Choosing Your Northeast Laser And Electropolish: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for northeast laser and electropolish

In the ever-evolving landscape of industrial manufacturing, sourcing reliable laser and electropolishing solutions poses a significant challenge for international B2B buyers. As companies seek to enhance product quality and precision, understanding the intricate world of Northeast laser and electropolish services becomes imperative. This guide is designed to equip decision-makers, particularly in regions like Africa, South America, the Middle East, and Europe—including key markets such as Saudi Arabia and Nigeria—with the essential knowledge needed to navigate this specialized market.

From an overview of various laser technologies, including CO2 and fiber lasers, to insights on electropolishing processes, this comprehensive resource covers a broad spectrum of applications, such as medical device manufacturing, industrial components, and decorative products. Buyers will also find practical advice on supplier vetting, cost considerations, and the importance of quality assurance in ensuring operational efficiency and product integrity.

By leveraging the insights presented in this guide, B2B buyers can make informed purchasing decisions, ultimately leading to enhanced product performance and competitive advantage in their respective markets. Understanding these facets of Northeast laser and electropolish services will empower businesses to streamline operations and foster long-term partnerships with trusted suppliers.

Understanding northeast laser and electropolish Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CO2 Laser Systems | Utilizes carbon dioxide as a gain medium; versatile for cutting and engraving | Industrial manufacturing, signage, packaging | Pros: High efficiency, cost-effective for large cuts. Cons: Limited to specific materials. |

| Fiber Laser Systems | Uses fiber optics for high precision and speed; suitable for metals | Automotive, aerospace, and medical device industries | Pros: Excellent beam quality, low maintenance. Cons: Higher initial investment. |

| Nd:YAG Laser Systems | Solid-state laser with high power; ideal for deep penetration | Heavy industrial applications, military, and medical | Pros: Versatile; effective for welding and cutting. Cons: More complex operation. |

| Electropolishing | Electrochemical process that smoothens surfaces; enhances corrosion resistance | Medical device manufacturing, aerospace components | Pros: Improves surface finish and cleanliness. Cons: Requires specific setup and expertise. |

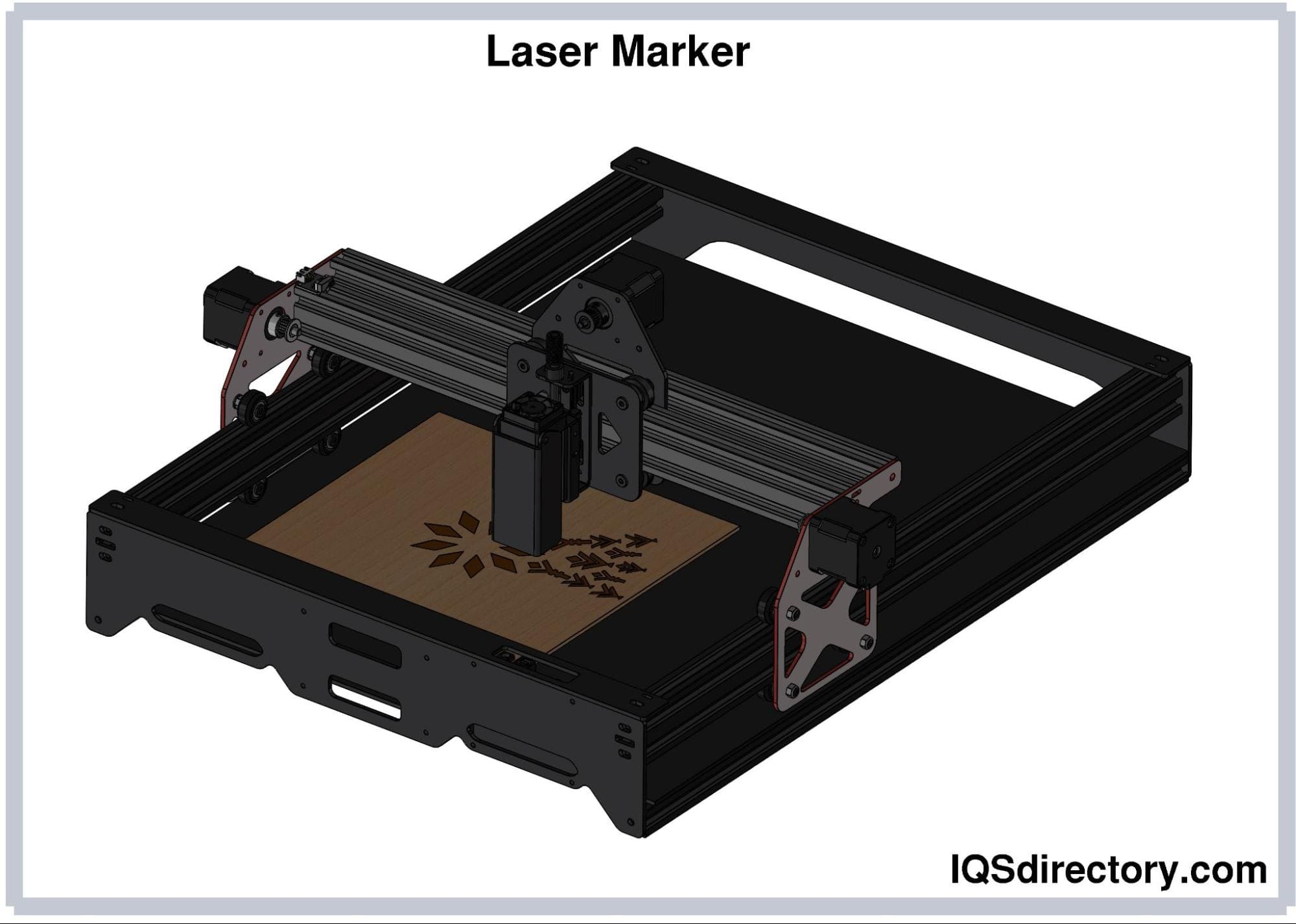

| Laser Marking | Non-contact marking method; creates permanent, precise markings | Product identification, branding, and traceability | Pros: Fast and accurate; minimal material alteration. Cons: Limited to surface-level applications. |

What are the Key Characteristics of CO2 Laser Systems?

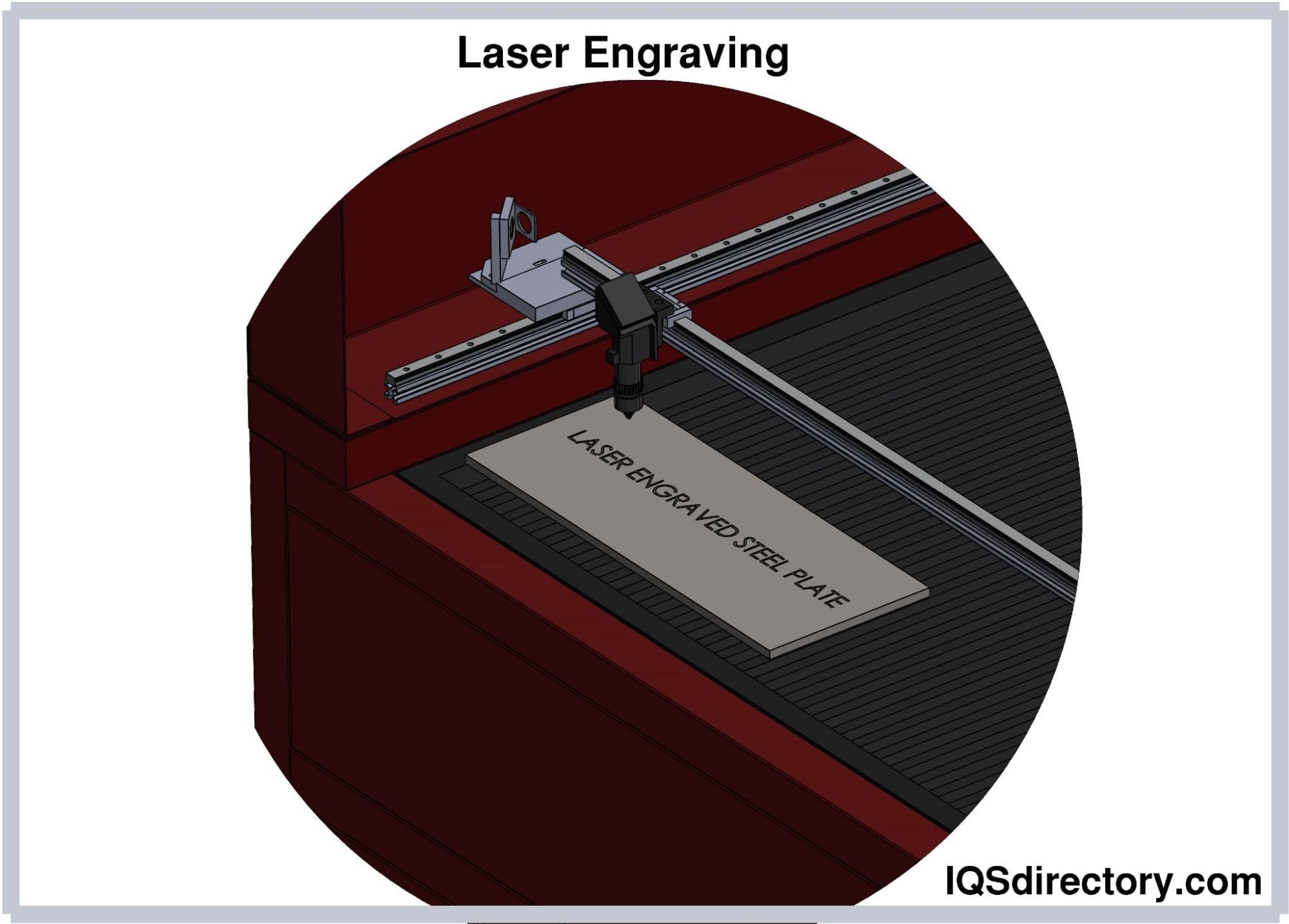

CO2 laser systems are characterized by their use of carbon dioxide gas as the gain medium, which allows for efficient energy conversion and high output power. These systems are particularly effective for cutting, engraving, and marking a variety of materials, including plastics, wood, and some metals. B2B buyers should consider CO2 lasers for applications that require large-area cuts and versatile material processing. However, it is essential to note that CO2 lasers may not be suitable for all metal types, limiting their application scope.

How Do Fiber Laser Systems Stand Out?

Fiber laser systems utilize fiber optics to produce high-energy laser beams, offering exceptional precision and speed. Their compact design and efficiency make them ideal for applications in industries such as automotive and aerospace, where high-quality metal cutting and engraving are crucial. Buyers should evaluate the initial investment against the long-term operational savings due to low maintenance needs and high throughput. However, the complexity of fiber laser systems may require skilled personnel for operation.

What are the Advantages of Nd:YAG Laser Systems?

Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) laser systems are solid-state lasers known for their high power output and deep penetration capabilities. These systems are commonly used in heavy industrial applications, including welding and cutting of thick materials. B2B buyers should consider Nd:YAG lasers for their versatility across various applications, but they should also be aware of the complexity involved in their operation and the necessity for specialized training.

Why is Electropolishing Essential in Manufacturing?

Electropolishing is an electrochemical process that enhances the surface finish of metal components, making them smoother and more resistant to corrosion. This process is particularly vital in the medical device manufacturing and aerospace industries, where cleanliness and surface integrity are paramount. Buyers must consider the expertise required for electropolishing setups, as well as the benefits of improved product longevity and performance. While it offers significant advantages, the process may involve higher costs due to specialized equipment and labor.

What Makes Laser Marking a Preferred Choice for Product Identification?

Laser marking is a non-contact method that creates precise, permanent markings on various materials, making it ideal for product identification and branding. This technique is widely adopted in industries that require traceability, such as food and pharmaceuticals. B2B buyers should weigh the speed and accuracy of laser marking against its limitations, which include its inability to penetrate deeper into materials. Overall, it provides a fast and reliable solution for enhancing product visibility and compliance.

Key Industrial Applications of northeast laser and electropolish

| Industry/Sector | Specific Application of northeast laser and electropolish | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Laser marking and engraving of surgical instruments | Enhances traceability and compliance with regulatory standards | Precision requirements for materials and customization |

| Aerospace | Laser cutting and welding of structural components | Increases manufacturing efficiency and reduces waste | Certifications for aerospace-grade materials and processes |

| Electronics | Electropolishing of circuit boards and housings | Improves conductivity and reduces corrosion | Compatibility with various substrates and finishes |

| Automotive | Laser welding for lightweight components | Reduces weight and enhances fuel efficiency | Adherence to industry standards and rapid turnaround times |

| Decorative Products | Custom laser engraving for promotional items | Elevates brand visibility and customer engagement | Flexibility in design and scalability for mass production |

How is Northeast Laser and Electropolish Used in the Medical Device Sector?

In the medical device industry, Northeast Laser & Electropolish specializes in laser marking and engraving surgical instruments, ensuring precise identification and traceability. This capability addresses the critical need for compliance with strict regulatory standards, which is vital for international markets. Buyers from regions such as Africa and Europe must ensure that the materials used meet biocompatibility and sterilization requirements, while also considering the need for customization to fit specific product lines.

What Role Does Northeast Laser and Electropolish Play in Aerospace Manufacturing?

In aerospace, Northeast Laser provides laser cutting and welding services for structural components, improving manufacturing efficiency and significantly reducing waste. These processes help meet the stringent safety and performance criteria essential in the aerospace sector. International buyers, particularly from the Middle East, should focus on sourcing from providers with certifications for aerospace-grade materials and processes to ensure compliance with industry standards.

How Does Electropolishing Benefit Electronics Manufacturers?

Electropolishing is crucial in the electronics sector, where Northeast Laser enhances circuit boards and housings to improve conductivity and minimize corrosion. This process is essential for ensuring the longevity and reliability of electronic components. Buyers from South America and Europe should prioritize suppliers who can guarantee compatibility with various substrates and finishes, enabling optimal performance in diverse applications.

Why is Laser Welding Important for the Automotive Industry?

Northeast Laser’s laser welding services are instrumental in producing lightweight automotive components that contribute to improved fuel efficiency. The precision of laser welding allows for strong, durable joints without adding excessive weight. Automotive manufacturers in Africa and the Middle East should consider sourcing from providers that adhere to industry standards and can offer rapid turnaround times to meet production schedules.

How Can Custom Laser Engraving Enhance Decorative Products?

In the decorative products sector, Northeast Laser excels in custom laser engraving for promotional items, which elevates brand visibility and enhances customer engagement. This service allows businesses to personalize products, making them more appealing to consumers. Buyers from Europe and South America should look for suppliers who offer flexibility in design and scalability for mass production, ensuring they can meet market demands effectively.

3 Common User Pain Points for ‘northeast laser and electropolish’ & Their Solutions

Scenario 1: Inconsistent Quality in Laser Processing Services

The Problem: B2B buyers often face challenges related to the quality and consistency of laser processing services. For instance, a medical device manufacturer may experience variability in laser marking or engraving results, leading to discrepancies in product labeling or component identification. This inconsistency can result in compliance issues, increased waste, and costly rework. Furthermore, it undermines customer trust and can jeopardize relationships with regulatory bodies that require stringent adherence to quality standards.

The Solution: To mitigate these quality concerns, buyers should prioritize vendors like Northeast Laser & Electropolish that have a proven track record in quality assurance. It’s essential to ask potential suppliers about their quality control measures, such as certifications (e.g., ISO 9001) and their processes for maintaining consistency. Engaging in a thorough initial consultation can help in specifying requirements clearly. Buyers should also request samples and performance data from previous projects to assess the vendor’s capabilities. Establishing a detailed contract that outlines quality benchmarks and penalties for non-compliance can further safeguard against quality issues.

Scenario 2: Long Lead Times Affecting Production Schedules

The Problem: Buyers in fast-paced industries often grapple with extended lead times for laser and electropolishing services. Delays in receiving components can cascade through production schedules, resulting in missed deadlines and lost revenue. For instance, a manufacturer might need critical surgical components processed quickly, but standard turnaround times of several weeks can severely disrupt project timelines, especially in the medical sector where timing is crucial.

The Solution: To address lead time challenges, it’s vital for buyers to select a partner like Northeast Laser that emphasizes rapid turnaround capabilities. During the sourcing phase, inquire about the company’s current capacity and any expedited service options they offer. Establishing a long-term relationship with a preferred vendor can also lead to prioritized service and faster response times. Additionally, consider implementing a Just-In-Time (JIT) inventory approach, which allows for more flexible production scheduling and can reduce the pressure on lead times. Regular communication with the supplier regarding upcoming needs can also help them manage workloads effectively.

Scenario 3: Complexity in Custom Laser Solutions

The Problem: B2B buyers often encounter difficulties when seeking custom laser solutions tailored to specific applications. For example, a company may require a unique laser engraving system for a new product line, but the technical specifications and requirements can be complex. This complexity can lead to misunderstandings, project delays, and even failure to meet product specifications if the supplier does not fully grasp the buyer’s needs.

The Solution: To navigate the complexities of custom laser solutions, buyers should engage in a collaborative approach with Northeast Laser. Initiating discussions early in the design phase can help clarify requirements and expectations. Utilize the vendor’s expertise by inviting their engineering team to participate in brainstorming sessions. Providing detailed specifications, including material types, intended use, and any regulatory standards, will help ensure that the custom solution aligns with your needs. Furthermore, consider setting up a prototype phase where initial designs can be tested and refined based on real-world performance, ensuring that the final product meets all specifications before full-scale production begins.

Strategic Material Selection Guide for northeast laser and electropolish

What Are the Key Properties of Common Materials Used in Laser Processing and Electropolishing?

When selecting materials for laser processing and electropolishing, understanding their properties is crucial for ensuring optimal performance in various applications. Here are analyses of four common materials frequently used in this context: stainless steel, aluminum, titanium, and plastics.

How Does Stainless Steel Perform in Laser Processing and Electropolishing?

Stainless steel is renowned for its excellent corrosion resistance, strength, and durability. It typically withstands high temperatures and pressures, making it suitable for various industrial applications, including medical devices and automotive components. The most common grades used are 304 and 316, with 316 offering superior resistance to pitting and crevice corrosion.

Pros: Stainless steel is durable and can be easily laser cut or welded. It also provides a high-quality finish after electropolishing, enhancing its aesthetic appeal and functionality.

Cons: The cost of stainless steel can be higher than other materials, and its manufacturing complexity may increase due to the need for specialized equipment for laser processing.

Impact on Application: Stainless steel’s compatibility with various media, including corrosive substances, makes it ideal for medical and industrial applications. However, international buyers should be aware of compliance with standards like ASTM A240 for stainless steel.

What Are the Advantages and Disadvantages of Using Aluminum?

Aluminum is lightweight, corrosion-resistant, and has good thermal and electrical conductivity. It is often used in applications where weight savings are critical, such as in aerospace and automotive industries.

Pros: Aluminum is generally less expensive than stainless steel and easier to machine. Its ability to be anodized further enhances its corrosion resistance.

Cons: While aluminum is durable, it is not as strong as stainless steel and may require additional coatings for high-stress applications. Additionally, the laser processing of aluminum can produce rough edges if not managed properly.

Impact on Application: Aluminum’s compatibility with a variety of environments makes it suitable for both industrial and decorative applications. Buyers from regions like the Middle East should consider the impact of high temperatures on aluminum’s structural integrity.

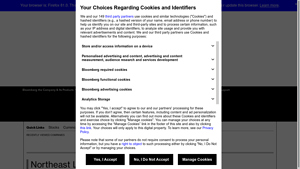

Illustrative image related to northeast laser and electropolish

Why Is Titanium Considered a Premium Material for Laser Processing?

Titanium is known for its exceptional strength-to-weight ratio and outstanding corrosion resistance, particularly in harsh environments. It is commonly used in aerospace, medical implants, and high-performance automotive components.

Pros: Titanium is incredibly durable and can withstand extreme conditions. Its biocompatibility makes it ideal for medical applications.

Cons: The cost of titanium is significantly higher than that of stainless steel and aluminum, and its machining can be complex, often requiring specialized tools.

Impact on Application: Titanium’s unique properties make it suitable for applications that demand high performance. International buyers must ensure compliance with standards such as ASTM F136 for titanium used in medical devices.

How Do Plastics Fit into the Laser Processing and Electropolishing Landscape?

Plastics, particularly engineering plastics like polycarbonate and nylon, are increasingly used in various applications due to their versatility and lightweight nature. They are often employed in consumer products, automotive parts, and medical devices.

Illustrative image related to northeast laser and electropolish

Pros: Plastics are generally less expensive and easier to process than metals. They can be laser marked or engraved with precision, providing excellent detail.

Cons: Plastics may not offer the same level of durability or heat resistance as metals, limiting their use in high-stress applications. Additionally, their electropolishing capabilities are limited compared to metals.

Impact on Application: The compatibility of plastics with various chemicals makes them suitable for a wide range of applications. However, international buyers should consider the specific standards applicable to plastics in their regions, such as ISO 9001 for quality management.

Summary Table of Material Selection for Northeast Laser and Electropolish

| Material | Typical Use Case for northeast laser and electropolish | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Medical devices, automotive components | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Aerospace, automotive parts | Lightweight and cost-effective | Lower strength compared to steel | Medium |

| Titanium | Aerospace, medical implants | Exceptional strength and durability | Very high cost and complex machining | High |

| Plastics | Consumer products, automotive parts | Versatile and easy to process | Limited durability in high-stress applications | Low |

This guide provides a foundational understanding of material selection for laser processing and electropolishing, helping international B2B buyers make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for northeast laser and electropolish

What Are the Key Manufacturing Processes Employed by Northeast Laser and Electropolish?

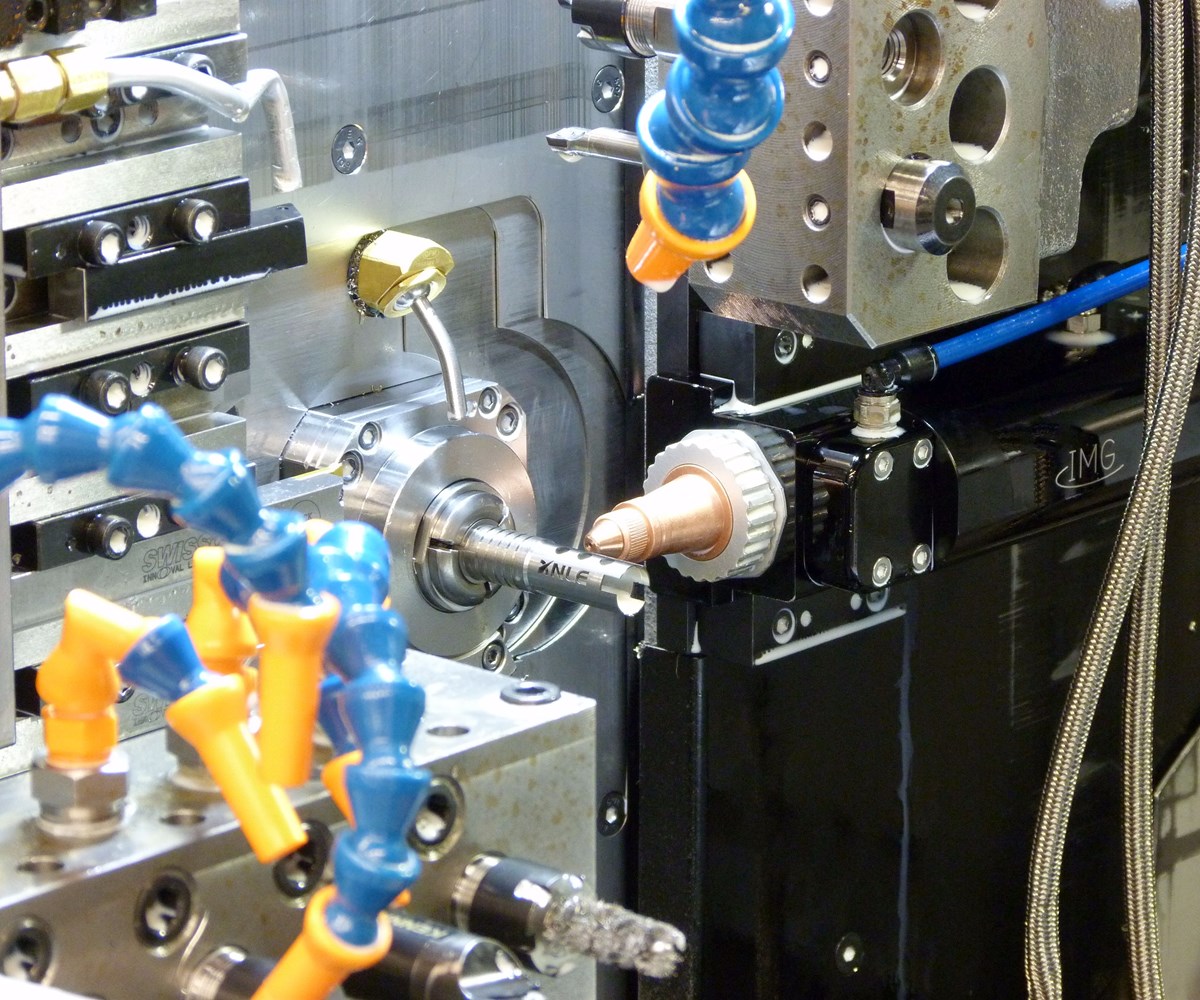

Northeast Laser and Electropolish (NLE) employs a series of well-defined manufacturing processes tailored to meet the needs of diverse industries, including medical, industrial, and military applications. Each phase is meticulously designed to ensure precision and quality, making the company a trusted partner for international B2B buyers.

Illustrative image related to northeast laser and electropolish

Material Preparation: How Is the Right Material Selected and Prepared?

The manufacturing process begins with rigorous material selection. NLE specializes in a wide range of materials, including metals, plastics, ceramics, and wood, which are chosen based on the specific requirements of each project. The materials undergo a thorough inspection and testing to ensure they meet the necessary standards for durability and performance.

Once selected, materials are prepared through cutting, shaping, or other preliminary processes. For instance, metals may be cut into specific dimensions using laser cutting technology, ensuring precision from the outset. This initial phase sets the foundation for the subsequent stages, reducing waste and enhancing efficiency.

What Forming Techniques Are Utilized in the Manufacturing Process?

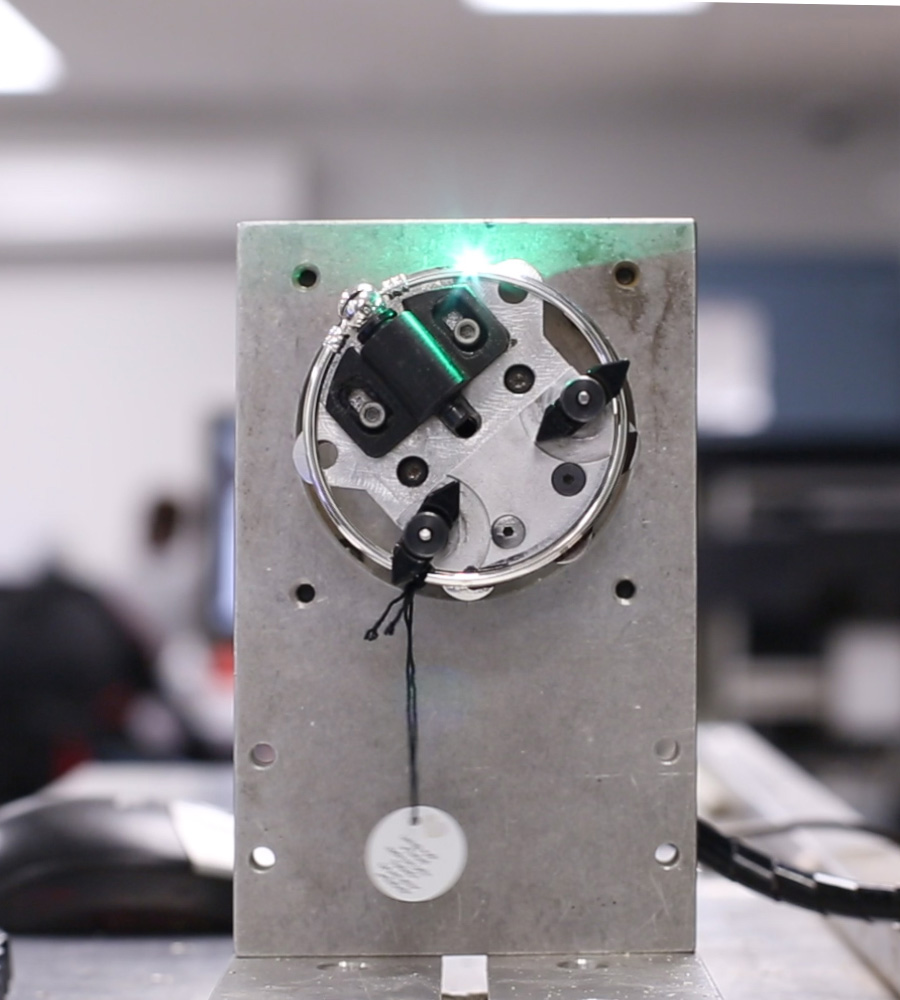

Forming techniques at NLE include advanced laser processing methods such as laser welding, marking, and engraving. These techniques allow for high levels of precision and versatility, catering to various applications from intricate medical devices to robust industrial components.

-

Laser Welding: This technique is crucial for joining materials without compromising their structural integrity. NLE uses state-of-the-art laser welding systems to create strong, clean seams that meet stringent quality requirements.

-

Laser Marking and Engraving: These processes are employed for product identification and branding. The high precision of laser marking ensures that markings remain clear and legible, even on small or complex components.

How Does the Assembly Process Ensure Quality and Efficiency?

After the forming stage, components are assembled into the final product. This process often involves integrating various parts, which may include electronic components, mechanical assemblies, or decorative elements. NLE employs skilled technicians who follow detailed assembly protocols to maintain product integrity.

During assembly, real-time monitoring and documentation are conducted to ensure that all components meet the specified design criteria. This systematic approach minimizes errors and enhances the overall quality of the final product.

Illustrative image related to northeast laser and electropolish

What Finishing Techniques Are Used to Enhance Product Quality?

Finishing processes are critical in achieving the desired surface quality and functionality. NLE offers several finishing techniques, with electropolishing being a standout service. This process enhances surface smoothness and corrosion resistance, which is particularly important in the medical and aerospace industries.

-

Electropolishing: This technique removes surface imperfections and improves the aesthetic quality of metals. It is especially beneficial for stainless steel components, which require a high degree of cleanliness and smoothness to prevent contamination in medical applications.

-

Passivation: Following electropolishing, components may undergo passivation to further enhance their corrosion resistance. This is vital for products intended for harsh environments or those exposed to bodily fluids in medical settings.

What Quality Assurance Measures Are in Place at Northeast Laser and Electropolish?

Quality assurance (QA) is integral to NLE’s operations, ensuring that all products meet international standards and customer specifications. The company adheres to ISO 9001 standards, which outline a framework for a quality management system focused on continuous improvement and customer satisfaction.

Which International Standards Are Relevant for Quality Assurance?

NLE’s commitment to quality is demonstrated through its compliance with several international standards, including:

-

ISO 9001: This standard emphasizes quality management principles, including a strong customer focus, the involvement of top management, and a process-based approach.

-

CE Certification: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

-

API Standards: When dealing with products for the oil and gas industry, adherence to American Petroleum Institute (API) standards is crucial.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

NLE implements multiple quality control checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specified standards before being used in production.

-

In-Process Quality Control (IPQC): Continuous monitoring during manufacturing allows for immediate identification and rectification of any issues that may arise, ensuring consistent quality throughout the process.

-

Final Quality Control (FQC): Upon completion of the manufacturing process, each product undergoes a final inspection to verify that it meets all requirements before shipment.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is essential. Here are several strategies to consider:

-

Conduct Audits: Regular audits of the supplier’s facilities can provide insight into their manufacturing processes and quality control measures. This is especially important for buyers in regulated industries.

-

Request Documentation and Reports: Suppliers should be able to provide quality assurance documentation, including inspection reports and certifications, which offer transparency into their quality management systems.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s capabilities and adherence to quality standards.

What Are the Nuances of Quality Certification for International Buyers?

When sourcing from Northeast Laser and Electropolish, international buyers should be aware of the nuances related to quality certifications. Different regions may have specific requirements that impact product acceptance. For instance:

-

Regulatory Compliance: Buyers in the medical sector must ensure that products comply with local regulations regarding medical devices, which may include additional certifications beyond ISO or CE marking.

-

Cultural Considerations: Understanding the cultural context of quality expectations can aid in establishing a productive relationship with suppliers. Buyers from different regions may prioritize different aspects of quality and service.

In conclusion, Northeast Laser and Electropolish’s structured manufacturing processes and rigorous quality assurance measures position it as a reliable partner for international B2B buyers. By understanding these processes and the relevant standards, buyers can make informed decisions and foster successful collaborations.

Illustrative image related to northeast laser and electropolish

Practical Sourcing Guide: A Step-by-Step Checklist for ‘northeast laser and electropolish’

To assist international B2B buyers in effectively sourcing laser and electropolishing services from Northeast Laser & Electropolish, this guide provides a structured approach to ensure informed decision-making. Whether you are in Africa, South America, the Middle East, or Europe, following this checklist will help you identify the right supplier that meets your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, it’s essential to outline your technical requirements. This includes the type of laser technology needed (CO2, fiber, Nd:YAG, etc.) and the specific applications (cutting, welding, marking). Clearly defined specifications will help you communicate effectively with suppliers and ensure they can meet your needs.

- Application Type: Specify whether you need laser cutting, marking, or electropolishing.

- Material Compatibility: Identify the materials you will be working with, such as metals, plastics, or ceramics.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify suppliers who specialize in laser and electropolishing services. Look for companies with a strong reputation and relevant industry experience.

- Industry Experience: Aim for suppliers with a proven track record in your specific sector (e.g., medical, industrial).

- Customer Reviews: Check testimonials and case studies to assess customer satisfaction and service quality.

Step 3: Evaluate Supplier Capabilities

Assess the technical capabilities of shortlisted suppliers. This involves understanding their equipment, technology, and service offerings.

- Advanced Technologies: Ensure they utilize modern laser systems that can handle your requirements efficiently.

- Service Range: Check if they offer additional services like maintenance, repairs, and custom solutions.

Step 4: Verify Quality Standards and Certifications

Quality control is critical in laser processing and electropolishing. Verify that potential suppliers adhere to industry standards and possess relevant certifications.

Illustrative image related to northeast laser and electropolish

- ISO Certifications: Look for ISO 9001 or similar quality management certifications.

- Quality Control Processes: Inquire about their quality assurance measures to ensure consistent product reliability.

Step 5: Request Quotes and Compare Pricing

Once you have a shortlist of potential suppliers, request detailed quotes. Ensure that the quotes include all costs associated with the services offered.

- Breakdown of Costs: Look for transparency in pricing, including labor, materials, and any additional fees.

- Turnaround Times: Compare lead times for service delivery, as this can significantly impact your project timelines.

Step 6: Conduct Site Visits or Virtual Tours

If feasible, conduct site visits or request virtual tours to evaluate the supplier’s facilities. This will give you insights into their operational capabilities and adherence to safety standards.

- Facility Inspection: Look for cleanliness, organization, and the presence of advanced machinery.

- Safety Compliance: Ensure that safety protocols are in place, especially when dealing with laser technologies.

Step 7: Establish Communication and Support Channels

Effective communication is vital for a successful partnership. Establish clear lines of communication and support before finalizing any agreements.

- Dedicated Account Manager: Ensure that you have a point of contact who understands your project needs.

- Customer Support Availability: Confirm the availability of support services for troubleshooting and assistance during the project.

By following these steps, B2B buyers can make informed decisions when sourcing laser and electropolishing services from Northeast Laser & Electropolish, ensuring a successful and efficient procurement process.

Comprehensive Cost and Pricing Analysis for northeast laser and electropolish Sourcing

When considering the costs associated with sourcing laser and electropolish services from Northeast Laser & Electropolish, it is essential to analyze the various components that contribute to the overall pricing structure. Understanding these elements can empower international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, to make informed decisions.

What Are the Key Cost Components in Laser and Electropolish Services?

-

Materials: The cost of raw materials significantly influences the pricing of laser and electropolish services. Different metals, plastics, and ceramics come with varying price points and availability. For example, high-grade stainless steel may incur higher costs compared to aluminum, but offers enhanced durability and corrosion resistance, which can justify the investment depending on application needs.

-

Labor: Skilled labor is critical in the laser processing and electropolishing sectors. The cost of labor includes not only the wages of technicians and engineers but also ongoing training and development to maintain high-quality standards. Suppliers with a strong commitment to quality will invest in their workforce, which can be reflected in their pricing.

-

Manufacturing Overhead: This includes operational costs such as utilities, equipment maintenance, and facility expenses. Companies like Northeast Laser & Electropolish that offer advanced laser systems and high-quality services tend to have higher overheads, which can impact their pricing structure.

-

Tooling and Setup: The initial setup costs for custom jobs can vary significantly based on project specifications. Custom tooling for specialized applications may require additional investment, impacting the overall cost. Buyers should inquire about setup fees and consider them when evaluating quotes.

-

Quality Control (QC): A robust QC process is essential in ensuring the reliability and safety of the products. Companies that have established quality assurance protocols may charge a premium for their services, but this often leads to lower total costs over time due to reduced defects and improved product performance.

-

Logistics: Transportation and shipping can significantly affect the final pricing, especially for international buyers. Understanding Incoterms is crucial as they dictate who bears the costs and risks during transport. Buyers should consider these terms carefully to avoid unexpected charges.

-

Margin: Suppliers will include a margin to ensure profitability. This margin can vary based on the supplier’s business model, market positioning, and competitive landscape.

How Do Price Influencers Impact Sourcing Decisions?

Several factors can influence pricing beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounts, making it advantageous for buyers to negotiate larger quantities when feasible. Understanding the MOQ can help buyers plan their purchases effectively.

-

Specifications and Customization: Custom solutions tailored to specific applications typically command higher prices. Buyers should clearly define their needs to avoid unnecessary costs associated with modifications.

-

Quality and Certifications: Products that meet specific industry certifications may cost more due to the rigorous standards they must comply with. Buyers should weigh the benefits of certification against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established companies may charge more due to their proven track record, but they may also offer better service and quality assurance.

What Tips Can Help Buyers Optimize Costs?

-

Negotiation: Always engage in discussions regarding pricing and terms. Suppliers may offer discounts for long-term contracts or larger orders.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront costs. Consider factors like maintenance, durability, and performance, which can lead to savings in the long run.

-

Pricing Nuances for International Buyers: Understand the implications of currency fluctuations, import duties, and taxes, especially for buyers from regions like Africa and South America. Establishing relationships with local representatives can also provide insights into market conditions and pricing trends.

-

Request for Quotes (RFQs): When sourcing, consider issuing RFQs to multiple suppliers to compare pricing and service offerings comprehensively. This practice can uncover competitive pricing and help identify the best value for your needs.

Disclaimer

Prices can vary significantly based on the specifics of each project, and the details provided here are indicative. It is advisable for buyers to obtain detailed quotes based on their unique requirements and circumstances.

Alternatives Analysis: Comparing northeast laser and electropolish With Other Solutions

When evaluating industrial solutions for precision laser processing and electropolishing, it’s essential to consider various alternatives that may fit specific operational needs. This section compares Northeast Laser and Electropolish with two viable alternatives: traditional mechanical polishing and plasma polishing. Each method has distinct advantages and potential drawbacks, making it crucial for B2B buyers to assess which option aligns best with their objectives.

| Comparison Aspect | Northeast Laser And Electropolish | Traditional Mechanical Polishing | Plasma Polishing |

|---|---|---|---|

| Performance | High precision and repeatability | Moderate precision; surface finish varies | Excellent uniformity; minimal damage |

| Cost | Moderate to high initial investment | Generally lower upfront costs | Higher cost, but reduced labor |

| Ease of Implementation | Requires specialized training and setup | Easier to implement; less training needed | Complex setup; requires specialized equipment |

| Maintenance | Regular maintenance for lasers and electropolishing tanks | Low maintenance; regular abrasive changes needed | Low maintenance; routine checks required |

| Best Use Case | Medical devices, intricate parts requiring high accuracy | General manufacturing, less critical applications | High-end applications needing minimal surface damage |

What Are the Advantages and Disadvantages of Traditional Mechanical Polishing?

Traditional mechanical polishing utilizes abrasive materials to achieve a desired surface finish. One of its primary advantages is its lower initial cost and simpler implementation, making it accessible for many businesses. However, the precision can be inconsistent, especially for intricate components, and the process may generate more waste. Additionally, mechanical polishing can introduce surface imperfections that could lead to functional issues in sensitive applications, such as medical devices.

How Does Plasma Polishing Compare to Northeast Laser and Electropolish?

Plasma polishing is a more advanced technique that uses ionized gas to achieve a smooth, uniform surface. It excels in providing excellent surface finishes with minimal risk of damage to the underlying material. However, the equipment required for plasma polishing is typically more expensive and complex to set up. While it offers a clean and efficient process, the high cost can be a barrier for smaller manufacturers or those with limited budgets.

Illustrative image related to northeast laser and electropolish

Conclusion: Which Solution is Right for Your Business Needs?

When deciding between Northeast Laser and Electropolish and its alternatives, B2B buyers must evaluate their specific needs, budget constraints, and the nature of their applications. For industries where precision and surface integrity are paramount, such as medical device manufacturing, Northeast Laser and Electropolish may provide the best value despite a higher initial investment. Conversely, businesses with less stringent requirements might find mechanical polishing to be a cost-effective choice, while those in need of high-end finishes without surface damage could consider plasma polishing as a viable option. Ultimately, understanding the strengths and weaknesses of each solution will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for northeast laser and electropolish

What Are the Key Technical Properties Relevant to Northeast Laser and Electropolish?

When evaluating laser and electropolishing services, several critical technical properties must be considered to ensure that products meet industry standards and specific application requirements. Here are some of the essential specifications:

-

Material Grade

Material grade refers to the quality of the metal or substrate being processed. Common materials include stainless steel, aluminum, and titanium. In B2B transactions, understanding material grade is crucial as it affects durability, corrosion resistance, and overall performance in various applications. Higher grades often entail better mechanical properties and longer service life. -

Tolerance

Tolerance defines the allowable variation in a physical dimension of a part. Precision in laser cutting and engraving is vital, especially for industries like medical devices and aerospace where even minor deviations can lead to failures. Ensuring tight tolerances enhances product quality and reliability, making it a key consideration for buyers. -

Surface Finish

Surface finish is a measure of the texture of a surface, often specified in Ra (Roughness Average) values. This property is particularly significant in applications requiring high cleanliness and aesthetic appeal, such as in the medical field. A smoother surface finish can improve performance characteristics, including reduced friction and better adhesion for coatings. -

Power Output

The power output of a laser system, measured in watts, affects the cutting speed and depth of penetration into materials. Higher wattage can lead to faster processing times but may also require more robust safety measures. Understanding power output is essential for optimizing production efficiency and ensuring that the laser system is suitable for specific applications. -

Wavelength

Different laser types (e.g., CO2, fiber, Nd:YAG) operate at varying wavelengths, influencing their suitability for different materials. Wavelength impacts absorption rates in materials, which is critical for effective cutting or marking. Buyers should consider the laser wavelength in relation to the materials they work with to achieve optimal results.

Which Trade Terms Are Essential for Understanding Northeast Laser and Electropolish Services?

Familiarity with industry jargon is vital for making informed decisions. Here are some common trade terms relevant to Northeast Laser and Electropolish:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the laser processing sector, understanding OEM relationships can help buyers identify trusted suppliers and gauge the quality of components used in production. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and production planning. Knowing the MOQ can help businesses negotiate better pricing and ensure they meet their operational needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a formal process in which a buyer solicits price offers from suppliers for specific services or products. This term is vital for B2B transactions as it enables buyers to compare costs and services, ensuring they receive the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify details such as delivery points, risk transfer, and cost allocation. Understanding Incoterms is essential for avoiding disputes and ensuring smooth logistics in cross-border transactions. -

Passivation

Passivation refers to the process of treating metal surfaces to reduce corrosion. This is particularly important in industries that require high standards of cleanliness and longevity. Buyers should consider passivation services as part of their laser processing needs to enhance the durability of their products. -

Electropolishing

Electropolishing is an electrochemical process that removes material from a metallic surface, improving its finish and corrosion resistance. Understanding this term helps buyers appreciate the value of surface treatment in enhancing product performance, particularly in specialized industries such as aerospace and medical devices.

By being well-versed in these technical properties and trade terms, B2B buyers can make informed decisions when sourcing laser and electropolishing services, ultimately leading to more successful partnerships and superior product outcomes.

Navigating Market Dynamics and Sourcing Trends in the northeast laser and electropolish Sector

What are the Current Trends Influencing the Northeast Laser and Electropolish Market?

The northeast laser and electropolish sector is experiencing significant transformations driven by technological advancements, evolving customer needs, and global market dynamics. A notable trend is the increasing demand for precision and customization in laser applications, particularly in industries such as medical devices and aerospace. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to enhance their manufacturing capabilities, they are gravitating towards suppliers that offer tailored solutions. This trend is also fueled by advancements in laser technologies, such as fiber lasers and hybrid systems, which provide higher efficiency and versatility.

Furthermore, the push towards automation and Industry 4.0 is reshaping sourcing strategies. Businesses are increasingly adopting smart manufacturing practices, integrating laser systems with IoT devices for real-time monitoring and predictive maintenance. This shift allows buyers to optimize production processes and reduce downtime, making suppliers who can offer integrated solutions more attractive.

Another key market dynamic is the growing emphasis on speed and agility in supply chains. With the rise of just-in-time manufacturing, companies are prioritizing suppliers who can ensure quick turnaround times, as evidenced by Northeast Laser’s ability to offer 2-3 day service. This responsiveness is critical for international buyers who need to remain competitive in fast-paced markets.

How Does Sustainability and Ethical Sourcing Impact the Northeast Laser and Electropolish Sector?

Sustainability is becoming a cornerstone of sourcing strategies for businesses globally, and the northeast laser and electropolish sector is no exception. Environmental concerns related to manufacturing processes are prompting buyers to seek suppliers who prioritize eco-friendly practices. This includes the use of sustainable materials and energy-efficient laser systems, which not only reduce environmental impact but also align with the corporate social responsibility goals of many organizations.

Ethical sourcing is also gaining traction, particularly among international buyers who are increasingly scrutinizing supply chains for compliance with labor and environmental standards. Suppliers that can demonstrate a commitment to ethical practices, such as fair labor conditions and environmentally responsible waste management, will have a competitive edge. Certifications such as ISO 14001 for environmental management systems or adherence to the Global Reporting Initiative can enhance a supplier’s credibility and appeal.

Illustrative image related to northeast laser and electropolish

Moreover, the integration of ‘green’ materials in laser and electropolishing processes is becoming more prevalent. Buyers are looking for innovations that minimize chemical usage and reduce emissions during manufacturing. This shift not only supports sustainability goals but can also lead to cost savings in the long run, making it a critical consideration for B2B partnerships.

What is the Evolution of the Northeast Laser and Electropolish Sector?

The northeast laser and electropolish sector has evolved significantly over the past few decades, transitioning from basic laser marking technologies to advanced, high-precision applications. Founded with a singular focus on laser marking, companies like Northeast Laser & Electropolish have expanded their offerings to include a wide range of laser services, such as cutting, welding, and custom solutions tailored to various industries, including medical, aerospace, and telecommunications.

The merger of Northeast Laser with Biomerics in 2019 marked a pivotal moment, creating a comprehensive metals division that enhanced capabilities in metal processing for medical devices. This evolution reflects a broader trend within the industry, where collaboration and consolidation among companies are driving innovation and expanding service offerings. Today, the sector is characterized by its commitment to quality, customer service, and the continuous pursuit of technological advancements that meet the dynamic needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of northeast laser and electropolish

-

How can I ensure the quality of laser and electropolishing services from suppliers?

To ensure quality, conduct thorough research on potential suppliers. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Request samples of their previous work and customer testimonials to assess their capabilities. Additionally, consider visiting the supplier’s facility if possible, or request a virtual tour. Establishing clear communication about quality expectations and performance metrics will further help in verifying their commitment to quality. -

What factors should I consider when selecting a supplier for laser processing and electropolishing?

Key factors include the supplier’s experience in your industry, their technological capabilities, and the range of services offered. Evaluate their expertise in specific applications relevant to your needs, such as medical devices or industrial components. Assess their production capacity and turnaround times to ensure they can meet your demands. It’s also essential to consider their customer service, responsiveness, and willingness to collaborate on custom solutions. -

What is the minimum order quantity (MOQ) for laser and electropolishing services?

MOQs can vary significantly based on the supplier, the complexity of the project, and the materials used. Some suppliers may have flexible MOQs for custom projects, while others may require a minimum to justify setup and production costs. When negotiating with a supplier, clarify their MOQ policies and discuss your specific needs to find a mutually beneficial arrangement. This is particularly important for international buyers who may face additional logistical considerations. -

What are the payment terms typically offered by suppliers in the laser and electropolishing industry?

Payment terms can differ based on the supplier’s policies and your business relationship. Common terms include net 30 or net 60 days, where payment is due 30 or 60 days after invoicing. Some suppliers may require a deposit upfront, especially for custom projects. Ensure you discuss payment methods, such as bank transfers or letters of credit, particularly for international transactions, to avoid any misunderstandings. -

How can I customize laser and electropolishing services to meet my specific needs?

Most reputable suppliers are open to customization, especially for specialized industries. Start by clearly defining your project requirements, including dimensions, materials, and desired finishes. Engage in discussions with your supplier to explore available options and their capabilities for custom solutions. Providing detailed specifications and examples of desired outcomes will help the supplier better understand your needs and create a tailored solution. -

What are the logistics considerations for sourcing laser and electropolishing services internationally?

Logistics is crucial when sourcing internationally. Consider shipping times, costs, and customs regulations for your specific region. It’s essential to understand the supplier’s capabilities regarding shipping and whether they can assist with logistics. Additionally, factor in any potential delays at customs and ensure proper documentation is in place to facilitate a smooth delivery process. Collaborating with a logistics partner may also help streamline the process. -

What types of materials can be processed with laser technology and electropolishing?

Laser processing can handle a wide array of materials, including metals, plastics, ceramics, and wood. Commonly processed metals include stainless steel, aluminum, and titanium, which are often used in medical and industrial applications. Electropolishing is particularly effective for stainless steel and other non-ferrous metals, enhancing their surface finish and corrosion resistance. Always confirm with your supplier about their capabilities with specific materials to ensure compatibility with your project. -

How can I verify the supplier’s compliance with international standards?

To verify compliance, request documentation of certifications such as ISO 13485 for medical devices or other relevant industry standards. Conducting audits or assessments of their facilities can also provide insight into their adherence to regulations. Additionally, inquire about their quality control processes and practices to ensure they align with international norms. Building a strong relationship based on transparency will facilitate better collaboration and trust throughout your business dealings.

Top 5 Northeast Laser And Electropolish Manufacturers & Suppliers List

1. Northeast Laser & Electropolish – Laser Marking Systems

Domain: markingmachinery.com

Registered: 2000 (25 years)

Introduction: Northeast Laser & Electropolish, LLC specializes in high-quality marking machinery solutions, particularly laser marking systems. Their product line includes fiber laser markers, CO2 laser markers, UV laser markers, and green laser markers, designed for various industrial applications. These marking machines are used across industries such as aerospace, automotive, medical, defense, and electronic…

2. Northeast Laser & Electropolish – Laser Welding & Marking Services

Domain: qmed.com

Registered: 1995 (30 years)

Introduction: Northeast Laser & Electropolish provides contract laser welding services, laser marking services, laser cut parts and laser cutting services, and laser engraving services. They are one of the only laser job shop facilities with an in-house electropolishing and passivating division. The company operates around-the-clock with unmatched capacity, offering turnaround times typically of 2-3 days, with …

3. Northeast Laser & Electropolish – Laser Processing & Finishing Services

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Northeast Laser & Electropolish provides chemical etching, laser engraving, deep engraving, electropolishing, and other laser processing and finishing services. They work with bare and coated metals, glass, leather, marble, plastics, and wood.

4. Northeast Laser & Electropolish – Laser Processing & Finishing Services

Domain: pitchbook.com

Registered: 2004 (21 years)

Introduction: Northeast Laser & Electropolish provides laser processing and finishing services, including laser marking, welding, cutting, engraving, electropolishing, and passivating. They serve various industries in the US, processing precision parts, components, and sub-assemblies made from metals, plastics, ceramics, and wood. The company emphasizes rapid turn-around, flexibility, and precise quality contro…

5. Northeast Laser & Electropolish – Metal Processing Services

Domain: bloomberg.com

Registered: 1993 (32 years)

Introduction: Northeast Laser & Electropolish LLC operates in the metal processing industry, providing contract manufacturing, laser processing, machining, and metal finishing services. The company serves customers in the United States.

Strategic Sourcing Conclusion and Outlook for northeast laser and electropolish

In today’s competitive landscape, strategic sourcing of laser and electropolishing services is paramount for businesses aiming to enhance operational efficiency and product quality. Northeast Laser & Electropolish, with over 30 years of industry expertise, stands out as a reliable partner, offering a diverse range of laser technologies and custom solutions tailored to meet specific application needs. Their commitment to quality and customer satisfaction ensures that buyers receive not only advanced products but also exceptional service, including rapid turnaround times and comprehensive support.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should recognize the strategic advantage of collaborating with a seasoned provider like Northeast Laser. By leveraging their capabilities in precision laser marking, welding, and electropolishing, companies can significantly improve their production processes and product durability.

Looking ahead, the merger of Northeast Laser with Biomerics signals a promising expansion of services in the medical device sector, enhancing their offerings and geographic reach. This is an opportune moment for businesses to explore partnerships that can drive innovation and competitive advantage. Engage with Northeast Laser today to discover how their solutions can elevate your operations and meet your specific requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.