A Deep Dive into Paint Booth Paint Solution

Introduction: Navigating the Global Market for paint booth paint

Navigating the complexities of sourcing paint booth paint can present significant challenges for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe (including key markets like Saudi Arabia and Germany) ramp up their production capabilities, the demand for high-quality, effective paint booth coatings is on the rise. This comprehensive guide addresses the critical aspects of selecting the right paint booth paint, from understanding the various types available—such as peelable, water-based, and solvent-resistant coatings—to identifying the specific applications that meet operational needs.

In this guide, we delve into essential topics that empower buyers to make informed decisions, including supplier vetting processes, cost considerations, and the importance of product specifications. By understanding the nuances of paint booth paint, buyers can enhance their procurement strategies, ensuring optimal performance and longevity of their paint booths. This resource is designed to be a go-to reference for businesses looking to streamline their purchasing processes while maintaining high standards of quality and efficiency. With actionable insights and practical advice, this guide will equip you with the knowledge necessary to navigate the global market effectively and secure the best solutions for your paint booth requirements.

Understanding paint booth paint Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Peelable Coatings | Water-based, easily removable, protects surfaces from overspray | Automotive refinishing, industrial painting | Pros: Easy application and removal; reduces cleanup time. Cons: May need frequent reapplication. |

| Clear Coatings | Transparent, non-tacky finish, resists dirt and discoloration | Paint booths, light fixtures, and windows | Pros: Maintains visibility and cleanliness; protects surfaces. Cons: May require careful application to avoid smudging. |

| Solvent-Based Coatings | Durable, excellent solvent resistance, ideal for heavy-duty environments | Industrial applications, high-traffic areas | Pros: Strong protection; withstands harsh chemicals. Cons: Longer drying time; potential odor issues. |

| Specialty Coatings | Formulated for specific conditions (e.g., dust control) | Spray booths in dusty environments | Pros: Tailored solutions enhance performance; improves finish quality. Cons: Typically higher cost. |

| Floor Coatings | Designed for high-traffic areas, protects against spills and wear | Manufacturing floors, automotive service areas | Pros: Enhances safety; easy maintenance. Cons: Limited to floor applications; may require more frequent reapplication. |

What Are Peelable Coatings and Their B2B Relevance?

Peelable coatings are a versatile choice for businesses needing quick and efficient protection against paint overspray. These water-based solutions can be applied to various surfaces within a paint booth and are designed to be easily removed once the job is complete. B2B buyers should consider their ease of application and the reduction in cleanup time, which can lead to increased productivity. However, frequent reapplication may be necessary, depending on the booth’s usage and the type of paints being used.

How Do Clear Coatings Enhance Paint Booth Operations?

Clear coatings provide a transparent protective layer that maintains visibility and cleanliness within a paint booth. These non-tacky finishes resist dirt and discoloration, ensuring that the environment remains optimal for painting tasks. B2B buyers in the automotive and industrial sectors value these coatings for their ability to protect surfaces without compromising light quality. While they enhance the aesthetic and functional aspects of the booth, careful application is essential to avoid smudging or uneven finishes.

Illustrative image related to paint booth paint

What Benefits Do Solvent-Based Coatings Offer for Heavy-Duty Environments?

Solvent-based coatings are known for their durability and excellent resistance to solvents, making them ideal for heavy-duty industrial applications. These coatings provide robust protection for surfaces exposed to harsh chemicals and high-traffic conditions. B2B buyers should weigh the benefits of strong surface protection against potential drawbacks, such as longer drying times and odors associated with solvent-based products. Understanding the specific needs of their operation will help buyers make informed decisions.

Why Consider Specialty Coatings for Unique Environmental Challenges?

Specialty coatings are designed to meet specific environmental challenges, such as controlling dust in spray booths. These tailored solutions can significantly enhance the performance of painting operations, leading to better finish quality and higher customer satisfaction. Buyers should evaluate the added value these coatings bring to their processes against their typically higher costs. Investing in specialty coatings can yield long-term benefits through improved operational efficiency.

How Do Floor Coatings Contribute to Safety and Maintenance?

Floor coatings are specifically formulated to protect high-traffic areas from spills, wear, and tear. These coatings enhance safety by providing slip-resistant surfaces, making them essential in manufacturing and automotive service environments. B2B buyers should consider the long-term maintenance advantages of floor coatings, which can simplify cleaning and upkeep. However, they are limited to floor applications, and businesses may need to reapply them more frequently than other types of coatings.

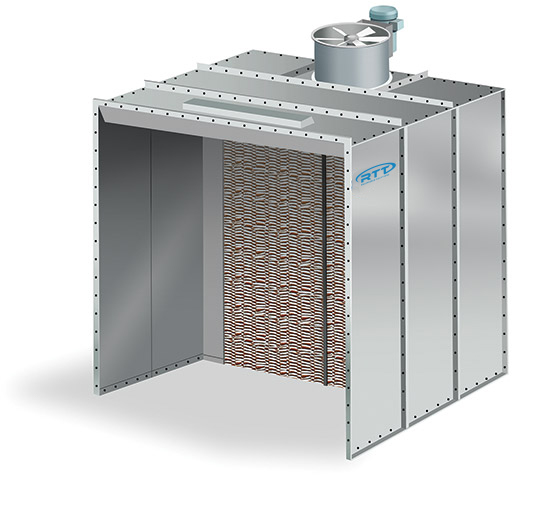

Illustrative image related to paint booth paint

Key Industrial Applications of paint booth paint

| Industry/Sector | Specific Application of paint booth paint | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Protection of paint booths in vehicle assembly plants | Ensures high-quality finishes, reduces overspray cleanup costs | Compliance with local regulations, solvent resistance, ease of application |

| Aerospace | Coating for aircraft painting facilities | Enhances safety by maintaining clean work environments | Need for high-temperature resistance, compatibility with aviation standards |

| Furniture Production | Coating for spray booths in furniture manufacturing | Improves production efficiency by minimizing downtime for cleaning | Availability of various colors, quick-drying properties, and peelability |

| Industrial Equipment | Surface protection in equipment painting processes | Protects against corrosion and extends equipment lifespan | Consideration for environmental impact, durability, and ease of removal |

| Electronics Assembly | Coating for PCB assembly lines | Reduces contamination risks, enhancing product reliability | Non-toxic options, compliance with electronic industry standards |

How is Paint Booth Paint Used in Automotive Manufacturing?

In the automotive sector, paint booth paint is applied to protect the walls, ceilings, and floors of paint booths where vehicles are finished. The primary challenge faced by manufacturers is managing overspray, which can lead to contamination and inconsistent paint application. Using high-quality peelable coatings minimizes the need for extensive cleanup, thus enhancing operational efficiency and ensuring a pristine environment for optimal paint adhesion. Buyers in regions like Germany and Saudi Arabia should prioritize coatings that comply with stringent environmental regulations while offering excellent solvent resistance.

What Role Does Paint Booth Paint Play in Aerospace Applications?

In aerospace manufacturing, paint booth paint is crucial for maintaining the cleanliness and safety of aircraft painting facilities. The coatings protect surfaces from paint overspray, which can impede visibility and create hazardous working conditions. The specific requirements for aerospace applications include high-temperature resistance and compliance with aviation industry standards. International buyers, especially in the Middle East, must ensure that the coatings used do not compromise the integrity of aircraft materials while providing easy removal when necessary.

How is Paint Booth Paint Beneficial for Furniture Production?

Furniture manufacturers utilize paint booth paint to maintain clean and efficient spraying environments. The application of peelable coatings on booth surfaces helps reduce dust and contaminants, resulting in superior finishes on products. This not only enhances customer satisfaction but also lowers labor costs related to cleanup. Buyers from South America should look for coatings that offer a variety of color options and quick drying times to optimize production schedules while meeting aesthetic demands.

Why is Paint Booth Paint Important for Industrial Equipment?

In the industrial equipment sector, paint booth paint serves as a protective layer during the painting of heavy machinery. It prevents corrosion and wear from paint and primer overspray, extending the lifespan of equipment. The key sourcing considerations include the durability of the coating, environmental impact, and ease of removal to facilitate maintenance. Buyers in Africa should prioritize coatings that meet local environmental standards while ensuring effective protection against harsh industrial conditions.

How Does Paint Booth Paint Improve Electronics Assembly?

In electronics assembly, paint booth paint is utilized to coat surfaces in PCB assembly lines, reducing the risk of contamination that could affect product performance. The coatings help maintain a clean workspace, which is critical for the reliability of electronic components. Buyers in this sector, particularly in Europe, should consider non-toxic options that comply with industry standards to ensure safety and sustainability in their manufacturing processes.

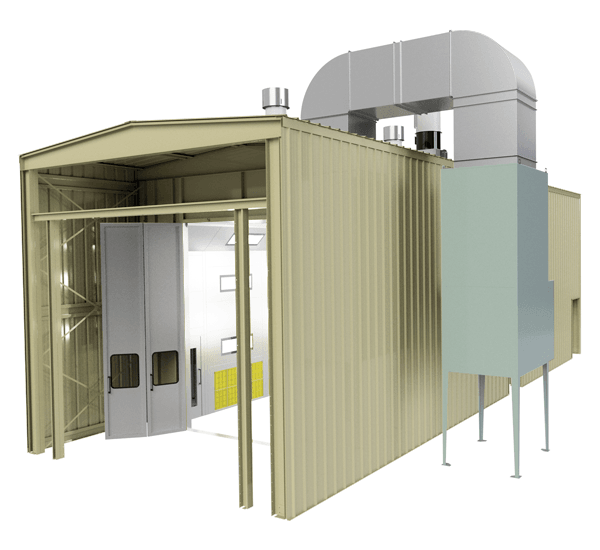

Illustrative image related to paint booth paint

3 Common User Pain Points for ‘paint booth paint’ & Their Solutions

Scenario 1: Overcoming Frequent Paint Booth Cleanup Challenges

The Problem: Maintaining cleanliness in paint booths is a persistent challenge for many businesses, especially those in the automotive and industrial sectors. Frequent overspray from paint and primer can lead to unsightly messes and operational inefficiencies. This not only increases labor costs associated with cleaning but can also compromise the quality of paint applications, leading to customer dissatisfaction. Buyers often find themselves stuck between the need for a clean environment and the limitations of traditional cleaning solutions that may not be effective or environmentally friendly.

The Solution: Investing in high-quality peelable booth coatings can significantly alleviate this issue. Products like Boothcoat 1700 or 3M™ Booth Coating provide a protective layer that can be easily applied to walls, ceilings, and floors of the paint booth. These coatings are designed to capture overspray, allowing for a quick and efficient cleanup—simply peel off the layer when it becomes too soiled. When sourcing these products, it’s essential to evaluate the coverage area and drying times to ensure that the coating meets the operational needs of your facility. For example, applying a single coat of a high-quality peelable coating can often be sufficient, reducing the need for multiple applications and thus saving time and resources.

Scenario 2: Navigating Environmental Compliance and Safety Regulations

The Problem: B2B buyers in regions like Europe and the Middle East often face stringent environmental regulations concerning VOC emissions and hazardous waste management. Selecting paint booth coatings that meet these regulations while still delivering the desired performance can be a daunting task. Non-compliance can lead to hefty fines and operational shutdowns, which makes it imperative for buyers to choose the right products carefully.

The Solution: To navigate these challenges, buyers should prioritize water-based, low-VOC coatings, such as those offered by General Chemical Corporation or Global Finishing Solutions. These products not only comply with environmental regulations but also provide excellent protection against overspray without compromising performance. When sourcing paint booth coatings, buyers should request safety data sheets (SDS) and technical data sheets (TDS) to confirm that the products meet local regulations. Additionally, engaging with suppliers who can provide insights on compliance and application techniques can enhance operational efficiency and ensure that businesses remain within legal parameters.

Illustrative image related to paint booth paint

Scenario 3: Ensuring Consistent Quality in Paint Application

The Problem: Achieving a uniform finish is critical for customer satisfaction in industries that rely on paint booths, such as automotive refinishing and industrial manufacturing. Variability in the application process can lead to defects, rework, and ultimately dissatisfied customers. B2B buyers often struggle with maintaining consistent quality due to factors such as inadequate booth cleanliness, improper application techniques, or subpar paint booth coatings.

The Solution: To ensure consistent quality, it is crucial to implement a comprehensive maintenance and application strategy. First, investing in high-quality booth coatings that are easy to apply and remove can help maintain a clean working environment. For instance, using products like Booth Shield® provides a robust protective layer while being easy to clean, thus minimizing the risk of defects caused by overspray. Additionally, training staff on proper application techniques, including the right use of spray equipment and the correct thickness of the coating, can significantly improve outcomes. Regular audits of the paint booth conditions and the application process can further help identify areas for improvement, ensuring that the quality of the final product meets the high standards expected by customers.

Strategic Material Selection Guide for paint booth paint

What Are the Key Materials Used for Paint Booth Paint?

When selecting paint booth coatings, international B2B buyers must consider various materials that offer distinct properties and benefits. This guide analyzes four common materials used in paint booth paints: water-based coatings, solvent-based coatings, peelable coatings, and epoxy coatings. Each material presents unique advantages and challenges that can significantly impact operational efficiency and compliance with international standards.

How Do Water-Based Coatings Perform in Paint Booth Applications?

Water-based coatings are increasingly popular due to their lower environmental impact and ease of application. These coatings typically exhibit excellent adhesion and flexibility, making them suitable for various surfaces in paint booths. They are also less toxic and easier to clean up compared to solvent-based options.

Illustrative image related to paint booth paint

Pros: Water-based coatings are non-flammable, have low VOC emissions, and are easy to apply and remove. They also dry quickly, allowing for faster turnaround times in busy operations.

Cons: However, they may not offer the same level of solvent resistance as their solvent-based counterparts. In high-temperature environments, their durability can be compromised, potentially leading to premature failure.

International Considerations: Buyers in regions with stringent environmental regulations, such as Europe, may prefer water-based coatings due to their compliance with low VOC standards. However, they should ensure that the specific formulation meets local industry standards.

Illustrative image related to paint booth paint

What Are the Benefits of Solvent-Based Coatings?

Solvent-based coatings are known for their durability and resistance to chemicals and solvents. They are often used in high-traffic paint booths where heavy overspray occurs. These coatings provide a robust barrier against paint and primer overspray, ensuring longevity.

Pros: The primary advantage of solvent-based coatings is their excellent solvent resistance and durability, making them suitable for challenging environments. They also tend to have a longer shelf life compared to water-based options.

Cons: The main drawback is their higher VOC emissions, which can lead to regulatory challenges in certain regions. They also require more extensive safety measures during application due to their flammability.

International Considerations: Buyers in regions like the Middle East and South America should be aware of local regulations regarding VOC emissions. Compliance with standards such as ASTM or DIN is crucial, particularly in industries with strict environmental controls.

Why Choose Peelable Coatings for Paint Booths?

Peelable coatings are designed for easy application and removal, providing a protective layer that can be stripped away when needed. This feature is particularly beneficial in maintaining cleanliness and operational efficiency in paint booths.

Illustrative image related to paint booth paint

Pros: The ease of removal and minimal cleanup required after application are significant advantages. These coatings also help maintain a clean environment, reducing the risk of contamination in paint applications.

Cons: While peelable coatings are convenient, they may not provide the same level of protection against heavy overspray as more durable coatings. Additionally, they can be more expensive due to their specialized formulations.

International Considerations: Buyers should consider the local climate, as extreme temperatures may affect the performance of peelable coatings. Compliance with international standards for safety and environmental impact is also essential.

How Do Epoxy Coatings Compare in Paint Booth Applications?

Epoxy coatings are renowned for their exceptional durability and chemical resistance. They are often used in industrial settings where heavy-duty performance is required.

Pros: Epoxy coatings offer superior adhesion, resistance to abrasion, and long-lasting performance, making them ideal for high-use paint booths. They can withstand harsh chemicals and solvents, ensuring a clean and safe working environment.

Cons: The application process can be more complex, requiring specific conditions such as temperature and humidity control. They also tend to have longer curing times, which can delay operations.

International Considerations: Buyers should ensure that epoxy coatings comply with local regulations regarding chemical use and environmental safety. In regions like Germany, adherence to DIN standards is crucial for product acceptance.

Summary Table of Material Selection for Paint Booth Paint

| Material | Typical Use Case for paint booth paint | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Water-Based Coatings | General protection for walls and ceilings | Low VOC emissions, easy cleanup | Limited solvent resistance, less durable | Medium |

| Solvent-Based Coatings | High-traffic areas with heavy overspray | Excellent durability and solvent resistance | Higher VOC emissions, flammability concerns | High |

| Peelable Coatings | Maintaining cleanliness and easy removal | Quick application and removal | May lack durability against heavy overspray | Medium to High |

| Epoxy Coatings | Industrial applications requiring heavy-duty performance | Superior durability and chemical resistance | Complex application, longer curing times | High |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for paint booth paint

What Are the Key Stages in the Manufacturing Process of Paint Booth Paint?

The manufacturing process of paint booth paint involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages helps B2B buyers assess the reliability and suitability of suppliers.

Material Preparation: What Raw Materials Are Used?

The first step in manufacturing paint booth paint is material preparation. This phase involves sourcing high-quality raw materials such as pigments, binders, solvents, and additives. For water-based paints, the choice of water as a solvent is crucial, as it impacts both environmental compliance and performance. Suppliers often conduct rigorous checks on these materials to ensure they meet specific standards, such as ASTM or ISO certifications, before they enter the production line.

Forming: How Is the Paint Mixed and Processed?

Once the materials are prepared, they undergo a mixing process. This involves combining the pigments, binders, and solvents in precise ratios to achieve the desired color, viscosity, and application properties. Advanced mixing techniques, such as high-speed dispersers or triple-roll mills, are often employed to ensure a homogenous mixture. This stage is critical, as inconsistencies can lead to performance issues, such as uneven application or inadequate adhesion.

Assembly: What Techniques Are Used to Package Paint Booth Paint?

After mixing, the paint is subjected to an assembly process, where it is packaged into various container sizes, ranging from one-gallon to 55-gallon drums. This stage often includes automated filling and sealing processes to maintain efficiency and hygiene. Labeling is another essential aspect, as it must comply with international regulations regarding safety and handling instructions. B2B buyers should inquire about the packaging options available and whether they align with their logistical needs.

Illustrative image related to paint booth paint

Finishing: How Is Quality Enhanced Before Shipping?

The final stage is finishing, where the paint undergoes rigorous quality control measures. This may include filtration to remove impurities, viscosity adjustments, and final color checks. The paint is then stored under controlled conditions to maintain its stability before shipping. This stage also involves preparing samples for testing to ensure they meet specified performance criteria.

What Quality Assurance Standards Are Relevant for Paint Booth Paint?

Quality assurance is paramount in the manufacturing of paint booth paint, as it directly affects the product’s performance and safety. Buyers should be familiar with both international and industry-specific standards that govern quality.

What Are the Key International Standards for Paint Booth Paint?

ISO 9001 is one of the most recognized international standards for quality management systems. It emphasizes a process-oriented approach and continuous improvement, ensuring that manufacturers consistently meet customer and regulatory requirements. B2B buyers should verify if their suppliers have ISO 9001 certification, as this reflects a commitment to quality.

Illustrative image related to paint booth paint

Which Industry-Specific Certifications Should Buyers Look For?

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also be relevant, depending on the application of the paint. CE certification indicates compliance with European health, safety, and environmental protection standards, which is particularly important for buyers in Europe. Understanding these certifications helps buyers assess the reliability and safety of products.

What Are the Key Quality Control Checkpoints in Paint Booth Paint Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that the final product meets the required specifications.

What Are the Stages of Quality Control?

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before they enter production. Suppliers should have documented procedures for verifying the quality of incoming materials, including certificates of compliance and testing reports.

-

In-Process Quality Control (IPQC): During production, samples are taken at various stages to monitor consistency in mixing, viscosity, and color. This ongoing assessment helps identify any deviations from established standards early in the process.

-

Final Quality Control (FQC): Before packaging, the final product undergoes comprehensive testing, including adhesion tests, drying time assessments, and performance under various conditions. This ensures that the paint will perform as expected once applied.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are several methods to consider:

What Auditing Processes Are Effective for Supplier Verification?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control practices. Buyers can request access to audit reports or even conduct their own audits to evaluate compliance with international standards and internal quality practices.

What Role Do Third-Party Inspections Play?

Engaging a third-party inspection agency to review the manufacturing process and quality control measures can provide an unbiased assessment. These agencies can perform tests on samples and verify that the products meet specified standards, offering additional peace of mind to buyers.

Illustrative image related to paint booth paint

How Can Buyers Use Documentation for Quality Assurance?

Buyers should request comprehensive documentation from suppliers, including quality control reports, test results, and certifications. This documentation serves as evidence of the supplier’s commitment to quality and compliance with industry standards.

What Are the Unique QC Considerations for International Buyers?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, there are additional considerations regarding quality control.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have varying regulations governing the use of chemicals and paints. Buyers must ensure that suppliers are compliant with local regulations in their respective markets, such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) in the EU.

Illustrative image related to paint booth paint

What Are the Common Challenges Faced by International Buyers?

Challenges such as language barriers, differing quality standards, and logistical issues can complicate the procurement process. Buyers should establish clear communication with suppliers and consider working with local representatives who understand the regional market dynamics.

By understanding the manufacturing processes and quality assurance measures in the paint booth paint industry, B2B buyers can make informed decisions when selecting suppliers. This knowledge is crucial for ensuring that the products meet their operational needs and quality expectations, ultimately leading to greater customer satisfaction and operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘paint booth paint’

To assist B2B buyers in the procurement of paint booth paint, this practical sourcing guide offers a structured checklist that ensures a systematic approach to selecting the right products and suppliers. By following these steps, you can make informed decisions that align with your operational needs and budget.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for ensuring that the paint booth paint meets your operational requirements. Consider factors such as the type of surfaces to be coated (walls, ceilings, floors), the expected durability, and the environmental conditions of your workspace. Additionally, determine whether you need peelable coatings for easy maintenance or coatings with specific solvent resistance properties.

Step 2: Identify Regulatory Compliance Requirements

Understanding the regulatory landscape is essential when sourcing paint booth paint, particularly in international markets. Different regions may have specific regulations regarding volatile organic compounds (VOCs), safety standards, and disposal methods. Ensure that the products you consider comply with local regulations, as this will help avoid potential legal issues and enhance workplace safety.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Look for suppliers with a proven track record in providing high-quality paint booth coatings. Request case studies, customer testimonials, and references, particularly from companies in similar industries or regions. A reputable supplier will also be willing to provide detailed product specifications and safety data sheets.

Step 4: Assess Product Performance and Application Method

Different products may offer varying levels of performance based on their formulation and application method. Assess whether the paint booth paint is easy to apply with your existing equipment, such as conventional spray systems. Additionally, inquire about drying times, coverage rates, and ease of removal, as these factors can significantly impact your operational efficiency.

Step 5: Compare Pricing and Value Propositions

While cost is an important consideration, focus on the overall value proposition rather than just the price. Compare prices across different suppliers for similar products, but also take into account factors such as product longevity, ease of application, and maintenance requirements. A higher upfront cost might lead to lower long-term expenses due to reduced labor and maintenance needs.

Step 6: Request Samples for Testing

Before finalizing your purchase, request samples of the paint booth paint for testing. This step allows you to evaluate the product’s performance in your specific environment and application conditions. Conduct tests to assess adhesion, durability, and ease of cleaning, ensuring that the product meets your expectations and operational requirements.

Illustrative image related to paint booth paint

Step 7: Finalize Order and Establish Communication Channels

Once you have selected a supplier and product, finalize your order with clear terms regarding delivery timelines, payment methods, and after-sales support. Establish effective communication channels with your supplier to address any potential issues promptly. Clear communication can help streamline the procurement process and ensure that you receive the necessary support throughout your project.

By following these steps, B2B buyers can effectively navigate the sourcing process for paint booth paint, ensuring they choose products and suppliers that meet their specific needs and compliance requirements.

Comprehensive Cost and Pricing Analysis for paint booth paint Sourcing

What Are the Key Cost Components in Paint Booth Paint Sourcing?

When sourcing paint booth paint, understanding the cost structure is vital for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The type of materials used significantly impacts the cost. Water-based, peelable coatings may have different price points compared to solvent-based alternatives. Buyers should evaluate the longevity and performance of materials against their cost.

-

Labor: Labor costs encompass the wages of personnel involved in production and application. Efficient labor practices can help reduce overall costs, making it essential to consider the labor force’s skill level and experience.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and equipment maintenance. Companies with advanced manufacturing processes may achieve lower overhead costs, leading to competitive pricing.

-

Tooling: Depending on the complexity of the paint formulation, tooling costs may vary. Custom formulations may require specialized equipment, influencing the overall cost.

-

Quality Control (QC): Implementing stringent QC processes ensures that the paint meets industry standards, which may add to the costs but is crucial for maintaining product integrity.

-

Logistics: Shipping and handling costs can fluctuate based on the distance from the manufacturer to the buyer’s location, especially for international shipments.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the supplier’s margin can help buyers negotiate better deals.

How Do Price Influencers Impact the Cost of Paint Booth Paint?

Several factors influence the pricing of paint booth paint, which can vary significantly across different regions such as Africa, South America, the Middle East, and Europe.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts, reducing the unit price. Buyers should assess their needs against MOQ requirements to maximize cost efficiency.

-

Specifications and Customization: Custom formulations or specific color requirements can lead to higher costs. Buyers should weigh the necessity of customization against potential price increases.

-

Materials and Quality Certifications: Higher-quality materials or certifications (e.g., environmental compliance) may come at a premium. Buyers should consider the Total Cost of Ownership (TCO) when assessing quality against price.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their track record, but they often provide better service and product consistency.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they define the responsibilities of buyers and sellers in shipping. This can affect overall logistics costs and delivery timelines.

What Are Effective Buyer Tips for Paint Booth Paint Procurement?

Navigating the procurement process for paint booth paint requires strategic planning and negotiation skills. Here are some actionable tips for B2B buyers:

Illustrative image related to paint booth paint

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Negotiating terms can lead to better pricing and flexible payment options.

-

Cost-Efficiency: Consider the Total Cost of Ownership, which includes not just the purchase price but also application costs, maintenance, and disposal. A cheaper product might lead to higher long-term costs due to frequent replacements or application issues.

-

Market Research: Conduct thorough research on various suppliers and products available in your target region. Comparing different offerings will help in making informed decisions.

-

Understand Regional Nuances: Pricing structures can vary by region due to local regulations, tariffs, and market demand. Understanding these nuances will enable buyers to negotiate better terms and identify cost-effective solutions.

-

Stay Updated on Trends: Keep abreast of industry trends, such as innovations in paint technology or changes in environmental regulations, which could impact costs and supplier offerings.

Disclaimer on Indicative Prices

Prices for paint booth paint can fluctuate based on various factors, including market conditions and supplier pricing strategies. The ranges provided in this analysis are indicative and should not be considered fixed. B2B buyers are encouraged to request quotes from suppliers to obtain the most accurate pricing information tailored to their specific needs.

Alternatives Analysis: Comparing paint booth paint With Other Solutions

When considering the best solutions for protecting paint booths, it is essential for B2B buyers to explore various alternatives to traditional paint booth paint. Each option has unique characteristics, benefits, and limitations that can significantly impact operational efficiency, cost-effectiveness, and overall performance in maintaining paint booth cleanliness and functionality.

Comparison Table

| Comparison Aspect | Paint Booth Paint | Peelable Coatings | Protective Booth Films |

|---|---|---|---|

| Performance | High durability; withstands solvents | Good solvent resistance; easy removal | Excellent protection; less mess |

| Cost | Moderate ($65 – $1,955 per gallon) | Affordable ($30 – $45 per gallon) | Variable, typically higher initial cost |

| Ease of Implementation | Requires proper application techniques | Simple application; spray or roll | Fast to apply, dries quickly |

| Maintenance | May require frequent reapplication | Easily peelable; reduces cleanup | Minimal maintenance; easy to clean |

| Best Use Case | Ideal for long-term protection | Short-term projects or frequent changes | Continuous use with minimal downtime |

What Are the Pros and Cons of Peelable Coatings?

Peelable coatings offer a practical alternative to traditional paint booth paints. These water-based solutions, such as those provided by General Chemical Corporation, are designed for easy application and quick removal. They provide adequate protection against overspray while allowing for a clean surface underneath. However, while they are cost-effective and reduce labor time during removal, they may not provide the same long-term durability as conventional paints, requiring more frequent application in high-use environments.

What Are the Advantages and Disadvantages of Protective Booth Films?

Protective booth films, like Booth Shield® from Global Finishing Solutions, are another viable option. These films are designed to be sprayed or rolled onto surfaces and can be easily removed without damaging the underlying material. The benefits of using protective booth films include superior ease of application and maintenance, along with minimal mess. However, these films can be more expensive initially and may require specific conditions for optimal adhesion and performance, which can be a consideration for budget-conscious buyers.

Conclusion: How to Choose the Right Solution for Your Paint Booth Needs?

In selecting the right solution for paint booth protection, B2B buyers should assess their specific operational requirements, budget constraints, and maintenance capabilities. Paint booth paint is ideal for long-term, high-durability needs, while peelable coatings and protective films provide flexibility for businesses that require frequent changes or lower initial costs. By understanding the strengths and weaknesses of each option, buyers can make informed decisions that align with their operational goals and improve their overall paint booth efficiency.

Illustrative image related to paint booth paint

Essential Technical Properties and Trade Terminology for paint booth paint

What Are the Key Technical Properties of Paint Booth Paint?

When considering paint booth paint, several technical properties are critical for ensuring optimal performance and protection. Understanding these specifications can aid B2B buyers in making informed decisions.

-

Material Composition

Paint booth paints are often water-based or solvent-based. Water-based paints, like Booth Coat 1700, are favored for their low VOC emissions, making them environmentally friendly and safer for workers. In contrast, solvent-based paints may offer better durability but can release harmful fumes. Selecting the right type aligns with regulatory compliance and workplace safety standards. -

Peelability

Many paint booth coatings are designed to be peelable, allowing for easy removal without damaging the underlying surfaces. This property is crucial for maintaining cleanliness in the booth and reducing labor costs associated with frequent clean-ups. Peelable coatings, such as those from General Chemical Corporation, enable facilities to maintain a pristine environment, ensuring high-quality paint applications and customer satisfaction. -

Coverage Area

Coverage area refers to the amount of surface that can be covered with a specific quantity of paint. For instance, one gallon of paint might cover approximately 150 square feet at a thickness of 10 mils. Understanding coverage is essential for B2B buyers to estimate material requirements accurately and avoid over-ordering or under-ordering, which can impact project timelines and budgets. -

Drying Time

The drying time of paint booth coatings can vary significantly. Quick-drying formulations allow businesses to resume operations shortly after application, minimizing downtime. For example, 3M’s booth coating dries quickly to a clear film, facilitating efficient workflow and reducing the potential for contamination from dust or other airborne particles. -

Solvent Resistance

This property indicates how well a paint can withstand exposure to various solvents without degrading. Excellent solvent resistance is vital in paint booths where overspray from paints and primers can occur frequently. A coating that offers high solvent resistance will provide better protection, thereby extending the lifespan of booth surfaces and reducing maintenance costs.

Which Trade Terms Are Essential for Understanding Paint Booth Paint Purchases?

Familiarity with industry jargon is crucial for B2B transactions, especially in the context of paint booth paint. Here are some key terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of paint booth paints, understanding OEM relationships can help buyers ensure compatibility with existing equipment and systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory effectively and avoid excessive stock that could tie up capital. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products. For B2B buyers, issuing an RFQ can help in comparing prices and terms from multiple vendors, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms helps businesses manage logistics, shipping costs, and risk during the delivery process, which is particularly important in global trade. -

SDS (Safety Data Sheet)

An SDS provides detailed information about the handling, storage, and safety measures related to a chemical product. For paint booth paints, reviewing the SDS is critical to ensure compliance with health and safety regulations and to protect workers.

By grasping these technical properties and trade terminologies, B2B buyers can enhance their procurement strategies, ensuring they select the most suitable paint booth solutions for their operations.

Illustrative image related to paint booth paint

Navigating Market Dynamics and Sourcing Trends in the paint booth paint Sector

What Are the Current Market Trends Impacting the Paint Booth Paint Sector?

The global paint booth paint market is experiencing significant growth, driven by the increasing demand for high-quality finishing in various industries, including automotive, aerospace, and manufacturing. Key trends include the adoption of advanced spray booth technologies and the rise of water-based coatings that offer superior performance and environmental benefits. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should note the shift towards peelable and easily removable coatings, which enhance efficiency in maintenance and reduce labor costs.

Emerging B2B technologies like automated paint application systems and smart monitoring solutions are gaining traction. These innovations not only streamline operations but also provide data analytics that help businesses optimize their paint usage and minimize waste. Buyers should consider suppliers that offer integrated solutions, including software for inventory management and predictive maintenance, as these can significantly enhance operational efficiency.

Additionally, the market dynamics are influenced by fluctuating raw material prices and regulatory changes aimed at reducing VOC emissions. Buyers must stay informed about these factors to negotiate better terms and ensure compliance with local and international standards. Understanding the competitive landscape will also be crucial, as more manufacturers are expanding their product lines to include eco-friendly options, which are becoming increasingly sought after in global markets.

How Can Sustainability and Ethical Sourcing Influence Purchasing Decisions in Paint Booth Paint?

Sustainability is becoming a critical factor for B2B buyers in the paint booth paint sector. The environmental impact of paint production and application is under scrutiny, prompting buyers to seek suppliers who prioritize eco-friendly practices. This includes the use of low-VOC and water-based coatings, which not only reduce harmful emissions but also align with global sustainability goals.

Ethical sourcing is equally important, as buyers are increasingly aware of the social implications of their purchasing decisions. Opting for suppliers that adhere to fair labor practices and have transparent supply chains can enhance a company’s reputation and appeal to environmentally conscious customers. Certifications such as Green Seal and EcoLabel are valuable indicators of a product’s sustainability credentials. Buyers should prioritize partnerships with manufacturers that possess these certifications to ensure they are investing in responsible and sustainable products.

Illustrative image related to paint booth paint

Moreover, incorporating sustainable practices into procurement strategies can lead to long-term cost savings. By investing in high-quality, durable coatings that require less frequent application, businesses can reduce overall operational costs. Thus, aligning purchasing decisions with sustainability and ethical sourcing not only fulfills corporate social responsibility but can also provide a competitive edge in the market.

What Historical Developments Have Shaped the Paint Booth Paint Industry?

The evolution of the paint booth paint industry reflects broader technological and environmental trends. Initially dominated by solvent-based paints, the sector has seen a shift towards water-based formulations in response to increasing regulatory pressures and environmental awareness. This transition began in earnest in the late 20th century, as manufacturers started prioritizing worker safety and environmental sustainability.

In the early 2000s, advancements in coating technology, such as peelable coatings and improved application methods, began to emerge, enhancing both efficiency and effectiveness in paint booth operations. The introduction of advanced spray equipment and automated systems further revolutionized the sector, enabling businesses to achieve higher quality finishes with less waste.

As the industry continues to evolve, ongoing innovations in materials science and coatings technology promise to shape the future of paint booth applications. Buyers should remain vigilant about these developments, as they can impact product offerings and sourcing strategies in the years to come.

Frequently Asked Questions (FAQs) for B2B Buyers of paint booth paint

-

How do I solve paint overspray issues in my booth?

To effectively manage paint overspray, consider using peelable booth coatings designed for easy application and removal. These coatings protect booth surfaces from overspray, ensuring a cleaner environment and reducing cleanup time. Choose a product with excellent solvent resistance to withstand various paints and primers. Implementing a regular maintenance schedule for applying and removing the coatings can significantly enhance your booth’s efficiency and prolong its lifespan. -

What is the best type of paint booth coating for my needs?

The optimal paint booth coating depends on your specific application requirements. For general protection, a white peelable coating is ideal as it reflects light and makes the booth brighter. If you require a more versatile solution, clear spray-on coatings can protect walls, windows, and fixtures without altering visibility. Evaluate your operational needs, such as the type of paint used and frequency of booth cleaning, to select the most effective product. -

How can I verify the credibility of a paint booth paint supplier?

To vet a supplier, start by researching their reputation in the industry. Look for customer reviews, testimonials, and case studies that demonstrate reliability and product quality. Check for certifications and compliance with international standards relevant to your region. Establish direct communication to discuss product specifications and ask for references from other businesses that have sourced from them. This proactive approach helps ensure you partner with a trustworthy supplier. -

What are the typical minimum order quantities (MOQs) for paint booth coatings?

MOQs for paint booth coatings can vary significantly depending on the supplier and product type. Generally, manufacturers may set MOQs ranging from one gallon to several hundred gallons. It’s advisable to inquire about bulk purchase discounts, as higher quantities often reduce per-unit costs. When negotiating with suppliers, discuss your anticipated usage to see if they can accommodate smaller orders or flexible terms tailored to your business needs. -

What payment terms should I expect when purchasing paint booth paint internationally?

Payment terms for international purchases can vary, but common practices include advance payment, letters of credit, or net payment terms (e.g., net 30 or 60 days). Be aware of currency exchange rates and potential transaction fees. Establish clear terms upfront to avoid misunderstandings. It’s also wise to confirm the payment methods accepted by the supplier and consider using escrow services for large transactions to protect your investment. -

How do I ensure quality assurance (QA) for paint booth paint?

Quality assurance can be ensured by requesting detailed product specifications and compliance certifications from suppliers. Ask for samples to conduct tests on adhesion, durability, and overspray resistance before committing to larger orders. Implement an incoming inspection process to verify that the products meet your quality standards upon delivery. Establish a feedback loop with the supplier for addressing any quality issues that may arise during production or usage. -

What logistics considerations should I keep in mind when sourcing paint booth paint?

When sourcing paint booth paint, consider shipping options, delivery times, and costs associated with international freight. Ensure that the supplier can handle customs clearance and is knowledgeable about regulations in your region. Evaluate the packaging to prevent damage during transport, especially for liquid products. Additionally, plan for storage requirements upon arrival, considering temperature and humidity conditions that may affect the paint’s integrity. -

Can I customize paint booth coatings to meet specific operational needs?

Many manufacturers offer customization options for paint booth coatings, including specific colors, finishes, and formulations tailored to unique operational requirements. Discuss your needs with potential suppliers to explore available customization options. Be prepared to provide details about your booth environment, the types of paints used, and any specific performance characteristics you require. Custom solutions can enhance the effectiveness of your paint booth and improve overall operational efficiency.

Top 7 Paint Booth Paint Manufacturers & Suppliers List

1. Sherwin-Williams – Ultra-Low VOC Latex Paint

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Sherwin-Williams latex paint, single stage white paint, PPG 2 part epoxy paint, ultra-low VOC latex paint.

2. General Chemical Corp – White Booth Coating

Domain: cookmfg.com

Registered: 2020 (5 years)

Introduction: {“Product Name”: “White Booth Coating”, “Manufacturer”: “General Chemical Corp”, “Model”: “1700”, “Price Range”: “$65.45 – $1,955.95”, “Available Sizes”: [“1 Gallon”, “5 Gallons”, “55 Gallons”], “Color”: “White”, “SKU”: “1700”, “Weight”: “9 lbs”, “Coverage”: “Approximately 150 square feet at 10 mils thickness”, “Description”: “Booth Coat 1700 is a white peelable water based paint spray booth coati…

3. 3M – Booth Coating

Domain: 3m.com

Registered: 1988 (37 years)

Introduction: 3M™ Booth Coating is a spray-on protective coating designed for paint booths. Key features include:

– Convenient application with conventional spray equipment, such as the Accuspray™ 2.0 disposable spray nozzle.

– Protects paint booth walls, windows, lights, and fixtures, ensuring optimal lighting and cleanliness.

– Excellent solvent resistance against paint and primer overspray.

– Washes off …

4. GeneralChem – Boothcoat 1700

Domain: generalchem.com

Registered: 1997 (28 years)

Introduction: [{‘name’: ‘Boothcoat 1700’, ‘description’: ‘Low Gloss Protective White Coating for Painting’, ‘price’: ‘$30.00’}, {‘name’: ‘Boothcoat 5140’, ‘description’: ‘Clear Peelable Coating to Protect from Paint and Enamel Overspray’, ‘price’: ‘$41.50’}, {‘name’: ‘Boothcoat 5201’, ‘description’: ‘Peelable White Protective Coating for Spray Paint Application’, ‘price’: ‘$32.00’}, {‘name’: ‘Peelkleer 5358’, ‘…

5. Rustoleum – Industrial Paint

Domain: garagejournal.com

Registered: 2006 (19 years)

Introduction: Rustoleum industrial paint, item # 8781402 (primer for galvanized surfaces), Sherwin Williams industrial etching primer, peelable booth coatings from Binks and 3M, Devilbiss GTI guns, Power Fist HVLP gun.

6. Global Finishing – Booth Shield®

Domain: globalfinishing.com

Registered: 2003 (22 years)

Introduction: Booth Shield® is a peelable protective coating designed for walls, ceilings, windows, and lights in paint booths. It offers superior protection with minimal cleanup and surface preparation, easier application than traditional paper wraps, and fast removal. The coating can be sprayed or rolled on, typically requiring only one coat for wall applications. It dries quickly, allowing for full use of th…

7. Like90 – White Out Peelable Coating

Domain: like90.net

Registered: 2007 (18 years)

Introduction: {“products”:[{“name”:”White Out Peelable Coating”,”description”:”Sprays on fast with minimal preparation, provides superior film strength and durability, can be recoated between maintenance cycles, reduces noise.”,”part_numbers”:[10031,10032,10033]},{“name”:”White Wash Washable Coating”,”description”:”Washable formula, easy application, can be recoated up to four times, safe to sewer, biodegradabl…

Strategic Sourcing Conclusion and Outlook for paint booth paint

The strategic sourcing of paint booth paint is a critical investment for businesses aiming to optimize their operational efficiency and maintain high-quality standards. As highlighted throughout this guide, selecting the right peelable coatings can significantly enhance booth cleanliness, reduce maintenance costs, and improve overall paint application quality. Options like water-based and solvent-resistant coatings provide flexibility and convenience, ensuring that your paint booth remains functional while minimizing downtime.

Illustrative image related to paint booth paint

In the context of international markets, particularly in regions such as Africa, South America, the Middle East, and Europe, sourcing high-quality paint booth paint can provide a competitive edge. By establishing reliable partnerships with leading manufacturers, businesses can ensure access to innovative solutions tailored to their specific needs.

Looking ahead, the demand for advanced paint booth coatings is expected to grow as industries continue to prioritize sustainability and efficiency. It is crucial for B2B buyers to stay informed about the latest technologies and sourcing strategies. We encourage you to engage with suppliers who can provide insights and customized solutions that align with your operational goals. Embrace this opportunity to enhance your production capabilities and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.