Everything You Need to Know About Stainless Steel Structure Sourcing in 2025

Introduction: Navigating the Global Market for stainless steel structure

In the rapidly evolving global market, sourcing high-quality stainless steel structures presents a significant challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With the increasing demand for durable and corrosion-resistant materials across various industries, understanding the nuances of stainless steel sourcing is essential. This guide provides a comprehensive overview of stainless steel structural products, including beams, channels, and custom shapes, while addressing critical factors such as applications, supplier vetting, and cost considerations.

Navigating the complexities of stainless steel procurement can be daunting. Different grades and finishes serve unique purposes, from construction and architectural applications to manufacturing in chemical and food processing industries. Buyers will benefit from insights into how to evaluate suppliers, ensuring they align with industry standards and sustainability practices. Additionally, this guide will equip readers with the knowledge needed to make informed purchasing decisions, optimizing their supply chains and mitigating risks associated with quality and compliance.

By leveraging this resource, international B2B buyers can confidently approach the market, ensuring they select the right stainless steel structures for their specific needs while maximizing value and performance. As you delve into the following sections, you’ll gain actionable insights and expert guidance tailored to your geographical and industrial context, empowering you to make strategic sourcing decisions that drive success.

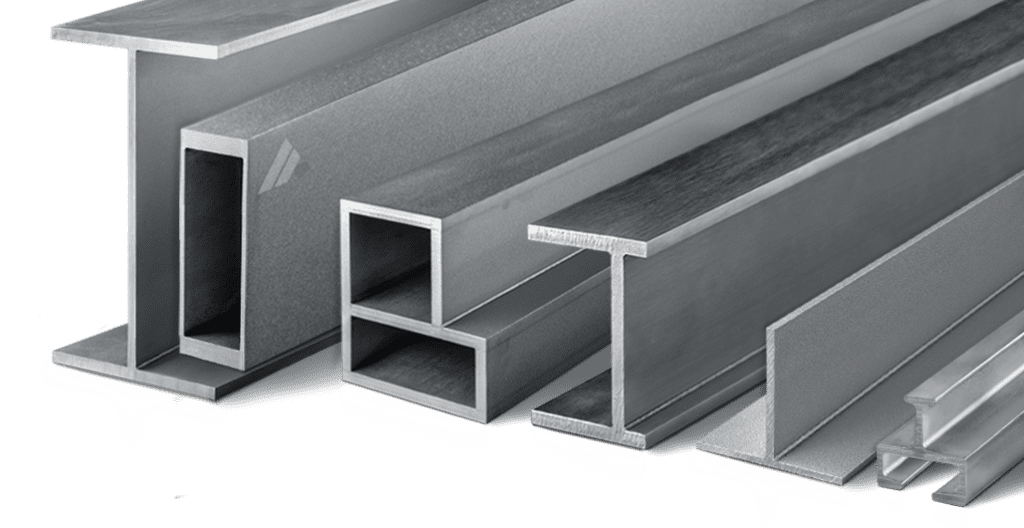

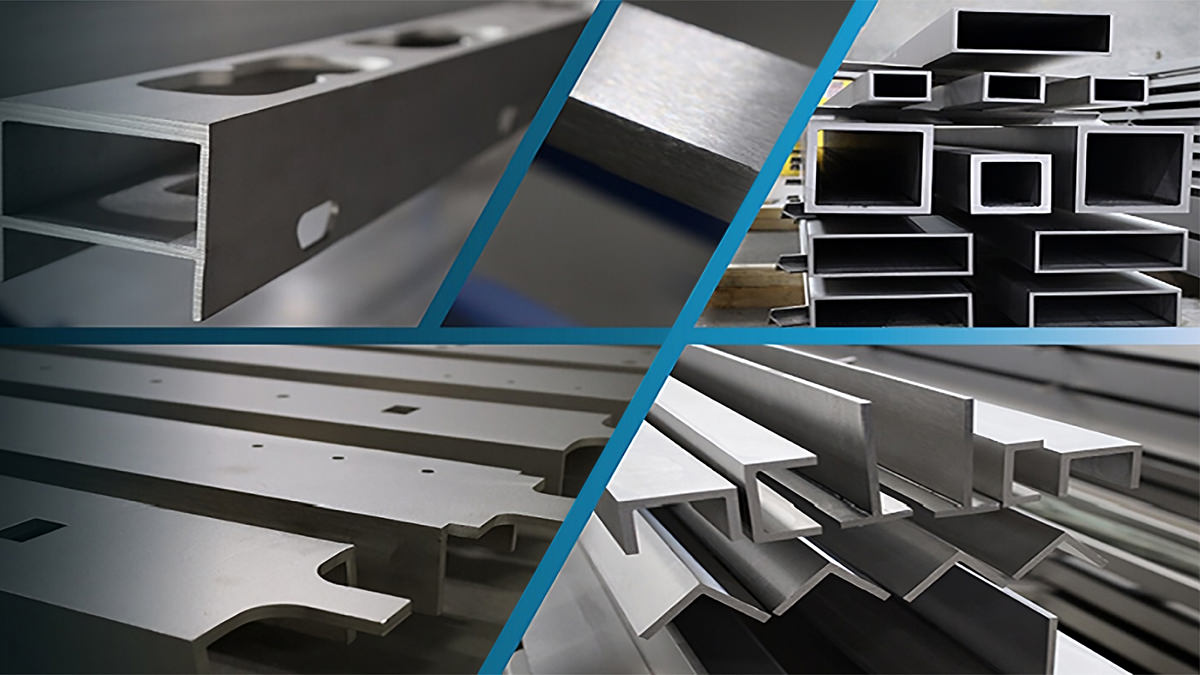

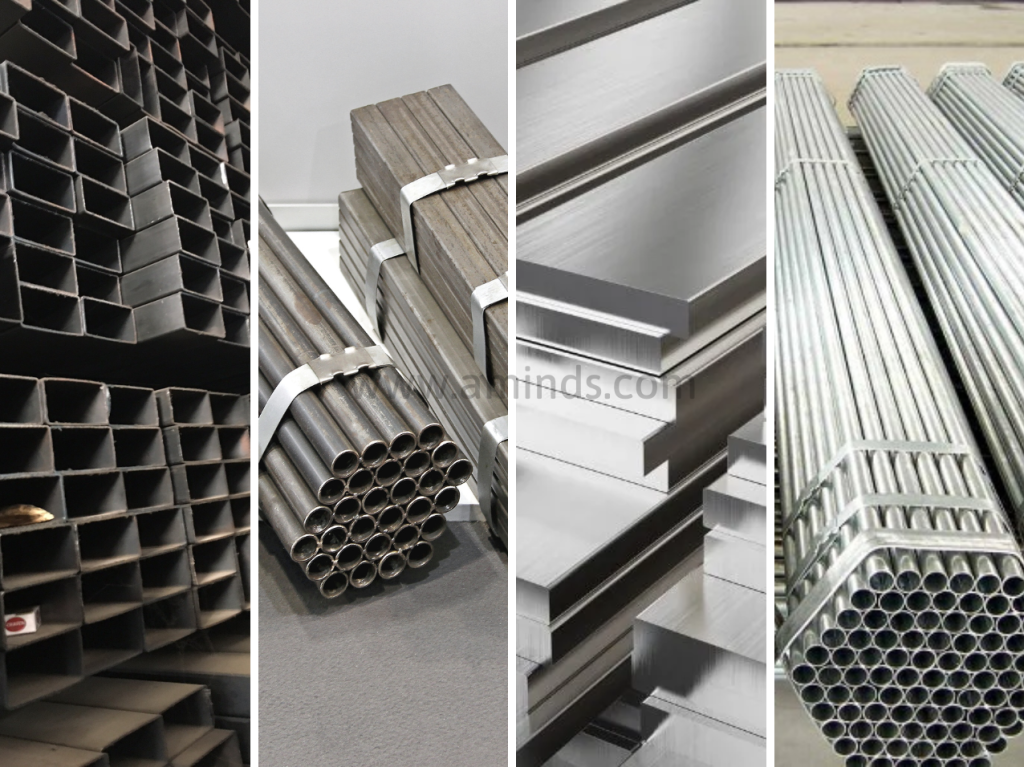

Understanding stainless steel structure Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Beams | I-beam or H-beam shape; high load-bearing capacity | Construction, Infrastructure, Manufacturing | Pros: Excellent strength-to-weight ratio, corrosion resistance. Cons: Higher initial cost compared to carbon steel. |

| Stainless Steel Channels | U-shaped profile; available in tapered and non-tapered | Structural support in buildings, bridges, and machinery | Pros: Versatile, easy to weld, good for various applications. Cons: Limited load capacity compared to beams. |

| Stainless Steel Angles | L-shaped cross-section; available in equal and unequal leg | Framing, bracing, and support structures | Pros: Economical, can be used in tight spaces. Cons: May require additional materials for complex structures. |

| Stainless Steel Tubes | Round, square, or rectangular; seamless or welded | Piping, railings, and structural frameworks | Pros: High corrosion resistance, aesthetic appeal. Cons: Costlier than traditional materials for non-visible applications. |

| Custom Stainless Steel Profiles | Tailored shapes to meet specific project requirements | Specialized applications across industries | Pros: Optimized for unique applications, enhances design flexibility. Cons: Longer lead times and potentially higher costs. |

What Are the Characteristics of Stainless Steel Beams?

Stainless steel beams, typically shaped as I-beams or H-beams, are renowned for their robust load-bearing capabilities. They are primarily used in construction and infrastructure projects, providing essential support in buildings and bridges. When considering a purchase, B2B buyers should evaluate the specific load requirements of their projects, as well as the higher initial costs compared to carbon steel alternatives. However, the long-term benefits, including durability and corrosion resistance, often justify the investment.

How Are Stainless Steel Channels Utilized in Industry?

Stainless steel channels feature a U-shaped profile and are available in both tapered and non-tapered variants. Their versatility makes them suitable for various structural applications, including support in buildings and machinery. B2B buyers should consider the specific load requirements and installation conditions when selecting channels. While they are easy to weld and adaptable, their load capacity is limited compared to beams, which may necessitate the use of additional supports in certain applications.

What Advantages Do Stainless Steel Angles Offer?

Stainless steel angles are characterized by their L-shaped cross-section and can be found in equal and unequal leg configurations. They are often employed for framing, bracing, and support structures, making them a staple in construction and manufacturing. Buyers appreciate their economical nature and ability to fit into tight spaces. However, for more complex structural needs, additional materials may be required to ensure stability, which should be factored into project planning.

Why Choose Stainless Steel Tubes for Your Projects?

Available in round, square, or rectangular shapes, stainless steel tubes can be seamless or welded, making them ideal for various applications, including piping and railings. Their aesthetic appeal and high corrosion resistance make them particularly valuable in both functional and visible applications. B2B buyers should weigh the benefits against the higher costs compared to traditional materials, especially for non-visible installations where cost savings may be prioritized.

What Are the Benefits of Custom Stainless Steel Profiles?

Custom stainless steel profiles are designed to meet specific project requirements, offering tailored solutions across various industries. This flexibility allows for optimized designs that enhance functionality and aesthetics. However, buyers should be prepared for potentially longer lead times and higher costs associated with custom orders. Understanding the unique needs of a project is crucial for determining whether the investment in custom profiles will yield sufficient returns in terms of performance and design.

Key Industrial Applications of stainless steel structure

| Industry/Sector | Specific Application of stainless steel structure | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft components and frames | High strength-to-weight ratio and corrosion resistance | Compliance with aviation standards and certifications |

| Food & Beverage | Processing equipment and storage tanks | Hygiene, durability, and resistance to corrosion | Food safety certifications and material grade specifications |

| Oil & Gas | Pipelines and offshore platforms | Structural integrity in extreme environments | Resistance to harsh chemicals and environmental conditions |

| Architecture and Construction | Structural beams and facades | Aesthetic appeal and longevity | Design flexibility and sustainability considerations |

| Pharmaceutical | Cleanroom structures and equipment supports | Compliance with stringent health regulations | Material traceability and cleanroom standards |

How is Stainless Steel Used in Aerospace Applications?

In the aerospace industry, stainless steel structures are critical for manufacturing aircraft components, such as frames, brackets, and fasteners. The unique properties of stainless steel, including its high strength-to-weight ratio and exceptional resistance to corrosion, make it ideal for use in environments exposed to extreme temperatures and pressures. International buyers must ensure that their suppliers comply with aviation industry standards and certifications, which vary by region. This guarantees that the materials meet the stringent safety and performance requirements necessary for aircraft applications.

What Role Does Stainless Steel Play in Food & Beverage Processing?

In the food and beverage sector, stainless steel is extensively used for processing equipment, storage tanks, and piping systems. Its non-reactive nature prevents contamination and ensures product purity, which is essential for maintaining hygiene standards. Additionally, stainless steel’s durability minimizes maintenance costs and extends the lifespan of equipment. Buyers in this industry should prioritize suppliers that provide materials with food safety certifications, such as those compliant with FDA or EU regulations, to guarantee the safety and quality of their products.

How is Stainless Steel Essential for Oil & Gas Infrastructure?

Stainless steel structures are vital in the oil and gas industry, particularly for pipelines, offshore platforms, and storage tanks. These applications require materials that can withstand harsh environmental conditions, such as extreme temperatures, corrosive substances, and high pressures. The structural integrity provided by stainless steel ensures the safety and reliability of operations. International buyers should focus on sourcing from suppliers who understand the specific environmental challenges of their operational regions and can provide materials that meet relevant industry standards and certifications.

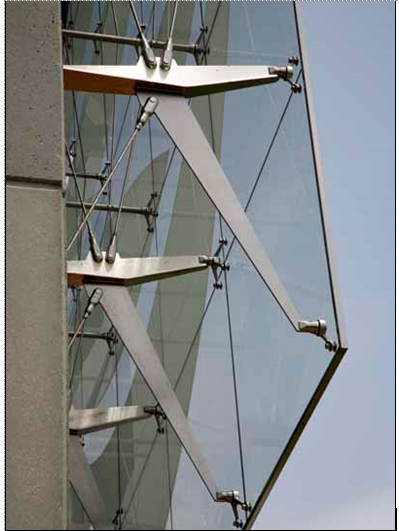

Why is Stainless Steel Important in Architectural Design?

In architecture and construction, stainless steel is favored for structural beams, facades, and decorative elements due to its aesthetic appeal and longevity. It can be fabricated into various shapes and finishes, allowing for innovative design solutions that enhance both functionality and visual impact. Buyers should consider sourcing stainless steel that meets local building codes and sustainability certifications, as these factors significantly influence project approval and overall environmental impact.

How is Stainless Steel Used in Pharmaceutical Facilities?

In the pharmaceutical industry, stainless steel is crucial for constructing cleanroom environments, equipment supports, and storage solutions. The material’s non-porous surface and resistance to corrosion facilitate compliance with strict health and safety regulations. Buyers must ensure that their suppliers can provide traceability of materials and adherence to cleanroom standards, which are essential for maintaining product integrity and safety in pharmaceutical manufacturing processes.

3 Common User Pain Points for ‘stainless steel structure’ & Their Solutions

Scenario 1: Supply Chain Delays Impacting Project Timelines

The Problem: B2B buyers often face significant delays in the supply chain for stainless steel structures, which can be detrimental to project timelines. This issue is especially pronounced in regions like Africa and South America, where logistical challenges, customs regulations, and limited local suppliers can lead to extended lead times. As a result, businesses may struggle to meet deadlines, leading to increased costs and potential loss of contracts.

The Solution: To mitigate supply chain delays, it is crucial to establish relationships with multiple suppliers across different regions. Buyers should conduct thorough market research to identify reliable stainless steel manufacturers and distributors who can provide not only the required products but also flexible delivery options. Utilizing a just-in-time inventory strategy can further alleviate pressure by ensuring materials arrive precisely when needed, rather than being stored for extended periods. Additionally, incorporating technology such as supply chain management software can improve visibility and tracking of orders, allowing buyers to anticipate delays and adjust their project schedules accordingly.

Scenario 2: Difficulty in Selecting the Right Stainless Steel Grade

The Problem: Many B2B buyers encounter confusion when selecting the appropriate grade of stainless steel for their specific applications. With various grades like 304 and 316, each offering different levels of corrosion resistance and strength, the wrong choice can lead to structural failures or increased maintenance costs. This is particularly critical in industries such as food and beverage, pharmaceuticals, and chemical processing, where hygiene and material compatibility are paramount.

The Solution: Buyers should start by consulting with material experts or manufacturers who can provide detailed information on the properties of different stainless steel grades. It’s essential to consider the specific environmental conditions and stresses the structures will face, such as exposure to chemicals, temperature variations, or moisture levels. Creating a comprehensive checklist of project requirements can help in making informed decisions. Additionally, utilizing case studies or industry benchmarks can illustrate how certain grades have performed in similar applications, guiding buyers toward the most suitable options for their needs.

Scenario 3: Challenges with Custom Fabrication of Stainless Steel Structures

The Problem: Custom fabrication of stainless steel structures poses unique challenges for B2B buyers, including design complexities, increased costs, and longer production times. This is often exacerbated by a lack of clear communication between buyers and fabricators, leading to misunderstandings about specifications and expectations. In industries where precision is critical, such as aerospace or architecture, these challenges can significantly impact project outcomes.

Illustrative image related to stainless steel structure

The Solution: To overcome these challenges, clear and detailed communication with fabricators is essential from the outset. Buyers should provide comprehensive design specifications, including dimensions, tolerances, and any required finishes. Engaging in a collaborative design process can help ensure that all parties are aligned on expectations. Furthermore, leveraging advanced fabrication technologies, such as laser cutting and 3D modeling, can improve precision and efficiency in the production process. Buyers should also consider requesting prototypes or smaller batches to test designs before full-scale production, minimizing the risk of costly errors down the line.

Strategic Material Selection Guide for stainless steel structure

What Are the Key Properties of Common Stainless Steel Materials for Structural Applications?

When selecting materials for stainless steel structures, it is crucial to understand the unique properties of different grades. The most commonly used stainless steel grades in structural applications include 304, 316, and duplex stainless steel. Each grade has distinct characteristics that influence their performance, durability, and suitability for various applications.

1. What Are the Key Properties of 304 Stainless Steel?

304 stainless steel is one of the most widely used grades due to its excellent corrosion resistance and good mechanical properties. It can withstand temperatures up to 870°C (1600°F) in intermittent service and 925°C (1700°F) in continuous service. Its resistance to oxidation and corrosion makes it suitable for a variety of environments, although it is less resistant to chlorides compared to grade 316.

Illustrative image related to stainless steel structure

Pros:

– High corrosion resistance in a wide range of environments.

– Good weldability and formability.

– Lower cost compared to other stainless steel grades.

Cons:

– Limited resistance to pitting and crevice corrosion in chloride environments.

– Not suitable for high-temperature applications beyond specified limits.

Impact on Application:

304 stainless steel is ideal for general applications in construction, food processing, and chemical industries, where exposure to mild corrosive environments is expected.

2. How Does 316 Stainless Steel Compare to 304?

316 stainless steel is often preferred for more demanding applications due to its enhanced corrosion resistance, particularly in chloride-rich environments. It can handle temperatures up to 870°C (1600°F) in intermittent service and 925°C (1700°F) in continuous service. The addition of molybdenum improves its resistance to pitting.

Pros:

– Superior corrosion resistance, especially against chlorides.

– High strength and toughness at elevated temperatures.

– Excellent weldability.

Cons:

– Higher cost compared to 304 stainless steel.

– Slightly less formable than 304.

Impact on Application:

316 stainless steel is commonly used in marine environments, chemical processing, and medical equipment, where corrosion resistance is critical.

3. What Are the Advantages of Duplex Stainless Steel?

Duplex stainless steel combines the properties of both austenitic and ferritic stainless steels, offering high strength and excellent corrosion resistance. It can withstand temperatures up to 300°C (572°F) and provides greater resistance to stress corrosion cracking.

Pros:

– High strength-to-weight ratio, allowing for lighter structures.

– Excellent resistance to pitting and crevice corrosion.

– Good weldability.

Illustrative image related to stainless steel structure

Cons:

– More complex manufacturing processes may increase costs.

– Requires careful control of heat treatment to avoid brittleness.

Impact on Application:

Duplex stainless steel is suitable for applications in the oil and gas industry, chemical processing, and marine environments, where high strength and corrosion resistance are essential.

What Specific Considerations Should International B2B Buyers Keep in Mind?

International buyers, particularly from Africa, South America, the Middle East, and Europe, must consider compliance with local standards such as ASTM, DIN, or JIS when selecting stainless steel materials. Understanding regional preferences for specific grades and their certifications is crucial for ensuring product acceptance in local markets. Additionally, factors such as import tariffs, shipping logistics, and supplier reliability can significantly impact procurement decisions.

Summary Table of Stainless Steel Materials

| Material | Typical Use Case for stainless steel structure | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 304 Stainless Steel | General construction, food processing | High corrosion resistance, low cost | Limited resistance to chlorides | Low |

| 316 Stainless Steel | Marine environments, chemical processing | Superior corrosion resistance | Higher cost than 304 | Med |

| Duplex Stainless Steel | Oil and gas, chemical processing | High strength-to-weight ratio | Complex manufacturing, higher cost | High |

This strategic material selection guide provides essential insights for B2B buyers looking to optimize their procurement of stainless steel structural components, ensuring they choose the right materials for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel structure

The manufacturing process and quality assurance of stainless steel structures are critical for ensuring that the final products meet the stringent demands of various industries. For B2B buyers, understanding these processes can help in making informed purchasing decisions and ensuring the reliability and longevity of the products they source.

What Are the Main Stages in the Manufacturing Process of Stainless Steel Structures?

The manufacturing of stainless steel structures typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial in producing high-quality products that meet specific engineering requirements.

1. Material Preparation

The process begins with the selection and preparation of raw materials. Stainless steel, primarily in grades 304 and 316, is chosen for its corrosion resistance and strength. Suppliers often source their materials from certified mills, ensuring compliance with international standards. The material is then cut to size, and any surface contaminants are removed through methods such as acid pickling or sandblasting, preparing it for further processing.

2. Forming Techniques: How Are Stainless Steel Structures Shaped?

Forming is a critical step where the raw stainless steel is shaped into structural components. Common techniques include:

Illustrative image related to stainless steel structure

- Hot Rolling: This involves heating the steel above its recrystallization temperature and shaping it into beams, channels, and angles. Hot-rolled sections provide excellent structural integrity and are often used in construction.

- Cold Rolling: In contrast, cold rolling involves shaping the metal at room temperature, which enhances its strength through strain hardening. This method is often used for thinner sections and provides a smoother finish.

- Extrusion and Welding: Custom shapes may be produced through extrusion processes. Laser welding is increasingly popular for creating high-strength joints with minimal distortion, particularly for complex profiles.

3. Assembly: What Are the Key Steps in Joining Components?

After forming, the components are assembled. This may involve various joining techniques, such as welding, bolting, or riveting. Quality welding is essential, often requiring skilled technicians who adhere to strict welding standards to ensure the integrity of the joints.

4. Finishing: How Is Surface Quality Achieved?

Finishing processes enhance the aesthetic and functional properties of stainless steel structures. Common finishing methods include:

- Polishing: This improves the surface finish and provides corrosion resistance. Various grades of polish are available, depending on the application.

- Coating: Protective coatings may be applied to enhance durability, particularly in aggressive environments.

What Quality Assurance Measures Are Essential for Stainless Steel Structures?

Quality assurance is paramount in the manufacturing of stainless steel structures, ensuring that products meet both regulatory and customer standards.

Relevant International and Industry-Specific Standards

B2B buyers should be aware of international standards such as ISO 9001, which emphasizes quality management systems. Additionally, industry-specific standards may include:

- CE Marking: This indicates compliance with European safety, health, and environmental protection standards.

- API Standards: Relevant for the oil and gas industry, ensuring that products meet specific performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): This involves monitoring the production process, including dimensional checks and weld quality assessments.

- Final Quality Control (FQC): Finished products undergo thorough inspection, including dimensional checks, visual inspections, and functional testing.

What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are employed to verify the quality of stainless steel structures:

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiographic testing, and magnetic particle testing help identify defects without damaging the material.

- Destructive Testing: This includes tensile tests and impact tests, which provide information about the material’s mechanical properties.

- Corrosion Resistance Tests: These are critical for applications in harsh environments, ensuring that the product will withstand its intended use.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to high-quality standards, B2B buyers should consider the following methods:

Illustrative image related to stainless steel structure

- Supplier Audits: Conducting regular audits of suppliers can help verify compliance with quality standards and assess their manufacturing capabilities.

- Requesting Quality Reports: Buyers should ask for detailed QC reports, including test results and certifications, to understand the quality assurance processes in place.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing process and product quality.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding local regulations and market requirements is vital. Different countries may have varying standards for stainless steel products, which can affect compliance and certification.

- Regional Standards: Buyers should familiarize themselves with regional compliance requirements, which can differ significantly between markets like Brazil and Saudi Arabia.

- Documentation: Ensuring that all necessary documentation, including material certifications and test reports, accompanies shipments is crucial for smooth customs clearance and acceptance of goods.

By grasping these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring that they procure high-quality stainless steel structures that meet their specific needs and comply with relevant industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel structure’

Introduction

This sourcing guide provides B2B buyers with a comprehensive checklist for procuring stainless steel structures. By following these steps, you can ensure that you select the right materials and suppliers for your projects, ultimately leading to successful and sustainable outcomes.

Step 1: Define Your Technical Specifications

Start by clearly outlining your project’s technical requirements. This includes dimensions, load-bearing capabilities, and environmental conditions where the stainless steel structures will be used.

– Considerations: Identify whether you need standard profiles or custom shapes, and specify the grades of stainless steel (e.g., 304, 316) based on corrosion resistance needs.

Illustrative image related to stainless steel structure

Step 2: Research Suppliers

Conduct thorough research to identify potential suppliers specializing in stainless steel structures. Look for companies with a solid reputation in your target market, particularly in regions like Africa, South America, the Middle East, and Europe.

– Action Items: Review supplier websites, check their product catalogs, and read customer testimonials. Utilize platforms like LinkedIn to gauge their industry presence and credibility.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– What to Look For: Assess their manufacturing capabilities, lead times, and quality assurance processes. A supplier’s experience with projects similar to yours can provide insight into their reliability.

Step 4: Verify Certifications and Compliance

Ensure that your selected suppliers meet relevant international standards and certifications for stainless steel products. Compliance with industry standards is essential for quality assurance and safety.

– Key Certifications: Look for certifications such as ISO 9001 for quality management and specific standards related to stainless steel (e.g., ASTM, EN). This guarantees that their products meet necessary regulations.

Step 5: Request Samples and Specifications

Before finalizing your order, request samples of the stainless steel structures to assess quality and finish. This step allows you to verify that the products meet your specifications.

– Considerations: Evaluate the samples for dimensions, surface finish, and overall quality. Ensure that they align with your project’s requirements, especially in terms of aesthetics and functionality.

Illustrative image related to stainless steel structure

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, it’s time to negotiate pricing and terms. Transparent communication can lead to better deals and long-term relationships.

– What to Discuss: Address minimum order quantities, payment terms, delivery timelines, and after-sales support. Ensure that both parties understand expectations to avoid any misunderstandings later.

Step 7: Plan for Logistics and Delivery

Finally, coordinate logistics for the delivery of your stainless steel structures. Efficient logistics are crucial to maintaining project timelines and avoiding delays.

– Action Items: Confirm shipping methods, insurance coverage, and delivery schedules. It’s advisable to have a contingency plan in place for any potential disruptions in the supply chain.

By following this practical checklist, B2B buyers can streamline their procurement process for stainless steel structures, ensuring they achieve the best outcomes for their projects.

Illustrative image related to stainless steel structure

Comprehensive Cost and Pricing Analysis for stainless steel structure Sourcing

What Are the Key Cost Components in Stainless Steel Structure Sourcing?

When sourcing stainless steel structures, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: Stainless steel grades, such as 304 and 316, significantly impact costs. Grade 316, known for its superior corrosion resistance, typically commands a higher price than grade 304. The raw material price can fluctuate based on market demand and supply chain factors.

-

Labor: This encompasses the workforce needed for manufacturing and assembly. Labor costs vary by region; for instance, labor in Europe might be more expensive than in parts of Africa or South America.

-

Manufacturing Overhead: This includes utilities, facility costs, and equipment depreciation. Efficient manufacturing processes can lower overhead, influencing the final price.

-

Tooling: Costs associated with molds, dies, and other equipment needed for production. Custom tooling for specialized shapes can add to initial costs but may yield savings in mass production.

-

Quality Control (QC): Ensuring that products meet specifications involves rigorous testing and inspections. Investing in quality assurance can prevent costly returns and enhance customer satisfaction.

-

Logistics: Transportation, warehousing, and handling costs are vital, especially for international shipments. The complexity of logistics can vary greatly depending on the destination, impacting overall pricing.

-

Margin: Suppliers typically apply a margin to cover their costs and profit. Understanding the margin expectations of suppliers can aid in negotiations.

How Do Pricing Influencers Affect the Cost of Stainless Steel Structures?

Several factors influence pricing in the stainless steel structure market:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounted rates. Buyers should assess their needs against supplier MOQ policies to maximize savings.

-

Specifications and Customization: Custom shapes or specific dimensions can increase costs. Clear communication of requirements can help suppliers provide accurate quotes.

-

Material Quality and Certifications: Higher quality materials that meet industry standards (e.g., ASTM, ISO) can lead to increased costs but are essential for compliance in certain sectors.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can impact pricing. Established suppliers may charge more for their expertise and reliability.

-

Incoterms: Understanding terms of trade (e.g., FOB, CIF) is crucial for calculating total costs, including shipping and insurance. Incoterms dictate who bears responsibility for costs and risks during transit.

What Are the Best Buyer Tips for Cost-Efficiency in Stainless Steel Structure Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Negotiation: Establishing long-term relationships with suppliers can lead to better pricing and terms. Don’t hesitate to negotiate on volume discounts or payment terms.

-

Total Cost of Ownership (TCO): Consider all costs associated with a purchase, including maintenance, logistics, and potential downtime. A lower upfront cost may lead to higher TCO if quality is compromised.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that can affect pricing. Understanding the local market dynamics and economic conditions can aid in making informed decisions.

-

Market Research: Regularly monitor material prices and market trends. Being informed about fluctuations can help in timing your purchases strategically.

Disclaimer on Indicative Prices

Prices for stainless steel structures can vary widely based on the factors discussed above. The information provided here is indicative and should be verified with suppliers to obtain accurate quotes tailored to specific project needs. Always request detailed quotations and consider all cost components before making purchasing decisions.

Alternatives Analysis: Comparing stainless steel structure With Other Solutions

When evaluating structural solutions for various applications, it’s essential to explore alternatives to stainless steel structures. While stainless steel offers a range of benefits, including durability and resistance to corrosion, other materials and technologies can also meet specific project requirements. This section compares stainless steel structures with two viable alternatives: carbon steel structures and aluminum structures.

| Comparison Aspect | Stainless Steel Structure | Carbon Steel Structure | Aluminum Structure |

|---|---|---|---|

| Performance | High strength, excellent corrosion resistance | Good strength but susceptible to rust without treatment | Lightweight, good corrosion resistance, but lower strength |

| Cost | Generally higher initial cost | Lower initial cost, but requires protective coating | Moderate cost, often higher than carbon steel but lower than stainless steel |

| Ease of Implementation | Requires specialized welding techniques | Easier to work with due to lower melting point | Lightweight and easy to handle, but requires specific welding methods |

| Maintenance | Low maintenance due to corrosion resistance | Higher maintenance due to rust potential | Low maintenance, especially with protective coatings |

| Best Use Case | Applications in harsh environments (food, chemical, marine) | General construction, infrastructure | Aerospace, automotive, and applications requiring lightweight structures |

What Are the Advantages and Disadvantages of Carbon Steel Structures?

Carbon steel is a popular alternative due to its lower cost and ease of availability. It performs well in general construction applications and can be easily fabricated. However, carbon steel structures are more susceptible to corrosion, necessitating protective coatings that can increase long-term maintenance costs. While suitable for many applications, carbon steel may not be ideal for environments exposed to moisture or corrosive substances.

Illustrative image related to stainless steel structure

How Do Aluminum Structures Compare?

Aluminum structures offer a lightweight alternative that is particularly beneficial in applications where weight is a critical factor, such as in aerospace and automotive industries. They exhibit good corrosion resistance, especially when anodized or coated. However, aluminum typically has lower strength compared to stainless steel and may require specialized welding techniques. Its cost can also vary, often being higher than carbon steel but lower than stainless steel, depending on the specific alloy and treatment used.

Conclusion: How Should B2B Buyers Choose the Right Structural Solution?

When selecting the right structural solution, B2B buyers should consider the specific requirements of their projects, including environmental conditions, budget constraints, and performance needs. Stainless steel structures excel in durability and corrosion resistance, making them ideal for demanding applications. In contrast, carbon steel may be a cost-effective option for general construction, while aluminum serves well in lightweight applications. Ultimately, the decision should be based on a thorough assessment of these factors to ensure that the chosen material aligns with project goals and longevity expectations.

Essential Technical Properties and Trade Terminology for stainless steel structure

What Are the Key Technical Properties of Stainless Steel Structures?

When considering stainless steel structures, understanding specific technical properties is crucial for decision-making. Here are the essential specifications that B2B buyers should prioritize:

-

Material Grade: Stainless steel is available in various grades, with 304 and 316 being the most common for structural applications. Grade 304 offers good corrosion resistance and is suitable for many environments, while 316 provides enhanced resistance to chlorides, making it ideal for marine or chemical applications. Selecting the right grade is vital to ensure durability and compliance with industry standards.

-

Tolerance: Tolerance refers to the allowable deviation from specified dimensions. It plays a critical role in ensuring that components fit together correctly during assembly. Inaccurate tolerances can lead to structural weaknesses or increased costs due to rework. Understanding the required tolerances helps buyers ensure that products meet their project specifications without compromising quality.

-

Yield Strength: This property indicates the maximum stress a material can withstand while still returning to its original shape. Higher yield strength means that the material can bear more weight or pressure before deforming. For structural applications, knowing the yield strength helps buyers assess the load-bearing capacity necessary for their specific projects.

-

Corrosion Resistance: Stainless steel is favored for its ability to resist rust and corrosion, a critical factor in various industries, including food processing and chemical manufacturing. Buyers should evaluate the corrosion resistance of different grades based on their environmental conditions to ensure longevity and reduce maintenance costs.

-

Weldability: The ability to weld stainless steel without compromising its structural integrity is essential for many applications. Different grades exhibit varying levels of weldability, which affects fabrication processes. Understanding weldability allows buyers to select materials that can be easily integrated into their designs while maintaining strength.

What Are Common Trade Terms in the Stainless Steel Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B stainless steel market. Here are some key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are used in another company’s end products. Understanding OEM relationships can help buyers identify reliable suppliers who can meet specific manufacturing needs.

-

MOQ (Minimum Order Quantity): MOQ represents the smallest quantity a supplier is willing to sell. This term is crucial for buyers as it influences inventory management and cost-effectiveness. Knowing the MOQ helps companies plan their purchasing strategies effectively.

-

RFQ (Request for Quotation): An RFQ is a document used to solicit price quotes from suppliers for specific products or services. Buyers should prepare detailed RFQs to ensure they receive accurate and competitive pricing, which is essential for budgeting and project planning.

-

Incoterms (International Commercial Terms): These are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for buyers to clarify shipping, insurance, and liability responsibilities, which can affect overall costs and delivery schedules.

-

Lead Time: This term refers to the time taken from placing an order to receiving the goods. Knowing the lead time is essential for project planning and ensuring that materials arrive in sync with construction schedules.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance project efficiency, cost-effectiveness, and overall success in the stainless steel industry.

Illustrative image related to stainless steel structure

Navigating Market Dynamics and Sourcing Trends in the stainless steel structure Sector

What Are the Key Trends Shaping the Stainless Steel Structure Market?

The global stainless steel structure market is experiencing dynamic growth, driven by rising demand across various industries including construction, automotive, and manufacturing. Key trends influencing this market include the increasing preference for lightweight yet durable materials, particularly in construction and infrastructure projects. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly focused on sourcing materials that offer both strength and corrosion resistance, which stainless steel provides. The integration of advanced manufacturing technologies, such as laser welding and 3D printing, is also reshaping the sourcing landscape, allowing for more customized and efficient product offerings.

Another significant trend is the digital transformation of supply chains, where businesses are leveraging platforms for real-time inventory management and streamlined procurement processes. This is especially relevant for international buyers who must navigate varying regulations and standards across countries. Additionally, the ongoing shift towards modular construction methods enhances the demand for standardized stainless steel profiles and components, allowing for quicker assembly and reduced labor costs. As construction projects become more complex, the need for innovative and adaptable structural solutions will continue to grow.

How Is Sustainability Influencing B2B Sourcing in the Stainless Steel Sector?

Sustainability has emerged as a critical focus area for B2B buyers in the stainless steel structure market. The environmental impact of sourcing and manufacturing practices is under scrutiny, prompting companies to adopt more sustainable methods. For instance, the use of recycled stainless steel not only reduces waste but also lowers the carbon footprint associated with new steel production. Buyers are increasingly seeking suppliers that demonstrate a commitment to sustainability through certifications like ISO 14001 or adherence to guidelines set by the Global Reporting Initiative (GRI).

Illustrative image related to stainless steel structure

Ethical sourcing practices are also gaining traction, as stakeholders demand transparency in supply chains. This includes ensuring that raw materials are sourced responsibly, minimizing the risk of human rights violations, and adhering to environmental regulations. Suppliers that can offer ‘green’ certifications or materials, such as low-impact stainless steel or products made from post-consumer recycled content, stand to gain a competitive advantage. As sustainability becomes a business imperative, B2B buyers must evaluate their partners not just on price and quality, but also on their environmental and ethical practices.

What Is the Historical Context of the Stainless Steel Structure Market?

The use of stainless steel in structural applications dates back to the early 20th century when it was first developed as a corrosion-resistant alloy. Its unique properties made it ideal for demanding environments, leading to its adoption in various industries, from aerospace to food processing. Over the decades, advancements in manufacturing technologies have expanded the capabilities of stainless steel, enabling the production of complex shapes and profiles that cater to modern architectural and engineering needs.

As global infrastructure demands grew post-World War II, stainless steel became a preferred choice for construction due to its durability, aesthetic appeal, and low maintenance requirements. Today, it plays a crucial role in sustainable building practices, as its recyclability and longevity align with the growing emphasis on environmental responsibility. Understanding this evolution is essential for B2B buyers, as it highlights the material’s adaptability and ongoing relevance in meeting modern industrial challenges.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel structure

-

How do I ensure the quality of stainless steel structures from suppliers?

To guarantee the quality of stainless steel structures, it’s essential to request certification documents such as ISO 9001 or ASTM standards. Conduct supplier audits to inspect their manufacturing processes and facilities. Additionally, ask for material test reports and third-party inspections. Establish a clear quality assurance plan that includes periodic checks throughout the production and delivery process. Building a strong relationship with your supplier can also enhance transparency and accountability. -

What is the best grade of stainless steel for construction in harsh environments?

For construction in harsh environments, particularly those exposed to corrosive elements, 316 stainless steel is often the best choice. It offers superior corrosion resistance due to its molybdenum content, making it ideal for marine, chemical, and food processing industries. In contrast, 304 stainless steel, while versatile and cost-effective, may not withstand the same level of corrosive exposure. Always consider the specific environmental conditions and project requirements when selecting the appropriate grade. -

What customization options are available for stainless steel structures?

Many suppliers offer extensive customization options for stainless steel structures, including bespoke sizes, shapes, and finishes. You can request custom profiles like beams, channels, and angles tailored to your project specifications. Additionally, modifications such as polishing, welding, and coating can enhance the aesthetic and functional properties of the structures. Engage directly with your supplier to discuss your unique needs, and obtain samples if necessary to ensure alignment with your design. -

What are the minimum order quantities (MOQs) for stainless steel structures?

Minimum order quantities for stainless steel structures can vary significantly depending on the supplier and the specific product. Generally, MOQs may range from a few tons for standard profiles to larger quantities for custom orders. It’s important to clarify these terms before placing an order, especially if you’re working with limited project budgets. Some suppliers may offer flexible options for smaller orders, so it’s worthwhile to negotiate based on your needs. -

What payment terms should I expect when sourcing stainless steel structures internationally?

Payment terms for international orders of stainless steel structures typically include options like advance payment, letters of credit, or staggered payments based on production milestones. Standard practices often require a deposit, followed by the remaining balance upon shipment or delivery. Be sure to discuss and agree on payment methods and timelines with your supplier upfront. Understanding currency exchange rates and potential transaction fees is also crucial for budgeting purposes. -

How can I vet potential suppliers for stainless steel structures?

To effectively vet suppliers, start by checking their industry reputation through online reviews and client testimonials. Request references from previous clients and conduct background checks to verify their financial stability and business history. Visiting the supplier’s facility can provide insights into their production capabilities and quality control processes. Additionally, assess their compliance with international standards and certifications to ensure they meet your quality requirements. -

What logistics considerations should I be aware of when importing stainless steel structures?

When importing stainless steel structures, consider logistics aspects such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with the specific requirements for importing metal products to your region. Understand the potential tariffs and taxes that may apply to your order. Additionally, ensure that the supplier provides accurate documentation to facilitate smooth customs clearance and avoid delays. -

What are the common applications of stainless steel structures in various industries?

Stainless steel structures are widely used across multiple industries, including construction, food processing, pharmaceuticals, and oil and gas. In construction, they serve as beams, columns, and frameworks due to their strength and corrosion resistance. In food processing, stainless steel is essential for hygienic equipment and surfaces. The pharmaceutical industry utilizes stainless steel for its durability and ease of cleaning, while the oil and gas sector relies on it for pipelines and storage tanks. Understanding these applications can help you identify potential use cases for your projects.

Top 3 Stainless Steel Structure Manufacturers & Suppliers List

1. Stainless Structurals – Stainless Steel Profiles

Domain: stainless-structurals.com

Registered: 2005 (20 years)

Introduction: Stainless Structurals offers a range of stainless steel standard profiles and custom shapes, including: Stainless Steel Profiles (Angles, Beams, Channels, Tees, Flats, Tubes), Custom Shapes, Carbon Steel Profiles, Architectural Steel Profiles, Sharp Corner Tubing, Sharp Corner T-sections. Production technologies include Laser Welded Sections, Low Impact Laser Welded Profiles, Hot Rolled Sections, …

2. Stainless & Alloy – Stainless Steel Structural Products

Domain: stainlessandalloy.com

Registered: 1999 (26 years)

Introduction: Stainless Steel Structural Products include: 304 and 316 stainless steel tapered and non-tapered channels, tapered and non-tapered beams, equal and unequal leg angles. Sizes range from 3/4″ to 12″. Minimum order of $300 applies to all long products.

3. Outokumpu – Stainless Steel Ranges

Domain: outokumpu.com

Registered: 1996 (29 years)

Introduction: Stainless Steel Ranges: Moda (mildly corrosive environments), Core (corrosive environments), Supra (highly corrosive environments), Forta (Duplex and other high strength), Ultra (extremely corrosive environments), Dura (high hardness), Therma (high service temperatures), Prodec (superior machinability), Deco (special surfaces). Stainless Steel Types: Ferritic, Martensitic and PH grades, Duplex, Au…

Strategic Sourcing Conclusion and Outlook for stainless steel structure

In the evolving landscape of stainless steel structures, strategic sourcing has emerged as a critical component for businesses seeking to enhance their operational efficiency and competitiveness. By prioritizing quality, sustainability, and supplier collaboration, B2B buyers can ensure they are equipped with the best materials for their projects. The durability and corrosion resistance of stainless steel make it an ideal choice for a variety of industries, from construction to food processing, thereby offering significant long-term value.

Illustrative image related to stainless steel structure

Investing in reliable suppliers who understand local market dynamics—particularly in regions like Africa, South America, the Middle East, and Europe—can lead to substantial cost savings and improved project timelines. As global demand for stainless steel continues to rise, fostering relationships with trusted partners will be essential for navigating supply chain challenges and ensuring timely delivery of high-quality products.

Looking ahead, international buyers are encouraged to leverage advancements in manufacturing technologies and sustainable practices. By doing so, they can not only meet current market needs but also position themselves as leaders in their respective industries. Embrace the opportunity to innovate and collaborate—your strategic sourcing decisions today will shape the success of your projects tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to stainless steel structure

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.