A Deep Dive into Air Driyer Solution

Introduction: Navigating the Global Market for air driyer

Navigating the global market for air dryers presents a unique set of challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. One of the primary concerns is sourcing air dryers that not only meet technical specifications but also align with local regulations and environmental standards. This guide aims to provide a comprehensive overview of the air dryer market, covering essential topics such as types of air dryers, their applications across various industries, and the critical process of supplier vetting.

In today’s competitive landscape, understanding the nuances of air dryer technology is vital for making informed purchasing decisions. From refrigerated and desiccant air dryers to cycling and non-cycling options, each type has specific advantages that can impact operational efficiency and cost-effectiveness. Furthermore, this guide will delve into the factors influencing pricing, helping buyers assess value against budget constraints.

By equipping international B2B buyers with actionable insights, this guide empowers them to navigate the complexities of the air dryer market with confidence. Whether you are in Saudi Arabia looking for reliable suppliers or in Vietnam evaluating the latest technologies, the information provided will enable you to optimize your procurement strategies and enhance your operational capabilities. Embrace the opportunity to streamline your purchasing process and elevate your business performance with the right air dryer solutions.

Understanding air driyer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Refrigerated Air Dryer | Uses a refrigeration cycle to cool and condense moisture | Manufacturing, Automotive, Food Processing | Pros: Efficient moisture removal, compact design; Cons: Higher initial cost, may require more maintenance. |

| Desiccant Air Dryer | Utilizes desiccant materials to absorb moisture | Pharmaceutical, Electronics, Aerospace | Pros: Low operating costs, effective in low temperatures; Cons: Limited capacity, requires regular media replacement. |

| Membrane Air Dryer | Employs selective permeation to remove moisture | Oil & Gas, Chemical Processing, Textile | Pros: Compact and lightweight, low energy consumption; Cons: Limited moisture removal capacity, sensitive to pressure changes. |

| High-Temperature Air Dryer | Designed to handle elevated temperatures | Metalworking, Heavy Machinery | Pros: Durable and robust, suitable for high-temperature applications; Cons: Higher energy costs, less efficient at lower temperatures. |

| Cycling Refrigerated Air Dryer | Adjusts cooling based on demand to save energy | Industrial Applications, Compressed Air Systems | Pros: Energy-efficient, reduces wear on components; Cons: More complex design, potential for increased maintenance. |

What Are Refrigerated Air Dryers and Their Suitability for B2B Buyers?

Refrigerated air dryers are prevalent in various industries due to their efficiency in moisture removal. They operate by cooling compressed air to condense moisture, which is then removed. This type is suitable for manufacturing, automotive, and food processing sectors where consistent air quality is essential. B2B buyers should consider the initial investment versus long-term savings on maintenance and energy costs, as these units tend to require more upkeep than other types.

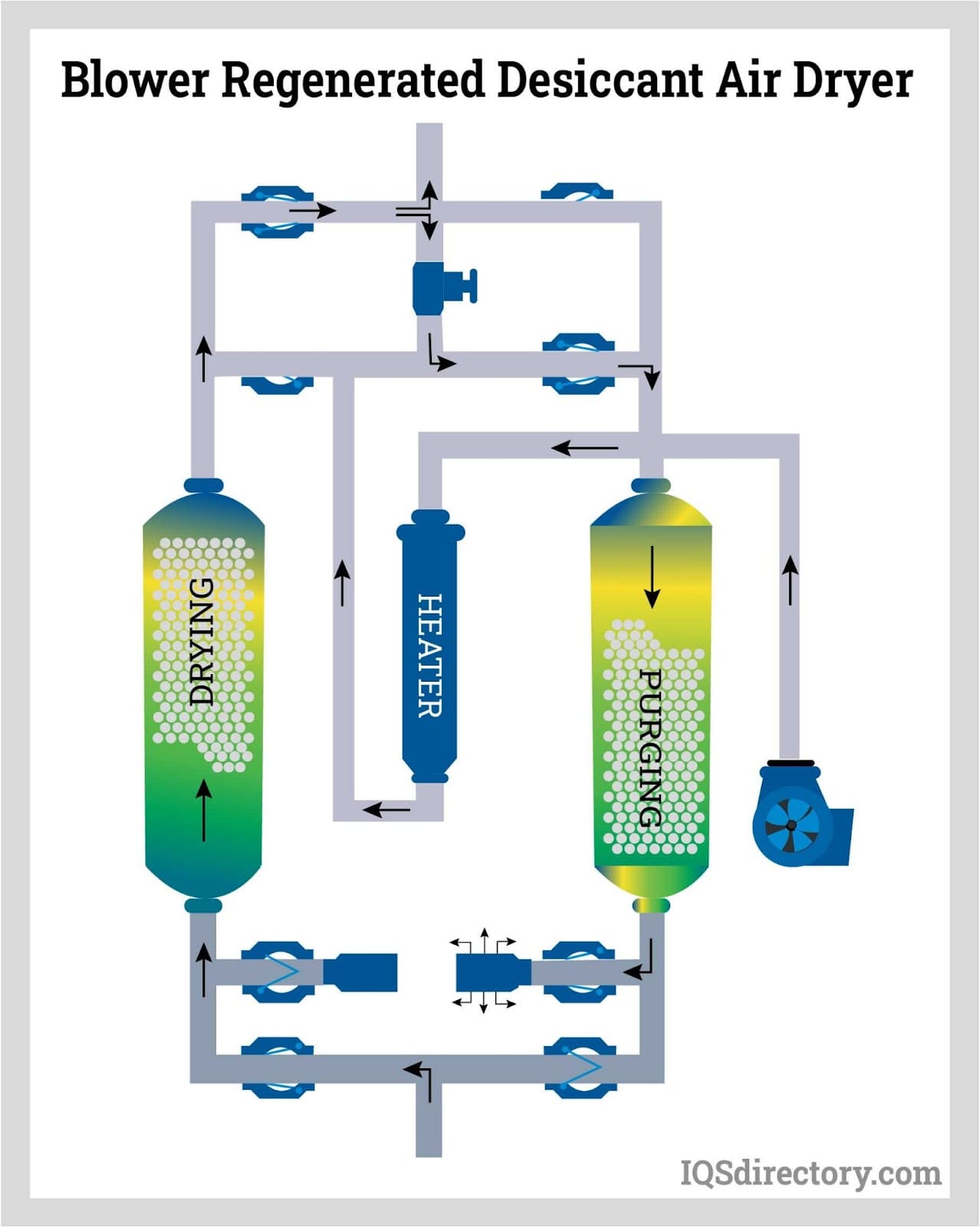

How Do Desiccant Air Dryers Work and When Should They Be Used?

Desiccant air dryers utilize hygroscopic materials to absorb moisture from the air. They are particularly effective in environments where low dew points are necessary, making them ideal for pharmaceuticals, electronics, and aerospace applications. For B2B buyers, the lower operating costs and effectiveness in colder temperatures are significant advantages. However, the need for regular replacement of desiccant media can be a downside that must be factored into total cost calculations.

What Are the Advantages of Membrane Air Dryers in Specific Industries?

Membrane air dryers operate on the principle of selective permeation, allowing moisture to pass through a membrane while retaining the air. These are particularly suitable for oil and gas, chemical processing, and textile industries where space is limited and energy efficiency is paramount. B2B buyers should weigh the compact design and low energy consumption against the limited moisture removal capacity, especially in high-demand situations.

Why Choose High-Temperature Air Dryers for Heavy Industries?

High-temperature air dryers are engineered to withstand elevated temperatures, making them ideal for metalworking and heavy machinery applications. They offer durability and robustness, which are essential in demanding environments. However, B2B buyers must consider the potential for higher energy costs and reduced efficiency at lower temperatures, making them less versatile than other dryer types.

How Do Cycling Refrigerated Air Dryers Enhance Efficiency in Industrial Applications?

Cycling refrigerated air dryers are designed to adjust their cooling capacity based on demand, enhancing energy efficiency. They are commonly used in industrial applications and compressed air systems. B2B buyers benefit from the energy savings and reduced wear on components, although the more complex design may lead to increased maintenance needs. Careful evaluation of operational requirements can help determine if this option aligns with business goals.

Key Industrial Applications of air driyer

| Industry/Sector | Specific Application of Air Dryer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Compressed Air Systems for CNC Machines | Enhances precision and reduces downtime | Capacity, energy efficiency, maintenance support |

| Food & Beverage | Packaging and Processing Equipment | Ensures product quality and extends shelf life | Compliance with food safety standards, moisture removal rates |

| Pharmaceutical | Cleanroom Environments | Maintains sterility and product integrity | Reliability, low dew point, certification requirements |

| Automotive | Paint Spraying and Finishing Processes | Improves finish quality and reduces rework | Airflow capacity, temperature tolerance, durability |

| Construction | Pneumatic Tools and Equipment | Increases productivity and tool lifespan | Portability, energy consumption, compatibility with tools |

How is Air Dryer Used in Manufacturing and What Problems Does It Solve?

In the manufacturing sector, air dryers are integral to compressed air systems used in CNC machines and other precision tools. These devices remove moisture from compressed air, preventing corrosion and wear on machinery. This leads to enhanced precision and reduced downtime due to maintenance or part failures. For international buyers, especially from regions like Africa and South America, sourcing air dryers with adequate capacity and energy efficiency is crucial to ensure operational reliability and cost-effectiveness.

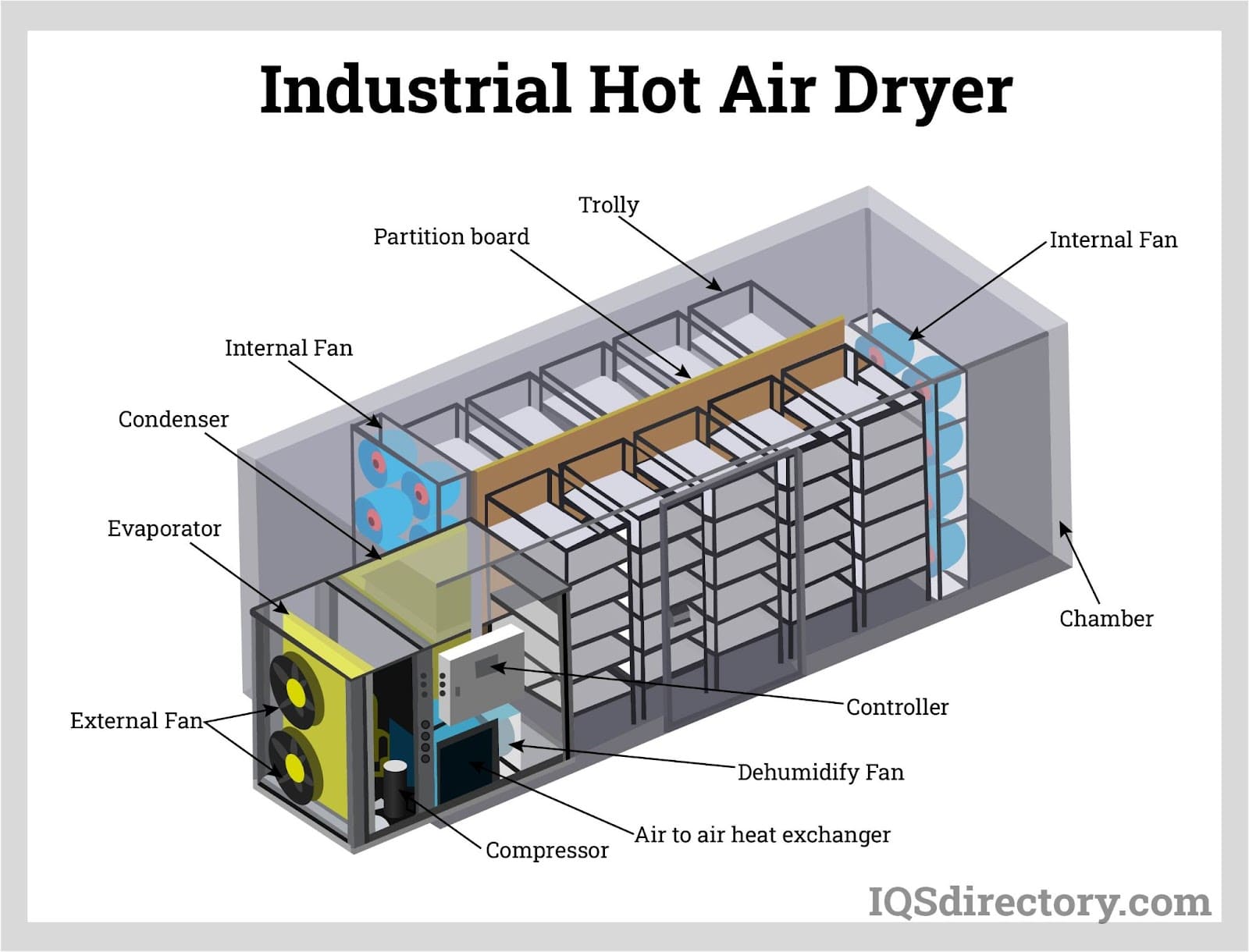

Illustrative image related to air driyer

What Role Do Air Dryers Play in the Food & Beverage Industry?

In the food and beverage industry, air dryers are essential for packaging and processing equipment. They remove moisture to prevent spoilage and maintain product quality, which is vital for extending shelf life. Compliance with food safety standards is a critical consideration for buyers in this sector. Thus, selecting air dryers that meet specific moisture removal rates and have certifications for food safety is imperative for international buyers from regions like the Middle East and Europe.

How Do Air Dryers Maintain Sterility in Pharmaceutical Applications?

In pharmaceutical manufacturing, air dryers are used in cleanroom environments to maintain sterility and product integrity. They help control humidity levels, which is crucial for producing sensitive medications. Reliability and a low dew point are essential requirements for air dryers in this sector. Buyers must ensure that the dryers meet stringent certification requirements to comply with industry regulations, particularly when sourcing from international markets.

What Benefits Do Air Dryers Provide in Automotive Finishing Processes?

In the automotive industry, air dryers are employed in paint spraying and finishing processes. They ensure that the compressed air used in spray guns is free from moisture, which can lead to defects in the paint finish and increased rework costs. For automotive manufacturers, selecting air dryers with adequate airflow capacity and temperature tolerance is critical. International buyers need to consider the durability and compatibility of air dryers with their existing equipment to optimize production efficiency.

Illustrative image related to air driyer

How Do Air Dryers Enhance Productivity in Construction?

In the construction sector, air dryers are essential for powering pneumatic tools and equipment. They provide dry air, which enhances tool efficiency and extends the lifespan of equipment. Increased productivity is a direct benefit of using air dryers, as they reduce downtime caused by tool malfunctions. When sourcing air dryers, construction companies should focus on portability and energy consumption to ensure they meet the demands of various job sites, particularly in diverse international environments.

3 Common User Pain Points for ‘air driyer’ & Their Solutions

Scenario 1: Inconsistent Air Quality Impacts Production Efficiency

The Problem: B2B buyers often struggle with the challenge of inconsistent air quality due to moisture in the compressed air supply. This is particularly crucial for industries like manufacturing and food processing, where dry air is essential for optimal operation. Moisture can lead to equipment corrosion, product spoilage, and decreased efficiency, ultimately affecting the bottom line. For buyers in regions with high humidity, such as parts of Africa and South America, this issue can be exacerbated, leading to unplanned downtime and costly repairs.

The Solution: To combat moisture-related issues, it’s vital to select the right type of air dryer based on your specific operational needs. Consider investing in refrigerated air dryers, which efficiently remove moisture from compressed air. Ensure that the chosen air dryer has the appropriate CFM (Cubic Feet per Minute) rating to match your system’s airflow requirements. Additionally, implementing a regular maintenance schedule for the air dryer can help maintain optimal performance. This includes checking for clogs, ensuring proper drainage, and replacing filters as needed. Investing in quality air dryers and maintenance will lead to more consistent air quality, enhancing overall production efficiency.

Scenario 2: High Operating Costs Due to Inefficient Equipment

The Problem: Many B2B buyers face skyrocketing operational costs due to inefficient air drying systems. Older or improperly sized air dryers can lead to excessive energy consumption, which not only inflates utility bills but also reduces the overall efficiency of compressed air systems. This is a common concern for businesses in regions where energy costs are high, such as parts of Europe and the Middle East.

The Solution: To address this issue, evaluate the efficiency ratings of your current air dryers and consider upgrading to more energy-efficient models. Look for air dryers with features such as variable speed drives or heat recovery systems that can significantly lower energy consumption. When sourcing new equipment, work with reputable suppliers who can provide energy audits and help you select the right equipment for your specific needs. This can also involve consulting with manufacturers to ensure proper sizing of the air dryer, which can lead to substantial savings in operational costs over time.

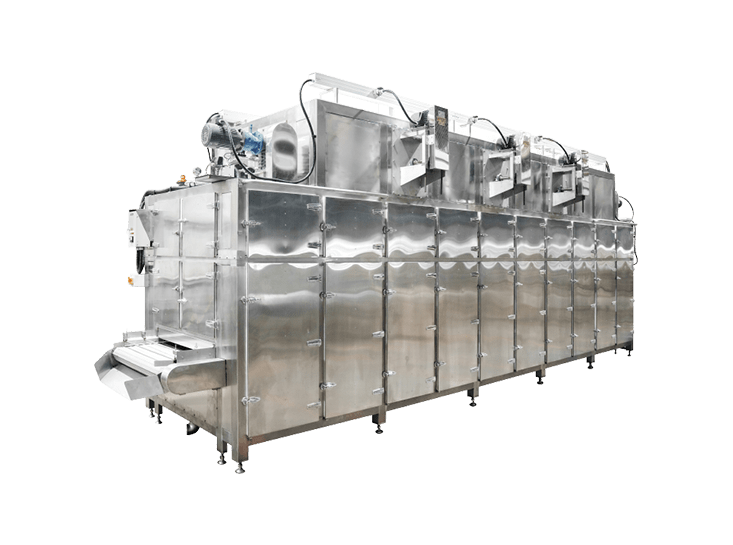

Illustrative image related to air driyer

Scenario 3: Difficulty in Sourcing Reliable Replacement Parts

The Problem: B2B buyers often encounter challenges when it comes to sourcing reliable replacement parts for air dryers. This issue can lead to prolonged downtime, especially in industries that rely heavily on compressed air for their operations. In regions with limited access to quality suppliers, such as some areas in Africa and South America, this can become a major pain point.

The Solution: To mitigate this risk, establish strong relationships with multiple suppliers who can provide a steady stream of replacement parts. Consider partnering with manufacturers that offer comprehensive support services, including expedited shipping for critical components. Additionally, maintain an inventory of essential spare parts based on the specific models of air dryers in use. This proactive approach can significantly reduce lead times for repairs and ensure that operations can resume quickly. Investing in reliable suppliers and maintaining an inventory will help avoid costly downtimes and ensure continuous operation.

Strategic Material Selection Guide for air driyer

What Are the Key Materials Used in Air Dryers and Their Properties?

Air dryers are essential components in compressed air systems, used to remove moisture and contaminants from the air. The selection of materials for air dryers significantly influences their performance, durability, and compatibility with various applications. Here, we analyze four common materials used in air dryer construction: aluminum, stainless steel, carbon steel, and plastic.

Illustrative image related to air driyer

How Does Aluminum Benefit Air Dryer Performance?

Aluminum is widely used in air dryer manufacturing due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of up to 200°C and can withstand moderate pressure levels. Aluminum’s corrosion resistance is also notable, especially when anodized, making it suitable for humid environments.

Pros: Aluminum is durable, lightweight, and cost-effective. Its excellent thermal properties enhance the efficiency of heat exchange processes in refrigerated air dryers.

Cons: While aluminum is resistant to corrosion, it can be susceptible to certain chemicals, which may limit its compatibility with specific media. Additionally, it may not be suitable for very high-pressure applications.

For international buyers, especially in regions like the Middle East and South America, compliance with standards such as ASTM B221 for aluminum extrusions is crucial. Buyers should also consider local environmental factors that may affect aluminum’s longevity.

Why Choose Stainless Steel for Air Dryers?

Stainless steel is another popular choice for air dryer components, particularly in environments where corrosion resistance is paramount. It can handle high temperatures (up to 600°C) and pressures, making it ideal for industrial applications.

Illustrative image related to air driyer

Pros: Stainless steel is highly durable and resistant to corrosion, making it suitable for harsh environments. It also maintains structural integrity under varying temperatures.

Cons: The primary drawback is its higher cost compared to aluminum and carbon steel. Manufacturing stainless steel components can also be more complex, leading to longer lead times.

International buyers should ensure that the stainless steel used complies with standards such as ASTM A240 or DIN 1.4301, which specify material properties for industrial applications. This is particularly important in regions like Europe, where compliance is strictly regulated.

What Role Does Carbon Steel Play in Air Dryer Construction?

Carbon steel is often used in air dryer frames and structural components due to its strength and cost-effectiveness. It can support high pressures and is typically rated for temperatures up to 400°C.

Illustrative image related to air driyer

Pros: Carbon steel is very strong and can be produced at a lower cost than stainless steel. Its robustness makes it suitable for heavy-duty applications.

Cons: However, carbon steel is prone to corrosion if not properly coated or treated. This can lead to premature failure in humid environments.

For international buyers, especially in Africa, it is essential to consider the environmental conditions where the air dryer will be used. Compliance with local standards, such as ASTM A36 for structural steel, is also vital to ensure product reliability.

Illustrative image related to air driyer

How Do Plastics Fit into Air Dryer Applications?

Plastics, particularly engineered thermoplastics, are increasingly being used in specific air dryer components, such as filters and valves. They can handle moderate temperatures (up to 80°C) and pressures but are generally not suitable for high-stress applications.

Pros: Plastics are lightweight, resistant to corrosion, and often less expensive than metals. They can be molded into complex shapes, allowing for innovative designs.

Cons: The main limitation is their lower temperature and pressure ratings compared to metals, which can restrict their use in more demanding applications.

Illustrative image related to air driyer

For international buyers, understanding the specific plastic grades and their compliance with standards such as ASTM D638 is crucial. This is particularly important in regions like Europe, where material certifications are often required.

Summary Table of Material Selection for Air Dryers

| Material | Typical Use Case for air dryer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Heat exchangers, casings | Lightweight, excellent thermal conductivity | Susceptible to certain chemicals | Low |

| Stainless Steel | Structural components, frames | High durability, corrosion resistant | Higher cost, complex manufacturing | High |

| Carbon Steel | Heavy-duty structural parts | Strong, cost-effective | Prone to corrosion if untreated | Medium |

| Plastic | Filters, valves | Lightweight, corrosion resistant | Lower temperature/pressure ratings | Low |

This material selection guide provides a comprehensive overview for B2B buyers, enabling informed decisions based on specific application needs and regional considerations.

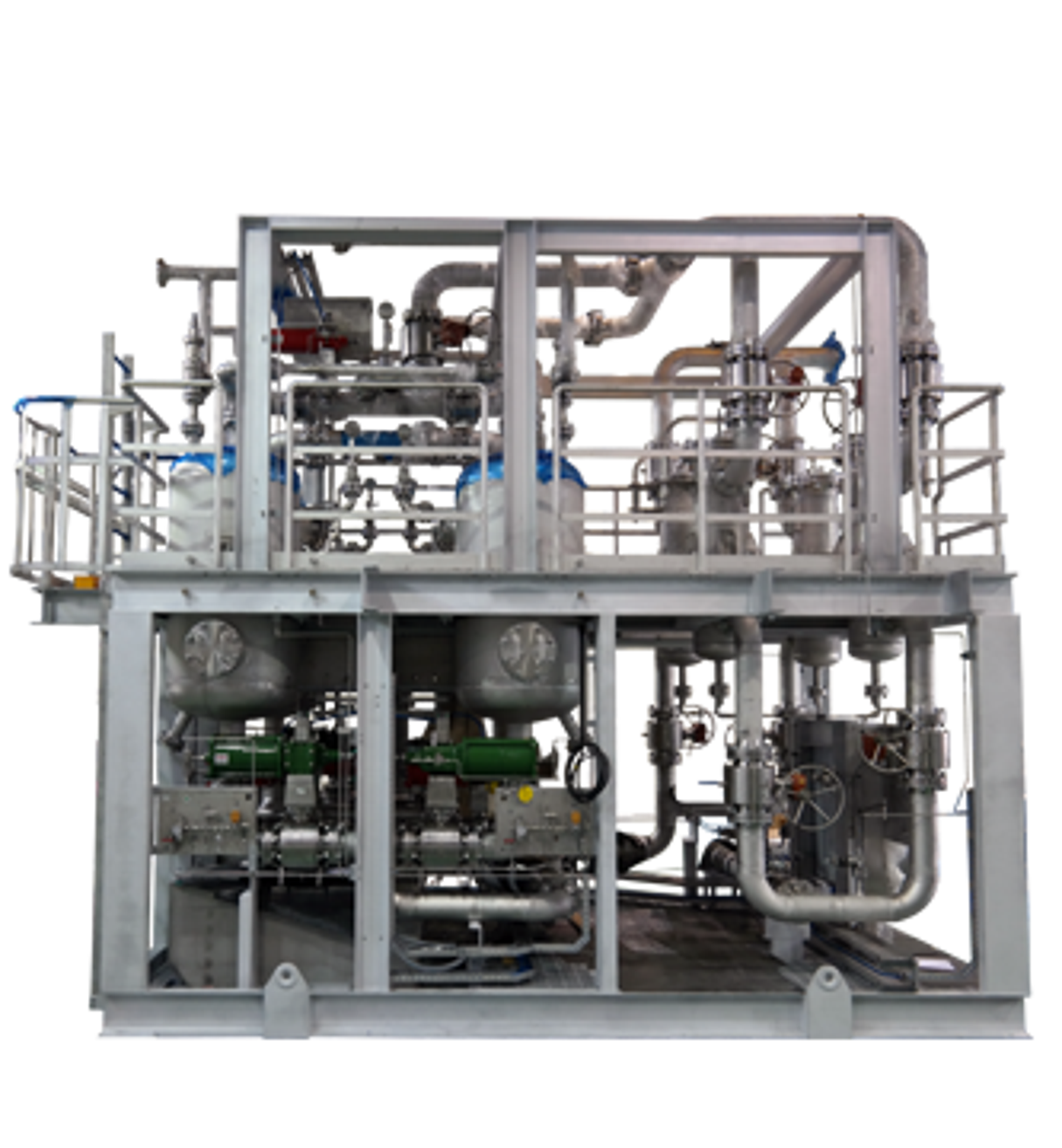

In-depth Look: Manufacturing Processes and Quality Assurance for air driyer

What Are the Main Stages of Air Dryer Manufacturing?

The manufacturing process of air dryers involves several critical stages that ensure efficiency, reliability, and quality. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality materials essential for constructing air dryers. Common materials include aluminum, stainless steel, and specific polymers that can withstand pressure and moisture. Suppliers often conduct preliminary quality checks to ensure that the materials meet industry specifications.

-

Forming: In this stage, raw materials are shaped into components using techniques such as machining, stamping, or casting. Advanced CNC (Computer Numerical Control) machines are frequently employed to achieve precise dimensions and tolerances, which are vital for the proper functioning of air dryers.

-

Assembly: Once components are formed, they are assembled into the final product. This step can involve manual labor as well as automated processes, such as robotic assembly lines, depending on the manufacturer’s capabilities. Components such as filters, heat exchangers, and condensate drains are integrated to create a fully functional air dryer.

-

Finishing: The final stage involves applying protective coatings, surface treatments, or painting to enhance durability and aesthetics. This is crucial in preventing corrosion and ensuring that the air dryer can perform optimally in various environmental conditions.

What Quality Control Measures Are Essential in Air Dryer Manufacturing?

Quality control (QC) is a fundamental aspect of the air dryer manufacturing process, ensuring that products meet international and industry-specific standards.

-

Relevant International Standards: Compliance with ISO 9001 is critical for manufacturers as it outlines the requirements for a quality management system. This certification demonstrates the manufacturer’s commitment to quality and continuous improvement. Other certifications such as CE mark (for compliance with European health, safety, and environmental protection standards) and API (American Petroleum Institute) standards for specific applications are also relevant.

-

QC Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival at the manufacturing facility. Materials that do not meet specifications are rejected or returned.

– In-Process Quality Control (IPQC): During manufacturing, various checkpoints ensure that processes are followed correctly. This includes monitoring machine settings, tolerances, and assembly techniques.

– Final Quality Control (FQC): Before shipping, finished products undergo rigorous testing to ensure they meet all specifications and performance standards. This can include pressure tests, leak tests, and functionality assessments. -

Common Testing Methods: Testing methods for air dryers can include:

– Performance Testing: Assessing the dryer’s ability to remove moisture and contaminants from compressed air under specified conditions.

– Durability Testing: Simulating extended use to evaluate the lifespan of components.

– Electrical Safety Testing: Ensuring that electrical components comply with safety standards to prevent hazards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is paramount to ensuring product reliability. Here are several methods:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, QC processes, and compliance with international standards firsthand. This can be an effective way to gauge the supplier’s commitment to quality.

-

Quality Assurance Reports: Requesting detailed QC reports from suppliers can provide insights into their testing methodologies and results. Buyers should look for documented evidence of compliance with relevant standards and any certifications the supplier holds.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing and QC processes. These inspections often include material checks, production monitoring, and final product inspections.

What Are the Nuances of Quality Control for International Buyers?

International buyers must be aware of specific nuances regarding QC certifications and practices, particularly in different regions:

-

Regional Standards Variability: Different countries may have varying quality standards and regulations. For instance, while ISO 9001 is globally recognized, some regions may have additional local certifications that are necessary for compliance.

-

Cultural and Communication Factors: Effective communication is critical in ensuring that quality expectations are understood. Language barriers or cultural differences may affect the clarity of specifications and requirements.

-

Logistical Considerations: Shipping and logistics can impact product quality during transport. Buyers should ensure that their suppliers have proper packaging and handling procedures in place to prevent damage during shipment.

-

Post-Sale Support and Warranty Terms: Understanding the supplier’s warranty and support terms is essential for managing quality issues that may arise after purchase. Clear terms regarding repairs, replacements, and service availability can significantly impact the buyer’s experience.

Conclusion

The manufacturing processes and quality assurance measures for air dryers are intricate and vital for ensuring product reliability. By understanding these processes, B2B buyers can make informed decisions, ensuring they partner with manufacturers that prioritize quality and compliance with international standards. Through careful verification of supplier practices and leveraging established QC frameworks, businesses can enhance their operational efficiency and product performance, ultimately leading to greater customer satisfaction and success in their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air driyer’

Introduction

This sourcing guide is designed to help international B2B buyers navigate the complexities of procuring air dryers. With various types and specifications available, understanding the essential steps in the sourcing process is crucial for making informed purchasing decisions that align with operational needs and budget constraints.

1. Identify Your Application Requirements

Understanding the specific application for which the air dryer will be used is fundamental. Different industries and processes may require varying levels of moisture removal, air flow rates, and operational temperatures.

– Consider factors such as: the type of compressor used, the environment in which the dryer will operate, and the quality of air required for downstream applications.

2. Define Your Technical Specifications

Clearly outline the technical requirements of the air dryer you need. This includes aspects like flow rate (measured in CFM), pressure drop, energy efficiency ratings, and the type of dryer (refrigerated, desiccant, or membrane).

– Look for: manufacturers’ data sheets that detail performance metrics, ensuring they meet your operational standards.

3. Research and Shortlist Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in air dryers. This step is critical to ensuring product quality and supplier reliability.

– Key actions include: checking industry certifications, reading reviews, and requesting product samples or demonstrations to assess quality firsthand.

Illustrative image related to air driyer

4. Evaluate Supplier Certifications and Compliance

Verify that potential suppliers adhere to international standards and regulations relevant to your market. Compliance with safety and quality certifications can significantly impact the reliability of the air dryer.

– Important certifications may include: ISO 9001 for quality management systems, CE marking for European markets, and local regulatory compliance in your region.

5. Request Quotes and Compare Pricing

Once you have a shortlist of suppliers, request detailed quotes that outline pricing, terms of sale, and delivery timelines. This is essential for budget planning and financial negotiations.

– Be mindful of: hidden costs such as shipping, installation, and maintenance services that may not be included in the initial quote.

6. Assess After-Sales Support and Warranty Options

Evaluate the after-sales support offered by suppliers, including warranty terms, maintenance services, and availability of replacement parts. Reliable support can save significant costs and downtime in the long run.

– Inquire about: the duration of the warranty, what it covers, and the supplier’s process for handling service requests.

7. Finalize Your Purchase and Establish Payment Terms

Once you have selected a supplier based on your evaluations, finalize your purchase agreement. Ensure that all terms, including payment schedules, delivery dates, and installation requirements, are clearly defined.

– Consider payment options: such as credit terms or financing that may benefit your cash flow, especially for larger orders.

Illustrative image related to air driyer

By following this checklist, B2B buyers can streamline their sourcing process for air dryers, ensuring they make well-informed decisions that align with their operational needs and budgetary constraints.

Comprehensive Cost and Pricing Analysis for air driyer Sourcing

What are the Key Cost Components in Air Dryer Sourcing?

When sourcing air dryers, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality metals and components used in the construction of air dryers can increase initial costs but may lead to enhanced performance and longevity.

-

Labor: Labor costs vary by region and affect the pricing of air dryers. In areas with higher labor costs, such as Europe, manufacturing expenses will be higher compared to regions in Africa or South America where labor may be less expensive.

-

Manufacturing Overhead: This encompasses all indirect costs associated with the production of air dryers, such as utilities, rent, and equipment maintenance. Efficient production processes can help mitigate these costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom air dryer designs. This is a one-time investment but can significantly influence the per-unit cost.

-

Quality Control: Ensuring that air dryers meet regulatory and performance standards requires a robust QC process, which adds to the overall expense. Certifications such as ISO and CE can also influence pricing.

-

Logistics: Shipping costs, including freight and customs duties, can vary greatly based on the destination. International buyers should account for these costs when assessing total expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and make a profit. This margin can vary significantly based on competition, brand reputation, and product uniqueness.

How Do Price Influencers Impact Air Dryer Costs?

Several factors influence the pricing of air dryers, which are crucial for B2B buyers to consider:

-

Volume/MOQ: Purchasing in bulk can significantly lower the unit cost due to economies of scale. Suppliers often offer discounts for larger orders, making it essential to assess your needs accurately.

-

Specifications and Customization: Custom-designed air dryers tailored to specific requirements can incur additional costs. Buyers should weigh the benefits of customization against the potential for higher pricing.

-

Materials: The quality of materials used directly affects both performance and cost. Opting for higher-grade materials may yield better durability but will come at a higher initial investment.

-

Quality and Certifications: Air dryers that meet stringent quality standards or certifications often come with a premium price. However, investing in certified products can lead to reduced operational issues and long-term savings.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with proven track records may charge more but provide better service and product quality.

-

Incoterms: Understanding the terms of shipment is vital for international buyers. Different Incoterms can affect the total landed cost, including responsibilities for shipping, insurance, and duties.

What Tips Can Help Buyers Optimize Air Dryer Sourcing Costs?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-effectiveness in sourcing air dryers:

-

Negotiation: Engage in negotiations with suppliers to secure better pricing or favorable terms. Leveraging volume commitments or long-term contracts can strengthen your position.

-

Focus on Total Cost of Ownership (TCO): Rather than just considering the purchase price, evaluate the total cost of ownership, including maintenance, energy consumption, and operational efficiency. This approach can reveal the true value of the investment.

-

Understand Pricing Nuances: Be aware of regional pricing variations and the factors that influence them. For example, logistics costs can differ widely depending on the supplier’s location and the chosen shipping method.

-

Evaluate Multiple Suppliers: Compare offerings from various suppliers to ensure competitive pricing. This also allows you to assess the quality of service and support each supplier provides.

-

Stay Informed About Market Trends: Keeping abreast of industry trends and innovations can provide insights into pricing shifts and new technologies that may offer better performance or cost savings.

Disclaimer on Indicative Prices

Prices for air dryers can fluctuate based on market conditions, supplier pricing strategies, and regional economic factors. The figures provided are indicative and should be verified with suppliers for accuracy. Always request quotes that reflect your specific requirements and purchasing conditions.

Illustrative image related to air driyer

Alternatives Analysis: Comparing air driyer With Other Solutions

Exploring Alternatives to Air Dryers: What Are Your Options?

In the industrial sector, maintaining air quality is crucial for operational efficiency and equipment longevity. While air dryers are a popular solution for removing moisture from compressed air, several alternatives exist that may suit specific operational needs better. This section evaluates air dryers against viable alternatives, helping B2B buyers make informed decisions based on performance, cost, and ease of implementation.

Comparison Table

| Comparison Aspect | Air Dryer | Desiccant Dryer | Membrane Dryer |

|---|---|---|---|

| Performance | High efficiency; removes moisture effectively | Excellent moisture removal; ideal for low temperatures | Moderate efficiency; suitable for low to medium flow rates |

| Cost | Moderate initial investment; ongoing energy costs | Higher upfront cost; lower operational costs | Lower upfront cost; moderate energy consumption |

| Ease of Implementation | Requires specific installation space and power supply | More complex installation; needs precise settings | Simple setup; minimal space requirements |

| Maintenance | Routine filter changes; moderate upkeep | Frequent media replacement; higher maintenance | Low maintenance; occasional cleaning required |

| Best Use Case | Ideal for high-volume applications needing consistent quality | Best for environments with low temperatures and critical moisture levels | Suitable for compact spaces and lower flow applications |

Detailed Breakdown of Alternatives

Desiccant Dryer

Desiccant dryers utilize hygroscopic materials to absorb moisture from compressed air. They excel in environments where low dew points are essential, making them ideal for industries like pharmaceuticals and food processing. While they offer excellent moisture removal, they typically come with a higher upfront cost and require regular media replacement, which can increase maintenance efforts. Their complexity in installation may also deter some businesses, particularly those with limited technical resources.

Membrane Dryer

Membrane dryers employ selective permeation technology to separate moisture from compressed air. They are a cost-effective solution for low to medium flow applications and can be easily installed in various settings. Their compact design is an advantage for companies with space constraints. However, they may not provide the same level of efficiency as air or desiccant dryers, particularly in high-demand scenarios. Maintenance is minimal, but users should be aware of their limitations regarding dew point performance.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right air treatment solution depends on your specific operational requirements, including moisture levels, space availability, and budget constraints. Air dryers are ideal for high-volume applications with consistent moisture removal needs. In contrast, desiccant dryers are better suited for critical environments requiring low moisture levels, albeit at a higher initial cost. Membrane dryers offer a compact and simple solution for lower flow applications but may not match the performance of the other two options. Assessing these factors will empower B2B buyers to choose the best solution that aligns with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for air driyer

What Are the Essential Technical Properties of Air Dryers?

Understanding the key technical properties of air dryers is crucial for B2B buyers, particularly when making purchasing decisions that will affect operational efficiency and product quality. Here are some essential specifications to consider:

1. CFM Rating (Cubic Feet per Minute)

The CFM rating indicates the volume of air an air dryer can process per minute. This is a critical factor as it determines the dryer’s capacity to handle air from compressors effectively. Selecting an air dryer with the appropriate CFM rating ensures that your operations run smoothly without bottlenecks, preventing potential damage to tools or equipment due to excess moisture.

2. Pressure Drop

Pressure drop refers to the reduction in pressure as air passes through the dryer. A lower pressure drop indicates better efficiency, as it minimizes energy loss. For B2B buyers, understanding the pressure drop is essential for cost management, as higher drops can lead to increased energy consumption and operational costs.

3. Temperature Control

The ability to control the temperature of the air being dried is vital for maintaining optimal performance. Air dryers may come with built-in temperature controls or sensors that ensure the air is cooled effectively. This feature is particularly important in regions with high ambient temperatures, as it helps prevent equipment failure and ensures product quality.

4. Filtration Capability

Air dryers often include filters to remove oil, particulates, and moisture from the air. Understanding the filtration capability, including the type and efficiency of the filters used, is crucial for ensuring that the air quality meets industry standards. This is particularly important in sectors like manufacturing and pharmaceuticals, where air quality directly impacts product integrity.

5. Material and Build Quality

The materials used in the construction of an air dryer affect its durability and performance. Stainless steel and high-grade aluminum are commonly used for their resistance to corrosion and wear. Buyers should assess the material quality to ensure longevity and reliability, particularly in harsh operational environments.

Which Trade Terms Are Commonly Used in the Air Dryer Industry?

Familiarity with industry jargon is vital for effective communication and negotiation. Here are some common terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers seeking replacement parts or new equipment that meets specific standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers as it can impact inventory levels and cost management. Buyers should negotiate MOQs that align with their operational needs to avoid excess stock or supply shortages.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request a quote for specific products or services. This process allows buyers to compare pricing and terms from different suppliers, ensuring they make informed purchasing decisions.

Illustrative image related to air driyer

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, insurance, and liability, ensuring smoother transactions across borders.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for planning and inventory management, particularly in industries where timely delivery is critical.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed decisions when purchasing air dryers, ultimately enhancing operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the air driyer Sector

What Are the Current Market Dynamics and Key Trends in the Air Dryer Sector?

The global air dryer market is witnessing significant growth, driven by increasing demand across various industries such as manufacturing, automotive, and food processing. Key trends shaping the market include the rise of energy-efficient systems, advancements in technology, and a growing focus on automation. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, seek reliable solutions, understanding these dynamics becomes crucial.

Illustrative image related to air driyer

Emerging technologies such as IoT (Internet of Things) are playing a pivotal role in enhancing operational efficiency. Smart air dryers equipped with sensors and remote monitoring capabilities allow businesses to optimize performance and reduce downtime. Furthermore, the emphasis on sustainability is prompting manufacturers to develop eco-friendly models that utilize refrigerants with lower global warming potential (GWP).

Market dynamics are also influenced by regional factors. For instance, in Africa and the Middle East, rapid industrialization is driving demand for efficient air drying solutions. Conversely, European buyers are increasingly focused on compliance with stringent environmental regulations, pushing for innovations that align with sustainability goals. Understanding these trends allows B2B buyers to make informed decisions, ensuring they choose products that not only meet their operational needs but also align with their long-term strategies.

How Important Is Sustainability and Ethical Sourcing in the Air Dryer Sector?

Sustainability and ethical sourcing are becoming integral components of the air dryer sector. As businesses increasingly recognize their environmental impact, there is a growing demand for products that are manufactured responsibly. B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainable practices, including the use of recyclable materials and energy-efficient technologies.

The environmental impact of air dryers is significant, particularly concerning energy consumption and emissions. Manufacturers that invest in greener technologies, such as energy-efficient compressors and eco-friendly refrigerants, are more likely to attract international buyers looking to enhance their corporate social responsibility (CSR) credentials. Certifications like ENERGY STAR, ISO 14001, and various green labels serve as benchmarks for buyers assessing a supplier’s sustainability efforts.

Ethical supply chains are also gaining importance. Buyers are increasingly scrutinizing their suppliers to ensure fair labor practices and transparent sourcing. This focus on ethics not only improves brand reputation but also fosters long-term partnerships built on trust and shared values. For international B2B buyers, selecting suppliers with robust sustainability credentials can lead to better market positioning and customer loyalty.

What Has Been the Evolution of the Air Dryer Sector?

The air dryer sector has evolved significantly over the past few decades, transitioning from simple mechanical solutions to sophisticated, energy-efficient systems. Initially, air dryers were primarily designed to remove moisture from compressed air, a critical function in preventing equipment corrosion and ensuring product quality.

As industrial processes became more complex, the need for enhanced performance and reliability grew. This led to the development of advanced technologies, including refrigeration and desiccant drying methods. In recent years, the advent of digital technologies has transformed the landscape, with IoT-enabled air dryers offering real-time monitoring and predictive maintenance capabilities.

This evolution reflects broader trends in manufacturing and industry, where the focus is increasingly on efficiency, sustainability, and automation. For B2B buyers, understanding this historical context is essential for making informed purchasing decisions and selecting products that are aligned with future industry standards.

Frequently Asked Questions (FAQs) for B2B Buyers of air driyer

-

How do I choose the right air dryer for my industrial application?

Selecting the right air dryer involves evaluating your specific needs, such as the required airflow capacity (measured in CFM), the type of contaminants you want to remove, and the ambient conditions of your operating environment. Consider whether a refrigerated or desiccant dryer is more suitable for your application. Refrigerated dryers are typically better for general applications, while desiccant dryers excel in low-temperature or critical moisture removal situations. Always consult with suppliers for technical specifications and recommendations tailored to your industry. -

What are the key factors to consider when sourcing air dryers internationally?

When sourcing air dryers from international suppliers, focus on factors such as product quality, compliance with local regulations, and the supplier’s reputation. It’s crucial to verify certifications and quality assurance processes. Evaluate logistics capabilities, including shipping times and costs, as well as warranty and support services. Additionally, consider the supplier’s experience in your region, as this can influence their understanding of specific market needs and regulatory requirements. -

What is the typical minimum order quantity (MOQ) for air dryers?

Minimum order quantities for air dryers can vary significantly based on the manufacturer and the model you are interested in. Generally, MOQs can range from a single unit to several units, especially for specialized or customized equipment. It’s advisable to discuss your specific requirements with potential suppliers to determine their MOQs and whether they can accommodate smaller orders, especially if you’re testing the market or require a trial unit. -

What payment terms should I expect when purchasing air dryers internationally?

Payment terms for international purchases of air dryers often include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, typically ranging from 30% to 50%, with the balance due before shipment or upon delivery. It’s important to negotiate terms that are favorable and ensure that they align with your cash flow and financial strategies. Always clarify payment methods accepted, including bank transfers, credit cards, or escrow services. -

How can I ensure the quality of air dryers before purchasing?

To ensure product quality, request samples or visit the supplier’s production facilities if possible. Review the supplier’s quality assurance certifications and ask for references from other clients who have purchased similar products. Additionally, consider third-party quality inspections before shipment to verify that the air dryers meet your specifications and standards. Establishing clear quality criteria in your purchase agreement can also help mitigate risks associated with product quality. -

What are the logistics considerations when importing air dryers?

Logistics plays a critical role in importing air dryers. Ensure you understand the shipping methods available, including sea or air freight, and their associated costs and transit times. Be aware of import duties, taxes, and any applicable tariffs in your country. Choose a reliable freight forwarder who can assist with customs clearance and provide tracking information. Additionally, consider the warehousing and handling requirements upon arrival, especially for bulky or heavy equipment. -

Can I customize air dryers to meet specific operational needs?

Many manufacturers offer customization options for air dryers, allowing you to specify features such as size, capacity, or additional filtration systems. Customization can enhance the performance of the dryer in your specific operational context. Discuss your requirements with potential suppliers, and inquire about the feasibility and costs associated with custom orders. Keep in mind that customizations may lead to longer lead times, so plan accordingly. -

What are the common maintenance requirements for air dryers?

Regular maintenance of air dryers is essential to ensure optimal performance and longevity. Common maintenance tasks include checking and replacing filters, inspecting and cleaning condensate drains, and monitoring pressure gauges. Depending on usage, some air dryers may require more frequent servicing. Establish a maintenance schedule in collaboration with the supplier or manufacturer, and consider training your staff on basic maintenance procedures to prevent downtime and costly repairs.

Top 3 Air Driyer Manufacturers & Suppliers List

1. Compressed Air Advisors – Super-Dry D1 & Nano DXR 105

Domain: compressedairadvisors.com

Registered: 2015 (10 years)

Introduction: Air Dryers for Air Compressors: Refrigerated & Desiccant. Key products include: Super-Dry D1 – Desiccant Air Dryer – up to 70 CFM, priced at $759.00 (originally $795.00); Nano DXR 105 Direct Expansion Refrigerated Air Dryer – 105 SCFM, 115V/1Ph/60Hz, priced at $3,351.00 (originally $3,986.00).

2. Atlas Copco – Compressed Air Dryers

Domain: atlascopco.com

Registered: 1995 (30 years)

Introduction: Compressed Air Dryers – Complete Range from Atlas Copco USA. Key features include:

– Efficient moisture removal to prevent corrosion, equipment damage, and product spoilage.

– Dew points ranging from +3 to -70 °C (37.4 to -94°F) for precise air quality control.

– Eco-friendly design to reduce operational costs and carbon footprint.

– Types of air dryers offered:

1. Desiccant Air Dryers:

– T…

3. Reddit – Inline Desiccant Dryer

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: inline desiccant dryer, $250 inline containers that hold a gallon of desiccant, pressure vessel, aftercooler, filter with auto drain, standard desiccant dryer, refrigerated air dryer, filter unit from Amazon (B07Y41DZ75)

Strategic Sourcing Conclusion and Outlook for air driyer

In conclusion, strategic sourcing for air dryers is essential for businesses seeking efficiency, reliability, and cost-effectiveness. As companies in Africa, South America, the Middle East, and Europe evaluate their options, understanding the diverse range of air dryer technologies—from refrigerated to desiccant—will empower them to select the most suitable solutions for their specific operational needs. Key considerations should include the dryer’s capacity, energy consumption, and maintenance requirements, which can significantly impact overall productivity and operational costs.

International buyers are encouraged to leverage strategic partnerships with reputable suppliers to ensure they receive high-quality products that meet industry standards. Furthermore, exploring local pickup options can enhance supply chain efficiency, reduce shipping costs, and facilitate quicker access to necessary equipment.

Looking ahead, as demand for compressed air systems continues to rise globally, investing in advanced air dryer solutions will be pivotal in maintaining competitive advantages. It is an opportune time for businesses to refine their sourcing strategies, engage with trusted suppliers, and position themselves for success in an evolving market landscape. Let’s take the next step together towards sustainable and efficient air management solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.