A Deep Dive into Protective Covering Crossword Clue Solution

Introduction: Navigating the Global Market for protective covering crossword clue

In today’s interconnected global market, sourcing effective protective coverings can present unique challenges for international B2B buyers. Whether you are searching for materials that shield products from environmental damage, enhance safety in industrial applications, or offer aesthetic appeal, the term “protective covering” encompasses a wide range of solutions. This comprehensive guide delves into various types of protective coverings, their applications across different industries, and critical factors to consider during supplier vetting processes.

Understanding the diverse range of options—from tarps and liners to sheaths and armor—empowers businesses to make informed purchasing decisions. Each type serves specific needs, and knowing the distinctions can significantly affect operational efficiency and product integrity. Additionally, we will explore cost considerations, helping buyers assess budget implications while maintaining quality standards.

For B2B buyers from Africa, South America, the Middle East, and Europe—regions characterized by distinct market demands and regulatory environments—this guide offers valuable insights tailored to your unique contexts. By equipping you with the knowledge to navigate the complexities of the protective covering market, we aim to enhance your strategic sourcing efforts, ultimately driving value and competitive advantage in your operations.

Understanding protective covering crossword clue Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sheath | A protective layer that envelops an object, often flexible. | Electronics, cable manufacturing | Pros: Lightweight, customizable. Cons: May not provide adequate protection against severe impacts. |

| Armor | Rigid protective covering designed for high-impact resistance. | Military, automotive, and construction | Pros: Excellent durability, high protection level. Cons: Heavier, more expensive. |

| Coating | Liquid application that hardens to form a protective layer. | Manufacturing, aerospace, and automotive | Pros: Versatile, can enhance aesthetics. Cons: Requires proper application for effectiveness. |

| Casing | A sturdy outer shell designed to protect contents inside. | Packaging, shipping, and storage solutions | Pros: Provides physical protection, often waterproof. Cons: Can add bulk and weight to products. |

| Tarp | A flexible, waterproof cover made of durable materials. | Construction, agriculture, and outdoor events | Pros: Cost-effective, easily transportable. Cons: Limited lifespan, less protective against sharp objects. |

What Are the Key Features of a Sheath as a Protective Covering?

A sheath serves as a flexible protective layer that wraps around various objects, particularly in electronics and cable manufacturing. Its lightweight nature allows for customization to fit specific dimensions, making it ideal for applications where space is limited. Buyers should consider the sheath’s material properties, including thermal resistance and flexibility, to ensure it meets the requirements of their specific applications. However, while sheaths are effective for minor protection, they may not withstand severe impacts, which can be a drawback for industries requiring robust solutions.

How Does Armor Function as a Protective Covering?

Armor is engineered to provide high-impact resistance, making it suitable for military, automotive, and construction applications. Its rigid structure offers superior durability and protection against various threats, including ballistic impacts and environmental hazards. When purchasing armor, buyers need to evaluate the level of protection required, as well as weight and cost considerations. While armor delivers exceptional safety, its heavier weight and higher price point can be limiting factors for some applications.

What Are the Benefits of Using a Coating as a Protective Layer?

Coatings are liquid applications that harden upon drying, forming a protective layer over surfaces. They are widely used in manufacturing, aerospace, and automotive sectors for their versatility and ability to enhance the aesthetic appeal of products. Buyers should consider the specific type of coating needed, as different formulations offer varying degrees of resistance to chemicals, abrasion, and moisture. However, proper application is crucial to achieving the desired protective effect, and any application errors can lead to compromised performance.

Why Choose Casing as a Protective Covering Solution?

Casing provides a sturdy outer shell that safeguards the contents inside, commonly used in packaging, shipping, and storage solutions. Its design often includes waterproofing features, making it an effective choice for protecting sensitive items during transit. When selecting a casing, buyers should assess the material strength and weight, as well as any additional features such as insulation. While casings offer reliable physical protection, they can add bulk and weight to the overall product, which may be a concern for some industries.

What Makes Tarps a Popular Choice for Protective Covering?

Tarps are flexible, waterproof covers made from durable materials and are frequently used in construction, agriculture, and outdoor events. Their cost-effectiveness and portability make them an attractive option for temporary protective solutions. Buyers should consider the tarp’s material thickness and UV resistance when making a selection. However, tarps have a limited lifespan and may not provide adequate protection against sharp objects, which can impact their effectiveness in certain applications.

Key Industrial Applications of protective covering crossword clue

| Industry/Sector | Specific Application of protective covering crossword clue | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Use of tarps for site protection | Prevents damage from weather, enhances safety on-site | Durability, weather resistance, and compliance with local regulations. |

| Automotive | Application of liners in vehicle manufacturing | Enhances vehicle longevity and performance | Material compatibility, weight considerations, and supplier reliability. |

| Electronics | Protective sheathing for cables and components | Reduces risk of damage, improves safety and efficiency | Insulation properties, flexibility, and certification standards. |

| Oil and Gas | Use of armor plates for equipment protection | Increases equipment lifespan, reduces operational downtime | Resistance to corrosion, weight, and material sourcing. |

| Food and Beverage | Implementation of protective covers for machinery | Ensures hygiene and safety compliance, reduces contamination risks | Food-grade materials, ease of cleaning, and regulatory compliance. |

How Are Protective Coverings Used in Construction?

In the construction sector, protective coverings like tarps are essential for safeguarding materials and equipment from adverse weather conditions. They prevent water damage, dust accumulation, and physical impacts during construction activities. For international buyers, especially in regions prone to extreme weather, sourcing durable and weather-resistant tarps is crucial. Buyers should consider the material’s UV resistance, thickness, and compliance with local environmental standards to ensure optimal performance on-site.

What Role Do Protective Coverings Play in the Automotive Industry?

In the automotive industry, protective coverings such as liners are critical in vehicle manufacturing. These liners protect sensitive components from moisture, dust, and mechanical wear, ultimately extending the vehicle’s lifespan and enhancing performance. For B2B buyers, especially in regions with varying climates, selecting liners that offer excellent insulation and durability is vital. Buyers should also prioritize suppliers who provide materials that comply with industry standards to ensure safety and reliability.

How Are Protective Coverings Utilized in Electronics?

Protective sheathing is widely used in the electronics sector to safeguard cables and components from environmental damage and interference. This application is particularly important for maintaining the integrity and performance of electronic devices. International buyers must focus on sourcing materials that offer excellent insulation properties and flexibility, especially in regions with high humidity or temperature fluctuations. Additionally, ensuring that the materials meet international safety standards is essential for compliance and reliability.

Why Are Armor Plates Important in the Oil and Gas Industry?

In the oil and gas industry, armor plates serve as protective coverings for critical equipment, shielding them from harsh environmental conditions and physical impacts. This application enhances equipment longevity and minimizes operational downtime due to repairs. B2B buyers should consider sourcing materials that are resistant to corrosion and high temperatures, particularly in regions with extreme operational conditions. Supplier reliability and the ability to provide customized solutions are also key factors in the sourcing process.

How Do Protective Covers Ensure Safety in Food and Beverage?

In the food and beverage sector, protective coverings are crucial for machinery to ensure hygiene and safety compliance. These covers help prevent contamination during processing and storage, which is vital for maintaining product quality. For international buyers, sourcing food-grade protective materials is essential, and they must ensure that these materials meet local and international health regulations. Ease of cleaning and durability are also important considerations for maintaining operational efficiency and compliance.

Illustrative image related to protective covering crossword clue

3 Common User Pain Points for ‘protective covering crossword clue’ & Their Solutions

Scenario 1: Navigating Unfamiliar Terminology in Crossword Solutions

The Problem: B2B buyers often encounter difficulties when sourcing solutions for crossword clues, particularly when the terminology is not industry-specific. For instance, terms like “protective cover” or “sheath” may not be immediately recognizable, leading to confusion and inefficiencies in sourcing the right products or information. This lack of clarity can hinder the decision-making process, especially for buyers who are new to crossword puzzle solutions or those looking for specific items related to protective coverings in various industries.

The Solution: To overcome this challenge, buyers should invest in comprehensive dictionaries or online platforms that specialize in crossword terminology. Utilizing resources that provide not only definitions but also context about how these terms are used in puzzles can help clarify meanings. Additionally, engaging with communities or forums focused on crossword puzzles can offer insights into common terms and their applications. Buyers can also compile a glossary of terms relevant to their needs, which can serve as a reference point when dealing with suppliers or searching for specific solutions.

Scenario 2: Difficulty in Matching Crossword Clue Answers with Products

The Problem: Many B2B buyers struggle with the challenge of aligning crossword clue answers with actual products or solutions available in the market. For example, while “armor” or “casing” may be appropriate answers for a crossword clue, buyers may find it difficult to identify products that match these terms. This disconnect can lead to wasted time and resources as they sift through irrelevant options or incorrect assumptions about product specifications.

The Solution: To address this issue, buyers should adopt a systematic approach to product research that includes cross-referencing crossword answers with product catalogs and specifications. Creating a matrix that connects crossword clues to potential products can streamline the search process. Additionally, leveraging digital tools and databases that allow for keyword searches can help buyers find the right products more efficiently. Collaborating with suppliers who understand the nuances of crossword terminology can also facilitate a smoother procurement process, ensuring that buyers receive accurate product recommendations that match their crossword needs.

Scenario 3: Inconsistent Quality and Availability of Crossword Solutions

The Problem: Another significant pain point for B2B buyers is the inconsistency in the quality and availability of solutions related to crossword clues. When sourcing answers for “protective covering,” buyers may encounter variations in product quality, leading to frustration and dissatisfaction. This inconsistency can result in delays in project timelines, especially when the required solutions are not readily available from their usual suppliers.

The Solution: To mitigate this issue, buyers should establish relationships with multiple suppliers to diversify their sourcing options. Implementing a vendor evaluation process that includes criteria for quality assurance can also help in selecting reliable suppliers. Regularly reviewing supplier performance and seeking feedback from end-users can provide insights into product reliability and quality. Furthermore, buyers can consider participating in industry trade shows or networking events to discover new suppliers that offer high-quality solutions. By fostering a broad supplier base and maintaining open communication, buyers can ensure a consistent supply of high-quality crossword-related products.

Strategic Material Selection Guide for protective covering crossword clue

When selecting materials for protective coverings, B2B buyers must consider various factors that influence product performance, cost, and suitability for specific applications. This analysis focuses on four common materials used for protective coverings: Polyethylene (PE), Polyvinyl Chloride (PVC), Metal, and Fabric. Each material has distinct properties, advantages, and limitations that can affect their use in different industries.

What Are the Key Properties of Polyethylene (PE) for Protective Coverings?

Polyethylene is a widely used thermoplastic known for its excellent chemical resistance and durability. It can withstand a temperature range of -50°C to 80°C, making it suitable for various environments. PE is also lightweight and offers good impact resistance, which enhances its protective capabilities.

Pros and Cons:

The advantages of PE include its low cost and ease of manufacturing, which make it a popular choice for packaging and temporary coverings. However, its lower tensile strength compared to other materials may limit its use in high-stress applications. Additionally, PE can degrade under UV exposure unless treated, which may affect long-term performance.

Impact on Application:

PE is compatible with a wide range of media, including water and various chemicals, making it suitable for agricultural, construction, and packaging applications. Buyers should consider the specific environmental conditions where the protective covering will be used.

How Does Polyvinyl Chloride (PVC) Compare as a Protective Covering Material?

PVC is another versatile plastic that offers excellent durability, chemical resistance, and fire retardance. It can handle temperatures from -15°C to 60°C, making it suitable for indoor and outdoor applications.

Pros and Cons:

PVC’s key advantage is its robustness and resistance to environmental factors, which makes it ideal for long-term use in harsh conditions. However, it can be more expensive than PE and may require complex manufacturing processes. Additionally, PVC can become brittle over time when exposed to extreme temperatures, which may limit its lifespan.

Impact on Application:

PVC is often used in construction, electrical insulation, and protective sheathing. International buyers should be aware of compliance with standards such as ASTM and DIN, particularly for construction-related applications.

What Role Does Metal Play in Protective Coverings?

Metal, particularly aluminum and steel, is frequently used for protective coverings in applications requiring high strength and durability. Metals can withstand extreme temperatures and pressures, making them suitable for industrial applications.

Pros and Cons:

The primary advantage of metal coverings is their exceptional durability and resistance to physical damage. However, they can be significantly heavier and more expensive than plastic alternatives. Additionally, metal may be prone to corrosion if not properly treated, which can affect longevity.

Impact on Application:

Metal coverings are commonly used in the automotive and aerospace industries, where strength and durability are paramount. B2B buyers should consider corrosion resistance and compliance with industry standards when selecting metal materials.

How Do Fabrics Function as Protective Coverings?

Fabric materials, such as nylon or polyester, are often used for protective coverings due to their flexibility and lightweight nature. These materials can be treated for water resistance and UV protection, making them suitable for various applications.

Pros and Cons:

The key advantage of fabric coverings is their versatility and comfort, making them ideal for temporary and portable applications. However, they may not offer the same level of protection against physical damage as harder materials. Additionally, fabrics can be more susceptible to wear and tear over time.

Impact on Application:

Fabrics are widely used in outdoor applications, such as tents and tarps, where lightweight and portability are essential. Buyers should consider the specific environmental conditions and required durability when selecting fabric materials.

Summary Table of Material Selection for Protective Coverings

| Material | Typical Use Case for protective covering crossword clue | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Temporary coverings, packaging | Low cost and lightweight | Lower tensile strength | Low |

| Polyvinyl Chloride (PVC) | Construction, electrical insulation | Excellent durability and fire resistance | Higher cost and brittleness over time | Medium |

| Metal | Automotive, aerospace applications | Exceptional strength and durability | Heavier and prone to corrosion | High |

| Fabric | Outdoor applications (tents, tarps) | Versatile and lightweight | Susceptible to wear and tear | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used for protective coverings, helping them make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for protective covering crossword clue

What Are the Main Stages in the Manufacturing Process for Protective Coverings?

Manufacturing protective coverings involves several key stages that ensure the final product meets the required standards for quality and functionality. Understanding these stages is crucial for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe.

1. Material Preparation

The first step in manufacturing protective coverings is material preparation. This involves selecting the appropriate raw materials based on the intended use of the protective cover. For example, materials such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC) are commonly used for tarps, while metals may be used for armor plating.

The preparation process includes testing the raw materials for compliance with international standards, such as ISO certifications. This ensures that materials are suitable for their intended application and can withstand environmental factors, such as UV exposure and moisture.

2. Forming Techniques

Once materials are prepared, the next stage is forming. This involves shaping the raw materials into the desired form for protective coverings. Common techniques include:

- Injection Molding: Suitable for creating complex shapes and sizes, often used for plastic protective covers.

- Extrusion: This method is often used for continuous shapes, such as tubes or sheets, allowing for uniform thickness.

- Die Cutting: Employed for cutting materials into specific shapes, particularly for protective liners and covers.

These techniques are selected based on the material properties and the final application requirements. For instance, a protective cover that needs to be flexible may be formed using different techniques than one requiring rigidity.

3. Assembly

The assembly stage is critical for products that consist of multiple components. For example, a protective cover may include zippers, fasteners, or additional layers for added protection. During assembly, manufacturers must ensure that all parts fit seamlessly and function as intended.

This stage often involves:

- Sewing: Common for fabric-based coverings, ensuring that seams are durable and water-resistant.

- Adhesive Bonding: Used for materials that cannot be sewn, providing a strong bond while maintaining flexibility.

4. Finishing Processes

Finishing processes enhance the protective cover’s durability and aesthetic appeal. Techniques may include:

- Coating: Applying protective coatings to enhance water resistance, UV stability, or chemical resistance.

- Printing: Custom branding or instructional printing on the surface of the protective cover.

Finishing is essential for ensuring that the protective cover not only performs well but also meets market expectations for appearance and brand representation.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is vital in the manufacturing of protective coverings. Buyers should familiarize themselves with relevant international standards and industry-specific certifications.

International Standards

ISO 9001 is the most recognized quality management standard, ensuring that organizations meet customer and regulatory requirements. Companies manufacturing protective coverings often pursue this certification to demonstrate their commitment to quality and continuous improvement.

Industry-Specific Standards

Depending on the application, different standards may apply:

- CE Marking: Essential for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: For protective coverings used in the oil and gas industry, adherence to American Petroleum Institute (API) standards ensures safety and reliability.

How Do Quality Control Checkpoints Work?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure compliance with standards and specifications. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help identify defects early, minimizing waste and rework.

- Final Quality Control (FQC): The final inspection before shipping ensures that the product meets all specifications and is ready for use.

What Common Testing Methods Are Used in Quality Assurance?

Testing methods are critical to verifying the performance and safety of protective coverings. Common testing methods include:

- Tensile Testing: Measures the strength and elasticity of materials.

- Water Resistance Testing: Evaluates the ability of the protective cover to resist water penetration.

- UV Resistance Testing: Assesses the material’s durability against UV exposure.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are effective strategies:

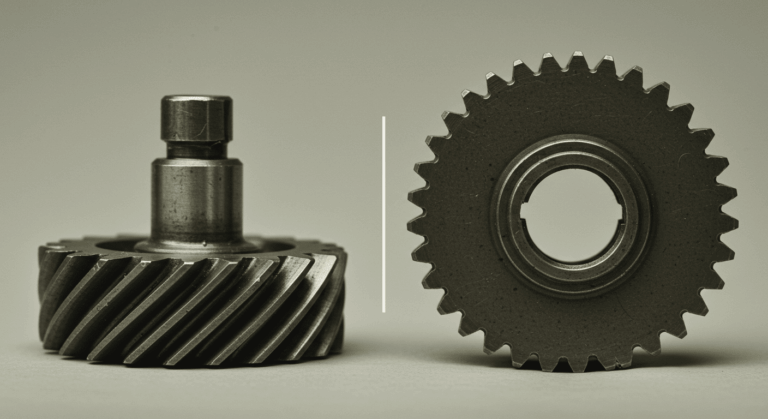

Illustrative image related to protective covering crossword clue

Supplier Audits

Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing practices, quality management systems, and adherence to safety protocols. This hands-on approach provides insight into the supplier’s operational capabilities.

Quality Reports

Requesting regular quality reports from suppliers can help buyers track performance metrics, such as defect rates and compliance with testing standards. These reports serve as an ongoing assurance of product quality.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections often include comprehensive evaluations of the manufacturing process and final products.

Illustrative image related to protective covering crossword clue

What Are the Nuances of Quality Control for International Buyers?

B2B buyers from different regions may face unique challenges concerning quality control. For instance:

- Cultural Differences: Understanding local manufacturing practices and quality expectations is crucial, especially in emerging markets in Africa and South America.

- Regulatory Compliance: Buyers must be aware of varying regulations and standards in different countries, which can impact product acceptance.

- Logistics and Transportation: Quality assurance is also affected by how products are stored and transported. Ensuring that protective covers are handled correctly during shipping is essential for maintaining quality.

In conclusion, understanding the manufacturing processes and quality assurance measures for protective coverings is essential for B2B buyers. By familiarizing themselves with material preparation, forming techniques, assembly, and finishing, as well as international standards and quality control checkpoints, buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘protective covering crossword clue’

In today’s competitive landscape, sourcing the right protective coverings for your business needs is critical. This guide provides a structured approach for B2B buyers looking to procure solutions that match the crossword clue “protective covering.” Follow these steps to ensure you make informed decisions that align with your operational requirements.

Step 1: Define Your Technical Specifications

Understanding your specific needs is the first step in the sourcing process. Determine the type of protective covering required, whether it’s for physical items, equipment, or personnel. Consider factors such as material durability, environmental resistance, and compliance with industry standards.

Illustrative image related to protective covering crossword clue

- Material Types: Evaluate options like tarps, casings, or armor based on their intended use.

- Performance Requirements: Specify criteria such as temperature resistance, tensile strength, and waterproofing.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in protective coverings. Look for companies with a solid reputation in your target regions, such as Europe, Africa, South America, or the Middle East.

- Supplier Directories: Use online resources and industry networks to compile a list of potential suppliers.

- Market Reviews: Check reviews and testimonials to gauge supplier reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before proceeding with any procurement, verify that suppliers hold relevant certifications. This step ensures that they meet industry standards and regulations, which can vary by region.

- Quality Management Systems: Check for ISO certifications or equivalent that indicate adherence to quality standards.

- Environmental Compliance: Ensure they comply with local environmental regulations to avoid future liabilities.

Step 4: Request Samples and Prototypes

Once you have a shortlist of suppliers, request samples or prototypes of the protective coverings. This hands-on evaluation allows you to assess material quality and suitability for your specific applications.

- Performance Testing: Conduct tests to see how the samples perform under your expected conditions.

- Feedback from Stakeholders: Involve relevant team members in the evaluation process to gather diverse insights.

Step 5: Compare Pricing and Terms

With evaluations completed, compare pricing and contractual terms from your shortlisted suppliers. This step is vital for budget adherence and understanding the total cost of ownership.

- Price Breakdown: Ensure quotes include all potential costs, such as shipping, taxes, and duties.

- Payment Terms: Review payment options and conditions to ensure they align with your cash flow management.

Step 6: Negotiate Contracts

Engage in negotiations with your chosen supplier(s) to finalize terms that are beneficial for both parties. This step is crucial to secure favorable conditions and build a collaborative relationship.

Illustrative image related to protective covering crossword clue

- Volume Discounts: Discuss pricing structures based on order volumes to maximize savings.

- Service Level Agreements: Establish clear expectations for delivery timelines, quality assurance, and support services.

Step 7: Establish a Review Process

After procurement, implement a review process to assess the performance of the protective coverings and the supplier’s service. Continuous evaluation ensures that your needs are consistently met and allows for adjustments as necessary.

- Feedback Mechanism: Create channels for team members to report on product performance and supplier interactions.

- Long-term Relationships: Consider ongoing partnerships with suppliers who consistently meet or exceed expectations.

By following these steps, B2B buyers can navigate the complexities of sourcing protective coverings effectively, ensuring that their procurement decisions align with operational goals and industry standards.

Comprehensive Cost and Pricing Analysis for protective covering crossword clue Sourcing

What Are the Key Cost Components in Protective Covering Production?

When sourcing protective coverings, a thorough understanding of the cost structure is essential. The primary components include:

- Materials: The choice of materials significantly affects costs. Common options for protective coverings like tarps, sheaths, and armor include polyethylene, vinyl, or specialized fabrics, each varying in price based on quality and durability.

- Labor: Labor costs can fluctuate based on location and the complexity of the manufacturing process. Countries with lower labor costs may provide competitive pricing, but quality assurance must be prioritized.

- Manufacturing Overhead: This encompasses utilities, rent, and equipment maintenance. Efficient production processes can help reduce overhead costs, impacting overall pricing.

- Tooling: The initial investment in tooling for custom designs can be substantial. However, tooling costs can be amortized over larger production runs, making economies of scale a crucial consideration.

- Quality Control (QC): Implementing rigorous QC processes ensures product reliability and can prevent costly returns. While this adds to initial costs, it safeguards against potential losses from defective products.

- Logistics: Transportation and shipping costs, influenced by distance and mode of transport, can significantly affect the final price. This is especially relevant for international buyers who must account for customs duties and tariffs.

- Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the supplier’s cost structure can aid in negotiation for better pricing.

How Do Price Influencers Impact Sourcing Decisions for Protective Coverings?

Several factors influence pricing that international B2B buyers should consider:

- Volume/MOQ: The minimum order quantity (MOQ) often dictates pricing tiers. Larger orders typically result in lower per-unit costs, making it beneficial to consolidate purchases.

- Specifications and Customization: Custom designs or specific certifications (e.g., fire-retardant materials) can lead to higher costs. Buyers should balance their needs against budget constraints.

- Material Quality and Certifications: Higher quality materials that meet specific certifications often carry a premium. Ensure the selected supplier provides the necessary documentation to avoid compliance issues.

- Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers might charge more but offer better quality assurance and customer service.

- Incoterms: Understanding shipping terms (Incoterms) is vital, as they determine who bears the cost and risk at different stages of the supply chain. This knowledge can prevent unexpected charges.

What Are Some Effective Buyer Tips for Negotiating Costs in Protective Covering Sourcing?

To optimize cost-efficiency when sourcing protective coverings, consider the following strategies:

- Negotiate Terms: Engage in discussions with suppliers to negotiate better pricing based on volume, payment terms, or long-term contracts. Building a strong relationship can lead to favorable terms.

- Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess factors like durability, maintenance, and potential replacement costs to determine the overall value of the protective covering.

- Research Market Trends: Stay informed about material costs and market conditions. This knowledge can empower buyers during negotiations and sourcing decisions.

- Consider Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing from local suppliers can reduce logistics costs and lead times, enhancing overall efficiency.

- Understand Pricing Nuances: Be aware of regional pricing variations. Factors such as currency fluctuations, local economic conditions, and demand-supply dynamics can influence costs.

Disclaimer

The pricing and cost structures discussed are indicative and can vary significantly based on specific project requirements, market conditions, and supplier negotiations. Always conduct thorough research and engage with multiple suppliers to ensure competitive pricing in your sourcing strategy.

Illustrative image related to protective covering crossword clue

Alternatives Analysis: Comparing protective covering crossword clue With Other Solutions

When considering the concept of a protective covering crossword clue, it’s essential to evaluate viable alternatives that fulfill similar protective roles in various applications. These alternatives can vary widely in terms of performance, cost, ease of implementation, and overall utility across different industries. Below is a comparative analysis of the protective covering crossword clue against two notable alternatives: “Protective Coating” and “Protective Layering System.”

| Comparison Aspect | Protective Covering Crossword Clue | Protective Coating | Protective Layering System |

|---|---|---|---|

| Performance | Varies based on context | High durability and resistance | Variable, depends on materials used |

| Cost | Minimal (for puzzle enthusiasts) | Moderate to high | High initial investment but cost-effective over time |

| Ease of Implementation | Simple (solving puzzles) | Requires skilled application | Requires planning and installation |

| Maintenance | None (once solved) | Low to moderate (depends on usage) | Moderate (regular inspections needed) |

| Best Use Case | Entertainment and cognitive training | Industrial applications (corrosion resistance) | Aerospace, military, and high-performance sectors |

What Are the Pros and Cons of Protective Coating?

Protective coatings are widely used in various industries, providing a layer of protection against environmental factors, corrosion, and wear. Their advantages include excellent durability and the ability to enhance the lifespan of machinery and structures. They are particularly effective in industrial settings where equipment is exposed to harsh conditions. However, the application process can be complex, requiring skilled labor and specific conditions for optimal results, which can lead to increased costs. Additionally, regular maintenance might be necessary to ensure the coating remains effective over time.

How Does a Protective Layering System Compare?

A protective layering system involves multiple layers of materials that provide enhanced protection through redundancy. This method is highly effective in sectors requiring extreme durability and resistance, such as aerospace and military applications. The main advantage of this approach is its ability to absorb shocks and resist punctures effectively. However, the initial investment can be substantial due to the complexity of design and installation, and ongoing maintenance is essential to ensure all layers remain intact and functional.

Conclusion: How Should B2B Buyers Choose the Right Solution?

B2B buyers should carefully assess their specific needs when choosing between a protective covering crossword clue, protective coatings, or protective layering systems. Factors such as the intended application, budget constraints, and maintenance capabilities should guide the decision-making process. Buyers focused on entertainment and cognitive engagement might find crossword clues beneficial, while those in industrial or high-performance sectors may prioritize the durability and resilience of coatings or layering systems. Ultimately, understanding the unique requirements of their operations will lead to a more informed and effective selection of protective solutions.

Essential Technical Properties and Trade Terminology for protective covering crossword clue

What Are the Key Technical Properties of Protective Coverings?

When considering protective coverings, several critical specifications should be evaluated to ensure that the product meets business needs effectively. Understanding these properties can guide B2B buyers in selecting the right materials for their applications.

1. Material Grade

Material grade refers to the classification of the material used in protective coverings, which can significantly affect durability and performance. Common materials include polymers, metals, and composites. For B2B buyers, understanding material grades is essential for ensuring that the protective covering can withstand environmental stresses, such as UV radiation, moisture, and mechanical wear. A higher-grade material often results in longer-lasting products, reducing replacement costs over time.

2. Tolerance

Tolerance is the permissible limit of variation in a physical dimension. In the context of protective coverings, it affects how well a covering fits its intended application. For example, a protective casing with tight tolerances ensures a snug fit, which can enhance protection against contaminants. B2B buyers should prioritize products with appropriate tolerances to ensure compatibility with other components in their systems, minimizing risks of failure.

3. Thickness

Thickness is a critical property that determines the level of protection a covering provides. Thicker coverings generally offer better resistance to impacts and environmental factors. For businesses in industries like construction or manufacturing, selecting the right thickness can be vital for safety and compliance with regulations. Understanding thickness specifications helps in making informed decisions based on the specific risks associated with the intended use.

Illustrative image related to protective covering crossword clue

4. Chemical Resistance

Chemical resistance indicates how well a protective covering can withstand exposure to various chemicals without degrading. This property is particularly important in industries such as agriculture, pharmaceuticals, and manufacturing, where exposure to harsh substances is common. B2B buyers must assess chemical resistance ratings to ensure that the selected protective covering will maintain its integrity and functionality over time.

5. Fire Resistance

Fire resistance is a property that signifies a material’s ability to withstand fire or prevent the spread of flames. In many industries, such as construction and transportation, fire safety regulations necessitate the use of fire-resistant materials. Understanding fire resistance ratings helps B2B buyers comply with safety standards and protect their investments from fire-related damages.

What Are Common Trade Terms Related to Protective Coverings?

In addition to technical properties, familiarity with industry terminology is crucial for effective communication and negotiation in B2B transactions involving protective coverings.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of protective coverings, OEMs often provide specialized solutions tailored to specific applications. Understanding OEM relationships can help businesses secure high-quality components that meet their unique needs.

Illustrative image related to protective covering crossword clue

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for buyers who require large volumes of protective coverings. Knowing the MOQ can aid in budgeting and inventory planning, ensuring that businesses do not overcommit resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For businesses looking to procure protective coverings, issuing an RFQ can streamline the procurement process and enable comparison of offers. This ensures that buyers receive competitive pricing while meeting their technical specifications.

4. Incoterms

Incoterms (International Commercial Terms) are a set of international rules that define the responsibilities of buyers and sellers in shipping and freight transactions. Understanding Incoterms is essential for businesses involved in international trade, as they clarify who is responsible for shipping costs, insurance, and risk during transit. Proper comprehension of these terms can prevent misunderstandings and additional costs in the procurement of protective coverings.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In industries where protective coverings are critical for operations, understanding lead times can help businesses manage their supply chains effectively. Knowledge of lead times allows for better planning and reduces the risk of operational delays.

By grasping these essential technical properties and trade terminologies, B2B buyers can make more informed decisions regarding protective coverings, ensuring they select the best solutions for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the protective covering crossword clue Sector

What are the Current Market Dynamics and Sourcing Trends in the Protective Covering Sector?

The protective covering sector is witnessing significant growth driven by various global factors. Key market drivers include increasing industrialization, a surge in construction activities, and heightened awareness around safety and protection across various industries. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, are increasingly seeking advanced protective solutions that offer durability and efficiency. Emerging technologies such as smart materials and nanotechnology are influencing sourcing trends, enabling manufacturers to produce coverings that are not only protective but also multifunctional—offering features like UV resistance and thermal insulation.

Furthermore, the rise of e-commerce has transformed sourcing practices, allowing buyers to procure protective coverings from global suppliers with greater ease. However, buyers must navigate the complexities of international logistics and tariffs, particularly when importing from regions like Asia, where many manufacturers are based. Additionally, regional factors, such as political stability and economic policies, can impact sourcing decisions, necessitating a strategic approach to supplier selection and risk management.

How is Sustainability Shaping the Sourcing Strategies for Protective Coverings?

Sustainability is becoming an essential consideration in the sourcing of protective coverings. The environmental impact of production processes and materials used is under scrutiny, prompting buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. The demand for eco-friendly materials, such as biodegradable plastics and recycled fabrics, is on the rise, particularly in markets that are increasingly aware of climate change and its implications.

Ethical sourcing is also gaining traction, with buyers looking for transparency in supply chains. This includes ensuring fair labor practices and minimizing waste throughout the production process. Certifications such as ISO 14001 for environmental management and Global Organic Textile Standard (GOTS) for organic textiles are becoming critical benchmarks for buyers evaluating suppliers. By aligning sourcing strategies with sustainability goals, B2B buyers can enhance their brand reputation and meet the expectations of environmentally conscious consumers.

What is the Historical Context of Protective Coverings in B2B Markets?

The evolution of protective coverings can be traced back to ancient civilizations, where basic forms of protection, such as animal hides and woven materials, were used for shielding against environmental elements. As industries evolved, so did the materials and technologies used in protective coverings. The 20th century saw significant advancements with the introduction of synthetic materials, providing enhanced durability and versatility.

In contemporary markets, protective coverings have expanded into a wide array of applications, from industrial safety gear to protective layers in construction and automotive industries. This evolution reflects not only technological advancements but also a growing recognition of the importance of safety and protection in various sectors. As the market continues to innovate, B2B buyers can expect to see more sophisticated and tailored solutions that meet specific industry needs while adhering to modern sustainability standards.

Frequently Asked Questions (FAQs) for B2B Buyers of protective covering crossword clue

-

How do I solve the crossword clue for protective covering?

To solve a crossword clue for “protective covering,” consider the context of the puzzle, including the number of letters in the answer. Common solutions include terms like “armor,” “tarp,” and “shelter.” If you have certain letters already filled in, utilize online crossword solvers or databases to filter options that match your criteria. Engaging with crossword communities can also provide insights and alternative answers you may not have considered. -

What is the best material for a protective covering?

The best material for a protective covering often depends on the intended application. For outdoor use, durable materials like tarpaulin or heavy-duty plastic are ideal due to their weather resistance. In industrial settings, options like metal sheaths or reinforced fabrics provide robust protection against physical damage. For electronics, consider silicone or rubber coatings that offer insulation and moisture resistance. Always assess the specific needs of your project to choose the most effective material. -

How can I source protective coverings from international suppliers?

Sourcing protective coverings from international suppliers involves researching manufacturers in your target regions, such as Asia or Europe. Utilize trade platforms like Alibaba or Global Sources to find reputable vendors. Attend industry trade shows to meet suppliers in person and evaluate product quality. Ensure to verify supplier credentials, including certifications and customer reviews, to establish reliability before committing to any orders. -

What factors should I consider when vetting suppliers of protective coverings?

When vetting suppliers for protective coverings, consider their production capacity, quality control processes, and industry certifications. Check for compliance with international standards, especially if you are importing to regions with strict regulations. Request samples to evaluate material quality and durability. Additionally, assess their communication responsiveness and willingness to provide detailed product information, as these factors often indicate a supplier’s professionalism and reliability. -

What are typical minimum order quantities (MOQs) for protective coverings?

Minimum order quantities (MOQs) for protective coverings can vary widely based on the supplier and the type of product. Generally, MOQs can range from 100 to 1,000 units for custom products. For standard items, suppliers may have lower MOQs. It’s crucial to discuss MOQs upfront with potential suppliers to align your purchasing needs with their capabilities. If your order volume is low, inquire about the possibility of sample orders or mixed product shipments. -

What payment terms are common in international B2B transactions for protective coverings?

Common payment terms in international B2B transactions for protective coverings include advance payment, letters of credit, and payment upon delivery. Many suppliers may request a 30% deposit upfront, with the remaining balance due before shipment. Ensure to clarify payment methods accepted, such as bank transfers or credit cards, and consider the impact of currency fluctuations on pricing. Establish clear payment terms in your contract to avoid misunderstandings. -

How can I ensure quality assurance (QA) for protective coverings sourced internationally?

To ensure quality assurance for protective coverings sourced internationally, implement a thorough QA process that includes supplier audits, material inspections, and product testing. Consider hiring third-party inspection services to assess product quality before shipment. Establish clear specifications and standards with your supplier, and request regular updates during production. Having a robust QA framework helps mitigate risks associated with international sourcing and ensures that products meet your quality expectations. -

What logistics considerations should I keep in mind when importing protective coverings?

When importing protective coverings, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose between air or sea freight based on your budget and urgency. Be aware of import duties and taxes applicable in your country, and ensure all necessary documentation is in order to facilitate smooth customs clearance. Partnering with a reliable freight forwarder can help navigate the complexities of international shipping, ensuring timely delivery of your products.

Top 6 Protective Covering Crossword Clue Manufacturers & Suppliers List

1. Wordplays – Crossword Solver

Domain: wordplays.com

Registered: 1999 (26 years)

Introduction: This company, Wordplays – Crossword Solver, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Dictionary.com – Crossword Clue Solutions

Domain: dictionary.com

Registered: 1995 (30 years)

Introduction: Crossword Clue: protective covering. Matching Answers: TARP (95% confidence), ARMOR (88% confidence), SKIN (88% confidence), LINER (88% confidence), SHEATH (88% confidence), COCOON (88% confidence), ENAMEL (60% confidence), TESTA (60% confidence), BRA (60% confidence), APRON (60% confidence).

3. Danword – Crossword Puzzle Solutions

Domain: danword.com

Registered: 2012 (13 years)

Introduction: Protective covering crossword puzzle clue; possible answers include: SHELL, SKIN, ARMOUR, SHROUD, SHELTER, CASINGS, HEATH, FACE MASK, COCOONS, MOCK, TARPS, SHIELD, ARMOR, PLATE, COAT, ROOF.

4. Crossword Tracker – Protective Coverings

Domain: crosswordtracker.com

Registered: 2010 (15 years)

Introduction: Protective covering is a crossword puzzle clue that has been spotted over 20 times. Related clues include COAT, ARMOR, TARP, SKIN, ROOF, LINER, SHEATH, SHIELD, SMOCK, COCOON, ARMOUR, ARMATURE, and ARMORPLATE. Recent usage in crossword puzzles includes various publications such as the Canadiana Crossword, Evening Standard, Penny Dell, LA Times, WSJ Daily, The Guardian Quick, USA Today, Newsday, and…

5. Crossword Solver – Protective Covering

Domain: crossword-solver.io

Registered: 2019 (6 years)

Introduction: Protective covering crossword clue with 40 possible answers. Most likely answer is ‘SKIN’ (4 letters). Other answers include ‘SHROUD’ (6), ‘SHELTER’ (7), ‘COCOON’ (6), ‘ARMOUR’ (6), ‘ARMORPLATE’ (10), ‘COAT’ (4), ‘ROOF’ (4), ‘TARP’ (4), ‘ARMOR’ (5). The clue was last seen in Newsday.

6. The Crossword Solver – Protective Covering Solutions

Domain: the-crossword-solver.com

Registered: 2012 (13 years)

Introduction: The crossword clue “PROTECTIVE COVERING” has 24 solutions ranging from 4 to 11 letters long. The top answers include: 4-letter words like SKIN, COAT, and ROOF; 5-letter words like ARMOR and SHELL; 6-letter words like ARMOUR and SHIELD; 7-letter words like HARNESS; 8-letter words like CARAPACE; 9-letter words like TARPAULIN; 10-letter words like ARMORPLATE; and the longest 11-letter word BREASTPLAT…

Strategic Sourcing Conclusion and Outlook for protective covering crossword clue

As businesses across Africa, South America, the Middle East, and Europe seek to enhance their operational resilience, understanding the nuances of protective coverings—often represented in various ways, such as “armor,” “casing,” and “sheath”—is crucial. Strategic sourcing plays a pivotal role in this process, enabling companies to identify high-quality materials and suppliers that align with their specific needs and industry standards. By focusing on these protective solutions, organizations can mitigate risks associated with product damage, enhance safety protocols, and ultimately improve customer satisfaction.

Furthermore, as global supply chains evolve, leveraging strategic sourcing to build relationships with diverse suppliers can provide a competitive edge. Companies that prioritize this approach are better positioned to adapt to market changes and capitalize on emerging trends in protective coverings.

Looking ahead, international B2B buyers are encouraged to actively engage with suppliers who demonstrate innovation and reliability in protective solutions. By doing so, they not only secure their products but also contribute to a more sustainable and resilient supply chain. Embrace the opportunities that strategic sourcing presents, and invest in protective coverings that will safeguard your business’s future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to protective covering crossword clue

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.