The Definitive Guide to Electric Heater Filament: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for electric heater filament

In today’s rapidly evolving industrial landscape, sourcing high-quality electric heater filament can pose a significant challenge for international B2B buyers. The demand for efficient heating solutions across diverse applications—from residential water heating systems to large-scale industrial processes—requires meticulous attention to detail in selecting the right materials and suppliers. This comprehensive guide delves into the intricacies of electric heater filament, covering essential aspects such as types, applications, supplier vetting processes, and cost considerations.

With a focus on the unique needs of buyers from Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—this resource aims to empower decision-makers by providing actionable insights and best practices. By exploring the various types of electric heater filaments available, such as metallic and ceramic options, and their suitability for specific applications, readers will gain a clearer understanding of how to make informed purchasing decisions.

Furthermore, the guide addresses the critical factors for vetting suppliers, ensuring that buyers can establish reliable partnerships that prioritize quality and efficiency. Ultimately, this resource serves as a vital tool for B2B buyers seeking to navigate the global market for electric heater filament, equipping them with the knowledge needed to optimize their sourcing strategies and enhance operational productivity.

Understanding electric heater filament Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Molybdenum Disilicide | High-temperature resistance, long lifespan | Industrial heating, furnace applications | Pros: Excellent durability; Cons: Higher initial cost. |

| Silicon Carbide | High power, customizable designs, even heating | Semiconductor processing, metal heating | Pros: Versatile and efficient; Cons: Requires specific installation expertise. |

| Metallic Heating Elements | Made from alloys, available in various forms | General heating applications, appliances | Pros: Cost-effective; Cons: Limited temperature range. |

| Tubular Heating Elements | Tubular design, versatile installation options | Water heating, industrial heating | Pros: Easy to install; Cons: Less efficient in larger applications. |

| Cartridge Heaters | Compact design, high watt density | Medical equipment, small industrial ovens | Pros: Space-saving; Cons: May require custom solutions for specific applications. |

What are the characteristics of Molybdenum Disilicide filaments?

Molybdenum disilicide (MoSi₂) filaments are renowned for their ability to withstand extremely high temperatures, making them ideal for industrial heating applications. They can operate effectively in environments exceeding 1,600°C (2,912°F) and have a long lifespan, reducing replacement frequency and downtime. B2B buyers should consider the initial investment, as these elements can be pricier than alternatives, but their durability often justifies the cost in high-demand settings.

How do Silicon Carbide filaments stand out in industrial applications?

Silicon carbide (SiC) heating elements are distinguished by their high power output and customizable designs, suitable for various industrial processes. They provide even heating and can reach temperatures up to 1,625°C (2,927°F), making them ideal for applications in semiconductor processing and metal heating. When purchasing, B2B buyers should evaluate the specific heating requirements and installation capabilities, as these elements may necessitate specialized setups.

What makes Metallic Heating Elements a popular choice among buyers?

Metallic heating elements, typically made from Kanthal® or Nikrothal® alloys, are versatile and widely used across numerous industries. They are available in various forms, including wire and ribbon, which allows for flexibility in installation. These elements are a cost-effective solution for general heating applications, though buyers should note that their temperature range may be limited compared to more specialized options. Understanding the operational environment is crucial for optimal performance.

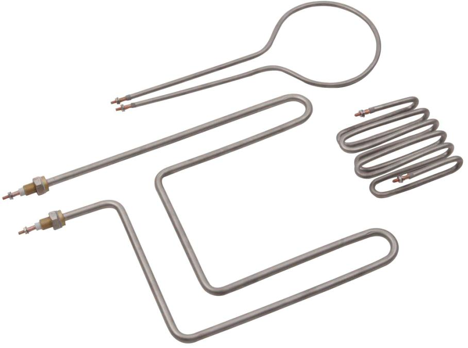

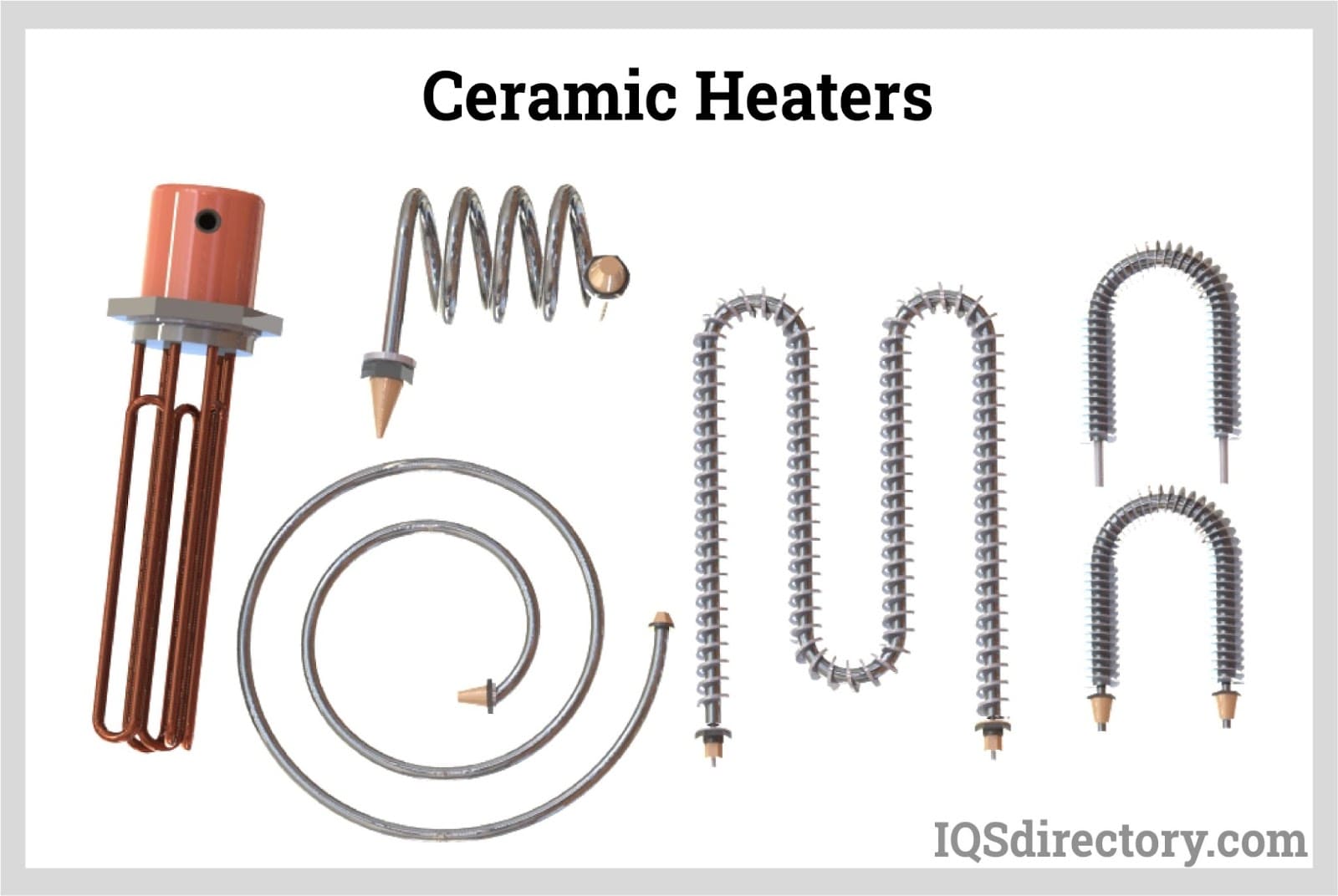

Illustrative image related to electric heater filament

Why choose Tubular Heating Elements for your heating needs?

Tubular heating elements are designed for easy installation and can be utilized in various heating applications, including water heaters and industrial furnaces. Their robust construction allows for effective heating in multiple environments. B2B buyers should consider their efficiency in larger systems, as they may not perform as well in extensive applications compared to other heating types. However, their adaptability makes them a practical choice for many businesses.

What advantages do Cartridge Heaters offer in compact spaces?

Cartridge heaters are compact and designed for high watt density, making them suitable for small-scale industrial ovens and medical equipment. Their design allows for easy integration into limited spaces, which is essential in many modern applications. Buyers should be aware that while they are space-efficient, specific applications may require custom solutions, which could increase costs. Evaluating the exact heating needs and available space will help in making the right purchasing decision.

Key Industrial Applications of electric heater filament

| Industry/Sector | Specific Application of electric heater filament | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Heating | Electric water heaters for residential and commercial use | Efficient heating with quick response times | Wattage requirements, material durability, and compatibility with existing systems |

| Industrial Manufacturing | Heating elements in industrial furnaces and kilns | Enhanced process efficiency and product quality | High-temperature resistance, customization options, and energy consumption rates |

| Food Processing | Electric heaters for sterilization and cooking | Improved food safety and quality control | Compliance with health regulations, energy efficiency, and ease of maintenance |

| HVAC Systems | Electric heating elements in heating, ventilation, and air conditioning systems | Cost-effective heating solutions | Voltage and wattage specifications, safety certifications, and integration with control systems |

| Laboratory Equipment | Heating elements for lab equipment like incubators and sterilizers | Precise temperature control for experiments | Temperature range, material compatibility, and reliability under continuous use |

How is Electric Heater Filament Utilized in Water Heating Applications?

Electric heater filaments are integral to water heating solutions found in both residential and commercial settings. These elements convert electrical energy into heat, ensuring rapid water heating for showers, dishwashing, and heating systems. Businesses benefit from efficient heating that reduces energy costs and improves customer satisfaction. For international buyers, especially in regions like Africa and the Middle East, sourcing durable elements capable of withstanding varying water quality is crucial. Key considerations include wattage compatibility, material resilience, and compliance with local electrical standards.

In What Ways Do Electric Heater Filaments Enhance Industrial Manufacturing Processes?

In industrial manufacturing, electric heater filaments are employed in furnaces and kilns to achieve high-temperature heating necessary for processes like metal treatment and ceramics production. These heating elements improve operational efficiency by providing consistent and precise heating, which is vital for product quality. For manufacturers in Europe and South America, selecting heating elements that can withstand extreme conditions and offer energy efficiency is essential. Buyers should consider the filament’s temperature ratings, customization options, and the supplier’s ability to provide technical support for integration into existing systems.

What Role Do Electric Heater Filaments Play in Food Processing?

Electric heater filaments are essential in food processing applications, particularly for sterilization and cooking processes. They ensure that food products are heated uniformly, which is critical for safety and quality assurance. Businesses benefit from the reliability and efficiency of electric heating, which can lead to reduced operational costs. For B2B buyers in regions like Africa and the Middle East, sourcing heaters that comply with food safety regulations and are energy-efficient is paramount. Buyers must evaluate the elements’ material compatibility with food products and their maintenance requirements.

How Do Electric Heater Filaments Contribute to HVAC Systems?

In HVAC systems, electric heater filaments provide an effective heating solution, particularly in regions with cold climates. They are used to enhance the heating capabilities of ventilation systems, ensuring comfortable indoor environments. The cost-effectiveness and ease of installation of these elements are significant advantages for businesses. For international buyers, particularly in Europe, it’s essential to focus on the voltage and wattage specifications that meet local standards, as well as the safety certifications of the heating elements.

Why are Electric Heater Filaments Important in Laboratory Equipment?

Electric heater filaments are crucial in laboratory settings, utilized in incubators and sterilizers where precise temperature control is necessary. They help maintain stable conditions for experiments, ensuring reliable results. This reliability is particularly valuable for businesses in research and development sectors. International buyers must consider the temperature range and durability of the heating elements, as well as their compatibility with various lab equipment. Reliability under continuous use and adherence to safety standards are also key factors for sourcing decisions.

3 Common User Pain Points for ‘electric heater filament’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Electric Heater Filaments

The Problem: Many B2B buyers face challenges when sourcing electric heater filaments that meet specific performance standards. This is particularly true for industries such as manufacturing and construction, where quality and reliability are paramount. Buyers often encounter a wide array of suppliers, but distinguishing between those offering subpar materials and those providing high-performance filaments can be daunting. Additionally, fluctuating market prices can complicate procurement decisions, making it difficult to stick to budgets while ensuring product quality.

The Solution: To effectively source high-quality electric heater filaments, buyers should adopt a multi-faceted approach. First, it is essential to conduct thorough research on potential suppliers. Look for manufacturers with established reputations and positive customer reviews, particularly those that specialize in electric heating elements. Verify certifications and compliance with international standards, such as ISO 9001, to ensure product quality. Additionally, consider requesting samples for testing to evaluate performance under operational conditions before committing to larger orders. Establishing long-term relationships with reliable suppliers can also lead to better pricing and priority service, which is beneficial in managing costs.

Scenario 2: Incompatibility with Existing Systems

The Problem: Another common pain point for B2B buyers is finding electric heater filaments that are compatible with existing heating systems. Many companies utilize specific types of heating setups, and introducing new filaments that do not integrate seamlessly can lead to operational disruptions, inefficiencies, and increased costs. Buyers often struggle to find technical specifications that align with their current equipment, leading to trial-and-error scenarios that waste time and resources.

The Solution: To mitigate compatibility issues, buyers should engage in detailed technical discussions with suppliers prior to purchasing electric heater filaments. Clearly outline the specifications and requirements of existing systems, including wattage, voltage, and physical dimensions. Request detailed technical datasheets from suppliers, which should include compatibility information and installation guidelines. It may also be beneficial to involve engineering teams in the selection process to ensure that any new elements will integrate smoothly into current systems. Furthermore, consider investing in customizable heating solutions that can be tailored to specific applications, providing flexibility and reducing the risk of future incompatibility.

Scenario 3: Inefficiencies Leading to High Operational Costs

The Problem: Many businesses discover that their electric heater filaments are not operating at optimal efficiency, leading to excessive energy consumption and increased operational costs. This inefficiency can stem from outdated technology, poor maintenance, or inappropriate filament selection for specific heating tasks. For B2B buyers, this often translates into higher energy bills and reduced profitability, making it critical to identify and rectify these inefficiencies.

The Solution: To address inefficiencies, buyers should first conduct an energy audit of their heating systems to pinpoint areas of excessive consumption. This audit can help identify whether the current electric heater filaments are suitable for the intended applications or if they need upgrading. Opting for modern, high-efficiency filaments designed for specific tasks can significantly reduce energy usage. Additionally, implementing a regular maintenance schedule can prolong the lifespan of heating elements and ensure they operate at peak efficiency. Buyers should also consider collaborating with suppliers who offer energy-efficient solutions and consulting services that can provide tailored recommendations based on operational needs and energy-saving technologies.

Strategic Material Selection Guide for electric heater filament

What Are the Key Materials for Electric Heater Filament?

When selecting materials for electric heater filaments, understanding the properties, advantages, and limitations of each option is crucial for B2B buyers. Here, we analyze four common materials used in electric heater filaments: Kanthal® alloys, nickel-chromium alloys, stainless steel, and molybdenum disilicide (MoSi₂).

How Do Kanthal® Alloys Perform in Electric Heater Applications?

Kanthal® alloys are known for their excellent resistance to oxidation and high-temperature stability, making them ideal for applications requiring consistent performance at elevated temperatures. They can operate effectively up to 1,425°C (2,600°F) and have a high melting point, which enhances their durability.

Pros: Kanthal® alloys offer superior longevity and can withstand harsh environments, making them suitable for industrial applications. Their resistance to corrosion and oxidation ensures minimal maintenance and downtime.

Cons: The primary drawback is their cost, as Kanthal® alloys tend to be more expensive than other materials. Additionally, their manufacturing process can be complex due to the precise control required during production.

Impact on Application: Kanthal® is particularly effective in applications involving air or inert gas, where oxidation is a concern. Its high-temperature capability makes it suitable for industries like ceramics and glass.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is essential. Buyers from regions like Europe and the Middle East may prefer Kanthal® for its reliability and performance in high-temperature applications.

What Benefits Do Nickel-Chromium Alloys Offer?

Nickel-chromium alloys are widely used for electric heater filaments due to their excellent electrical resistance and ability to generate heat efficiently. They can withstand temperatures up to 1,200°C (2,192°F).

Pros: These alloys are cost-effective and provide good thermal stability, making them suitable for a range of heating applications. Their availability in various forms (wire, ribbon, etc.) adds to their versatility.

Cons: While durable, nickel-chromium alloys can be prone to oxidation at high temperatures if not properly protected. Their lifespan may be shorter in aggressive environments compared to Kanthal®.

Impact on Application: They are commonly used in domestic heating appliances and industrial furnaces, where moderate temperatures are required. Compatibility with various heating media makes them a popular choice.

Considerations for International Buyers: Buyers should ensure that the alloys meet local standards and regulations, particularly in regions such as South America and Africa, where compliance may vary.

Why Choose Stainless Steel for Electric Heater Filaments?

Stainless steel is another popular choice for electric heater filaments, particularly in applications where corrosion resistance is critical. It can operate at temperatures up to 1,000°C (1,832°F).

Pros: Stainless steel is widely available and relatively inexpensive compared to other materials. It offers good mechanical strength and resistance to corrosion, making it suitable for humid environments.

Cons: The thermal efficiency of stainless steel is lower than that of Kanthal® and nickel-chromium alloys, which may lead to higher energy consumption. Its performance may degrade at higher temperatures over time.

Impact on Application: Stainless steel is ideal for applications in food processing and medical equipment, where hygiene and corrosion resistance are paramount.

Considerations for International Buyers: Compliance with health and safety standards is crucial, especially in food-related industries. Buyers in Europe may prioritize stainless steel for its regulatory acceptance.

How Does Molybdenum Disilicide (MoSi₂) Compare?

Molybdenum disilicide is a high-performance material designed for extreme temperature applications, capable of withstanding temperatures up to 1,600°C (2,912°F).

Pros: MoSi₂ offers exceptional thermal stability and oxidation resistance, making it suitable for high-temperature furnaces and industrial heating applications. Its long lifespan reduces replacement frequency.

Cons: The high cost and complexity of manufacturing MoSi₂ can be a barrier for some buyers. Additionally, its brittleness can pose challenges during installation and handling.

Impact on Application: MoSi₂ is particularly effective in applications involving high-temperature processes, such as semiconductor manufacturing and advanced ceramics.

Considerations for International Buyers: Buyers should be aware of specific material certifications and standards, particularly in technologically advanced markets like Germany and Saudi Arabia.

Summary Table of Electric Heater Filament Materials

| Material | Typical Use Case for electric heater filament | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Kanthal® Alloys | Industrial heating applications | High-temperature stability | Higher cost | High |

| Nickel-Chromium Alloys | Domestic heating appliances | Cost-effective and versatile | Prone to oxidation | Medium |

| Stainless Steel | Food processing and medical equipment | Corrosion resistance | Lower thermal efficiency | Low |

| Molybdenum Disilicide | High-temperature industrial processes | Exceptional thermal stability | High cost and brittleness | High |

This guide provides actionable insights for B2B buyers looking to select the most suitable materials for electric heater filaments, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electric heater filament

What Are the Main Stages in the Manufacturing Process of Electric Heater Filament?

The manufacturing of electric heater filaments involves several key stages, each critical for ensuring high performance and reliability.

Illustrative image related to electric heater filament

Material Preparation

The process begins with selecting high-resistance materials, typically nickel-chromium or kanthal alloys, known for their durability and heat resistance. These materials are prepared by carefully controlling their chemical composition to achieve the desired electrical properties. This stage may also involve the melting and casting of metals into specific shapes or forms.

Forming the Filament

Once the materials are ready, they undergo forming processes. This can involve wire drawing, where metal rods are drawn through dies to create thin wires with precise diameters. Alternatively, strip or ribbon forms may be produced using specialized cutting techniques. The forming process must ensure that the dimensions of the filaments are consistent and meet the specifications required for various applications, such as water heaters or industrial furnaces.

Assembly of Components

In the assembly stage, the formed filaments are combined with other necessary components, such as insulators and terminals. This integration is crucial for the functionality of the heater element, ensuring that the electrical connections are secure and that the assembly can withstand operational stresses. Techniques such as welding, crimping, or soldering are commonly employed to ensure robust connections.

Finishing Processes

Finishing processes include surface treatments and coatings to enhance the durability and performance of the filaments. This might involve applying protective coatings to resist oxidation or corrosion, particularly in harsh environments. Additionally, the final products are often inspected for visual defects and to confirm that they meet industry standards.

Illustrative image related to electric heater filament

What Quality Assurance Measures Are Essential in Electric Heater Filament Manufacturing?

Quality assurance (QA) is vital in ensuring that electric heater filaments perform reliably and meet safety standards.

What International Standards Should B2B Buyers Be Aware Of?

International standards like ISO 9001 provide frameworks for quality management systems, ensuring consistent quality in manufacturing processes. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe, and API (American Petroleum Institute) standards for products used in oil and gas applications, are crucial. These certifications indicate that the products meet safety, health, and environmental protection requirements.

Which Quality Control Checkpoints Are Commonly Implemented?

Manufacturers typically incorporate several quality control checkpoints throughout the production process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps detect issues early. This can include measuring electrical resistance and inspecting dimensions.

- Final Quality Control (FQC): At this stage, the finished products undergo comprehensive testing to verify compliance with all specifications before shipment.

What Testing Methods Are Commonly Used?

Common testing methods for electric heater filaments include:

- Electrical Resistance Testing: Ensures that the filament operates within the specified resistance range.

- Thermal Cycling Tests: Evaluate how the filament withstands repeated heating and cooling cycles, simulating real-world operating conditions.

- Dimensional Inspection: Confirms that the filaments meet the required specifications and tolerances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential.

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality assurance reports that outline the supplier’s compliance with international standards. Regular audits by third-party organizations can also provide insights into the supplier’s adherence to quality processes. These audits should include evaluations of their manufacturing processes, quality control measures, and any certifications they hold.

How Important Are Third-Party Inspections?

Third-party inspections are crucial for ensuring unbiased verification of quality control processes. Buyers can arrange for these inspections at various stages of production, providing an additional layer of confidence in the products they are purchasing. This is particularly important in regions with varying regulatory standards.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

International B2B buyers must navigate different regulatory environments and certification requirements across regions. For instance, while CE marking is essential for products sold in Europe, products intended for the Middle East may require compliance with local standards such as SASO (Saudi Standards, Metrology and Quality Organization). Understanding these nuances ensures compliance and avoids potential market entry barriers.

How Can Buyers Ensure Compliance with Local Regulations?

Buyers should actively engage with suppliers to clarify which certifications are applicable to their specific markets. It is also beneficial to maintain open lines of communication regarding any changes in regulations that may affect product compliance.

Conclusion

The manufacturing processes and quality assurance measures for electric heater filaments are intricate and require meticulous attention to detail. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet both international standards and local regulations. With proper due diligence, buyers can mitigate risks and foster successful partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric heater filament’

Introduction

Navigating the procurement of electric heater filaments can be complex, particularly for international B2B buyers across diverse regions such as Africa, South America, the Middle East, and Europe. This guide provides a comprehensive checklist to streamline your sourcing process, ensuring you select the right product and supplier for your specific needs.

Step 1: Define Your Technical Specifications

Before initiating your search for electric heater filaments, clearly outline your technical requirements. This includes understanding the wattage, voltage, and material composition needed for your application. Knowing these specifications will help you filter potential suppliers and products that meet your operational demands.

- Wattage and Voltage: Assess the heating requirements of your application to determine the necessary wattage and voltage.

- Material Composition: Consider the operating environment and select materials that can withstand the required temperatures and conditions.

Step 2: Research Market Trends and Compliance Standards

Stay informed about the latest trends in electric heater technology and the regulatory standards applicable in your region. Compliance with local and international standards is critical for ensuring safety and reliability.

- Regulatory Compliance: Verify that products meet relevant safety standards (e.g., CE, UL, ISO certifications) to avoid legal issues and ensure quality.

- Market Trends: Understanding innovations in heating technology can help you choose products that improve efficiency and reduce costs.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your needs effectively. Request detailed company profiles, product catalogs, and case studies showcasing their experience and capabilities in your industry.

- Supplier Reputation: Look for reviews and testimonials from other businesses in your region to gauge reliability and product performance.

- Support and Services: Assess the level of customer support offered, including technical assistance, warranties, and return policies.

Step 4: Request Samples for Testing

Before making a bulk order, it’s prudent to request samples of the electric heater filaments you are considering. Testing these samples in your operational environment can provide insights into their performance and compatibility.

- Performance Testing: Evaluate the samples under real conditions to ensure they meet your heating requirements.

- Quality Assessment: Check for defects and consistency in manufacturing to avoid future operational disruptions.

Step 5: Negotiate Terms and Pricing

Once you’ve narrowed down your options, engage in negotiations with your selected suppliers. This is a critical step to ensure you get the best value for your investment while establishing a mutually beneficial relationship.

Illustrative image related to electric heater filament

- Pricing Structures: Understand the pricing model, including bulk discounts and payment terms.

- Delivery and Lead Times: Discuss logistics to ensure that the supplier can meet your delivery timelines without compromising quality.

Step 6: Finalize Your Order and Monitor Delivery

After agreeing on terms, finalize your order with clear documentation that outlines all specifications, pricing, and delivery expectations. Monitor the delivery process to ensure compliance with the agreed terms.

- Documentation: Ensure all agreements are in writing, covering product specifications and delivery timelines.

- Quality Control: Upon receipt, conduct a thorough inspection of the products to confirm they match your order specifications.

Conclusion

By following this practical sourcing checklist, B2B buyers can effectively navigate the complexities of procuring electric heater filaments. Each step is designed to enhance decision-making and ensure that your investment leads to successful outcomes.

Comprehensive Cost and Pricing Analysis for electric heater filament Sourcing

What Are the Key Cost Components in Electric Heater Filament Sourcing?

When sourcing electric heater filaments, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials include nickel-chromium alloys, Kanthal, and silicon carbide, each with varying thermal properties and price points. Higher quality materials typically lead to increased durability and efficiency, which can justify a higher upfront investment.

-

Labor: Labor costs encompass the wages of skilled workers involved in manufacturing and assembling the filaments. The complexity of the production process, including any specialized skills required, can influence these costs.

-

Manufacturing Overhead: This includes utilities, rent, and maintenance associated with the production facility. Efficient manufacturing processes can help reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: The initial investment in tooling and machinery can be substantial, especially for custom filament designs. Suppliers may factor these costs into the pricing, particularly for low-volume orders.

-

Quality Control (QC): Ensuring that filaments meet industry standards involves rigorous testing and inspection processes, contributing to overall costs. Certifications for quality and safety can also influence pricing.

-

Logistics: Shipping and handling costs vary significantly based on the destination, mode of transport, and size of the order. Freight costs can be a major factor, particularly for international shipments.

-

Margin: Suppliers will add a profit margin to cover their operational costs and risks. Understanding the average margins in your target market can help in negotiations.

What Influences Pricing for Electric Heater Filaments?

Several factors can influence the pricing of electric heater filaments, including:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Larger orders often benefit from economies of scale, leading to lower per-unit costs. Conversely, small orders may incur higher rates due to the less efficient production run.

-

Specifications and Customization: Custom designs or unique specifications can lead to increased costs due to the additional labor and materials involved. It’s essential to communicate your exact requirements upfront to avoid unexpected price hikes.

-

Materials and Quality Certifications: The choice of materials directly affects both cost and performance. High-quality materials with certifications (e.g., ISO, CE) may command premium pricing but can lead to better long-term performance and reduced maintenance costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence costs. Established suppliers may charge more but offer better quality assurance and customer service.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who bears costs and risks during shipping, which can affect the overall price.

How Can Buyers Negotiate Effectively for Electric Heater Filaments?

Effective negotiation strategies can yield significant savings and enhance overall value:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the purchase price but the long-term costs associated with energy consumption, maintenance, and potential downtime. A higher upfront cost may result in lower TCO if the filament is more durable and efficient.

-

Leverage Volume Discounts: If your business has the capacity, consider consolidating orders to meet MOQs and take advantage of bulk pricing.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing, improved service, and priority during stock shortages.

-

Be Aware of Pricing Nuances: International buyers, particularly from regions like Africa and South America, should be mindful of currency fluctuations, import tariffs, and local regulations that can affect pricing.

Conclusion

Sourcing electric heater filaments involves navigating a complex landscape of costs and pricing influences. By understanding these dynamics, international B2B buyers can make informed decisions that enhance their procurement strategies and ultimately improve their bottom line. Always remember that prices can fluctuate based on market conditions and supplier capabilities, so continuous market research and supplier assessment are essential.

Alternatives Analysis: Comparing electric heater filament With Other Solutions

In today’s competitive market, businesses are increasingly seeking efficient heating solutions to meet their operational needs. Electric heater filaments, known for their reliability and performance, are just one option among several alternatives. Understanding the advantages and disadvantages of each heating technology is essential for B2B buyers looking to optimize their heating systems.

Comparison Table

| Comparison Aspect | Electric Heater Filament | Infrared Heating Panels | Heat Pumps |

|---|---|---|---|

| Performance | Quick heating, effective for localized areas | Provides instant heat, ideal for large spaces | Energy-efficient, effective for whole-building heating |

| Cost | Moderate initial investment | Higher upfront cost, but lower operating costs | High initial investment, cost-effective in the long run |

| Ease of Implementation | Simple installation, requires electrical infrastructure | Requires professional installation | Complex installation, may need structural adjustments |

| Maintenance | Low maintenance, long lifespan | Minimal maintenance required | Regular maintenance needed for optimal performance |

| Best Use Case | Small workshops, laboratories, or specific equipment | Warehouses, showrooms, and open spaces | Residential and commercial buildings, especially in moderate climates |

What Are the Advantages and Disadvantages of Infrared Heating Panels?

Infrared heating panels offer a distinct alternative to electric heater filaments by providing instant heat through infrared radiation. They are particularly effective in larger spaces, such as warehouses and showrooms, where traditional heating methods may struggle to maintain a consistent temperature. While the upfront costs of infrared panels can be higher, they often result in lower operating costs due to their efficiency. However, their installation typically requires professional expertise, which can complicate the implementation process.

How Do Heat Pumps Compare to Electric Heater Filaments?

Heat pumps are another viable alternative, especially in regions with moderate climates. They work by transferring heat rather than generating it, making them an energy-efficient option for whole-building heating. The initial investment for heat pumps is usually significant, but they tend to provide substantial long-term savings on energy costs. However, their installation can be complex and may necessitate structural changes, which can pose challenges for some businesses. Additionally, heat pumps require regular maintenance to ensure optimal performance.

Conclusion: Which Heating Solution Should You Choose for Your Business?

Selecting the right heating solution depends on your specific operational requirements, budget constraints, and installation capabilities. Electric heater filaments are ideal for localized heating needs with low maintenance, making them suitable for workshops or laboratories. Conversely, infrared heating panels excel in larger, open spaces, while heat pumps offer a comprehensive solution for whole buildings, especially in climates conducive to their operation. By carefully assessing these alternatives against your business’s unique needs, you can make an informed decision that enhances efficiency and reduces costs.

Essential Technical Properties and Trade Terminology for electric heater filament

What are the Key Technical Properties of Electric Heater Filaments?

Understanding the technical properties of electric heater filaments is crucial for B2B buyers as they impact performance, durability, and cost-effectiveness. Here are the essential specifications to consider:

1. Material Grade

The material used in electric heater filaments significantly influences their performance. Common materials include nickel-chromium alloys (e.g., Kanthal®), stainless steel, and copper. Each material offers distinct properties such as corrosion resistance, thermal conductivity, and maximum operating temperature. For instance, nickel-chromium alloys are favored for their high resistance to oxidation and ability to withstand elevated temperatures, making them ideal for industrial applications.

2. Wattage Rating

Wattage indicates the power output of the heating element, directly correlating with its heating capability. Typical ratings range from 500W to over 5500W. Selecting the appropriate wattage is essential to ensure efficient heating for specific applications, such as water heating or industrial processes. Inadequate wattage can lead to insufficient heating, while excessive wattage can cause overheating and potential damage.

3. Temperature Tolerance

Temperature tolerance refers to the maximum temperature the filament can withstand without degradation. This specification is critical in applications involving high heat, such as furnaces or industrial ovens, where filaments may operate at temperatures exceeding 1200°C (2192°F). Understanding temperature tolerance helps buyers select filaments that meet the operational demands of their specific environments.

4. Resistance Value

The resistance value of a filament affects its efficiency and heat generation. Measured in ohms, the resistance determines how much electrical energy is converted into heat. For B2B buyers, knowing the resistance value is essential for ensuring compatibility with existing systems and optimizing energy consumption, which can lead to cost savings.

5. Length and Diameter

The physical dimensions of the filament, including length and diameter, influence both the heating surface area and installation compatibility. Longer filaments provide more heating surface area, while thicker filaments can handle higher current loads. When sourcing filaments, understanding these dimensions ensures that the product fits within the intended application and meets performance requirements.

6. Ingress Protection (IP) Rating

An IP rating indicates the level of protection against dust and moisture. For instance, an IP67 rating means the filament is dust-tight and can withstand submersion in water. This property is vital for applications in humid or dirty environments, as it ensures the longevity and reliability of the heating elements.

What are Common Trade Terms Related to Electric Heater Filaments?

Familiarity with trade terminology is essential for effective communication and negotiation in B2B transactions. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company. In the context of electric heater filaments, OEMs produce customized heating elements tailored to specific applications, which can be vital for ensuring compatibility with existing equipment.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it impacts inventory management and procurement strategies. Buyers must assess whether they can meet the MOQ without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This term is particularly relevant in B2B transactions for electric heater filaments, as it enables buyers to compare offers and negotiate terms effectively.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their obligations and manage risks associated with shipping electric heater filaments across borders.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the product. In industries where electric heater filaments are critical, understanding lead times is vital for maintaining production schedules and minimizing downtime.

By grasping these technical properties and trade terms, B2B buyers can make informed purchasing decisions, ensuring they select the right electric heater filaments for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the electric heater filament Sector

What Are the Current Market Dynamics and Key Trends in the Electric Heater Filament Sector?

The electric heater filament market is experiencing robust growth, driven by increasing energy efficiency demands and the need for sustainable heating solutions. Key drivers include rising electricity prices and the global shift towards renewable energy sources, which are compelling industries to seek more efficient heating solutions. The market is also witnessing a trend toward smart heating technologies, with IoT-enabled electric heaters becoming more prevalent. This innovation allows for remote monitoring and control, aligning with the growing demand for energy management systems across various sectors.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing electric heater filaments that offer both efficiency and reliability. The emergence of modular heating solutions is another notable trend, allowing for customized configurations that meet specific industrial requirements. Furthermore, the demand for high-performance materials, such as silicon carbide and molybdenum disilicide, is rising, as these materials provide superior thermal stability and longer lifespans, reducing replacement costs and downtime.

Additionally, global supply chain dynamics are influencing sourcing strategies, with buyers seeking suppliers that can ensure timely delivery and maintain quality amid fluctuations in raw material availability. The shift towards local sourcing in some regions is also notable, driven by a desire to mitigate risks associated with global supply chains and enhance responsiveness to market demands.

How Are Sustainability and Ethical Sourcing Addressed in the Electric Heater Filament Sector?

Sustainability has become a cornerstone of sourcing strategies in the electric heater filament sector. As concerns about climate change and resource depletion grow, companies are increasingly prioritizing environmentally friendly practices. The environmental impact of electric heater filaments is significant, particularly concerning energy consumption during their lifecycle. Therefore, many manufacturers are adopting greener production processes and materials to reduce carbon footprints.

Ethical sourcing practices are equally important. B2B buyers are increasingly scrutinizing their supply chains to ensure they align with corporate social responsibility (CSR) goals. This includes sourcing from manufacturers who adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and Energy Star for energy efficiency are becoming essential for suppliers aiming to prove their commitment to sustainability.

Furthermore, innovative materials that enhance energy efficiency, such as low-watt density alloys, are gaining traction. These materials not only reduce energy consumption but also contribute to longer-lasting products, thereby decreasing waste. As sustainability becomes a competitive differentiator, B2B buyers are encouraged to engage with suppliers who demonstrate a clear commitment to ethical sourcing and sustainable practices, ensuring they remain compliant with evolving regulations and consumer expectations.

What is the Evolution of the Electric Heater Filament Technology?

The evolution of electric heater filament technology can be traced back to the early 20th century, when basic resistive heating elements were developed for industrial applications. Initially, these elements were made from simple metals, which provided limited efficiency and lifespan. Over time, advancements in material science led to the creation of specialized alloys designed to withstand higher temperatures and offer improved thermal conductivity.

In the latter half of the century, innovations such as tubular heating elements and cartridge heaters emerged, allowing for more versatile applications across various industries, from domestic appliances to complex industrial processes. The introduction of smart technologies in recent years represents a significant leap forward, enabling enhanced control and efficiency in heating applications. Today, the electric heater filament sector stands at the forefront of energy-efficient technology, driven by ongoing research and development aimed at meeting the diverse needs of global markets.

This historical context not only highlights the technological advancements but also underscores the importance of adapting to market demands, paving the way for future innovations in the electric heater filament space.

Frequently Asked Questions (FAQs) for B2B Buyers of electric heater filament

-

How do I ensure the quality of electric heater filaments when sourcing internationally?

To ensure quality when sourcing electric heater filaments, it is essential to conduct thorough supplier vetting. Request product samples and certifications, such as ISO or CE, to assess quality. Additionally, consider visiting the manufacturing facility if possible or hiring a third-party inspection service to evaluate the production process and materials used. Establish clear quality assurance criteria and maintain open lines of communication with suppliers to address any concerns promptly. This proactive approach can mitigate risks associated with international sourcing. -

What specifications should I consider when selecting electric heater filaments?

When selecting electric heater filaments, consider specifications such as wattage, voltage, material composition, and dimensions. Identify the application requirements, including temperature ranges and environmental conditions, to ensure the filament’s durability and efficiency. Additionally, assess the heating element’s design, such as whether it’s tubular, cartridge, or customized for specific applications. Understanding these specifications will help you choose the right filament that meets your operational needs and enhances performance. -

What are the typical minimum order quantities (MOQs) for electric heater filaments?

Minimum order quantities (MOQs) for electric heater filaments can vary significantly based on the supplier and product type. Generally, MOQs range from 50 to several hundred units. Some suppliers may offer lower MOQs for standard products, while custom designs may have higher requirements. It is advisable to discuss your needs with potential suppliers upfront to negotiate MOQs that align with your purchasing capabilities and project timelines. -

How can I customize electric heater filaments for specific applications?

Customization of electric heater filaments typically involves discussing your specific requirements with the manufacturer. This may include altering dimensions, wattage, or materials to meet unique operational conditions. Provide detailed specifications regarding the intended use, such as temperature requirements and physical constraints. Many manufacturers offer design support and prototyping services, allowing you to test the customized filaments before full-scale production, ensuring they meet your expectations. -

What payment terms are common when purchasing electric heater filaments internationally?

Common payment terms for international purchases of electric heater filaments include advance payment, letter of credit, and payment upon delivery. The choice of terms often depends on the buyer-supplier relationship and the order’s size. It’s crucial to negotiate terms that provide security and flexibility for both parties. Consider using escrow services for large transactions to safeguard your investment until the product is received and meets quality standards. -

How do I handle shipping and logistics for electric heater filament orders?

When managing shipping and logistics for electric heater filament orders, it’s important to coordinate with your supplier to determine the best shipping method based on cost and urgency. Options typically include air freight for faster delivery or sea freight for larger shipments. Ensure that all customs documentation is prepared accurately to avoid delays. Working with a logistics partner experienced in international trade can help streamline the process and ensure compliance with local regulations. -

What are the common applications of electric heater filaments in different industries?

Electric heater filaments are widely used across various industries, including manufacturing, automotive, and healthcare. They serve applications such as water heating, industrial ovens, and sterilization equipment. In the manufacturing sector, they are integral to processes like drying and curing. Understanding the specific applications in your industry will help you select the appropriate filament type and design, enhancing efficiency and productivity. -

How can I assess the reliability of a supplier for electric heater filaments?

To assess supplier reliability, begin by researching their business history, customer reviews, and industry reputation. Request references from previous clients and inquire about their experience with product quality and service. Additionally, evaluate their manufacturing capabilities, certifications, and adherence to industry standards. Establishing a trial order can also help gauge their responsiveness and product quality before committing to larger orders, ensuring you partner with a dependable supplier.

Top 3 Electric Heater Filament Manufacturers & Suppliers List

1. Kanthal – Super Robust MoSi₂ Heating Elements

Domain: kanthal.com

Registered: 1996 (29 years)

Introduction: Kanthal® electric heating elements are the widest range on the market, operating in temperature ranges from 50 to 1,850°C (120-3,360°F). Key products include: 1. Kanthal® Super Robust electric molybdenum disilicide (MoSi₂) heating elements – designed for high temperatures, superior performance, extended lifespan, and unmatched flexibility. 2. Globar® SiC heating elements – deliver high-power, even…

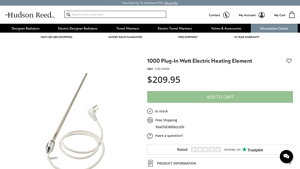

2. Hudson Reed – 1000W Plug-In Electric Heating Element

Domain: usa.hudsonreed.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “1000 Plug-In Watt Electric Heating Element”, “SKU”: “CHE1000W”, “Price”: “$209.95”, “Power”: “1000W”, “Installation”: “Easy plug-in installation”, “Element Cable Length”: “35.4 inches (includes plug)”, “Material”: [“ABS Plastic”, “Stainless Steel”], “Ingress Protection Rating”: “IP67”, “Approval”: “UL Approved”, “Style”: “Modern”, “Finish”: “Chrome”, “Warranty”: “2 Years”, “Shipp…

3. Durex Industries – Tubular Heating Elements

Domain: durexindustries.com

Registered: 1998 (27 years)

Introduction: Tubular Heating Elements are versatile and economical electric heating solutions used in various applications. Key features include:

– Capable of 600V or higher in specific applications.

– Available in straight or formed configurations.

– Heavy wall construction for high-pressure and corrosion applications.

– Diameters range from 0.26″ to 0.496″.

– Sheath materials include copper, steel, and high …

Strategic Sourcing Conclusion and Outlook for electric heater filament

In conclusion, the strategic sourcing of electric heater filaments is vital for businesses aiming to optimize performance, enhance energy efficiency, and reduce operational costs. By leveraging high-quality materials, such as Kanthal® and Nikrothal® alloys, companies can ensure durability and reliability in their heating applications, catering to the diverse needs of industrial, commercial, and consumer markets. Furthermore, understanding the regional market dynamics in Africa, South America, the Middle East, and Europe will empower B2B buyers to make informed purchasing decisions that align with their specific requirements.

As international markets continue to evolve, the demand for innovative and efficient heating solutions will only increase. Companies should prioritize building strong partnerships with reliable suppliers, focusing on quality, cost-effectiveness, and sustainability. By doing so, they can secure a competitive edge in an increasingly crowded marketplace.

We encourage B2B buyers to explore the latest advancements in electric heater filament technology and engage with trusted manufacturers to meet their sourcing needs. As you look toward the future, prioritize strategic sourcing to drive growth and success in your heating solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.