A B2B Buyer’s Guide to Commercial Glass Cutting Tools: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for commercial glass cutting tools

In today’s competitive landscape, sourcing high-quality commercial glass cutting tools presents a significant challenge for international B2B buyers. Whether you are operating in Africa, South America, the Middle East, or Europe, the need for efficient and reliable cutting solutions is paramount. This guide serves as a comprehensive resource, addressing critical aspects such as the various types of cutting tools available, their diverse applications across industries, and essential supplier vetting processes.

Understanding the intricacies of pricing and quality is crucial for making informed purchasing decisions. This guide empowers buyers by providing insights into the latest innovations in glass cutting technology, from oil-fed cutters to specialized cutting heads, ensuring you have the knowledge needed to select tools that enhance productivity while minimizing operational costs.

Moreover, we delve into the considerations specific to different regions, such as regulatory compliance and market trends, that can affect sourcing decisions. By equipping you with actionable strategies and expert advice, this guide aims to streamline your procurement process, enabling you to confidently navigate the global market for commercial glass cutting tools. Investing in the right tools not only boosts efficiency but also supports your overall business growth in an increasingly demanding environment.

Understanding commercial glass cutting tools Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Glass Cutters | Lightweight, portable, often ergonomically designed | Small to medium-sized glass projects | Pros: Cost-effective, easy to use. Cons: Limited to smaller cuts, requires manual skill. |

| Oil Feed Glass Cutters | Integrated oil supply for smoother cutting | High-precision applications | Pros: Reduces friction, enhances cutter longevity. Cons: Requires maintenance, higher initial cost. |

| Speed Cutters | Designed for quick, efficient cutting of large panes | Commercial glazing, large installations | Pros: Fast operation, suitable for bulk work. Cons: Heavier, may need trained operators. |

| Specialty Glass Cutters | Designed for intricate shapes and patterns | Decorative glasswork, custom projects | Pros: Versatile for creative applications. Cons: More expensive, may need specific training. |

| Replacement Cutting Heads | Interchangeable heads for different glass thicknesses | Maintenance of existing cutters | Pros: Cost-effective maintenance, tailored cutting capabilities. Cons: Requires knowledge of compatibility. |

What Are the Key Characteristics of Manual Glass Cutters?

Manual glass cutters are the most basic and widely used tools in the industry. They are lightweight and portable, making them suitable for small to medium-sized glass projects. These cutters typically feature a simple design that allows for easy operation, but they require a certain level of skill to achieve precise cuts. When purchasing manual glass cutters, buyers should consider the ergonomics of the handle and the durability of the cutting wheel, as these factors significantly impact the user experience and effectiveness.

How Do Oil Feed Glass Cutters Enhance Cutting Precision?

Oil feed glass cutters integrate a lubrication system that provides a continuous oil supply during cutting. This feature minimizes friction, resulting in smoother cuts and prolonging the life of the cutting wheel. Oil feed cutters are ideal for high-precision applications, such as creating intricate glass designs or cutting thick glass. Buyers should weigh the initial investment against the long-term benefits of reduced wear and enhanced performance, particularly for businesses focusing on quality and efficiency.

Why Are Speed Cutters Essential for Large Glass Projects?

Speed cutters are designed for quick and efficient cutting of large glass panes, making them indispensable in commercial glazing and large installations. They often come with integrated oil systems and specialized cutting heads that facilitate fast operation. While speed cutters are advantageous for bulk work, they tend to be heavier and may require trained operators to handle effectively. Buyers should evaluate the operational capacity of their workforce and the volume of glass they need to cut before investing in these tools.

In What Scenarios Are Specialty Glass Cutters Most Useful?

Specialty glass cutters are engineered for creating intricate shapes and patterns, making them ideal for decorative glasswork and custom projects. These tools offer versatility, allowing users to tackle a wide range of designs, from simple curves to complex motifs. However, the cost of specialty cutters can be higher, and they often require specific training to use effectively. B2B buyers should assess their project needs and the skill levels of their staff when considering these tools.

How Can Replacement Cutting Heads Extend Tool Lifespan?

Replacement cutting heads are crucial for maintaining the performance of existing glass cutters, allowing businesses to adapt their tools for different glass thicknesses and cutting styles. This option is cost-effective compared to purchasing new cutters and can significantly enhance the versatility of the tools in use. However, buyers must ensure compatibility with their current equipment and consider the availability of replacement heads in their region. Understanding the specifications and requirements of these heads is essential for optimal performance.

Key Industrial Applications of commercial glass cutting tools

| Industry/Sector | Specific Application of commercial glass cutting tools | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Precision cutting of glass panels for facades and windows | Enhances building aesthetics and energy efficiency | Quality of cutting tools, availability of replacement parts, and supplier reliability |

| Automotive Manufacturing | Cutting laminated and tempered glass for vehicle windows | Ensures safety and compliance with industry standards | Compliance with safety regulations, material compatibility, and bulk purchasing options |

| Electronics | Cutting glass for screens and displays in devices | Supports high-quality visuals and device longevity | Precision specifications, technology compatibility, and supplier support for customization |

| Home Decor & Furnishings | Custom glass cutting for furniture and decorative items | Adds unique design elements and increases product offerings | Material quality, design flexibility, and lead times for custom orders |

| Solar Energy | Fabrication of glass panels for solar panels | Promotes sustainable energy solutions and increases efficiency | Supplier certifications, material sourcing for durability, and cost-effectiveness in bulk orders |

In the construction and architecture sector, commercial glass cutting tools are essential for producing precise glass panels used in building facades and windows. These tools enable contractors to achieve high-quality finishes that enhance both aesthetics and energy efficiency. Buyers in this field should consider the durability and precision of cutting tools, as well as the availability of replacement parts to minimize downtime during projects.

In automotive manufacturing, the use of glass cutting tools is critical for creating laminated and tempered glass for vehicle windows. These tools must meet strict safety regulations to ensure that the glass can withstand impacts and provide protection for passengers. B2B buyers should prioritize suppliers who offer reliable, high-quality tools that comply with industry standards and can accommodate bulk orders to keep up with production demands.

The electronics industry utilizes commercial glass cutting tools for fabricating glass components for screens and displays. Precision is paramount, as any flaws can affect the visual quality of devices. Buyers need to ensure that the tools they source can deliver the necessary precision and are compatible with the specific materials used in their products. Additionally, strong supplier support for customization may be required to meet evolving technological demands.

In the home decor and furnishings sector, glass cutting tools are used to create custom pieces for furniture and decorative items. This application allows businesses to offer unique designs that can differentiate their products in a competitive market. Buyers should consider the quality of the materials and the flexibility of design options when sourcing these tools, as well as the lead times for custom orders to meet customer expectations.

The solar energy sector benefits from commercial glass cutting tools for the fabrication of glass panels used in solar installations. Efficient production of these panels is crucial for promoting sustainable energy solutions. When sourcing tools for this application, buyers should look for suppliers that provide certified materials for durability and cost-effective solutions for bulk orders, ensuring a steady supply chain for ongoing projects.

3 Common User Pain Points for ‘commercial glass cutting tools’ & Their Solutions

Scenario 1: Difficulty Achieving Precise Cuts in Various Glass Types

The Problem:

B2B buyers often face challenges when cutting different types of glass, such as tempered, laminated, or stained glass. Each type requires specific cutting techniques and tools, and failure to match the right tool with the glass type can lead to inaccurate cuts, increased waste, and potential safety hazards. For instance, using a standard cutter on tempered glass may result in shattering rather than clean edges, causing costly project delays and material loss. Additionally, varying thicknesses can complicate the cutting process, leaving buyers frustrated and apprehensive about future projects.

The Solution:

To overcome this challenge, B2B buyers should invest in specialized glass cutting tools tailored to the specific types of glass they commonly work with. For example, consider using oil-feed glass cutters that provide a consistent lubrication supply, reducing friction and ensuring smoother cuts, especially on thicker or harder glass types. Buyers should also familiarize themselves with the various cutting wheels available, such as carbide or diamond-tipped options, which are designed for harder materials. A comprehensive training session for staff on the proper techniques for each glass type can further enhance cutting precision. Additionally, sourcing tools from reputable suppliers that offer expert guidance and technical support can aid in making informed choices, thereby reducing the likelihood of errors.

Scenario 2: Frequent Tool Wear and Replacement Costs

The Problem:

Another common pain point for B2B buyers is the rapid wear and tear of glass cutting tools, leading to frequent replacements and increased costs. In high-volume environments, such as manufacturing or construction, tools can degrade quickly, impacting productivity and profitability. Buyers may find themselves caught in a cycle of purchasing lower-quality tools that fail to meet performance expectations, resulting in even higher long-term costs due to inefficiencies and downtime.

The Solution:

To address this issue, buyers should prioritize investing in high-quality, durable glass cutting tools designed for longevity. Tools made from premium materials, such as tungsten carbide or specialized alloys, often provide better performance and wear resistance. Establishing a maintenance schedule can extend the lifespan of these tools, including regular cleaning and proper storage techniques. Furthermore, sourcing tools from manufacturers that offer warranties or guarantees can mitigate financial risks associated with premature wear. Incorporating a cost-per-cut analysis into purchasing decisions can help buyers evaluate the true value of their tools over time, enabling them to make smarter, more sustainable choices.

Scenario 3: Inconsistent Results Leading to Quality Control Issues

The Problem:

Inconsistent cutting results can significantly impact the quality of finished products, leading to dissatisfaction among clients and potential reputational damage for B2B buyers. For example, variations in cut quality can arise from using inappropriate cutting techniques or tools that are not calibrated correctly. Such inconsistencies can lead to rework, additional labor costs, and project delays, which are particularly detrimental in competitive markets where timelines are tight.

The Solution:

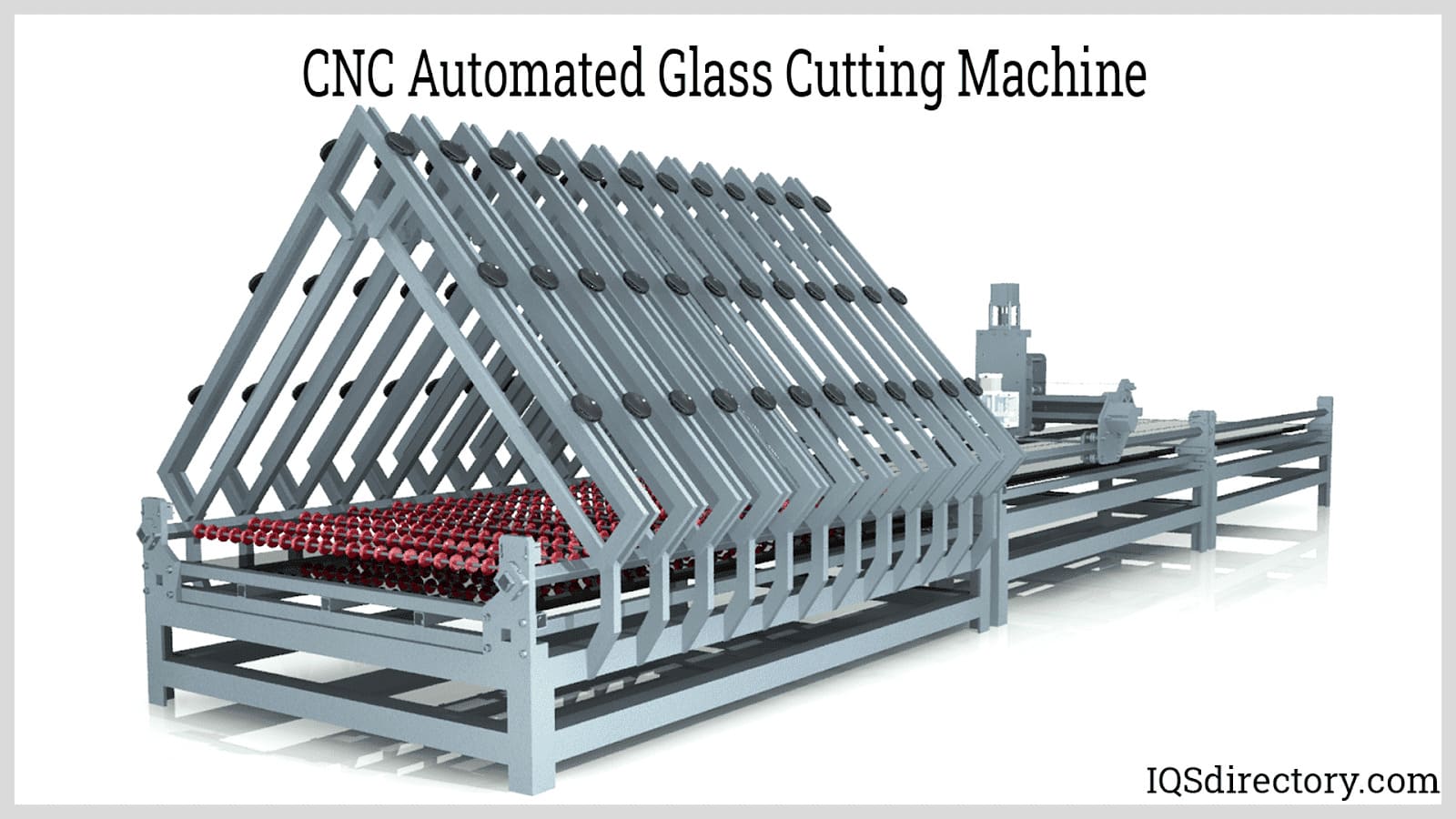

To combat inconsistent results, buyers should implement standardized operating procedures (SOPs) for glass cutting processes. This includes defining the correct tool for each specific application, ensuring that all equipment is calibrated and maintained regularly, and providing ongoing training for workers to reinforce best practices. Utilizing advanced glass cutting technology, such as CNC (Computer Numerical Control) machines, can also enhance precision and consistency in cuts. These machines can be programmed for specific tasks, ensuring uniformity across large production runs. Investing in quality control measures, such as regular audits of cutting processes and outcomes, will further help maintain high standards and reduce the risk of errors. By fostering a culture of quality and precision, businesses can improve client satisfaction and enhance their competitive edge.

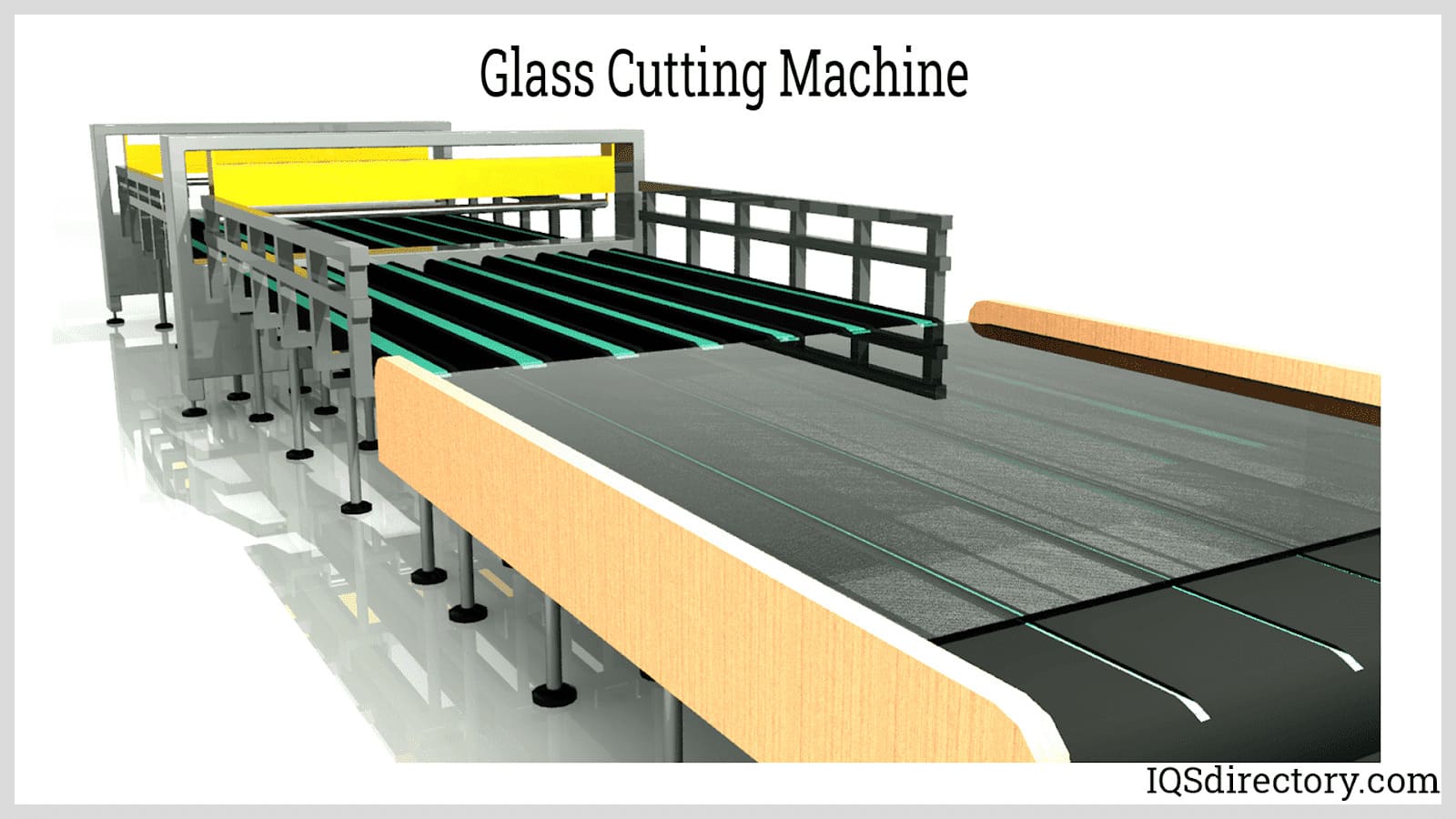

Illustrative image related to commercial glass cutting tools

Strategic Material Selection Guide for commercial glass cutting tools

What Are the Key Materials Used in Commercial Glass Cutting Tools?

When selecting commercial glass cutting tools, the choice of materials is critical to ensure optimal performance, durability, and cost-effectiveness. Here, we analyze four common materials used in these tools, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Impact the Performance of Glass Cutting Tools?

Steel is a prevalent material in the manufacturing of glass cutting tools, particularly for cutting heads and handles. Its key properties include high tensile strength and excellent wear resistance, making it suitable for handling the pressures involved in glass cutting. Steel’s corrosion resistance can be enhanced through coatings, which is vital for tools used in humid or corrosive environments.

Pros: Steel tools are durable and can withstand significant wear and tear. They are also relatively cost-effective compared to other materials, making them a popular choice for manufacturers.

Cons: The primary drawback of steel is its susceptibility to rust if not properly maintained. Additionally, high-quality steel can be more expensive, impacting overall production costs.

For international buyers, compliance with standards such as ASTM for steel quality is essential. Buyers from regions like Europe and the Middle East may prefer tools that meet specific corrosion resistance standards due to environmental conditions.

What Role Does Tungsten Carbide Play in Glass Cutting Tool Manufacturing?

Tungsten carbide is often used for the cutting wheels in glass cutting tools due to its exceptional hardness and durability. It can withstand high temperatures and pressures, ensuring clean cuts and extended tool life.

Pros: The main advantage of tungsten carbide is its longevity; it can last significantly longer than steel cutting wheels. This durability translates to lower replacement costs over time.

Cons: Tungsten carbide is more expensive than steel, which may deter some buyers. Additionally, the manufacturing process for tungsten carbide tools can be more complex, leading to longer lead times.

International buyers should consider the specific applications of tungsten carbide tools, especially in regions with high demand for precision cutting, such as Europe. Compliance with standards like DIN for material properties is also crucial.

Illustrative image related to commercial glass cutting tools

How Does Aluminum Affect the Design and Use of Glass Cutting Tools?

Aluminum is another material used in the construction of glass cutting tools, especially for handles and lightweight designs. It is known for its lightweight nature and resistance to corrosion, making it suitable for portable tools.

Pros: The lightweight characteristic of aluminum enhances user comfort, especially during prolonged use. Its corrosion resistance is beneficial in humid environments, making it ideal for diverse geographical locations.

Cons: While aluminum is resistant to corrosion, it is less durable than steel or tungsten carbide, leading to potential wear issues over time. Additionally, it may not be suitable for heavy-duty applications.

B2B buyers from regions like South America, where humidity can be a concern, may find aluminum tools appealing. However, they should ensure that the aluminum used meets relevant standards for strength and durability.

Illustrative image related to commercial glass cutting tools

What Are the Benefits of Using Composite Materials in Glass Cutting Tools?

Composite materials, including fiberglass and carbon fiber, are increasingly being used in glass cutting tools due to their unique properties. These materials offer a combination of strength, lightweight, and resistance to environmental factors.

Pros: Composites are incredibly lightweight while maintaining high strength, making them easy to handle. They are also resistant to corrosion and temperature fluctuations, which is advantageous in varying climates.

Cons: The primary limitation is the higher cost associated with composite materials, which can affect pricing strategies. Additionally, the manufacturing process may require specialized techniques, increasing complexity.

For international buyers, especially in Africa and the Middle East, the use of composite materials may align with preferences for innovative, lightweight tools. Compliance with international standards for composite materials is essential to ensure quality and safety.

Summary Table of Material Selection for Glass Cutting Tools

| Material | Typical Use Case for commercial glass cutting tools | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Cutting heads and handles | Durable and cost-effective | Susceptible to rust | Medium |

| Tungsten Carbide | Cutting wheels | Long-lasting and precise cuts | Higher cost and complex mfg | High |

| Aluminum | Lightweight handles | User comfort and corrosion-resistant | Less durable than steel | Medium |

| Composite | Innovative lightweight designs | High strength and lightweight | Higher cost and complex mfg | High |

This strategic material selection guide provides valuable insights for B2B buyers, helping them make informed decisions based on performance, cost, and regional compliance requirements.

Illustrative image related to commercial glass cutting tools

In-depth Look: Manufacturing Processes and Quality Assurance for commercial glass cutting tools

What Are the Main Stages in the Manufacturing Process of Commercial Glass Cutting Tools?

The manufacturing process of commercial glass cutting tools is a meticulous endeavor that encompasses several key stages: material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the careful selection of raw materials. High-quality materials such as tungsten carbide for cutting wheels and durable metals for handles are essential for producing reliable tools. Suppliers often utilize advanced techniques to ensure that the raw materials meet specific hardness and tensile strength requirements. This step might include pre-treatment processes like annealing, which enhance the material properties, making them suitable for high-stress applications.

Forming Techniques

Once the materials are prepared, they undergo various forming techniques. Cutting wheels are typically manufactured through precision machining, where the raw material is shaped and honed to achieve the desired dimensions and sharpness. Advanced techniques such as laser cutting or CNC machining are commonly employed to ensure accuracy. For handles, processes like die casting or injection molding can be utilized to create ergonomic shapes that enhance user comfort.

Assembly Process

Following the forming stage, assembly involves the integration of different components, such as cutting heads and handles. Automated assembly lines are often used to improve efficiency and consistency. This stage may also include the application of features like oil feed systems, which are crucial for maintaining cutting performance and extending tool life. Quality checks during assembly ensure that each component fits seamlessly and functions as intended.

Finishing Touches

The final stage, finishing, involves surface treatment processes like polishing, coating, or anodizing. These processes not only enhance the aesthetic appeal but also improve the durability and corrosion resistance of the tools. Quality control measures are integrated throughout the finishing process to ensure that each tool meets the required specifications and standards.

How Is Quality Assurance Implemented in the Production of Glass Cutting Tools?

Quality assurance (QA) is paramount in the manufacturing of glass cutting tools, particularly when catering to international markets.

What International Standards Are Relevant for Quality Assurance?

To maintain high quality, manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for an effective quality management system. Compliance with these standards ensures that products consistently meet customer and regulatory requirements. Additionally, industry-specific certifications, such as CE marking for products sold in Europe, provide further assurance of quality and safety.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production line. It ensures that all materials meet predefined quality standards and specifications.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC checks are conducted to monitor production processes and ensure adherence to quality parameters. This could involve measuring dimensions, testing cutting performance, or checking for defects.

-

Final Quality Control (FQC): Once the tools are assembled, FQC involves a thorough inspection of the finished products. This includes functionality tests, visual inspections, and sometimes performance tests to ensure the tools meet the required standards.

What Common Testing Methods Are Used in Quality Assurance?

Various testing methods are employed to validate the quality of glass cutting tools:

-

Performance Testing: This assesses the cutting efficiency and durability of the tools under simulated working conditions. Factors like cut quality, wheel longevity, and ease of use are evaluated.

-

Material Testing: Techniques such as hardness testing and tensile strength testing are used to assess the raw materials and finished products. These tests ensure that the tools can withstand the rigors of glass cutting.

-

Safety Testing: For compliance with safety standards, tools may undergo tests for sharpness, durability, and potential hazards during use.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial.

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is an effective way to assess the quality control processes in place. Buyers can schedule regular audits to evaluate the manufacturing facilities, QC checkpoints, and compliance with international standards. During these audits, buyers should focus on the following:

Illustrative image related to commercial glass cutting tools

-

Documentation Review: Examine records related to quality control processes, including test results and compliance certifications.

-

Process Observation: Observe the manufacturing and QC processes firsthand to ensure that they align with reported practices.

-

Employee Interviews: Speak with employees involved in quality assurance to gauge their understanding of processes and standards.

How Can Buyers Leverage Reports and Third-Party Inspections?

In addition to audits, requesting quality assurance reports from suppliers can provide insights into their QC practices. These reports often include data on defect rates, testing outcomes, and corrective actions taken.

Engaging third-party inspection services is another effective strategy. These independent organizations can conduct unbiased assessments of the supplier’s processes and products, providing an additional layer of assurance for buyers.

What Are the Nuances of Quality Control and Certification for International Buyers?

International buyers must be aware of the specific quality control and certification nuances that may vary by region. For instance, while European standards like CE marking are crucial for compliance in Europe, other regions may have different requirements.

Buyers should familiarize themselves with the regulatory landscape of their target markets to ensure that the products they procure meet local standards. This knowledge will help in making informed decisions and minimizing compliance risks.

Conclusion

The manufacturing processes and quality assurance for commercial glass cutting tools are critical components that directly impact product performance and reliability. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ensuring that they procure high-quality tools that meet their operational needs. Implementing robust verification strategies will further enhance buyer confidence and foster long-term supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘commercial glass cutting tools’

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure commercial glass cutting tools. By following these steps, you can ensure that your investment meets your operational needs and delivers optimal performance.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your glass cutting operations is crucial. Consider factors such as the thickness of the glass, the types of cuts you need (straight, curved, or intricate designs), and the volume of production. Clearly defined specifications will help you communicate effectively with suppliers and narrow down your options.

Step 2: Research Available Products

Investigate the range of commercial glass cutting tools on the market, including manual cutters, electric cutters, and specialized cutting oils. Pay attention to features that enhance usability, such as ergonomic designs and integrated oil supplies, which can prolong the life of the cutting wheel and improve cutting precision. This research will help you understand current market trends and innovations that can benefit your operations.

Step 3: Evaluate Potential Suppliers

Before making a purchasing decision, thoroughly vet potential suppliers. Request company profiles, product catalogs, and references from other businesses in your sector. Look for suppliers who demonstrate a solid track record in quality and reliability, as well as those who comply with international standards relevant to your region.

Step 4: Verify Certifications and Compliance

Ensure that the products you are considering meet industry standards and safety regulations. Check for certifications such as ISO, CE, or local compliance markers relevant to your market. This step is essential to mitigate risks associated with subpar equipment and to ensure that your tools are safe for use.

Step 5: Assess Warranty and After-Sales Support

Inquire about the warranty policies and after-sales support offered by suppliers. A robust warranty can protect your investment and provide peace of mind, while responsive customer service is vital for addressing any issues that may arise post-purchase. Confirm the availability of spare parts and maintenance services to keep your tools in optimal condition.

Step 6: Request Samples or Demonstrations

Whenever possible, request samples or arrange for demonstrations of the glass cutting tools you are considering. This firsthand experience will allow you to evaluate the performance and suitability of the products for your specific needs. Observe the ease of use, cutting quality, and any additional features that may enhance productivity.

Step 7: Negotiate Terms and Finalize Purchase

Once you have selected a supplier and product, negotiate the terms of the purchase, including pricing, delivery timelines, and payment conditions. Ensure that all agreements are documented to avoid misunderstandings. Confirm that the supplier can meet your delivery requirements, particularly if you are operating in regions with logistical challenges.

By following this checklist, you will be well-equipped to make informed decisions when sourcing commercial glass cutting tools, ensuring that your procurement process is efficient and effective.

Comprehensive Cost and Pricing Analysis for commercial glass cutting tools Sourcing

What Are the Key Cost Components for Commercial Glass Cutting Tools?

When sourcing commercial glass cutting tools, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to commercial glass cutting tools

-

Materials: The choice of materials directly affects the durability and performance of glass cutting tools. High-quality carbide or diamond-tipped cutting wheels, for instance, can significantly enhance cutting efficiency but may come at a higher upfront cost.

-

Labor: Labor costs vary based on the region and the skill level required for manufacturing. Skilled labor in regions with higher wage standards, such as Europe, can impact the overall pricing.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, rent, and maintenance. Efficient manufacturing processes can help reduce overhead, which in turn can lower prices.

-

Tooling: The costs associated with creating the molds and fixtures necessary for production can be substantial. Customization or specialized tooling for unique designs will further increase costs.

-

Quality Control (QC): Implementing stringent quality control processes ensures product reliability and compliance with international standards, which may add to the cost but is essential for maintaining a competitive edge.

-

Logistics: Shipping and handling costs are particularly pertinent for international buyers. Factors such as distance, shipping method, and customs regulations can significantly influence overall expenses.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit. Understanding the margin structure can help buyers negotiate better deals.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence the pricing of commercial glass cutting tools, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk often results in lower per-unit costs. Suppliers may offer discounts for larger orders, making it financially advantageous for businesses to consolidate purchases.

-

Specifications and Customization: Custom tools designed for specific applications can lead to increased costs. However, these can yield better performance and longer lifespan, justifying the investment.

-

Materials and Quality: The quality of materials directly influences durability and performance. Tools made from premium materials may be costlier initially but can reduce the total cost of ownership through increased lifespan and reduced maintenance.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with certifications may charge more due to their proven track record, but the assurance of quality can mitigate risks.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping costs, insurance, and customs clearance, which can significantly impact the final price.

What Are Some Buyer Tips for Cost-Efficiency in Sourcing Glass Cutting Tools?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency:

-

Negotiate Terms: Always negotiate pricing and payment terms. Suppliers may be willing to offer discounts for prompt payment or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the purchase price but also maintenance, operational costs, and longevity when evaluating tools. A higher initial investment may lead to lower TCO in the long run.

-

Stay Informed About Market Trends: Being aware of market fluctuations and technological advancements can provide leverage in negotiations. For example, emerging technologies in glass cutting may lead to more cost-effective solutions.

-

Assess Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Loyalty can be rewarded with discounts, better terms, and priority during high-demand periods.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and local regulations can impact pricing. It’s essential to account for these factors in your budget planning.

Disclaimer on Indicative Prices

The prices mentioned in various sources can serve as a reference but are subject to change based on market conditions, supplier pricing strategies, and specific buyer requirements. Always conduct thorough research and obtain updated quotes before making procurement decisions.

Alternatives Analysis: Comparing commercial glass cutting tools With Other Solutions

In the realm of glass cutting, commercial glass cutting tools have long been the standard for precision and efficiency. However, there are several alternative solutions that can achieve similar objectives, each with its unique advantages and disadvantages. Understanding these alternatives is crucial for B2B buyers, particularly when considering factors such as performance, cost, and specific application needs.

| Comparison Aspect | Commercial Glass Cutting Tools | Laser Cutting Technology | Water Jet Cutting Technology |

|---|---|---|---|

| Performance | High precision and control; suitable for various glass types | Extremely precise; ideal for complex designs | Excellent for thick materials; versatile with multiple materials |

| Cost | Moderate upfront cost; ongoing maintenance | High initial investment; lower operating costs over time | High initial investment; significant maintenance costs |

| Ease of Implementation | User-friendly; requires minimal training | Requires skilled operators; complex setup | Requires specialized equipment and training |

| Maintenance | Regular maintenance needed for optimal performance | Low maintenance; periodic calibration needed | High maintenance; requires skilled technicians |

| Best Use Case | Standard glass cutting; decorative glass work | Intricate designs and patterns; high-volume production | Cutting thick glass or multiple materials simultaneously |

What Are the Advantages and Disadvantages of Laser Cutting Technology?

Laser cutting technology uses high-powered lasers to cut glass and other materials with exceptional precision. This method is particularly beneficial for intricate designs, allowing for complex patterns and shapes that traditional cutting tools may struggle to achieve. However, the initial investment is significantly higher than that of commercial glass cutting tools. Additionally, laser cutting requires skilled operators to manage the technology effectively, making it less accessible for small businesses or those with limited training resources.

How Does Water Jet Cutting Technology Compare?

Water jet cutting technology utilizes high-pressure water streams, often mixed with abrasive materials, to cut through glass and other materials. This method excels in cutting thick glass and is versatile enough to handle various materials, from metal to stone. However, the equipment is expensive and requires a considerable amount of maintenance, including regular servicing and skilled technicians to operate it. While it offers excellent results for heavy-duty applications, it may not be the best choice for smaller-scale glass cutting tasks.

How Should B2B Buyers Choose the Right Glass Cutting Solution?

When selecting the appropriate glass cutting solution, B2B buyers should assess their specific needs, including the type of glass, the complexity of cuts required, and budget constraints. Commercial glass cutting tools are ideal for straightforward applications and offer a balanced cost-performance ratio. In contrast, laser cutting may be preferred for high-volume production with intricate designs, while water jet cutting is suited for heavy-duty tasks. By evaluating these factors, buyers can make informed decisions that align with their operational goals and financial capabilities.

Essential Technical Properties and Trade Terminology for commercial glass cutting tools

What Are the Essential Technical Properties of Commercial Glass Cutting Tools?

When selecting commercial glass cutting tools, understanding their technical properties is crucial for ensuring efficiency, durability, and precision. Here are some key specifications to consider:

1. Material Grade

The material used for the cutting wheel significantly influences the performance and longevity of the tool. Common materials include high-carbon steel and tungsten carbide. High-carbon steel is typically more affordable but may wear out faster. In contrast, tungsten carbide offers superior durability and sharpness, making it ideal for high-volume cutting operations. Choosing the right material grade can lead to reduced tool replacement costs and increased productivity.

2. Cutting Wheel Angle

The angle of the cutting wheel—usually between 120° and 160°—affects the tool’s cutting efficiency and precision. A sharper angle allows for cleaner cuts but may require more skill to operate effectively. Conversely, a wider angle can provide more stability, which is beneficial for beginners or less experienced operators. Understanding the optimal cutting wheel angle for specific glass types can enhance operational efficiency.

3. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of the glass being cut. Higher precision in cutting tools allows for tighter tolerances, which is crucial in applications requiring exact measurements. For B2B buyers, selecting tools that meet specific tolerance requirements can prevent costly errors and reduce material waste, ultimately leading to improved profitability.

4. Oil Feed Mechanism

An integrated oil feed mechanism lubricates the cutting wheel during operation, reducing friction and heat buildup. This feature extends the life of the cutter and improves cut quality. Tools with an oil feed system are particularly advantageous for high-volume cutting tasks, as they help maintain consistent performance and reduce downtime for maintenance.

5. Weight and Ergonomics

The weight of a glass cutting tool impacts user fatigue and precision. Lighter tools can offer better maneuverability, while heavier options may provide more stability during cutting. Ergonomically designed handles also enhance user comfort and control, leading to better accuracy in cuts. For B2B buyers, investing in ergonomic tools can lead to improved employee satisfaction and productivity.

What Are Common Trade Terms in the Commercial Glass Cutting Industry?

Understanding industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of glass cutting tools, an OEM supplier may provide cutting wheels or other components that are used by brands to assemble their products. Recognizing OEM relationships can help buyers identify quality sources and potential cost savings.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers, as it impacts inventory management and cash flow. Understanding MOQs can help businesses optimize their purchasing strategies and avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. It typically includes details about the required quantity, specifications, and delivery timelines. B2B buyers should utilize RFQs to solicit competitive pricing and ensure they are making informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B transactions, especially in international trade, as they help clarify costs and risks associated with shipping glass cutting tools.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is critical for effective inventory planning and ensuring timely project completion. B2B buyers should always clarify lead times with suppliers to manage expectations and project schedules.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing commercial glass cutting tools, ensuring better performance, reliability, and overall value.

Navigating Market Dynamics and Sourcing Trends in the commercial glass cutting tools Sector

What Are the Key Drivers and Trends Shaping the Commercial Glass Cutting Tools Market?

The commercial glass cutting tools market is currently experiencing significant growth, fueled by a combination of technological advancements and increasing demand across various sectors, including construction, automotive, and manufacturing. A pivotal driver is the rising demand for customized glass solutions, particularly in emerging markets in Africa, South America, and the Middle East. As industries evolve, the necessity for precision tools that can accommodate intricate designs is paramount. This trend is further supported by innovations such as automated cutting systems and AI-driven technologies that enhance efficiency and accuracy in glass cutting processes.

Illustrative image related to commercial glass cutting tools

In addition, the market is witnessing a surge in the adoption of smart technologies and IoT-enabled devices that allow for real-time monitoring and predictive maintenance. This technological shift is not only improving operational efficiency but also reducing downtime, making it a crucial consideration for international B2B buyers. Furthermore, sustainability is becoming a key theme, with an increasing number of buyers prioritizing suppliers who demonstrate eco-friendly practices and products.

How Is Sustainability Influencing the Sourcing of Commercial Glass Cutting Tools?

Sustainability is no longer a mere buzzword; it has become an essential criterion for B2B buyers in the commercial glass cutting tools sector. The environmental impact of production processes and materials used in glass cutting tools is under scrutiny, prompting buyers to seek suppliers who adhere to ethical sourcing practices. This includes the use of recycled materials and sustainable manufacturing processes that minimize waste and energy consumption.

Furthermore, certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are increasingly influencing purchasing decisions. Buyers are looking for products that carry these certifications, as they signify a commitment to environmental responsibility. Additionally, the integration of biodegradable lubricants and oils in glass cutting tools is gaining traction, as companies aim to reduce their carbon footprint and appeal to environmentally conscious consumers.

What Is the Historical Context of Commercial Glass Cutting Tools?

The evolution of commercial glass cutting tools can be traced back to the early 20th century when the first glass cutters were developed, primarily for the stained glass industry. Over the decades, advancements in materials and technology have transformed these tools into precision instruments capable of handling a variety of glass types, including tempered and laminated glass.

The introduction of specialized cutting wheels and the incorporation of lubricants significantly improved the efficiency and quality of cuts. The latter part of the 20th century saw the emergence of automated cutting systems, which revolutionized the industry by enhancing speed and reducing waste. Today, the landscape is characterized by a blend of traditional craftsmanship and cutting-edge technology, paving the way for further innovations in the commercial glass cutting tools sector.

Conclusion

As international B2B buyers navigate the complexities of sourcing commercial glass cutting tools, understanding market dynamics, prioritizing sustainability, and recognizing historical advancements will be crucial. The interplay between technology and ethical sourcing will define the future of this sector, making it imperative for buyers to align their purchasing strategies with these evolving trends. By staying informed and adaptable, companies can secure a competitive edge in this growing market.

Frequently Asked Questions (FAQs) for B2B Buyers of commercial glass cutting tools

-

How do I choose the right glass cutting tool for my business needs?

Selecting the appropriate glass cutting tool involves considering several factors: the type of glass you will be working with, the thickness of the material, and the complexity of the cuts needed. For instance, specialized cutters like oil feed cutters are ideal for thicker glass, while handheld cutters may suffice for thinner sheets. It’s also crucial to evaluate the durability and quality of the tool, as well as any additional features that may enhance precision and ease of use, such as ergonomic handles or integrated lubrication systems. -

What are the benefits of using cutting oil with glass cutting tools?

Utilizing cutting oil during the glass cutting process can significantly enhance tool performance. It lubricates the cutter wheel, reducing friction and heat, which prolongs the life of the cutting wheel. Moreover, cutting oil helps to achieve cleaner cuts by minimizing chipping and cracking, ensuring a smoother finish. For optimal results, choose a no-mix formula that is easy to apply and clean, thus streamlining the cutting process. -

What is the minimum order quantity (MOQ) for commercial glass cutting tools?

MOQs for glass cutting tools can vary significantly depending on the supplier and the specific product. Many suppliers may set a minimum order to cover production and shipping costs, typically ranging from 10 to 50 units. However, some manufacturers may offer flexibility for first-time buyers or for bulk orders. It’s advisable to discuss your requirements directly with the supplier to negotiate terms that work for both parties. -

How can I vet suppliers of glass cutting tools for quality and reliability?

Vetting suppliers involves assessing their reputation, product quality, and customer service. Start by reviewing online testimonials and case studies to gauge previous customer experiences. Request samples of the products to evaluate their quality firsthand. Additionally, check if the supplier complies with international standards and certifications, which can indicate their commitment to quality. Establishing a direct line of communication can also help you assess their responsiveness and willingness to address your concerns. -

What payment terms should I expect when purchasing glass cutting tools internationally?

Payment terms for international purchases can vary widely based on the supplier and the country of origin. Common terms include advance payment, letters of credit, and net payment options (like 30, 60, or 90 days after delivery). It’s essential to clarify these terms upfront and ensure they align with your cash flow requirements. Additionally, consider using secure payment methods that protect your transaction, such as escrow services or bank transfers. -

What are the common logistics considerations when importing glass cutting tools?

Importing glass cutting tools requires careful planning around logistics, including shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling glass products to minimize the risk of damage during transit. Be aware of any import tariffs or duties that may apply in your country, and ensure all necessary documentation, such as commercial invoices and packing lists, are in order to facilitate smooth customs clearance. -

How do I ensure quality assurance (QA) for glass cutting tools before purchase?

To ensure quality assurance, request detailed product specifications and certifications from the supplier. Establish a quality control checklist that includes aspects like material quality, cutting precision, and durability. If possible, schedule an on-site inspection or request third-party quality audits. It’s also beneficial to discuss return policies and warranties, which can provide added security in case the products do not meet your expectations. -

Can I customize glass cutting tools to meet specific project requirements?

Many suppliers offer customization options for glass cutting tools, allowing you to tailor features such as blade size, handle design, and even packaging. When discussing customization, provide clear specifications about your needs and any unique challenges your projects may present. Be aware that custom orders may come with longer lead times and potentially higher costs, so plan accordingly to ensure timely delivery for your projects.

Top 7 Commercial Glass Cutting Tools Manufacturers & Suppliers List

1. WGS Online – Glazing Tools & Glass Cutting Supplies

Domain: wgsonline.com

Registered: 2004 (21 years)

Introduction: Glazing Tools – Glass Cutting includes Oil Feed Glass Cutters, Oil Feed Glass Cutter Replacement Heads, Metal/Wood Handle Glass Cutters, T-Style Speed Glass Cutters, and various Glass Cutting Accessories. Additionally, it features Stained Glass Tools and Supplies, Glazing Specialty Tools, and Multi Tools for glass, tile, and stone drilling. Drill bits available include Carbide Spear Point Bits, Pr…

2. Bullseye Glass – Cutting Tools

Domain: shop.bullseyeglass.com

Registered: 2003 (22 years)

Introduction: Cutting tools for glass include handheld cutters, circle cutters, breaking pliers, grozing pliers, nippers, cutting systems, and accessories. Key products with prices: Breaking/Grozing Pliers – $11.50, Running Pliers – $17.00, Leponitt Carbide Nippers – $19.00, Toyo Self-Oiling Cutter – $25.20, Toyo Cutters (Set of 6) – $140.00, Replacement Pads for Running Pliers – $2.25, Bohle Silberschnitt Bras…

3. Bohle – Glass Cutters

Domain: delphiglass.com

Registered: 1997 (28 years)

Introduction: Glass Cutters, Bottle Cutters, Glass Cutting Tools & Supplies for Stained Glass, Fusing, and Mosaics. Categories include: Bottle, Circle & Strip Cutters, Glass Cutting Systems, Grinding Hand Tools, Pliers & Nippers, Rulers & Straight Edges. Brands featured: Bohle, Creator’s Stained Glass, Designed By Delphi, Diamond Tech, Ephrem’s Bottle Works, Glacial Art Glass, Morton Glass Works, Silberschnitt,…

4. Fletcher – Hand-held Glass Cutters

Domain: fletcher-terry.com

Registered: 1996 (29 years)

Introduction: Industrial Hand-held Glass Cutters | Fletcher Glass Cutters. Features include heavy-duty plastic and tile cutters, circle glass cutter, and circleMate II. Designed for scoring glass and mirrors. Part of a larger range of products including automated glass cutting tools and frame joining machinery.

5. Toyo – Brass Oil Fed Glass Cutter

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Toyo Brass Oil Fed Pencil Style Glass Cutter #Tc10b – Reliable, affordable, maintains quality for a long time, brass handle for weight, alternative grips available (Thomas grip, Pistol grip). 2. Gryphon Pistol Style Glass Cutter – Comfortable fit, great blade quality. 3. Carbide scoring tool – Recommended for longevity (lasts a decade or more), handle comfort is subjective. 4. Price range: $20-…

6. IQS Directory – Types of Glass Cutting Tools

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Types of Glass Cutting Tools: 1. Handheld Glass Cutter – Versatile and precise, suitable for various flat glass types. 2. Pencil Grip Glass Cutter – Slim shaft for control, often used by stained glass enthusiasts. 3. Custom Grip Glass Cutter – Ergonomic with customizable features for comfort. 4. Thomas Grip Glass Cutter – Compact with a swivel head for intricate cuts. 5. Fletcher Glass Cutter – Us…

7. FHC – Frameless Shower Door Solutions

Domain: fhc-usa.com

Registered: 2019 (6 years)

Introduction: This company, FHC – Frameless Shower Door Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for commercial glass cutting tools

In the competitive landscape of commercial glass cutting tools, strategic sourcing emerges as a pivotal element for B2B buyers. By understanding the nuances of product specifications, supplier reliability, and pricing structures, businesses can optimize their purchasing strategies. Key takeaways emphasize the importance of selecting high-quality cutting tools that enhance efficiency and longevity, ultimately reducing operational costs.

Moreover, investing in tools such as oil feed glass cutters and specialized cutting heads can significantly improve the quality of work, catering to diverse market needs across regions like Africa, South America, the Middle East, and Europe. As global demand for glass products continues to rise, establishing strong partnerships with reputable suppliers will be crucial.

Looking ahead, international buyers are encouraged to leverage technological advancements and innovative materials to stay ahead in their respective markets. By prioritizing strategic sourcing practices, businesses not only secure competitive pricing but also ensure they are equipped with the best tools to meet the evolving demands of the glass industry. Now is the time to take action—evaluate your sourcing strategies and position your company for success in the dynamic world of glass cutting.

Illustrative image related to commercial glass cutting tools

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.