Is Your Dc9V-24V / Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for dc9v-24v /

The global market for DC9V-24V power solutions presents a unique challenge for B2B buyers seeking reliable and efficient products for their diverse applications. As industries increasingly rely on these versatile voltage ranges for powering devices—from LED lighting systems to fast-charging modules—understanding how to source the right products becomes crucial. This comprehensive guide serves as a vital resource, covering a wide array of topics including product types, their applications, and the best practices for vetting suppliers.

International B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Vietnam—will find actionable insights tailored to their specific market needs. We delve into the nuances of cost considerations, quality standards, and the latest technological advancements, empowering decision-makers to make informed purchasing choices. By the end of this guide, you will not only be equipped with the knowledge to navigate the complexities of the DC9V-24V market but also gain confidence in sourcing products that align with your operational goals.

Whether you are looking to enhance your product offerings or streamline your supply chain, this guide is your roadmap to success in the dynamic landscape of DC9V-24V solutions.

Understanding dc9v-24v / Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| DC9V-24V Power Supplies | Versatile input range, commonly used in various devices | LED lighting, telecommunications | Pros: Wide compatibility; Cons: Power efficiency can vary. |

| DC9V-24V LED Controllers | Supports RGB and CCT, remote control capabilities | Smart lighting solutions | Pros: Enhanced user experience; Cons: Potential complexity in setup. |

| DC9V-24V Fast Charging Modules | High power output, supports multiple fast charging protocols | Mobile device charging stations | Pros: Quick charging; Cons: Higher initial cost. |

| DC9V-24V Sensors | Integrated with various sensors for automation | Smart buildings, industrial automation | Pros: Increases efficiency; Cons: Requires integration with other systems. |

| DC9V-24V Addressable LED Strips | Individually controllable LEDs, customizable colors | Decorative lighting, displays | Pros: Flexibility in design; Cons: More expensive than standard strips. |

What Are the Key Characteristics of DC9V-24V Power Supplies?

DC9V-24V power supplies are essential for providing stable voltage to a wide range of electronic devices, particularly in lighting and telecommunications. Their versatility makes them suitable for various applications, including LED lighting systems and communication equipment. When purchasing, B2B buyers should consider factors such as efficiency ratings and compatibility with existing systems to ensure seamless integration.

How Do DC9V-24V LED Controllers Enhance Lighting Solutions?

DC9V-24V LED controllers allow for advanced control over lighting systems, supporting RGB and CCT functionalities. This capability enables businesses to create dynamic lighting environments that can be adjusted remotely, enhancing user experience. Buyers should consider the ease of integration with existing systems and the potential need for additional setup when selecting these controllers.

What Advantages Do DC9V-24V Fast Charging Modules Offer?

Fast charging modules operating within the DC9V-24V range provide high power output and support multiple charging protocols, making them ideal for mobile device charging stations. This technology allows for quicker charging times, which can significantly improve customer satisfaction. However, buyers should weigh the initial investment against the long-term benefits and potential return on investment.

How Are DC9V-24V Sensors Used in Automation?

DC9V-24V sensors are integral to automation in smart buildings and industrial applications. They facilitate the seamless integration of various systems, enhancing operational efficiency. When sourcing these sensors, B2B buyers should focus on compatibility with existing systems and the reliability of the data provided to maximize efficiency.

Illustrative image related to dc9v-24v /

Why Choose DC9V-24V Addressable LED Strips for Decorative Lighting?

Addressable LED strips operating at DC9V-24V offer the unique advantage of individual LED control, allowing for customizable color patterns and effects. This flexibility is particularly beneficial in decorative lighting and display applications. Buyers should consider the cost-effectiveness of these strips against their design flexibility and the complexity of installation.

Key Industrial Applications of dc9v-24v /

| Industry/Sector | Specific Application of dc9v-24v / | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Solar Power Systems | Reliable power conversion for off-grid solar solutions | Ensure compatibility with various solar panel voltages and load requirements. |

| Automotive | Electric Vehicle Charging Stations | Fast charging capabilities improve customer satisfaction | Look for modules with safety certifications and international standards. |

| Smart Lighting | LED Lighting Control Systems | Energy efficiency and customizable lighting solutions | Consider dimming capabilities and compatibility with smart home systems. |

| Telecommunications | DC Power Supply for Communication Equipment | Stable power supply enhances equipment reliability | Evaluate the need for rugged designs to withstand harsh environments. |

| Industrial Automation | Control Systems for Machinery and Equipment | Improved operational efficiency and reduced downtime | Assess the integration with existing control systems and power requirements. |

How is dc9v-24v / Used in Renewable Energy Applications?

In renewable energy, particularly solar power systems, dc9v-24v / components are critical for converting and managing the energy produced. These systems often operate off-grid, requiring reliable power conversion to ensure energy is efficiently stored and utilized. B2B buyers in this sector must consider the compatibility of these components with various solar panel voltages and the load requirements for the specific applications. This ensures seamless integration and maximizes energy output, especially in regions with inconsistent power supply.

What Role Does dc9v-24v / Play in Automotive Charging Stations?

In the automotive industry, dc9v-24v / modules are essential for electric vehicle (EV) charging stations. These components provide fast charging capabilities, significantly improving customer satisfaction and reducing charging time. For international buyers, particularly in emerging markets, sourcing high-quality modules that meet safety certifications and international standards is crucial. This ensures not only the efficiency of the charging stations but also the safety of users and vehicles, fostering trust in EV infrastructure.

How is dc9v-24v / Integral to Smart Lighting Solutions?

In the realm of smart lighting, dc9v-24v / is utilized in LED lighting control systems. These systems offer energy efficiency and customizable lighting solutions, allowing businesses to adjust brightness and color temperature according to their needs. B2B buyers should focus on sourcing components that support dimming capabilities and are compatible with various smart home systems. This is particularly important for international buyers looking to implement smart lighting in diverse environments, ensuring adaptability and user-friendly operation.

Illustrative image related to dc9v-24v /

Why is dc9v-24v / Important for Telecommunications Equipment?

Telecommunications rely heavily on stable power supplies, where dc9v-24v / components are used to power communication equipment. A reliable power source enhances the performance and reliability of these systems, which is critical for maintaining communication networks. Buyers in this sector must evaluate the ruggedness of the components, especially for installations in challenging environments, to ensure longevity and minimal maintenance costs. This consideration is vital for international buyers operating in areas with harsh conditions.

How Does dc9v-24v / Enhance Industrial Automation?

In industrial automation, dc9v-24v / is employed in control systems for machinery and equipment. The application of these components improves operational efficiency and reduces downtime, which is essential for maintaining productivity. B2B buyers should assess how well these components integrate with existing control systems and their power requirements. This evaluation ensures that the automation solutions are both effective and scalable, particularly for businesses looking to expand operations in various international markets.

3 Common User Pain Points for ‘dc9v-24v /’ & Their Solutions

Scenario 1: Inconsistent Voltage Supply Causing Equipment Malfunction

The Problem: A B2B buyer sourcing DC power supplies for sensitive electronic equipment often encounters issues with inconsistent voltage supply. For instance, if the voltage fluctuates between 9V and 24V, it can lead to malfunctioning of devices, resulting in costly downtimes and potential damage to equipment. This is particularly concerning in industries like telecommunications or medical devices, where equipment reliability is paramount. Buyers may also struggle to find power supplies that can accommodate the varying voltage needs of different devices.

The Solution: To mitigate the risk of inconsistent voltage supply, B2B buyers should prioritize sourcing high-quality, adjustable DC power supplies that are specifically designed to handle a wide voltage range (from 9V to 24V). Suppliers should be evaluated based on their reputation, compliance with international safety standards, and user reviews. Additionally, implementing voltage regulators or DC-DC converters can stabilize the voltage output, ensuring that equipment receives a constant voltage level regardless of input fluctuations. Buyers should also consider investing in power monitoring systems that can alert them to voltage irregularities, allowing for proactive management of their electrical supply.

Scenario 2: Complexity in Selecting the Right LED Controller

The Problem: When integrating LED lighting solutions that operate on a DC9V-24V range, B2B buyers often face challenges in selecting the appropriate LED controllers. With various options available, including RGB, CCT, and smart controllers, the decision-making process can be overwhelming. This complexity can lead to purchasing the wrong controller, resulting in functionality issues, inefficient energy consumption, or even project delays.

The Solution: To simplify the selection process, buyers should first conduct a thorough analysis of their specific lighting needs, including desired features such as color-changing capabilities or smart integration with home automation systems. Creating a checklist that outlines the essential functions required from the LED controller can be beneficial. Suppliers should provide detailed specifications and compatibility information, which can guide buyers in making informed decisions. Furthermore, engaging with technical support teams from suppliers can clarify doubts and ensure compatibility between the power supply and the LED controller. Providing a trial period for new products could also help buyers assess their effectiveness before committing to larger orders.

Scenario 3: Difficulty in Ensuring Energy Efficiency

The Problem: Many B2B buyers are increasingly focused on sustainability and energy efficiency, yet they often encounter difficulties in sourcing DC9V-24V products that meet these criteria. Traditional power supplies may lead to energy wastage or excessive heat generation, which not only increases operational costs but also impacts the environment. Buyers may find it challenging to identify solutions that balance performance with energy-saving capabilities.

The Solution: To address energy efficiency concerns, buyers should prioritize sourcing DC power supplies that are labeled with energy efficiency ratings, such as those compliant with ENERGY STAR or similar international standards. Additionally, investing in power supplies that incorporate advanced technologies, such as pulse width modulation (PWM) or intelligent load management systems, can significantly reduce energy consumption. Buyers should also consider conducting energy audits to assess current power usage and identify areas for improvement. Collaborating with suppliers who offer eco-friendly options and can provide guidance on optimizing energy use will not only enhance sustainability efforts but also lead to cost savings in the long run.

Strategic Material Selection Guide for dc9v-24v /

What Are the Key Materials for dc9v-24v Applications?

When selecting materials for dc9v-24v applications, it is essential to consider the specific properties that impact product performance, durability, and compatibility with various media. Here, we analyze four common materials used in this voltage range, focusing on their advantages, limitations, and considerations for international B2B buyers.

1. Copper

Key Properties: Copper is known for its excellent electrical conductivity, thermal conductivity, and corrosion resistance. It can operate effectively in a temperature range from -200°C to 200°C and withstand moderate pressure.

Pros & Cons: The primary advantage of copper is its superior conductivity, which minimizes energy loss in electrical applications. However, it is relatively expensive compared to other materials and can be prone to corrosion in certain environments, necessitating protective coatings.

Impact on Application: Copper is ideal for wiring and connectors in dc9v-24v systems, especially in applications requiring high efficiency and reliability. However, its susceptibility to corrosion in humid or saline environments can limit its use without additional protective measures.

Considerations for International Buyers: Buyers in regions such as Africa and the Middle East should ensure compliance with local standards regarding electrical safety and corrosion resistance. Familiarity with ASTM and IEC standards is beneficial for ensuring product reliability.

2. Aluminum

Key Properties: Aluminum is lightweight, has good electrical conductivity, and offers excellent corrosion resistance. It typically operates well within a temperature range of -50°C to 150°C.

Pros & Cons: The advantages of aluminum include its low cost and lightweight nature, making it suitable for portable applications. However, its electrical conductivity is lower than that of copper, which may necessitate larger cross-sectional areas for wiring.

Impact on Application: Aluminum is often used in enclosures and structural components of dc9v-24v devices. Its corrosion resistance makes it suitable for outdoor applications, but care must be taken in high-temperature environments where its mechanical properties may degrade.

Considerations for International Buyers: Buyers in Europe and South America should be aware of the varying standards for aluminum alloys and their applications. Compliance with DIN standards can ensure that aluminum components meet necessary performance criteria.

3. Polycarbonate

Key Properties: Polycarbonate is a durable thermoplastic with high impact resistance and a temperature range of -40°C to 120°C. It is also resistant to UV light and various chemicals.

Pros & Cons: The key advantage of polycarbonate is its strength and durability, making it ideal for protective housings. However, it can be more expensive than other plastics and may not withstand extreme temperatures as well as metals.

Impact on Application: Polycarbonate is often used for casings and lenses in dc9v-24v devices, providing protection from environmental factors. Its chemical resistance makes it suitable for use in various industrial applications.

Considerations for International Buyers: Buyers from regions with stringent environmental regulations should ensure that the polycarbonate used complies with REACH and RoHS directives. Understanding local regulations regarding plastic materials is crucial for market entry.

4. Silicone

Key Properties: Silicone is known for its flexibility, thermal stability, and resistance to extreme temperatures ranging from -60°C to 200°C. It is also resistant to moisture and UV light.

Pros & Cons: The primary advantage of silicone is its versatility and ability to maintain performance in extreme conditions. However, it can be more costly than other elastomers and may not provide as strong a seal as some alternatives.

Impact on Application: Silicone is commonly used in sealing applications for dc9v-24v devices, particularly in environments where moisture and temperature fluctuations are a concern. Its flexibility allows for effective sealing in various configurations.

Considerations for International Buyers: Buyers should be aware of the differing silicone grades and their compliance with international safety standards. Familiarity with JIS and ASTM standards can help ensure that silicone products meet necessary performance and safety criteria.

Summary Table

| Material | Typical Use Case for dc9v-24v / | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and connectors | Superior electrical conductivity | Prone to corrosion without coatings | High |

| Aluminum | Enclosures and structural components | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Polycarbonate | Protective housings and lenses | High impact resistance | More expensive than other plastics | Medium |

| Silicone | Sealing applications | Versatile and thermally stable | Higher cost compared to alternatives | Medium |

This guide provides insights into the strategic selection of materials for dc9v-24v applications, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for dc9v-24v /

What Are the Main Stages of Manufacturing DC9V-24V Products?

The manufacturing process for DC9V-24V components, particularly in sectors such as electronics and lighting, involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential to ensure that the final product meets quality standards and performs reliably in diverse applications.

How Is Material Prepared for DC9V-24V Production?

Material preparation starts with sourcing high-quality raw materials, such as copper for wiring, silicone for insulation, and various plastic compounds for casings. Suppliers must be vetted for quality and reliability, often requiring certification to international standards. The selected materials undergo rigorous inspection to confirm they meet specifications. This initial step is crucial because the quality of raw materials directly impacts the durability and performance of the final product.

What Techniques Are Used in Forming DC9V-24V Components?

In the forming stage, raw materials are transformed into usable components through methods like injection molding for plastic parts and stamping for metal components. Advanced techniques such as surface-mount technology (SMT) are often employed for assembling circuit boards. These processes require precise machinery and skilled operators to ensure accuracy. Automation is increasingly utilized to enhance efficiency and reduce human error, but manual checks are still essential to maintain quality.

How Are DC9V-24V Products Assembled?

The assembly of DC9V-24V products typically involves integrating various components, such as circuit boards, connectors, and casing. This stage may also include soldering and wiring, which are critical for ensuring electrical connections are secure. Quality control checkpoints are established throughout the assembly line, with operators trained to identify defects immediately. Employing a lean manufacturing approach can help minimize waste and optimize workflow, resulting in cost savings and faster production times.

Illustrative image related to dc9v-24v /

What Finishing Processes Are Essential for Quality Assurance?

Finishing processes include surface treatments, painting, and the application of protective coatings. These steps not only enhance the aesthetic appeal of the product but also provide additional protection against environmental factors. For instance, waterproof coatings may be applied to products intended for outdoor use. Final inspections are conducted to ensure that each product meets the specified standards before packaging and shipping.

What Quality Assurance Measures Are Necessary for DC9V-24V Components?

Quality assurance is vital in the manufacturing of DC9V-24V products, ensuring that they comply with international standards and meet customer expectations. Various quality assurance measures are employed throughout the manufacturing process to maintain high product quality.

Which International Standards Should B2B Buyers Be Aware Of?

For DC9V-24V products, compliance with international standards such as ISO 9001 is critical. This standard focuses on quality management systems and is designed to enhance customer satisfaction through effective process management. Additionally, industry-specific certifications like CE mark for safety and environmental standards in Europe, and API standards in the oil and gas sector, are essential for B2B buyers to consider. These certifications indicate that the products meet rigorous safety and performance requirements.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated into different stages of the manufacturing process. Incoming Quality Control (IQC) checks raw materials upon arrival to ensure they meet specifications. In-Process Quality Control (IPQC) monitors the manufacturing process itself, ensuring that any deviations from standards are corrected in real-time. Finally, Final Quality Control (FQC) involves a comprehensive inspection of the finished products, including functionality tests and visual inspections, to ensure they are ready for market.

Illustrative image related to dc9v-24v /

What Common Testing Methods Are Used to Ensure Product Quality?

Common testing methods for DC9V-24V products include electrical testing, thermal cycling, and environmental testing. Electrical testing assesses the functionality and safety of the product under various voltage conditions. Thermal cycling tests the product’s durability under extreme temperature variations, while environmental testing evaluates performance under humidity, dust, and other environmental factors. These tests provide valuable data on the product’s reliability and lifespan, critical for B2B buyers concerned about performance in diverse conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Conducting audits is one of the most effective ways to assess a supplier’s quality management system. These audits can be performed internally or by third-party organizations specializing in quality assurance. Buyers should request reports and certifications that demonstrate compliance with relevant international standards and industry-specific regulations.

What Are the Nuances of QC and Certification for International Buyers?

For international buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is vital. Different regions may have varying regulatory requirements, and it’s essential to ensure that suppliers can meet these standards. Additionally, cultural differences may influence communication and expectations around quality, making it important for buyers to establish clear guidelines and maintain open lines of communication with suppliers.

How Can Buyers Leverage Third-Party Inspections?

Third-party inspections can provide an objective assessment of a supplier’s quality control processes. By engaging a reputable third-party inspection agency, buyers can obtain detailed reports on manufacturing practices, quality compliance, and product testing results. This transparency helps build trust and ensures that the products purchased meet the desired quality standards, ultimately reducing the risk of defects and enhancing customer satisfaction.

Conclusion

Understanding the manufacturing processes and quality assurance measures for DC9V-24V products is crucial for B2B buyers looking to make informed purchasing decisions. By focusing on the main stages of manufacturing, recognizing relevant quality standards, and leveraging inspections and audits, buyers can ensure they partner with reliable suppliers who deliver high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dc9v-24v /’

Introduction

This sourcing guide provides a practical checklist for B2B buyers looking to procure DC9V-24V components. Whether you’re sourcing LED controllers, power supplies, or fast charging modules, adhering to this checklist will help ensure you make informed decisions that align with your technical needs and business objectives.

Illustrative image related to dc9v-24v /

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your DC9V-24V products. This includes voltage range, power output, control methods (e.g., PWM, DMX), and compatibility with existing systems. Defining these specifications early will help streamline the sourcing process and ensure that you only consider products that meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in DC9V-24V products. Look for companies with a solid reputation in the industry, as well as those that have experience serving clients in your target regions, such as Africa, South America, the Middle East, and Europe. Utilize platforms like trade shows, online B2B marketplaces, and industry-specific directories to find credible suppliers.

Step 3: Evaluate Supplier Certifications

Before finalizing any deals, verify that suppliers have the necessary certifications and standards compliance. Look for certifications relevant to your industry, such as ISO, CE, or RoHS, which ensure that products meet safety and quality standards. This step is crucial for mitigating risks associated with product defects and ensuring compliance with local regulations.

Illustrative image related to dc9v-24v /

Step 4: Request Samples for Testing

Always request samples before making bulk purchases. Testing samples allows you to evaluate the quality, functionality, and performance of the products in real-world conditions. Pay attention to factors such as ease of installation, durability, and any specific features that align with your project requirements.

Step 5: Assess Pricing and Payment Terms

Compare pricing from multiple suppliers while considering the total cost of ownership, not just the initial purchase price. Look for flexible payment terms that suit your cash flow needs, such as net 30 or net 60 options. Additionally, inquire about bulk discounts or loyalty programs that could enhance your overall purchasing strategy.

Step 6: Check Shipping and Delivery Options

Confirm the shipping methods and delivery timelines offered by your chosen suppliers. Ensure that they can accommodate your project timelines and have reliable logistics in place, especially if you’re sourcing from international markets. Understanding shipping costs and potential customs duties is also vital to avoid unexpected expenses.

Step 7: Establish Ongoing Communication

After selecting a supplier, establish clear lines of communication. Regular updates on order status, product availability, and any potential issues will help maintain a smooth procurement process. Building a strong relationship with your supplier can also facilitate better support and responsiveness in future transactions.

Illustrative image related to dc9v-24v /

By following this checklist, B2B buyers can navigate the complexities of sourcing DC9V-24V products more effectively, ensuring they find reliable suppliers that meet their technical and business needs.

Comprehensive Cost and Pricing Analysis for dc9v-24v / Sourcing

Understanding the cost structure and pricing dynamics for DC9V-24V products is essential for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This section will provide a detailed analysis of the cost components, price influencers, and practical buyer tips to navigate the sourcing landscape effectively.

What Are the Key Cost Components Involved in DC9V-24V Sourcing?

-

Materials: The primary cost driver in the manufacturing of DC9V-24V products is the raw materials, which typically include high-quality electronic components, circuit boards, and housing materials. Prices can fluctuate based on global supply chain dynamics, availability of components, and the choice between standard and premium materials.

-

Labor: Labor costs vary significantly depending on the region of production. For instance, manufacturing in Asia may benefit from lower labor costs, whereas European production might incur higher wages. It’s crucial for buyers to consider the labor quality in relation to the product specifications.

-

Manufacturing Overhead: This encompasses costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these overheads, which can be reflected in the final pricing.

-

Tooling: Initial tooling costs can be substantial, particularly for customized or high-spec products. Buyers should assess whether these costs are amortized over large production runs, impacting the per-unit price.

-

Quality Control (QC): Rigorous QC processes are essential to ensure product reliability, especially for electrical components. Implementing stringent QC can add to costs but ultimately enhances product value and customer satisfaction.

-

Logistics: Shipping costs, which can vary widely based on distance, mode of transport, and current shipping rates, are a significant factor in the overall cost structure. International buyers should account for potential tariffs, customs fees, and insurance.

-

Margin: Supplier margins will vary based on market competition and perceived product value. Understanding the typical margins within the DC9V-24V market can help buyers gauge fair pricing.

What Influences Pricing for DC9V-24V Products?

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Bulk purchases often lead to lower per-unit costs, making it beneficial for larger buyers to negotiate favorable terms.

-

Specifications and Customization: Custom specifications can lead to higher costs due to specialized tooling and materials. Buyers should weigh the necessity of customization against its cost implications.

-

Quality and Certifications: Products with industry certifications (such as CE, RoHS) typically command higher prices due to the assurance of quality and safety. Buyers should consider whether such certifications are necessary for their market.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their track record of quality and service.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is vital, as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This can significantly impact the total cost of acquisition.

How Can International Buyers Optimize Their Sourcing Strategy?

-

Negotiation: Effective negotiation can lead to significant cost savings. Buyers should be prepared with market knowledge and competitor pricing to strengthen their negotiating position.

-

Focus on Total Cost of Ownership (TCO): Consider not only the initial purchase price but also the long-term operational costs, including energy consumption, maintenance, and potential failure rates. This holistic view aids in identifying the best value.

-

Understand Pricing Nuances: Pricing strategies can differ by region. For instance, buyers from Africa or South America may encounter higher shipping and customs costs compared to those in Europe. Being aware of these nuances can lead to better budget planning.

-

Seek Multiple Quotations: Obtaining quotes from multiple suppliers can provide insights into market pricing and help identify the best value options.

Final Considerations

While the prices for DC9V-24V products can vary widely based on the factors mentioned, it is crucial for buyers to conduct thorough due diligence to ensure they are making informed purchasing decisions. Prices mentioned in this analysis are indicative and may fluctuate based on market conditions and supplier negotiations. Always engage in detailed discussions with suppliers to clarify costs and expectations before finalizing any agreements.

Alternatives Analysis: Comparing dc9v-24v / With Other Solutions

Introduction to Alternative Solutions for DC9V-24V Applications

In the realm of power supply solutions, particularly for LED lighting and electronic devices, the DC9V-24V range has established itself as a versatile option. However, various alternatives exist that might better suit specific operational needs or budget constraints. Understanding these alternatives is crucial for B2B buyers who aim to optimize performance while managing costs effectively.

Comparison Table

| Comparison Aspect | DC9V-24V | Alternative 1: AC Power Supply | Alternative 2: DC5V-12V Power Supply |

|---|---|---|---|

| Performance | Suitable for high-power applications, stable output | Excellent for low-power devices, variable output | Limited to lower power applications, less versatile |

| Cost | Moderate to high initial investment | Generally lower initial cost | Lower cost, but may require more units for higher power |

| Ease of Implementation | Requires specialized knowledge for installation | Easier installation, common in residential setups | Simple to install, widely available components |

| Maintenance | Low maintenance if properly installed | Moderate maintenance; susceptible to wear | Low maintenance, but efficiency may decrease over time |

| Best Use Case | Ideal for commercial and industrial applications | Best for residential and small-scale applications | Suitable for low-power devices like small LED strips |

Detailed Breakdown of Alternatives

Alternative 1: AC Power Supply

AC power supplies convert alternating current to the required voltage, making them a common choice for residential and commercial lighting solutions. The primary advantage of AC power is its widespread availability and ease of installation, as many electrical systems are designed for AC. However, it may not deliver the same level of efficiency for high-power applications as DC9V-24V solutions. Additionally, the performance can vary depending on the load, which can lead to flickering lights or insufficient power delivery in certain situations.

Alternative 2: DC5V-12V Power Supply

DC5V-12V power supplies are often used for lower power applications, such as powering small LED strips and electronic devices. The main benefits include lower costs and simpler installation processes, making them accessible for smaller projects or DIY setups. However, they are limited in terms of power output and versatility. For larger installations or commercial applications requiring robust performance, DC5V-12V may fall short, necessitating multiple units or a more complex setup.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a power supply solution, B2B buyers should carefully consider their specific application requirements, including power needs, installation complexity, and budget constraints. The DC9V-24V range offers robust performance for high-demand applications, while alternatives like AC and DC5V-12V may be more suited for lower power needs or simpler setups. Evaluating these factors will enable buyers to make informed decisions that align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for dc9v-24v /

What Are the Key Technical Specifications for DC9V-24V Products?

Understanding the essential technical properties of DC9V-24V products is critical for B2B buyers looking to make informed purchasing decisions. Here are some key specifications that impact performance and application:

-

Input Voltage Range

The input voltage range for devices operating on DC9V-24V is crucial, as it defines the operational flexibility. Products designed to handle this voltage range can adapt to various applications, from consumer electronics to industrial machinery. Buyers should ensure compatibility with their existing power infrastructure to prevent equipment damage and inefficiencies. -

Output Power Rating

The output power rating, typically measured in watts (W), indicates the maximum power a device can deliver. For example, a DC9V-24V product may have a rating of 100W, meaning it can efficiently supply power to devices requiring up to this wattage. Understanding the output power is vital for selecting the right components to meet operational needs without overloading the system. -

Current Rating

Current rating, expressed in amperes (A), specifies the maximum current the device can handle. For DC9V-24V applications, a common rating might be 5A per channel for RGB outputs. This specification is essential for ensuring that the product can support the intended load without overheating or causing circuit failures. -

Control Protocols

Many DC9V-24V devices utilize specific control protocols (e.g., PWM, DMX, or DALI) for dimming or color control. Understanding the control capabilities is important for integration with existing systems and ensuring compatibility with smart technologies. This can enhance user experience through remote operation or automated lighting systems. -

Thermal Management

Effective thermal management, often indicated by heat dissipation features, is critical for the longevity and reliability of DC9V-24V products. Buyers should consider devices with built-in thermal protection or cooling mechanisms to prevent overheating, which can lead to reduced performance or failure. -

Material Quality and Durability

The materials used in the construction of DC9V-24V devices (e.g., plastic, aluminum) significantly impact their durability and suitability for various environments. High-quality materials can enhance resistance to moisture, dust, and physical impacts, making them ideal for outdoor or industrial applications.

What Common Trade Terms Should Buyers Understand in the DC9V-24V Market?

Navigating the B2B landscape involves familiarizing oneself with common trade terminology. Here are several key terms relevant to DC9V-24V transactions:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers looking for customized solutions or specific performance characteristics in DC9V-24V products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell in a single order. This term is critical for budget planning and inventory management, especially for businesses looking to purchase large quantities of DC9V-24V components for projects or resale. -

RFQ (Request for Quotation)

An RFQ is a standard business process in which a buyer requests pricing information from suppliers. This term is vital for B2B buyers as it helps them compare costs and terms across different suppliers before making a procurement decision. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can aid in understanding shipping costs, risks, and responsibilities associated with DC9V-24V product deliveries. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. In the context of DC9V-24V products, understanding lead times is crucial for project planning and ensuring timely delivery of components required for installations or production. -

Certification Standards

Certification standards (e.g., CE, RoHS) indicate that a product meets specific safety and environmental criteria. Knowledge of these certifications is essential for compliance, especially when sourcing DC9V-24V products for markets with strict regulatory requirements.

By understanding these technical specifications and trade terms, B2B buyers can make better-informed decisions, ensuring they select the right DC9V-24V products that align with their operational needs and market requirements.

Navigating Market Dynamics and Sourcing Trends in the dc9v-24v / Sector

What Are the Key Trends Shaping the DC9V-24V Market for International B2B Buyers?

The DC9V-24V sector is experiencing significant growth driven by the increasing demand for efficient power solutions across various applications, including consumer electronics, smart home devices, and industrial machinery. This trend is particularly pronounced in emerging markets such as Africa, South America, the Middle East, and Europe, where there is a growing adoption of technologies that require versatile voltage ranges. International B2B buyers are particularly interested in sourcing products that offer high efficiency, compatibility with multiple protocols, and support for fast charging, as seen in products like fast charging modules.

Emerging technologies such as IoT and smart lighting are influencing sourcing trends, with buyers seeking products that integrate seamlessly with these platforms. The rise of smart controllers, such as those that work with Amazon Alexa or Google Assistant, is indicative of this shift. Additionally, the demand for modular and customizable solutions is on the rise, as businesses look for ways to enhance their operational flexibility and reduce lead times. This inclination towards customization is a crucial market dynamic that B2B buyers must navigate when sourcing DC9V-24V products.

The competitive landscape is also evolving, with both local and international manufacturers stepping up their game to meet the growing demand. Buyers should be aware of the importance of supplier reliability, quality assurance, and the ability to provide technical support, as these factors can significantly impact their sourcing decisions.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the DC9V-24V Sector?

Sustainability is becoming a critical consideration in the DC9V-24V sector, with increasing awareness around environmental impacts and the importance of ethical supply chains. B2B buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, such as reducing carbon footprints and utilizing eco-friendly materials. This trend is not just about compliance; it is increasingly linked to brand reputation and consumer preferences.

Illustrative image related to dc9v-24v /

Certifications such as RoHS (Restriction of Hazardous Substances) and ISO 14001 (Environmental Management) are becoming essential criteria for buyers when selecting suppliers. These certifications indicate that products meet specific environmental standards and that manufacturers are committed to sustainable practices. Moreover, sourcing materials that are recyclable or made from renewable resources can further enhance a company’s sustainability profile.

The shift towards energy-efficient products is another crucial aspect of sustainability. Buyers should focus on sourcing DC9V-24V products that not only meet performance requirements but also contribute to energy savings over their lifecycle. This not only aligns with global sustainability goals but also offers potential cost savings for end-users, creating a compelling business case for ethical sourcing.

What Is the Historical Context of the DC9V-24V Sector for B2B Buyers?

The DC9V-24V market has evolved significantly over the past few decades, driven by advancements in technology and changing consumer demands. Initially, the sector was primarily focused on basic power supply solutions. However, with the advent of sophisticated electronic devices and smart technology, the market has shifted towards offering more versatile and efficient power solutions.

The introduction of smart technologies has been a game-changer, leading to increased demand for products that can operate within this voltage range. As energy efficiency and sustainability have gained prominence, manufacturers have adapted their offerings to meet these new requirements, leading to a broader range of products that cater to the diverse needs of international B2B buyers.

This evolution reflects a broader trend in the electronics industry, where adaptability and innovation are crucial for meeting the dynamic needs of the global market. For B2B buyers, understanding this historical context is essential for making informed sourcing decisions that align with future market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of dc9v-24v /

-

How do I solve compatibility issues with DC9V-24V products?

Compatibility issues often arise when sourcing DC9V-24V products due to variations in voltage requirements and connector types. To solve these problems, ensure you thoroughly review the product specifications provided by suppliers. Utilize a multimeter to test voltage levels, and consult with the manufacturer about compatibility with existing systems. Engaging in open communication with your supplier can also help clarify any uncertainties. If necessary, consider custom solutions or adapters that can bridge gaps in compatibility. -

What is the best DC9V-24V solution for my specific application?

The best DC9V-24V solution depends on your application requirements, such as power consumption, control options, and environmental conditions. For instance, LED lighting systems may require specific controllers for color and brightness adjustments, while power supplies must meet the wattage needs of your devices. Conduct a needs assessment to define the criteria, then reach out to multiple suppliers for samples and technical advice. This approach helps you identify the most suitable products tailored to your operational demands. -

How can I effectively vet suppliers for DC9V-24V products?

To vet suppliers for DC9V-24V products, start by researching their market reputation and reviews from other B2B buyers. Request references and case studies to assess their reliability and product quality. Additionally, evaluate their production capabilities, certifications, and compliance with international standards. Conducting site visits or audits, if feasible, can further confirm their operational integrity. Establishing a solid relationship through regular communication will also help ensure that the supplier aligns with your business goals. -

What are the minimum order quantities (MOQ) for DC9V-24V products?

Minimum order quantities (MOQ) for DC9V-24V products can vary significantly among suppliers, often depending on the product type and manufacturing processes. Many manufacturers set MOQs to ensure production efficiency and cost-effectiveness. It is advisable to discuss your requirements upfront with potential suppliers, as they may offer flexibility based on your business needs. If your order volume is low, consider negotiating for lower MOQs or exploring group purchasing options with other buyers. -

What payment terms should I expect when sourcing DC9V-24V products?

Payment terms for sourcing DC9V-24V products typically vary by supplier and region. Common terms include a deposit upfront, with the balance due upon shipment or delivery. Some suppliers may offer net 30 or net 60-day terms for established clients. Always clarify payment methods accepted, such as wire transfers, letters of credit, or online payment systems. Ensure that you receive a pro forma invoice detailing the payment structure to avoid surprises during the transaction. -

How can I ensure quality assurance for DC9V-24V products?

To ensure quality assurance for DC9V-24V products, establish clear quality standards and specifications with your supplier before production begins. Implementing a quality control plan that includes inspections at various production stages can help mitigate defects. Request samples for testing prior to placing large orders, and consider third-party inspection services for additional assurance. Documenting all agreements regarding quality standards can also protect your interests in case of discrepancies. -

What logistics considerations should I keep in mind when importing DC9V-24V products?

When importing DC9V-24V products, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Research the best shipping options—air freight for speed or sea freight for cost-efficiency. Understand the customs clearance process in your region to avoid delays and additional fees. It’s also wise to coordinate with your supplier to ensure proper labeling and documentation, which can streamline the import process and minimize potential complications. -

How can I customize DC9V-24V products to meet my specific needs?

Customizing DC9V-24V products typically involves collaborating closely with your supplier to define your specific requirements, such as voltage specifications, form factors, or additional features like smart technology. Many manufacturers offer customization options, but it’s essential to discuss lead times and any associated costs upfront. Providing detailed specifications and prototypes can help ensure that the final product meets your expectations. Additionally, consider a trial period for customized solutions to validate their performance in your application.

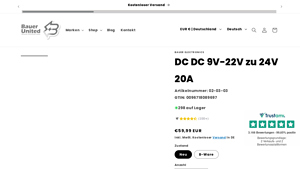

Top 6 Dc9V-24V / Manufacturers & Suppliers List

1. XY – XY-D100H Amplifier Board

Domain: aliexpress.com

Registered: 2006 (19 years)

Introduction: This company, XY – XY-D100H Amplifier Board, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Adapter – Device Compatibility Risks

Domain: electronics.stackexchange.com

Registered: 2009 (16 years)

Introduction: Adapter: 24V, 1A; Device: 9V, 2A; Potential negative effects of using the adapter on the device include damage to internal circuits, risk of overheating, and possible fire hazards.

3. Super Lighting – DC9V-24V RGB CCT Dimmer 3 in 1

Domain: superlightingled.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “DC9V-24V RGB CCT DIMMER 3 IN 1”, “control_distance”: “30-50 meters”, “features”: [“WIFI SMART APP”, “LED STRIP LIGHT CONTROLLER”, “WORK WITH AMAZON ECHO ALEXA”], “model_number”: “CONRGBCCT-WIFI-4”, “company_experience”: “14 years in business”, “shipping_info”: “Free shipping on orders over $199”}

4. Reddit – 24V AC Wall Adapter Circuit Components

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 24V AC wall adapter, 9V relay, full bridge rectifier circuit, resistors, zener diodes, transformer, nominal coil current: 40mA, 7809 linear regulator, 375 ohm resistor (1W), 390 ohm standard size resistor, capacitor for current boost.

5. L-com – Power Supplies & Accessories

Domain: l-com.com

Registered: 1996 (29 years)

Introduction: Power Supplies – AC, DC, 9V, 12V, 15V, 24V, 48V, 56V & Accessories

6. Bauer – DC DC 9V-22V zu 24V 20A Spannungswandler

Domain: bauer-united.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “DC DC 9V-22V zu 24V 20A Spannungswandler”, “item_number”: “02-03-03”, “gtin”: “0096718089697”, “price”: “€59,99”, “discounted_price”: “€59,99”, “stock”: “298”, “shipping”: “Kostenloser Versand in DE”, “condition”: “Neu”, “applications”: [“KFZ”, “Photovoltaik”, “Industrieanlagen”, “LKW”, “Boot”, “Landmaschinen”, “Camping”, “mobile Einrichtungen”, “Hobby und Heimwerken”, “Haus und …

Strategic Sourcing Conclusion and Outlook for dc9v-24v /

As the global demand for DC9V-24V solutions continues to rise, international B2B buyers have a unique opportunity to leverage strategic sourcing to enhance their operational efficiency and product offerings. By understanding the specifications and applications of DC9V-24V products—ranging from fast-charging modules to LED controllers—businesses can make informed purchasing decisions that align with market trends. Sourcing from reliable manufacturers not only ensures product quality but also fosters sustainable partnerships that can drive innovation and reduce costs.

Furthermore, emerging markets in Africa, South America, the Middle East, and Europe present untapped potential for growth. By investing in strategic relationships with suppliers who understand local needs and regulations, companies can gain a competitive edge. The ability to source high-quality components that meet diverse requirements will be crucial for businesses aiming to thrive in these regions.

Illustrative image related to dc9v-24v /

Looking ahead, it is imperative for B2B buyers to remain proactive in their sourcing strategies. Engaging with suppliers who offer transparency and adaptability will not only enhance supply chain resilience but also position businesses favorably in an ever-evolving marketplace. Take the next step—evaluate your sourcing strategy today to capitalize on the promising landscape of DC9V-24V solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.