Unlocking Value: A Strategic Analysis of the Mesh Types Market

Introduction: Navigating the Global Market for mesh types

In today’s competitive global market, sourcing the right mesh types can be a daunting task for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With the variety of mesh options available, from structured and unstructured meshes to surface and solid types, understanding their specific applications and benefits is crucial. This comprehensive guide not only outlines the various mesh types but also delves into their applications across multiple industries, enabling you to make informed purchasing decisions.

Throughout this guide, you will find detailed insights into the characteristics of different mesh types, including their geometric and topological representations, and how these factors influence performance in real-world applications. We will also discuss the essential criteria for vetting suppliers, providing you with the tools needed to ensure quality and reliability in your sourcing process. Additionally, an exploration of cost considerations will empower you to balance budget constraints with the need for high-quality materials.

By leveraging the information within this guide, international B2B buyers will gain a competitive edge, allowing them to navigate the complexities of the global mesh market with confidence. Whether you’re based in Germany, Saudi Arabia, or beyond, this resource is designed to streamline your sourcing efforts and optimize your procurement strategy.

Understanding mesh types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Surface Mesh | Composed of faces and vertices; represents surfaces only | CAD modeling, visualizations | Pros: Easier to handle complex geometries; Cons: Limited to surface representation only. |

| Solid Mesh | Represents the volume of an object; includes tetrahedral, polyhedral, and trimmed shapes | Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD) | Pros: Detailed analysis of internal structures; Cons: More complex to generate and manage. |

| Structured Mesh | Regularly arranged cells; follows a predictable grid pattern | Simulation in engineering, environmental modeling | Pros: Efficient computation and automatic connectivity; Cons: Limited flexibility for complex shapes. |

| Unstructured Mesh | Randomly arranged cells; allows for complex geometries | Complex simulations in mechanical engineering | Pros: High adaptability to intricate designs; Cons: Increased computational cost and complexity. |

| Curvilinear Mesh | Nodes arranged in a curvilinear coordinate system; retains structured properties | Aerodynamics simulations, fluid dynamics | Pros: Better suited for curved geometries; Cons: More challenging to implement than rectilinear meshes. |

What are the Characteristics and Suitability of Surface Meshes for B2B Buyers?

Surface meshes are primarily used to represent the outer surfaces of 3D objects, making them ideal for applications such as CAD modeling and visualizations. Their structure comprises faces (triangles) and vertices, which allow for the representation of intricate surface details. For B2B buyers, the ability to handle complex geometries efficiently is a significant advantage. However, it is crucial to note that surface meshes do not provide information about the internal volume, which may limit their applicability in certain engineering analyses.

How Does Solid Mesh Differ and What are Its Key Applications?

Solid meshes encompass the entire volume of an object, providing a more comprehensive analysis for applications such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). They can be created using various methods, including tetrahedral and polyhedral shapes. For B2B buyers, solid meshes offer detailed insights into internal structures, which are essential for product design and testing. However, the complexity of generating and managing solid meshes can present challenges, necessitating advanced software and expertise.

Why Choose a Structured Mesh for Engineering Simulations?

Structured meshes are characterized by their orderly arrangement of cells, which follow a predictable grid pattern. This regularity facilitates efficient computations and automatic connectivity, making structured meshes particularly advantageous for simulations in engineering and environmental modeling. B2B buyers should consider structured meshes for projects requiring high computational efficiency. Nonetheless, the inherent limitations in flexibility for accommodating complex geometries may restrict their use in certain scenarios.

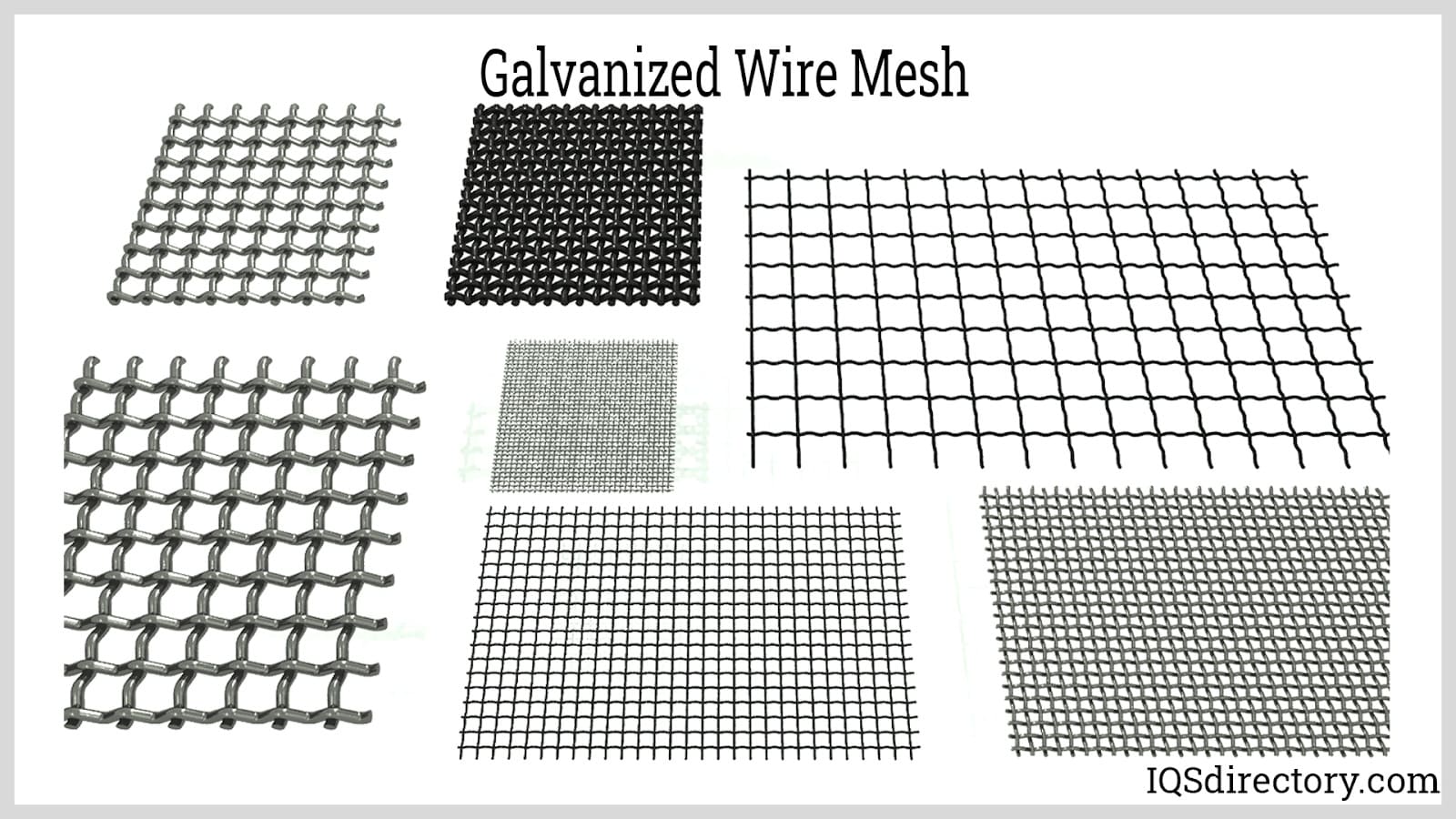

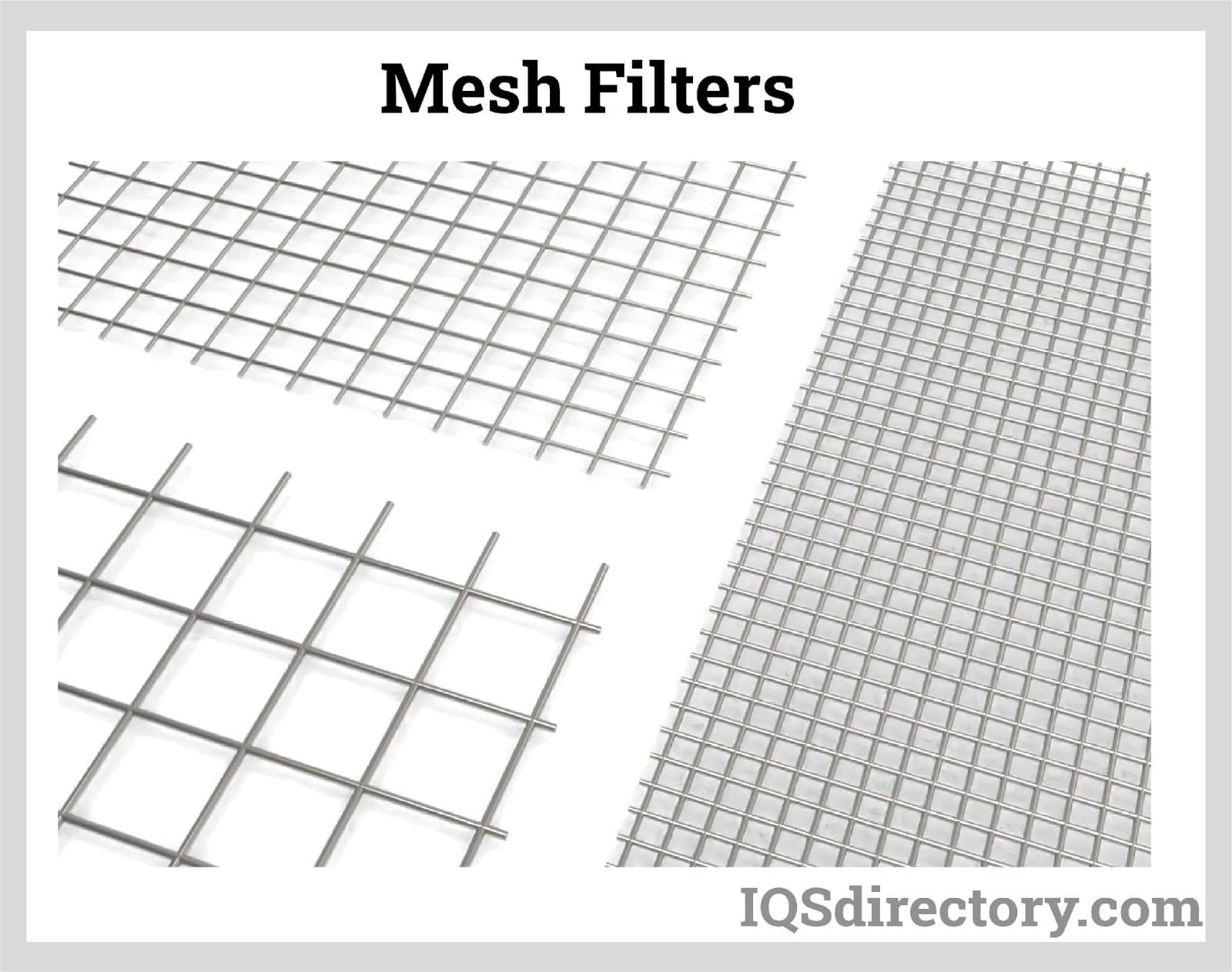

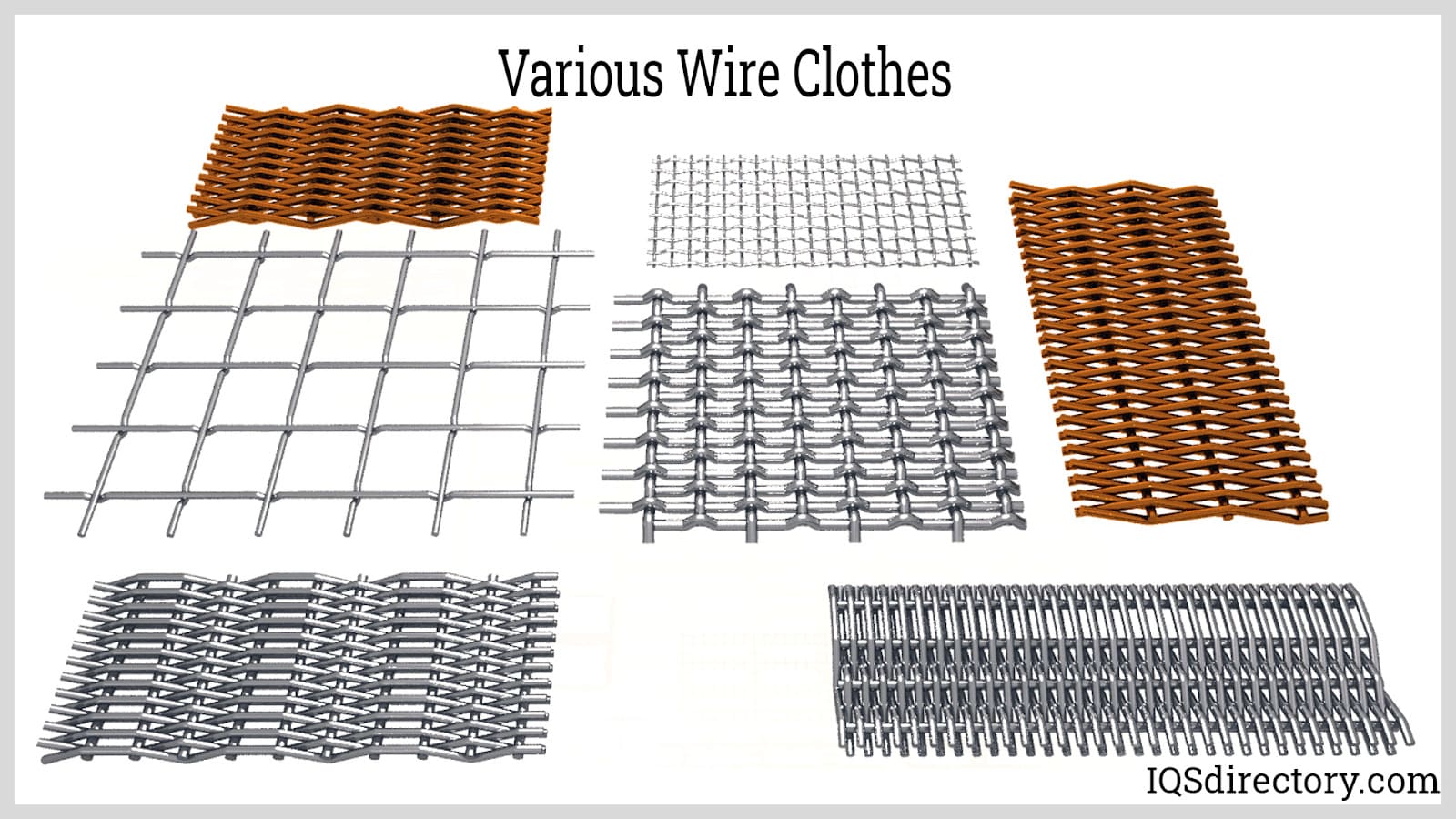

Illustrative image related to mesh types

What Advantages Do Unstructured Meshes Offer for Complex Designs?

Unstructured meshes are designed to accommodate complex geometries without adhering to a fixed grid pattern. This flexibility makes them suitable for intricate mechanical engineering simulations where detailed representation is crucial. For B2B buyers, the adaptability of unstructured meshes can lead to more accurate modeling of real-world scenarios. However, the trade-off includes higher computational costs and complexity, which may require more robust software solutions and processing power.

How Do Curvilinear Meshes Enhance Simulations in Fluid Dynamics?

Curvilinear meshes utilize a curvilinear coordinate system to arrange nodes, making them particularly effective for simulations involving curved geometries, such as in aerodynamics and fluid dynamics. They maintain some structured properties while allowing for greater geometric accuracy. B2B buyers in industries that deal with aerodynamics should consider curvilinear meshes for their enhanced performance in complex simulations. However, the implementation can be more challenging compared to traditional rectilinear meshes, requiring specialized knowledge and tools.

Key Industrial Applications of mesh types

| Industry/Sector | Specific Application of mesh types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aerodynamic simulations using structured meshes | Enhanced accuracy in predicting airflow, leading to optimized designs | Supplier’s capability to provide high-quality, precise meshes |

| Automotive | Crash simulations and structural analysis with solid meshes | Improved safety features and compliance with regulatory standards | Availability of advanced simulation software and support |

| Oil & Gas | Reservoir modeling using unstructured meshes | Better resource management and extraction efficiency | Experience in handling complex geological formations |

| Civil Engineering | Structural integrity assessments with surface meshes | Increased safety and longevity of infrastructure projects | Compliance with local building codes and standards |

| Environmental Science | Pollution dispersion modeling using curvilinear meshes | Effective environmental management and policy-making | Access to software that integrates with environmental data sources |

How are Mesh Types Applied in Aerospace for Enhanced Performance?

In the aerospace sector, structured meshes are essential for aerodynamic simulations. By accurately modeling airflow around aircraft, engineers can optimize designs for fuel efficiency and performance. The challenge lies in sourcing high-quality meshes that can accurately represent complex geometries. Buyers should ensure that suppliers can provide precise mesh generation tools and expertise to handle the intricacies of aerodynamic modeling.

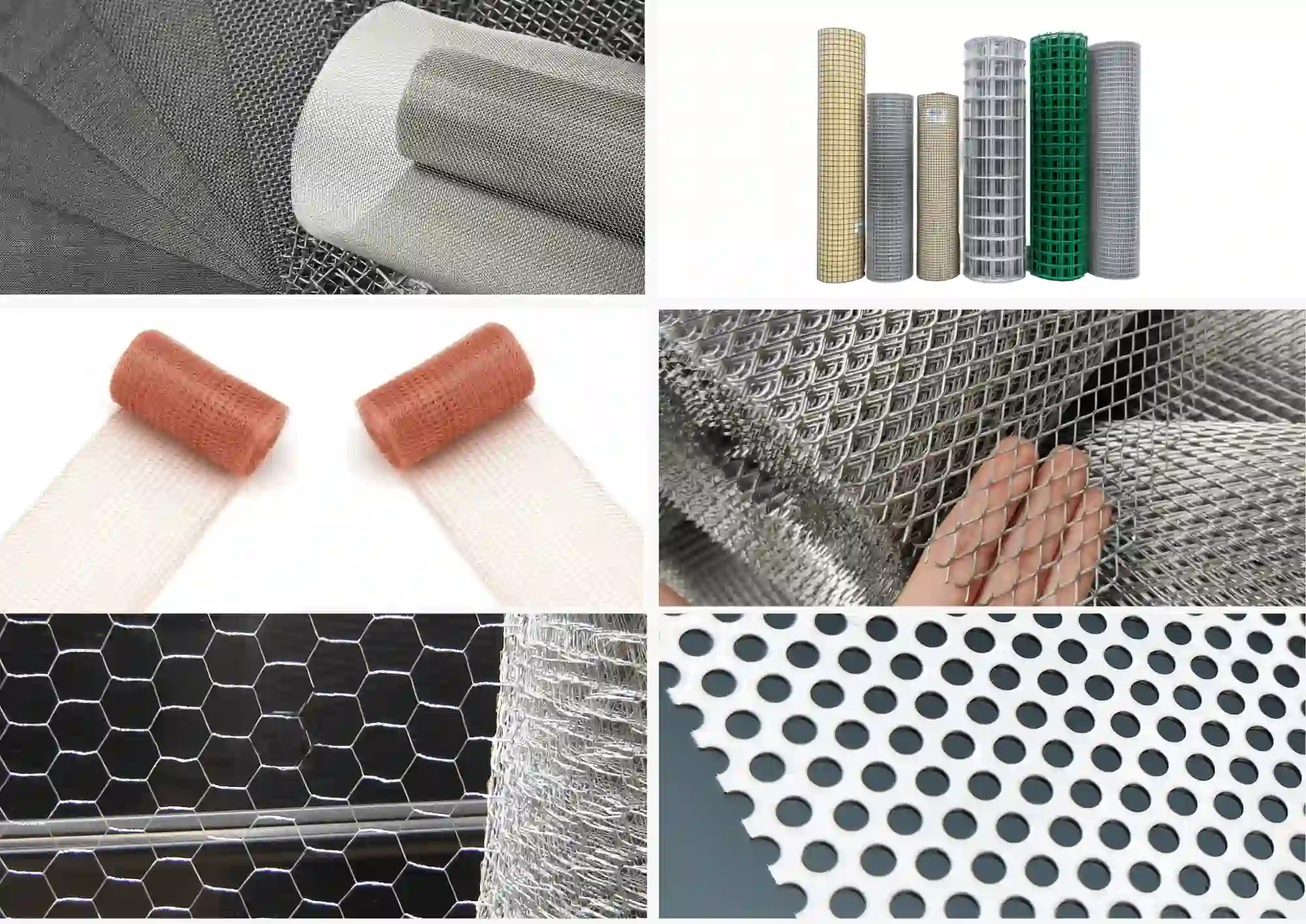

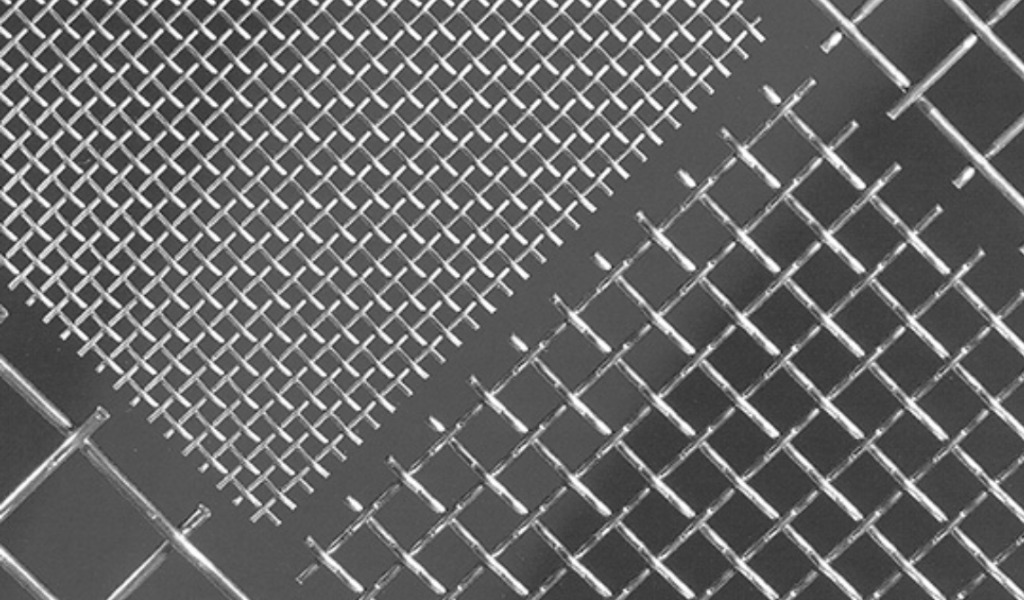

Illustrative image related to mesh types

What Role do Mesh Types Play in Automotive Safety Enhancements?

The automotive industry utilizes solid meshes for crash simulations, which are critical for developing safer vehicles. By simulating impact scenarios, manufacturers can identify weaknesses and enhance safety features before production. International buyers need to consider suppliers who offer advanced simulation capabilities and can demonstrate compliance with global safety standards, ensuring that their products meet rigorous regulations.

How are Mesh Types Beneficial in Oil & Gas Reservoir Modeling?

In the oil and gas sector, unstructured meshes are used for reservoir modeling, allowing for the representation of complex geological formations. This capability leads to more efficient resource extraction and management. Buyers should look for suppliers with experience in geological modeling and an understanding of the unique challenges presented by various terrains, particularly in regions with diverse geological structures.

Why are Surface Meshes Important in Civil Engineering Assessments?

Civil engineering relies heavily on surface meshes for conducting structural integrity assessments. These meshes help evaluate the stability of buildings and infrastructure projects, ensuring they can withstand environmental stresses. When sourcing mesh types for these applications, buyers must prioritize compliance with local building codes and the supplier’s ability to provide detailed analysis and support throughout the assessment process.

How do Curvilinear Meshes Support Environmental Science Initiatives?

Curvilinear meshes are particularly useful in environmental science for modeling pollution dispersion. These meshes allow for a more accurate representation of environmental factors and topography, leading to better management strategies. Buyers should seek suppliers who can integrate mesh generation with environmental data sources, providing comprehensive solutions for effective policy-making and environmental protection.

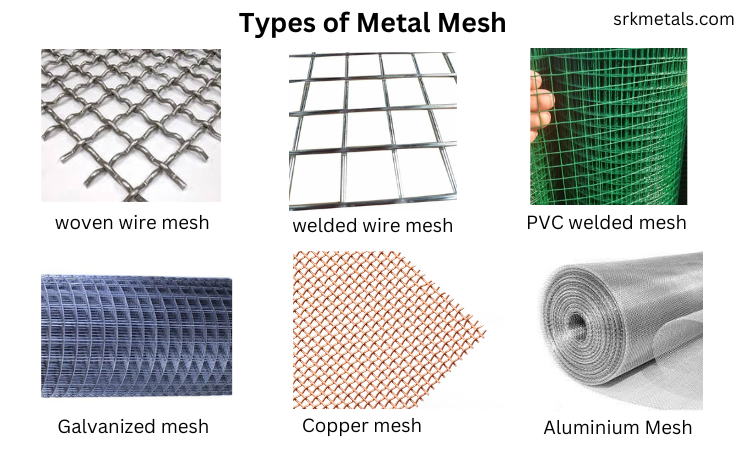

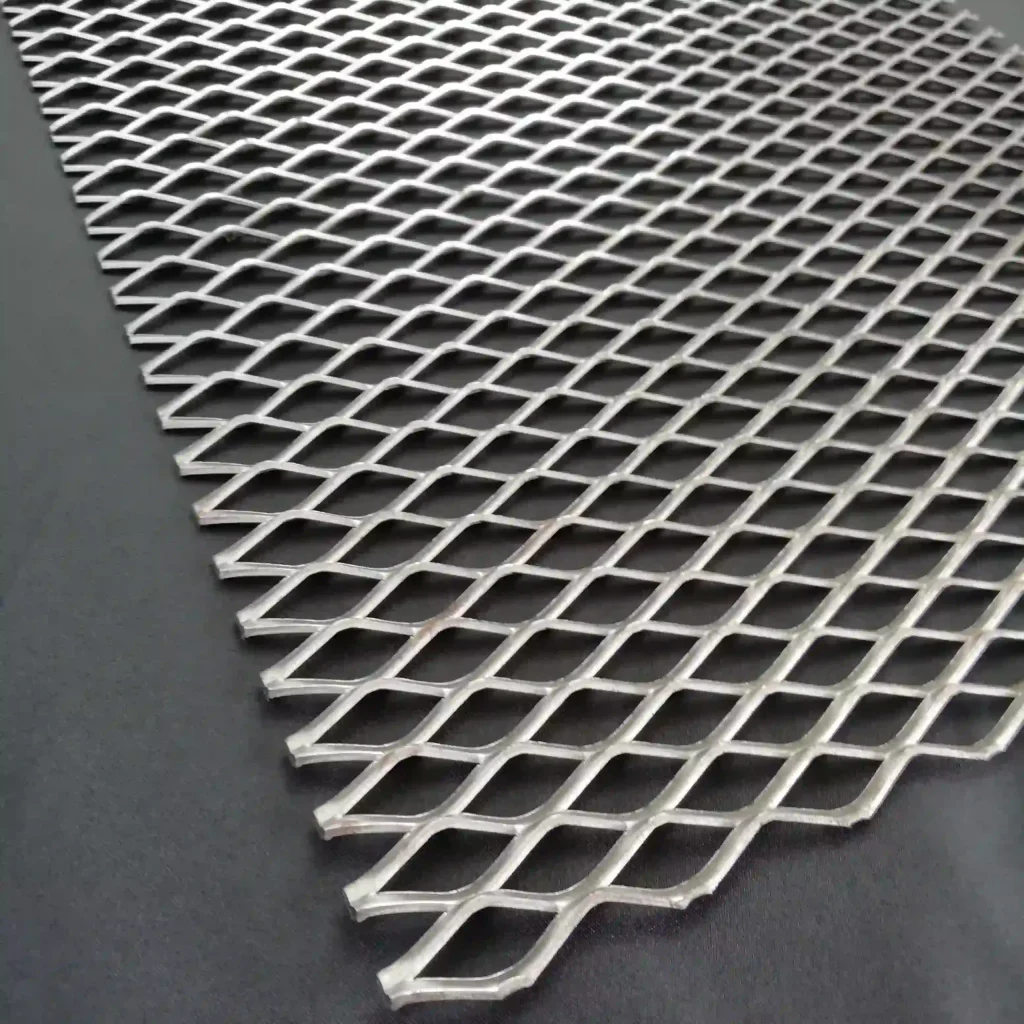

Illustrative image related to mesh types

3 Common User Pain Points for ‘mesh types’ & Their Solutions

Scenario 1: Navigating Complex Geometry with Structured Meshes

The Problem: Many B2B buyers face significant challenges when trying to apply structured meshes to complex geometries. For instance, industries such as aerospace and automotive often require precise simulations of fluid dynamics around intricate shapes. When using structured meshes, the rigid topology can lead to difficulties in accurately representing sharp features or curved surfaces. This often results in degenerate cells, which compromise the simulation’s accuracy and reliability. Buyers may find that the structured mesh does not adequately capture the nuances of their product designs, leading to potential errors in analysis and costly delays in product development.

The Solution: To effectively utilize structured meshes for complex geometries, buyers should consider employing a hybrid meshing approach. This involves integrating structured meshes with unstructured meshes in areas that demand flexibility. By using a block-structured meshing strategy, one can maintain the efficiency of structured meshes in simpler regions while allowing unstructured meshes to handle the complexities of intricate geometries. It’s also crucial to invest in advanced pre-processing software that can automate the mesh generation process. Such tools often provide features for local refinement and can seamlessly transition between mesh types, ensuring that both accuracy and computational efficiency are preserved.

Scenario 2: Quality Control Issues in Mesh Generation

The Problem: Quality control in mesh generation is a critical pain point for B2B buyers, particularly in industries like manufacturing and civil engineering. Poorly generated meshes can lead to inaccuracies in simulations, resulting in flawed product designs and increased costs. Buyers often struggle with ensuring that their meshes have the desired quality attributes, such as uniformity and absence of free edges. This is especially problematic when multiple teams are involved in the design process, as inconsistencies can emerge from different interpretations of mesh quality standards.

The Solution: To address quality control issues, B2B buyers should establish clear mesh quality standards that align with industry best practices. Implementing a comprehensive mesh validation process can significantly enhance mesh quality. This should include automated tools that check for common errors such as non-manifold edges, sharp angles, and irregular triangle sizes. Additionally, fostering collaboration among design teams through standardized templates and guidelines will help maintain consistency across different projects. Regular training sessions on the latest meshing technologies and techniques can further empower teams to produce high-quality meshes consistently.

Scenario 3: Cost Implications of Mesh Type Selection

The Problem: Selecting the appropriate mesh type can have profound cost implications for B2B buyers. For instance, while unstructured meshes offer flexibility for complex geometries, they often come with higher computational costs and longer simulation times. Buyers may find themselves torn between the accuracy offered by unstructured meshes and the efficiency of structured meshes. This dilemma can lead to budget overruns and project delays, ultimately affecting the bottom line.

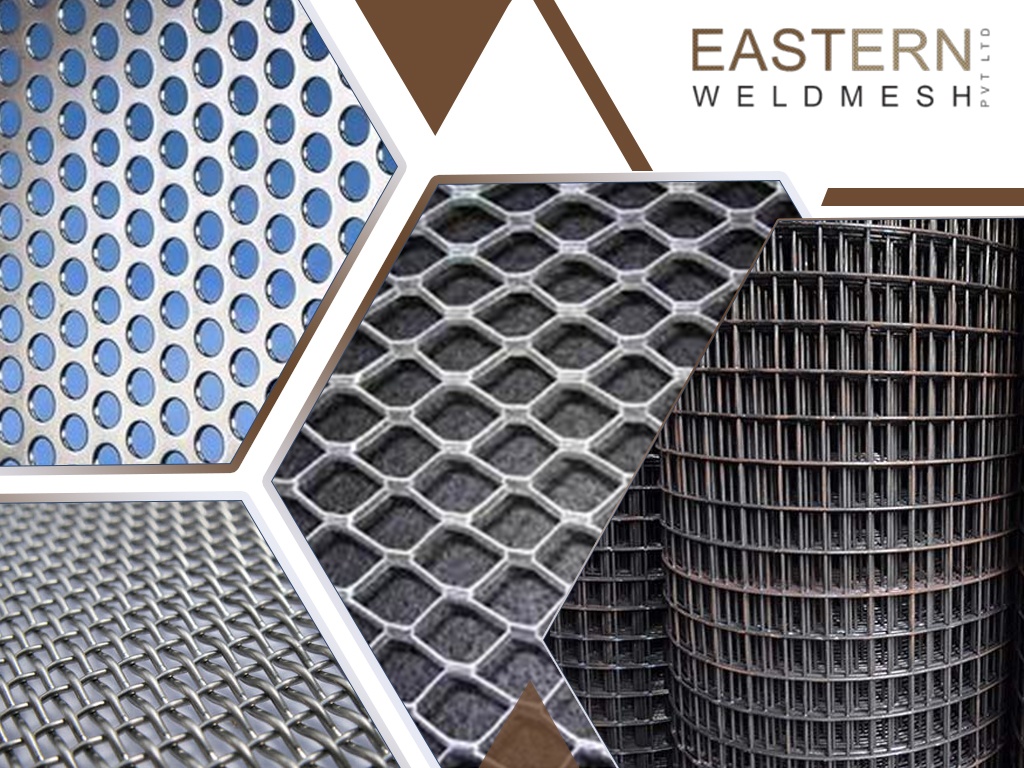

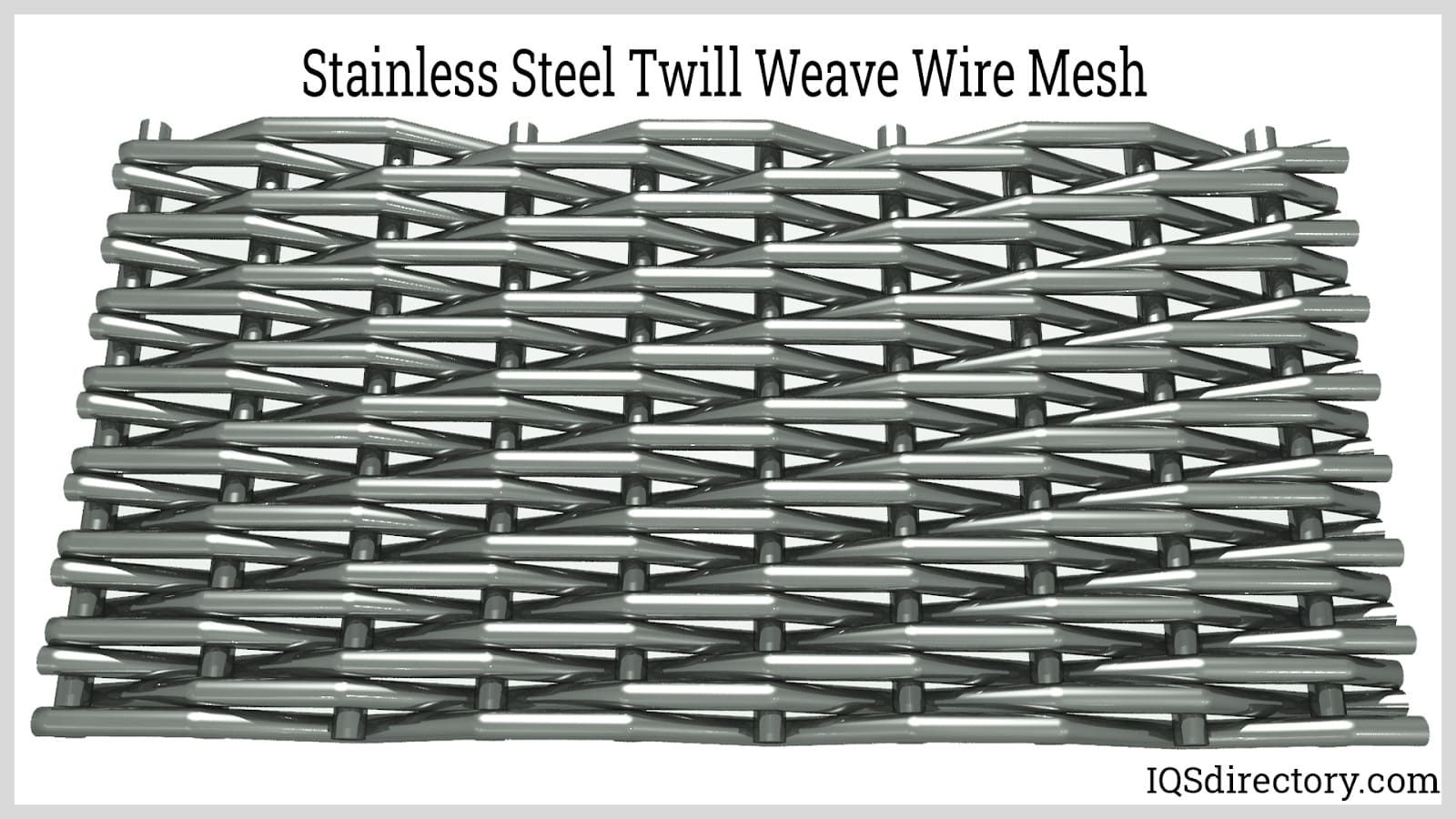

Illustrative image related to mesh types

The Solution: To mitigate cost implications, buyers should conduct a thorough cost-benefit analysis of different mesh types prior to selection. This analysis should consider not only the initial costs associated with mesh generation but also the long-term impacts on computational resources and time. Utilizing mesh optimization techniques, such as adaptive meshing, can strike a balance between accuracy and efficiency. Furthermore, leveraging cloud-based simulation services can provide access to high-performance computing resources without the need for significant capital investment in infrastructure. By being strategic in their mesh type selection, buyers can reduce costs while still achieving the desired simulation outcomes.

Strategic Material Selection Guide for mesh types

What Are the Key Materials Used for Mesh Types in B2B Applications?

When selecting materials for various mesh types, it is essential to consider properties such as temperature and pressure ratings, corrosion resistance, and overall durability. This analysis focuses on four common materials: stainless steel, nylon, aluminum, and fiberglass. Each material has unique characteristics that influence its suitability for different applications, particularly for international B2B buyers from regions like Africa, South America, the Middle East, and Europe.

How Does Stainless Steel Perform as a Mesh Material?

Stainless steel is renowned for its exceptional strength and corrosion resistance. It can withstand high temperatures and pressures, making it ideal for applications in the oil and gas, food processing, and chemical industries. The primary advantage of stainless steel mesh is its durability and long lifespan, which reduces the need for frequent replacements. However, the cost of stainless steel can be higher than other materials, and its manufacturing process may involve complex techniques such as welding and forming.

For B2B buyers, compliance with international standards like ASTM A240 for stainless steel sheets is crucial. Countries like Germany and Saudi Arabia often have stringent regulations regarding material quality, making stainless steel a preferred choice for critical applications.

What Advantages Does Nylon Offer for Mesh Applications?

Nylon mesh is lightweight, flexible, and resistant to abrasion, making it suitable for various applications, including filtration and protective barriers. It has good chemical resistance, particularly against acids and bases, but it may not perform well under extreme temperatures. The primary advantage of nylon is its cost-effectiveness and ease of manufacturing, as it can be easily molded and shaped.

Illustrative image related to mesh types

However, nylon mesh may not be suitable for high-pressure applications due to its lower tensile strength compared to metals. Buyers from regions with fluctuating temperatures, such as parts of Africa and South America, should consider nylon’s limitations in high-heat environments.

How Does Aluminum Compare as a Mesh Material?

Aluminum mesh is lightweight and has excellent corrosion resistance, making it ideal for applications in construction and automotive industries. Its thermal and electrical conductivity also adds to its versatility. The key advantage of aluminum is its balance between strength and weight, allowing for easy handling and installation.

On the downside, aluminum mesh may not withstand high temperatures as effectively as stainless steel, and its cost can vary significantly based on the alloy used. B2B buyers in Europe, particularly in Germany, may favor aluminum for its recyclability and compliance with environmental standards, but they must also consider its limitations in high-stress applications.

What Role Does Fiberglass Play in Mesh Applications?

Fiberglass mesh is known for its lightweight and high tensile strength, making it suitable for applications in construction, automotive, and aerospace industries. It is highly resistant to corrosion and does not conduct electricity, which can be advantageous in specific applications. The primary advantage of fiberglass is its cost-effectiveness and ease of installation.

However, fiberglass mesh can be brittle and may not perform well under extreme mechanical stress. For international buyers, particularly in the Middle East and South America, understanding the local climate and environmental conditions is essential, as fiberglass can degrade under UV exposure if not properly treated.

Illustrative image related to mesh types

Summary Table of Material Selection for Mesh Types

| Material | Typical Use Case for mesh types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil and gas, food processing, chemical industries | Exceptional strength and corrosion resistance | Higher cost and complex manufacturing | High |

| Nylon | Filtration, protective barriers | Cost-effective and easy to manufacture | Lower tensile strength under pressure | Low |

| Aluminum | Construction, automotive applications | Lightweight and good corrosion resistance | Limited high-temperature performance | Medium |

| Fiberglass | Construction, automotive, aerospace | Lightweight and corrosion-resistant | Brittle under mechanical stress | Low |

This guide provides a comprehensive overview of the strategic considerations for material selection in mesh types, helping B2B buyers make informed decisions tailored to their specific industry needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for mesh types

What Are the Main Stages of Manufacturing Mesh Types?

Manufacturing mesh types involves a series of well-defined stages, each critical to ensuring the quality and performance of the final product. The primary stages include material preparation, forming, assembly, and finishing.

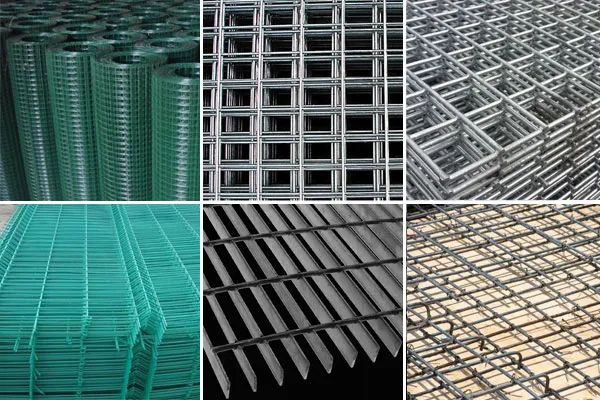

How Is Material Prepared for Mesh Production?

Material preparation is the foundational step in mesh manufacturing. The choice of material—be it metal, plastic, or composite—depends on the intended application and environmental factors. For instance, stainless steel is commonly chosen for its corrosion resistance in marine applications, while polymer meshes might be preferred for lightweight filtering solutions.

Illustrative image related to mesh types

In this stage, raw materials undergo various processes such as cutting, shearing, or extrusion to achieve the desired dimensions and properties. Quality checks are initiated at this point, ensuring that the materials meet specified standards before moving to the next stage.

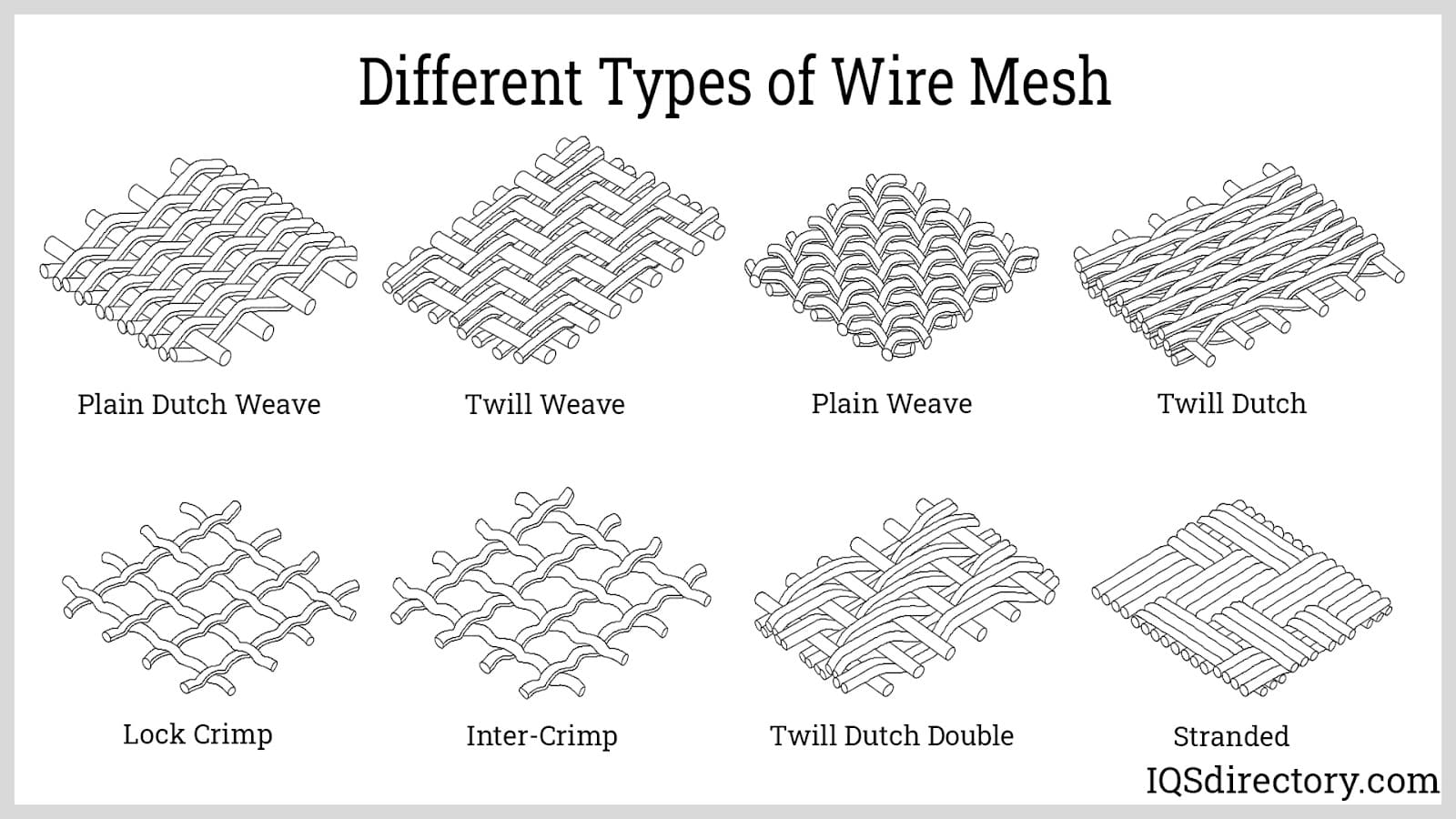

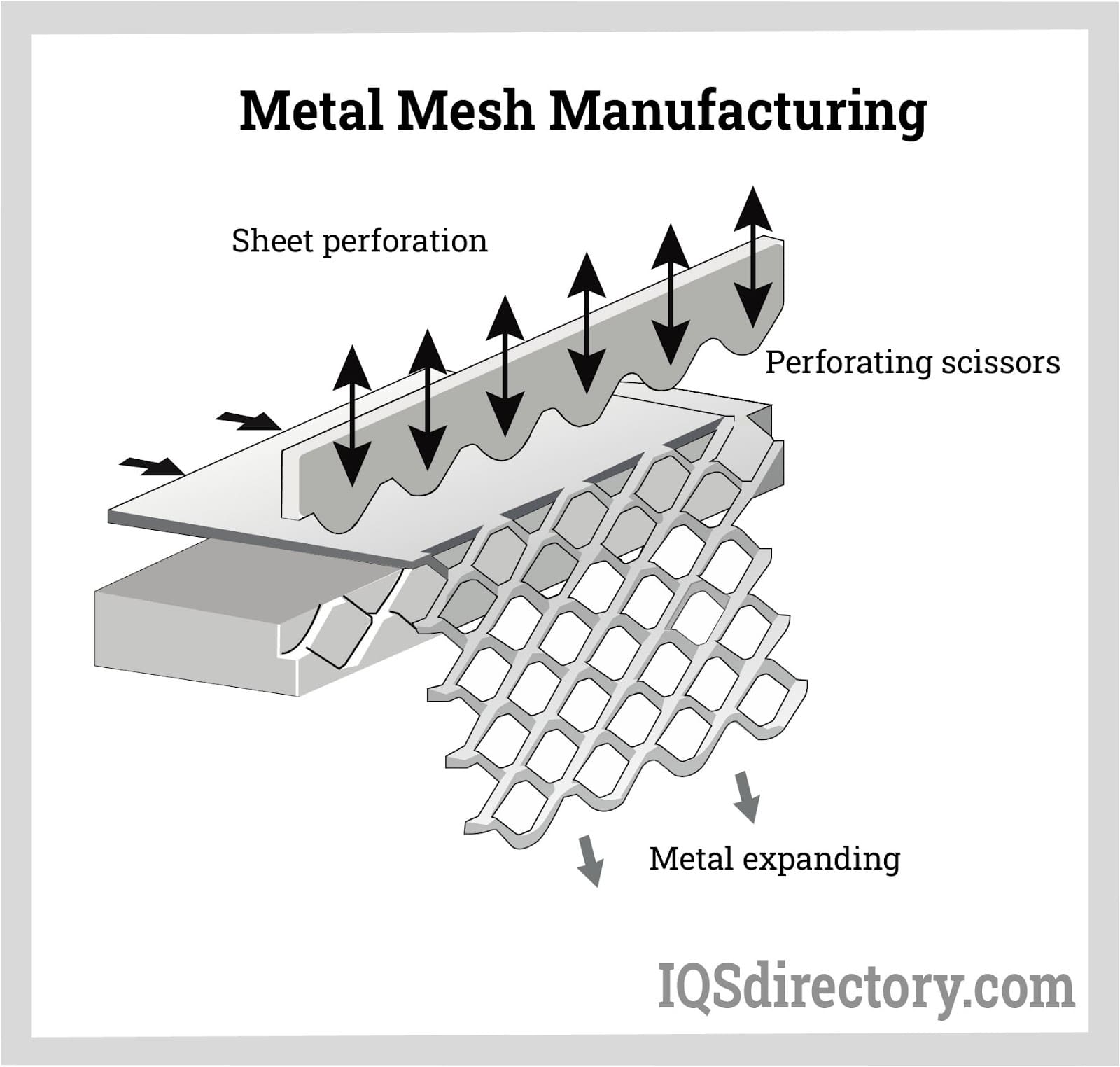

What Forming Techniques Are Commonly Used in Mesh Manufacturing?

The forming stage is crucial for creating the mesh structure. Different techniques are employed based on the type of mesh being produced:

-

Woven Mesh: This technique involves interlacing strands of material to create a grid-like structure. The weaving process can vary in tightness and pattern, impacting the mesh’s strength and flexibility.

-

Welded Mesh: In this method, wires are welded at intersections to form a robust mesh. This technique is ideal for heavy-duty applications where structural integrity is paramount.

-

Expanded Metal: This involves cutting and stretching a sheet of metal to create a mesh. It is particularly useful for applications requiring lightweight but strong materials.

-

3D Printing: An emerging technology that allows for the creation of complex mesh geometries with high precision. This method is gaining traction in industries such as aerospace and medical devices.

How Is Assembly and Finishing Done in Mesh Production?

After forming, the assembly stage may involve additional processes such as stitching, soldering, or further welding to ensure the mesh maintains its integrity during use.

The finishing stage is equally important, often involving treatments like galvanization, powder coating, or passivation to enhance the mesh’s properties, such as corrosion resistance and aesthetic appeal. These treatments not only improve durability but also ensure compliance with industry standards.

Illustrative image related to mesh types

What Quality Assurance Practices Are Essential for Mesh Types?

Quality assurance is critical in the manufacturing of mesh types, ensuring that the final products meet both international and industry-specific standards.

Which International Standards Should B2B Buyers Be Aware Of?

The ISO 9001 standard is a cornerstone of quality management systems across industries. It provides a framework for organizations to ensure consistent quality in their products and services. Additionally, industry-specific certifications, such as CE marking in Europe and API standards for oil and gas applications, are vital for demonstrating compliance with regulatory requirements.

Understanding these standards helps B2B buyers assess potential suppliers effectively.

What Are the Key Quality Control Checkpoints in Mesh Manufacturing?

Quality control (QC) checkpoints should be integrated throughout the manufacturing process:

-

Incoming Quality Control (IQC): This checkpoint verifies that the raw materials meet specified standards before production begins. This step helps prevent defects caused by subpar materials.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC ensures that each stage meets quality standards. Techniques such as visual inspections and automated measurements are commonly used.

-

Final Quality Control (FQC): The final inspection before products are shipped. This includes functional tests, dimensional checks, and aesthetic evaluations to ensure the mesh meets all requirements.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for B2B buyers, especially when sourcing internationally. Here are effective strategies:

-

Supplier Audits: Conducting on-site audits can provide insight into a supplier’s quality management practices. This helps assess whether they adhere to international standards and industry best practices.

-

Quality Reports: Requesting documentation such as inspection reports, certifications, and compliance documents can provide assurance of a supplier’s quality commitment.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s products and processes. This is particularly beneficial for buyers in regions with varying quality standards.

What Are the Nuances of Quality Certification for International B2B Buyers?

For B2B buyers, especially from Africa, South America, the Middle East, and Europe, understanding the nuances of quality certification is crucial. Different regions may have varying regulations and standards that impact product acceptance.

For instance, European buyers may prioritize CE certification for compliance with EU regulations, while Middle Eastern buyers might focus on local standards set by organizations such as the Saudi Standards, Metrology and Quality Organization (SASO).

It’s essential for buyers to communicate their specific quality requirements clearly and ensure that suppliers are equipped to meet those standards.

Conclusion: Why Is Quality Assurance Critical in Mesh Manufacturing?

In conclusion, the manufacturing processes and quality assurance measures for mesh types play a pivotal role in determining the performance and reliability of the final product. By understanding the stages of manufacturing and implementing robust QC practices, B2B buyers can ensure that they partner with suppliers who meet their quality expectations. This not only enhances product performance but also fosters long-term business relationships built on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mesh types’

To facilitate effective procurement of mesh types, this guide serves as a structured checklist for B2B buyers. Understanding the various mesh types, their applications, and how to evaluate potential suppliers is essential for making informed decisions.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline your technical requirements for the mesh types needed. This includes understanding the specific applications—such as whether you require surface mesh for fluid dynamics simulations or solid mesh for structural analysis.

– Consider the geometry: Identify if you need structured or unstructured meshes based on the complexity of your projects.

– Material and size: Specify the desired materials and dimensions to ensure compatibility with your applications.

Step 2: Research Mesh Types and Their Applications

Gain a solid understanding of the different mesh types available, including structured, unstructured, and hybrid meshes. Each type has unique characteristics that make them suitable for various applications.

– Structured Mesh: Ideal for simulations requiring high accuracy, often used in CFD.

– Unstructured Mesh: Better suited for complex geometries, providing flexibility in modeling intricate shapes.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region to gauge reliability and quality.

– Check their experience: Look for suppliers who specialize in the mesh types you require and have a proven track record.

– Request samples: Obtain mesh samples to assess quality and suitability for your specific applications.

Step 4: Verify Supplier Certifications and Quality Assurance

Ensure that potential suppliers adhere to international quality standards relevant to mesh production. Certifications can provide assurance of quality and compliance with industry regulations.

– ISO Certifications: Look for suppliers with ISO 9001 certifications, which indicate a commitment to quality management.

– Quality control processes: Inquire about their testing and quality assurance protocols to ensure the consistency and reliability of the mesh products.

Illustrative image related to mesh types

Step 5: Assess Technical Support and Customer Service

Evaluate the level of technical support and customer service offered by suppliers. A responsive supplier can provide invaluable assistance during the procurement process and post-purchase.

– Availability of experts: Check if they have specialists who can assist with technical inquiries or troubleshooting.

– Response times: Assess their responsiveness to inquiries, which can be a good indicator of their customer service quality.

Step 6: Negotiate Terms and Pricing

Once you have identified suitable suppliers, engage in negotiations regarding pricing, payment terms, and delivery schedules. This step is crucial for ensuring that the procurement aligns with your budget and timelines.

– Volume discounts: Discuss the possibility of discounts for bulk purchases.

– Lead times: Clarify lead times for delivery to ensure they meet your project deadlines.

Step 7: Finalize the Purchase and Monitor Performance

After agreeing on terms, finalize the purchase and establish a mechanism for monitoring the performance of the mesh products. This ensures that they meet the expected standards and functionality in your applications.

– Feedback loop: Create a system for providing feedback to suppliers on product performance and areas for improvement.

– Documentation: Keep thorough records of specifications, agreements, and any changes made during the procurement process for future reference.

By following this checklist, B2B buyers can streamline their procurement process for mesh types, ensuring they select the right products from reliable suppliers.

Illustrative image related to mesh types

Comprehensive Cost and Pricing Analysis for mesh types Sourcing

In the realm of sourcing mesh types, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This comprehensive analysis delves into the various cost components, pricing influencers, and actionable buyer tips that can lead to more informed purchasing decisions.

What Are the Key Cost Components in Mesh Type Sourcing?

When evaluating the costs associated with sourcing different mesh types, several core components should be taken into account:

-

Materials: The choice of materials significantly influences the overall cost. For instance, stainless steel, nylon, and fiberglass are common materials used in mesh production, each carrying different price points based on quality and availability.

-

Labor: Labor costs can vary widely based on geographical location and the complexity of the mesh manufacturing process. Skilled labor for custom mesh designs may command higher wages, impacting the total cost.

-

Manufacturing Overhead: This includes costs related to utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom tooling for specific mesh designs can be a significant upfront investment. Buyers should consider these costs, especially for bespoke projects.

-

Quality Control (QC): Ensuring that the mesh meets specified standards requires investment in quality control measures. This includes testing for durability, strength, and compliance with relevant certifications.

-

Logistics: Transportation costs can fluctuate based on distance, mode of transport, and shipping terms. Understanding Incoterms is essential to anticipate these expenses accurately.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions and competitive dynamics.

How Do Pricing Influencers Impact Mesh Costs?

Several factors can influence the pricing of mesh types:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often benefit from reduced per-unit costs. Buyers should negotiate MOQs to achieve better pricing, especially when dealing with overseas suppliers.

-

Specifications and Customization: Customized mesh solutions may incur additional costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Material Quality and Certifications: Higher quality materials and specific certifications (e.g., ISO, ASTM) can increase costs. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reliability and reputation of the supplier can affect pricing. Established suppliers may charge a premium for their assurance of quality and service.

-

Incoterms: Understanding Incoterms is vital for cost negotiation. Different terms (e.g., FOB, CIF) dictate who bears the cost and risk at various stages of shipping, impacting the total landed cost.

What Are Some Effective Buyer Tips for Cost-Efficient Sourcing?

To optimize purchasing decisions in mesh type sourcing, consider the following strategies:

-

Negotiate Effectively: Leverage volume discounts and establish long-term relationships with suppliers to secure favorable pricing.

-

Evaluate Total Cost of Ownership (TCO): Go beyond initial pricing by considering maintenance, durability, and lifecycle costs associated with the mesh type. This holistic view can lead to more cost-effective choices.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of currency fluctuations, tariffs, and import duties that may affect the final cost. Regularly review market conditions to make timely purchasing decisions.

-

Conduct Market Research: Stay informed about market trends and competitor pricing to strengthen your negotiating position. Understanding local market conditions in regions like Africa, South America, the Middle East, and Europe can provide leverage.

-

Request Samples: Before making large orders, request samples to assess quality and suitability. This can prevent costly mistakes and ensure that the chosen mesh type meets project requirements.

Conclusion

Navigating the complexities of mesh type sourcing requires a keen understanding of cost components, pricing influencers, and strategic negotiation tactics. By applying these insights, international B2B buyers can make informed decisions that enhance cost efficiency and ensure the successful procurement of mesh products.

Illustrative image related to mesh types

Disclaimer: Prices and cost structures provided herein are indicative and may vary based on market conditions, supplier capabilities, and specific buyer requirements.

Alternatives Analysis: Comparing mesh types With Other Solutions

Understanding Alternatives to Mesh Types in Computational Solutions

In the realm of computational modeling, mesh types play a crucial role in representing geometries and facilitating simulations. However, various alternative methods can achieve similar objectives, each with distinct advantages and drawbacks. B2B buyers must evaluate these options against their specific project requirements to ensure optimal outcomes.

| Comparison Aspect | Mesh Types | Finite Element Analysis (FEA) | Computational Fluid Dynamics (CFD) |

|---|---|---|---|

| Performance | High precision in complex geometries, especially with structured meshes. | Excellent for stress analysis, but may require fine meshing for accuracy. | Effective for flow simulations; may struggle with complex geometries. |

| Cost | Moderate to high due to software and expertise requirements. | Can be cost-effective for specific applications, but software licenses can add up. | Generally higher costs associated with advanced CFD software and hardware. |

| Ease of Implementation | Requires skilled personnel for optimal mesh generation and refinement. | User-friendly software available, but complex models can be challenging. | Often requires specialized training and experience to set up correctly. |

| Maintenance | Regular updates and revisions needed as models evolve. | Maintenance involves software updates and re-evaluation of models. | High maintenance due to the need for constant adjustments in simulations. |

| Best Use Case | Ideal for structural analysis in engineering and design. | Best for evaluating mechanical properties in structures. | Optimal for analyzing fluid flow and thermal dynamics in various industries. |

What Are the Advantages and Disadvantages of Finite Element Analysis (FEA)?

Finite Element Analysis (FEA) is a widely used numerical method for solving complex engineering problems. It excels in stress analysis and can effectively evaluate how structures respond to various forces. One of its primary advantages is the ability to handle complex geometries with relative ease, making it suitable for mechanical and civil engineering applications. However, the need for a fine mesh can lead to increased computational time and costs. Additionally, while FEA is user-friendly for basic models, it may present challenges for more intricate designs, necessitating skilled personnel.

Illustrative image related to mesh types

How Does Computational Fluid Dynamics (CFD) Compare as an Alternative?

Computational Fluid Dynamics (CFD) focuses on analyzing fluid flow, heat transfer, and related phenomena. It is particularly advantageous for industries such as aerospace and automotive, where understanding airflow dynamics is critical. CFD offers powerful visualization tools and can simulate various scenarios, enhancing decision-making. However, it often requires specialized knowledge and can be more expensive due to advanced software and computational power needs. Furthermore, CFD may not perform as well with complex geometries compared to mesh-based approaches.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right computational method depends on specific project requirements and objectives. B2B buyers should carefully assess the complexity of their geometries, the type of analysis required, and the resources available, including budget and expertise. Mesh types offer unique advantages in precision and adaptability, particularly for structural applications. However, alternatives like FEA and CFD may provide better solutions depending on the context. Ultimately, a thorough evaluation of each option will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for mesh types

What Are the Key Technical Properties of Different Mesh Types?

When evaluating mesh types for B2B applications, several technical properties are crucial. Understanding these specifications ensures that decision-makers can select the right mesh for their projects, balancing performance, quality, and cost.

1. Material Grade

The material grade of mesh refers to the quality and type of material used in its construction, such as stainless steel, aluminum, or polymer. Different grades offer varying levels of strength, corrosion resistance, and durability, which are essential for specific applications. For example, stainless steel mesh is ideal for environments prone to corrosion, while aluminum mesh may be preferred for lightweight applications. Selecting the appropriate material grade can significantly affect the longevity and reliability of the final product.

2. Tolerance

Tolerance defines the allowable deviation from a specified dimension in the mesh. It is critical in ensuring that the mesh fits correctly within the intended application, especially in precision engineering fields like aerospace and automotive. Tight tolerances may be necessary for high-stakes applications, while looser tolerances could suffice for less critical uses. Understanding tolerance requirements helps in minimizing waste and ensuring product quality.

Illustrative image related to mesh types

3. Mesh Density

Mesh density refers to the number of openings per unit area in a mesh. It impacts filtration efficiency, airflow, and structural integrity. In B2B contexts, selecting the right mesh density is vital for applications such as air filters, where too high a density can restrict airflow, while too low a density may fail to filter effectively. Buyers need to assess the specific performance requirements to choose the appropriate density for their needs.

4. Opening Size

The size of the openings in a mesh directly affects its functionality, determining what can pass through and what is retained. This is particularly important in industries like agriculture, food processing, and pharmaceuticals, where contamination control is paramount. Buyers should consider the application’s requirements for particle retention or fluid flow when selecting mesh opening sizes.

5. Coating or Finish

The coating or finish applied to a mesh can enhance its properties, such as corrosion resistance or aesthetic appeal. Common finishes include galvanization, powder coating, and anodizing. Understanding the benefits of different finishes is essential for buyers, as these can affect the lifespan and performance of the mesh in various environments.

What Are Common Trade Terms in the Mesh Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions involving mesh products. Here are several key terms to know:

Illustrative image related to mesh types

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the mesh industry, an OEM could provide specialized mesh products that are integrated into larger systems or machines. Understanding the role of OEMs is crucial for buyers looking for customized solutions.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. In the context of mesh types, knowing the MOQ helps businesses assess their budget and inventory needs. Suppliers often set MOQs to ensure that production and shipping costs are covered.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers requesting pricing and other details for specific products, such as mesh types. This process helps buyers compare options and negotiate favorable terms. Including detailed specifications in an RFQ can lead to more accurate and competitive quotes.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They specify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is essential for international buyers to manage risks and costs associated with importing mesh products.

5. Lead Time

Lead time refers to the time it takes from placing an order until it is delivered. In the mesh industry, lead times can vary based on production schedules and material availability. Buyers should consider lead times when planning projects to ensure timely delivery and avoid disruptions.

By understanding these properties and terms, B2B buyers can make informed decisions when selecting mesh types, enhancing the efficiency and success of their projects.

Navigating Market Dynamics and Sourcing Trends in the mesh types Sector

What Are the Key Market Trends Affecting Mesh Types in the B2B Sector?

The mesh types market is experiencing significant transformation driven by advancements in technology, changing customer expectations, and the increasing complexity of industrial applications. One of the primary global drivers is the growing demand for customized solutions across various sectors, including automotive, aerospace, and manufacturing. As industries continue to innovate, the need for both surface and solid mesh types, which offer detailed representations of complex geometries, is rising. Moreover, the integration of advanced simulation software and computational fluid dynamics (CFD) tools is facilitating the use of structured and unstructured meshes, enhancing the accuracy and efficiency of product designs.

Emerging trends such as the adoption of additive manufacturing and 3D printing are also reshaping sourcing strategies. B2B buyers are increasingly seeking suppliers who can provide not only traditional mesh types but also innovative solutions that accommodate rapid prototyping and production. In regions like Africa, South America, and the Middle East, local manufacturers are leveraging these technologies to reduce lead times and costs, thereby enhancing competitiveness in the global market. Additionally, European markets, particularly in Germany, are emphasizing precision and quality, leading to a surge in demand for high-performance mesh solutions that meet stringent regulatory standards.

How Are Sustainability and Ethical Sourcing Influencing Mesh Types Procurement?

The environmental impact of manufacturing processes is becoming a focal point for B2B buyers, particularly in the mesh types sector. As awareness of climate change and resource depletion grows, companies are under pressure to adopt sustainable practices. This includes sourcing materials that are environmentally friendly and adhering to ethical supply chain standards. Buyers are increasingly favoring suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001, which focuses on effective environmental management systems.

The introduction of “green” materials, such as biodegradable polymers or recycled metals, is gaining traction in the production of mesh types. These materials not only reduce the carbon footprint but also appeal to environmentally conscious consumers. Furthermore, the emphasis on ethical sourcing is prompting buyers to evaluate the entire supply chain, ensuring that materials are obtained responsibly and that labor practices align with international standards. By prioritizing sustainability and ethical sourcing, B2B buyers can enhance their brand reputation and appeal to a growing segment of eco-conscious customers.

Illustrative image related to mesh types

What Is the Historical Context of Mesh Types in B2B Markets?

The evolution of mesh types can be traced back to the early days of computational modeling and engineering design. Initially, meshes were rudimentary and primarily used for basic geometric representation. However, advancements in computer technology and software capabilities have significantly transformed the landscape. The introduction of sophisticated algorithms and modeling tools has allowed for the development of complex mesh types, including structured, unstructured, and curvilinear meshes, which are crucial for accurate simulations in engineering applications.

Over the decades, the focus has shifted from simple mesh generation to the optimization of mesh quality and performance. As industries demand higher precision and faster turnaround times, mesh generation techniques have evolved to meet these needs. Today, the mesh types market not only reflects technological advancements but also addresses the increasing requirements for sustainability and ethical practices, marking a significant shift in how B2B buyers approach sourcing and procurement in this sector.

Frequently Asked Questions (FAQs) for B2B Buyers of mesh types

-

How do I choose the right mesh type for my project?

Selecting the appropriate mesh type depends on various factors, including the complexity of the geometry, the intended application, and the required precision. For simpler geometries, structured meshes may be ideal due to their systematic arrangement and ease of use. In contrast, for complex shapes, unstructured meshes provide the flexibility needed to accurately represent intricate details. Consider conducting a thorough analysis of your project’s requirements and consulting with potential suppliers to ensure you select a mesh type that meets your specific needs. -

What is the best mesh type for computational fluid dynamics (CFD) simulations?

For CFD simulations, structured meshes are often preferred due to their organized topology, which facilitates efficient numerical computations. However, if the geometry is complex, unstructured meshes may be necessary to capture the details accurately. Tetrahedral and polyhedral meshes are commonly used in these applications. It’s essential to evaluate the simulation requirements, including mesh refinement and computational resources, to determine the most suitable mesh type for your CFD needs. -

What customization options are available when sourcing mesh types?

Many suppliers offer customization options for mesh types, allowing you to specify dimensions, materials, and cell shapes to meet your project requirements. When discussing your needs with suppliers, be clear about your application and any specific performance criteria. Additionally, inquire about the supplier’s capabilities for producing custom meshes, including their design tools and lead times, to ensure they can accommodate your requests effectively. -

What are the minimum order quantities (MOQ) for mesh products?

Minimum order quantities (MOQ) can vary significantly between suppliers and depend on the type of mesh and its specifications. Some suppliers may offer flexible MOQs for standard products, while custom meshes might have higher MOQs due to the specialized manufacturing processes involved. To avoid potential delays, clarify the MOQ with your supplier during the initial discussions and explore options for smaller test orders if necessary. -

How do I vet suppliers for mesh types?

Vetting suppliers is crucial to ensure product quality and reliability. Start by researching their industry reputation, customer reviews, and case studies. Verify their certifications and compliance with international standards, especially if you’re sourcing from regions with different regulatory environments. Additionally, request samples and assess their quality, and consider visiting their manufacturing facility if feasible. Establishing a solid communication channel with the supplier will also help gauge their responsiveness and professionalism. -

What payment terms should I expect when sourcing mesh types internationally?

Payment terms can vary widely based on the supplier and the nature of the transaction. Common terms include upfront deposits, net 30, or net 60 days after delivery. For international transactions, consider using secure payment methods, such as letters of credit or escrow services, to mitigate risks. Always clarify payment terms before placing an order to avoid misunderstandings and ensure a smooth transaction process. -

What quality assurance measures should I look for when sourcing mesh types?

Quality assurance is critical when sourcing mesh types. Look for suppliers who implement rigorous QA processes, including inspections at various production stages and adherence to international standards such as ISO certifications. Request documentation of their quality control procedures and any relevant testing results. Additionally, consider suppliers who offer warranties or guarantees on their products, as this can be an indicator of their commitment to quality. -

What logistics considerations should I keep in mind when importing mesh types?

When importing mesh types, consider logistics factors such as shipping methods, lead times, and customs regulations. It’s essential to work with suppliers who have experience in international shipping and can provide clear timelines. Verify that the supplier can assist with necessary documentation and compliance with local import laws. Additionally, factor in potential duties and taxes that may affect the total cost, and consider using a freight forwarder to streamline the logistics process.

Top 7 Mesh Types Manufacturers & Suppliers List

1. Pre-Scient – Mesh Solutions

Domain: pre-scient.com

Registered: 2000 (25 years)

Introduction: Mesh is a network consisting of cells and points used in reverse engineering and mechanical design. It involves converting a set of points into a polygonal model with vertices, edges, and faces. Mesh can take various shapes and sizes, with each cell representing an individual solution contributing to the overall mesh solution. Types of meshing include Surface Mesh and Solid Mesh, as well as Struct…

2. Autodesk – Molding Process Analysis

Domain: help.autodesk.com

Registered: 1989 (36 years)

Introduction: This company, Autodesk – Molding Process Analysis, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. SOLIDWORKS – Mesh Types Overview

Domain: help.solidworks.com

Registered: 1995 (30 years)

Introduction: Mesh Types in SOLIDWORKS 2021 include: 1. Solid Mesh: Created with tetrahedral 3D solid elements for bulky objects. 2. Shell Mesh: Automatically created for sheet metals with uniform thickness, located at the mid-surface. 3. Beam Mesh: Utilizes beam elements for structural members, capable of resisting various loads. 4. Mixed Mesh: Used when different geometries are present in the model.

4. Axom – Mesh Types Overview

Domain: axom.readthedocs.io

Introduction: Mesh Types in Axom are classified based on their Geometry and Topology representations: Implicit, Explicit, and Semi-Implicit. The taxonomy includes: 1. Curvilinear Mesh: explicit Geometry, implicit Topology; allows for bodies of arbitrary shape. 2. Rectilinear Mesh: semi-implicit Geometry, implicit Topology; Nodes aligned with Cartesian axes, spacing can vary. 3. Uniform Mesh: implicit Geometry a…

5. CFD Land – Mesh Types Overview

Domain: cfdland.com

Registered: 2024 (1 years)

Introduction: Mesh Types in CFD: Structured Mesh, Unstructured Mesh, Hybrid Mesh; Characteristics: Structured meshes have a grid-like arrangement, unstructured meshes use irregularly shaped cells, hybrid meshes combine both methods; Applications: Structured meshes for simpler geometries, unstructured meshes for complex geometries, hybrid meshes for precision and flexibility; Importance: Mesh quality impacts acc…

6. Altair – HyperMesh 2022

Domain: 2022.help.altair.com

Registered: 1992 (33 years)

Introduction: HyperMesh 2022 offers various mesh types for creating finite element models, including: 2D Meshing (surface or shell mesh for two-dimensional parts), Automatic Meshing (generates mesh of plate elements using surface geometry), 1D Meshing (for connectors like bolts), SPH Meshing (for analyzing large deformations in fluids), and 3D Meshing (solid meshing for fully 3D objects). Key features include m…

7. COMSOL – Multiphysics Meshing Solutions

Domain: comsol.com

Registered: 1992 (33 years)

Introduction: COMSOL Multiphysics offers various element types for meshing geometries in finite element problems, including tetrahedral (tets), brick, prism, and pyramid elements. Tetrahedral elements are the default and can mesh any 3D volume, supporting adaptive mesh refinement. Brick and prism elements can reduce the number of elements in a mesh and are used when the solution varies gradually in certain dire…

Strategic Sourcing Conclusion and Outlook for mesh types

As the landscape of mesh types continues to evolve, strategic sourcing has emerged as a critical component for B2B buyers looking to optimize their supply chains and product development processes. Understanding the distinctions between surface and solid meshes, as well as structured and unstructured grids, enables international buyers to make informed decisions that align with their specific engineering needs. The right mesh type can significantly impact the efficiency of simulations and the accuracy of results, ultimately influencing product performance and time-to-market.

For businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe, leveraging advanced meshing technologies can lead to competitive advantages. Companies can enhance their product offerings by selecting mesh types that best suit their operational requirements, whether that be for complex geometries or more straightforward applications.

Looking ahead, the demand for innovative mesh solutions will only grow as industries continue to prioritize efficiency and precision. International B2B buyers are encouraged to engage with suppliers who not only understand the technical specifications of mesh types but also offer tailored solutions that support long-term strategic goals. By embracing this approach, businesses can position themselves at the forefront of technological advancement and market leadership.

Illustrative image related to mesh types

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.