Pyrex Oil Burner Pipe: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for pyrex oil burner pipe

In the ever-evolving landscape of smoking accessories, sourcing high-quality Pyrex oil burner pipes presents a unique set of challenges for international B2B buyers. With the growing demand for durable and aesthetically appealing products, businesses must navigate the complexities of supplier selection, pricing structures, and market trends across diverse regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide is designed to empower buyers by providing valuable insights into various types of Pyrex oil burner pipes, their applications, and essential considerations for vetting suppliers effectively.

Within this guide, you will find an in-depth exploration of the different styles and designs of Pyrex oil burner pipes, emphasizing durability and functionality. We will discuss the importance of high-quality materials, particularly borosilicate glass, which is known for its resistance to thermal shock and breakage. Additionally, the guide will outline key factors influencing cost, including manufacturing processes, shipping logistics, and market demand.

By leveraging the knowledge provided in this guide, B2B buyers can make informed purchasing decisions that not only meet their business needs but also enhance customer satisfaction. Whether you are a distributor, retailer, or manufacturer, understanding the global market for Pyrex oil burner pipes will enable you to stay competitive and responsive to consumer preferences.

Understanding pyrex oil burner pipe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Straight Pipe | Simple design, typically 4-7 inches in length | Retail, wholesale, event giveaways | Pros: Affordable, easy to use. Cons: Less durable than reinforced options. |

| L-Shaped Bent Pipe | Angled design for improved ergonomics | Specialty smoke shops, online retailers | Pros: Comfortable grip, unique design. Cons: Slightly more complex to manufacture. |

| Jumbo Oil Burner Pipe | Larger size (9-10 inches), enhanced grip | High-end retail, exhibitions, gifting | Pros: Better handling, larger capacity. Cons: Higher shipping costs due to size. |

| Colorful Pyrex Oil Burner | Vibrant colors and designs | Trendy shops, online marketplaces | Pros: Attractive for younger consumers, unique branding opportunities. Cons: May not appeal to all demographics. |

| Unbreakable Reinforced Pipe | Made from specially reinforced glass | High-volume distributors, export markets | Pros: Exceptional durability, reduces replacement costs. Cons: Higher initial investment. |

What Are the Key Characteristics of Standard Straight Pipes?

Standard straight pipes are the most common type of pyrex oil burner, typically ranging from 4 to 7 inches in length. Their simplicity makes them an ideal choice for businesses looking for cost-effective options. They are easy to use and can be produced in bulk, making them suitable for retail and wholesale applications. However, their fragility compared to reinforced models can lead to higher replacement rates, impacting long-term profitability for businesses.

Why Choose L-Shaped Bent Pipes for Your Inventory?

L-shaped bent pipes feature an ergonomic design that allows users to hold the pipe comfortably while vaporizing oils. This type is particularly appealing to specialty smoke shops that want to differentiate their offerings. While they may require more intricate manufacturing processes, the unique design can attract a niche market willing to pay a premium for comfort and aesthetics. However, businesses must consider the potential complexities in stocking various designs.

What Advantages Do Jumbo Oil Burner Pipes Offer?

Jumbo oil burner pipes are larger, typically ranging from 9 to 10 inches, providing an enhanced grip and larger capacity for vaporizing materials. These pipes cater to high-end retail markets and are excellent for exhibitions or gifting due to their impressive size. While they are more expensive to produce and ship, their appeal lies in their functionality and presence, making them an attractive choice for retailers aiming for a premium product line.

How Do Colorful Pyrex Oil Burners Stand Out?

Colorful pyrex oil burners are designed with vibrant colors and patterns, making them particularly appealing to younger consumers and trend-focused markets. They are ideal for trendy smoke shops and online marketplaces that aim to attract a diverse clientele. While their aesthetic appeal can enhance branding opportunities, businesses must keep in mind that such designs may not resonate with all customer demographics, potentially limiting their market reach.

What Makes Unbreakable Reinforced Pipes a Smart Investment?

Unbreakable reinforced pipes are crafted from specially designed glass that can withstand impacts and thermal stress, making them exceptionally durable. This type is ideal for high-volume distributors and export markets, as they reduce the frequency of replacements, ultimately lowering long-term costs. While the initial investment may be higher, the durability and reliability of these pipes can significantly enhance customer satisfaction and loyalty, making them a wise choice for businesses focused on quality.

Key Industrial Applications of pyrex oil burner pipe

| Industry/Sector | Specific Application of Pyrex Oil Burner Pipe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Cannabis Industry | Vaporization of cannabis concentrates | Enhances product experience by providing efficient vaporization | Ensure compliance with local regulations and quality standards |

| Chemical Manufacturing | Laboratory use for heating and mixing chemicals | Facilitates precise temperature control and reduces contamination | Source from reputable suppliers to ensure material integrity |

| Aromatherapy & Wellness | Diffusion of essential oils | Improves product offerings with high-quality, durable equipment | Look for customization options and bulk purchasing discounts |

| Food & Beverage | Infusion of flavors in oils and extracts | Expands product range and increases customer satisfaction | Consider heat resistance and easy cleaning features |

| Artisanal Crafting | Creation of unique glass pieces | Supports creativity and unique product differentiation | Focus on sourcing from skilled artisans for quality craftsmanship |

How is Pyrex Oil Burner Pipe Used in the Cannabis Industry?

In the cannabis industry, Pyrex oil burner pipes are essential for vaporizing concentrates, which provides users with a cleaner and more potent experience. These pipes are made from high-quality borosilicate glass that can withstand high temperatures without cracking, ensuring a longer lifespan and reducing the need for replacements. For international buyers, especially in regions like Africa and South America, it is crucial to source products that comply with local laws regarding cannabis use and distribution.

What Role Does Pyrex Oil Burner Pipe Play in Chemical Manufacturing?

In the chemical manufacturing sector, Pyrex oil burner pipes are utilized in laboratories for heating and mixing various chemicals. The durability and thermal resistance of these pipes help maintain precise temperature control while minimizing contamination risks. For B2B buyers in the Middle East and Europe, sourcing pipes that meet stringent safety and quality standards is vital to ensure compliance with industry regulations and to protect laboratory personnel.

How is Pyrex Oil Burner Pipe Beneficial for Aromatherapy and Wellness?

Aromatherapy and wellness businesses use Pyrex oil burner pipes for the diffusion of essential oils. These pipes allow for efficient heating, which enhances the aromatic experience for users. Businesses looking to expand their offerings should consider sourcing high-quality, durable pipes that can withstand regular use. International buyers should also explore customization options to align with their brand aesthetics and customer preferences.

What is the Application of Pyrex Oil Burner Pipe in Food & Beverage?

In the food and beverage industry, Pyrex oil burner pipes are used for infusing oils and extracts with various flavors. This application helps businesses create unique products that cater to consumer trends. When sourcing these pipes, it’s essential to consider features like heat resistance and ease of cleaning, as they directly impact the efficiency of production processes. Buyers from regions like Africa and South America should also evaluate suppliers for their ability to meet local food safety standards.

How Does Pyrex Oil Burner Pipe Support Artisanal Crafting?

Artisans often use Pyrex oil burner pipes to create unique glass pieces, offering a distinctive edge in their product lines. The ability to withstand high temperatures allows for greater creativity in crafting. For B2B buyers focused on artisanal products, sourcing from skilled artisans ensures a high level of craftsmanship and quality. Additionally, buyers should consider the supplier’s reputation and the availability of bulk purchasing options to maximize cost-effectiveness.

Illustrative image related to pyrex oil burner pipe

3 Common User Pain Points for ‘pyrex oil burner pipe’ & Their Solutions

Scenario 1: Fragility Concerns with Pyrex Oil Burner Pipes

The Problem: Many B2B buyers face the recurring challenge of sourcing durable oil burner pipes that can withstand the rigors of daily use. Fragility is a significant concern, especially when dealing with international shipping where pipes are susceptible to breakage during transit. Buyers often report that they receive products that crack or shatter upon first use, leading to increased costs for replacements and delays in fulfilling customer orders.

The Solution: To mitigate fragility issues, it’s essential for buyers to focus on sourcing pipes made from high-grade borosilicate glass, known for its resistance to thermal shock. When selecting suppliers, prioritize those who offer a clear warranty or guarantee on their products’ durability. It is also beneficial to request samples before placing bulk orders to test the pipes’ resilience firsthand. Additionally, consider using reinforced or “unbreakable” models that are designed to withstand drops and impacts. Packaging is another critical factor; ensure that your supplier uses adequate cushioning and protective materials to prevent damage during shipping. By taking these steps, buyers can ensure they receive reliable products that meet their quality standards.

Scenario 2: Limited Variety and Customization Options

The Problem: B2B buyers often encounter a limited selection of pyrex oil burner pipes, which can restrict their ability to cater to diverse customer preferences. For instance, a buyer targeting different markets in Africa and Europe may find that specific styles, sizes, or colors are not available, hindering their ability to attract and retain customers who seek variety.

The Solution: To overcome this limitation, buyers should seek out suppliers who provide extensive customization options. When evaluating suppliers, inquire about their ability to create bespoke designs or color variations that align with your brand identity and customer preferences. Additionally, consider forming partnerships with manufacturers who specialize in custom orders and can offer competitive pricing for bulk purchases. Utilizing online platforms that aggregate multiple suppliers can also broaden your selection. Engage in market research to identify trending styles and demands in various regions, allowing you to adjust your offerings proactively. By prioritizing variety and customization, you can enhance your market appeal and better serve your customer base.

Illustrative image related to pyrex oil burner pipe

Scenario 3: Navigating Quality Control and Sourcing Challenges

The Problem: Quality control is a pressing issue for B2B buyers, particularly when sourcing pyrex oil burner pipes from international suppliers. Inconsistent quality can lead to dissatisfaction among end-users, damaging the buyer’s reputation and profitability. Buyers may struggle to verify the quality of materials used and the manufacturing processes employed, leading to uncertainty about the products they receive.

The Solution: To navigate these challenges, establish stringent quality control measures when selecting suppliers. Conduct thorough background checks on potential manufacturers, including reviewing their production processes and materials used. Request certifications or documentation proving that the glass is high-grade borosilicate and compliant with safety standards. Implement a system for regular audits or quality checks of incoming shipments to ensure consistency. Building strong relationships with trusted suppliers can also facilitate better communication regarding quality expectations. Consider joining industry trade shows or forums to connect with reputable manufacturers who prioritize quality. By taking proactive steps in quality assurance, buyers can significantly reduce the risk of receiving subpar products and maintain their business integrity.

Strategic Material Selection Guide for pyrex oil burner pipe

What Are the Key Materials Used in Pyrex Oil Burner Pipes?

When selecting materials for pyrex oil burner pipes, it is essential to consider their properties, advantages, and limitations. The most common materials used include borosilicate glass, tempered glass, ceramic, and stainless steel. Each material has unique characteristics that affect performance, durability, and suitability for specific applications.

Illustrative image related to pyrex oil burner pipe

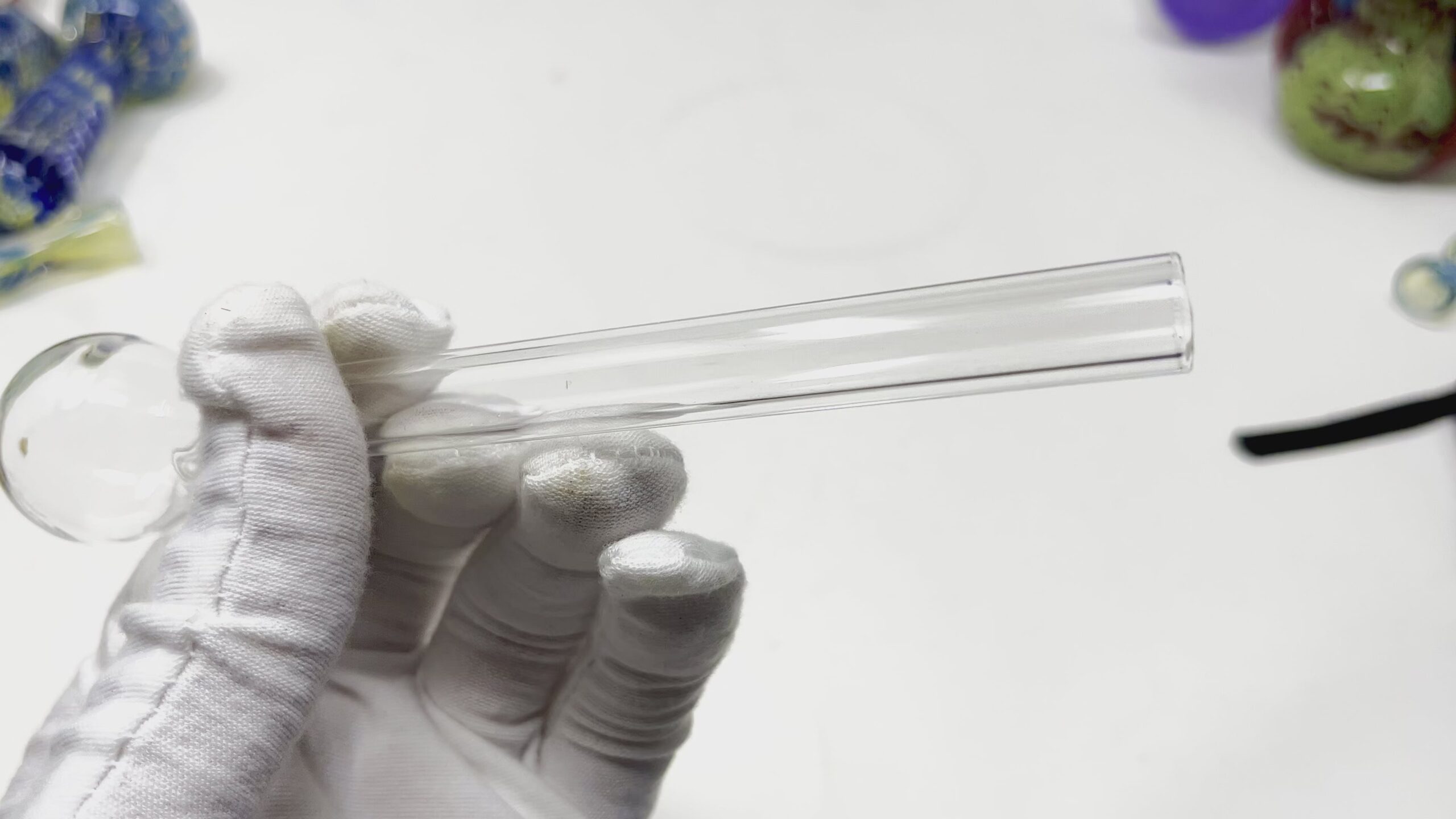

How Does Borosilicate Glass Perform in Pyrex Oil Burner Pipes?

Borosilicate glass is the primary material used in high-quality pyrex oil burner pipes. Known for its exceptional thermal resistance, borosilicate glass can withstand rapid temperature changes without cracking, making it ideal for vaporizing concentrates. It has a high-temperature rating, typically up to 500°C, and excellent chemical resistance, allowing it to handle various oils and solvents without degradation.

Pros: Its durability and thermal shock resistance make it a top choice for everyday use. Additionally, it can be manufactured in various shapes and sizes, catering to diverse consumer preferences.

Cons: While borosilicate glass is generally more expensive than standard glass, the long-term savings from reduced breakage can offset the initial investment. Manufacturing complexity can also increase costs, especially for custom designs.

Impact on Application: Due to its compatibility with high temperatures and various oils, borosilicate glass is suitable for both personal and commercial use, appealing to B2B buyers in sectors like retail and hospitality.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers in regions like Africa and South America should ensure that suppliers meet these standards to guarantee product safety and reliability.

What Role Does Tempered Glass Play in Pyrex Oil Burner Pipes?

Tempered glass is another option for pyrex oil burner pipes, known for its strength and resistance to thermal stress. It is created through a heating and rapid cooling process, which enhances its durability.

Pros: The primary advantage of tempered glass is its increased resistance to breakage compared to standard glass. It is also lighter, making it easier to handle.

Cons: However, tempered glass has a lower thermal resistance compared to borosilicate glass, making it less suitable for high-temperature applications. It can also be more challenging to manufacture into intricate designs.

Impact on Application: Tempered glass pipes are suitable for casual use, but they may not be ideal for high-performance applications requiring consistent heat exposure.

Considerations for International Buyers: Buyers should verify that tempered glass products meet local safety standards, especially in regions with strict regulations.

How Do Ceramic Materials Compare in Pyrex Oil Burner Pipes?

Ceramic materials offer a different approach to pyrex oil burner pipes, providing excellent heat retention and aesthetic appeal.

Pros: Ceramics can withstand high temperatures and are often available in various colors and designs, appealing to consumers looking for unique products.

Cons: The brittleness of ceramics makes them more susceptible to breakage compared to glass options. Additionally, they may not provide the same level of thermal shock resistance.

Impact on Application: Ceramic pipes are best suited for decorative purposes or occasional use rather than for daily, high-intensity applications.

Considerations for International Buyers: Buyers should be aware of the potential for variations in quality and ensure that ceramics comply with safety standards to avoid issues related to lead or other harmful substances.

What Advantages Does Stainless Steel Offer in Pyrex Oil Burner Pipes?

Stainless steel is increasingly being used in the design of oil burner pipes, particularly as a structural component or for hybrid designs.

Pros: Stainless steel is incredibly durable, resistant to corrosion, and can withstand high temperatures. It offers a modern aesthetic and is easy to clean.

Illustrative image related to pyrex oil burner pipe

Cons: However, stainless steel does not provide the same flavor purity as glass or ceramic, which may be a concern for users who prioritize taste.

Impact on Application: Stainless steel pipes are suitable for users looking for durability and ease of maintenance, making them a viable option for commercial settings.

Considerations for International Buyers: Buyers should ensure that stainless steel products are made from food-grade materials to comply with health and safety regulations.

Illustrative image related to pyrex oil burner pipe

Summary Table of Material Properties for Pyrex Oil Burner Pipes

| Material | Typical Use Case for pyrex oil burner pipe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Borosilicate Glass | High-performance daily use | Excellent thermal shock resistance | Higher initial cost | Medium |

| Tempered Glass | Casual use | Increased strength | Lower thermal resistance | Medium |

| Ceramic | Decorative or occasional use | Unique designs and heat retention | Brittle and prone to breakage | Medium |

| Stainless Steel | Durable and easy-to-clean applications | Corrosion-resistant and durable | May compromise flavor purity | High |

This guide provides a comprehensive overview of the materials used in pyrex oil burner pipes, helping international B2B buyers make informed decisions based on performance, durability, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pyrex oil burner pipe

What Are the Key Stages in the Manufacturing Process of Pyrex Oil Burner Pipes?

The manufacturing of Pyrex oil burner pipes involves several critical stages that ensure the final product meets the high standards required for safety, durability, and functionality. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Pyrex Oil Burner Pipes?

The first step in the manufacturing process is the preparation of borosilicate glass, known for its exceptional thermal resistance and strength. High-quality raw materials, including silica sand, boron trioxide, and soda ash, are sourced. These materials are then mixed in precise ratios and melted at high temperatures in a furnace. The molten glass is carefully monitored to ensure uniformity, as any inconsistencies can lead to weaknesses in the final product.

What Techniques Are Used for Forming Pyrex Oil Burner Pipes?

Once the glass is prepared, the forming process begins. This typically involves techniques such as blow molding and hand-blowing. In blow molding, air is introduced into the molten glass to shape it into the desired pipe design. Hand-blowing allows for intricate designs and variations, making each piece unique. Automated machines may also be employed for mass production, ensuring consistency in size and shape across batches.

How Is the Assembly Process Conducted for Pyrex Oil Burner Pipes?

After forming, the various components of the oil burner pipe, such as the bowl and stem, are assembled. This may involve additional heating to soften the glass at the connection points, allowing for a seamless bond. The assembly must be performed with precision to ensure that all parts fit correctly, as any misalignment could affect the pipe’s functionality.

What Finishing Techniques Are Applied to Pyrex Oil Burner Pipes?

The finishing stage includes several processes to enhance the pipe’s aesthetic and functional qualities. This may involve polishing the glass to achieve a smooth surface, applying decorative elements, or adding color through various techniques, including fuming or painting. Finally, each piece is thoroughly cleaned to remove any residues from manufacturing before being packaged for shipment.

What Quality Assurance Measures Are Essential in the Production of Pyrex Oil Burner Pipes?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each Pyrex oil burner pipe meets industry standards and customer expectations. A robust QA framework typically aligns with international standards such as ISO 9001, which emphasizes consistent quality management practices.

How Are International Standards and Industry-Specific Certifications Applied?

In addition to ISO 9001, products may also need to comply with specific regional standards, such as CE marking in Europe, which indicates conformity with health, safety, and environmental protection standards. Suppliers targeting international markets must be well-versed in these requirements to ensure compliance and avoid costly penalties.

What QC Checkpoints Are Critical During the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of production, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): At this stage, checks are conducted during manufacturing to monitor processes and detect any deviations from quality standards.

- Final Quality Control (FQC): Once the pipes are completed, FQC involves comprehensive inspections, including visual checks, dimensional measurements, and functional tests to ensure product integrity.

What Common Testing Methods Are Used for Quality Assurance?

Several testing methods are employed to verify the quality of Pyrex oil burner pipes, including:

- Thermal Shock Testing: This assesses the glass’s resistance to rapid temperature changes.

- Pressure Testing: Ensures that the pipe can withstand the pressures associated with vaporization without cracking.

- Visual Inspection: A thorough examination for defects, bubbles, or inconsistencies in the glass.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify a supplier’s QC processes. Here are some methods:

- Audits: Conduct on-site audits to review the supplier’s manufacturing practices and quality control measures. This direct assessment can reveal the supplier’s commitment to quality.

- Reports: Request detailed QC reports that outline the results of testing and inspections throughout the manufacturing process. These documents should include data on defect rates and corrective actions taken.

- Third-Party Inspections: Engage independent inspection agencies to evaluate the supplier’s processes and products. These inspections can provide an unbiased assessment of quality standards.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

When sourcing Pyrex oil burner pipes, international buyers should be aware of several nuances related to quality control:

- Cultural Differences: Understanding regional manufacturing practices and quality expectations can facilitate smoother communication and collaboration with suppliers.

- Regulatory Compliance: Buyers must familiarize themselves with the regulatory landscape in their target markets, including any specific certifications required for importation.

- Supply Chain Transparency: Establishing a transparent supply chain can enhance trust and ensure that quality standards are maintained throughout the production process.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing Pyrex oil burner pipes, ensuring they receive high-quality products that meet their needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pyrex oil burner pipe’

In the competitive landscape of B2B sourcing, procuring high-quality Pyrex oil burner pipes requires a structured approach. This guide outlines essential steps to ensure you make informed decisions that align with your business needs, particularly for international markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the products meet your operational needs. Consider factors such as size, design, material quality (e.g., high borosilicate glass), and durability. This clarity will help you communicate effectively with suppliers and avoid misunderstandings.

- Size Requirements: Determine whether you need smaller, portable options or larger models for heavy use.

- Material Quality: Prioritize suppliers offering high-grade Pyrex glass known for its thermal resistance.

Step 2: Conduct Market Research

Understanding the market landscape helps identify potential suppliers and trends. Research various suppliers to compare their offerings, prices, and customer reviews. This step is essential for benchmarking quality and ensuring competitive pricing.

- Identify Key Players: Look for suppliers with a strong reputation in the industry.

- Assess Pricing Trends: Analyze price ranges for different types of pipes to gauge what constitutes a fair price.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s vital to thoroughly vet potential suppliers. Request company profiles, product samples, and references from existing clients. This diligence ensures that you partner with reliable suppliers who can meet your quality and delivery expectations.

- Check Credentials: Verify certifications that indicate compliance with safety and quality standards.

- Request Samples: Assess product quality firsthand to ensure it aligns with your specifications.

Step 4: Negotiate Terms and Pricing

Effective negotiation can lead to better pricing and favorable terms. Discuss bulk order discounts, payment terms, and delivery timelines with your chosen suppliers. This step is critical for maximizing your procurement budget.

- Bulk Discounts: Inquire about price reductions for larger orders to enhance profitability.

- Payment Terms: Aim for flexible payment options that align with your cash flow.

Step 5: Review Shipping and Delivery Options

Understanding shipping logistics is essential for timely product availability. Inquire about shipping methods, estimated delivery times, and costs. Reliable shipping can significantly impact your inventory management and customer satisfaction.

- Shipping Partners: Ensure the supplier has reputable logistics partners for international shipping.

- Trackability: Look for options that provide tracking information to monitor your shipment.

Step 6: Establish a Quality Assurance Process

Implementing a quality assurance process ensures that the products received meet your standards. This may involve inspecting shipments upon arrival and maintaining communication with suppliers regarding quality issues.

Illustrative image related to pyrex oil burner pipe

- Inspection Protocols: Define clear criteria for product inspection upon receipt.

- Feedback Loop: Create a system for providing feedback to suppliers to address any quality concerns promptly.

Step 7: Build Long-term Relationships

Fostering strong relationships with suppliers can lead to better collaboration and support over time. Regular communication and feedback help establish trust and may yield benefits like priority service or exclusive offers.

- Frequent Engagement: Maintain regular contact to discuss new products and changes in your needs.

- Loyalty Incentives: Inquire about loyalty programs that may offer additional savings or benefits for repeat business.

By following these steps, B2B buyers can effectively source high-quality Pyrex oil burner pipes that meet their specific needs while ensuring a smooth procurement process.

Comprehensive Cost and Pricing Analysis for pyrex oil burner pipe Sourcing

What Are the Key Cost Components for Pyrex Oil Burner Pipe Sourcing?

Sourcing Pyrex oil burner pipes involves several cost components that buyers need to consider. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The most significant cost in producing Pyrex oil burner pipes is the borosilicate glass itself. This high-grade glass is known for its durability and thermal resistance, which can lead to higher material costs compared to standard glass. Additional costs may arise from any custom designs or colorations.

-

Labor: Labor costs are influenced by the region of production. Countries with higher labor costs will increase the overall manufacturing expense. Conversely, sourcing from regions with lower labor costs can provide significant savings, but may raise concerns regarding quality and compliance.

-

Manufacturing Overhead: This includes costs associated with facility operations, utilities, and equipment maintenance. Efficient production processes can help minimize overhead, impacting the overall cost structure positively.

-

Tooling: The initial setup for manufacturing, including molds and machinery specific to producing Pyrex pipes, can represent a substantial upfront investment. Buyers should consider whether they are sourcing standard or custom designs, as the latter may necessitate additional tooling expenses.

-

Quality Control (QC): Ensuring that the final product meets safety and performance standards is crucial. Investments in QC processes can increase costs but are essential for maintaining product integrity, especially in international markets where regulations may vary.

-

Logistics: Transportation costs can vary significantly based on the distance between the supplier and the buyer, as well as the chosen Incoterms (International Commercial Terms). Understanding the implications of shipping methods on overall costs is vital for budget planning.

-

Margin: Suppliers will typically include a profit margin in their pricing. This margin can vary based on the supplier’s market positioning, reputation, and the level of service offered.

What Factors Influence Pricing for Pyrex Oil Burner Pipes?

Several factors can influence the pricing structure for Pyrex oil burner pipes:

-

Volume/MOQ: Purchasing in bulk often results in lower per-unit costs. Buyers should negotiate Minimum Order Quantities (MOQs) to maximize savings.

-

Specifications and Customization: Custom designs or specific requirements can increase costs. Buyers should balance the need for customization with budget constraints.

-

Quality and Certifications: Higher quality standards and certifications can lead to increased costs. It’s essential to assess the quality required for your market and factor in any additional costs associated with compliance.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the shipping terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), can help buyers anticipate additional costs associated with delivery and customs clearance.

What Are the Best Practices for Negotiating Pyrex Oil Burner Pipe Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can enhance cost-efficiency:

-

Conduct Market Research: Understanding the market landscape and competitor pricing can provide leverage during negotiations. This knowledge allows buyers to make informed decisions and present reasonable counter-offers.

-

Evaluate Total Cost of Ownership: Beyond the initial purchase price, consider long-term costs associated with maintenance, durability, and replacement. Investing in higher-quality products may yield savings over time.

-

Establish Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often result in favorable negotiations and priority service.

-

Be Transparent About Needs: Clearly communicating your needs and constraints can help suppliers tailor their offers. This transparency may lead to innovative solutions or cost-saving alternatives.

-

Request Samples: Before committing to large orders, request samples to evaluate quality. This step can prevent costly mistakes and ensure that the products meet your expectations.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices for Pyrex oil burner pipes can range widely based on the factors discussed, buyers should remain vigilant about the total cost implications. By understanding the cost structure, pricing influencers, and effective negotiation strategies, international buyers can make informed decisions that align with their business objectives.

Illustrative image related to pyrex oil burner pipe

Alternatives Analysis: Comparing pyrex oil burner pipe With Other Solutions

Exploring Alternatives to Pyrex Oil Burner Pipes for B2B Buyers

When it comes to selecting a smoking solution, understanding the available alternatives to the Pyrex oil burner pipe can significantly influence purchasing decisions. Each option brings unique features, costs, and usability, which can be critical for businesses looking to cater to their customers’ diverse needs.

| Comparison Aspect | Pyrex Oil Burner Pipe | Silicone Oil Pipe | Metal Oil Pipe |

|---|---|---|---|

| Performance | High durability, excellent heat resistance, ideal for vaporizing concentrates | Flexible and unbreakable, good for casual use | Durable but may impart a metallic taste |

| Cost | Moderate price, often between $10-$50 per unit | Generally lower cost, typically $5-$25 | Varies widely, often $10-$30 |

| Ease of Implementation | Simple to use, requires a torch lighter | Very easy to handle, lightweight | Requires careful handling to prevent damage |

| Maintenance | Requires regular cleaning to maintain optimal performance | Easy to clean; can be washed in a dishwasher | Can corrode or tarnish, requiring special care |

| Best Use Case | Suitable for serious enthusiasts and businesses wanting high-quality products | Perfect for casual users and outdoor activities | Good for heavy users or those needing portable solutions |

Understanding Silicone Oil Pipes: Pros and Cons

Silicone oil pipes offer a flexible alternative to the traditional Pyrex option. Their unbreakable nature makes them ideal for casual users who prioritize convenience over performance. While they are generally less expensive and easier to clean, they may not provide the same quality of vaporization as Pyrex. Additionally, the material can sometimes affect the flavor profile of the smoke, which could be a concern for discerning customers.

Evaluating Metal Oil Pipes: Pros and Cons

Metal oil pipes are another viable alternative. They are typically more durable than glass and silicone, making them suitable for heavy users. However, they can impart a metallic taste to the smoke, which may not be appealing to everyone. Their maintenance requires more attention to avoid corrosion, and they may not provide the same aesthetic appeal as Pyrex or silicone options. Metal pipes are often favored for their portability, making them a good choice for on-the-go users.

How to Choose the Right Smoking Solution for Your Business

For B2B buyers, the decision on which smoking solution to offer should hinge on customer preferences, usage scenarios, and budget considerations. If your target market comprises serious enthusiasts, the Pyrex oil burner pipe remains a top choice due to its durability and performance. Conversely, if your customer base leans towards casual users or those seeking budget-friendly options, silicone pipes could fulfill their needs effectively. Metal pipes may cater to users looking for a rugged, portable solution, albeit with some compromises on flavor and maintenance.

By evaluating these alternatives, businesses can better align their product offerings with market demands, ensuring they meet the diverse needs of their clientele while also optimizing their supply chain for efficiency and profitability.

Essential Technical Properties and Trade Terminology for pyrex oil burner pipe

What Are the Key Technical Properties of Pyrex Oil Burner Pipes?

Understanding the essential technical properties of Pyrex oil burner pipes is crucial for B2B buyers looking to procure high-quality smoking accessories. Below are some critical specifications that determine the performance, durability, and value of these products.

1. Material Grade: What Makes Pyrex Glass Special?

Pyrex oil burner pipes are primarily made from high-grade borosilicate glass. This type of glass is known for its superior thermal resistance, making it ideal for high-temperature applications. Its ability to withstand sudden temperature changes without cracking is vital for users who frequently heat their pipes. For B2B buyers, sourcing products made from borosilicate glass ensures that they are offering their customers durable and reliable options.

2. Size Variability: How Does Size Affect Usability?

Pyrex oil burner pipes come in various sizes, typically ranging from 4 to 10 inches. Smaller pipes are more portable and discreet, making them suitable for on-the-go users. Conversely, larger pipes provide better grip and a more substantial smoking experience. Understanding the size preferences of your target market can significantly influence your purchasing decisions and inventory management.

3. Wall Thickness: Why Is It Important?

The wall thickness of a Pyrex oil burner pipe is a key indicator of its durability. Thicker walls generally provide better resistance to breakage and thermal shock. For B2B buyers, investing in pipes with adequate wall thickness can reduce the frequency of returns and replacements, thereby enhancing customer satisfaction.

4. Design Features: How Do They Enhance Functionality?

Design elements such as bends, shapes, and additional filtration systems can significantly affect the smoking experience. For example, bent designs allow for easier inhalation, while multiple chambers can enhance filtration and cooling. When sourcing products, it’s essential to consider the design features that resonate with your clientele, as these can be strong selling points.

5. Heat Resistance: What Temperature Can They Withstand?

Borosilicate glass can typically withstand temperatures up to 500°F (260°C) without deforming. This heat resistance is crucial for users who employ torch lighters or other high-heat sources. For B2B buyers, confirming the heat resistance specifications can ensure that the products meet consumer safety and performance standards.

What Are the Common Trade Terminology and Jargon Related to Pyrex Oil Burner Pipes?

Familiarity with industry-specific terms is essential for navigating the B2B landscape effectively. Here are some common jargon and trade terms relevant to Pyrex oil burner pipes.

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that manufacture products that are then sold under another brand’s name. In the context of Pyrex oil burner pipes, buyers can source from OEMs to ensure that they receive products that meet specific quality and branding requirements, thus enhancing their market offerings.

Illustrative image related to pyrex oil burner pipe

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ indicates the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory effectively and ensure they are not over-committing to stock that may not sell quickly.

3. RFQ (Request for Quotation): How Is It Used?

An RFQ is a formal document that buyers use to solicit price quotes from suppliers. For businesses looking to purchase Pyrex oil burner pipes in bulk, issuing an RFQ can help them compare prices, terms, and conditions from different suppliers, facilitating informed decision-making.

4. Incoterms: What Are They?

Incoterms (International Commercial Terms) are a set of pre-defined commercial terms published by the International Chamber of Commerce. They outline the responsibilities of buyers and sellers in international trade, such as who is responsible for shipping costs and insurance. Understanding Incoterms is vital for B2B transactions, especially for international buyers importing Pyrex oil burner pipes from different regions.

5. Lead Time: Why Should You Consider It?

Lead time refers to the period between placing an order and receiving the product. In the context of Pyrex oil burner pipes, knowing the lead time can help businesses plan their inventory and sales strategies effectively, ensuring they meet customer demand without overstocking.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed purchasing decisions, enhancing their competitiveness in the market for Pyrex oil burner pipes.

Navigating Market Dynamics and Sourcing Trends in the pyrex oil burner pipe Sector

What Are the Key Trends Driving the Pyrex Oil Burner Pipe Market?

The global pyrex oil burner pipe market is witnessing robust growth, driven by increasing consumer demand for durable and high-quality smoking accessories. As international markets expand, particularly in regions such as Africa, South America, the Middle East, and Europe, B2B buyers are focusing on sourcing products that combine quality with affordability. The popularity of borosilicate glass, renowned for its thermal resistance and durability, is shaping sourcing trends. Buyers are increasingly gravitating towards suppliers that offer a diverse range of designs, sizes, and colors to cater to varying consumer preferences.

Emerging technologies such as e-commerce platforms are transforming how businesses connect with suppliers. Online marketplaces are making it easier for B2B buyers to access a wide array of products, compare prices, and evaluate supplier reliability through customer reviews and ratings. Additionally, the shift towards direct sourcing from manufacturers is gaining traction, allowing buyers to reduce costs and enhance supply chain efficiency. The introduction of innovative designs and customizable options is also becoming a trend, as businesses aim to differentiate themselves in a competitive market.

How Is Sustainability and Ethical Sourcing Impacting the Pyrex Oil Burner Pipe Industry?

Sustainability is becoming a critical factor in the sourcing of pyrex oil burner pipes. With increasing awareness of environmental issues, B2B buyers are seeking suppliers who prioritize eco-friendly practices. The production of borosilicate glass can involve significant energy consumption, and buyers are encouraged to look for manufacturers that utilize renewable energy sources or have energy-efficient production processes.

Ethical sourcing is equally important, as businesses strive to ensure that their supply chains are transparent and responsible. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can signal to buyers that a supplier is committed to sustainable practices. Moreover, the use of recycled materials in the manufacturing of pyrex products is gaining attention, as it reduces waste and promotes resource conservation. Buyers who prioritize sustainability not only contribute to environmental protection but also cater to a growing consumer base that values ethical consumption.

What Is the Historical Context of the Pyrex Oil Burner Pipe Market?

The pyrex oil burner pipe has a rich history rooted in the development of borosilicate glass. First created in the early 20th century, borosilicate glass was initially used for laboratory equipment due to its resistance to thermal shock. Over time, its application expanded to include smoking accessories, leading to the creation of durable and functional oil burner pipes.

The evolution of design has paralleled advancements in glass-making techniques, allowing for more intricate and aesthetically pleasing products. As smoking culture evolved and diversified, so did the demand for unique and high-quality smoking accessories. Today, the pyrex oil burner pipe stands as a testament to both craftsmanship and innovation, appealing to a global market that values durability and style. As B2B buyers navigate this dynamic landscape, understanding the historical context can provide valuable insights into consumer preferences and market trends.

Illustrative image related to pyrex oil burner pipe

Frequently Asked Questions (FAQs) for B2B Buyers of pyrex oil burner pipe

-

How do I ensure the quality of Pyrex oil burner pipes before purchasing?

To ensure quality, conduct thorough research on potential suppliers. Request samples to assess durability and craftsmanship firsthand. Look for certifications or quality assurances that guarantee the pipes are made from high-grade borosilicate glass, which is resistant to thermal shock. Additionally, check reviews and testimonials from other buyers to gauge the supplier’s reliability and product performance. Establishing a relationship with suppliers who have a solid track record can help mitigate risks associated with quality. -

What is the best size of Pyrex oil burner pipe for international shipping?

The best size for international shipping typically balances functionality and cost. A 4 to 7-inch Pyrex oil burner pipe is ideal, as these sizes are portable and popular among consumers. They also fit well into standard shipping boxes, reducing shipping costs. However, consider your target market’s preferences; larger pipes may attract buyers looking for enhanced usability. Ultimately, offering a variety of sizes can cater to diverse customer needs while optimizing shipping efficiency. -

What customization options are available for Pyrex oil burner pipes?

Many suppliers offer customization options, including color, design, and branding. Custom colors or patterns can help differentiate your product in a competitive market. Additionally, you may request specific sizes or shapes to meet customer demands. When discussing customization, ensure that the supplier can meet your quality standards and production timelines. Be prepared to share your design specifications and minimum order quantities (MOQs) to facilitate the customization process. -

What are the typical minimum order quantities (MOQs) for Pyrex oil burner pipes?

MOQs can vary significantly based on the supplier and the type of customization required. Generally, MOQs for standard Pyrex oil burner pipes range from 100 to 500 units. For customized designs, MOQs may be higher, depending on the complexity of the request. It’s advisable to clarify MOQs during initial negotiations to align your purchasing strategy with your supplier’s capabilities. This can also help you manage inventory effectively and meet market demand. -

What payment terms should I expect when sourcing Pyrex oil burner pipes?

Payment terms can vary by supplier and region, but common practices include a 30% upfront deposit and 70% upon shipment. Some suppliers may offer net 30 or net 60 terms for established buyers. It’s crucial to negotiate payment terms that align with your cash flow and risk tolerance. Always use secure payment methods that provide buyer protection, especially for large orders, to minimize the risk of fraud or disputes. -

How do I vet suppliers for Pyrex oil burner pipes in international markets?

To vet suppliers, start by researching their business history and customer reviews. Verify their production capabilities, quality certifications, and compliance with international safety standards. Request references from previous clients and, if possible, conduct factory visits or audits. Utilizing platforms that provide supplier ratings and feedback can also be beneficial. Establishing clear communication and understanding their operational processes can further help in assessing their reliability and credibility. -

What logistics considerations should I keep in mind when importing Pyrex oil burner pipes?

Logistics considerations include understanding customs regulations in your country, potential tariffs, and shipping options. Choose a reliable freight forwarder experienced in handling glass products to minimize the risk of damage during transit. Additionally, consider shipping times, insurance options, and the best ports of entry for your goods. Proper packaging is essential to protect the pipes from breakage during transportation. Collaborating with your supplier on logistics can streamline the importing process. -

What are the best practices for managing inventory of Pyrex oil burner pipes?

Effective inventory management starts with accurate demand forecasting to avoid overstocking or stockouts. Implement an inventory tracking system to monitor stock levels in real-time. Establish reorder points based on sales velocity and lead times from suppliers. Regularly analyze sales data to identify trends and adjust your purchasing strategy accordingly. Additionally, maintain good relationships with suppliers to enable quick replenishment when needed, ensuring you can meet customer demand without delay.

Top 7 Pyrex Oil Burner Pipe Manufacturers & Suppliers List

1. SmokeMEGA – Unbreakable Oil Burner Pipes

Domain: smokemega.com

Registered: 2023 (2 years)

Introduction: Unbreakable Oil Burner Pipes | Pyrex & Glass | SmokeMEGA

– Free Shipping on All Orders $14.99+

– Easy, Hassle-Free 14-Day Returns

– Collection includes various sizes and styles: 4-inch, 6-inch, 7-inch, 9-inch, 10-inch, and jumbo options.

– Made from high-grade, heat-resistant borosilicate glass.

– Features colorful designs and reinforced glass for durability.

– Affordable pricing with discounts up…

2. DHgate – High Borosilicate Glass Oil Pipe Set

Domain: dhgate.com

Registered: 2004 (21 years)

Introduction: {“Product Name”:”High Borosilicate Glass Pipe New Clear Thick Oil Burner Pyrex Glass Oil Pipe Smoking Pipe Set”,”Material”:”High borosilicate glass”,”Shape”:”Straight”,”Color”:”Clear”,”Size”:”10cm”,”Minimum Order Quantity (MOQ)”:”10 Pieces”,”Price”:”US $1.25 / Piece”,”Shipping Cost”:”Free Shipping Local To United States Via USPS”,”Estimated Delivery Time”:”7 Days”,”Features”:”Durable, tough, facto…

3. Simple Glass Pipe – Oil Burner Pipe

Domain: simpleglasspipe.com

Registered: 2013 (12 years)

Introduction: Oil Burner Pipe – Free Discreet Shipping – SimpleGlassPipe.com

– Made in USA

– High-quality glass construction

– Available in multiple sizes: 4″ and 6″

– Price range: From $13.99 USD to $14.99 USD

– Bulk discounts available (5, 10, 15, 20 pieces)

– Clear and Pink color options

– Designed for enhanced flavor of smoking oils

– Compact and convenient for on-the-go use

– Oil Burner Pipe attachment for…

4. Pinterest – Pyrex Glass Oil Burner Pipe

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Oil burner pipe, vial tube shaped, made of Pyrex glass, designed as a bubbler water pipe, available in 2025. Features include free discreet shipping, US made, best price, and options for portable or customized oil burners.

5. Wish – 53 Pyrex Glass Oil Burner Pipe

Domain: wish.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “53 Pyrex Glass Oil Burner Pipe”, “type”: “hand water pipe”, “material”: “Pyrex glass”, “usage”: “concentrate oil pipes”, “product_id”: “5f1188f5f877e90225fe66d8”}

6. Smoking Cats – Oil Burner Pipes

Domain: smokingcats.com

Registered: 2018 (7 years)

Introduction: Oil Burner Pipe – Free & Discreet Shipping from Texas. Available types include: Glass Pyrex Oil Burner Pipes, Color Change Oil Burner Pipes, Jumbo Oil Burner Pipes, Oil Burner Bubbler Pipes, Water Dog Oil Burner Pipes, and glowing in dark Oil Burner Pipes. Prices range from $10.99 to $19.99. Featured products include: 5.5″ Quartz Glass Oil Burner Pipe, Striped Glass Oil Burner Pipe, Glass Oil Burn…

7. msglasspipe – Pyrex Glass Solutions

Domain: msglasspipe.com

Registered: 2023 (2 years)

Introduction: Pyrex glass is a type of high-resistance borosilicate glass known for its outstanding heat resistance, durability, and chemical inertness. It can withstand temperatures up to 500°C (932°F) and has a moderate density of 2.23 g/cm³ with a Mohs hardness of 5.5. Pyrex glass offers excellent chemical resistance, preserving the flavor of concentrates and oils, and is easy to clean due to its refined sur…

Strategic Sourcing Conclusion and Outlook for pyrex oil burner pipe

In conclusion, the strategic sourcing of Pyrex oil burner pipes presents significant opportunities for international B2B buyers. By prioritizing quality and durability, especially with high-grade borosilicate glass options, businesses can enhance customer satisfaction and reduce replacement costs. The diverse range of designs and sizes ensures that there is a product to meet every market need, from the vibrant and colorful to the more classic and functional styles.

As buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable suppliers, establishing partnerships with manufacturers who emphasize both craftsmanship and affordability will be paramount. Fast and reliable shipping options further enhance the value proposition, ensuring that businesses can maintain a steady supply chain.

Looking ahead, it is crucial for B2B buyers to stay informed about emerging trends in the smoking accessories market. Engaging with suppliers who offer innovative products and exceptional service will not only meet current demand but also position businesses favorably for future growth. Take action today—explore partnerships that align with your vision for quality and sustainability in the Pyrex oil burner pipe market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.