball valve symbols. Misunderstanding these symbols can lead to improper installations or the selection of inappropriate valve types, resulting in operational inefficiencies or safety risks. For example, confusion between a 2-way and a 3-way valve can result in misrouting of fluids, potentially causing system failures.

The Solution: To overcome this challenge, buyers should invest time in familiarizing themselves with standard P&ID symbols and their meanings. Resources such as industry-specific training sessions, webinars, or online courses can significantly enhance understanding. Additionally, collaborating with experienced engineers during the design and planning phases can provide valuable insights into the correct application of ball valves as represented in P&IDs. Manufacturers often provide detailed documentation and guides explaining the symbols used in their diagrams, so buyers should leverage these resources to ensure they make informed decisions regarding the installation and operation of ball valves.

Scenario 3: Managing Maintenance Challenges for Automated Ball Valves

The Problem: Automated ball valves, while offering significant advantages in efficiency and control, can pose maintenance challenges for B2B buyers. These challenges often arise from the complexity of the actuation systems, which may include pneumatic, hydraulic, or electric components. For example, if a pneumatic ball valve fails due to a lack of proper maintenance, it can lead to unexpected downtimes and costly repairs, impacting production schedules.

The Solution: To mitigate maintenance issues, buyers should establish a comprehensive maintenance plan that includes regular inspections and servicing of the valve actuation components. Implementing a predictive maintenance program can be beneficial, utilizing sensors and monitoring systems to track the performance and health of the valves over time. This proactive approach allows for early detection of potential issues before they escalate into failures. Furthermore, buyers should work closely with suppliers to ensure they receive proper training on the maintenance of automated ball valves, including understanding the specific requirements of different actuation types. By prioritizing maintenance and leveraging supplier expertise, businesses can enhance the reliability and longevity of their automated ball valve systems.

Strategic Material Selection Guide for diagram of a ball valve

When selecting materials for ball valves, it is essential to consider the specific requirements of the application, including the type of media being handled, operating conditions, and regulatory compliance. Below is an analysis of four common materials used in ball valve construction, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Stainless Steel for Ball Valves?

Stainless steel is a popular choice for ball valves due to its excellent corrosion resistance and high strength. It typically has a temperature rating of up to 400°F (204°C) and can withstand high pressures, making it suitable for various applications, including oil and gas, chemical processing, and food and beverage industries.

Pros: Stainless steel is durable and can handle extreme conditions, ensuring a long service life. It is also relatively easy to manufacture and can be produced in various forms, including forged and cast.

Cons: The primary drawback is the higher cost compared to other materials like PVC or carbon steel. Additionally, stainless steel can be prone to galling, which may complicate assembly and maintenance.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances. However, it is essential to ensure that the specific grade (e.g., 304, 316) is suitable for the intended application.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN, particularly in regions like Germany and South America, where specific grades may be mandated for certain applications.

Why Choose PVC for Ball Valves?

PVC (polyvinyl chloride) is commonly used in applications involving water and other non-corrosive fluids. It has a temperature rating of around 140°F (60°C) and can handle pressures up to 150 psi, making it ideal for irrigation and plumbing systems.

Pros: PVC is lightweight, cost-effective, and resistant to corrosion and chemical reactions. Its ease of installation and low maintenance requirements make it a popular choice for many applications.

Cons: The temperature and pressure limitations of PVC can restrict its use in high-performance applications. Additionally, it may not be suitable for handling certain chemicals, which could lead to degradation over time.

Impact on Application: PVC ball valves are best suited for non-hazardous media, such as water and some chemicals. Buyers should verify compatibility with specific fluids to avoid premature failure.

Considerations for International Buyers: Compliance with local standards is crucial, especially in regions like Africa, where PVC quality may vary significantly. Buyers should look for certifications that guarantee material integrity.

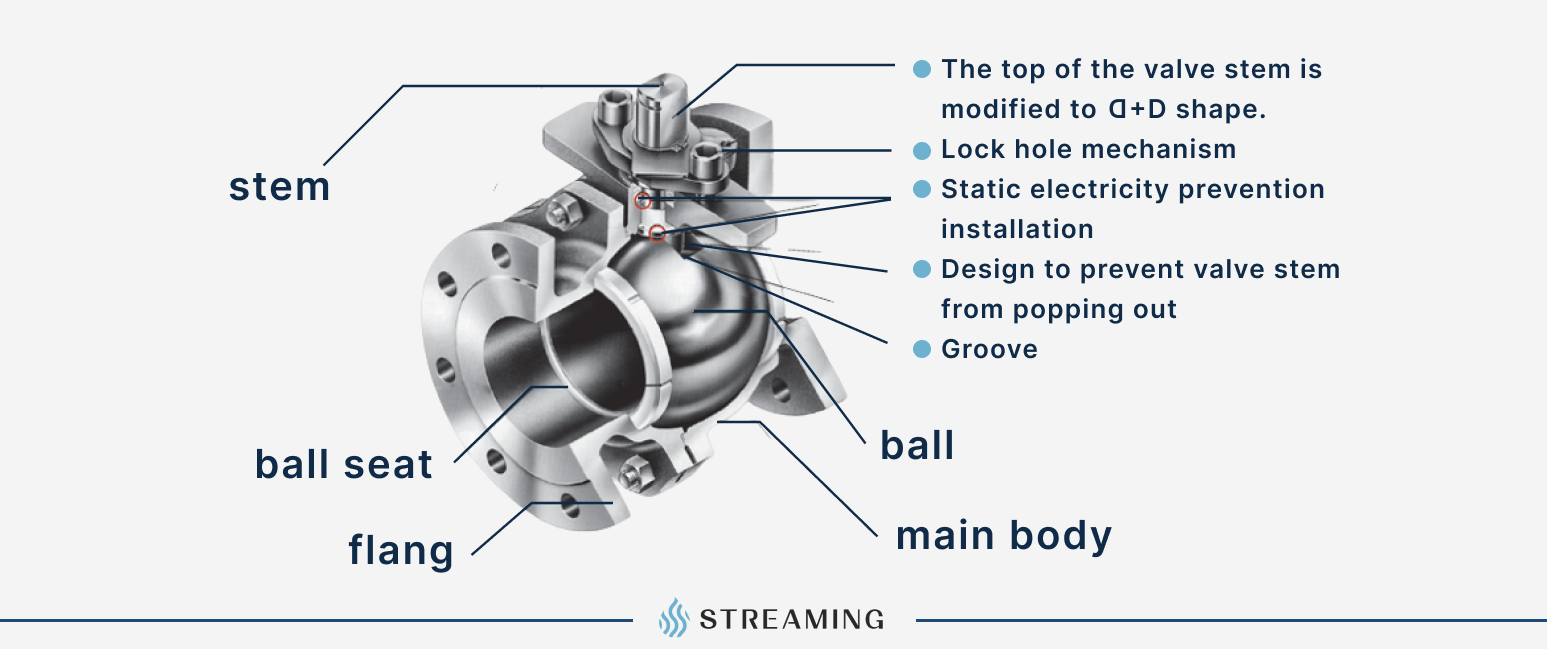

Illustrative image related to diagram of a ball valve

What Are the Benefits of Brass in Ball Valves?

Brass, an alloy of copper and zinc, is often used in ball valves for applications involving water and gas. It typically has a temperature rating of around 250°F (121°C) and can handle moderate pressures.

Pros: Brass offers good corrosion resistance, especially in water applications, and is relatively affordable. It is also easy to machine, allowing for intricate designs.

Cons: Brass can be susceptible to dezincification, particularly in aggressive water conditions, which can weaken the material. Additionally, it may not be suitable for high-pressure applications.

Impact on Application: Brass ball valves are ideal for plumbing and HVAC systems but may not be appropriate for highly corrosive environments. Buyers should consider the specific media and environmental conditions.

Considerations for International Buyers: Buyers from regions like the Middle East should ensure that brass valves meet local standards for potable water applications, as regulations can vary significantly.

Illustrative image related to diagram of a ball valve

How Does Carbon Steel Compare for Ball Valves?

Carbon steel is often used in industrial applications where strength and durability are paramount. It can handle high temperatures and pressures, making it suitable for oil and gas, power generation, and chemical processing.

Pros: Carbon steel is strong and can be manufactured to withstand extreme conditions. It is also generally less expensive than stainless steel.

Cons: The primary drawback is its susceptibility to corrosion, which can limit its application unless properly coated or treated. Maintenance may also be more intensive compared to corrosion-resistant materials.

Impact on Application: Carbon steel ball valves can be used in high-pressure applications but require careful consideration of the media to prevent corrosion-related failures.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards (e.g., ASTM) and consider the need for protective coatings in humid or corrosive environments, especially in tropical regions like parts of Africa.

Summary Table of Material Selection for Ball Valves

| Material | Typical Use Case for diagram of a ball valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, oil & gas | Excellent corrosion resistance | Higher cost, prone to galling | High |

| PVC | Irrigation, plumbing systems | Lightweight, cost-effective | Limited temperature/pressure tolerance | Low |

| Brass | Plumbing, HVAC systems | Good corrosion resistance, affordable | Susceptible to dezincification | Medium |

| Carbon Steel | Industrial applications, oil & gas | Strong, durable | Corrosion susceptibility | Medium |

This strategic material selection guide provides a comprehensive overview of the key materials used in ball valves, enabling international B2B buyers to make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for diagram of a ball valve

What Are the Main Stages of the Manufacturing Process for a Ball Valve?

The manufacturing process of a ball valve involves several critical stages, each designed to ensure that the final product meets the stringent requirements of various industries. Understanding these stages can help B2B buyers assess the quality and reliability of potential suppliers.

How Are Materials Prepared for Ball Valve Manufacturing?

The first stage in the manufacturing process is material preparation. Common materials used for ball valves include stainless steel, brass, PVC, and carbon steel. Suppliers typically source raw materials from certified vendors to ensure compliance with international standards.

-

Material Inspection: Incoming materials undergo rigorous inspection to verify their chemical composition and mechanical properties. This step often includes tests for hardness, tensile strength, and corrosion resistance.

-

Cutting and Shaping: Once materials are approved, they are cut into required shapes and sizes. This process may involve advanced techniques such as laser cutting or water jet cutting, which provide precision and reduce waste.

What Techniques Are Employed in the Forming Stage?

After material preparation, the next step is forming. This stage shapes the raw materials into the necessary components of the ball valve.

-

Forging and Casting: Depending on the design and material, components may be forged or cast. Forging is typically used for high-strength applications, while casting allows for complex shapes and designs.

-

Machining: Following forging or casting, components undergo machining to achieve precise dimensions. Techniques such as CNC (Computer Numerical Control) machining are commonly used, offering high accuracy and repeatability.

-

Surface Treatment: Surface treatments like shot blasting or polishing are applied to enhance corrosion resistance and aesthetic appeal. This is particularly important for valves used in industries like food and beverage, where hygiene is crucial.

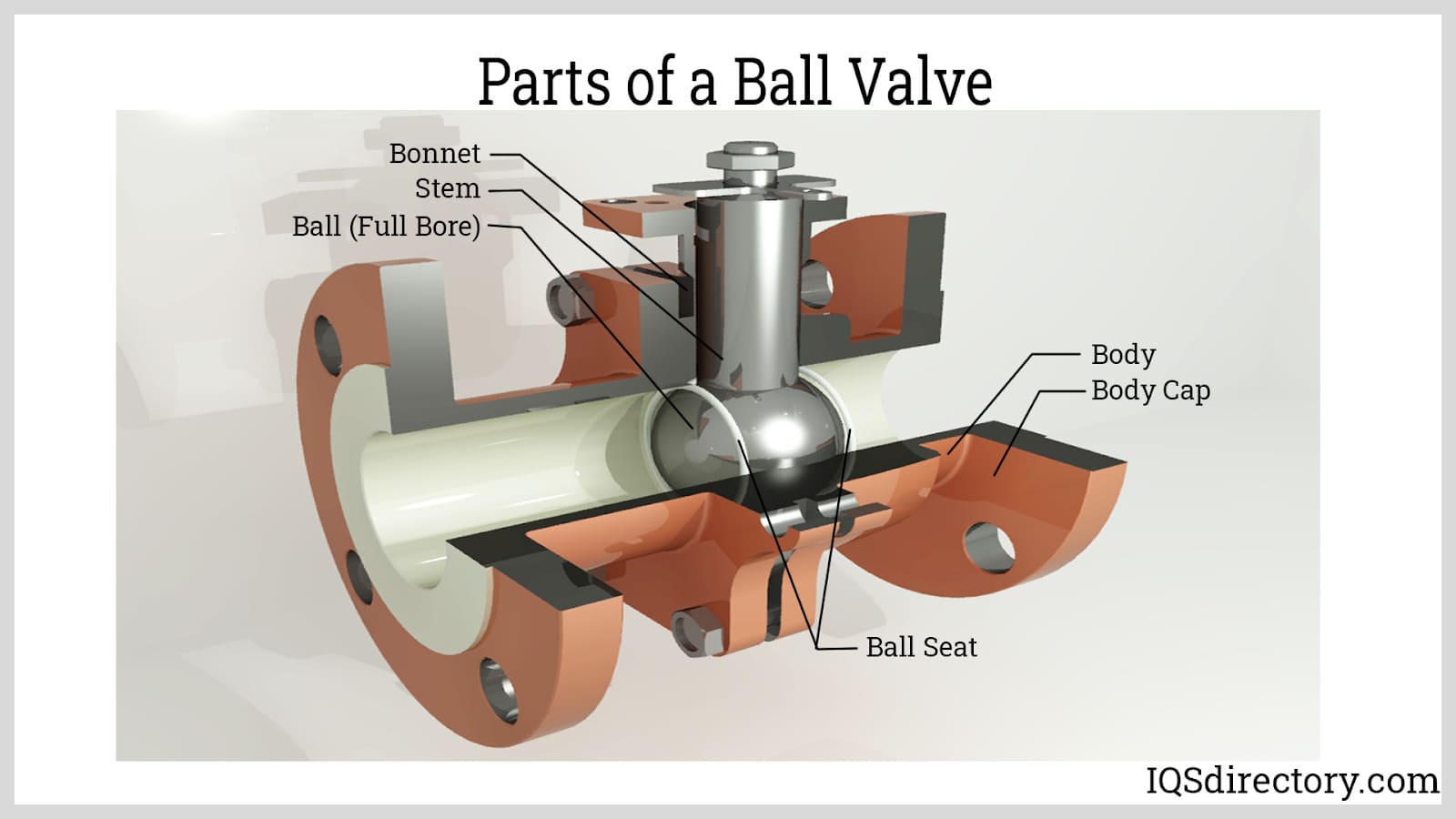

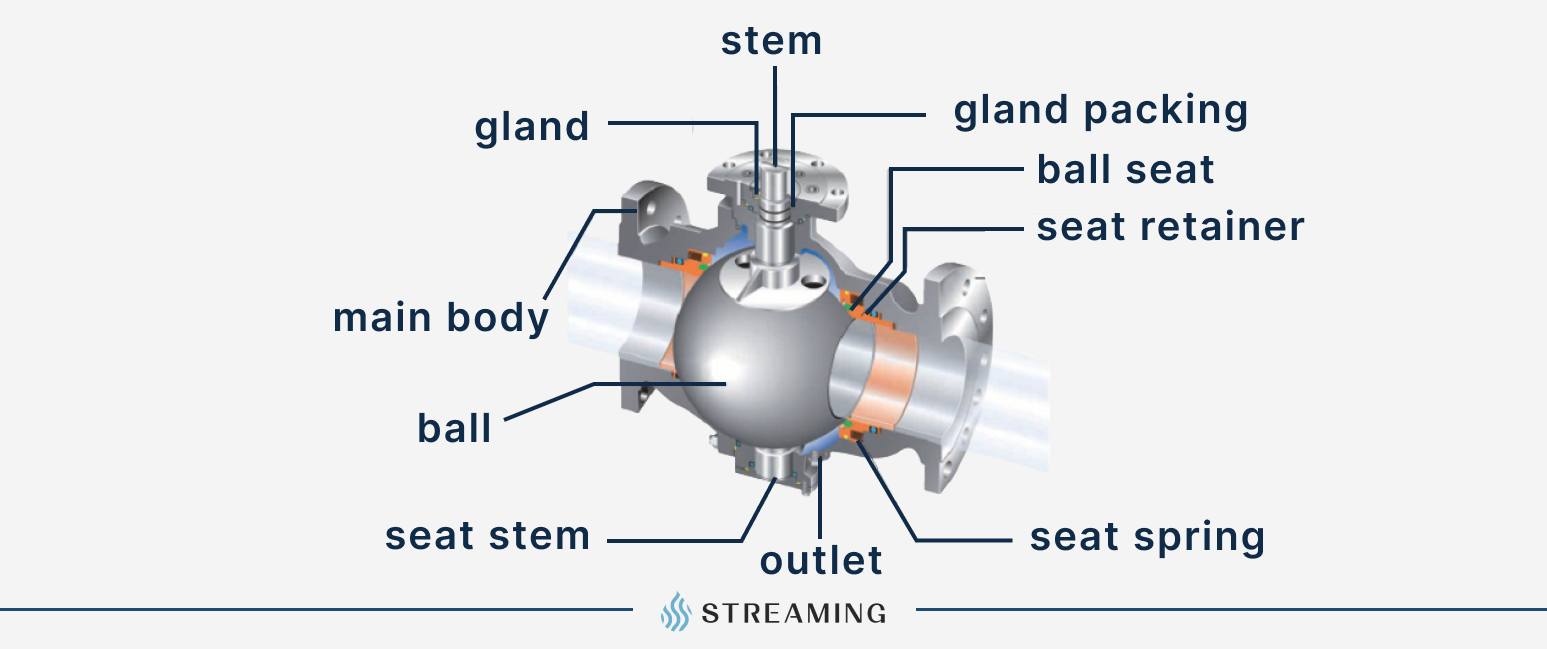

How Are Ball Valves Assembled?

The assembly stage is where the individual components come together to form the final ball valve.

-

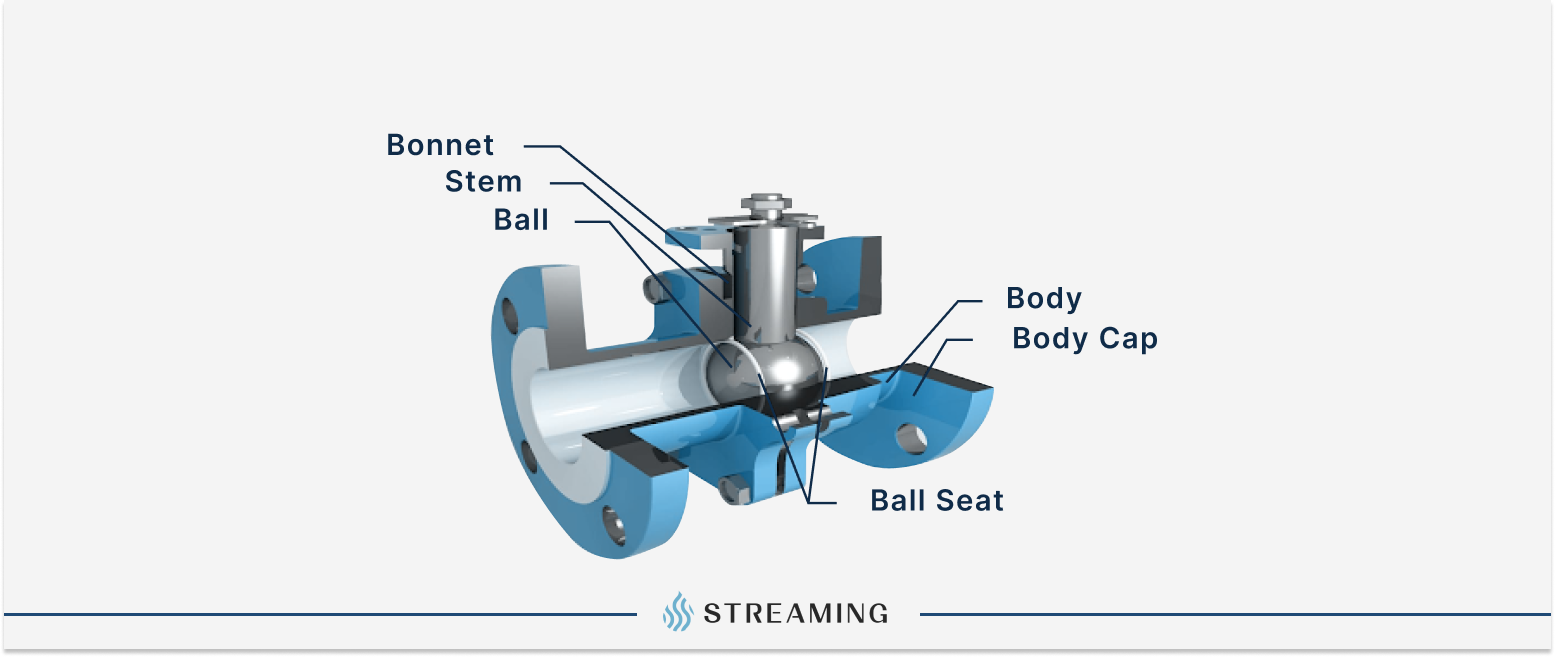

Component Assembly: Each part, including the body, ball, stem, and seals, is meticulously assembled. This process often involves the use of jigs and fixtures to ensure proper alignment.

-

Sealing: Sealing components are critical for preventing leaks. The use of high-quality gaskets and O-rings is essential, and suppliers often test these materials for durability and compatibility with various media.

-

Final Assembly Check: Before moving to the finishing stage, a final assembly check is performed to ensure that all components fit correctly and function as intended.

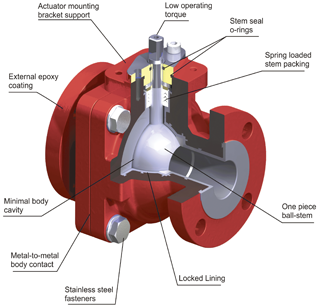

What Finishing Techniques Are Used in Ball Valve Production?

Finishing processes enhance the performance and appearance of the ball valves.

-

Coating and Painting: Many manufacturers apply protective coatings to prevent corrosion and wear. Coatings may vary based on the intended application and environmental conditions.

-

Final Inspection: A thorough inspection occurs after finishing to ensure the valve meets all specifications. This may include visual inspections and dimensional checks.

What Quality Assurance Practices Should B2B Buyers Expect?

Quality assurance (QA) is an integral part of the manufacturing process for ball valves, ensuring that products meet international and industry-specific standards. Buyers should be aware of the following practices.

Which International Standards Are Relevant for Ball Valve Quality Assurance?

Manufacturers often adhere to several international standards to ensure quality and reliability.

-

ISO 9001 Certification: This standard outlines a framework for quality management systems (QMS) and is essential for manufacturers looking to demonstrate their commitment to quality. It requires regular audits and continuous improvement processes.

-

Industry-Specific Standards: Certifications such as CE marking for European markets and API (American Petroleum Institute) standards for oil and gas applications ensure compliance with specific industry requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components before they enter the production line. Non-conforming materials are rejected at this stage.

-

In-Process Quality Control (IPQC): During manufacturing, various checks are performed to ensure that components are being produced to specifications. This may include monitoring machining tolerances and assembly alignment.

-

Final Quality Control (FQC): Before shipping, finished ball valves undergo comprehensive testing to ensure they meet performance standards. This includes pressure testing, leak testing, and functional testing.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial.

What Are the Best Practices for Supplier Audits?

-

Supplier Audits: Conducting on-site audits is one of the most effective ways to assess a supplier’s quality assurance processes. Buyers should evaluate the supplier’s adherence to quality standards, inspection capabilities, and manufacturing processes.

-

Reviewing Quality Reports: Requesting quality assurance reports and certifications can provide insight into the supplier’s commitment to quality. Look for documented evidence of compliance with ISO and industry-specific standards.

How Do Third-Party Inspections Work?

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes. These services can conduct random checks and audits to verify compliance with specifications and standards.

What Nuances Should International B2B Buyers Consider for Quality Control?

When sourcing ball valves internationally, B2B buyers must navigate various nuances that can affect quality assurance.

-

Cultural Differences: Different regions may have varying standards and practices related to quality control. Buyers should be aware of these differences and adjust their expectations accordingly.

-

Regulatory Compliance: Ensure that the supplier understands and complies with local regulations and standards in your region. This is particularly important for industries like oil and gas, where compliance is critical for safety and environmental concerns.

-

Supply Chain Transparency: Buyers should seek suppliers who offer transparency throughout the supply chain. Understanding where and how materials are sourced and processed can impact the overall quality of the final product.

By comprehensively understanding the manufacturing processes and quality assurance practices associated with ball valves, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only helps in sourcing high-quality products but also fosters long-term business relationships built on trust and reliability.

Illustrative image related to diagram of a ball valve

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diagram of a ball valve’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring a diagram of a ball valve. Whether you are in Africa, South America, the Middle East, or Europe, understanding the essential elements of ball valve diagrams will streamline your decision-making process and ensure you select the right product for your application.

Step 1: Define Your Technical Specifications

Clearly outline your requirements before starting your search. Determine the type of ball valve you need, including the size, material (such as steel or PVC), and specific applications (e.g., oil and gas, food processing). This clarity will help you communicate effectively with suppliers and ensure that the diagrams you receive match your needs.

Step 2: Research Industry Standards

Familiarize yourself with relevant industry standards. Knowing the standards applicable to ball valves in your region will guide you in evaluating diagrams. Look for compliance with ISO, API, or other regional standards that ensure quality and safety in valve operation.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers. Review company profiles, request references, and examine case studies from similar industries. Engaging with suppliers that have proven experience in your specific sector can enhance your confidence in their ability to provide accurate and reliable diagrams.

- Check for certifications: Ensure that suppliers have the necessary certifications, such as ISO 9001, which indicate a commitment to quality management.

- Inquire about previous projects: Understanding their past projects can provide insights into their capabilities and reliability.

Step 4: Request Detailed Diagrams

Ask suppliers for detailed ball valve diagrams. A good diagram should not only show the valve’s components but also illustrate the connections and flow paths. Ensure that the diagrams are clear, well-labeled, and comply with the standards you identified earlier.

Illustrative image related to diagram of a ball valve

- Look for variations: Inquire if they can provide diagrams for different types of ball valves (e.g., 2-way, 3-way) and configurations.

- Assess readability: The diagrams should be easy to read and interpret, facilitating better understanding for your engineering team.

Step 5: Compare Pricing and Terms

Gather and compare pricing from multiple suppliers. Pricing can vary significantly based on materials, complexity of the valve, and supplier reputation. Ensure that the quotes you receive include all relevant costs, including shipping and handling.

- Review terms of service: Pay attention to the warranty, return policies, and lead times associated with each supplier.

- Negotiate: Don’t hesitate to negotiate terms to secure a deal that fits your budget while maintaining quality.

Step 6: Verify Support and Maintenance Options

Check what support and maintenance services are offered. Understanding the level of after-sales support can be crucial, especially in complex applications. Ensure that the supplier can provide technical assistance and replacement parts if necessary.

- Ask about training: Some suppliers may offer training for your team on how to interpret the diagrams and operate the valves effectively.

- Evaluate response times: Quick response times for support inquiries can be a significant advantage in maintaining operational efficiency.

Step 7: Finalize Your Order

Once all evaluations are complete, finalize your order. Ensure that all specifications, diagrams, and agreed terms are documented clearly in the purchase order. This documentation will help prevent misunderstandings and ensure that you receive exactly what you need.

By following these steps, you can effectively navigate the procurement process for ball valve diagrams, ensuring you make informed decisions that align with your operational requirements.

Comprehensive Cost and Pricing Analysis for diagram of a ball valve Sourcing

What Are the Key Cost Components in Sourcing a Diagram of a Ball Valve?

Understanding the cost structure for sourcing a ball valve diagram involves several critical components. Each element contributes to the final price that B2B buyers will encounter.

Materials: The type of materials used in manufacturing ball valves significantly impacts cost. Common materials such as stainless steel, brass, or PVC each come with different price points. Buyers should consider the specific application requirements when selecting materials, as this can affect both performance and pricing.

Labor: Labor costs encompass the wages of skilled workers who assemble and test the valves. The complexity of the valve design, including any customization, can lead to increased labor costs. Countries with higher labor costs, such as Germany, may result in higher pricing compared to regions with lower wage structures, such as Nigeria.

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. These costs are usually factored into the pricing of the valves and can vary widely by region, affecting competitiveness.

Illustrative image related to diagram of a ball valve

Tooling: Tooling costs refer to the expenses associated with the machinery and tools required to produce the valves. Custom designs often require specialized tooling, which can add to the overall cost.

Quality Control (QC): Ensuring that the ball valves meet industry standards and specifications incurs QC costs. This is particularly relevant for international buyers who may require specific certifications, impacting the total cost of ownership.

Logistics: Transportation and shipping costs are vital components, especially for international buyers. Factors such as distance, shipping mode (air, sea), and Incoterms can influence logistics expenses significantly.

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the typical margins for suppliers in different regions can help buyers negotiate better pricing.

What Price Influencers Should Buyers Consider When Sourcing Ball Valve Diagrams?

Several factors can influence the pricing of ball valve diagrams.

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to reduced pricing per unit. Buyers should inquire about volume discounts or flexible MOQs to optimize costs.

Specifications and Customization: Customized valves tailored to specific operational needs can lead to higher costs. Buyers should evaluate whether standard products meet their requirements before opting for custom solutions.

Material Quality and Certifications: Higher-quality materials and certifications (such as ISO or API) typically come with increased costs but can ensure better performance and longevity. Buyers must weigh the benefits against the additional costs.

Supplier Factors: The reputation, reliability, and location of suppliers play a crucial role in pricing. Buyers should consider local suppliers to reduce logistics costs and mitigate potential delays.

Incoterms: Understanding Incoterms is essential for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the total landed cost of the valves.

Illustrative image related to diagram of a ball valve

What Negotiation Tips Can Help Buyers Achieve Cost-Efficiency in Ball Valve Sourcing?

To secure favorable pricing when sourcing ball valve diagrams, consider the following negotiation strategies:

Research and Benchmarking: Understand market prices and compare quotes from multiple suppliers. This knowledge empowers buyers during negotiations.

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Trust and communication often result in more favorable negotiations.

Discuss Total Cost of Ownership: Emphasize the long-term savings associated with quality and durability. A higher initial investment in a reliable product can lead to lower maintenance and replacement costs over time.

Be Clear About Specifications: Clearly communicate your requirements to avoid misunderstandings that could lead to unnecessary costs. Providing detailed specifications can streamline the process and reduce back-and-forth.

Be Flexible on Payment Terms: Offering to pay upfront or negotiating payment schedules can sometimes yield discounts, as it improves cash flow for the supplier.

Conclusion: Understanding Pricing Nuances for International Buyers

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, navigating the complexities of ball valve pricing requires awareness of various cost components and market dynamics. Pricing structures can vary significantly based on location, material selection, and supplier factors. Therefore, it is essential to approach sourcing with a clear strategy, keeping in mind the total cost of ownership and the potential for negotiation.

Disclaimer: Prices may vary based on specific requirements and market conditions. Always consult with multiple suppliers to obtain the most accurate pricing for your needs.

Alternatives Analysis: Comparing diagram of a ball valve With Other Solutions

Introduction to Alternatives in Flow Control Solutions

In the realm of flow control systems, the diagram of a ball valve is a well-established solution for regulating the flow of liquids and gases. However, various alternatives exist that can also serve similar functions, each with distinct advantages and drawbacks. Understanding these alternatives is crucial for B2B buyers seeking the best solution for their specific operational needs.

Comparison Table of Flow Control Solutions

| Comparison Aspect | Diagram Of A Ball Valve | Plug Valve | Gate Valve |

|---|---|---|---|

| Performance | High flow rates, quick shut-off | Moderate flow rates, good sealing | Slow opening and closing, good for on/off control |

| Cost | Moderate initial cost, longer lifespan | Lower initial cost, shorter lifespan | Generally lower cost, but can require more maintenance |

| Ease of Implementation | Simple installation with standardized connections | Requires more space for operation | Installation can be complex due to size and weight |

| Maintenance | Low maintenance, durable materials | Moderate maintenance, sealing issues can arise | High maintenance, prone to wear and tear |

| Best Use Case | Suitable for high-pressure and high-temperature applications | Best for applications needing tight sealing | Ideal for large diameter pipelines with infrequent operation |

Pros and Cons of Alternative Solutions

Plug Valve

Plug valves are another type of quarter-turn valve that provides excellent sealing capabilities. They are designed with a cylindrical or conical plug that fits into a hole in the valve body. This design allows for efficient flow control and is often used in applications requiring a tight seal, such as in chemical processing. However, plug valves typically have moderate flow rates and can be more challenging to maintain due to their complex internal structure. Their initial cost is generally lower than that of ball valves, but their lifespan can be shorter.

Gate Valve

Gate valves are characterized by a wedge-shaped gate that moves up and down to open or close the flow of media. They are primarily used for on/off applications rather than flow regulation, making them suitable for systems where the valve will either be fully open or fully closed. While gate valves are generally less expensive than ball valves and offer good flow capacity, they have a slower response time and can require significant maintenance over time. Additionally, their installation can be complex due to their larger size and weight.

Conclusion: Choosing the Right Flow Control Solution

When selecting the appropriate flow control solution, B2B buyers must consider their specific requirements, including performance expectations, budget constraints, and maintenance capabilities. The diagram of a ball valve stands out for its versatility and durability, making it suitable for a wide range of applications, particularly in high-pressure environments. However, alternatives like plug and gate valves may offer advantages in certain scenarios, such as cost-effectiveness or specific sealing needs. Ultimately, a thorough analysis of operational requirements and potential challenges will guide buyers to the most suitable valve solution for their applications.

Essential Technical Properties and Trade Terminology for diagram of a ball valve

What Are the Key Technical Properties of a Ball Valve Diagram?

Understanding the technical specifications of a ball valve is crucial for B2B buyers, as these properties directly influence the valve’s performance, reliability, and suitability for specific applications. Here are some critical technical properties to consider:

1. Material Grade

The material used in ball valve construction significantly affects its durability and resistance to corrosion, temperature, and pressure. Common materials include stainless steel, brass, PVC, and bronze. For instance, stainless steel is favored for its strength and resistance to corrosion, making it ideal for oil and gas applications. Selecting the right material ensures the valve can withstand the operational environment, minimizing maintenance costs and downtime.

2. Pressure Rating

Pressure rating indicates the maximum pressure the valve can handle without risking failure. This specification is essential when selecting valves for high-pressure applications, such as in the oil and gas sector. Understanding the pressure rating helps buyers ensure safety and compliance with industry standards, preventing catastrophic failures that could result in costly disruptions.

3. Temperature Tolerance

Temperature tolerance defines the range of temperatures within which the valve operates effectively. Ball valves can be designed for high-temperature applications, making them suitable for processes involving steam or hot liquids. Buyers must consider this parameter to ensure that the valve will function correctly under the specific thermal conditions of their operations, thereby enhancing reliability and longevity.

4. Flow Coefficient (Cv Value)

The flow coefficient (Cv) measures the valve’s ability to allow fluid flow. A higher Cv indicates greater flow capacity, which is vital for applications that require rapid fluid movement. Understanding the Cv value aids buyers in selecting valves that meet their flow requirements, optimizing system efficiency and performance.

5. Actuation Type

Ball valves can be manually operated or automated using pneumatic, hydraulic, or electric actuators. The choice of actuation type affects the valve’s operation speed and control. For instance, pneumatic actuators are ideal for high-cycle applications requiring quick response times. Assessing the actuation type ensures that the valve aligns with operational needs, enhancing workflow efficiency.

What Are Common Trade Terms Related to Ball Valves?

Familiarity with industry jargon is vital for effective communication between buyers and suppliers. Here are some common terms associated with ball valves:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components that are used in another company’s end product. In the context of ball valves, working with OEMs can provide customized solutions tailored to specific operational needs, ensuring compatibility and performance.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it affects procurement strategies and inventory management. A lower MOQ can be beneficial for smaller businesses or projects with limited budgets.

3. RFQ (Request for Quotation)

An RFQ is a formal document requesting a price quotation for specific products or services. Issuing an RFQ is a common practice in B2B transactions, allowing buyers to compare prices and terms from multiple suppliers, ensuring they get the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms is essential for international B2B transactions, as they clarify costs, risks, and logistics responsibilities, helping to avoid disputes.

5. P&ID (Piping and Instrumentation Diagram)

P&ID is a detailed diagram that illustrates the piping, valves, and instrumentation in a process system. Understanding P&IDs is crucial for buyers as they provide a visual representation of how ball valves integrate into larger systems, facilitating better decision-making in system design and implementation.

By grasping these technical properties and trade terms, B2B buyers can make informed purchasing decisions, ensuring that the ball valves they select meet their operational requirements and industry standards.

Navigating Market Dynamics and Sourcing Trends in the diagram of a ball valve Sector

What Are the Global Drivers Influencing the Ball Valve Market?

The ball valve market is currently driven by several global factors, including industrial growth, advancements in automation, and increased demand for energy-efficient solutions. As industries such as oil and gas, chemical processing, and water treatment expand, the need for reliable, durable, and efficient flow control solutions becomes paramount. In regions like Africa and South America, where infrastructure development is ongoing, there is a growing reliance on ball valves for various applications, from irrigation systems to industrial manufacturing.

Emerging technologies are also reshaping the sourcing landscape for international buyers. The integration of Industry 4.0 principles, including IoT and smart manufacturing, is enhancing the efficiency of valve production and monitoring. This trend enables companies to offer more sophisticated valve solutions that can be remotely monitored and controlled, appealing to B2B buyers seeking innovative products. Moreover, the shift towards digital procurement platforms is streamlining sourcing processes, allowing buyers to easily compare options and make informed purchasing decisions.

What Are the Current Sourcing Trends in the Ball Valve Sector?

International B2B buyers are increasingly prioritizing suppliers who can offer comprehensive solutions, including customization and rapid delivery. This trend is particularly evident in regions like the Middle East, where project timelines are often tight, and the demand for specialized valves is high. Suppliers who can provide quick turnarounds and tailored products are becoming more competitive in the global market.

Additionally, there is a rising emphasis on transparency in the supply chain. Buyers are demanding detailed information about the sourcing of materials and the manufacturing processes used, particularly in regions with stringent regulatory environments like Europe. Suppliers who can demonstrate ethical sourcing practices and compliance with international standards are likely to gain a competitive edge.

How Is Sustainability Shaping Sourcing Decisions for Ball Valves?

The environmental impact of manufacturing processes is a critical consideration for B2B buyers today. With growing awareness of climate change and resource depletion, companies are increasingly seeking suppliers who prioritize sustainable practices. This includes the use of eco-friendly materials and processes that minimize waste and energy consumption.

Illustrative image related to diagram of a ball valve

Furthermore, certifications such as ISO 14001 for environmental management and compliance with REACH regulations are becoming essential for suppliers aiming to enter or expand in the European market. Buyers are looking for ball valves made from recyclable materials or those that have a lower carbon footprint during production. By focusing on sustainability, companies can not only meet regulatory requirements but also enhance their brand reputation among environmentally-conscious customers.

Why Is Ethical Sourcing Important in the Ball Valve Industry?

Ethical supply chains are gaining traction in the ball valve sector as businesses recognize the importance of responsible sourcing. This involves ensuring that materials are obtained from suppliers who adhere to labor laws, environmental standards, and fair trade practices. Buyers, particularly from Europe and North America, are increasingly scrutinizing their suppliers to avoid reputational risks associated with unethical sourcing.

Additionally, the adoption of ‘green’ materials, such as those certified for low emissions or produced through sustainable methods, is becoming a key factor in purchasing decisions. This trend reflects a broader shift towards corporate social responsibility, where companies are expected to contribute positively to society and the environment. Suppliers that embrace ethical sourcing not only enhance their marketability but also align with the values of their customers, leading to stronger business relationships.

What Is the Historical Context of Ball Valve Development Relevant to Today’s Market?

The evolution of ball valves dates back to the early 20th century, where they emerged as a solution for more efficient flow control compared to traditional gate valves. Initially used in simple applications, advancements in materials and manufacturing processes have expanded their applicability across various industries. Today, ball valves are integral to sectors such as oil and gas, pharmaceuticals, and food processing, where reliability and precision are paramount.

As the market continues to evolve, innovations in automation and smart technologies are shaping the future of ball valves. The development of electric and pneumatic actuation systems has transformed how these valves are integrated into modern industrial processes, allowing for enhanced control and efficiency. Understanding this historical context helps B2B buyers appreciate the ongoing advancements and the potential for future innovations in the ball valve market.

Frequently Asked Questions (FAQs) for B2B Buyers of diagram of a ball valve

-

How do I choose the right ball valve diagram for my application?

Choosing the right ball valve diagram involves understanding your specific application requirements. Look for diagrams that clearly depict the valve’s components, such as the body, rotary ball, and actuation methods. Consider the type of flow control you need—whether a 2-way, 3-way, or multi-port valve—and ensure the diagram reflects this. Additionally, assess the materials and construction types (1-piece, 2-piece, or 3-piece) that suit your operational environment, as well as any specific industry standards that may apply. -

What are the key features to look for in a ball valve diagram?

Key features in a ball valve diagram include detailed representations of the valve body, ball, and stem, along with clear indications of the connection types (threaded or flanged). Look for diagrams that also illustrate the actuation method, whether manual, electric, pneumatic, or hydraulic. Additionally, symbols used in the diagram should align with industry standards, such as those found in Piping and Instrumentation Diagrams (P&IDs), to ensure clarity in communication across engineering teams. -

What is the typical lead time for ordering ball valves internationally?

Lead times for international orders of ball valves can vary significantly based on the supplier, customization requirements, and shipping logistics. Standard lead times typically range from 4 to 12 weeks, depending on whether the valves are stocked or made to order. It’s advisable to discuss timelines upfront with suppliers, especially if your project has tight deadlines. Additionally, consider potential customs delays when planning your order. -

How can I ensure the quality of the ball valves I am sourcing?

To ensure the quality of sourced ball valves, request certifications such as ISO 9001 or specific industry-related certifications that verify manufacturing standards. Conducting supplier audits or site visits can also be beneficial. Request sample products to evaluate material quality and performance. Additionally, establish clear quality assurance criteria in your purchase agreements, including testing procedures and acceptable tolerance levels, to mitigate risks. -

What are the minimum order quantities (MOQ) for ball valves?

Minimum order quantities for ball valves can vary widely among suppliers. Some may offer flexible MOQs, allowing you to order as few as one unit, especially for standard items. However, for customized or specialized valves, MOQs may be set at higher levels, often ranging from 50 to 100 units. It’s crucial to communicate your needs with potential suppliers to negotiate terms that align with your project requirements. -

What payment terms should I expect when sourcing ball valves internationally?

Payment terms for international ball valve orders typically include options such as upfront payment, partial payment upon order confirmation, or payment upon delivery. Common methods include wire transfers, letters of credit, or payment via escrow services to protect both parties. It’s important to clarify payment terms during initial discussions and ensure they are documented in the purchase agreement to avoid misunderstandings later in the transaction process. -

How do I verify the credibility of a ball valve supplier?

Verifying the credibility of a ball valve supplier involves researching their business history, client testimonials, and industry reputation. Check for certifications and memberships in industry associations, which can indicate a commitment to quality. Additionally, request references from previous clients and analyze their performance in delivering products on time and meeting quality standards. Engaging third-party verification services can also provide an unbiased assessment of the supplier’s reliability. -

What logistics considerations should I be aware of when importing ball valves?

When importing ball valves, consider logistics factors such as shipping methods, incoterms, and customs regulations for your destination country. Choose a reliable freight forwarder who understands the complexities of international shipping, including the best routes and potential delays. Ensure that all necessary documentation, such as invoices, packing lists, and certificates of origin, is in order to facilitate smooth customs clearance. Understanding local regulations, tariffs, and duties can also help you avoid unexpected costs.

Top 4 Diagram Of A Ball Valve Manufacturers & Suppliers List

1. Tameson – Ball Valve Symbols and Types

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: Ball Valve Symbols: 2-way ball valve symbol (two equilateral triangles pointing towards each other), 3-way and 4-way ball valve symbols (additional triangles for multiport valves), actuated ball valve symbols (indicating actuation type with lines and symbols). Types of ball valves: manually operated, electric, and pneumatic. P&ID (Piping and Instrumentation Diagram) is used for schematic represent…

2. Adamant Valves – Ball Valves

Domain: adamantvalves.com

Registered: 2013 (12 years)

Introduction: Ball valves are shut-off valves consisting of a ball with a borehole and a handle, allowing for the flow of liquids and gases. They can be made from various materials, including PVC for low pressure and stainless steel for high temperatures and pressures. Ball valves can be manually operated or motorized for high-pressure applications. Common sizes include 2 inch, 1 inch, ¾ inch, ½ inch, ⅜ inch, a…

3. Pinterest – Ball Valve

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: A ball valve is a flow control device that uses a hollow, perforated, and pivoting ball to regulate fluid flow. It consists of various parts, types, and working mechanisms.

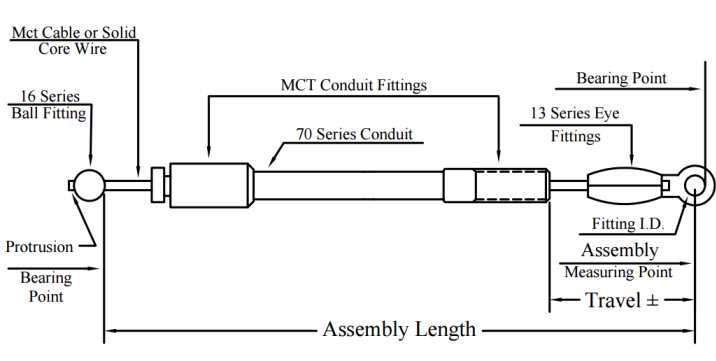

4. Agrinautics – Valve Diagrams and Key Products

Domain: agrinautics.com

Registered: 2000 (25 years)

Introduction: Valve Diagrams include various types of valves and their assemblies. Key products include:

– 2-Inch Body Mounted Valves

– 2-Inch Case Mounted Valves

– 2-1/2 to 3-Inch High Volume Hydraulic Valves

– 1-1/2 Inch and 2-Inch Manually Actuated Valves

– Electrically Actuated Spray Valves

– Loading Valves in sizes 2-Inch and 2-1/2 to 3-Inch

– Strainers including Line Strainers and T-Boom Strainers….

Strategic Sourcing Conclusion and Outlook for diagram of a ball valve

In the dynamic landscape of industrial applications, ball valves stand out as essential components that ensure efficient media control across various sectors. The strategic sourcing of ball valves involves not only understanding their intricate designs and functionalities but also evaluating suppliers based on quality, reliability, and compliance with international standards. By leveraging the insights gained from the diagrams and specifications discussed, B2B buyers can make informed decisions that align with their operational needs and regulatory requirements.

Engaging with reputable manufacturers and suppliers is crucial for securing high-performance ball valves that can withstand the demands of high-pressure and high-temperature environments. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the need for efficient sourcing strategies becomes paramount.

As you consider your next procurement cycle, prioritize partnerships that emphasize innovation and reliability. Explore the various actuation options and body styles available, ensuring that your choices optimize system performance while reducing downtime. Embrace the future of industrial fluid control by investing in high-quality ball valves that not only meet today’s standards but are also adaptable for tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.