A Deep Dive into Companies That Rebuild Mikuni Bn38 Carburetors For Kawasaki Js550…

Introduction: Navigating the Global Market for companies that rebuild mikuni bn38 carburetors for kawasaki js550

In the competitive landscape of the global market, sourcing reliable companies that rebuild Mikuni BN38 carburetors for Kawasaki JS550 can be a daunting task for B2B buyers. The challenge lies not only in identifying suppliers who deliver high-quality remanufactured parts but also in ensuring they meet stringent performance standards essential for optimal engine functionality. This guide aims to demystify the process of sourcing these critical components by providing a comprehensive overview of the types of services available, applications of the Mikuni BN38 carburetor, and best practices for supplier vetting.

Within these pages, you will find detailed insights into the various rebuild options, including OEM parts and aftermarket alternatives, as well as cost considerations that affect your purchasing decisions. We will explore the specific needs of international buyers, particularly those from Africa, South America, the Middle East, and Europe, highlighting regional suppliers and their capabilities. By equipping you with the necessary knowledge and tools, this guide empowers you to make informed purchasing decisions that not only enhance the performance of your Kawasaki JS550 but also strengthen your supply chain. As the demand for high-quality jet ski components continues to grow, ensuring that you partner with reputable companies is more crucial than ever.

Understanding companies that rebuild mikuni bn38 carburetors for kawasaki js550 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Remanufacturers | Comprehensive rebuilding process, using OEM parts, warranty offered | High-volume repair shops, dealerships | Pros: Quality assurance, long-lasting repairs. Cons: Higher costs, longer turnaround times. |

| Specialized Rebuilders | Focus on specific carburetor types, often custom solutions | Niche markets, specialized racing teams | Pros: Tailored services, expertise in specific models. Cons: Limited scalability, potentially higher prices. |

| Aftermarket Kit Suppliers | Offer rebuild kits with essential components at competitive prices | DIY enthusiasts, small repair shops | Pros: Cost-effective, easy to source. Cons: May lack quality control, parts may not be OEM. |

| Local Repair Shops | Personalized service, local sourcing of parts | Small businesses, individual mechanics | Pros: Quick service, community support. Cons: Variable quality, limited part availability. |

| Online Retailers | Wide selection, often with customer reviews and ratings | E-commerce platforms, international buyers | Pros: Convenience, competitive pricing. Cons: Risk of miscommunication, potential shipping delays. |

What Are the Characteristics of Full Remanufacturers?

Full remanufacturers are companies that provide a comprehensive rebuilding service for Mikuni BN38 carburetors, often using original equipment manufacturer (OEM) parts. They typically offer warranties on their work, ensuring that buyers receive a reliable product. These companies cater primarily to high-volume repair shops and dealerships that require consistent, high-quality refurbishments. When considering this option, B2B buyers should evaluate the cost versus the assurance of quality and longevity that comes with OEM components.

How Do Specialized Rebuilders Cater to Niche Markets?

Specialized rebuilders focus on specific carburetor models, providing tailored solutions that cater to niche markets, such as racing teams or vintage vehicle restorers. Their expertise allows them to offer custom modifications and enhancements that can improve performance. B2B buyers in these sectors should consider the level of expertise and customization available, as well as the implications for performance and reliability, which can justify higher costs.

What Advantages Do Aftermarket Kit Suppliers Offer?

Aftermarket kit suppliers provide essential components for rebuilding Mikuni BN38 carburetors at competitive prices. These kits are appealing to DIY enthusiasts and small repair shops looking for cost-effective solutions. However, buyers should be cautious about the quality of the parts, as they may not always meet OEM standards. Evaluating the supplier’s reputation and customer reviews can help mitigate risks associated with quality.

Illustrative image related to companies that rebuild mikuni bn38 carburetors for kawasaki js550

How Do Local Repair Shops Provide Personalized Service?

Local repair shops often offer a personalized approach to carburetor rebuilding, leveraging local sourcing for parts and providing quick turnaround times. This option is particularly attractive to small businesses and individual mechanics who value community support and direct communication. However, the quality of service can vary significantly, and buyers should assess the shop’s experience and customer feedback before proceeding.

Why Are Online Retailers a Convenient Option for B2B Buyers?

Online retailers provide a wide selection of Mikuni BN38 carburetor rebuild kits and services, often accompanied by customer reviews and ratings. This convenience is ideal for international buyers seeking competitive pricing and easy access to products. However, buyers must be aware of potential risks, such as miscommunication regarding specifications and possible shipping delays. Ensuring clear communication and understanding return policies can help mitigate these risks.

Key Industrial Applications of companies that rebuild mikuni bn38 carburetors for kawasaki js550

| Industry/Sector | Specific Application of companies that rebuild mikuni bn38 carburetors for kawasaki js550 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine Recreation | Restoration and maintenance of jet skis, particularly vintage models like the Kawasaki JS550. | Ensures optimal performance and longevity of equipment, enhancing customer satisfaction. | Quality of rebuild parts, turnaround time, and technical expertise in vintage models. |

| Motorsports | Custom tuning and performance upgrades for racing jet skis. | Improved throttle response and fuel efficiency for competitive edge. | Compatibility with racing standards, availability of specialized parts, and technical support. |

| Outdoor Equipment Rentals | Servicing fleets of jet skis to maintain operational readiness and safety. | Reduces downtime and repair costs, ensuring a reliable rental service. | Reliability of service, speed of turnaround, and warranty on rebuilt components. |

| Vintage Vehicle Collectors | Restoration of classic jet ski carburetors for collectors and enthusiasts. | Preserves the value and functionality of vintage models, appealing to niche markets. | Authenticity of parts, expertise in vintage restoration, and availability of rare components. |

| Export and Distribution | Sourcing rebuilt carburetors for resale in international markets. | Expands product offerings and meets demand for quality refurbished parts. | Shipping logistics, compliance with international trade regulations, and pricing competitiveness. |

How Do Companies That Rebuild Mikuni BN38 Carburetors Support Marine Recreation?

In the marine recreation industry, companies that rebuild Mikuni BN38 carburetors play a crucial role in restoring and maintaining jet skis, particularly vintage models like the Kawasaki JS550. These carburetors are essential for optimal engine performance, and regular rebuilding ensures that the jet skis operate efficiently. For international buyers in regions like Africa and South America, the focus on quality materials and expert craftsmanship is vital. They need assurance that the rebuilt carburetors will not only meet performance expectations but also endure the rigors of marine environments.

What Role Do Rebuilt Carburetors Play in Motorsports?

In the motorsports sector, companies specializing in rebuilding Mikuni BN38 carburetors provide essential services for custom tuning and performance upgrades. Racing jet skis require precise fuel delivery and throttle response to gain a competitive edge, making these rebuilt carburetors invaluable. B2B buyers in Europe, particularly in countries with a strong motorsports culture like Germany, seek high-quality components that comply with racing standards. These businesses prioritize suppliers that can provide specialized parts and expert technical support to enhance their racing capabilities.

How Do Companies Facilitate Outdoor Equipment Rentals?

For outdoor equipment rental businesses, the reliability of jet skis is paramount. Companies that rebuild Mikuni BN38 carburetors ensure that rental fleets are serviced and maintained to prevent breakdowns during peak seasons. This proactive approach minimizes downtime and repair costs, crucial for maintaining customer satisfaction. Buyers in the Middle East, where water sports are a popular pastime, look for suppliers that can guarantee quick turnaround times and reliable service to keep their rentals operational.

Why Are Rebuilt Carburetors Important for Vintage Vehicle Collectors?

Vintage vehicle collectors and enthusiasts often seek out companies that specialize in the restoration of classic jet ski carburetors. By using rebuilt Mikuni BN38 carburetors, collectors can preserve the value and functionality of their vintage models. These businesses require authentic parts and expertise in vintage restoration, which are essential for maintaining the integrity of their prized possessions. Buyers from Europe and Africa, where vintage motorsports have a dedicated following, value suppliers who understand the nuances of vintage equipment.

How Do Rebuilt Carburetors Benefit Export and Distribution Businesses?

Export and distribution companies that deal with refurbished parts benefit significantly from sourcing rebuilt Mikuni BN38 carburetors. These companies can expand their product offerings and meet the growing demand for quality refurbished parts in international markets. When sourcing these components, businesses must consider shipping logistics and compliance with international trade regulations to ensure smooth operations. Competitive pricing and reliable suppliers are also crucial for maintaining a profitable business model in this sector.

3 Common User Pain Points for ‘companies that rebuild mikuni bn38 carburetors for kawasaki js550’ & Their Solutions

Scenario 1: Difficulty in Assessing Carburetor Condition Before Rebuilding

The Problem: B2B buyers often struggle with accurately assessing the condition of Mikuni BN38 carburetors before sending them for rebuilding. Without a thorough understanding of the specific issues—such as internal wear, corrosion, or damage—buyers may face unexpected costs or delays when the rebuild process reveals additional repairs are needed. This lack of clarity can lead to frustration and dissatisfaction, especially when budgets and timelines are tight.

The Solution: To mitigate this issue, companies should develop a standard operating procedure for assessing carburetor conditions prior to sending them for rebuilding. This can include a checklist of visual inspections, such as checking for cracks, rust, or missing components. Providing detailed photographs of the carburetors from various angles can also help rebuilding companies offer more accurate assessments and cost estimates. Additionally, fostering open communication with the rebuilding service about specific issues experienced during previous use can ensure that all parties have a clear understanding of the expectations and limitations of the rebuild process.

Scenario 2: Concerns About Quality and Authenticity of Replacement Parts

The Problem: Another common pain point for buyers is the uncertainty regarding the quality and authenticity of replacement parts used in the carburetor rebuilding process. Many buyers fear that inferior or counterfeit parts may be used, which could compromise the performance and longevity of the rebuilt carburetor. This concern is amplified when sourcing from international markets, where standards can vary significantly.

The Solution: To address these concerns, buyers should prioritize working with rebuilding companies that guarantee the use of OEM (Original Equipment Manufacturer) parts or high-quality aftermarket alternatives. Requesting documentation or certifications that verify part authenticity can also provide peace of mind. Furthermore, engaging in discussions about the rebuilding company’s sourcing practices and their commitment to quality can enhance trust. Buyers can also look for testimonials or case studies from previous clients to gauge the reliability of the service provider.

Scenario 3: Long Turnaround Times Affecting Business Operations

The Problem: Timeliness is crucial in the B2B space, and lengthy turnaround times for carburetor rebuilding can severely disrupt business operations. For companies that rely on jet skis for commercial activities—such as rentals, tours, or racing—delays in receiving rebuilt carburetors can lead to lost revenue and dissatisfied customers. Buyers often find themselves caught between needing high-quality work and the urgency of getting their equipment back in operation.

The Solution: To combat this challenge, buyers should establish clear timelines and expectations with rebuilding companies from the outset. When initiating the rebuilding process, inquire about average turnaround times and any potential factors that may cause delays. It may also be beneficial to negotiate expedited service options, even if they come at a premium, to ensure critical equipment is prioritized. Additionally, consider building a relationship with multiple service providers to create a backup plan for future rebuilding needs, allowing for more flexibility and reliability in managing operational downtime.

Strategic Material Selection Guide for companies that rebuild mikuni bn38 carburetors for kawasaki js550

What Materials Are Commonly Used in Rebuilding Mikuni BN38 Carburetors for Kawasaki JS550?

When rebuilding Mikuni BN38 carburetors for Kawasaki JS550 jet skis, selecting the right materials is crucial for ensuring optimal performance, durability, and compliance with international standards. Below, we analyze four common materials used in this application, considering their properties, advantages, disadvantages, and implications for international B2B buyers.

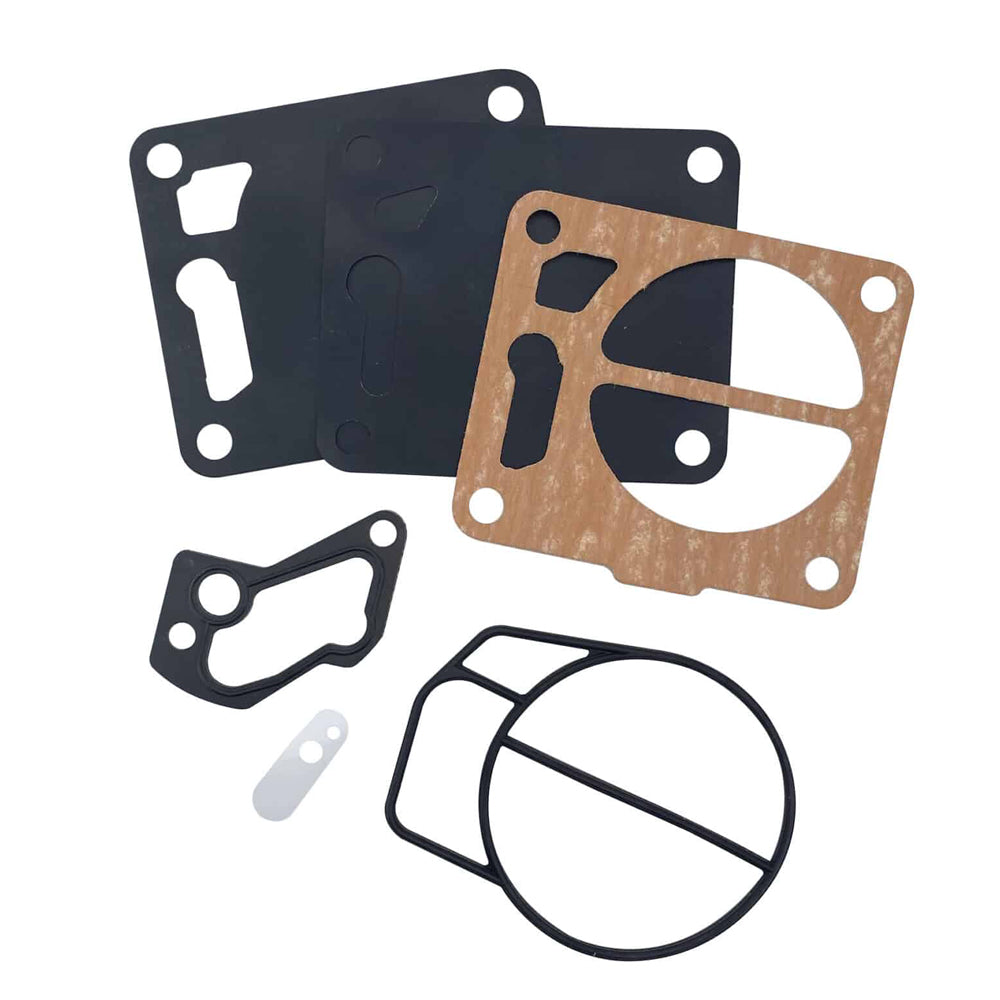

Illustrative image related to companies that rebuild mikuni bn38 carburetors for kawasaki js550

1. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It typically withstands temperatures up to 400°F (204°C) and pressures around 150 psi, making it suitable for carburetor components.

Pros & Cons:

Aluminum’s lightweight nature enhances performance but can lead to wear over time. It is relatively inexpensive and easy to machine, making it a popular choice. However, it may not be as durable as other materials under extreme conditions.

Impact on Application:

Aluminum is compatible with gasoline and various fuel mixtures, which is essential for carburetor functionality. However, it may corrode if exposed to saltwater without proper treatment.

Considerations for International Buyers:

Buyers must ensure that the aluminum used complies with international standards such as ASTM or DIN. In regions like Europe and the Middle East, preferences may lean towards high-grade aluminum alloys for enhanced performance.

2. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, high tensile strength, and can withstand temperatures up to 1,500°F (815°C). It is also resistant to oxidation and rust, making it ideal for marine environments.

Pros & Cons:

While stainless steel is highly durable and resistant to wear, it is heavier and more expensive than aluminum. The manufacturing complexity is higher due to the material’s hardness, which may increase production costs.

Impact on Application:

Stainless steel is compatible with various fuels and is less likely to suffer from corrosion, making it ideal for carburetor components exposed to harsh conditions.

Considerations for International Buyers:

Compliance with standards such as ASTM A240 is critical. Buyers from Africa and South America may prefer stainless steel for its longevity, especially in coastal regions where saltwater exposure is common.

Illustrative image related to companies that rebuild mikuni bn38 carburetors for kawasaki js550

3. Nitrile Rubber

Key Properties:

Nitrile rubber is known for its excellent resistance to fuel, oil, and heat. It can operate effectively at temperatures ranging from -40°F to 250°F (-40°C to 121°C), making it suitable for carburetor seals and gaskets.

Pros & Cons:

Nitrile rubber is flexible and cost-effective, providing a good seal against leaks. However, it has a limited lifespan compared to metals and can degrade over time when exposed to high temperatures or certain chemicals.

Impact on Application:

It is ideal for sealing components in carburetors, ensuring that fuel does not leak and performance is optimized. However, it may not be suitable for high-performance applications requiring extreme durability.

Considerations for International Buyers:

Buyers should ensure that nitrile rubber components meet specific standards such as ASTM D2000. In regions like Vietnam, where humidity can affect rubber materials, selecting high-quality nitrile is essential.

4. Viton

Key Properties:

Viton is a high-performance fluoropolymer known for its exceptional chemical resistance and ability to withstand high temperatures (up to 400°F or 204°C). It is often used in applications requiring superior sealing.

Pros & Cons:

Viton offers excellent durability and resistance to a wide range of chemicals, making it suitable for various fuel types. However, it is more expensive than nitrile rubber and can be less flexible.

Impact on Application:

Viton seals and gaskets provide a robust solution for carburetors, ensuring that they perform optimally under various conditions. Its chemical resistance makes it ideal for high-performance applications.

Considerations for International Buyers:

Buyers must verify that Viton materials comply with international standards such as ASTM D1418. In Europe, there may be a preference for Viton due to its superior performance in demanding environments.

Summary Table of Material Selection

| Material | Typical Use Case for companies that rebuild mikuni bn38 carburetors for kawasaki js550 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Carburetor bodies and components | Lightweight and cost-effective | Less durable under extreme conditions | Low |

| Stainless Steel | High-stress components and parts exposed to harsh environments | Excellent corrosion resistance | Heavier and more expensive | High |

| Nitrile Rubber | Seals and gaskets in carburetors | Flexible and cost-effective | Limited lifespan under high temperatures | Med |

| Viton | High-performance seals and gaskets for carburetors | Superior chemical resistance | More expensive and less flexible | High |

This strategic material selection guide provides valuable insights for companies involved in rebuilding Mikuni BN38 carburetors for Kawasaki JS550 jet skis, aiding in informed decision-making that aligns with international standards and market preferences.

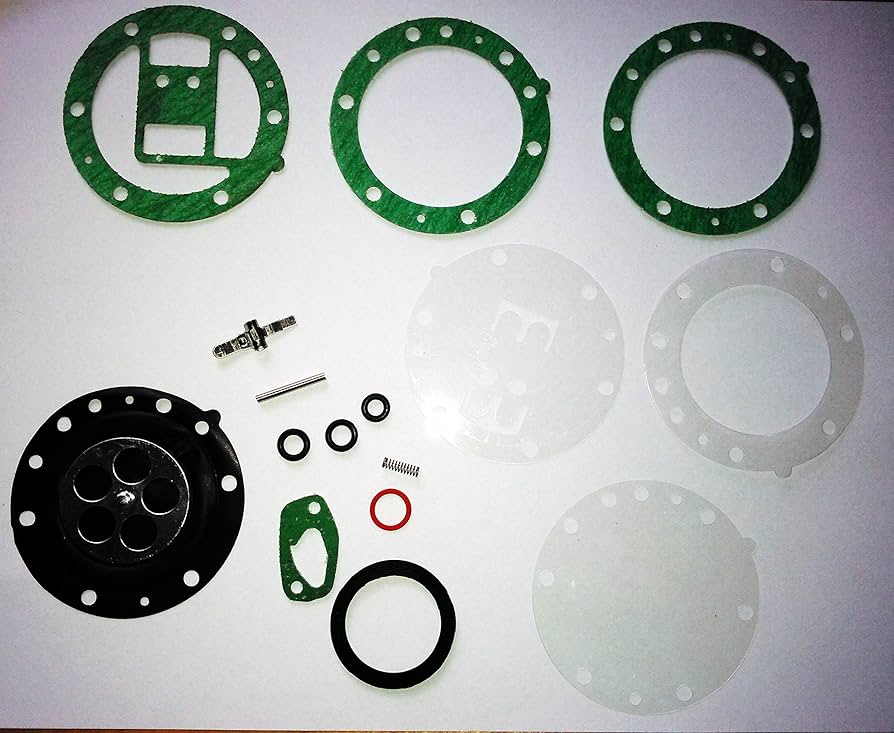

Illustrative image related to companies that rebuild mikuni bn38 carburetors for kawasaki js550

In-depth Look: Manufacturing Processes and Quality Assurance for companies that rebuild mikuni bn38 carburetors for kawasaki js550

What Are the Key Stages in the Manufacturing Process of Mikuni BN38 Carburetors?

The manufacturing process for companies that rebuild Mikuni BN38 carburetors involves several critical stages, each designed to ensure the final product meets stringent performance and quality standards. Here are the main stages:

Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Companies typically use high-grade aluminum and other durable materials that resist corrosion and wear. These materials are sourced from reliable suppliers who provide certification for quality and compliance with industry standards. Prior to production, raw materials undergo inspection to verify their specifications, ensuring that only the best materials are used in the rebuilding process.

Forming

Once the materials are prepared, they undergo various forming processes. This may include precision machining, where components are shaped using computer numerical control (CNC) machines. CNC machining allows for high levels of accuracy and repeatability, which are crucial for the performance of carburetors. Additional processes such as casting and forging may also be employed depending on the specific part being manufactured.

Illustrative image related to companies that rebuild mikuni bn38 carburetors for kawasaki js550

Assembly

The assembly stage is where the individual components are brought together. This process is often carried out in a clean room environment to minimize contamination. Skilled technicians follow detailed assembly instructions, ensuring that each carburetor is assembled to the exact specifications. During this stage, components such as gaskets, diaphragms, and check valves are integrated, often utilizing OEM (Original Equipment Manufacturer) parts to guarantee compatibility and performance.

Finishing

The finishing process is essential for enhancing the durability and aesthetic appeal of the carburetors. This may involve anodizing, polishing, or coating to protect against corrosion and wear. Quality companies will often conduct a visual inspection at this stage to identify any defects or inconsistencies before the carburetors are packaged for shipment.

How Do Companies Ensure Quality Assurance in Carburetor Rebuilding?

Quality assurance is a critical aspect of the manufacturing process for rebuilt Mikuni BN38 carburetors. Companies typically adhere to international standards and industry-specific regulations to ensure high-quality output.

What International Standards Are Commonly Followed?

Many companies involved in carburetor rebuilding seek to achieve ISO 9001 certification, which establishes a framework for quality management systems. This certification helps organizations improve their processes, enhance customer satisfaction, and ensure consistent quality in their products. Additionally, compliance with CE marking requirements may be necessary for companies selling in the European market, indicating that products meet EU safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure that each carburetor meets quality standards. These checkpoints typically include:

Illustrative image related to companies that rebuild mikuni bn38 carburetors for kawasaki js550

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified criteria before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor the quality of components and assembly processes. This includes dimensional checks and functional tests.

-

Final Quality Control (FQC): After assembly, each carburetor undergoes a thorough inspection and testing process. This may include performance tests to verify that the carburetor functions correctly under various operating conditions.

What Testing Methods Are Commonly Used for Quality Assurance?

Companies utilize a range of testing methods to validate the performance and reliability of rebuilt carburetors. Common testing methods include:

-

Flow Testing: This assesses the carburetor’s ability to deliver the correct fuel-air mixture under different conditions, ensuring optimal performance.

-

Leak Testing: Ensuring there are no leaks in the carburetor is crucial for performance and safety. This may involve pressure testing to detect any leaks in the fuel system.

-

Performance Testing: Carburetors are often tested in simulated operating conditions to evaluate their performance, responsiveness, and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential. Here are several strategies:

Conducting Supplier Audits

B2B buyers should consider conducting audits of potential suppliers. This can involve visiting manufacturing facilities to observe processes, quality control measures, and compliance with standards. Audits help buyers assess the capabilities and reliability of suppliers firsthand.

Requesting Quality Control Reports

Buyers can ask suppliers for detailed quality control reports that outline testing procedures, inspection results, and compliance with industry standards. These documents provide transparency and assurance regarding the supplier’s commitment to quality.

Utilizing Third-Party Inspection Services

Engaging third-party inspection agencies can be an effective way to verify supplier quality. These agencies can perform independent assessments of manufacturing processes and product quality, providing an unbiased evaluation that can inform purchasing decisions.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers should be aware of specific nuances in quality control when dealing with suppliers from different regions. Factors such as cultural differences, regulatory environments, and language barriers can impact quality assurance practices. It is vital for buyers to establish clear communication channels and set explicit quality expectations at the outset of the business relationship.

Illustrative image related to companies that rebuild mikuni bn38 carburetors for kawasaki js550

Furthermore, understanding local regulations and compliance requirements is crucial. Buyers must ensure that suppliers are not only following international standards but also adhering to specific local regulations that may apply in their region.

Conclusion

The rebuilding of Mikuni BN38 carburetors for Kawasaki JS550 models involves a comprehensive manufacturing process supported by rigorous quality assurance protocols. For B2B buyers, understanding these processes and the relevant quality control measures is essential to ensure they source high-quality products that meet their operational needs. By engaging with suppliers who adhere to international standards and employing effective verification strategies, buyers can mitigate risks and enhance their procurement outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘companies that rebuild mikuni bn38 carburetors for kawasaki js550’

Introduction

This practical sourcing guide is designed for B2B buyers seeking to procure services from companies that specialize in rebuilding Mikuni BN38 carburetors for Kawasaki JS550 jet skis. The process of sourcing reliable suppliers is critical to ensure quality, efficiency, and cost-effectiveness. This checklist will help you navigate the selection process with confidence.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for ensuring that the rebuilt carburetors meet your operational needs. Consider factors such as the specific model year of the Kawasaki JS550, performance requirements, and any modifications you may need.

– Key Considerations:

– Identify compatibility with various models (e.g., JS440, JS300).

– Specify performance enhancements if required.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in Mikuni BN38 carburetor rebuilds. Use industry directories, trade shows, and online marketplaces to compile a list of potential candidates.

– Where to Look:

– Online B2B platforms like Alibaba or ThomasNet.

– Industry-specific forums and community recommendations.

Illustrative image related to companies that rebuild mikuni bn38 carburetors for kawasaki js550

Step 3: Evaluate Supplier Experience and Reputation

Before engaging with a supplier, it’s crucial to assess their experience and reputation in the industry. Look for companies with a proven track record in carburetor remanufacturing.

– What to Check:

– Years in business and expertise with Mikuni products.

– Customer testimonials and case studies demonstrating successful projects.

Step 4: Request Detailed Quotes and Service Options

Once you have narrowed down potential suppliers, request detailed quotes that outline the services offered, turnaround times, and pricing. This will help you compare and contrast what each supplier can provide.

– Key Elements in Quotes:

– Breakdown of costs, including labor and parts.

– Warranty information on the rebuilt carburetors.

Step 5: Verify Quality Assurance Processes

Quality assurance is paramount in carburetor rebuilding to prevent future failures. Inquire about the supplier’s quality control measures and the types of materials used in the rebuild process.

– Important Questions:

– What specific testing procedures are in place?

– Are genuine Mikuni parts used in the rebuilds?

Step 6: Check Certifications and Compliance

Ensure that the suppliers adhere to relevant industry standards and certifications. This is particularly important for international buyers, as compliance with local regulations can affect operations.

– What to Look For:

– ISO certifications or similar quality management standards.

– Compliance with environmental regulations for parts used.

Step 7: Establish Communication and Support Channels

Effective communication is vital for a successful partnership. Ensure that the supplier provides clear channels for support and consultation throughout the rebuild process.

– Key Considerations:

– Availability of technical support and customer service.

– Responsiveness to inquiries and concerns during the rebuild.

By following this step-by-step checklist, B2B buyers can make informed decisions when sourcing companies that rebuild Mikuni BN38 carburetors for Kawasaki JS550 jet skis, ultimately leading to improved operational efficiency and satisfaction.

Comprehensive Cost and Pricing Analysis for companies that rebuild mikuni bn38 carburetors for kawasaki js550 Sourcing

What Are the Key Cost Components for Rebuilding Mikuni BN38 Carburetors?

When analyzing the costs associated with rebuilding Mikuni BN38 carburetors for Kawasaki JS550, several key components contribute to the overall pricing structure.

-

Materials: The cost of genuine Mikuni parts is significant, as using high-quality components is essential for durability and performance. Rebuild kits typically include gaskets, diaphragms, o-rings, and check valves, with prices ranging from $16 to $57 per kit, depending on the supplier and specific components included.

-

Labor: Skilled labor is required to ensure precision in the rebuilding process. Labor costs can vary widely based on geographic location and the complexity of the rebuild, ranging from $30 to $100 per hour.

-

Manufacturing Overhead: Overhead costs encompass utilities, equipment depreciation, and facility maintenance. These costs are generally allocated per unit based on production volume, influencing the final pricing for both small and large orders.

-

Tooling: Specialized tools and equipment may be necessary for specific carburetor models, leading to additional costs. These expenses are typically amortized over production runs, affecting unit pricing.

-

Quality Control (QC): Ensuring that each rebuilt carburetor meets stringent performance standards necessitates a robust QC process. This can add 5-10% to the total manufacturing cost.

-

Logistics: Shipping and handling costs can vary based on the destination and order volume. International shipments may incur customs duties and tariffs, particularly for buyers in Africa, South America, the Middle East, and Europe.

-

Margin: Suppliers will add a profit margin to cover their operational costs and risk. This can range from 20% to 50%, depending on market conditions and competition.

How Do Price Influencers Affect the Cost of Carburetor Rebuilding?

Several factors can significantly influence pricing for B2B buyers:

-

Volume/MOQ: Larger orders often benefit from economies of scale, reducing the per-unit cost. Suppliers may offer discounts for minimum order quantities (MOQs), making it cost-effective for businesses looking to stock up.

-

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should consider whether standard rebuild kits meet their needs or if custom solutions are necessary, as these can significantly impact pricing.

-

Materials and Quality Certifications: The quality of materials used directly affects performance and longevity. Suppliers offering certified components may charge a premium, but the investment can lead to lower Total Cost of Ownership (TCO) through enhanced durability.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers with a history of quality may command higher prices, while newer or less reputable companies may offer lower rates but at the risk of inferior quality.

-

Incoterms: Understanding shipping terms is crucial. Incoterms dictate who bears the costs and risks during transportation, which can affect the overall cost to the buyer.

What Are Some Buyer Tips for Negotiating Prices on Carburetor Rebuilding?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation strategies are essential:

-

Understand Total Cost of Ownership (TCO): Consider not just the initial purchase price but also long-term costs associated with maintenance and potential failures. Investing in higher-quality components may yield better TCO.

-

Leverage Volume Discounts: If purchasing in bulk, negotiate for better rates. Suppliers are often willing to reduce prices for larger orders, which can enhance profitability.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of costs, allowing for better comparison between suppliers. This transparency aids in negotiation and helps identify areas for cost reduction.

-

Build Relationships: Establishing a solid relationship with suppliers can lead to better pricing and service. Long-term partnerships often yield more favorable terms.

-

Stay Informed About Market Trends: Understanding industry trends and competitor pricing can provide leverage during negotiations, helping buyers secure better deals.

By considering these factors and employing strategic negotiation techniques, B2B buyers can effectively navigate the cost landscape of rebuilding Mikuni BN38 carburetors for Kawasaki JS550.

Illustrative image related to companies that rebuild mikuni bn38 carburetors for kawasaki js550

Alternatives Analysis: Comparing companies that rebuild mikuni bn38 carburetors for kawasaki js550 With Other Solutions

Understanding Alternatives for Rebuilding Mikuni BN38 Carburetors

In the realm of jet ski maintenance, specifically for the Kawasaki JS550, the rebuilding of Mikuni BN38 carburetors is a critical service. While there are companies specializing in this service, exploring alternative solutions can provide buyers with additional options that may better suit their operational needs, budget constraints, or maintenance capabilities.

Comparison Table

| Comparison Aspect | Companies That Rebuild Mikuni BN38 Carburetors For Kawasaki JS550 | DIY Rebuild Kits | Aftermarket Carburetors |

|---|---|---|---|

| Performance | Restored to factory specifications, using OEM parts | Variable; depends on user skill | Often improved flow and performance |

| Cost | Higher upfront cost for service | Lower initial cost, but potential for additional tools | Moderate; can vary widely based on brand |

| Ease of Implementation | Minimal; professional service handles all aspects | Requires knowledge and tools | Plug-and-play, often easy installation |

| Maintenance | Low post-service maintenance if done right | Requires ongoing skill for upkeep | Minimal, but may need tuning |

| Best Use Case | Ideal for classic restoration or high-performance needs | Suitable for experienced DIYers | Good for performance upgrades or replacements |

Evaluating DIY Rebuild Kits for Mikuni BN38 Carburetors

DIY rebuild kits provide a cost-effective solution for those who possess the technical skills necessary to undertake the rebuilding process. These kits typically include essential components such as gaskets, diaphragms, and o-rings. The primary advantage is the lower upfront cost compared to professional services. However, the effectiveness of the rebuild heavily relies on the user’s experience and precision during the installation. In cases where the rebuild is not executed properly, it can lead to performance issues or additional costs for professional repairs.

Assessing Aftermarket Carburetors as an Alternative

Aftermarket carburetors can serve as a viable alternative to rebuilding existing Mikuni BN38 units. They are often designed to enhance performance, providing better throttle response and fuel efficiency. Installation is generally straightforward, making them appealing for users who prefer a quick upgrade. However, the quality and compatibility of aftermarket options can vary significantly, and some may not meet the same performance standards as OEM parts. Moreover, tuning might be required post-installation to achieve optimal performance, which could increase maintenance efforts.

Conclusion: Choosing the Right Solution for Your Needs

When deciding on the best approach for carburetor maintenance or replacement for the Kawasaki JS550, B2B buyers must consider their specific operational needs, budget, and technical capabilities. Companies that specialize in rebuilding Mikuni BN38 carburetors offer a reliable and hassle-free solution, particularly for those focused on maintaining original specifications. On the other hand, DIY rebuild kits and aftermarket carburetors provide alternative paths that can be more cost-effective or performance-oriented, depending on the buyer’s expertise and objectives. Ultimately, the right choice hinges on balancing performance requirements with resource availability, ensuring that the selected solution aligns with the buyer’s long-term operational strategy.

Essential Technical Properties and Trade Terminology for companies that rebuild mikuni bn38 carburetors for kawasaki js550

What Are the Critical Technical Properties of Mikuni BN38 Carburetors?

When engaging with companies that rebuild Mikuni BN38 carburetors for the Kawasaki JS550, understanding key technical specifications is essential. Here are several critical properties to consider:

1. Material Grade

The material used in the construction of carburetors significantly affects their durability and performance. High-grade aluminum alloys are typically used for the body due to their lightweight and corrosion-resistant properties. For B2B buyers, ensuring that suppliers use OEM (Original Equipment Manufacturer) materials is crucial for maintaining the integrity and longevity of the carburetor.

2. Tolerance Levels

Precision in manufacturing is vital for carburetor components. Tolerance refers to the allowable deviation from a standard dimension. Carburetors must operate within tight tolerances (often within ±0.01 mm) to ensure optimal air-fuel mixture and performance. For businesses, understanding tolerance levels can help assess the reliability of the rebuilding process and the performance of the final product.

3. Flow Rate

The flow rate of a carburetor indicates the amount of air-fuel mixture it can handle, typically measured in cubic feet per minute (CFM). For the Mikuni BN38, flow rates are designed to match specific engine requirements. B2B buyers should verify that the rebuilt carburetors meet the appropriate flow rates to ensure compatibility with their engines, impacting overall performance.

4. Diaphragm Quality

Diaphragms in carburetors control the fuel flow based on engine demand. High-quality diaphragms made from durable materials (such as rubber compounds) are essential for responsiveness and longevity. Buyers must confirm that rebuilders use genuine or high-quality aftermarket diaphragms to prevent premature wear and maintain engine efficiency.

5. Gasket Composition

Gaskets are crucial for preventing air leaks in the carburetor system. The composition of gaskets, often made from rubber or composite materials, affects their sealing capability and resistance to fuel. B2B companies should prioritize suppliers that utilize high-quality gaskets to ensure optimal performance and reliability of the rebuilt carburetor.

6. Adjustment Mechanisms

Adjustment mechanisms in carburetors, such as needle and seat configurations, are vital for tuning performance. Properly functioning adjustments can enhance fuel efficiency and throttle response. Buyers should seek rebuilders who offer adjustable components or detailed tuning instructions to optimize carburetor performance for specific applications.

What Are Common Trade Terms in the Carburetor Rebuilding Industry?

Understanding industry jargon is equally important for B2B transactions. Here are several common terms relevant to the carburetor rebuilding sector:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle or equipment. When sourcing carburetor components, ensuring they are OEM can assure quality and compatibility. B2B buyers often prefer OEM parts for reliability and performance consistency.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory effectively and reduce excess costs. Negotiating lower MOQs can help smaller businesses obtain necessary components without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. Submitting an RFQ allows businesses to compare offers and negotiate terms, ensuring they receive competitive pricing and favorable conditions for their carburetor rebuilding needs.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, delivery, and risk management. Familiarity with these terms helps B2B buyers understand their obligations in international transactions, ensuring clear communication and reducing the risk of misunderstandings during shipping.

5. Aftermarket Parts

Aftermarket parts are components made by third-party manufacturers, not the original manufacturer. While they may offer cost savings, it’s essential to assess their quality and compatibility. B2B buyers should evaluate the reputation of aftermarket suppliers before making procurement decisions.

Illustrative image related to companies that rebuild mikuni bn38 carburetors for kawasaki js550

By understanding these technical properties and trade terms, businesses can make informed decisions when sourcing and rebuilding Mikuni BN38 carburetors for the Kawasaki JS550, ensuring optimal performance and reliability in their operations.

Navigating Market Dynamics and Sourcing Trends in the companies that rebuild mikuni bn38 carburetors for kawasaki js550 Sector

What Are the Key Market Dynamics and Trends in the Mikuni BN38 Carburetor Rebuilding Sector?

The market for companies specializing in the rebuilding of Mikuni BN38 carburetors for Kawasaki JS550 models is influenced by several global drivers. A notable trend is the increasing demand for vintage jet ski models, which has prompted a resurgence in aftermarket support for older carburetors. As enthusiasts seek to maintain or restore these classic machines, businesses that provide specialized remanufacturing services are positioned to thrive. Furthermore, technological advancements in carburetor rebuilding processes—such as precision machining and enhanced materials—allow companies to offer superior products with longer lifespans and better performance metrics.

Emerging B2B technologies are also reshaping sourcing strategies. Digital platforms and marketplaces facilitate international trade, enabling buyers from regions like Africa, South America, and Europe to connect with suppliers more efficiently. These platforms often provide detailed product specifications and customer reviews, empowering buyers to make informed purchasing decisions. Additionally, the rise of data analytics helps businesses forecast demand trends and manage inventory more effectively, aligning their offerings with market needs.

How Is Sustainability and Ethical Sourcing Impacting the Mikuni BN38 Carburetor Market?

Sustainability has become a crucial consideration for B2B buyers in the carburetor rebuilding sector. The environmental impact of manufacturing processes and materials used in carburetors is under scrutiny, with increasing pressure on companies to adopt greener practices. Buyers are increasingly prioritizing suppliers that utilize sustainable materials and processes, such as recycled components or low-emission manufacturing techniques.

Ethical sourcing is also gaining traction, as buyers demand transparency in supply chains. Companies that can demonstrate their commitment to ethical labor practices and responsible sourcing are likely to gain a competitive edge. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ certifications can enhance a supplier’s credibility and appeal to environmentally-conscious buyers. This shift not only aligns with global sustainability goals but also enhances brand loyalty among consumers who value responsible business practices.

What Is the Historical Context Behind the Mikuni BN38 Carburetor Rebuilding Industry?

The Mikuni BN38 carburetor has a rich history tied to the early days of personal watercraft, particularly within the Kawasaki brand. First introduced in the 1980s, the BN38 was designed to deliver enhanced performance and fuel efficiency, making it a popular choice for models like the Kawasaki JS550. Over the years, as these models became collector’s items, the need for specialized rebuilding services emerged.

Companies focused on rebuilding these carburetors have evolved from small workshops to more sophisticated operations, leveraging modern technology and materials to meet growing demand. This evolution reflects broader industry trends towards specialization and customer-centric service models. As a result, businesses that rebuild Mikuni BN38 carburetors are now better equipped to meet the needs of a diverse international clientele, ensuring that classic watercraft remain operational and enjoyable for enthusiasts worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of companies that rebuild mikuni bn38 carburetors for kawasaki js550

-

How do I ensure quality when sourcing rebuilt Mikuni BN38 carburetors?

To ensure quality, verify that the supplier uses OEM (Original Equipment Manufacturer) parts and follows strict remanufacturing processes. Request certifications or quality assurance documentation that details their rebuilding methods. Additionally, ask for customer testimonials or case studies showcasing previous work. It’s also beneficial to request samples or photographs of rebuilt carburetors before placing a bulk order to assess their workmanship and adherence to specifications. -

What is the typical turnaround time for carburetor rebuilding services?

Turnaround times can vary significantly based on the company and the complexity of the rebuild. Generally, expect a timeframe of 2-4 weeks for standard services. For urgent requests, some suppliers may offer expedited services at an additional cost. Always clarify the expected delivery timeline during negotiations to ensure it aligns with your operational needs. -

What payment terms are commonly offered by companies that rebuild Mikuni BN38 carburetors?

Payment terms can differ between suppliers, but many offer options such as upfront payment, net 30, or net 60 days. Some may require a deposit before beginning work, especially for larger orders. It’s advisable to negotiate terms that provide you with sufficient cash flow while ensuring the supplier’s security. Always confirm accepted payment methods, including wire transfers or credit card payments, particularly for international transactions. -

Are there minimum order quantities (MOQs) for rebuilding carburetors?

Most companies have MOQs, which can range from a single unit to several dozen, depending on their production capacity and the specific service offered. If you’re a smaller buyer, inquire about the possibility of placing a smaller order or consolidating orders with others to meet MOQ requirements. Understanding these terms upfront can help you plan your procurement strategy effectively. -

What customization options are available for rebuilt Mikuni BN38 carburetors?

Customization options may include tuning for specific performance enhancements, color finishes, or modifications for unique applications. Discuss your specific needs with the supplier to see if they can accommodate any modifications to the standard rebuild process. Ensure that any customizations are documented in the service agreement to avoid misunderstandings. -

How can I vet a supplier for rebuilding Mikuni BN38 carburetors?

To vet a supplier, start by checking their industry reputation through reviews and testimonials from previous clients. Look for suppliers with certifications in quality management, such as ISO 9001. Additionally, visit their facility if possible or request a virtual tour to observe their operations and quality control measures. Engaging in direct communication to gauge their responsiveness and expertise can also provide insights into their reliability. -

What logistics considerations should I keep in mind when importing rebuilt carburetors?

When importing rebuilt carburetors, consider shipping methods, customs regulations, and potential tariffs. Ensure that the supplier provides proper documentation for customs clearance, including invoices and certificates of origin. It’s also wise to compare shipping options for cost-effectiveness and speed. Collaborating with a freight forwarder familiar with international shipping can help streamline the logistics process. -

What should I do if I receive a defective rebuilt carburetor?

If you receive a defective unit, contact the supplier immediately to report the issue. Document the defect with photographs and provide a detailed description of the problem. Most reputable suppliers will have a return policy or warranty that covers defective products, allowing you to request a repair, replacement, or refund. Make sure to understand the supplier’s policies on returns and warranties before finalizing your order to avoid complications later.

Top 2 Companies That Rebuild Mikuni Bn38 Carburetors For Kawasaki Js550 Manufacturers & Suppliers List

1. Jet Ski Solutions – Carburetor Remanufacture Services

Domain: jetskisolutions.com

Registered: 2002 (23 years)

Introduction: Carburetor Remanufacture/Rebuild Services for Kawasaki JS550, 550sx, JS440, Mikuni BN44, BN38. Jet Ski Solutions uses high-grade materials and enhanced specifications to eliminate known failure modes. Service includes restoration to like-new condition using genuine Mikuni parts. Customers are required to send photos of their carburetor for condition assessment and pricing.

2. Blowsion – Mikuni Carburetor Rebuild Kit MK-BN38/44 SPR

Domain: blowsion.com

Registered: 1998 (27 years)

Introduction: Mikuni Carburetor Rebuild Kit Super BN | MK-BN38/44 SPR

Strategic Sourcing Conclusion and Outlook for companies that rebuild mikuni bn38 carburetors for kawasaki js550

In conclusion, the strategic sourcing of Mikuni BN38 carburetors for Kawasaki JS550 jet skis presents a lucrative opportunity for international B2B buyers. By aligning with reputable rebuilders who utilize high-quality materials and proven processes, companies can enhance their product offerings while ensuring reliability and performance. These rebuild services not only restore vintage carburetors to like-new condition but also contribute to sustainability by reducing waste through refurbishment.

As the demand for performance parts continues to rise across regions like Africa, South America, the Middle East, and Europe, establishing solid partnerships with specialized rebuilders can drive competitive advantage. Buyers should prioritize suppliers that emphasize genuine parts and comprehensive rebuild kits, which significantly improve engine efficiency and throttle response.

Looking ahead, the market for vintage watercraft restoration is set to grow. International buyers are encouraged to explore these partnerships, fostering relationships that will not only meet current demands but also anticipate future trends in the jet ski industry. Engage with trusted rebuilders today to secure the quality and performance your customers expect.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.