A B2B Buyer’s Guide to Cement Blanket: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for cement blanket

In the ever-evolving landscape of construction and infrastructure development, sourcing high-quality cement blankets poses a significant challenge for international B2B buyers. These essential materials, designed to protect and cure concrete in various conditions, are crucial for ensuring structural integrity and longevity. As buyers in Africa, South America, the Middle East, and Europe (including markets like Vietnam and Germany) navigate this global market, understanding the nuances of cement blanket types, their applications, and supplier reliability becomes paramount.

This comprehensive guide delves into the myriad options available, from flexible concrete-impregnated fabrics to durable curing blankets suited for extreme weather conditions. We will explore the various applications of cement blankets across different industries, highlighting their importance in preventing damage, optimizing curing processes, and enhancing overall project efficiency. Additionally, buyers will find valuable insights on how to effectively vet suppliers, understand pricing structures, and identify cost-saving opportunities without compromising on quality.

By equipping international B2B buyers with actionable information and expert recommendations, this guide aims to empower informed purchasing decisions. Whether you are managing a large-scale construction project or seeking solutions for smaller applications, understanding the global market for cement blankets will enhance your procurement strategy, ensuring you select the right products for your specific needs.

Understanding cement blanket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Concrete Canvas | Flexible, concrete-impregnated fabric that hardens when wet. | Pond liners, landscaping, erosion control | Pros: Easy installation, durable, versatile. Cons: Higher upfront cost. |

| Wet Concrete Curing Blankets | Dual-layer design with burlap and polyethylene for moisture retention. | Concrete curing in hot conditions | Pros: Reduces evaporation, reusable. Cons: Requires maintenance for optimal performance. |

| StrongCure Curing Blankets | Insulated with bubble cell cores for cold weather applications. | Winter construction, temporary enclosures | Pros: Excellent insulation, moisture-resistant. Cons: May be more expensive than standard options. |

| Cement Blankets | Reinforced poly skins with varying thickness for durability. | Construction sites, industrial uses | Pros: Cost-effective, lightweight. Cons: Limited insulation properties compared to specialized blankets. |

| Erosion Control Blankets | Designed for soil stabilization and erosion prevention. | Construction sites, landscaping projects | Pros: Effective for erosion control, environmentally friendly. Cons: Less suitable for high-traffic areas. |

What are the Characteristics and Suitability of Concrete Canvas?

Concrete Canvas is a unique, flexible material that combines the properties of fabric and concrete. It hardens upon hydration, providing a durable layer ideal for applications such as pond liners and erosion control. Its lightweight nature allows for easy installation, making it suitable for projects with tight timelines. For B2B buyers, the initial investment may be higher, but the long-term benefits of durability and protection against environmental factors can justify the cost.

How Do Wet Concrete Curing Blankets Function in Hot Conditions?

Wet Concrete Curing Blankets feature a dual-layer construction that includes a burlap layer for moisture retention and a polyethylene layer to reflect UV rays. This design helps maintain the moisture necessary for proper curing, especially in hot climates. Buyers should consider the reusability of these blankets, which can lead to cost savings over time. However, they require periodic maintenance, such as rewetting, to ensure optimal performance.

What Makes StrongCure Curing Blankets Ideal for Cold Weather?

StrongCure Curing Blankets are specifically designed for cold weather applications, featuring an insulated construction with bubble cell cores. This insulation helps maintain the necessary temperature for curing, preventing premature drying and potential cracking. Buyers in colder regions will find these blankets invaluable for ensuring concrete strength. While they may come at a premium, the investment can prevent costly delays and quality issues.

How Do Cement Blankets Compare for General Construction Use?

Cement Blankets are typically made from reinforced poly skins and are available in various thicknesses. They are versatile and can be used across multiple construction applications, including temporary coverings and ground protection. Their cost-effectiveness makes them appealing for budget-conscious projects, although they may lack the insulation capabilities of more specialized products. Buyers should assess the specific needs of their projects to determine the best fit.

What Role Do Erosion Control Blankets Play in Construction?

Erosion Control Blankets are designed to stabilize soil and prevent erosion, making them ideal for construction sites and landscaping projects. These blankets are often made from biodegradable materials, contributing to environmentally sustainable practices. While effective in preventing soil loss, they may not be suitable for areas with heavy foot traffic or machinery. Buyers should evaluate their project’s environmental impact and traffic conditions when considering this option.

Key Industrial Applications of cement blanket

| Industry/Sector | Specific Application of cement blanket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Insulation for curing concrete in cold weather | Prevents premature drying and cracking, ensuring quality | Durability, insulation value, and compliance with local standards |

| Water Management | Protection for pond liners and water features | Extends lifespan of liners, reduces maintenance costs | Ease of installation, resistance to environmental factors |

| Landscaping | Erosion control and stabilization for slopes and embankments | Minimizes soil erosion, enhances aesthetic appeal | Compatibility with local vegetation, ease of application |

| Mining | Dust suppression and surface stabilization | Improves safety and environmental compliance | Material strength, ease of application, and local regulations |

| Infrastructure | Temporary weather protection for construction projects | Reduces delays due to weather, ensures project timelines | Size and weight for transport, reusability, and cost-effectiveness |

How is Cement Blanket Used in Construction for Curing Concrete?

In the construction industry, cement blankets are primarily utilized for curing concrete in cold weather conditions. They provide thermal insulation, which helps maintain optimal temperatures for concrete hydration, preventing premature drying and subsequent cracking. For international buyers, especially in regions with extreme weather, sourcing blankets that meet local standards and offer robust insulation properties is essential to ensure the structural integrity of their projects.

What Role Does Cement Blanket Play in Water Management?

Cement blankets serve as protective layers for pond liners and other water features, effectively shielding them from physical damage caused by animals or human activity. This application is particularly valuable in public spaces where vandalism or accidental damage can lead to costly repairs. Buyers should prioritize products that are easy to install and resistant to environmental factors, ensuring long-term durability and reduced maintenance costs.

How is Cement Blanket Effective in Landscaping for Erosion Control?

In landscaping, cement blankets are employed for erosion control and stabilization of slopes. They help prevent soil erosion, particularly in areas susceptible to heavy rainfall or runoff. The aesthetic appeal of the landscape is also enhanced, making it a preferred choice for residential and commercial projects. Buyers need to consider compatibility with local vegetation and the ease of application when sourcing these materials.

Why is Cement Blanket Important in Mining Operations?

Cement blankets are used in mining for dust suppression and surface stabilization, contributing to safer working environments and improved compliance with environmental regulations. By controlling dust emissions, these blankets help maintain air quality and reduce health risks for workers. For international buyers in the mining sector, sourcing durable materials that can withstand harsh conditions while being cost-effective is crucial.

How Does Cement Blanket Provide Temporary Weather Protection in Infrastructure Projects?

In infrastructure projects, cement blankets offer temporary weather protection, allowing construction to proceed without delays due to adverse weather conditions. They create a barrier that minimizes the impact of rain and cold, ensuring that work can continue efficiently. When sourcing these blankets, businesses should consider their size, weight for transport, and reusability to maximize cost-effectiveness and operational efficiency.

3 Common User Pain Points for ‘cement blanket’ & Their Solutions

Scenario 1: Protecting Concrete from Extreme Weather Conditions

The Problem: B2B buyers in regions with extreme temperature fluctuations often struggle with ensuring proper curing of concrete. In hot climates, rapid evaporation can lead to surface cracking, while cold weather can slow down curing processes, affecting overall strength and durability. These issues not only compromise the integrity of the concrete but can also lead to costly repairs and project delays, making it a significant pain point for construction companies.

The Solution: To combat these challenges, sourcing high-quality cement blankets designed specifically for temperature control is essential. For instance, consider using dual-layer blankets that combine a moisture-retaining burlap layer with a reflective polyethylene layer to prevent premature drying in hot conditions. In colder climates, insulated cement blankets with bubble cell cores can effectively retain heat and minimize moisture loss. When selecting a cement blanket, ensure it meets industry standards and is tailored to your specific climate conditions. Proper installation is crucial; lay the blanket flat over the concrete and secure it with weights or anchors to prevent wind displacement. This proactive approach will ensure consistent curing and long-lasting results.

Scenario 2: Preventing Damage from Wildlife and Human Activity

The Problem: Construction sites in rural or urban areas often face the risk of damage to freshly poured concrete from wildlife, such as rodents or larger animals, as well as human interference, including vandalism or accidental trampling. Such incidents can lead to significant rework, additional costs, and delays in project timelines, creating frustration for buyers managing these projects.

The Solution: Implementing cement blankets as a protective barrier is an effective strategy to mitigate these risks. When selecting a cement blanket, choose one that is reinforced and designed to withstand external pressures. For instance, blankets made from durable, high-strength poly fabrics can prevent animals from digging or clawing at the concrete. To enhance security, consider combining the blanket with a lightweight fencing solution around the perimeter of the site. This added layer of protection will deter both wildlife and unauthorized access, safeguarding your investment in the concrete pouring process. Additionally, ensure that the blanket is installed properly, covering the entire surface and extending beyond the edges of the slab to prevent any potential damage.

Scenario 3: Managing Project Timelines and Cost Efficiency

The Problem: Delays in curing concrete can severely impact project timelines, leading to increased labor costs and missed deadlines. B2B buyers often find themselves in situations where they need to expedite the curing process to keep projects on track, particularly in fast-paced construction environments. Traditional methods of curing, such as frequent rewetting, can be labor-intensive and inefficient.

The Solution: Cement blankets that offer quick and efficient curing solutions can be a game changer in these scenarios. Look for products that provide moisture retention without the need for constant maintenance. For example, high-quality curing blankets with built-in moisture retention properties allow for a single application, reducing labor costs significantly. When applying these blankets, ensure they are tightly secured to avoid moisture loss and maximize efficiency. Additionally, consider implementing a schedule for monitoring the curing process, allowing for adjustments as needed without disrupting the workflow. By adopting these practices, buyers can streamline their operations, maintain project timelines, and ultimately save on costs associated with extended labor and material expenses.

Strategic Material Selection Guide for cement blanket

What Are the Common Materials Used in Cement Blankets for B2B Applications?

When selecting a cement blanket for industrial applications, understanding the various materials available is essential for optimizing performance and cost-effectiveness. Below, we analyze four common materials used in cement blankets, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Polyethylene (PE) Laminated Fabrics

Key Properties: Polyethylene laminated fabrics are known for their excellent water resistance and durability. They typically have a temperature tolerance ranging from -40°F to 180°F (-40°C to 82°C) and are resistant to UV rays, making them suitable for outdoor applications.

Pros & Cons: The main advantage of PE laminated fabrics is their lightweight nature, which simplifies transportation and installation. They are also cost-effective, making them popular among budget-conscious buyers. However, they may not perform as well in extreme temperatures compared to other materials, and their longevity can be affected by prolonged exposure to harsh environmental conditions.

Impact on Application: PE laminated fabrics are particularly effective in applications where moisture control is critical, such as in curing concrete or protecting surfaces from water damage. Their compatibility with various media makes them versatile for different construction needs.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local environmental regulations regarding plastic use. Additionally, familiarity with ASTM standards can aid in selecting the right product.

2. Woven Polypropylene (PP)

Key Properties: Woven polypropylene is a robust material that offers high tensile strength and excellent resistance to chemicals and moisture. Its temperature rating typically ranges from -20°F to 120°F (-29°C to 49°C).

Pros & Cons: The durability of woven polypropylene makes it ideal for heavy-duty applications, providing long-term performance in demanding conditions. However, its higher cost compared to polyethylene can be a barrier for some buyers. Additionally, while it is resistant to moisture, it may not be as effective in extreme temperatures.

Impact on Application: This material is well-suited for applications that require high strength, such as construction sites with heavy machinery. Its chemical resistance also allows for use in environments where exposure to solvents is likely.

Considerations for International Buyers: In Europe, compliance with DIN standards is crucial, while buyers in the Middle East should consider the material’s performance in high-temperature conditions.

3. Insulated Bubble Blankets

Key Properties: Insulated bubble blankets feature a dual-layer design with a bubble core that provides excellent thermal insulation. They are effective in maintaining temperature, with R-values ranging from 2.2 to 3.3 depending on the thickness.

Pros & Cons: The primary advantage of insulated bubble blankets is their ability to minimize heat loss during the curing process, which is critical in colder climates. However, their complexity in manufacturing can lead to higher costs, making them less accessible for some projects.

Impact on Application: These blankets are particularly beneficial in regions with extreme cold, ensuring optimal curing conditions for concrete. Their insulation properties also protect against temperature fluctuations that could compromise structural integrity.

Considerations for International Buyers: Buyers in colder climates, such as parts of Europe, should prioritize insulated bubble blankets. Compliance with ASTM C518 standards is essential for ensuring product reliability.

4. Non-Woven Geotextiles

Key Properties: Non-woven geotextiles are made from synthetic fibers that are bonded together, providing excellent drainage and filtration properties. They are typically resistant to rot and mildew, with a temperature range of -10°F to 140°F (-23°C to 60°C).

Pros & Cons: The main advantage of non-woven geotextiles is their ability to manage water effectively, making them ideal for applications requiring drainage. However, they may not provide the same level of insulation as other materials, which could be a limitation in colder climates.

Impact on Application: These materials are often used in applications involving soil stabilization and erosion control, where water management is critical.

Considerations for International Buyers: Compliance with JIS standards is important for buyers in Asia, while European buyers should ensure the material meets local environmental regulations.

Summary Table

| Material | Typical Use Case for Cement Blanket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene Laminated Fabrics | Curing concrete in moist conditions | Lightweight and cost-effective | Limited performance in extreme temps | Low |

| Woven Polypropylene | Heavy-duty construction applications | High tensile strength and durability | Higher cost compared to alternatives | Medium |

| Insulated Bubble Blankets | Cold weather curing | Excellent thermal insulation | Higher manufacturing complexity | High |

| Non-Woven Geotextiles | Soil stabilization and drainage | Effective water management | Limited insulation properties | Medium |

This analysis provides a comprehensive overview of the materials commonly used in cement blankets, allowing international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cement blanket

What Are the Key Stages in the Manufacturing Process of Cement Blankets?

The manufacturing process of cement blankets involves several critical stages, each designed to ensure that the final product meets the high standards required for durability and performance.

Material Preparation: What Raw Materials Are Used?

The primary materials used in cement blanket production include high-quality polyethylene for the outer layer and reinforced insulation materials, such as bubble cores or poly skins, to enhance thermal efficiency. These materials are sourced from reputable suppliers to ensure consistency and reliability. Before production begins, raw materials undergo stringent quality checks to verify their compliance with industry standards.

How Are Cement Blankets Formed?

Once the materials are prepared, the forming process commences. This typically involves layering the insulation between two sheets of polyethylene. Advanced techniques such as heat welding or adhesive bonding are employed to securely attach the layers. This step is crucial, as it impacts the blanket’s insulation properties and durability. Manufacturers may also use automated machinery to ensure precise and uniform application, reducing human error and increasing efficiency.

What Is the Assembly Process for Cement Blankets?

After the initial forming, the blankets undergo assembly. This includes cutting the large sheets into specified sizes and adding features such as grommets for easy installation. Depending on the product’s intended use, additional layers or protective coatings may be added. This stage is essential for tailoring the blankets to meet specific client requirements, whether for winter insulation or moisture retention.

Finishing Touches: How Are Cement Blankets Prepared for Market?

The finishing process involves quality assurance measures and packaging. Each blanket is inspected for defects, ensuring that any irregularities are addressed before shipment. Proper packaging is vital for protecting the blankets during transportation. Manufacturers often employ eco-friendly practices in packaging to appeal to environmentally conscious B2B buyers.

What Quality Assurance Standards Are Relevant for Cement Blankets?

Quality assurance is a crucial aspect of cement blanket manufacturing. International standards such as ISO 9001 play a significant role in ensuring that products meet specific quality benchmarks. Additionally, industry-specific certifications like CE and API may apply, depending on the intended application of the blankets.

How Are Quality Control Checkpoints Integrated?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify any deviations from established standards.

- Final Quality Control (FQC): Before packaging, the finished products undergo a comprehensive inspection to verify they meet all quality criteria.

What Testing Methods Are Commonly Used for Cement Blankets?

Manufacturers utilize several testing methods to ensure that cement blankets perform as expected. Common tests include:

- Thermal Resistance Testing: This assesses how well the blankets insulate against temperature fluctuations.

- Moisture Resistance Testing: Ensures that the blankets can effectively repel water and protect the underlying surfaces.

- Durability Testing: Simulates environmental conditions to evaluate the longevity and performance of the blankets under stress.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in diverse international markets, verifying a supplier’s quality control practices is essential. Here are some actionable steps:

- Request Documentation: Buyers should ask for quality assurance documentation, including ISO certification and test reports, to verify compliance with international standards.

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can be done either by the buyer’s team or through third-party inspection services.

- Seek Third-Party Inspections: Engaging third-party inspection firms can provide unbiased evaluations of product quality and adherence to industry standards. This is especially important for buyers in regions like Africa and South America, where standards may vary.

- Review Customer Feedback: Investigating reviews and testimonials from other businesses can provide an indication of a supplier’s reliability and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must be aware of regional variations in quality standards and certification requirements. For example, European buyers may prioritize CE marking, while those in the Middle East may require compliance with local standards. Understanding these nuances can help buyers make informed decisions and foster better supplier relationships.

Moreover, cultural differences can affect communication and expectations regarding quality. Buyers should ensure clear agreements on quality expectations and consider incorporating penalties for non-compliance to safeguard their interests.

Conclusion: Why Quality Assurance Matters in Cement Blanket Manufacturing

In summary, the manufacturing processes and quality assurance practices for cement blankets are intricate and vital for ensuring product performance and durability. By understanding these processes, B2B buyers can make informed purchasing decisions, ultimately leading to successful project outcomes and long-term supplier relationships. Emphasizing quality assurance not only protects investments but also enhances the overall effectiveness of construction and industrial applications across various global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cement blanket’

In the competitive landscape of construction and industrial projects, sourcing the right cement blanket is crucial for ensuring quality and efficiency. This guide provides an actionable checklist to aid B2B buyers in making informed procurement decisions.

Step 1: Define Your Technical Specifications

Start by identifying the specific requirements for your project. Consider factors such as insulation thickness, material durability, and environmental conditions. Understanding these specifications will help you narrow down your options and ensure that the cement blanket meets the performance criteria for your intended application.

- Key considerations:

- Thickness: Choose from options like 3/16″, 3/8″, or 1/2″ based on climate and project needs.

- Material: Look for reinforced polyethylene or other durable materials that offer moisture resistance and thermal insulation.

Step 2: Research Potential Suppliers

Conduct thorough research on suppliers to find those with a solid reputation in the industry. Look for established companies that specialize in cement blankets and have a history of reliability and quality.

- What to assess:

- Experience: Evaluate how long the supplier has been in business and their expertise in your specific region.

- Customer reviews: Seek feedback from previous clients to gauge satisfaction and product performance.

Step 3: Evaluate Supplier Certifications

Confirm that potential suppliers have the necessary certifications and comply with industry standards. This step is vital to ensure that the products meet safety and quality regulations.

- Important certifications may include:

- ISO certification: Indicates adherence to international quality standards.

- ASTM compliance: Ensures the product meets specific performance and safety criteria.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the cement blankets for testing. This allows you to assess the quality and suitability of the product for your application.

- Testing should include:

- Durability tests: Check for resistance to weathering and physical stress.

- Performance metrics: Evaluate insulation properties and moisture retention capabilities.

Step 5: Compare Pricing and Terms

Once you have a shortlist of suppliers, compare their pricing structures and terms of sale. This will help you identify the best value for your investment without compromising on quality.

- Consider the following:

- Bulk discounts: Look for suppliers offering better rates for larger orders.

- Shipping costs: Factor in logistics, especially if you are sourcing internationally.

Step 6: Confirm Warranty and After-Sales Support

Ensure that the supplier provides a warranty for their products and has a responsive after-sales support system. This protects your investment and provides peace of mind should issues arise post-purchase.

- What to check:

- Warranty duration: Longer warranties indicate confidence in product quality.

- Support availability: Assess how easy it is to reach customer service for inquiries or issues.

Step 7: Finalize the Order and Monitor Delivery

Once you have selected a supplier and agreed on terms, finalize your order. Keep communication open during the delivery process to ensure that your cement blankets arrive on time and in good condition.

- Monitor:

- Delivery schedules: Confirm timelines and track shipments to avoid project delays.

- Condition upon arrival: Inspect the products immediately to address any discrepancies or damages.

By following this checklist, B2B buyers can effectively source cement blankets that meet their project needs, ensuring durability and performance in various applications.

Comprehensive Cost and Pricing Analysis for cement blanket Sourcing

What Are the Key Cost Components in Cement Blanket Sourcing?

When sourcing cement blankets, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials, such as polyethylene and insulation, significantly influences the overall pricing. Higher quality materials can lead to better performance and durability but will increase costs.

-

Labor: Labor costs associated with manufacturing processes, including cutting, sewing, and assembly, also contribute to the total cost. Labor costs can vary based on geographic location and the complexity of the manufacturing process.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial investment in tooling and machinery can be substantial. Customization or special features may require additional tooling, which can increase initial costs.

-

Quality Control (QC): Rigorous QC processes ensure that the cement blankets meet industry standards. This adds to the overall cost but is essential for maintaining product quality and compliance.

-

Logistics: Transportation costs can fluctuate based on distance, mode of transport, and fuel prices. International shipping may involve tariffs and customs fees that can significantly impact the final price.

-

Margin: Suppliers add a profit margin to their costs, which varies based on market conditions and competition.

How Do Price Influencers Affect Cement Blanket Costs?

Several factors influence the pricing of cement blankets, including:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities often leads to lower per-unit costs. Suppliers are more willing to negotiate prices for bulk orders, making it beneficial for buyers who can commit to larger volumes.

-

Specifications and Customization: Customized solutions or specific performance requirements can drive up costs. Buyers should balance their needs with budget constraints.

-

Material Quality and Certifications: Higher-quality materials or those that meet specific certifications will typically command a higher price. Buyers should consider long-term benefits versus initial costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to attract business.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international buyers. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, directly impacting total costs.

What Are Effective Negotiation Strategies for Cement Blanket Buyers?

To maximize value when sourcing cement blankets, consider the following tips:

-

Research Market Prices: Understanding the market price range for different types of cement blankets will empower buyers during negotiations. Use this knowledge to negotiate better pricing or terms.

-

Leverage Relationships: Establishing a good relationship with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but the long-term costs associated with maintenance, durability, and performance. This perspective can justify higher upfront costs for superior products.

-

Be Aware of Pricing Nuances: Different regions may have unique pricing structures based on local demand, supply chain logistics, and regulatory requirements. Buyers should be prepared to adapt their strategies accordingly.

-

Utilize Bulk Discounts: If possible, consolidate orders across multiple projects to meet MOQs and take advantage of bulk pricing.

Conclusion: Understanding Pricing Dynamics in Cement Blanket Sourcing

In summary, sourcing cement blankets requires a keen understanding of various cost components and pricing influencers. By leveraging negotiation strategies and keeping an eye on the Total Cost of Ownership, B2B buyers can make informed decisions that align with their project needs while optimizing their budgets. Prices can vary significantly based on multiple factors; thus, it is essential to approach sourcing with a comprehensive understanding to ensure cost-effectiveness and quality.

Alternatives Analysis: Comparing cement blanket With Other Solutions

When evaluating construction materials for protection and insulation, it’s essential to consider various alternatives to cement blankets. Cement blankets are widely used for their durability and effectiveness, but there are other viable solutions that may better suit specific project needs. Below, we explore how cement blankets compare with two alternatives: Concrete Curing Blankets and Insulated Tarps.

| Comparison Aspect | Cement Blanket | Concrete Curing Blanket | Insulated Tarp |

|---|---|---|---|

| Performance | High durability, excellent insulation, and protection against environmental factors | Effective in temperature control and moisture retention for curing concrete | Good insulation and moisture protection, but less durable |

| Cost | Moderate to high initial investment | Generally lower cost, but varies by material quality | Low to moderate, depending on insulation type |

| Ease of Implementation | Requires minimal setup; can be laid out and hydrated easily | Simple installation, often requiring no additional maintenance | Easy to install but may need additional securing methods |

| Maintenance | Low maintenance once installed; long-lasting | Reusable but requires drying after use | Low maintenance, but wear and tear may reduce lifespan |

| Best Use Case | Ideal for permanent installations and high-traffic areas | Best for short-term projects requiring concrete curing | Suitable for temporary cover and protection in various weather conditions |

What are the Advantages and Disadvantages of Concrete Curing Blankets?

Concrete curing blankets are designed specifically for maintaining moisture and temperature during the curing process of concrete. Their dual-layer design typically consists of a burlap layer for water retention and a polyethylene layer for UV protection. This makes them particularly effective in hot and sunny conditions. However, while they are reusable and cost-effective, they may not provide the same level of durability as cement blankets, especially in high-traffic areas. The need for periodic drying and maintenance can also be a drawback for some users.

How Do Insulated Tarps Compare as an Alternative?

Insulated tarps offer a versatile solution for temporary coverage and insulation needs. They are lightweight, easy to deploy, and can provide decent insulation and moisture protection. However, their overall durability may not match that of cement blankets, particularly in rugged environments. While they are generally more affordable and suitable for various applications, they may require additional securing methods to withstand wind or heavy rain, potentially complicating their use in certain conditions.

Conclusion: Which Solution Should B2B Buyers Choose?

Selecting the right solution for your project ultimately depends on specific needs and circumstances. If durability and long-term protection are paramount—especially in high-traffic or harsh environments—cement blankets may be the best choice. Conversely, for projects focused on curing concrete in moderate conditions or requiring a cost-effective solution, concrete curing blankets can be an excellent alternative. Insulated tarps work well for temporary needs but may not be suitable for permanent installations. Assessing project requirements, budget constraints, and environmental conditions will guide B2B buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for cement blanket

What Are the Key Technical Properties of Cement Blankets?

When selecting cement blankets for construction projects, understanding their technical properties is crucial for ensuring performance, durability, and cost-effectiveness. Here are some essential specifications to consider:

1. Material Grade

Cement blankets are typically made from high-density polyethylene (HDPE) or reinforced polypropylene. The material grade affects durability, resistance to environmental factors, and overall lifespan. For B2B buyers, selecting a high-grade material ensures the blanket can withstand harsh conditions, reducing the need for replacements and maintenance.

2. Thickness

The thickness of cement blankets usually ranges from 6 mil to 8 mil or more. Thicker blankets provide better insulation and moisture retention, which are critical during the curing process of concrete. Understanding the thickness options helps buyers choose the right product based on their project’s specific climate and curing requirements.

3. R-Value

The R-value indicates the thermal resistance of the blanket. Higher R-values signify better insulation properties, which is essential for maintaining the ideal curing temperature in colder conditions. Buyers should consider the R-value when purchasing cement blankets for winter projects to ensure optimal concrete strength and prevent cracking.

4. Moisture Retention

Cement blankets are designed to retain moisture during the curing process. The ability to maintain moisture levels is crucial for preventing premature drying, which can compromise the integrity of the concrete. Buyers should look for blankets with proven moisture retention capabilities to enhance the quality of their concrete work.

5. Weight and Handling

The weight of cement blankets can influence ease of installation and transportation. Lightweight options are easier to handle and deploy, making them suitable for projects with limited manpower or machinery. Understanding the weight specifications allows buyers to plan for efficient logistics and installation processes.

6. Durability and Reusability

Durability is a key factor that impacts the overall cost-effectiveness of cement blankets. Buyers should assess the expected lifespan and whether the product is reusable across multiple projects. Investing in durable blankets can lead to significant savings over time, especially for companies engaged in frequent construction activities.

What Are Common Trade Terms Used in the Cement Blanket Industry?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the B2B market. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of cement blankets, understanding whether a supplier is an OEM can indicate the quality and reliability of the product.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product a supplier is willing to sell. This term is important for B2B buyers to understand, as it can impact purchasing decisions, particularly for smaller projects or companies with limited budgets.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and details on specific products. It is a critical step in the procurement process, allowing buyers to compare options and make informed decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping agreements. Understanding these terms is vital for international buyers to manage shipping costs and logistics effectively.

5. Lead Time

Lead time is the duration from placing an order to receiving the product. For cement blankets, shorter lead times can be crucial for meeting project deadlines. Buyers should always inquire about lead times when negotiating contracts.

6. Warranty Period

The warranty period defines the time frame in which the manufacturer guarantees the product’s performance and quality. Knowing the warranty terms can protect buyers from potential defects and ensure they receive a reliable product.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing cement blankets, ultimately leading to successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the cement blanket Sector

What are the Key Market Dynamics and Trends Affecting the Cement Blanket Sector?

The cement blanket sector is experiencing transformative growth driven by several global factors. Increasing infrastructure investments across developing regions, particularly in Africa, South America, and parts of the Middle East, are significantly propelling demand. As urbanization accelerates, the need for effective concrete curing solutions that can withstand diverse environmental conditions has never been more critical. Moreover, the rise of sustainable construction practices is influencing sourcing decisions, as companies increasingly prioritize materials that reduce environmental impact.

Emerging technologies are reshaping the procurement landscape. B2B buyers are now leveraging digital platforms for sourcing, facilitating easier access to suppliers and enabling comparative analysis of product specifications and pricing. Additionally, innovations in material science have led to the development of advanced cement blankets, such as those that incorporate insulation properties for temperature regulation during curing, thus improving concrete quality.

For international buyers, particularly those in Europe and Asia, understanding regional compliance standards is essential. Buyers must navigate various regulations regarding material safety and environmental impact, which can vary significantly across markets. Engaging with suppliers that offer transparent compliance documentation will not only streamline procurement but also mitigate risks associated with non-compliance.

How Can Sustainability and Ethical Sourcing Enhance My B2B Strategy in the Cement Blanket Sector?

Sustainability is becoming a cornerstone of competitive advantage in the cement blanket sector. As environmental regulations tighten globally, B2B buyers are increasingly held accountable for the environmental impact of their sourcing decisions. Cement blankets made from recycled materials or those that minimize waste during installation are gaining traction. Buyers are encouraged to seek suppliers that prioritize sustainable practices in their manufacturing processes.

Ethical sourcing is equally important. Companies are now focusing on supply chain transparency, ensuring that their suppliers adhere to fair labor practices and responsible environmental stewardship. The demand for certifications such as ISO 14001 (Environmental Management) and other ‘green’ certifications is on the rise. These certifications not only validate the sustainability claims of suppliers but also enhance brand reputation, making them attractive to environmentally conscious clients.

Moreover, the integration of sustainability into procurement strategies can lead to cost savings in the long run. For example, investing in high-quality cement blankets that reduce the need for frequent replacements can lower operational costs over time. By aligning sourcing strategies with sustainability goals, companies can improve their overall market positioning and appeal to a broader customer base.

What is the Historical Context Behind the Evolution of Cement Blankets?

The evolution of cement blankets can be traced back to the early 20th century when concrete curing techniques began to gain importance in construction practices. Initially, traditional methods relied heavily on water application and manual coverings, which were labor-intensive and often ineffective. As the construction industry evolved, so did the need for more efficient solutions that could address the challenges of curing concrete in varying climates.

The introduction of synthetic materials in the mid-20th century marked a significant turning point. The development of insulated and moisture-retaining blankets provided enhanced performance, reducing the risk of cracking and ensuring optimal curing conditions. Today, the market features a variety of advanced cement blankets designed to meet specific project requirements, including temperature control and environmental protection.

This historical context underscores the importance of innovation and adaptability in the cement blanket sector. As B2B buyers seek to optimize their construction processes, understanding the evolution of these products can inform better sourcing decisions and foster collaboration with suppliers who prioritize innovation and quality.

Frequently Asked Questions (FAQs) for B2B Buyers of cement blanket

-

How do I solve issues with concrete curing in extreme weather?

To effectively address concrete curing challenges in extreme weather conditions, consider using specialized curing blankets. These products, such as wet concrete curing blankets, help maintain the necessary moisture and temperature for proper curing. In hot climates, dual-layer blankets that reflect UV rays and retain moisture are ideal. In colder regions, insulated blankets that prevent heat loss and protect against freezing temperatures are essential. Always select blankets that meet industry standards to ensure optimal results and minimize the risk of cracks or compromised strength. -

What is the best cement blanket for high-traffic areas?

For high-traffic areas, look for cement blankets that offer durability and protection against physical damage. Products like Concrete Canvas® provide a flexible, concrete-impregnated fabric that hardens upon hydration, forming a robust barrier against vandalism and wear from foot traffic. The ability to easily cut and install the material is also a significant advantage in busy environments. Ensure that the blanket can withstand the specific conditions of your project, including exposure to water and potential animal interference. -

What customization options are available for cement blankets?

Many suppliers offer customization options for cement blankets, including size, thickness, and material composition. When sourcing, inquire about the ability to tailor products to specific project requirements, such as enhanced insulation for colder climates or increased UV protection for sunny regions. Custom branding may also be available for companies looking to promote their identity. Discuss these options with your supplier to ensure that the final product meets your functional and aesthetic needs. -

What are the minimum order quantities (MOQ) for cement blankets?

Minimum order quantities can vary significantly among suppliers, typically ranging from a few rolls to several pallets. When negotiating with potential suppliers, clarify their MOQ policies, especially if you’re working on a large project that requires substantial quantities. Some manufacturers may offer flexibility for first-time buyers or smaller businesses, so it’s worth discussing your specific needs. Bulk purchasing can often lead to cost savings, so consider your project scale when planning your order. -

What payment terms should I expect when purchasing cement blankets?

Payment terms for cement blankets can vary by supplier and region. Common practices include upfront payments, partial deposits, or net terms (e.g., 30, 60, or 90 days). International buyers should be aware of the payment methods accepted, such as bank transfers, credit cards, or letters of credit, which can provide additional security. Always confirm terms before finalizing an order, as negotiating favorable payment conditions can significantly impact cash flow and project budget. -

How can I vet suppliers for cement blankets?

Vetting suppliers involves evaluating their credibility, product quality, and customer service. Start by checking their certifications, industry experience, and client testimonials. Request product samples to assess material quality firsthand. Additionally, consider their manufacturing capabilities and delivery times, particularly for international shipping. Engaging with previous clients for references can provide insights into their reliability and responsiveness. Conducting thorough research will help ensure you partner with a reputable supplier. -

What quality assurance measures should be in place for cement blankets?

Quality assurance is crucial when sourcing cement blankets. Ensure that suppliers adhere to industry standards, such as ASTM or AASHTO specifications, which indicate reliable performance. Request documentation on quality control processes, including testing for durability, insulation properties, and resistance to environmental factors. Regular audits and inspections of manufacturing facilities can also help ensure that products consistently meet the agreed-upon specifications, providing peace of mind for your investment. -

What logistics considerations are important when importing cement blankets?

When importing cement blankets, consider logistics factors such as shipping methods, lead times, and customs regulations. Evaluate whether you need air or sea freight based on urgency and budget. Understand the import duties and taxes applicable in your country to avoid unexpected costs. Additionally, ensure that your supplier can provide the necessary documentation for customs clearance. Collaborating with a freight forwarder can streamline the process and help you navigate the complexities of international shipping effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cement Blanket Manufacturers & Suppliers List

1. Concrete Canvas – Erosion Control Solution

Domain: concretecanvas.com

Registered: 1998 (27 years)

Introduction: Concrete Canvas® (CC) is a versatile erosion control solution that allows for quick and easy installation of concrete with minimal training. It consists of a 3-dimensional fiber matrix with a dry cementitious mix and a waterproof PVC backing. CC can be hydrated with fresh or salt water and is available in three variations: CCT1™, CCT2™, and CCT3™. Key benefits include rapid installation (up to 215…

2. Curelap – Wet Concrete Curing Blankets

Domain: tarpsnow.com

Registered: 2010 (15 years)

Introduction: {“Product Name”: “Wet Concrete Curing Blankets”, “Brand”: “Curelap”, “SKU”: “ICWCCB10100”, “Price”: “$222.95”, “Discounted Price”: “$65.90”, “Bulk Pricing”: [{“Quantity”: 5, “Price”: “$211.80”}, {“Quantity”: 10, “Price”: “$200.66”}, {“Quantity”: 25, “Price”: “$189.51”}], “Size”: “10′ x 100′”, “Quantity per Skid”: “25 rolls”, “Material”: “10 oz. burlap layer, 5 mil white opaque polyethylene layer”,…

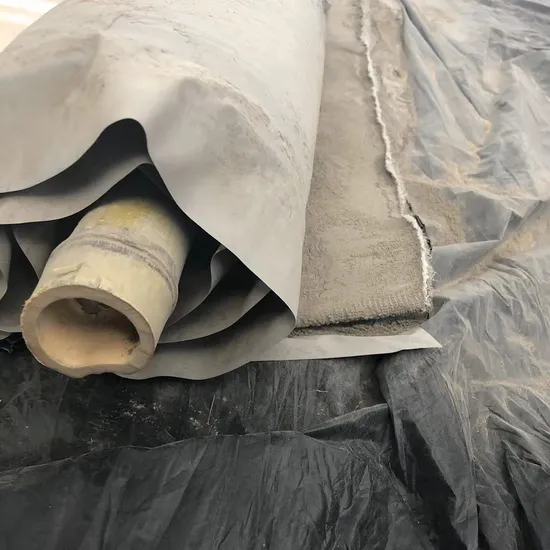

3. Aquascape – Concrete Canvas® 3.28′ X 32.8′ Roll

Domain: aquascapeinc.com

Registered: 2005 (20 years)

Introduction: Aquascape Concrete Canvas® – 3.28′ X 32.8′ Roll (1 x 10 m) is a flexible concrete-impregnated fabric that hardens upon hydration to form a durable concrete layer. It effectively protects pond liners from digging animals, human traffic, and damage from large rocks or boulders. The product is easy to install by laying the matting in the desired location and saturating the top side with water. The to…

4. Facebook – Magic Blanket

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Magic Blanket, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Concrete Curing – Temperature Considerations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Concrete Curing – Temperature Considerations, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Strongman – StrongCure Concrete Curing Blanket

Domain: strongman.com

Registered: 1996 (29 years)

Introduction: StrongCure Concrete Curing Blanket is designed for cold weather applications in construction and industrial maintenance. Key features include: 8×8 weave poly tarp with layered Bubble Cell cores, grommets at corners and midpoints for easy installation, moisture and mildew resistance, insulation for temperature control, and durability. The blanket is lightweight, long-lasting, and 100% reusable. Ava…

7. Eagle Industries – 1 Layer Winter Concrete Blanket

Domain: eagleind.com

Registered: 1995 (30 years)

Introduction: {“product_name”:”1 Layer Winter Concrete Blanket”,”series”:”CB1 Series”,”dimensions”:”6′ x 25′”,”material”:”Woven coated reinforced outer shell with SnowBlok™ coating”,”insulation”:”1 layer foam insulation”,”features”:[“Grommets spaced every 2 feet”,”UV protection for sunlight exposure”,”Border edges stitched to secure foam layers”],”benefits”:[“Winter protection enclosure tarp”,”Concrete curing f…

Strategic Sourcing Conclusion and Outlook for cement blanket

How Can Strategic Sourcing Enhance Your Procurement of Cement Blankets?

Strategic sourcing is pivotal for international B2B buyers looking to optimize their procurement processes for cement blankets. By understanding the diverse applications and benefits of various types of cement blankets—such as concrete curing and protective layers—you can make informed purchasing decisions that align with your project requirements. Products like Concrete Canvas and specialized curing blankets not only enhance durability but also reduce maintenance and repair costs, making them a valuable investment.

Moreover, establishing strong supplier relationships can lead to better pricing, availability, and support, particularly in regions like Africa, South America, the Middle East, and Europe. This is essential in navigating market fluctuations and ensuring consistent supply chains.

As you look to the future, consider how innovative materials and sustainable practices can be integrated into your sourcing strategy. Embrace the opportunity to enhance your project outcomes while contributing to environmental stewardship. Engage with suppliers who demonstrate commitment to quality and sustainability, and take action now to secure the best solutions for your business needs. The time to optimize your sourcing strategy is now—maximize your investments in cement blankets and watch your projects thrive.