Top 8 Ironer For Sale Suppliers (And How to Choose)

Introduction: Navigating the Global Market for ironer for sale

In today’s competitive landscape, sourcing high-quality ironers for sale can be a daunting task for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying reliable suppliers but also in understanding the various types of ironers available and their specific applications. This guide serves as a comprehensive resource to navigate the complexities of the ironer market, detailing everything from different models—such as cylinder and chest types—to considerations for energy efficiency, operational capacity, and maintenance requirements.

By equipping buyers with insights into supplier vetting processes, cost analysis, and market trends, this guide empowers you to make informed purchasing decisions. Whether you are looking to enhance your laundry operations with pre-owned equipment or seeking the latest innovations in commercial ironers, our detailed analysis will help streamline your procurement process. With the right information at your fingertips, you can confidently invest in equipment that meets your operational needs while optimizing your budget. Let this guide be your partner in exploring the global market for ironers, ensuring you find the best solutions tailored to your business’s unique requirements.

Understanding ironer for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cylinder Type Ironer | Uses cylindrical rollers for continuous pressing; efficient for large volumes. | High-capacity laundry operations, hotels, and hospitals. | Pros: Fast processing, consistent results. Cons: Larger footprint, may require more maintenance. |

| Chest Type Ironer | Features flat pressing surfaces, suitable for delicate items; versatile. | Small to medium-sized laundries, catering services. | Pros: Gentle on fabrics, space-efficient. Cons: Slower processing speed, lower capacity. |

| Combo Ironer | Combines ironing and folding in one machine; multifunctional. | Facilities with limited space; diverse laundry needs. | Pros: Saves time and labor, versatile for various items. Cons: Higher initial investment, may be complex to operate. |

| Electric Ironer | Operates using electricity; often compact and easy to install. | Small businesses, residential use, and self-service laundries. | Pros: Lower operational costs, easy setup. Cons: Limited capacity, slower than gas or steam options. |

| Gas Heated Ironer | Utilizes gas for heating, offering rapid warm-up times and efficiency. | Large-scale laundries, industrial applications. | Pros: Quick heating, cost-effective in high-volume settings. Cons: Requires gas supply, safety considerations. |

What Are the Characteristics of Cylinder Type Ironers?

Cylinder type ironers are designed for high-capacity operations, featuring a series of cylindrical rollers that continuously press linens as they pass through the machine. This design allows for efficient processing of large volumes, making it ideal for hotels, hospitals, and industrial laundries. Buyers should consider the machine’s size and maintenance needs, as these ironers often require more space and regular upkeep compared to smaller models.

How Do Chest Type Ironers Work and Where Are They Suitable?

Chest type ironers feature flat surfaces that apply pressure to the fabric, making them suitable for delicate items such as table linens and uniforms. They are versatile and can accommodate various fabric types, making them a preferred choice for small to medium-sized laundries and catering services. While they are gentler on fabrics, buyers should be aware that their processing speed is slower compared to cylinder type ironers, which may affect overall productivity.

What Are the Benefits of Using Combo Ironers in Commercial Settings?

Combo ironers integrate both ironing and folding functions, significantly streamlining the laundry process. This multifunctionality is particularly beneficial for facilities with limited space or diverse laundry needs, such as restaurants and small hotels. While they save time and reduce labor costs, buyers should consider the higher initial investment and potential complexity in operation, which may require additional training for staff.

Why Choose Electric Ironers for Small Businesses?

Electric ironers are an excellent choice for small businesses and residential applications due to their compact design and ease of installation. They typically have lower operational costs and are straightforward to operate, making them ideal for self-service laundries. However, buyers should note that electric ironers usually have limited capacity and may not handle high volumes as efficiently as gas or steam options.

What Advantages Do Gas Heated Ironers Offer for Large-Scale Operations?

Gas heated ironers are favored in large-scale laundry operations due to their rapid warm-up times and efficient energy use. They can handle significant volumes of linens, making them suitable for industrial applications such as hospitals and hotels. While they offer quick heating and cost savings in high-volume settings, buyers must ensure a reliable gas supply and consider safety measures associated with gas equipment.

Key Industrial Applications of ironer for sale

| Industry/Sector | Specific Application of ironer for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Ironing linens for hotels and restaurants | Ensures high-quality presentation of linens, enhancing guest experience | Consider capacity, heating method (steam/gas/electric), and energy efficiency. |

| Healthcare | Processing hospital bed linens and uniforms | Maintains hygiene standards while ensuring quick turnaround times | Look for models with high throughput and easy maintenance. |

| Commercial Laundries | Ironing service for various clients | Increases efficiency, reduces labor costs, and improves service quality | Evaluate durability, compatibility with existing equipment, and after-sales support. |

| Textile Manufacturing | Finishing fabric and garments | Enhances product quality and reduces rework costs | Assess the ability to handle different fabric types and production volumes. |

| Education Institutions | Ironing uniforms and linens for schools | Promotes professionalism and cleanliness in school settings | Ensure ease of use for staff and availability of spare parts. |

How is an Ironer Used in the Hospitality Sector?

In the hospitality industry, ironers are crucial for processing linens such as bed sheets, tablecloths, and napkins. Hotels and restaurants rely on ironers to provide a crisp, professional finish that enhances the overall guest experience. By investing in an efficient ironer, businesses can significantly reduce labor costs and improve turnaround times for laundry services. International buyers should consider the specific heating methods available, as steam or gas options may vary in efficiency and operational cost based on local energy prices.

What Role Does an Ironer Play in Healthcare Facilities?

Healthcare facilities require ironers to process bed linens, patient gowns, and uniforms efficiently. The need for hygiene is paramount, and ironers help ensure that all textiles are sanitized while achieving a high-quality finish. Fast processing times are essential in hospitals where linens must be quickly returned for use. Buyers in this sector should prioritize models that offer high throughput and easy maintenance, as this will ensure compliance with stringent health regulations and minimize downtime.

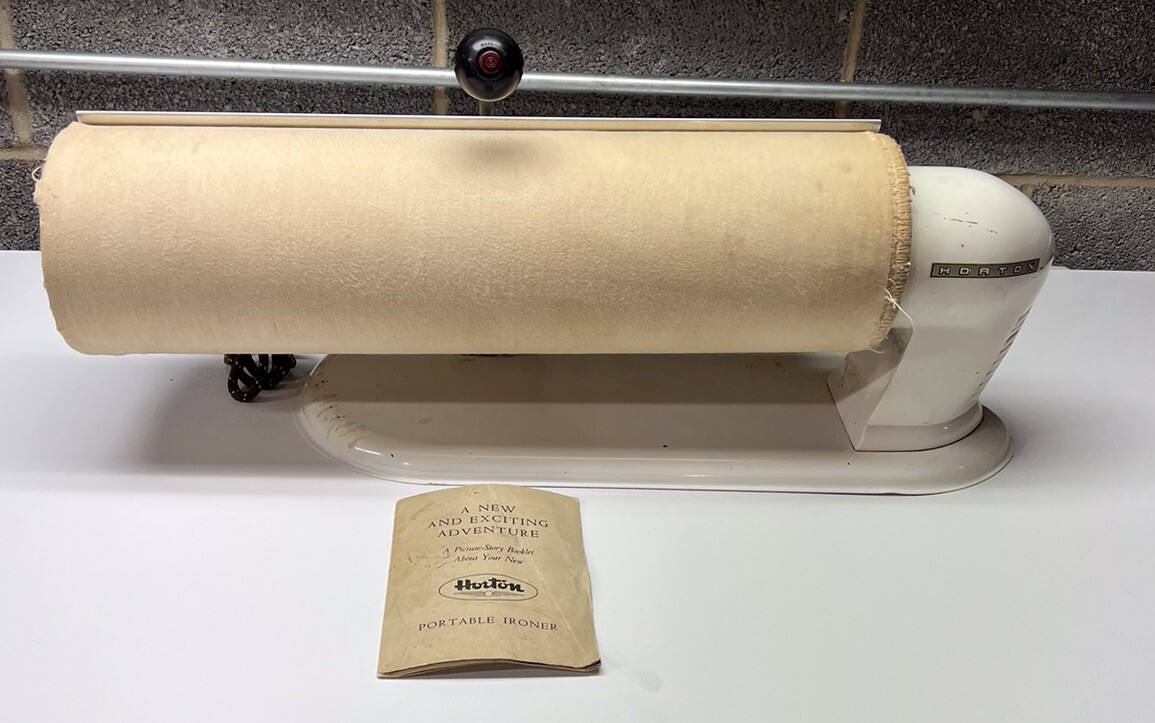

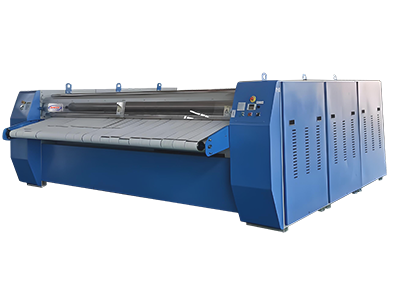

Illustrative image related to ironer for sale

How Do Commercial Laundries Benefit from Ironers?

Commercial laundries serve a diverse clientele, including hotels, gyms, and restaurants, and require efficient ironers to meet varying demands. These machines help streamline operations by allowing for simultaneous ironing, folding, and steaming, thereby maximizing productivity. Businesses should evaluate the durability and compatibility of ironers with existing equipment to ensure seamless integration. Additionally, after-sales support and availability of spare parts are critical factors for maintaining operational efficiency.

Why Are Ironers Important for Textile Manufacturing?

In textile manufacturing, ironers are used to finish fabrics and garments, providing a polished look that is essential for retail presentation. The quality of the finish can directly impact customer satisfaction and reduce the likelihood of returns due to defects. Buyers in this sector should assess the ironer’s capability to handle various fabric types and production volumes, ensuring that it aligns with their manufacturing processes and quality standards.

How Can Education Institutions Utilize Ironers?

Educational institutions, from schools to universities, often require ironers to maintain uniforms and linens for dormitories and dining facilities. A well-pressed appearance promotes professionalism and cleanliness among students and staff. Institutions should look for ironers that are user-friendly, as staff may not have extensive training in laundry operations. Additionally, the availability of spare parts is crucial to ensure that the equipment remains functional throughout the academic year.

Illustrative image related to ironer for sale

3 Common User Pain Points for ‘ironer for sale’ & Their Solutions

Scenario 1: The Challenge of Finding Reliable Used Ironers

The Problem: B2B buyers, particularly in regions like Africa and South America, often encounter difficulties in sourcing reliable used ironers. Many suppliers may offer equipment that looks good on the surface but has hidden flaws that can lead to costly repairs and operational downtime. This challenge is exacerbated by the lack of local suppliers who can provide adequate support and maintenance services. Buyers may feel overwhelmed by the vast choices available, unsure of which brands or models will deliver consistent performance and longevity.

The Solution: To navigate this landscape, buyers should prioritize sourcing from reputable suppliers who specialize in used industrial laundry equipment. Conduct thorough research on suppliers, looking for those with a strong track record, verified customer reviews, and a transparent refurbishment process. When selecting an ironer, request detailed specifications, maintenance history, and any warranties that may be offered. Additionally, consider visiting the supplier’s facility to inspect the equipment firsthand. Building a relationship with a local technician or service provider can also help ensure that any issues can be resolved quickly, maintaining operational efficiency.

Scenario 2: Understanding Different Ironer Types and Their Suitability

The Problem: B2B buyers often struggle to understand the differences between various types of ironers available for sale, such as cylinder and chest type. This confusion can lead to purchasing the wrong equipment for their specific laundry needs, resulting in inefficiencies and increased operational costs. For instance, a facility that processes large volumes of linens might require a high-capacity cylinder ironer, while a smaller operation might benefit from a chest-type ironer, which is more compact but may not handle the same volume.

The Solution: To make an informed decision, buyers should evaluate their specific operational requirements, including the volume of laundry processed, the types of fabrics handled, and the available floor space. Creating a checklist of these factors can assist in narrowing down the options. Engaging with industry experts or consulting with suppliers who can provide insights on the performance and suitability of different models will also be beneficial. Moreover, consider investing in a demo or trial period if available, which allows for hands-on experience with the ironer before making a significant financial commitment.

Scenario 3: Budget Constraints and Total Cost of Ownership

The Problem: Budget constraints are a significant pain point for many B2B buyers looking to invest in ironers. While the initial purchase price is crucial, many buyers overlook the total cost of ownership (TCO), which includes maintenance, energy consumption, and potential downtime costs. This oversight can lead to financial strain and operational disruptions down the line, especially for businesses that operate on tight margins.

Illustrative image related to ironer for sale

The Solution: Buyers should adopt a holistic approach to budgeting by not only considering the purchase price but also evaluating the TCO of the ironers they are interested in. This includes researching the energy efficiency ratings of different models, potential maintenance costs, and the availability of replacement parts. Suppliers should be asked to provide a breakdown of expected operating costs, and buyers should also consult with current users of the equipment to gain insights into long-term reliability and performance. Additionally, exploring financing options or leasing agreements can help manage cash flow while ensuring access to high-quality equipment that meets operational needs without compromising on performance or safety.

Strategic Material Selection Guide for ironer for sale

What Materials Are Commonly Used in Ironers for Sale?

When selecting an ironer for sale, understanding the materials used in their construction is crucial for B2B buyers. Different materials offer distinct properties that can significantly affect performance, durability, and cost-effectiveness. Below, we analyze four common materials used in ironers, focusing on their key properties, advantages, disadvantages, and considerations for international buyers.

1. Stainless Steel

Key Properties:

Stainless steel is renowned for its high corrosion resistance and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 800°F (427°C), making it suitable for steam-heated applications.

Pros & Cons:

The durability of stainless steel is a significant advantage, as it resists rust and staining, ensuring longevity. However, it can be more expensive than other materials, and its manufacturing complexity may increase production costs.

Illustrative image related to ironer for sale

Impact on Application:

Stainless steel is compatible with various media, including steam and water, making it ideal for ironers that require consistent heating. Its non-reactive nature ensures that it does not impart any unwanted flavors or contaminants to the linens being processed.

International Considerations:

For buyers in regions like Europe and the Middle East, compliance with standards such as ASTM and DIN for material quality is essential. Additionally, the preference for durable equipment in harsh environments makes stainless steel a favored choice.

2. Cast Iron

Key Properties:

Cast iron is known for its excellent heat retention and distribution properties. It can handle high temperatures, typically up to 600°F (316°C), making it suitable for heavy-duty applications.

Pros & Cons:

The primary advantage of cast iron is its ability to maintain consistent temperatures, resulting in high-quality finishes. However, it is heavy and can be prone to cracking under thermal shock, which may lead to higher maintenance costs.

Impact on Application:

Cast iron is particularly effective in applications requiring robust performance and durability. Its weight can be a disadvantage in terms of mobility and installation, especially in facilities with limited space.

International Considerations:

In regions like Africa and South America, where infrastructure may vary, the weight of cast iron ironers could pose logistical challenges. Buyers should consider local transportation capabilities and installation requirements.

3. Aluminum

Key Properties:

Aluminum is lightweight and has good thermal conductivity, with a maximum temperature rating of around 400°F (204°C). It is resistant to corrosion, especially when anodized.

Pros & Cons:

The lightweight nature of aluminum makes it easier to handle and install, reducing labor costs. However, its lower temperature tolerance compared to stainless steel and cast iron may limit its application in high-heat environments.

Impact on Application:

Aluminum is suitable for lighter-duty ironers and those requiring frequent mobility. Its corrosion resistance makes it a good choice for humid environments, but it may not provide the same finish quality as heavier materials.

International Considerations:

Buyers in humid regions, such as parts of Brazil and Saudi Arabia, may prefer aluminum for its resistance to corrosion. However, they should ensure that the ironer meets local standards for performance and safety.

Illustrative image related to ironer for sale

4. Composite Materials

Key Properties:

Composite materials, often a blend of plastics and metals, can be engineered for specific performance characteristics, including heat resistance and durability. They can handle temperatures up to 500°F (260°C).

Pros & Cons:

The versatility of composites allows for customization based on specific needs, often resulting in lower manufacturing costs. However, they may not be as durable as metals and can be susceptible to damage from high heat or chemicals.

Impact on Application:

Composites are suitable for applications where weight and cost are critical factors. Their unique properties can enhance performance in specific environments, but buyers must assess their long-term reliability.

Illustrative image related to ironer for sale

International Considerations:

For international buyers, especially in emerging markets, the cost-effectiveness of composite materials can be appealing. However, they should verify compliance with local regulations and standards to ensure product safety and performance.

Summary Table

| Material | Typical Use Case for ironer for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty industrial applications | High corrosion resistance | Higher manufacturing costs | High |

| Cast Iron | High-performance, heavy-duty ironers | Excellent heat retention | Prone to cracking under thermal shock | Medium |

| Aluminum | Lightweight, mobile ironers | Easy to handle and install | Lower temperature tolerance | Medium |

| Composite | Cost-effective, versatile applications | Customizable properties | Potentially less durable | Low |

This guide provides essential insights into material selection for ironers, helping B2B buyers make informed decisions that align with their operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ironer for sale

What Are the Key Stages in the Manufacturing Process of Commercial Ironers?

The manufacturing process of commercial ironers involves several critical stages designed to ensure efficiency and quality. Understanding these stages is vital for B2B buyers who want to assess the value and reliability of the equipment they are purchasing.

1. Material Preparation: How Are Components Selected and Processed?

Material preparation is the foundational stage where raw materials are chosen based on the specifications required for the ironers. Common materials include high-grade steel for the frame and heating elements, which are essential for durability and thermal efficiency. Suppliers often source materials that comply with international standards, ensuring they can withstand the rigors of industrial use.

Once selected, these materials undergo processes such as cutting, bending, and machining to create the components that will make up the ironer. Advanced techniques, such as laser cutting and CNC machining, ensure precision and consistency, which are critical for the assembly of high-quality equipment.

2. Forming: What Techniques Are Used to Shape Ironer Components?

In the forming stage, the pre-processed materials are shaped into their final forms. This typically involves techniques such as stamping, forging, and welding. For instance, the body of the ironer may be stamped from sheets of steel, while more complex parts, like the heating chamber, are often welded together to create a robust structure.

The choice of forming techniques directly influences the performance of the ironer, particularly in terms of heat distribution and pressure application. Buyers should inquire about the specific methods used, as they can impact the longevity and efficiency of the equipment.

3. Assembly: How Are the Components Brought Together?

Assembly is a critical step where all the manufactured components come together. This process usually involves a combination of manual labor and automated systems to ensure precision. Key components, such as rollers, heating elements, and control systems, are meticulously assembled in a controlled environment to reduce the risk of contamination or defects.

Illustrative image related to ironer for sale

During assembly, manufacturers often employ best practices to ensure that every part fits seamlessly. Quality checks at this stage can include torque testing of fasteners and alignment checks of moving parts, which are essential for the operational integrity of the ironers.

4. Finishing: What Processes Ensure a High-Quality Surface and Functionality?

The finishing stage is where the ironer’s aesthetics and functionality are enhanced. This may involve painting, powder coating, or applying protective finishes to prevent rust and wear. Additionally, manufacturers may conduct surface treatments to improve heat resistance and durability.

Finishing touches can also include the installation of user interfaces and safety features. It is advisable for buyers to verify the types of finishes used, as these can significantly affect the ironer’s longevity and maintenance requirements.

What Quality Assurance Measures Are Typically Employed in Ironer Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each ironer meets industry standards and customer expectations. B2B buyers should be familiar with these measures to make informed purchasing decisions.

1. What International Standards Are Relevant for Ironer Quality Assurance?

Ironers should comply with several international standards, including ISO 9001 for quality management systems. This standard ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Additionally, certifications such as CE mark indicate compliance with European health, safety, and environmental protection standards, which is particularly relevant for buyers in Europe.

For regions like Africa and South America, understanding local regulations and compliance standards is crucial. Buyers should request documentation that verifies compliance with both international and local standards.

Illustrative image related to ironer for sale

2. What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for defects before they enter the production line.

-

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process itself, ensuring that each stage meets the established quality benchmarks.

-

Final Quality Control (FQC): Before shipment, finished ironers undergo rigorous testing to assess functionality, safety, and compliance with specifications.

Each of these checkpoints is vital to maintaining the overall quality of the ironers and ensuring they perform reliably in industrial settings.

3. What Testing Methods Are Commonly Used to Verify Ironer Quality?

Manufacturers employ various testing methods to validate the performance and safety of ironers:

-

Performance Testing: This assesses the ironer’s ability to handle different types of fabrics under various conditions. It includes checking steam output, heating efficiency, and ironing quality.

-

Safety Testing: This ensures that all safety features function correctly, such as emergency shut-off systems and temperature controls.

-

Durability Testing: This simulates long-term use, checking for wear and tear over extended periods.

Buyers should inquire about the specific testing methods used and request any available performance reports or certifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those from regions like Africa, South America, and the Middle East, verifying a supplier’s quality control practices is critical. Here are some effective strategies:

1. What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed audits and quality reports from suppliers. These documents should outline the manufacturing processes, quality checks, and compliance with relevant standards. A reputable supplier will readily provide this information to demonstrate their commitment to quality.

2. How Can Third-Party Inspections Enhance Confidence in Supplier Quality?

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. These inspections can verify compliance with industry standards and ensure that products meet the buyer’s specific requirements before shipment.

3. What Are the Nuances of Quality Certifications for International Buyers?

International buyers should be aware of the nuances in quality certifications. For example, certain certifications may be recognized in one region but not in another. Understanding the specific standards applicable to their markets will help buyers assess the credibility of the supplier’s claims.

By taking these steps, B2B buyers can ensure they are investing in high-quality ironers that will meet their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ironer for sale’

In the competitive landscape of industrial laundry operations, sourcing a flatwork ironer is a critical decision that can impact efficiency and productivity. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before exploring options, clearly outline the specifications that meet your operational needs. Consider factors such as the volume of linens processed, type of ironer (e.g., cylinder or chest type), and heating method (steam, gas, or electric). This clarity will streamline your search and ensure that you acquire equipment that aligns with your workflow.

Step 2: Research Market Trends and Pricing

Understanding the current market landscape is essential for making informed decisions. Investigate the latest trends in flatwork ironers, including technological advancements and pricing benchmarks. This knowledge will empower you to negotiate better deals and recognize value propositions from suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough due diligence. Review company profiles, check for industry certifications, and request references from other clients, particularly those in your region or industry. A reputable supplier will have a proven track record of reliability and customer satisfaction.

Step 4: Assess Equipment Condition and History

When considering used ironers, it’s vital to evaluate the equipment’s condition and maintenance history. Ask for documentation regarding previous usage, repairs, and servicing. This insight will help you gauge potential longevity and performance, ultimately influencing your return on investment.

Illustrative image related to ironer for sale

Step 5: Request Demonstrations and Trials

Whenever possible, request a demonstration of the ironer in action. Observing the equipment’s performance firsthand allows you to assess its efficiency, ease of use, and suitability for your operations. Some suppliers may also offer trial periods, providing an opportunity to evaluate the ironer’s performance within your facility.

Step 6: Understand Warranty and After-Sales Support

A strong warranty and reliable after-sales support are crucial aspects of any equipment purchase. Review the warranty terms and the supplier’s commitment to servicing and parts availability. This assurance can mitigate risks associated with equipment failure and downtime.

Step 7: Plan for Installation and Training

Finally, consider the logistics of installation and staff training. Verify if the supplier provides installation services and whether they offer training for your team on how to operate the ironer efficiently. Proper installation and training can significantly enhance operational efficacy and reduce the learning curve for your staff.

By following this checklist, B2B buyers can confidently navigate the sourcing process for flatwork ironers, ensuring that their investment aligns with operational goals and enhances productivity.

Comprehensive Cost and Pricing Analysis for ironer for sale Sourcing

What Are the Key Cost Components for Sourcing Ironers?

When sourcing ironers for commercial laundry operations, understanding the cost structure is crucial. The primary components include:

Illustrative image related to ironer for sale

-

Materials: The cost of materials varies significantly based on the type of ironer (e.g., cylinder or chest type) and the heating method (steam, gas, or electric). High-quality components, such as stainless steel for durability, can increase initial costs but may reduce maintenance expenses over time.

-

Labor: Labor costs encompass both the workforce needed for manufacturing and installation. Skilled labor is often required for assembly and quality checks, particularly for customized ironers.

-

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, equipment depreciation, and administrative expenses. Efficient production processes can help keep these costs in check.

-

Tooling and Setup: Initial tooling for specialized or custom ironers can lead to higher upfront costs. This is particularly relevant for buyers seeking unique specifications or features.

-

Quality Control (QC): Investing in rigorous QC processes ensures that the ironers meet industry standards, which can prevent costly defects and returns in the future.

-

Logistics: Shipping costs can fluctuate based on the size and weight of the ironers, as well as the distance from the supplier to the buyer. Understanding the impact of shipping logistics is essential for accurate cost estimations.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on competition and market demand.

What Influences Pricing for Ironers in the B2B Market?

Several factors significantly influence the pricing of ironers:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often results in reduced per-unit costs. Suppliers may offer better rates for bulk orders, making it economically advantageous for larger operations.

-

Specifications and Customization: Custom features or specifications can lead to increased costs. Buyers should evaluate whether the added functionalities justify the price increase.

-

Materials and Quality Certifications: Ironers made from premium materials or those that have specific industry certifications (e.g., ISO, CE) may carry higher prices. These certifications can enhance reliability and performance, making them worthwhile investments.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Well-established suppliers may command higher prices due to perceived quality and service levels.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) agreed upon can influence the total landed cost. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the costs and risks at different stages of the shipping process.

How Can Buyers Negotiate for Better Pricing on Ironers?

Effective negotiation is key to securing favorable pricing. Here are some tips:

-

Research Market Prices: Understand the standard pricing for the type of ironer you need. This knowledge empowers you to negotiate from a position of strength.

-

Emphasize Total Cost of Ownership (TCO): Highlighting the long-term savings associated with energy-efficient or durable models can justify a higher upfront investment.

-

Leverage Volume Purchases: If possible, consolidate orders across multiple facilities to increase order volume, thereby reducing per-unit costs.

-

Seek Flexible Payment Terms: Negotiating payment terms can improve cash flow and reduce financial strain, making it easier to commit to larger purchases.

-

Be Open to Alternative Suppliers: Exploring various suppliers can provide insights into competitive pricing and may reveal options that better meet your budget without compromising quality.

What Pricing Nuances Should International Buyers Consider?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can significantly impact costs. Buyers should consider locking in prices or negotiating in their local currency to mitigate risks.

-

Import Duties and Taxes: Understanding local tariffs and taxes associated with importing industrial equipment is crucial for accurate cost forecasting.

-

Logistics and Supply Chain: International shipping can introduce delays and additional costs. Buyers should factor in potential delays when planning procurement timelines.

-

Cultural Differences in Negotiation: Different regions may have varying negotiation styles and expectations. Familiarizing yourself with these cultural nuances can enhance communication and lead to better deals.

Disclaimer on Indicative Prices

Prices for ironers can vary widely based on the factors discussed above. While this analysis provides a framework for understanding costs and pricing, actual prices should be confirmed with suppliers to account for specific requirements and market conditions.

Alternatives Analysis: Comparing ironer for sale With Other Solutions

Exploring Alternatives to Ironers for Sale

When considering the best solutions for commercial laundry needs, B2B buyers often explore various options to ensure they invest wisely. While ironers for sale provide a reliable method for achieving crisp, flat linens, it’s essential to compare them against other technologies that may offer similar or enhanced benefits. This analysis focuses on two viable alternatives: flatwork finishing machines and rotary ironers.

| Comparison Aspect | Ironer For Sale | Flatwork Finishing Machine | Rotary Ironer |

|---|---|---|---|

| Performance | High-quality pressing and folding | Excellent finish with less labor | Efficient for large volumes |

| Cost | Moderate initial investment | Higher upfront cost | Varies widely; can be economical |

| Ease of Implementation | Requires skilled operation | Straightforward installation | Simple setup, minimal training needed |

| Maintenance | Regular upkeep needed | Generally low maintenance | Higher maintenance due to moving parts |

| Best Use Case | Ideal for large commercial laundries | Suitable for hotels and restaurants | Great for high-volume environments |

What Are the Advantages and Disadvantages of Flatwork Finishing Machines?

Flatwork finishing machines are designed to automate the pressing and folding of linens. Their primary advantage is the reduced labor requirement, allowing for higher throughput with fewer staff. They often achieve a consistent finish across various fabric types, making them ideal for hotels and restaurants where presentation matters. However, they tend to have a higher upfront cost compared to used ironers, which can be a barrier for smaller operations or those with tighter budgets.

How Do Rotary Ironers Compare to Ironers for Sale?

Rotary ironers are another alternative that can be particularly effective for high-volume laundry operations. They provide a fast and efficient means of processing large amounts of linens, making them suitable for industrial laundries or facilities that deal with bulk laundry. Their design typically allows for continuous feeding of linens, which maximizes productivity. However, rotary ironers can be more complex to maintain due to the moving parts involved, and they may require more extensive training for operators to achieve optimal results.

How Can B2B Buyers Decide on the Right Solution?

Choosing the right solution for your laundry operations involves evaluating your specific needs, budget, and volume requirements. Ironers for sale are an excellent choice for businesses looking for reliable and proven technology, especially when considering used equipment to save costs. Flatwork finishing machines may appeal to those prioritizing labor efficiency and consistent quality, while rotary ironers are best suited for high-volume environments where speed is crucial.

Ultimately, the decision should align with your operational goals, the nature of the fabrics you handle, and the scale of your laundry operations. By weighing the performance, cost, and maintenance requirements of each alternative, B2B buyers can make informed choices that enhance their productivity and profitability.

Essential Technical Properties and Trade Terminology for ironer for sale

What Are the Key Technical Properties of Ironers for Sale?

When evaluating ironers for sale, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that buyers should consider:

1. Heating Type

Ironers can utilize various heating methods, including steam, gas, or electric. The heating type impacts operational efficiency and energy consumption. Steam-heated ironers generally provide faster processing times and better finishing quality, making them ideal for high-volume operations. Understanding the heating type helps businesses align their equipment with energy costs and workflow requirements.

2. Roll Configuration

The roll configuration, such as single-roll, two-roll, or multi-roll designs, directly affects the machine’s capacity and efficiency. Multi-roll ironers tend to handle larger volumes of linens and provide more consistent pressure across fabrics, resulting in superior finishing quality. For businesses with high throughput, selecting the right roll configuration can significantly enhance productivity.

Illustrative image related to ironer for sale

3. Working Width

This specification refers to the width of linens that the ironer can process in a single pass. A broader working width can accommodate larger items, such as tablecloths and bed linens, reducing the number of passes required for finishing. B2B buyers should assess their typical laundry sizes to select an ironer that minimizes processing time and maximizes throughput.

4. Speed of Operation

Measured in meters per minute (m/min), the speed of operation indicates how quickly the ironer can process linens. Higher speeds can lead to increased productivity, making it essential for businesses that need quick turnaround times. Understanding the speed capabilities allows buyers to match their production needs with the appropriate equipment.

5. Energy Efficiency Rating

With rising energy costs, the energy efficiency of an ironer is a vital consideration. Models with better energy ratings can lead to substantial cost savings over time. Buyers should inquire about the energy consumption metrics of potential ironers to ensure they are making environmentally and financially sound investments.

6. Build Quality and Material Grade

The durability of an ironer often depends on the material grade used in its construction. Ironers made from high-grade stainless steel or heavy-duty alloys tend to have longer lifespans and better resistance to wear and tear. For B2B buyers, investing in high-quality materials can reduce maintenance costs and extend the life of the equipment.

What Trade Terminology Should Buyers Know When Purchasing Ironers?

Familiarity with industry jargon can facilitate smoother negotiations and decision-making processes. Here are some common terms related to ironers for sale:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce equipment that may be marketed under another brand name. Understanding OEM relationships can help buyers identify the quality and reputation of the equipment they are considering, as well as the availability of parts and support.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for buyers to ensure they meet supplier requirements and can negotiate effectively based on their purchasing needs.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. Submitting an RFQ can help businesses compare prices, terms, and specifications, leading to more informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding the transportation and delivery of goods. Familiarity with these terms helps buyers understand shipping costs, risks, and liability, which is crucial for international transactions.

5. Lead Time

Lead time is the duration from placing an order to its delivery. This term is critical for businesses that rely on timely equipment arrival to meet operational demands. Understanding lead times can aid in planning and ensure that production schedules are maintained.

6. Warranty Period

The warranty period refers to the length of time a manufacturer guarantees the performance of the equipment. Knowing the warranty terms can provide buyers with peace of mind and protect their investment against potential defects or malfunctions.

In summary, understanding the essential technical properties and trade terminology related to ironers is vital for B2B buyers seeking to make informed purchasing decisions. By considering these specifications and familiarizing themselves with industry jargon, buyers can ensure they select the right ironer for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the ironer for sale Sector

What Are the Key Trends Shaping the Global Ironer for Sale Market?

The global market for ironers is experiencing significant transformation driven by several key factors. As industries worldwide, especially in regions like Africa, South America, the Middle East, and Europe, continue to focus on efficiency and cost-effectiveness, the demand for high-performance, multifunctional laundry equipment, such as flatwork ironers, is on the rise. Notably, used and refurbished ironers are gaining traction among international B2B buyers due to their affordability and reliability, presenting a viable option for businesses looking to optimize their operations without the hefty price tag of new machinery.

Emerging technologies are also influencing sourcing trends. Automation and smart technology integration are becoming essential for enhancing operational efficiency. Features like automated loading and folding systems can reduce labor costs and increase throughput, making these machines an attractive investment. Additionally, the trend toward online sourcing platforms is changing the way buyers connect with suppliers, enabling easier comparisons and quicker access to inventory across global markets.

Furthermore, sustainability is becoming a crucial consideration. Buyers are increasingly seeking equipment that minimizes energy consumption and reduces environmental impact. This focus on sustainability is not only a response to regulatory pressures but also aligns with the growing consumer demand for eco-friendly practices across industries.

How Does Sustainability and Ethical Sourcing Impact the Ironer for Sale Sector?

Sustainability and ethical sourcing are paramount in today’s B2B environment, particularly in the ironer sector. The environmental impact of industrial laundry operations can be significant, encompassing energy consumption, water usage, and waste generation. As a result, buyers are urged to consider equipment that incorporates energy-efficient technologies and sustainable materials. For instance, ironers designed to operate with lower steam and energy consumption can drastically reduce a facility’s carbon footprint, making them more appealing to environmentally conscious companies.

Ethical supply chains are also crucial. International buyers are increasingly looking for suppliers who uphold ethical standards, ensuring that their equipment is sourced responsibly. This includes certifications that verify the sustainability of materials and the labor practices involved in manufacturing. Certifications such as ISO 14001 for environmental management systems or Energy Star ratings for energy efficiency can serve as indicators of a supplier’s commitment to sustainability.

Incorporating ‘green’ certifications into purchasing decisions not only enhances a company’s reputation but also aligns with global efforts to promote sustainable industrial practices. As businesses strive to meet both regulatory standards and customer expectations, prioritizing sustainability in sourcing will be key to long-term success in the ironer market.

Illustrative image related to ironer for sale

What Is the Evolution of Ironers and Their Relevance in Today’s Market?

The evolution of ironers traces back to the early days of industrial laundry, where manual processes dominated the landscape. Over the decades, advancements in technology have led to the development of highly efficient machines capable of performing multiple functions, such as steaming, ironing, and folding, all in one cycle. The introduction of steam-heated and thermal oil ironers revolutionized the market, providing businesses with faster processing times and superior results.

Today, the relevance of ironers in the industrial laundry sector is underscored by their role in enhancing productivity and operational efficiency. With the increasing demand for high-quality linens in hospitality and healthcare sectors, ironers remain an essential piece of equipment for facilities aiming to deliver impeccable service. The ongoing trend towards automation and smart technology integration further solidifies their position as indispensable tools in modern laundry operations. As international buyers navigate the complexities of sourcing, understanding the historical context of ironers can inform better purchasing decisions that align with current market dynamics and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of ironer for sale

-

How do I choose the right ironer for my industrial laundry needs?

Choosing the right ironer involves assessing your specific laundry volume, types of fabrics processed, and available space. Consider the ironer type—cylinder or chest—based on your workload. Cylinder ironers are efficient for high-volume operations, while chest types may be suitable for smaller, specialized tasks. Additionally, review heating options such as steam or thermal oil based on your facility’s capabilities and budget. Consulting with suppliers about your needs can lead to tailored recommendations that optimize efficiency and minimize costs. -

What are the key features to look for in a commercial ironer?

When evaluating commercial ironers, prioritize features like heating method (steam, gas, or electric), size, and automation capabilities. Look for adjustable speed settings, ergonomic design for operator comfort, and integrated folding functions to streamline workflow. Additionally, ensure the machine can handle the types of linens you process, whether they are bed sheets, tablecloths, or uniforms. Reliability and ease of maintenance are also crucial, as they can significantly impact long-term operational costs. -

What are the typical payment terms for international ironer purchases?

Payment terms can vary widely among suppliers, but common practices include upfront payments, partial payments, or payment upon delivery. For international transactions, letters of credit are often used to secure payments, providing protection for both parties. It’s vital to clarify terms before finalizing a purchase, including currency exchange considerations, to avoid unexpected costs. Discussing payment terms openly with your supplier can lead to a mutually beneficial agreement, ensuring a smooth transaction process. -

How can I vet potential suppliers for ironers?

Vetting suppliers involves researching their reputation, experience, and customer feedback. Start by checking online reviews and ratings from previous clients. Request references and case studies to understand their track record in fulfilling orders. Additionally, assess their certifications and compliance with international quality standards. Engaging in direct communication can provide insights into their responsiveness and willingness to accommodate your specific needs, which is crucial for long-term partnerships. -

What is the minimum order quantity (MOQ) for ironers?

Minimum order quantities (MOQ) vary by supplier and are influenced by factors such as production capabilities and inventory levels. Some suppliers may offer flexibility for first-time buyers or smaller operations, while others may have strict MOQs. It’s important to discuss your needs upfront and negotiate terms that work for both parties. Understanding the MOQ can also help you plan your budget and logistics accordingly, ensuring that you receive the necessary equipment without excess inventory. -

How do logistics impact the purchase of ironers internationally?

Logistics play a critical role in the international purchase of ironers, affecting delivery times, costs, and overall supply chain efficiency. Consider factors such as shipping methods, customs clearance, and local regulations that may influence the import process. It’s advisable to work with suppliers who have experience in international shipping and can provide clear timelines and cost estimates. Establishing a reliable logistics partner can streamline the process and help mitigate potential delays or complications. -

What quality assurance measures should I consider when buying an ironer?

Quality assurance is vital when purchasing ironers, particularly in a B2B context where reliability impacts operational efficiency. Look for suppliers who provide warranties or guarantees on their equipment. Inquire about their quality control processes, including inspections and certifications from recognized industry standards. Additionally, consider whether the supplier offers post-sale support and maintenance services, as ongoing assistance can ensure the longevity and performance of your ironer. -

Can I customize the specifications of the ironer I want to purchase?

Many suppliers offer customization options for ironers to meet specific operational requirements. Customizable features may include size, heating methods, control systems, and additional attachments for specialized tasks. Discussing your unique needs with the supplier can lead to tailored solutions that enhance productivity. However, be aware that customization may affect lead times and costs, so it’s essential to balance your requirements with budgetary constraints and project timelines.

Top 8 Ironer For Sale Manufacturers & Suppliers List

1. R.W. Martin – Used Laundry Flatwork Ironers

Domain: rwmartin.com

Registered: 1999 (26 years)

Introduction: Used Laundry Flatwork Ironer for Sale at R.W. Martin Company. Various models available including: 1. Used Chicago Steam Heated Flatwork Ironer, Model Imperial 28 Classic – Pressure Tested. 2. Used Chicago Natural Gas Heated Flatwork Ironer, Model GO-16-136 F. 3. Used Girbau Natural Gas Heated Flatwork Ironer, Model X20125F1NP1. 4. Used Sharper Finish Electric Heated Flatwork Ironer, Model Impress …

2. Braun – Industrial Flatwork Ironers

Domain: surplusrecord.com

Registered: 1995 (30 years)

Introduction: This company, Braun – Industrial Flatwork Ironers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. eBay – Clothes Rotary Irons

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Clothes Rotary Irons for sale on eBay. Related products include Steam Clothes Irons, Rowenta Laundry Steam Irons, Rowenta Clothes Irons & Presses, Cordless Cloth Irons, and Tefal Clothes Steam Irons. Categories include Laundry Supplies such as Clothes Drying Racks, Clothes Folders, Detergents, Ironing Boards, and more. Specific items mentioned include Miele Electronic Unit # 7664001 (Brand New, $8…

4. Fagor – Wall Flatwork Ironer

Domain: fagorcommercial.com

Registered: 2003 (22 years)

Introduction: Laundry Flatwork Ironers – Industrial Flatwork Ironers

Key Features:

– Ergonomic design for enhanced and faster drying and ironing processes.

– Minimal maintenance costs due to simple operation.

– Wall-mounted design allows front-only operation for space efficiency.

Models:

1. Wall Flatwork Ironers:

– Roller sizes: Ø 7.87″ and Ø 12.8″

– Ironing capacity: 22 to 265 lb/hour (depending on mod…

5. Unimac – Industrial Roller System

Domain: unimac.com

Registered: 1995 (30 years)

Introduction: Model Numbers: FCU, FCUR, FCUF, FCUFF; Control: Micro control; Roller Diameters: 320mm, 500mm, 800mm; Working Widths: 1664mm, 2000mm, 2600mm, 3200mm; Features: High output for industrial applications, energy-saving settings, safety stop bar, alarm system for component failure; Warranty: Limited parts warranty for non-textile components for three years.

6. Machinio – Used Industrial Equipment

Domain: machinio.com

Registered: 2013 (12 years)

Introduction: Used Ironer for sale. Categories include various industrial equipment such as Foundry & Casting, Bakery & Pastry Equipment, Industrial Laundry Equipment, and more. Manufacturers listed include John Deere, Powermatic, and JET. The site features a wide range of products with specifications like T-slotted cast iron construction and various dimensions for angle plates and floor plates. Locations for i…

7. Speed Queen – 79 Flatwork Iron

Domain: tristatelaundryequipment.com

Registered: 2003 (22 years)

Introduction: {“product_name”: “SPEED QUEEN 79″ FLATWORK IRON”, “model”: “UD13F079GB2”, “condition”: “Used”, “year”: “2004”, “working_space”: “79 inches”, “heated_drum_size”: “13 inches”, “heat_source”: “Natural gas”, “voltage”: “120v”, “price”: “$5000.00”, “shipping”: “shipped anywhere in the lower 48”}

8. Rowenta – Steam Irons

Domain: rowentausa.com

Registered: 1996 (29 years)

Introduction: Steam Irons by Rowenta are designed for power, precision, and performance. They feature precision soleplates and powerful steam for exceptional performance and wrinkle-free results. Key product types include SteamForce+, Pro Master X-CEL, Focus Excellence, Access Steam, Duo Force, and SteamForce Pro. Prices range from $59.99 to $169.99. The irons come in various colors such as Black and Copper, Bl…

Strategic Sourcing Conclusion and Outlook for ironer for sale

In the rapidly evolving landscape of industrial laundry solutions, strategic sourcing of flatwork ironers remains a pivotal decision for businesses aiming to enhance operational efficiency. By opting for pre-owned or refurbished ironers, buyers can significantly reduce capital expenditure without compromising on performance. This approach not only allows for immediate cost savings but also aligns with sustainable practices by extending the lifecycle of existing equipment.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize suppliers who offer a diverse range of models tailored to their specific operational needs. The ability to source high-quality equipment, such as steam and gas-heated ironers, ensures that facilities can achieve optimal results in linen processing while minimizing labor costs and maximizing throughput.

Looking ahead, the demand for efficient laundry solutions is set to grow, driven by increasing consumer expectations and the need for operational excellence. Now is the ideal time for B2B buyers to explore the extensive offerings available and make informed purchasing decisions. Engage with reputable suppliers to unlock opportunities that will propel your laundry operations into a more efficient and profitable future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.