How to Source Types Of Hot Glue Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for types of hot glue

Navigating the complexities of sourcing the right types of hot glue can be a daunting task for international B2B buyers. With a myriad of options available—from standard high-temperature formulations to specialty adhesives designed for specific applications—making the right choice is critical for ensuring product performance and operational efficiency. This comprehensive guide delves into the diverse world of hot glue, providing insights into various types, their applications across industries, supplier vetting processes, and cost considerations.

By empowering buyers with essential knowledge, this guide facilitates informed purchasing decisions, particularly for businesses operating in dynamic markets such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Brazil. Understanding the nuances of hot glue types not only enhances product quality but also optimizes supply chain processes and reduces costs.

As you explore this guide, you will gain clarity on the different formulations, the benefits of each type, and how to align them with your unique project requirements. Ultimately, the goal is to equip you with actionable insights that will lead to more effective sourcing strategies and better outcomes for your business.

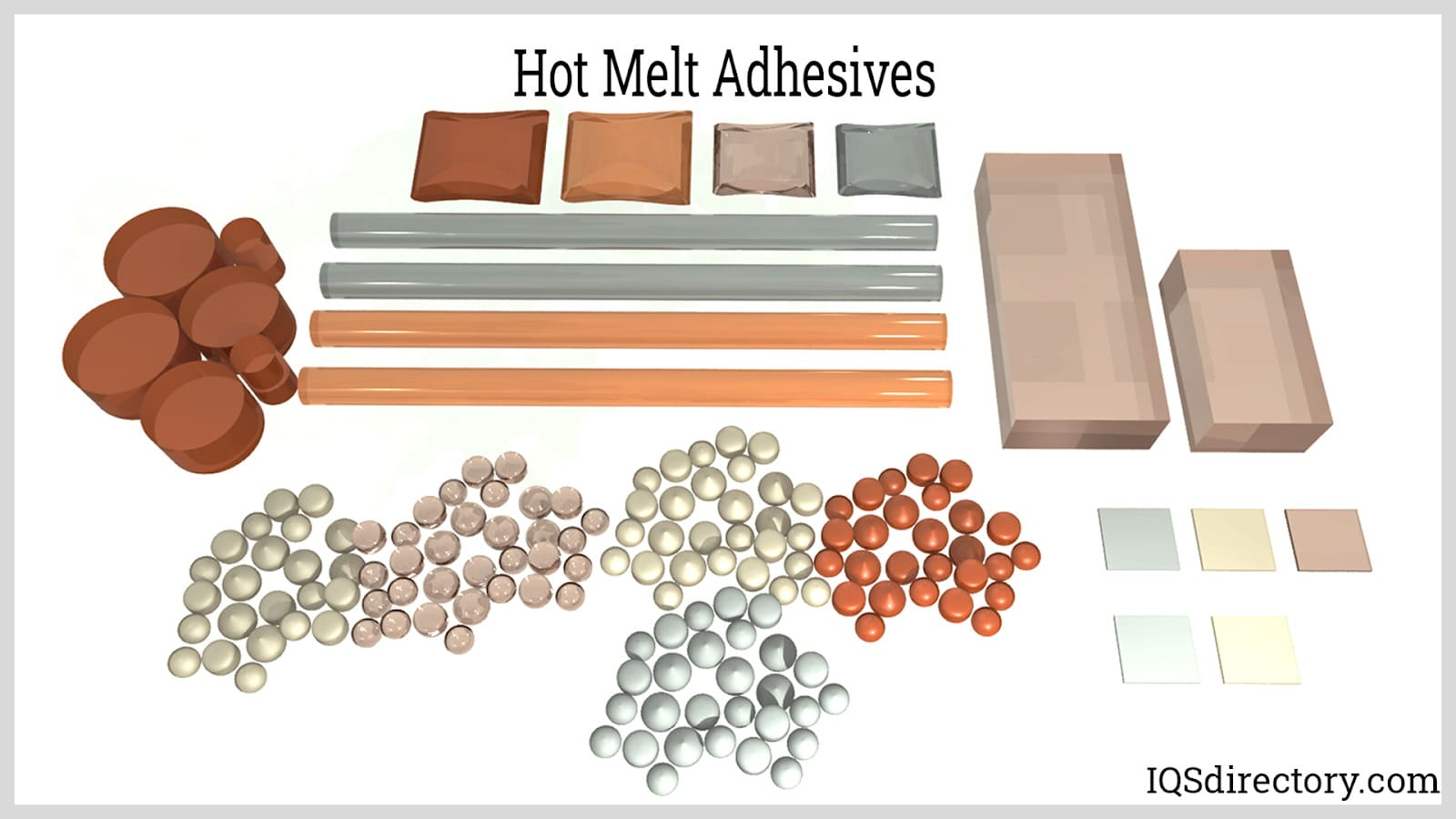

Understanding types of hot glue Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| General Purpose Hot Glue | Versatile, suitable for a wide range of materials | Packaging, crafts, general assembly | Pros: Cost-effective, easy to use. Cons: May not bond well with specific substrates. |

| Low Temperature Hot Glue | Melts at lower temperatures, safer for sensitive materials | Electronics, fabric bonding | Pros: Reduces burn risk, ideal for delicate items. Cons: Weaker bond strength compared to high temp glues. |

| High Temperature Hot Glue | Melts at higher temperatures, provides stronger bonds | Woodworking, heavy-duty assembly | Pros: Strong adhesive properties, durable. Cons: Risk of burns, may damage heat-sensitive materials. |

| Specialty Hot Glue | Formulated for specific applications (e.g., fabric, foam) | Crafts, automotive, electronics | Pros: Tailored solutions for unique materials. Cons: Higher cost, may require specific applicators. |

| Acrylic Hot Glue | High performance, excellent for bonding acrylics and plastics | Signage, display manufacturing | Pros: Strong bond for challenging substrates. Cons: More expensive, requires precise application. |

What are the Characteristics of General Purpose Hot Glue?

General purpose hot glue is designed for versatility, making it suitable for a broad range of applications, including packaging, crafts, and general assembly tasks. It typically works well with materials like paper, wood, and some plastics. When considering purchasing, businesses should evaluate the adhesive’s compatibility with their specific materials and the cost-effectiveness for bulk purchasing. While it is easy to use and widely available, it may not provide the strongest bond for specialized applications.

How Does Low Temperature Hot Glue Benefit Sensitive Materials?

Low temperature hot glue is designed to melt at lower temperatures, making it ideal for bonding sensitive materials such as electronics and fabrics. This type reduces the risk of burns during application and is particularly useful for projects that involve delicate substrates. B2B buyers should consider the specific temperature requirements of their applications, as this glue may not be suitable for high-stress environments where a stronger bond is necessary. Its ease of use and safety features make it a popular choice in various industries.

Why Choose High Temperature Hot Glue for Heavy-Duty Applications?

High temperature hot glue melts at higher temperatures, providing a robust adhesive solution for applications like woodworking and heavy-duty assembly. This type is known for its strong bonding capabilities, making it suitable for materials that require a durable hold. B2B buyers should be aware of the potential burn risk and ensure that the materials they are working with can withstand the heat. While it offers a strong bond, the application process requires careful handling to avoid damage to sensitive materials.

What Makes Specialty Hot Glue a Unique Option?

Specialty hot glue is formulated for specific applications, such as fabric, foam, or automotive uses. These glues are engineered to meet the unique bonding requirements of various materials, providing tailored solutions for businesses. When considering specialty hot glue, B2B buyers should evaluate the compatibility of the adhesive with their specific materials and the potential need for specialized applicators. Although these glues tend to be more expensive, their performance in niche applications can justify the investment.

How Does Acrylic Hot Glue Stand Out in the Market?

Acrylic hot glue is known for its high performance, particularly when bonding acrylics and plastics. This type provides a strong bond that is essential for applications in signage and display manufacturing. B2B buyers should consider the precise application requirements, as acrylic hot glue can be more expensive and may require specific equipment for optimal use. Its strength and durability make it a valuable option for businesses looking to create long-lasting bonds in demanding environments.

Key Industrial Applications of types of hot glue

| Industry/Sector | Specific Application of types of hot glue | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics | Securing wires and components in circuit boards | Enhances durability and reliability of products | Ensure compatibility with low and high-temperature requirements; look for self-extinguishing properties. |

| Packaging | Carton sealing and packaging assembly | Improves efficiency and reduces production costs | Consider the open time and flexibility of the adhesive; evaluate temperature performance for shipping conditions. |

| Furniture and Woodworking | Bonding wood, fabric, and upholstery | Provides strong, lasting bonds for high-usage items | Verify adhesion properties for various substrates; assess impact resistance for durability. |

| Automotive | Assembling interior components and trims | Streamlines production processes and reduces weight | Look for high-temperature formulations; ensure compliance with automotive safety standards. |

| Arts and Crafts | Fabric and decorative item assembly | Allows for creative flexibility and quick assembly | Source specialty hot glues that cater to specific materials like foam, fabric, or plastics. |

How is Hot Glue Used in Electronics Applications?

In the electronics industry, hot glue is pivotal for securing wires and components on circuit boards. It prevents movement that could lead to breakage, enhancing the durability and reliability of electronic devices. For international buyers, particularly in regions like Africa and South America, sourcing hot glue with self-extinguishing properties is crucial to meet safety standards. Additionally, understanding the temperature requirements for low and high-volume applications can optimize production processes.

What Role Does Hot Glue Play in Packaging?

Hot glue is extensively used in packaging for carton sealing and assembly. It improves efficiency by providing a quick bonding solution that reduces production costs. Buyers should focus on the adhesive’s open time and flexibility, particularly for products that will be exposed to varying temperatures during shipping. In regions with fluctuating climates, such as the Middle East, sourcing hot glue that performs well in both hot and cold conditions is essential.

How is Hot Glue Essential in Furniture and Woodworking?

In the furniture and woodworking sector, hot glue serves to bond wood, fabric, and upholstery effectively. This application is vital for creating durable products that withstand everyday use. International buyers need to ensure that the adhesives they procure have the right adhesion properties for various substrates, particularly when working with composite materials. Additionally, impact resistance is a key consideration to maintain the integrity of furniture in high-traffic environments.

Illustrative image related to types of hot glue

Why is Hot Glue Important in Automotive Manufacturing?

In the automotive industry, hot glue is utilized for assembling interior components and trims. This application not only streamlines production processes but also contributes to weight reduction, which is critical for fuel efficiency. Buyers must prioritize high-temperature formulations that can withstand the heat generated in vehicles. Compliance with automotive safety standards is another critical factor for international buyers, particularly in Europe, where regulations are stringent.

How is Hot Glue Used in Arts and Crafts?

Hot glue is a staple in the arts and crafts sector, facilitating the assembly of fabric and decorative items. It allows for creative flexibility, enabling artisans to quickly piece together various materials. Buyers should look for specialty hot glues designed for specific applications, such as those that work well with foam or fabric. This is particularly important for international buyers in diverse markets, where the availability of suitable materials can vary significantly.

3 Common User Pain Points for ‘types of hot glue’ & Their Solutions

Scenario 1: Selecting the Right Hot Glue for Diverse Materials

The Problem: A common challenge faced by B2B buyers, particularly those in manufacturing and assembly, is the difficulty in selecting the appropriate type of hot glue for various materials. For example, a buyer may need to bond wood, fabric, and plastic in a single project. Each material often requires a different adhesive formulation due to factors such as temperature sensitivity, moisture resistance, and surface texture. This can lead to frustration, as using the wrong type of glue can result in weak bonds, product failures, and increased production costs.

Illustrative image related to types of hot glue

The Solution: To overcome this issue, buyers should invest time in understanding the specific properties of different hot glue types and their compatibility with the materials they plan to bond. Create a materials matrix that outlines the properties of each glue type—such as high-temperature or low-temperature formulations, flexibility, and drying time. Suppliers like 3M and Surebonder offer detailed specifications and guidelines on their products. Utilize these resources to match the glue with the materials in question. Furthermore, conducting small-scale tests before committing to large orders can help ensure optimal performance and reduce risks in production.

Scenario 2: Managing Production Downtime Due to Glue Gun Compatibility

The Problem: In many manufacturing environments, using multiple types of hot glue guns that are incompatible with certain glue stick sizes can lead to significant downtime. For instance, if a production line is using a specific glue gun that only accepts 5/8″ glue sticks, running out of those sticks while having a surplus of ½” sticks can cause delays and disrupt workflow. This scenario not only affects productivity but also increases costs due to wasted materials and labor.

The Solution: To mitigate these issues, B2B buyers should standardize equipment across their operations. Assess the glue stick sizes and types currently in use and consolidate to a limited number of glue gun models that can accommodate the most frequently used glue stick sizes. Additionally, maintain a well-organized inventory management system that tracks glue stick usage and replenishes supplies in advance to prevent shortages. Partnering with suppliers who offer bulk purchasing options can also ensure consistent availability and lower costs, while training staff to understand equipment compatibility can further streamline operations.

Scenario 3: Addressing Safety Concerns with High-Temperature Hot Glue

The Problem: Many industries, particularly those involving electronics or sensitive materials, face safety concerns when using high-temperature hot glue. The risk of burns during application can deter employees from using these adhesives, leading to inefficiencies and potential workplace injuries. Buyers must consider not only the effectiveness of the adhesive but also the safety of their workforce when choosing hot glue options.

The Solution: To enhance workplace safety, consider switching to low-temperature hot glue formulations that are safer for users while still providing adequate bonding strength. These glues operate at lower application temperatures, significantly reducing the risk of burns. Training sessions should be conducted to educate employees on the safe handling of hot glue guns, emphasizing the importance of using protective equipment and implementing safe operating procedures. Additionally, sourcing adhesives from suppliers that prioritize safety features, such as non-toxic and eco-friendly formulations, can align with corporate responsibility goals while ensuring a safer working environment.

Strategic Material Selection Guide for types of hot glue

What Are the Key Properties of Hot Glue for Common Materials?

When selecting hot glue for various applications, understanding the specific properties of the materials involved is crucial. Here, we analyze four common materials used in hot glue applications: wood, fabric, plastics, and metals. Each material has unique characteristics that affect performance, durability, and suitability for specific applications.

How Do Hot Glue Properties Affect Wood Adhesion?

Key Properties: Hot glue designed for wood typically has a high-temperature rating, allowing it to withstand the heat generated during the bonding process. These adhesives may also exhibit good shear strength and flexibility, which is essential for wood applications that experience movement.

Pros & Cons: The advantages of using hot glue for wood include quick setting times and ease of application, which can enhance productivity. However, the durability may be lower compared to traditional wood adhesives, especially in high-stress applications. Additionally, hot glue may not penetrate porous surfaces as effectively as other adhesives.

Impact on Application: When bonding wood, the glue must be compatible with various finishes and treatments. Hot glue can be used for crafts, furniture assembly, and temporary fixtures, but it may not be suitable for load-bearing joints.

Illustrative image related to types of hot glue

Considerations for International Buyers: Compliance with regional standards (e.g., ASTM in the U.S. or DIN in Europe) is essential. Buyers should also consider the climatic conditions of their region, as temperature fluctuations can affect glue performance.

What Are the Advantages of Using Hot Glue for Fabric?

Key Properties: Fabric hot glue is often formulated to remain flexible after curing, which is crucial for applications in textiles. These adhesives typically have lower melting points to prevent damage to delicate fabrics.

Pros & Cons: The primary advantage of fabric hot glue is its ability to bond quickly without the need for sewing. However, it may not provide the same strength as traditional fabric adhesives, and certain fabrics may not adhere well, particularly those with high oil content.

Impact on Application: Hot glue is ideal for crafting, costume design, and upholstery work. However, it may not be suitable for outdoor applications where exposure to moisture could weaken the bond.

Considerations for International Buyers: Buyers should ensure that the glue meets safety and environmental regulations specific to textiles in their region. Additionally, understanding the local market’s preferences for fabric types can guide material selection.

How Do Hot Glue Properties Affect Plastic Adhesion?

Key Properties: Hot glue for plastics often includes formulations that enhance adhesion to low-energy surfaces, which are common in many plastic types. These adhesives may also offer resistance to chemicals and moisture.

Pros & Cons: The significant advantage of using hot glue for plastics is its fast setting time, which can streamline production processes. However, the bond may not be as strong as that achieved with specialized plastic adhesives, particularly for high-stress applications.

Impact on Application: Hot glue is commonly used in packaging, assembly, and crafting. However, the choice of hot glue must consider the specific type of plastic, as some formulations may not adhere well to certain plastics like polyethylene.

Considerations for International Buyers: Compliance with international standards for plastic products is critical. Buyers should also be aware of the specific properties of the plastics they are working with to ensure compatibility.

What Are the Key Properties of Hot Glue for Metal Applications?

Key Properties: Hot glue for metal applications typically features high-temperature resistance and strong adhesion properties. These adhesives can withstand the thermal expansion and contraction that metals experience.

Pros & Cons: The primary advantage is the ability to bond metals quickly and easily without the need for complex equipment. However, the bond may be less durable than traditional metal adhesives, particularly under extreme conditions.

Impact on Application: Hot glue is suitable for lightweight metal assemblies, decorative applications, and temporary fixtures. It may not be ideal for structural applications where high strength is required.

Considerations for International Buyers: Buyers should ensure that the hot glue complies with relevant metal bonding standards in their region. Additionally, understanding the specific types of metals and their coatings is essential for effective bonding.

Summary Table of Hot Glue Material Selection

| Material | Typical Use Case for types of hot glue | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture assembly, crafts | Quick setting time | Lower durability than traditional adhesives | Medium |

| Fabric | Costume design, upholstery | Fast bonding without sewing | May not bond well with all fabric types | Low |

| Plastics | Packaging, assembly | Fast setting, easy application | Weaker bond for high-stress applications | Medium |

| Metals | Lightweight assemblies, decorative applications | Easy to use, quick bonding | Less durable under extreme conditions | Medium |

This strategic guide provides valuable insights for international B2B buyers, ensuring informed decisions when selecting hot glue for diverse applications across various materials.

In-depth Look: Manufacturing Processes and Quality Assurance for types of hot glue

What Are the Main Stages in the Manufacturing Process of Hot Glue?

The manufacturing of hot glue involves several critical stages that ensure the final product meets the required specifications and quality standards. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to types of hot glue

-

Material Preparation: The process begins with the selection of raw materials, which typically include thermoplastic polymers, resins, and additives. Suppliers must source high-quality materials that comply with international standards. This stage often includes thorough testing of raw materials for purity and performance characteristics.

-

Forming: In this stage, the prepared materials are melted and mixed in precise proportions. This is usually done using industrial mixers and extruders, which ensure consistent blending and optimal viscosity. The mixture is then formed into sticks, pellets, or other shapes depending on the intended use. The forming process may vary based on the type of hot glue being produced, such as low-temperature or high-temperature formulations.

-

Assembly: For certain specialty hot glue products, additional components may be added during the assembly stage. This could include colorants for aesthetic purposes or specific additives to enhance bonding capabilities. Automated systems are often employed to ensure accuracy and efficiency during this stage.

-

Finishing: The final stage involves cooling and packaging the hot glue products. Quality control checks are conducted at this stage to ensure that the glue sticks are free from defects. The finished products are then packaged according to customer specifications and international shipping standards.

What Key Techniques Are Used in Hot Glue Manufacturing?

Various techniques are employed throughout the manufacturing process to ensure product consistency and quality. These include:

- Extrusion: A common technique for forming hot glue sticks, where the melted material is forced through a die to achieve the desired shape.

- Quality Control Sampling: Random sampling of products during and after manufacturing to verify consistency with specifications.

- Temperature Regulation: Maintaining precise temperature control throughout the melting and forming stages is crucial for achieving the desired viscosity and bonding properties.

How Is Quality Assurance Implemented in Hot Glue Manufacturing?

Quality assurance (QA) is critical to ensuring that hot glue products meet both industry and customer standards. This involves adherence to international standards such as ISO 9001, which outlines the requirements for a quality management system.

-

International Standards: Compliance with standards like ISO 9001 ensures that manufacturers implement consistent quality management processes. Additionally, industry-specific certifications such as CE for Europe or API for oil-related products can be relevant, depending on the application of the hot glue.

-

Quality Control Checkpoints: The QA process typically includes several checkpoints:

– Incoming Quality Control (IQC): Assessment of raw materials to ensure they meet specifications before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify any issues immediately.

– Final Quality Control (FQC): A comprehensive evaluation of the finished product to confirm it meets all requirements before packaging and shipping. -

Common Testing Methods: Various testing methods are employed to assess the performance of hot glue, including:

– Shear Strength Tests: To evaluate the adhesive strength of the glue.

– Heat Resistance Tests: To determine how well the glue performs under elevated temperatures.

– Viscosity Tests: To ensure the glue can be easily applied using standard equipment.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is paramount. Here are several strategies to consider:

-

Supplier Audits: Conducting on-site audits can provide valuable insights into a manufacturer’s processes, capabilities, and adherence to quality standards. This also allows buyers to assess the working environment and employee training programs.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand the testing methodologies employed and the results obtained for specific products.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and the quality of the products being produced.

What Are the Nuances of QC and Certification for International B2B Buyers?

Understanding the nuances of quality control and certification is essential for B2B buyers, particularly in diverse markets. Here are some key considerations:

-

Regional Compliance: Different regions may have specific regulatory requirements. For instance, CE marking is necessary for products sold within the European Union, while other certifications may be required in the Middle East or Africa.

-

Documentation and Traceability: Ensuring that suppliers maintain comprehensive documentation of their quality control processes and product traceability can significantly enhance the reliability of the supply chain.

-

Cultural and Language Barriers: Buyers should be aware of potential cultural and language differences that may impact communication with suppliers. Establishing clear expectations and maintaining open lines of communication can help mitigate misunderstandings.

In conclusion, understanding the manufacturing processes and quality assurance measures for hot glue is crucial for B2B buyers. By focusing on the key stages of production, techniques used, and effective quality control strategies, buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their specific needs.

Illustrative image related to types of hot glue

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of hot glue’

To assist B2B buyers in procuring the right types of hot glue, this guide outlines a practical, step-by-step checklist. This process will help ensure that you select the most suitable products for your specific applications while navigating supplier options effectively.

Step 1: Define Your Technical Specifications

Before exploring suppliers, clearly outline your technical requirements. Consider the materials you will be bonding (e.g., wood, fabric, plastics), the necessary temperature resistance, and the environmental conditions (e.g., humidity, temperature extremes) the glue will be exposed to. This clarity will guide your search and enable you to communicate effectively with potential suppliers.

Step 2: Identify Required Hot Glue Types

Different applications necessitate various types of hot glue. Research the specific formulations available, such as low-temperature glues for delicate materials or high-temperature options for more robust applications. Familiarize yourself with specialty glues tailored for industries like electronics, woodworking, or packaging to ensure compatibility with your projects.

Illustrative image related to types of hot glue

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in your specific application area, as this can significantly impact performance and reliability.

- Check Certifications: Ensure suppliers have relevant certifications that meet your quality and safety standards.

- Assess Product Range: A supplier with a diverse range of products can better meet your evolving needs.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the hot glue types you are considering. Testing these samples in your specific application environment allows you to evaluate performance aspects such as adhesion strength, drying time, and compatibility with your materials. This step is essential to avoid costly mistakes later.

Step 5: Review Pricing and Terms

Compare pricing structures among your shortlisted suppliers. Look not just at the unit price but also consider bulk purchasing discounts, shipping costs, and payment terms. Ensure that the total cost aligns with your budget while not compromising on quality.

- Negotiate Terms: Don’t hesitate to negotiate better terms, especially for larger orders or long-term partnerships.

Step 6: Assess After-Sales Support and Service

Good after-sales support can be a significant advantage. Inquire about the level of technical support offered, including guidance on application techniques or troubleshooting. Suppliers that provide comprehensive support can help ensure your projects run smoothly and efficiently.

Step 7: Finalize Your Order with Clear Specifications

Before placing your order, ensure that all specifications are documented clearly, including the type of hot glue, quantity, and delivery timelines. This helps avoid misunderstandings and ensures you receive the correct products on time. Establish a reliable communication channel for any follow-up queries.

By following this checklist, B2B buyers can streamline their sourcing process for hot glue, ensuring they select the right products from reputable suppliers while meeting their technical and budgetary requirements.

Comprehensive Cost and Pricing Analysis for types of hot glue Sourcing

What Are the Key Cost Components in Hot Glue Sourcing?

Understanding the cost structure of hot glue is essential for B2B buyers looking to optimize their sourcing strategies. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of adhesive polymer used significantly affects the price. Specialty hot glue sticks, such as those designed for electronics or fabric, often command higher prices due to their advanced formulations and specific applications.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with lower labor costs, such as parts of Africa and South America, may offer more competitive pricing. However, labor quality must also be considered, as skilled labor may lead to better product quality.

-

Manufacturing Overhead: This includes the costs associated with running the manufacturing facility, such as utilities and maintenance. Efficient production lines can reduce these costs, impacting the overall price of hot glue.

-

Tooling: Initial tooling costs can be significant, especially for customized products. Buyers should factor these costs into their total pricing analysis, particularly when ordering specialized adhesive formulations.

-

Quality Control: High-quality adhesives often undergo rigorous testing, which can increase costs. Buyers should evaluate whether the price reflects appropriate certifications and quality assurance measures.

-

Logistics: Shipping costs can vary based on distance, weight, and the chosen Incoterms. Buyers should consider the total logistics cost when evaluating suppliers.

-

Margin: Suppliers typically add a margin to cover operational costs and profit. Understanding the competitive landscape can help buyers negotiate better prices.

How Do Price Influencers Impact Hot Glue Costs?

Several factors influence the pricing of hot glue beyond the basic cost structure.

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Bulk purchases often lead to discounts, making it advantageous for companies with high consumption rates.

-

Specifications and Customization: Custom formulations or specific sizes can lead to higher costs due to the additional resources required for development and production. Buyers should be clear about their requirements to avoid unnecessary expenses.

-

Material Quality and Certifications: Hot glue sticks that meet industry standards or certifications may be priced higher. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more for their products, but they might also offer better quality and service.

-

Incoterms: The choice of Incoterms can influence the total cost of ownership. Understanding responsibilities for shipping, insurance, and customs can help buyers manage costs more effectively.

What Are Essential Buyer Tips for Cost-Efficiency in Hot Glue Sourcing?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to enhance cost-efficiency when sourcing hot glue.

-

Negotiation: Engage in discussions with suppliers to negotiate better pricing, especially for bulk orders. Highlighting potential for long-term partnerships can yield favorable terms.

-

Total Cost of Ownership (TCO): Evaluate the overall costs associated with purchasing, including shipping, storage, and disposal. A lower upfront price may not always equate to better value if additional costs arise.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and import tariffs that could impact final costs. Understanding the local market dynamics can provide leverage in negotiations.

-

Supplier Diversification: Relying on multiple suppliers can mitigate risks related to pricing and supply chain disruptions. It also provides opportunities for competitive pricing.

-

Trial Orders: Before committing to large orders, consider trial purchases to assess product quality and supplier reliability. This can prevent costly mistakes in larger procurement processes.

In conclusion, understanding the cost structure and pricing influencers in hot glue sourcing is vital for making informed purchasing decisions. By employing strategic negotiation and evaluating total costs, buyers can ensure they receive the best value for their investments.

Illustrative image related to types of hot glue

Alternatives Analysis: Comparing types of hot glue With Other Solutions

Understanding Alternatives to Hot Glue

In the diverse landscape of adhesive technologies, hot glue stands out for its versatility and ease of use. However, depending on specific applications and requirements, there are alternative solutions that may offer better performance, cost-effectiveness, or ease of implementation. This analysis compares different types of hot glue with viable alternatives, helping B2B buyers make informed decisions tailored to their unique needs.

Comparison Table

| Comparison Aspect | Types Of Hot Glue | Polyurethane Adhesives | Epoxy Adhesives |

|---|---|---|---|

| Performance | Quick setting, versatile; ideal for various materials | High strength, excellent flexibility; good for outdoor use | Superior strength and durability; ideal for heavy-duty applications |

| Cost | Generally low to moderate | Moderate to high | High |

| Ease of Implementation | User-friendly, requires minimal equipment | Moderate; requires careful mixing | More complex; requires precise mixing and curing time |

| Maintenance | Minimal; clean-up with solvents | Moderate; ensure proper storage to prevent moisture | Low; once cured, very stable |

| Best Use Case | Crafts, light manufacturing, temporary bonds | Outdoor applications, flexible joints | Structural bonding, high-stress environments |

In-Depth Look at Alternative Solutions

Polyurethane Adhesives

Polyurethane adhesives are a robust alternative to hot glue, particularly suitable for applications that require flexibility and resistance to moisture. They offer excellent bonding strength and are ideal for outdoor projects due to their durability. However, they typically have a higher cost and require careful mixing before application, which can complicate the implementation process. For businesses looking to create long-lasting bonds in varying environmental conditions, polyurethane adhesives are a strong contender.

Epoxy Adhesives

Epoxy adhesives are renowned for their exceptional strength and durability, making them a preferred choice for heavy-duty applications. They provide a strong bond that is resistant to heat, chemicals, and moisture, making them ideal for industries such as automotive and construction. However, epoxy adhesives come with a higher price tag and a more complicated application process, requiring precise mixing and curing time. This can lead to longer lead times in production, which may not be suitable for all businesses.

Making the Right Choice: What Should B2B Buyers Consider?

When deciding between types of hot glue and its alternatives, B2B buyers should evaluate their specific application needs, including performance requirements, budget constraints, and implementation ease. Hot glue is ideal for quick, versatile applications in crafting and light manufacturing, while polyurethane and epoxy adhesives offer superior strength and durability for more demanding environments. Ultimately, the choice will depend on balancing these factors to find the most effective adhesive solution for your business.

Essential Technical Properties and Trade Terminology for types of hot glue

What Are the Key Technical Properties of Hot Glue That B2B Buyers Should Know?

Understanding the technical properties of hot glue is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the composition of the hot glue, which can include thermoplastic elastomers, polyolefins, or other synthetic materials. Different grades are designed for specific applications, such as bonding fabrics or plastics. For B2B buyers, selecting the appropriate material grade ensures compatibility with the substrates being bonded, which can significantly impact product durability and performance.

Illustrative image related to types of hot glue

2. Melting Temperature

The melting temperature indicates the heat required to liquefy the glue for application. Hot glues are typically categorized into low-temperature (around 250°F) and high-temperature (around 380°F) formulations. This specification is critical for B2B buyers because using the wrong melting temperature can lead to substrate damage or insufficient bonding strength. Knowing the melting temperature helps in selecting the right glue for temperature-sensitive applications.

3. Viscosity

Viscosity measures the glue’s thickness and flow characteristics when heated. Low-viscosity hot glues flow easily and are ideal for intricate applications, while high-viscosity options provide thicker bonds. For B2B buyers, understanding viscosity helps determine the glue’s suitability for specific machinery and the desired application method, influencing production efficiency.

4. Set Time

Set time refers to how quickly the glue solidifies after application. Fast-setting glues are advantageous in high-speed manufacturing environments where quick turnaround is essential. Buyers should consider set time when choosing hot glue to optimize their production processes, as it can affect overall throughput and labor costs.

Illustrative image related to types of hot glue

5. Bond Strength

Bond strength indicates the adhesive’s ability to hold materials together under stress. This property is vital for applications where durability and load-bearing capacity are critical. B2B buyers must evaluate bond strength to ensure that the hot glue meets the requirements of their specific applications, reducing the risk of product failure.

What Are Common Trade Terms Related to Hot Glue for B2B Buyers?

Familiarity with industry jargon is essential for effective communication and negotiation in the hot glue market. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the hot glue industry, OEMs often provide customized adhesive solutions tailored to specific applications. Understanding OEM partnerships can help B2B buyers find specialized products that meet their unique needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cash flow. Knowing the MOQ helps companies plan their purchases and avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a formal document requesting price quotes from suppliers. B2B buyers use RFQs to solicit competitive pricing and terms for bulk orders of hot glue. This process aids in budget planning and supplier selection.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding the delivery of goods. They cover aspects like shipping costs, risk, and ownership transfer. For B2B buyers, understanding Incoterms is vital for negotiating contracts and ensuring compliance in international trade.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the hot glue industry, lead times can vary based on manufacturing capabilities and logistics. B2B buyers should consider lead times when planning production schedules to avoid delays.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing hot glue, ensuring they choose the right products for their applications while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the types of hot glue Sector

What Are the Current Market Dynamics and Key Trends in the Hot Glue Sector?

The global hot glue market is currently experiencing significant growth driven by various factors, including increased demand from industries such as packaging, automotive, electronics, and furniture manufacturing. As businesses adapt to rapid technological changes, there is a notable shift towards automation in adhesive application processes, which boosts efficiency and reduces labor costs. Moreover, the rise of e-commerce has amplified the need for reliable packaging solutions, further propelling the hot glue sector’s growth.

Emerging trends include the development of specialty hot glue formulations tailored to specific applications, such as low-temperature adhesives for sensitive materials and high-performance glues for demanding environments. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should stay informed about these trends to ensure they are sourcing the most suitable products for their unique requirements. Additionally, the competitive landscape is evolving, with manufacturers investing in innovative technologies and expanding their product lines to meet the diverse needs of global markets.

Furthermore, the ongoing supply chain disruptions caused by global events necessitate a closer look at sourcing strategies. Buyers are encouraged to diversify their supplier base and consider localized sourcing options to mitigate risks associated with international shipping and trade policies.

Illustrative image related to types of hot glue

How Does Sustainability and Ethical Sourcing Impact the Hot Glue Market?

Sustainability has become a pivotal concern in the hot glue sector, influencing both product development and sourcing practices. Environmental impact assessments are increasingly essential as manufacturers seek to reduce their carbon footprints. Buyers should prioritize suppliers who demonstrate a commitment to eco-friendly practices, such as using biodegradable materials or implementing energy-efficient production processes.

Ethical sourcing is equally important, particularly for international buyers. Establishing transparent supply chains ensures that products are sourced responsibly, minimizing risks related to labor practices and environmental degradation. Certifications such as ISO 14001 (Environmental Management) and Cradle to Cradle can serve as benchmarks for assessing the sustainability of hot glue products.

Moreover, the demand for ‘green’ adhesives is rising, leading manufacturers to invest in the development of eco-friendly hot glue sticks made from renewable resources. B2B buyers are encouraged to inquire about the environmental credentials of their adhesive suppliers, as this not only reflects corporate responsibility but also resonates with increasingly eco-conscious consumers.

Illustrative image related to types of hot glue

What Is the Brief Evolution and History of Hot Glue?

The history of hot glue dates back to the 1940s when the first hot melt adhesives were developed. Initially utilized in packaging and woodworking, these adhesives quickly gained popularity due to their rapid setting times and strong bonding capabilities. Over the decades, advancements in polymer chemistry have led to the formulation of various types of hot glue tailored for diverse applications, including electronics and automotive industries.

The introduction of specialty hot glue sticks, designed for specific substrates and environmental conditions, has further expanded the market. Today, the evolution of hot glue continues with a focus on sustainability and technological integration, marking a transformative era for B2B buyers seeking innovative adhesive solutions. As businesses increasingly prioritize efficiency and environmental responsibility, the hot glue sector is poised for continued growth and innovation in the coming years.

Frequently Asked Questions (FAQs) for B2B Buyers of types of hot glue

-

How do I solve issues with adhesive performance in different climates?

To address adhesive performance challenges in varying climates, it’s essential to select hot glue formulations specifically designed for those conditions. High-temperature hot melts perform well in warm climates, while low-temperature options are suited for cooler environments. Additionally, consider the substrate materials; some formulations bond better with specific materials under particular environmental conditions. Collaborating with suppliers who understand regional climate variations can also provide insights into the best products for your needs. -

What is the best hot glue for bonding fabric and textiles?

For fabric and textile applications, specialty hot glue sticks such as Fabric Stik are highly recommended. These formulations are designed to provide a strong bond without damaging delicate materials. Low-temperature hot glue is also beneficial, as it reduces the risk of burns and minimizes fabric damage. Always test the adhesive on a small sample of the fabric to ensure compatibility and performance before full-scale application. -

How can I ensure the quality of hot glue products from suppliers?

To ensure quality, establish a thorough vetting process for suppliers. Request samples and conduct performance tests to evaluate the adhesive’s effectiveness with your specific materials. Additionally, inquire about the supplier’s quality assurance processes and certifications, such as ISO standards. Regular audits and feedback loops can also help maintain quality over time, ensuring that the adhesives meet your specifications consistently. -

What are the minimum order quantities (MOQ) for hot glue products?

Minimum order quantities can vary widely among suppliers, often ranging from a few boxes to pallets of hot glue sticks. It’s advisable to discuss your requirements directly with the supplier to negotiate favorable terms, especially if you are a smaller business. Some suppliers may offer flexibility on MOQs for first-time buyers or bulk orders, allowing you to test products before committing to larger purchases. -

What payment terms should I expect when sourcing hot glue internationally?

Payment terms vary by supplier and region but typically include options like upfront payment, net 30, or net 60 days. When sourcing internationally, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Discuss payment terms during the negotiation phase to ensure they align with your financial capabilities and cash flow management. -

How can I customize hot glue formulations for specific applications?

Many suppliers offer customization options for hot glue formulations to meet specific application requirements. Engage with the supplier’s technical team to discuss your needs, including bonding strength, temperature resistance, and substrate compatibility. Customization may involve adjusting the adhesive’s composition or adding specific additives. Keep in mind that custom formulations may require minimum order quantities and longer lead times. -

What logistical considerations should I keep in mind when importing hot glue?

When importing hot glue, consider shipping costs, customs duties, and lead times. It’s essential to work with logistics partners experienced in handling adhesives, as they may have specific regulations to comply with. Also, ensure that your suppliers provide the necessary documentation, including safety data sheets (SDS), to facilitate smooth customs clearance. Planning for potential delays and understanding the supply chain dynamics can help mitigate risks. -

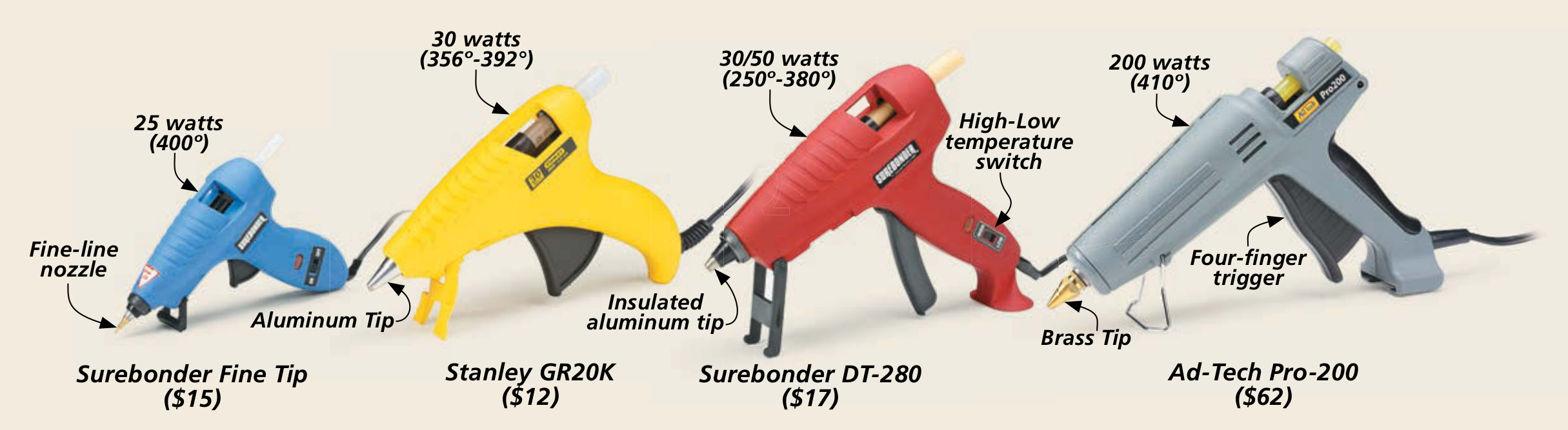

How do I choose the right hot glue gun for my adhesive?

Selecting the appropriate hot glue gun involves matching it to the size and type of glue stick you intend to use. Ensure the gun’s specifications align with the adhesive’s temperature requirements—low-temperature guns for low-temp sticks and vice versa. Consider factors like the gun’s output rate, nozzle size, and ease of use for your specific applications. Consulting with suppliers can provide recommendations based on your production needs and adhesive choices.

Top 3 Types Of Hot Glue Manufacturers & Suppliers List

1. Surebonder – Specialty Hot Glue Sticks

Domain: surebonder.com

Registered: 2000 (25 years)

Introduction: Specialty Hot Glue Sticks from Surebonder are designed for specific materials and applications. Key details include:

– **Types of Glue Sticks**: Fabric Stik, Cool Shot, Wood Stik, Tough Stik, Foam Stik, Jewelry Stik, Cosplay Stik, Glow Stik, Best Stik.

– **Sizes Available**: Full Size (10″), Mini Size (4″).

– **Pack Sizes**: Ranges from 8 to 50 sticks per pack.

– **Formulas**: Includes 925 Acr…

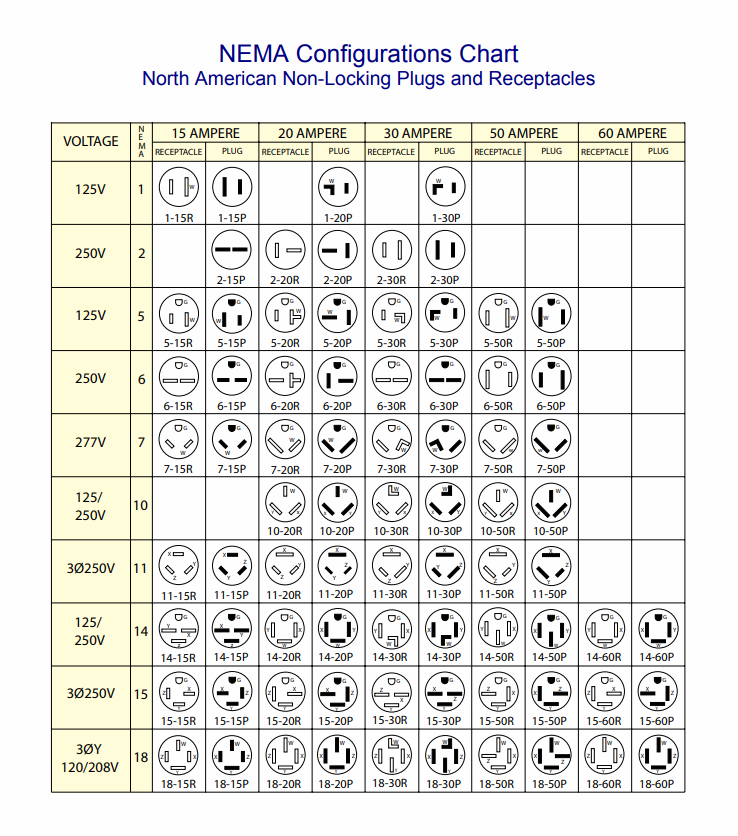

2. Gluegun – Hot Glue Sticks

Domain: gluegun.com

Registered: 1997 (28 years)

Introduction: Hot Glue Sticks available in various sizes and types including 1/2″ (12mm), 5/8″ (15mm), and 1″ x 3″ PG Glue Sticks. Brands include 3M, Infinity Bond, Ad Tech, Surebonder, and Power Adhesives. Applications include construction, hobby & craft, packaging, product assembly, and woodworking. Features include high temperature, low temperature, and variable temperature options. Properties may include bi…

3. Reddit – Hot Glue Strengths and Application Techniques

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Different types of hot glue, including ‘high adhesion’ hot glue versus normal hot glue, have varying strengths. Users suggest that almost all hot glue has similar strength but emphasize the importance of proper application techniques, such as heating the bonding surfaces with a heat gun to enhance adhesion. For stronger bonds, two-part epoxy is recommended. Strength analysis indicates that hot glu…

Strategic Sourcing Conclusion and Outlook for types of hot glue

In today’s competitive landscape, understanding the diverse types of hot glue available is crucial for international B2B buyers. Strategic sourcing not only enables companies to select the right adhesive solutions tailored to their specific applications—be it for electronics, packaging, or woodworking—but also fosters long-term supplier relationships that can enhance operational efficiency and cost-effectiveness. By leveraging specialty hot glue formulations, businesses can improve product quality and streamline production processes, which is particularly beneficial in regions such as Africa, South America, the Middle East, and Europe.

As you navigate the sourcing landscape, consider factors such as temperature requirements, material compatibility, and application methods to ensure optimal performance of your adhesive products. Future trends indicate a growing demand for eco-friendly and high-performance adhesives, highlighting the importance of staying informed about innovations in hot glue technology.

Embrace the opportunity to enhance your sourcing strategy by engaging with reliable suppliers who can offer insights into the latest developments. By investing in quality hot glue solutions, you position your business for success in an ever-evolving marketplace. Take the next step in your sourcing journey and explore the vast array of hot glue options available to meet your unique needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to types of hot glue