Choosing Your Aluminum Forging Companies: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for aluminum forging companies

In an increasingly competitive global marketplace, sourcing aluminum forging companies that meet stringent quality, performance, and cost requirements poses a significant challenge for international B2B buyers. The aluminum forging process is vital for producing high-strength components used across industries, from aerospace to automotive, where safety and efficiency are paramount. This guide serves as a comprehensive resource, detailing various types of aluminum forgings, their specific applications, and insights into the supplier vetting process.

Buyers will gain critical knowledge on how to assess potential suppliers based on their capabilities, certifications, and past performance. Additionally, this guide addresses the cost factors associated with aluminum forgings, helping businesses in regions such as Africa, South America, the Middle East, and Europe—particularly countries like Saudi Arabia and Nigeria—make informed purchasing decisions. With an emphasis on actionable insights, this resource empowers B2B buyers to navigate the complexities of sourcing aluminum forgings effectively, ensuring they partner with reliable suppliers who can meet their specific needs and standards. By leveraging this guide, companies can enhance their supply chain resilience and drive operational success in their respective markets.

Understanding aluminum forging companies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Closed Die Forging | Utilizes enclosed dies for precise shaping | Aerospace, automotive, industrial | Pros: High precision, better strength; Cons: Higher initial setup costs. |

| Open Die Forging | Involves shaping the metal between flat dies | Heavy machinery, construction | Pros: Lower costs, versatile; Cons: Less precision compared to closed die. |

| Precision Forging | Focuses on tight tolerances and detailed designs | Aerospace, medical devices | Pros: High accuracy, custom solutions; Cons: Longer lead times. |

| Roll Forging | Involves rolling the metal into shape | Automotive, rail, marine | Pros: Efficient for long parts, cost-effective; Cons: Limited to simpler shapes. |

| Hot Forging | Performed at high temperatures to enhance ductility | Aerospace, defense, oil & gas | Pros: Improved material properties; Cons: Requires more energy and equipment. |

What Are the Characteristics of Closed Die Forging?

Closed die forging, also known as impression die forging, is characterized by its use of dies that completely enclose the metal being forged. This method is particularly advantageous for producing complex shapes with high precision, making it suitable for critical applications in the aerospace and automotive industries. B2B buyers should consider the initial setup costs, which can be higher due to the need for custom dies, but the resulting parts often exhibit superior strength and durability.

How Does Open Die Forging Differ from Other Methods?

Open die forging is distinct in that it involves shaping the metal between flat dies, allowing for a wider range of sizes and shapes. This technique is often used for larger components in heavy machinery and construction applications. Buyers can benefit from lower costs and greater versatility, but they should be aware that this method may not achieve the same level of precision as closed die forging, potentially impacting part performance in critical applications.

Why Choose Precision Forging for Your B2B Needs?

Precision forging is designed for applications that require tight tolerances and intricate designs, making it ideal for industries such as aerospace and medical devices. The process allows for the creation of highly customized components that meet specific performance standards. However, buyers should note that while precision forging provides exceptional accuracy, it often comes with longer lead times, which may affect project timelines.

What Are the Advantages of Roll Forging?

Roll forging is a unique method that involves the continuous rolling of metal to achieve the desired shape. This process is particularly efficient for producing long, uniform parts used in automotive and rail applications. Buyers can appreciate the cost-effectiveness and efficiency of roll forging; however, it is generally limited to simpler shapes, which may not meet the needs of all projects.

When Is Hot Forging the Best Option?

Hot forging is performed at elevated temperatures, which improves the material’s ductility and allows for easier shaping. This method is commonly used in demanding industries such as aerospace, defense, and oil & gas. While hot forging enhances material properties, buyers should consider the increased energy requirements and equipment costs associated with this process, as well as the potential for thermal distortion in certain applications.

Key Industrial Applications of aluminum forging companies

| Industry/Sector | Specific Application of aluminum forging companies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft components (fittings, brackets) | High strength-to-weight ratio enhances fuel efficiency | Compliance with stringent aerospace standards |

| Automotive | Suspension systems and brake components | Improved performance and safety in vehicles | Need for precise specifications and tolerances |

| Defense | Military equipment and munitions | Durability under extreme conditions ensures reliability | Certification for defense-grade materials |

| Marine | Structural components for vessels | Resistance to corrosion prolongs lifespan at sea | Sourcing from certified suppliers for quality assurance |

| Industrial Machinery | Gearboxes and housing for machinery | Enhanced strength reduces maintenance costs | Customization to fit specific machinery requirements |

How is Aluminum Forging Used in Aerospace Applications?

In the aerospace industry, aluminum forging is critical for manufacturing lightweight yet robust components like fittings and brackets. These parts must withstand significant stress and are designed to enhance fuel efficiency, which is vital for reducing operational costs. Buyers in this sector must ensure that suppliers comply with strict aerospace standards, including certifications and quality assurance processes. The ability to provide detailed documentation and traceability of materials is essential for international buyers, particularly in regions like Europe and the Middle East.

Illustrative image related to aluminum forging companies

What Role Does Aluminum Forging Play in Automotive Manufacturing?

Aluminum forging is widely utilized in the automotive sector for producing suspension systems and brake components. The lightweight nature of aluminum contributes to improved vehicle performance and safety, making it an attractive choice for manufacturers. Buyers should focus on suppliers who can meet precise specifications and tolerances, as even minor deviations can affect vehicle dynamics. Sourcing from companies with a reputation for quality control is particularly important for B2B buyers in Africa and South America, where reliability is paramount.

How is Aluminum Forging Applied in Defense Industries?

In defense applications, aluminum forgings are essential for creating military equipment and munitions. The durability and strength of forged aluminum components ensure that they can withstand extreme conditions, which is critical for operational reliability. Suppliers must provide materials that meet stringent defense-grade standards, including certifications and testing. International buyers, especially from regions like Saudi Arabia and Nigeria, should prioritize sourcing from companies that have proven experience in defense applications to ensure compliance and quality.

What are the Benefits of Aluminum Forging in Marine Applications?

Marine industries benefit significantly from aluminum forging for structural components used in vessels. The corrosion resistance of aluminum makes it ideal for marine environments, extending the lifespan of critical parts. When sourcing these components, businesses must consider suppliers with a track record of providing certified materials that comply with marine safety standards. This is particularly relevant for international buyers in coastal regions, where exposure to saltwater can accelerate material degradation.

How Does Aluminum Forging Improve Industrial Machinery Performance?

Aluminum forging is pivotal in the production of gearboxes and housings for industrial machinery, providing enhanced strength that reduces maintenance costs over time. The forging process allows for the creation of complex shapes that are critical for machine functionality. Buyers should seek suppliers capable of customizing forgings to meet specific machinery requirements, ensuring compatibility and performance. This is especially important for B2B buyers in emerging markets, where machinery reliability can significantly impact operational efficiency.

3 Common User Pain Points for ‘aluminum forging companies’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Aluminum Forgings

The Problem: Many B2B buyers struggle to identify reliable aluminum forging companies that can deliver high-quality products consistently. This issue is particularly pronounced in regions like Africa and South America, where local supply chains may be less developed. Buyers often face challenges related to varying material quality, inconsistent lead times, and lack of transparency in production processes. As a result, they risk receiving subpar components that may not meet their stringent specifications, leading to production delays and increased costs.

The Solution: To effectively source quality aluminum forgings, buyers should adopt a comprehensive supplier evaluation process. Start by conducting thorough research on potential forging companies, focusing on their reputation in the industry, certifications (such as ISO 9001), and customer reviews. Request samples of previous work and verify their material certifications to ensure compliance with international standards. Establish clear communication about your specific requirements, including alloy specifications, tolerances, and finishing processes. Building a long-term relationship with a select few trusted suppliers can also help streamline the procurement process and ensure consistency in quality.

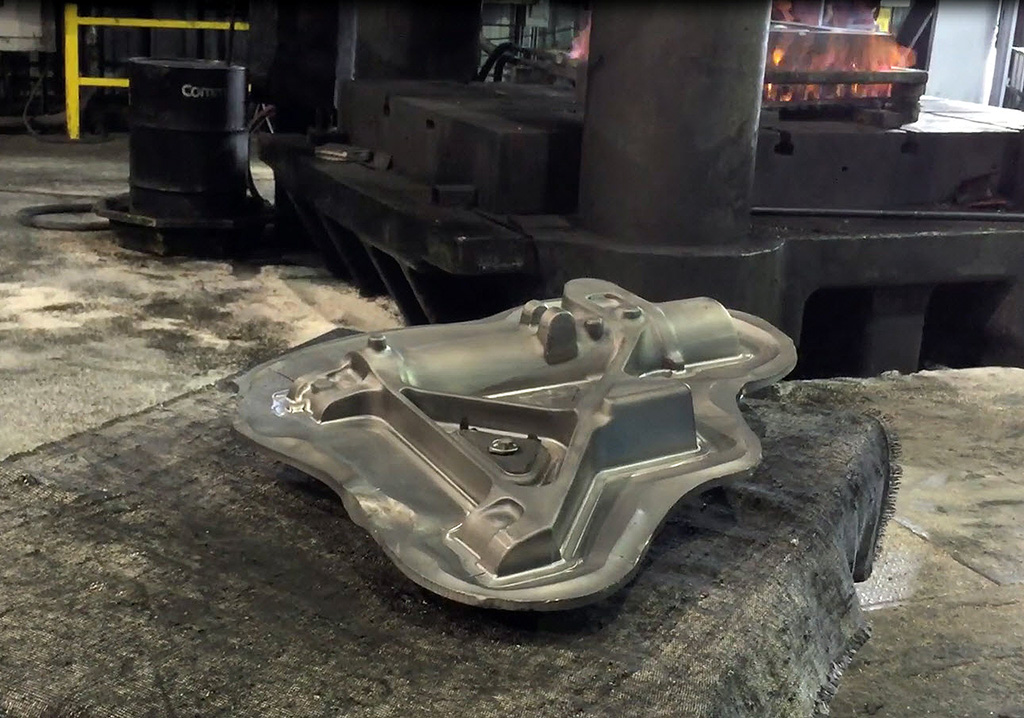

Illustrative image related to aluminum forging companies

Scenario 2: Challenges in Customizing Forged Aluminum Parts

The Problem: B2B buyers often face difficulties when needing custom aluminum forgings tailored to unique specifications. Many forging companies offer limited customization options or lack the technical expertise to meet specific industry requirements, particularly in sectors like aerospace and automotive. This limitation can hinder innovation and lead to product development delays, ultimately affecting time-to-market and competitiveness.

The Solution: To navigate customization challenges, buyers should prioritize working with aluminum forging companies that specialize in bespoke solutions. When initiating a project, provide detailed drawings, specifications, and performance expectations to facilitate accurate quotations. Engage in collaborative discussions with the supplier’s engineering team early in the design process. This interaction allows for leveraging the supplier’s technical expertise to refine designs for manufacturability. Additionally, consider forging partners that offer prototyping services, which can significantly reduce the time needed for adjustments and ensure the final product aligns with expectations.

Scenario 3: Uncertainty Around Lead Times and Delivery Schedules

The Problem: Unpredictable lead times and delivery schedules can create significant hurdles for B2B buyers relying on aluminum forgings for their operations. Buyers often experience frustration when suppliers fail to meet deadlines, leading to production bottlenecks and potential financial losses. This issue is exacerbated by global supply chain disruptions, which can further delay material availability and exacerbate the problem.

The Solution: To mitigate lead time uncertainties, buyers should establish clear communication channels with aluminum forging companies from the outset. When placing orders, request detailed timelines that outline each phase of the production process, from material sourcing to final delivery. Incorporating buffer times into project planning can also help accommodate unforeseen delays. Additionally, consider suppliers that offer real-time tracking systems for order status, allowing for proactive management of any potential delays. Building a flexible supply chain strategy, including alternative suppliers, can provide additional security against disruptions and ensure continuity in operations.

Illustrative image related to aluminum forging companies

Strategic Material Selection Guide for aluminum forging companies

What Are the Key Properties of Common Aluminum Alloys Used in Forging?

When selecting materials for aluminum forging, it is essential to understand the properties and applications of various aluminum alloys. This knowledge enables international buyers to make informed decisions that align with their specific needs and regulatory standards.

1. 6061 Aluminum Alloy

Key Properties: 6061 aluminum is known for its excellent corrosion resistance, good weldability, and medium to high strength. It performs well under temperature variations, making it suitable for a range of applications.

Pros & Cons: The advantages of 6061 include its versatility and ease of machining. However, it may not perform as well as other alloys in high-stress applications due to its lower strength compared to alloys like 7075. Its cost is moderate, making it a popular choice for many industries.

Illustrative image related to aluminum forging companies

Impact on Application: 6061 is commonly used in automotive and aerospace applications, where lightweight and strength are critical. It is compatible with various media, including water and oils, but may not be ideal for highly corrosive environments.

Considerations for International Buyers: Buyers from regions like the Middle East and Africa should ensure compliance with local standards such as ASTM or EN. The availability of 6061 can vary, so it’s crucial to confirm sourcing capabilities with suppliers.

2. 7075 Aluminum Alloy

Key Properties: 7075 aluminum is recognized for its high strength-to-weight ratio and excellent fatigue resistance. It is often used in applications requiring high performance and structural integrity.

Pros & Cons: The primary advantage of 7075 is its strength, making it suitable for aerospace and military applications. However, it is more expensive than other alloys and can be challenging to machine, which may increase manufacturing complexity.

Impact on Application: This alloy is ideal for components subjected to high stress, such as aircraft fittings and automotive parts. Its compatibility with harsh environments makes it a preferred choice for defense applications.

Considerations for International Buyers: Buyers must consider the higher costs associated with 7075 and ensure that their suppliers can meet stringent quality standards. Compliance with industry-specific regulations is crucial, especially in sectors like aerospace.

3. 2024 Aluminum Alloy

Key Properties: 2024 aluminum offers excellent fatigue resistance and is known for its high strength. It is less corrosion-resistant than other alloys, making protective coatings necessary in certain applications.

Pros & Cons: The alloy’s high strength makes it suitable for aerospace applications. However, its lower corrosion resistance can be a drawback, necessitating additional surface treatment, which can increase costs and complexity.

Illustrative image related to aluminum forging companies

Impact on Application: 2024 is primarily used in aircraft structures and components where weight savings and strength are critical. Its compatibility with aviation fuels and lubricants makes it a reliable option for aerospace applications.

Considerations for International Buyers: Buyers in Europe and South America should be aware of the specific certifications required for aerospace materials. Ensuring compliance with standards such as JIS or ASTM is essential for successful procurement.

4. 2014 Aluminum Alloy

Key Properties: 2014 aluminum is known for its high strength and excellent machinability. It has good resistance to stress corrosion cracking but is less corrosion-resistant than other alloys.

Pros & Cons: The key advantage of 2014 is its high strength, making it suitable for structural applications. However, its lower corrosion resistance can limit its use in certain environments, and it may require protective coatings.

Impact on Application: This alloy is commonly used in aerospace and military applications, particularly for components that require high strength and low weight. Its compatibility with various media is generally good, but careful consideration is needed for corrosive environments.

Illustrative image related to aluminum forging companies

Considerations for International Buyers: Buyers should verify that their suppliers can provide materials that meet international standards and certifications. Understanding the local market’s preferences and compliance requirements is crucial for successful transactions.

Summary Table of Aluminum Alloys for Forging

| Material | Typical Use Case for aluminum forging companies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 Aluminum | Automotive and aerospace components | Excellent corrosion resistance | Lower strength compared to 7075 | Medium |

| 7075 Aluminum | Aerospace and military applications | High strength-to-weight ratio | Higher cost and machining complexity | High |

| 2024 Aluminum | Aircraft structures | Excellent fatigue resistance | Lower corrosion resistance | Medium |

| 2014 Aluminum | Aerospace and military components | High strength and machinability | Requires protective coatings | Medium |

This comprehensive guide to aluminum alloys provides international B2B buyers with critical insights into material selection, enabling them to make informed decisions that align with their operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum forging companies

What Are the Main Stages of Manufacturing in Aluminum Forging?

Aluminum forging is a complex process that involves several key stages, each critical to producing high-quality components that meet stringent performance and safety standards. The primary stages of manufacturing include material preparation, forming, assembly, and finishing.

How is Material Prepared for Aluminum Forging?

The first step in the aluminum forging process is material preparation, which entails selecting the appropriate aluminum alloy based on the specific application requirements. Commonly used alloys include 6061, 7075, and 2024, each offering unique properties such as strength, weight, and corrosion resistance.

Illustrative image related to aluminum forging companies

Once the material is selected, it is cut into billets of the desired size. The billets are then preheated to a specific temperature, enhancing their malleability and making them easier to forge. Proper material preparation is crucial, as it directly impacts the quality and mechanical properties of the final product.

What Techniques Are Used in the Forming Stage?

The forming stage is where the actual forging takes place. This can be accomplished through various techniques, including open-die forging, closed-die (or impression die) forging, and extrusion. Closed-die forging is often preferred for its ability to produce complex shapes and tighter tolerances while minimizing material waste.

In closed-die forging, the heated billet is placed between two dies that shape the metal under immense pressure. This process alters the grain structure of the aluminum, enhancing its strength and durability. Advanced techniques such as isothermal forging may also be employed to further improve mechanical properties, particularly for high-performance applications in aerospace and automotive sectors.

What Are the Assembly and Finishing Processes in Aluminum Forging?

After forming, components may require assembly, especially when multiple parts are involved in a single product. This stage often includes tasks such as welding, fastening, or fitting components together to create a final assembly.

Finishing processes follow assembly and are essential for achieving the desired surface finish and dimensional accuracy. Common finishing techniques include machining, anodizing, and coating. Machining may be necessary to achieve precise tolerances, while anodizing enhances corrosion resistance and improves aesthetic qualities.

How Do Aluminum Forging Companies Ensure Quality Control?

Quality assurance is paramount in the aluminum forging industry, particularly given the applications in critical sectors such as aerospace, defense, and automotive. Companies typically adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE marking and API standards may be relevant depending on the application.

What Are the Key Quality Control Checkpoints in Aluminum Forging?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that products meet the required specifications. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify their compliance with specified standards. This initial step is crucial for preventing defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular monitoring is conducted to ensure that each stage adheres to quality standards. This may include measuring dimensions, monitoring temperature during forging, and assessing surface finishes.

-

Final Quality Control (FQC): Before products are shipped, they undergo final inspections to confirm that they meet all specifications and standards. This may involve non-destructive testing methods such as ultrasonic testing, X-ray inspection, or visual inspection to detect any defects.

What Testing Methods Are Commonly Used in Aluminum Forging Quality Assurance?

Quality assurance in aluminum forging often employs various testing methods to validate the integrity and performance of the final products. Common testing methods include:

- Mechanical Testing: This assesses the strength, ductility, and hardness of the forged components, ensuring they meet performance requirements.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiography, and magnetic particle inspection are used to detect internal and surface defects without damaging the components.

- Dimensional Inspection: Precision measuring tools and techniques are employed to verify that the dimensions of the forged parts are within specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of aluminum forging suppliers is critical. Here are several strategies to ensure quality:

Illustrative image related to aluminum forging companies

-

Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes, quality management systems, and compliance with international standards.

-

Request Quality Documentation: Buyers should ask for quality control reports, certifications, and testing results. Documentation should clearly outline the methodologies used in testing and quality assurance.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and the integrity of the finished products.

-

Evaluate Supplier Certifications: Verify that suppliers hold relevant certifications such as ISO 9001, CE, or other industry-specific qualifications. This can serve as a benchmark for their commitment to quality.

What Are the Nuances of Quality Control for International B2B Buyers?

For B2B buyers operating in diverse markets, understanding the nuances of quality control in aluminum forging is essential. Buyers should be aware of specific regional regulations and standards that may influence quality requirements. For instance, certain industries may have more stringent safety and performance standards in Europe compared to other regions.

Additionally, cultural differences may affect communication and expectations regarding quality. Establishing clear, consistent communication with suppliers and understanding their quality assurance practices will foster stronger partnerships and ensure that the products meet the buyers’ requirements.

In conclusion, the manufacturing processes and quality assurance protocols in aluminum forging are crucial factors for B2B buyers to consider when selecting suppliers. By understanding these processes and implementing thorough verification methods, buyers can ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum forging companies’

In the competitive landscape of aluminum forging, sourcing the right supplier is crucial for ensuring quality, reliability, and performance in your products. This step-by-step guide provides actionable insights to help B2B buyers effectively navigate the procurement process.

Illustrative image related to aluminum forging companies

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, clearly outline your technical requirements. This includes dimensions, tolerances, alloy types, and surface finishes. Having a detailed specification helps ensure that suppliers understand your needs and can provide accurate quotes.

- Considerations:

- Identify the specific aluminum alloys required (e.g., 6061, 7075).

- Specify any heat treatment or finishing processes necessary for your application.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of aluminum forging companies that align with your specifications. Utilize online directories, industry trade shows, and recommendations from industry peers to identify reputable suppliers.

- Key Actions:

- Look for companies with a strong online presence and positive customer reviews.

- Verify their experience in your industry sector, such as aerospace or automotive.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of shortlisted suppliers to ensure they can meet your requirements. This includes evaluating their production capacity, technology, and expertise in aluminum forging processes.

- Focus Areas:

- Inquire about their forging methods (e.g., closed die forging).

- Understand their quality control measures and certifications (e.g., ISO standards).

Step 4: Request Quotes and Proposals

Once you have identified potential suppliers, request detailed quotes that include pricing, lead times, and terms of service. This will help you compare options effectively.

- Important Points:

- Ensure quotes cover all aspects, including tooling, machining, and finishing services if applicable.

- Be clear about your timeline and delivery expectations to avoid delays.

Step 5: Verify Supplier Certifications and Standards

Before finalizing a supplier, confirm that they adhere to industry standards and possess relevant certifications. This is vital for ensuring product quality and compliance with regulations.

- What to Check:

- Look for certifications such as ISO 9001 for quality management.

- Ask for documentation regarding their material sourcing and environmental practices.

Step 6: Conduct Site Visits or Virtual Assessments

If feasible, arrange site visits or virtual assessments to get a firsthand look at the supplier’s operations. This can provide valuable insights into their processes, equipment, and overall production environment.

Illustrative image related to aluminum forging companies

- Assessment Focus:

- Evaluate their machinery and technology.

- Observe the working conditions and employee expertise.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful partnership. Establish clear points of contact and preferred methods of communication to ensure a smooth flow of information.

- Communication Tips:

- Define expectations for updates and feedback throughout the production process.

- Utilize project management tools to track progress and address issues promptly.

By following these steps, B2B buyers can make informed decisions when sourcing aluminum forging companies, ultimately leading to successful partnerships and high-quality products.

Comprehensive Cost and Pricing Analysis for aluminum forging companies Sourcing

What Are the Key Cost Components in Aluminum Forging?

In the aluminum forging industry, understanding the cost structure is vital for B2B buyers. The primary cost components include:

-

Materials: Aluminum prices fluctuate based on market conditions. Common alloys like 6061 and 7075 are widely used due to their favorable properties, but sourcing materials from domestic versus international suppliers can impact costs significantly.

-

Labor: Skilled labor is crucial in the forging process, particularly for tasks that require precision and expertise. Labor costs vary by region; for instance, labor in Europe may be more expensive than in parts of Africa or South America.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient operations can help mitigate these costs, which are often passed on to the customer.

-

Tooling: Custom dies and tooling represent a significant upfront investment. The complexity of the design will affect the tooling cost, which is often amortized over larger production runs.

-

Quality Control (QC): Maintaining high standards through rigorous QC processes incurs additional costs. Certifications like ISO can enhance product credibility but may also increase pricing due to compliance costs.

-

Logistics: Shipping and handling costs can be substantial, particularly for international buyers. Factors such as Incoterms and shipping distances play a critical role in determining logistics expenses.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on market demand and competition.

How Do Price Influencers Affect Aluminum Forging Costs?

Several factors influence pricing in the aluminum forging sector:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs due to economies of scale. Negotiating for better rates on bulk purchases can yield significant savings.

-

Specifications and Customization: Customized parts can increase costs due to additional design and manufacturing requirements. Buyers should clearly define specifications to avoid unexpected charges.

-

Material Quality and Certifications: Higher-grade materials or those with specific certifications command premium prices. Buyers in industries like aerospace or defense should prioritize certified materials, understanding that this could impact their overall budget.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established companies may charge more but offer better quality assurance and customer service.

-

Incoterms: Understanding Incoterms is essential for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, significantly affecting total costs.

What Are Effective Buyer Tips for Sourcing Aluminum Forgings?

To ensure cost-effective sourcing of aluminum forgings, buyers should consider the following strategies:

Illustrative image related to aluminum forging companies

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for larger orders. Be prepared to leverage multiple quotes to strengthen your negotiating position.

-

Focus on Total Cost of Ownership (TCO): Rather than only considering the initial purchase price, evaluate long-term costs including maintenance, durability, and performance. Forged components often provide better performance, which can lead to lower TCO.

-

Understand Pricing Nuances for International Markets: Different regions may have varying pricing structures due to local economic conditions. Buyers from Africa, South America, the Middle East, and Europe should factor in currency fluctuations, import duties, and local market dynamics when budgeting.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of costs associated with materials, labor, and other components. This transparency helps in comparing offers from different suppliers.

Disclaimer on Pricing

Prices in the aluminum forging industry can vary widely based on the factors discussed. It’s advisable for buyers to conduct thorough research and seek multiple quotes to ascertain fair market pricing. Always consider that indicative prices may change based on market conditions, supplier negotiations, and order specifics.

Alternatives Analysis: Comparing aluminum forging companies With Other Solutions

Introduction: Exploring Alternatives to Aluminum Forging

In the quest for high-performance components, aluminum forging is a widely recognized method due to its strength, lightweight properties, and versatility. However, B2B buyers should also consider alternative manufacturing processes that may meet their specific needs more effectively. This section compares aluminum forging companies with two viable alternatives: aluminum casting and machining. Each method has its unique strengths and weaknesses, making it essential to evaluate them against key performance metrics.

Comparison Table

| Comparison Aspect | Aluminum Forging Companies | Aluminum Casting | CNC Machining |

|---|---|---|---|

| Performance | High strength, excellent fatigue resistance, ideal for high-stress applications | Good for complex shapes, lower strength compared to forging | High precision, can produce tight tolerances |

| Cost | Generally higher due to material and labor | Typically lower initial cost, but can incur higher costs in post-processing | Variable costs based on complexity and material |

| Ease of Implementation | Requires specialized equipment and skilled labor | Easier setup for larger production runs, less specialized equipment needed | High setup costs for custom designs, but flexible |

| Maintenance | Low maintenance due to robust parts | Moderate maintenance, susceptibility to defects | Regular maintenance required for machinery |

| Best Use Case | Aerospace, automotive, defense industries | Consumer products, intricate designs, low-stress applications | Prototyping, low-volume custom parts, high-precision needs |

Detailed Breakdown of Alternatives

Aluminum Casting

Aluminum casting involves pouring molten aluminum into a mold to create components. This method excels in producing complex shapes with intricate details, making it suitable for consumer products and applications where aesthetic appearance is critical. While casting typically has a lower initial cost compared to forging, it may lead to higher long-term expenses due to the potential for defects and the need for post-processing. Moreover, cast parts often have lower strength and fatigue resistance than forged components, limiting their use in high-stress environments.

CNC Machining

CNC (Computer Numerical Control) machining is a subtractive manufacturing method that shapes materials by removing excess material from a solid block. This process offers exceptional precision, making it ideal for producing parts that require tight tolerances. CNC machining is versatile and can accommodate various materials beyond aluminum, including plastics and composites. However, the setup costs can be significant, especially for custom designs. While machining can produce high-quality parts, it may not be as efficient for large-scale production compared to forging or casting, particularly when it comes to material waste.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate manufacturing method depends on the specific requirements of your project. Aluminum forging companies excel in producing high-strength components for demanding applications, making them a top choice for aerospace and automotive industries. In contrast, aluminum casting may be more suitable for projects that prioritize intricate designs and lower initial costs, while CNC machining offers precision and flexibility for custom parts. B2B buyers should carefully assess their performance needs, budget constraints, and production volume to determine the best solution for their unique circumstances. By doing so, they can optimize their manufacturing processes and ensure they receive the highest quality components for their operations.

Essential Technical Properties and Trade Terminology for aluminum forging companies

What Are the Key Technical Properties of Aluminum Forging?

Understanding the technical properties of aluminum forging is essential for B2B buyers seeking high-quality components. Here are some critical specifications that define the quality and performance of forged aluminum products:

-

Material Grade

Material grades, such as 6061, 7075, and 2014, indicate the specific alloy composition and properties of aluminum. Each grade offers distinct benefits, such as strength, corrosion resistance, and machinability. For instance, 7075 is known for its high strength and is often used in aerospace applications, while 6061 provides good weldability and is suitable for structural applications. Selecting the appropriate material grade ensures that the forged components meet performance requirements. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension or measurement of a forged part. Tight tolerances are critical in applications where precision is vital, such as in aerospace and automotive industries. Meeting specified tolerances minimizes the need for additional machining and reduces production costs, making it a crucial factor in the procurement process. -

Heat Treatment

Heat treatment processes, such as T6 or T651, enhance the mechanical properties of aluminum alloys, improving strength and hardness. This step is essential for applications that experience high stress and require components to maintain their integrity under load. Buyers should inquire about the heat treatment processes used by suppliers to ensure they align with the intended application. -

Surface Finish

The surface finish of forged components can affect both performance and aesthetics. Common finishes include anodizing and painting, which enhance corrosion resistance and improve appearance. A quality surface finish can also reduce friction and wear in moving parts, thereby extending the life of the component. Buyers should consider the required surface finish for their specific applications to ensure optimal performance. -

Yield Strength

Yield strength is the maximum stress that a material can withstand while still returning to its original shape. It is a key indicator of how much load a forged part can handle before deforming. In industries such as aerospace and automotive, selecting materials with adequate yield strength is critical to ensure safety and functionality. -

Ductility

Ductility measures a material’s ability to deform under tensile stress. For forged aluminum components, adequate ductility is important to prevent brittleness and failure during use. Understanding the ductility of the selected alloy helps buyers anticipate how the material will behave in real-world applications.

Which Common Trade Terms Should B2B Buyers Know in Aluminum Forging?

Familiarity with industry jargon is crucial for effective communication and negotiation. Here are some common trade terms in aluminum forging:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify potential suppliers who can provide high-quality forged components that meet specific requirements. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is essential for budget planning and inventory management, as it can impact overall costs and supply chain efficiency. Buyers should clarify MOQs with suppliers to align with their purchasing strategies. -

RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers requesting price quotes for specific products or services. This process helps buyers compare costs and terms across different suppliers, facilitating informed purchasing decisions. Providing detailed specifications in an RFQ can lead to more accurate quotes. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand shipping costs, risks, and delivery responsibilities. Key Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight), which dictate when ownership and risk transfer from seller to buyer. -

Lead Time

Lead time is the time taken from placing an order to delivery. Understanding lead times is crucial for project planning and ensuring timely delivery of forged components. Buyers should inquire about lead times when requesting quotes to avoid potential delays in their supply chain. -

Closed Die Forging

Closed die forging, also known as impression die forging, involves shaping metal within a die to create complex shapes. This method typically results in stronger parts with improved mechanical properties. Buyers should consider the advantages of closed die forging when evaluating their manufacturing options.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they procure high-quality aluminum forgings that meet their specific needs.

Illustrative image related to aluminum forging companies

Navigating Market Dynamics and Sourcing Trends in the aluminum forging companies Sector

What Are the Current Trends Influencing the Global Aluminum Forging Market?

The aluminum forging market is experiencing significant growth, driven by a confluence of global factors. The increasing demand for lightweight, high-strength materials across industries, particularly aerospace and automotive, is a major catalyst. Companies are increasingly turning to aluminum forgings for their superior strength-to-weight ratio and excellent corrosion resistance, essential for applications demanding high performance. Furthermore, the rise of electric vehicles and renewable energy sectors is spurring innovation in aluminum forging techniques, allowing for more complex geometries and enhanced performance characteristics.

Emerging B2B technologies, such as advanced manufacturing techniques and Industry 4.0 solutions, are reshaping sourcing strategies. Automation, AI-driven analytics, and IoT integrations enable aluminum forging companies to optimize production processes, reduce lead times, and minimize waste. For international buyers, particularly those in Africa, South America, the Middle East, and Europe, these innovations present opportunities to streamline procurement and improve supply chain efficiency. As competition intensifies, buyers are encouraged to seek partnerships with suppliers who not only demonstrate technological prowess but also align with their operational goals and sustainability objectives.

How Are Sustainability and Ethical Sourcing Changing the Aluminum Forging Landscape?

Sustainability is becoming an imperative in the aluminum forging sector, as companies face growing pressure from consumers, regulators, and investors to adopt environmentally responsible practices. The production of aluminum can be energy-intensive, and the environmental impact associated with sourcing raw materials is significant. Thus, international B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, including the use of recycled aluminum and energy-efficient manufacturing processes.

Ethical sourcing is also gaining traction, with buyers seeking transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and the Aluminum Stewardship Initiative (ASI) provide frameworks for companies to ensure responsible sourcing and production practices. Buyers from regions like Saudi Arabia and Nigeria are particularly mindful of the ethical implications of their procurement choices, as local regulations and community expectations evolve. By partnering with aluminum forging companies that prioritize sustainability and ethical sourcing, buyers can enhance their brand reputation while contributing positively to global environmental goals.

Illustrative image related to aluminum forging companies

How Has the Aluminum Forging Industry Evolved Over Time?

The aluminum forging industry has undergone significant transformation since its inception, evolving from traditional blacksmithing techniques to sophisticated manufacturing processes. Initially focused on producing simple components, advancements in metallurgy and forging technology have enabled the creation of complex, high-performance parts that cater to various sectors, including aerospace, automotive, and defense. The advent of computer-aided design (CAD) and precision machining has further refined the forging process, allowing for greater customization and efficiency.

In recent decades, as global competition intensified, aluminum forging companies have prioritized innovation and quality control. This evolution is marked by the adoption of advanced materials and techniques, including closed die forging and heat treatment processes that enhance the mechanical properties of aluminum. For B2B buyers, understanding this historical context is crucial, as it underscores the capabilities and advancements that modern aluminum forging suppliers bring to the table, making them valuable partners in meeting the demands of today’s fast-paced markets.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum forging companies

-

How do I choose the right aluminum forging supplier for my business needs?

Selecting the right aluminum forging supplier involves several key factors. Start by evaluating their industry experience and reputation, particularly in your specific application area (e.g., aerospace or automotive). Request case studies or references to gauge their past performance. Assess their production capabilities, including the range of aluminum alloys they can forge and any custom solutions they offer. Additionally, ensure they have robust quality assurance processes in place to meet international standards. Finally, consider their logistical capabilities, including shipping times and costs, especially if you are sourcing from overseas. -

What are the common applications of aluminum forgings in various industries?

Aluminum forgings are widely used across multiple sectors due to their strength-to-weight ratio and corrosion resistance. In the aerospace industry, they are integral to components such as aircraft fittings and landing gear. The automotive sector relies on aluminum forgings for parts like brake calipers and suspension systems, which require both performance and lightweight characteristics. Additionally, industries like defense and marine utilize these forgings for critical applications that demand reliability and high performance under stress. Understanding these applications can help you identify the right supplier for your specific needs. -

What customization options should I consider when sourcing aluminum forgings?

Customization is a crucial aspect of sourcing aluminum forgings. Look for suppliers that offer tailored solutions, including specific alloy selections, heat treatment processes, and finishing options. Discuss your design requirements and ensure the supplier has the capability to produce parts that meet your specifications. Additionally, inquire about their ability to accommodate varying order quantities and lead times. A collaborative approach in the design phase can enhance product performance and reduce costs by minimizing machining needs. -

What is the typical minimum order quantity (MOQ) for aluminum forgings?

Minimum order quantities (MOQs) for aluminum forgings can vary significantly among suppliers, often depending on the complexity of the part and the materials used. Typically, MOQs may range from a few hundred to several thousand units. It is essential to communicate your specific requirements with potential suppliers to understand their MOQ policies. If your needs are lower than the MOQ, some suppliers may offer flexibility or suggest alternative solutions, such as batch production. -

How can I ensure quality assurance in aluminum forging processes?

Quality assurance in aluminum forging is critical to ensure the durability and reliability of the finished products. Look for suppliers that implement rigorous quality control measures, including material inspections, process monitoring, and testing of finished parts. Certifications such as ISO 9001 can indicate adherence to international quality standards. Additionally, ask about their testing methodologies, including mechanical property testing and non-destructive testing, to confirm the integrity of the forgings before shipment. -

What payment terms are typically offered by aluminum forging companies?

Payment terms can vary widely among aluminum forging suppliers and are influenced by factors such as order size and the buyer’s creditworthiness. Common arrangements include net 30 or net 60 days, where payment is due within 30 or 60 days of invoice receipt. Some suppliers may offer discounts for early payments or require upfront deposits for larger orders. It’s advisable to clarify payment terms during the negotiation phase to ensure both parties have a clear understanding of expectations. -

What logistics considerations should I keep in mind when sourcing aluminum forgings internationally?

When sourcing aluminum forgings from international suppliers, logistics play a crucial role in the overall procurement process. Consider the shipping methods and associated costs, as well as the lead times for production and delivery. Verify whether the supplier can handle customs clearance and provide necessary documentation for international shipping. Additionally, evaluate potential tariffs or duties that may apply to your imports, as these can impact your overall cost. Building a reliable logistics plan will help ensure timely delivery and minimize disruptions. -

How can I request a quote for an aluminum forging project?

To request a quote for an aluminum forging project, start by identifying potential suppliers and gathering their contact information. Prepare a detailed project brief that includes specifications such as material requirements, dimensions, tolerances, and any finishing processes needed. Providing as much information as possible will enable suppliers to give you accurate estimates. Reach out via email or phone, and be ready to discuss your project in detail. Most suppliers will appreciate your clarity and may offer additional insights or suggestions based on their expertise.

Top 3 Aluminum Forging Companies Manufacturers & Suppliers List

1. IQS Directory – Aluminum Forgings

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Aluminum forgings are fabricated by compressing aluminum into specific configurations, resulting in a stronger product compared to fabrication, casting, or welding. They are used in industries such as aerospace and racing due to their strength-to-weight ratio, low production cost, and ability to withstand harsh conditions. Common applications include wheels for racing cars, missiles, engines, oil …

2. Cerro Fabricated Products – Premium Forged Aluminum Components

Domain: cerrofabricated.com

Registered: 2000 (25 years)

Introduction: Cerro Fabricated Products specializes in custom manufacturing premium-quality forged aluminum components for various industries. Key benefits of aluminum forging include high strength-to-weight ratio, excellent corrosion resistance, and suitability for high-temperature applications. Cerro forges aluminum alloys such as 2014, 6061, and 7075, and offers in-house heat treating to tempers like T6, T65…

3. Aluminum Precision Products – Aluminum Forgings

Domain: aluminumprecision.com

Registered: 1998 (27 years)

Introduction: Aluminum Precision Products (APP) specializes in aluminum precision forgings for the aerospace, defense, and automotive industries. With over 60 years of experience, APP is recognized for delivering exceptional precision in conventional and hand forgings. Their components are used in commercial airliners, business and private aircraft, helicopters, military fixed-wing aircraft, high-performance au…

Strategic Sourcing Conclusion and Outlook for aluminum forging companies

The landscape of aluminum forging presents a wealth of opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Strategic sourcing in this sector allows businesses to capitalize on the lightweight, high-strength properties of aluminum, making it an ideal choice for industries such as aerospace, automotive, and defense. By partnering with reputable aluminum forging companies, buyers can access custom solutions tailored to their specific needs, ensuring superior performance and safety in their applications.

Investing in strategic sourcing not only enhances product quality but also optimizes supply chain efficiency. Companies that prioritize local sourcing, as highlighted by industry leaders, can mitigate risks associated with global supply chains, such as delays and fluctuating costs. Moreover, the ability to obtain forged components with reduced machining requirements can lead to significant cost savings and faster turnaround times.

As the demand for advanced aluminum solutions grows, now is the time for B2B buyers to engage with trusted aluminum forging partners. By leveraging the expertise of these companies, businesses can position themselves competitively in their markets, driving innovation and growth. Reach out today to explore how strategic sourcing can transform your operations and meet your aluminum forging needs effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to aluminum forging companies