Everything You Need to Know About Pvc Extruder Sourcing in 2025

Introduction: Navigating the Global Market for pvc extruder

In today’s rapidly evolving manufacturing landscape, sourcing an efficient PVC extruder is crucial for businesses aiming to enhance production quality and reduce operational costs. The global market for PVC extruders presents a unique set of challenges, particularly for international B2B buyers in regions like Africa, South America, the Middle East, and Europe. With various options ranging from single screw to twin screw extruders, understanding the nuances of each type is essential for making informed decisions that align with specific production needs.

This comprehensive guide delves into the intricacies of the PVC extruder market, exploring the different types of extruders available, their applications across various industries, and the latest technological advancements. Additionally, it offers valuable insights on supplier vetting processes to ensure buyers partner with reliable manufacturers who can meet their quality standards and production demands. Cost considerations are also addressed, providing a clearer understanding of investment potential and long-term value.

Empowered by this guide, B2B buyers will gain the knowledge necessary to navigate the complexities of sourcing PVC extruders effectively. Whether your focus is on enhancing product quality, achieving sustainability goals, or maximizing production efficiency, this resource is designed to support your purchasing decisions in the competitive global market.

Understanding pvc extruder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Screw Extruder | Simple design, low cost, suitable for lower viscosity materials | Pipes, profiles, and simple shapes | Pros: Cost-effective, easy maintenance. Cons: Limited mixing capability. |

| Twin Screw Extruder | Enhanced mixing, higher efficiency, suitable for complex formulations | Compounding, recycling, high-performance applications | Pros: Excellent homogenization, versatility. Cons: Higher initial investment. |

| Co-Extruder | Capable of processing multiple materials simultaneously | Multilayer pipes, profiles, and films | Pros: Cost-effective material use, improved product performance. Cons: Complexity in setup. |

| Planetary Roller Extruder | Unique design for high shear and gentle processing | Calender feeding, coatings, and specialized profiles | Pros: Efficient for specific applications, good for sensitive materials. Cons: Limited to specific tasks. |

| Recycling Extruder | Designed for reprocessing scrap materials | Waste management, recycling of PVC and other plastics | Pros: Supports sustainability, reduces raw material costs. Cons: May require additional maintenance. |

What Are the Key Characteristics of Single Screw Extruders?

Single screw extruders are the most basic type of extrusion machinery, characterized by a single helical screw inside a barrel. They are particularly effective for processing low-viscosity materials such as PVC, making them a popular choice for producing pipes and profiles. B2B buyers should consider their straightforward design and low maintenance costs, which make them an attractive option for companies just starting in plastic processing. However, their limited mixing ability might not be suitable for applications requiring complex formulations.

How Do Twin Screw Extruders Enhance Production Efficiency?

Twin screw extruders feature two intermeshing screws that provide superior mixing and compounding capabilities. This design allows for greater efficiency and is ideal for high-performance applications, including the processing of PVC for specialized products. B2B buyers should note that while the initial investment is higher, the enhanced homogenization and versatility justify the cost for companies focused on producing high-quality materials. Their ability to handle complex formulations makes them a valuable asset for manufacturers looking to innovate.

What Advantages Do Co-Extruders Offer for Multilayer Products?

Co-extruders are designed to process multiple materials simultaneously, allowing manufacturers to create multilayer products that combine the benefits of different polymers. This capability is particularly valuable in producing multilayer pipes and profiles, which can enhance product performance and durability. B2B buyers should consider the cost-effectiveness of material usage and the potential for improved product quality. However, the complexity of setup and operation may require additional training and expertise.

In What Situations Are Planetary Roller Extruders Most Effective?

Planetary roller extruders utilize a unique design that allows for high shear forces while maintaining gentle processing, making them ideal for applications such as calender feeding and coatings. They are particularly suitable for sensitive materials that require careful handling. B2B buyers should evaluate the specific needs of their production processes, as these extruders excel in niche applications but may not be as versatile as other types. Their efficiency in specialized tasks can lead to significant time and cost savings.

How Do Recycling Extruders Support Sustainable Practices?

Recycling extruders are specifically engineered to reprocess scrap materials, making them essential for waste management and sustainability initiatives in the plastics industry. These machines can effectively handle PVC and other plastics, allowing companies to reduce raw material costs and environmental impact. For B2B buyers, investing in recycling extruders can align with corporate social responsibility goals, although they may require additional maintenance and operational adjustments. The long-term savings and sustainability benefits often outweigh these considerations.

Key Industrial Applications of pvc extruder

| Industry/Sector | Specific Application of PVC Extruder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | PVC Pipes and Fittings | Durable, lightweight, and corrosion-resistant solutions for plumbing and drainage systems. | Ensure compatibility with local regulations and standards for plumbing materials. |

| Automotive | Interior Trim and Components | Lightweight, cost-effective parts that improve vehicle efficiency and design. | Focus on precision and customization capabilities to meet automotive specifications. |

| Medical Devices | Medical Tubing and Components | High-quality, sterile products that comply with health regulations. | Look for suppliers with certifications for medical-grade materials and processes. |

| Furniture | PVC Profiles for Furniture Components | Aesthetic, durable solutions that enhance furniture design and longevity. | Evaluate the flexibility and design options available for customization. |

| Packaging | PVC Film and Containers | Versatile, moisture-resistant packaging that preserves product integrity. | Assess the extruder’s ability to produce thin films and the material’s recyclability. |

How is PVC Extruder Used in Construction and What Problems Does It Solve?

In the construction industry, PVC extruders are pivotal in producing pipes and fittings used in plumbing and drainage systems. These extruded products are valued for their durability, lightweight nature, and resistance to corrosion, making them ideal for various environmental conditions. For international buyers, especially from regions with strict building regulations, sourcing PVC extruders that comply with local standards is crucial. This ensures that the materials used in construction meet safety and quality benchmarks, reducing the risk of project delays or compliance issues.

What Role Does PVC Extrusion Play in the Automotive Sector?

In the automotive sector, PVC extruders are employed to manufacture interior trim and components that contribute to vehicle aesthetics and functionality. The lightweight nature of PVC helps improve fuel efficiency while maintaining design flexibility. B2B buyers in this industry should prioritize suppliers that offer precision engineering and customization capabilities, as automotive components often require specific dimensions and material properties to meet rigorous standards. Additionally, sourcing from manufacturers with expertise in automotive-grade materials can ensure compliance with industry regulations.

How Are PVC Extruders Essential in the Medical Device Industry?

PVC extruders play a critical role in producing medical tubing and components that require high levels of sterility and compliance with health regulations. The extruded products must meet stringent quality standards to ensure safety in medical applications. For buyers in the medical sector, it is essential to partner with manufacturers who have the necessary certifications for medical-grade materials and processes. This not only guarantees product quality but also minimizes risks associated with non-compliance in a highly regulated industry.

What Advantages Does PVC Extrusion Offer in Furniture Manufacturing?

In the furniture industry, PVC extruders are used to create profiles and components that enhance both the aesthetic and functional aspects of furniture design. PVC’s versatility allows for various textures and colors, catering to diverse consumer preferences. Buyers should consider the customization options available when sourcing PVC extruders, as the ability to tailor products to specific design requirements can significantly impact market competitiveness. Additionally, durability and ease of maintenance are critical factors that buyers should evaluate when selecting materials for furniture applications.

How Is PVC Extrusion Applied in Packaging Solutions?

PVC extruders are instrumental in producing films and containers for packaging applications, offering moisture resistance and versatility. These properties are crucial for preserving the integrity of packaged goods. B2B buyers looking for packaging solutions should assess the extruder’s capability to produce thin films and consider the recyclability of the materials used. Sourcing from manufacturers who prioritize sustainable practices can also align with growing consumer demand for eco-friendly packaging solutions, providing a competitive edge in the market.

3 Common User Pain Points for ‘pvc extruder’ & Their Solutions

Scenario 1: Inefficient Energy Consumption Leading to High Operational Costs

The Problem: B2B buyers often face escalating energy costs due to inefficient PVC extruders. This issue arises when machinery is outdated or not optimized for energy consumption, leading to excessive electricity usage during production. In regions like Africa and South America, where energy costs can significantly impact overall manufacturing expenses, this becomes a pressing concern. Buyers may find themselves caught in a cycle of high operational costs that erode profit margins, making it difficult to remain competitive in the market.

The Solution: To combat high energy consumption, buyers should prioritize sourcing energy-efficient PVC extruders. Look for models that feature optimized screw geometries and advanced heating technologies, such as induction heating systems. These innovations can significantly reduce energy usage while enhancing output quality. Additionally, conducting a thorough energy audit of existing machinery can help identify inefficiencies. Partnering with manufacturers who offer comprehensive after-sales support and long-term collaboration can ensure continuous improvements in energy efficiency over time.

Scenario 2: Difficulty in Achieving Consistent Product Quality

The Problem: Achieving consistent product quality can be a major hurdle for manufacturers using PVC extruders. Variability in raw material quality, machine settings, and environmental conditions can lead to defects in the final product, such as inconsistent thickness or surface imperfections. This inconsistency not only affects customer satisfaction but can also lead to increased waste and rework, further straining resources.

The Solution: Implementing a robust quality control system is essential. Buyers should invest in extruders equipped with advanced monitoring technologies that provide real-time data on process parameters. This allows for immediate adjustments to be made, ensuring that the extrusion process remains stable and within specified tolerances. Additionally, working closely with raw material suppliers to ensure the quality of PVC resins is crucial. Customizing extruder settings based on specific material characteristics can also help maintain product quality. Regular training for operators on best practices in extrusion can further enhance the consistency of the output.

Scenario 3: Challenges in Adapting to Market Trends and Customization Needs

The Problem: The PVC market is continually evolving, with increasing demand for customized products tailored to specific applications. B2B buyers may struggle to adapt their extrusion processes to meet these changing market needs, particularly if their equipment lacks flexibility or is not designed for rapid changeovers. This can hinder a company’s ability to innovate and respond quickly to customer demands, putting them at a competitive disadvantage.

The Solution: Buyers should seek flexible PVC extruders that allow for quick adjustments in settings and configurations. Investing in modular extruders can facilitate faster changeovers and enable the production of a wider range of products without extensive downtime. Additionally, collaborating with suppliers who offer bespoke solutions can help manufacturers stay ahead of trends. This may involve engaging in co-development projects to create specialized formulations or product designs. Regular market research and feedback loops with customers can also guide adjustments in production capabilities, ensuring that manufacturers remain responsive to market demands.

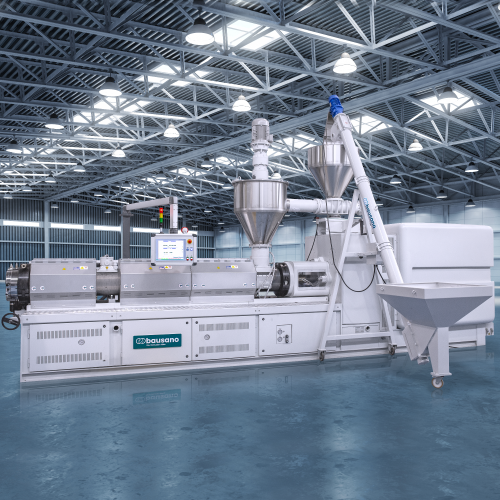

Illustrative image related to pvc extruder

Strategic Material Selection Guide for pvc extruder

What Are the Key Properties of PVC for Extrusion Applications?

Polyvinyl chloride (PVC) is one of the most widely used thermoplastics in the extrusion industry. Its key properties include excellent chemical resistance, durability, and versatility. PVC can withstand temperatures up to 60°C (140°F) without significant degradation, making it suitable for various applications, including pipes and profiles. Additionally, PVC can be modified with plasticizers to enhance flexibility, which is essential for applications requiring bendable materials.

What Are the Advantages and Disadvantages of Using PVC in Extruders?

The advantages of using PVC in extrusion processes are numerous. Its durability and resistance to corrosion make it ideal for long-lasting products. Furthermore, PVC is cost-effective, particularly when produced in bulk, which is a significant consideration for international buyers looking to optimize production costs. However, there are limitations to consider. PVC can be challenging to process due to its tendency to degrade at high temperatures and its sensitivity to environmental conditions. Additionally, the need for additives to achieve desired properties can complicate the manufacturing process.

How Does the Material Selection Impact Application in PVC Extrusion?

The compatibility of PVC with various media is crucial for its application. For instance, in plumbing applications, PVC’s resistance to chemicals and moisture makes it a preferred choice. However, it is essential for manufacturers to ensure that the PVC used meets specific industry standards, such as ASTM or DIN, especially when exporting to regions like Europe or the Middle East. Compliance with these standards not only guarantees product safety but also enhances marketability.

What Are the Specific Considerations for International B2B Buyers in Material Selection?

When selecting materials for PVC extrusion, international buyers should consider local regulations and market preferences. For example, in regions like Africa and South America, there may be a growing demand for sustainable materials, prompting manufacturers to explore recycled PVC options. Additionally, understanding the local standards and certifications can help in avoiding compliance issues that may arise during importation. Buyers should also evaluate the supply chain reliability for sourcing raw materials, as this can significantly affect production timelines.

Illustrative image related to pvc extruder

Summary Table of Material Selection for PVC Extruders

| Material | Typical Use Case for PVC Extruder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Pipes, profiles, and medical devices | Excellent chemical resistance and durability | Processing challenges at high temperatures | Low |

| HDPE (High-Density Polyethylene) | Containers, bottles, and piping | High impact resistance and flexibility | Higher cost compared to PVC | Medium |

| PP (Polypropylene) | Automotive parts and packaging | Good chemical resistance and low density | Less rigid than PVC, potentially limiting use | Medium |

| PET (Polyethylene Terephthalate) | Food packaging and textiles | High clarity and excellent barrier properties | More expensive and less versatile than PVC | High |

This comprehensive analysis provides B2B buyers with essential insights into material selection for PVC extrusion, enabling informed decisions that align with their production needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc extruder

The manufacturing of PVC extruders is a complex process that combines advanced engineering techniques with stringent quality control measures. Understanding these processes is crucial for international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, where the demand for high-performance extrusion machinery is growing. This guide delves into the manufacturing stages, key techniques, and quality assurance protocols that ensure the reliability and efficiency of PVC extruders.

What Are the Main Stages in the Manufacturing Process of PVC Extruders?

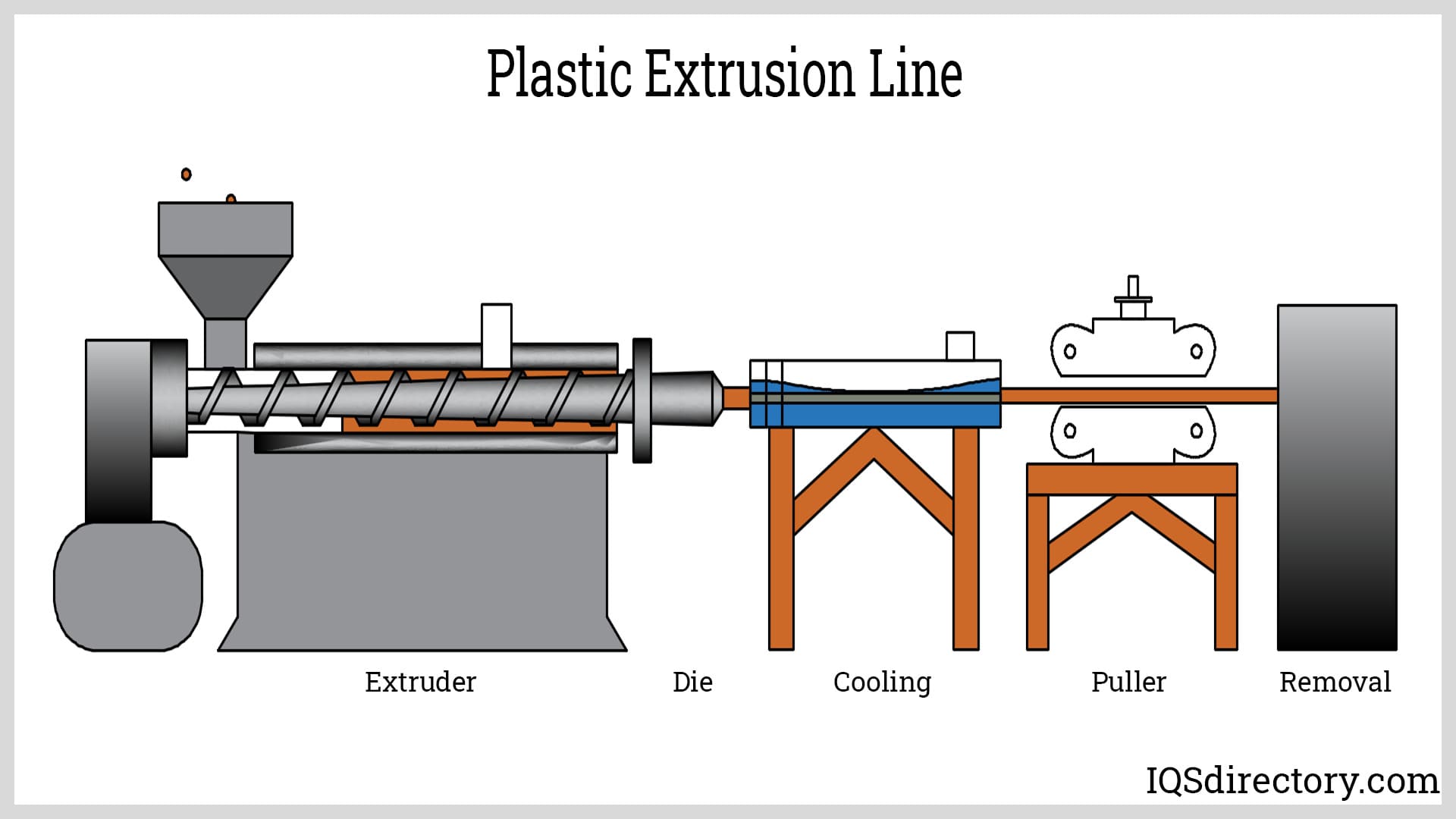

The manufacturing process of PVC extruders typically consists of several main stages: material preparation, forming, assembly, and finishing. Each stage involves specific techniques and quality checks to ensure the final product meets the required specifications.

How Is Material Prepared for PVC Extruders?

Material preparation is the foundational step in the manufacturing process. PVC granules or pellets, along with any necessary additives such as stabilizers or plasticizers, are carefully selected based on the intended application of the extruder. This stage involves:

- Material Sourcing: Selecting high-quality PVC materials from reputable suppliers to ensure consistency and reliability.

- Blending: Mixing PVC with additives to enhance performance characteristics, such as flexibility, UV resistance, or flame retardance.

- Quality Control: Conducting initial quality checks on raw materials to verify compliance with industry standards (e.g., ASTM, ISO).

What Techniques Are Used in the Forming Stage of PVC Extruder Manufacturing?

Once materials are prepared, the next step is the forming stage, which involves shaping the raw materials into the desired components of the extruder. Key techniques include:

- Extrusion Process: The prepared PVC is fed into the extruder, where it is heated and forced through a die to create profiles, pipes, or sheets. The choice of single-screw or twin-screw extruders can significantly affect the material flow and final product quality.

- Cooling and Cutting: After forming, the extruded material is cooled and cut into specified lengths. This step is critical to maintaining dimensional accuracy and surface quality.

How Is the Assembly of PVC Extruders Conducted?

The assembly stage integrates various components of the extruder, including the barrel, screw, and drive system. This stage involves:

- Precision Assembly: Skilled technicians assemble components with a focus on precision and alignment, which is crucial for ensuring optimal performance.

- Integration of Control Systems: Advanced digital control systems are integrated for monitoring temperature, pressure, and speed, enhancing the machine’s operational efficiency.

- Initial Testing: After assembly, initial tests are conducted to ensure all components work harmoniously before the final quality checks.

What Finishing Processes Are Applied to PVC Extruders?

Finishing processes are essential for enhancing the durability and aesthetic appeal of PVC extruders. These processes may include:

- Surface Treatment: Applying coatings or treatments to improve resistance to wear, corrosion, or chemicals.

- Final Quality Checks: Conducting comprehensive inspections to ensure that all specifications are met before the product is shipped.

What Quality Assurance Measures Are Implemented in PVC Extruder Manufacturing?

Quality assurance is a vital aspect of the manufacturing process, ensuring that the final product meets international standards and customer expectations. Key measures include:

Which International Standards Are Relevant for PVC Extruder Quality Control?

International quality standards play a crucial role in the manufacturing and certification of PVC extruders. Some of the most relevant standards include:

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring consistent quality in products and services.

- CE Marking: Required for products sold within the European Economic Area, CE marking indicates compliance with safety and environmental standards.

- API Standards: For extruders used in the oil and gas industries, adherence to API standards ensures reliability and safety.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early. Key checkpoints include:

Illustrative image related to pvc extruder

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect any deviations from quality standards.

- Final Quality Control (FQC): A thorough examination of the finished product before shipment, including performance tests and dimensional checks.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is essential to ensure reliability and performance. Buyers can take several steps:

- Supplier Audits: Conducting on-site audits to assess the manufacturer’s quality management systems and production processes.

- Requesting Quality Reports: Asking suppliers for detailed quality reports and certifications that demonstrate compliance with international standards.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing process and final products, ensuring unbiased assessments.

What Are the Nuances of Quality Control for International B2B Buyers?

Quality control nuances may vary significantly for international buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Key considerations include:

- Cultural Differences: Understanding local business practices and communication styles can enhance collaboration with suppliers.

- Regulatory Compliance: Familiarizing oneself with the specific regulations and standards applicable in the buyer’s region, as these may differ from the manufacturer’s location.

- Logistics and Supply Chain: Considering the logistics of shipping and delivery, which can impact the quality of the extruders due to handling and environmental factors during transit.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when selecting PVC extruders, ensuring they invest in high-quality machinery that meets their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc extruder’

In the competitive landscape of manufacturing, sourcing a high-quality PVC extruder is crucial for optimizing production efficiency and ensuring product quality. This guide provides a structured checklist for B2B buyers to streamline their procurement process, ensuring that all necessary aspects are considered before making a purchase.

Illustrative image related to pvc extruder

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for your PVC extruder is essential. Consider factors such as the type of PVC you will be processing (rigid or flexible), the desired output capacity, and specific features like screw configuration (single or twin-screw). Clearly defined specifications will help narrow down your options and ensure the extruder meets your production needs.

Step 2: Research Market Trends and Technologies

Stay informed about the latest advancements in PVC extrusion technologies. Innovations such as energy-efficient designs and smart control systems can significantly enhance production capabilities and reduce costs. Understanding these trends will empower you to choose a machine that not only meets current demands but is also future-proof.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and case studies to assess their expertise and reliability. Pay special attention to customer testimonials and references, especially from companies in similar industries or regions, to gauge the supplier’s performance and support.

Step 4: Verify Supplier Certifications and Standards

Ensure that your chosen suppliers adhere to relevant industry certifications and standards. Certifications such as ISO 9001 can indicate a commitment to quality management practices. Additionally, check for compliance with safety and environmental regulations, especially if you operate in regions with strict manufacturing guidelines.

Illustrative image related to pvc extruder

Step 5: Assess Customization Options

Customization is key in the extrusion process. Discuss your specific needs with suppliers to understand their capabilities for tailoring machines to your requirements. This could include adjustments to screw designs, barrel configurations, or even the integration of recycling technologies that minimize waste and enhance sustainability.

Step 6: Consider After-Sales Support and Maintenance

Evaluate the after-sales support provided by suppliers. A strong after-sales service can significantly impact your operational efficiency. Inquire about warranty terms, availability of spare parts, and whether the supplier offers training for your staff. A supplier that provides comprehensive support can help minimize downtime and ensure seamless operation.

Step 7: Request Quotes and Compare Pricing

Finally, gather quotes from multiple suppliers to compare pricing and value. Ensure that each quote includes a breakdown of costs associated with the machine, installation, and training. While price is a critical factor, consider the total cost of ownership, including maintenance and energy consumption, to make a well-informed decision.

Illustrative image related to pvc extruder

By following this checklist, B2B buyers can effectively navigate the procurement process for PVC extruders, ensuring they select a machine that aligns with their operational goals and quality standards.

Comprehensive Cost and Pricing Analysis for pvc extruder Sourcing

What Are the Key Cost Components in Sourcing PVC Extruders?

When sourcing PVC extruders, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials, such as steel and specialized alloys for screws and barrels, significantly influences the overall price. Higher-grade materials often lead to better durability and performance but at a premium cost.

-

Labor: Skilled labor is required for both manufacturing and assembly of extruders. Labor costs can vary based on geographic location, with regions like Europe typically experiencing higher wages compared to some parts of Africa or South America.

-

Manufacturing Overhead: This encompasses utilities, maintenance, and depreciation of machinery. Efficient manufacturers often minimize overhead through automation and lean practices, which can be reflected in their pricing.

-

Tooling: Custom tooling for specific applications can add to the initial investment. The complexity of the tooling required will directly affect pricing, with more intricate designs demanding higher costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the extruders meet specified performance standards. This additional step can raise costs but is essential for maintaining product integrity.

-

Logistics: Shipping and handling costs vary significantly based on destination, shipping method, and weight. Import duties and taxes can also impact the final price for international buyers.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. The margin can vary based on the supplier’s market position, reputation, and the competitiveness of the pricing.

What Influences the Price of PVC Extruders?

Several factors influence the pricing of PVC extruders, which B2B buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounts due to economies of scale. Buyers should negotiate volume commitments to achieve better pricing.

-

Specifications and Customization: Custom features or specialized specifications can significantly impact price. Buyers should clearly define their requirements to avoid unexpected costs.

-

Materials Used: The type and quality of materials can greatly affect pricing. For instance, using recycled materials may lower costs but could impact performance.

-

Quality and Certifications: Extruders that meet specific industry standards or certifications may command higher prices. Buyers should assess the necessity of these certifications based on their end-use.

-

Supplier Factors: Supplier reputation, reliability, and location can influence pricing. Established suppliers may charge more for their expertise and service quality.

-

Incoterms: Understanding Incoterms is vital for managing shipping costs and responsibilities. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect total costs.

How Can Buyers Negotiate for Cost-Efficiency in PVC Extruder Sourcing?

International B2B buyers should adopt several strategies to enhance cost-efficiency when sourcing PVC extruders:

-

Conduct a Total Cost of Ownership (TCO) Analysis: Beyond the initial purchase price, consider maintenance, operational efficiency, and potential downtime costs. An extruder that seems expensive initially may offer long-term savings through lower energy consumption and less frequent repairs.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Frequent communication and feedback can foster loyalty, which may translate into discounts or priority service.

-

Explore Alternative Suppliers: Diversifying suppliers across different regions can yield cost benefits. For instance, sourcing from manufacturers in regions with lower labor costs may result in significant savings.

-

Stay Informed About Market Trends: Understanding market dynamics, such as changes in raw material prices or shifts in demand, can help buyers negotiate better terms.

-

Be Prepared to Walk Away: Establishing a clear budget and being willing to explore other options can empower buyers during negotiations. If a supplier cannot meet the desired price or terms, having alternatives can strengthen your position.

Conclusion

In summary, sourcing PVC extruders involves a complex interplay of various cost components and pricing influencers. B2B buyers should approach the procurement process with a strategic mindset, leveraging negotiation tactics and thorough market analysis to achieve the best possible outcomes. Keep in mind that prices can vary widely based on numerous factors, so always request detailed quotes and be prepared for fluctuations in the market.

Alternatives Analysis: Comparing pvc extruder With Other Solutions

Exploring Alternatives to PVC Extruders for Plastic Processing

In the competitive landscape of plastic manufacturing, it is essential for businesses to evaluate various solutions that can meet their production needs. While PVC extruders are widely recognized for their efficiency in processing polyvinyl chloride, alternative technologies can also provide unique advantages. This section compares PVC extruders against other viable methods, namely injection molding and blow molding, to help B2B buyers make informed decisions.

| Comparison Aspect | PVC Extruder | Injection Molding | Blow Molding |

|---|---|---|---|

| Performance | High throughput; ideal for continuous production of uniform profiles | Excellent for complex shapes; high precision | Best for hollow objects; efficient for large runs |

| Cost | Moderate initial investment; lower operational costs over time | Higher initial setup costs; cost-effective for large volumes | Moderate cost; economical for large-scale production |

| Ease of Implementation | Requires specialized setup; training needed for operators | Complex machinery setup; skilled labor necessary | Relatively straightforward; fewer steps than injection molding |

| Maintenance | Regular maintenance required; downtime can be minimized with proper care | Requires specialized knowledge for repairs; can be costly | Generally lower maintenance; less wear and tear on equipment |

| Best Use Case | Ideal for pipes, profiles, and sheets; continuous production | Best for intricate designs and parts requiring tight tolerances | Suitable for bottles, containers, and other hollow products |

Detailed Breakdown of Alternatives

Injection Molding

Injection molding is a manufacturing process that involves injecting molten plastic into a mold to create complex shapes. This method excels in producing parts with high precision and intricate designs. However, the initial setup costs can be significantly higher than those for PVC extruders. Once the molds are made, production runs can be very cost-effective, making it a preferred choice for high-volume production of small to medium-sized parts. The downside includes longer lead times for mold creation and the need for skilled labor to operate and maintain the machinery.

Blow Molding

Blow molding is primarily used for creating hollow plastic products such as bottles and containers. This method involves inflating a heated plastic tube until it conforms to the shape of a mold. Blow molding is efficient for mass production and offers a quicker turnaround time compared to injection molding. The cost of equipment is moderate, and the process is relatively straightforward, making it easier to implement. However, it is limited to hollow products and may not be suitable for all applications, especially where solid shapes are required.

Conclusion: Making the Right Choice for Your Business Needs

When selecting the right technology for plastic processing, B2B buyers must consider factors such as production volume, product complexity, and budget constraints. PVC extruders are ideal for continuous production of profiles and pipes, offering a balance of cost and performance. Conversely, injection molding provides high precision for intricate designs, while blow molding is efficient for hollow objects. By carefully evaluating these alternatives, businesses can align their production methods with their specific requirements, ensuring optimal efficiency and profitability in their operations.

Essential Technical Properties and Trade Terminology for pvc extruder

What Are the Key Technical Properties of PVC Extruders?

Understanding the essential technical specifications of PVC extruders is crucial for B2B buyers looking to optimize their production processes. Here are some critical properties that should be considered:

1. Material Grade

The material grade of the extruder components, such as the screw and barrel, significantly impacts performance and longevity. High-grade materials can withstand higher temperatures and pressures, reducing wear and tear. For instance, using corrosion-resistant materials can enhance durability, particularly for applications involving aggressive chemicals or additives. This is vital for ensuring consistent product quality and minimizing downtime due to maintenance.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of the extruded product. Tight tolerances are essential in applications where precision is critical, such as in medical devices or automotive parts. A high degree of tolerance ensures that the extruded components fit seamlessly into their intended applications, reducing the need for rework and enhancing customer satisfaction.

3. Output Capacity

Output capacity, measured in kilograms per hour (kg/h), indicates the volume of PVC that can be processed by the extruder within a specific timeframe. Higher output capacities can lead to increased efficiency and lower production costs, making it a critical factor for companies looking to scale their operations. Buyers should assess their production needs to select an extruder that aligns with their output requirements.

4. Energy Efficiency

Energy efficiency is becoming increasingly important in the production process due to rising energy costs and environmental concerns. Extruders designed with energy-saving technologies, such as optimized screw geometries and advanced heating systems, can significantly reduce energy consumption. This not only lowers operational costs but also aligns with sustainability goals, making it a key consideration for modern manufacturers.

5. Heating and Cooling Systems

Effective heating and cooling systems are essential for maintaining the desired processing temperatures and ensuring the quality of the final product. Variations in temperature can lead to defects or inconsistencies in the extruded PVC. Advanced temperature control systems enhance process stability and product quality, which is particularly important for high-performance applications.

What Are Common Trade Terms Related to PVC Extruders?

Familiarity with industry jargon is essential for B2B buyers to navigate procurement processes effectively. Here are some common terms you should know:

Illustrative image related to pvc extruder

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of PVC extruders, buyers may deal with OEMs who provide specialized components tailored to specific production needs. Understanding OEM relationships can help buyers ensure they receive high-quality parts that meet their specifications.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a supplier is willing to sell. This term is crucial for buyers, as it affects inventory management and purchasing decisions. Understanding the MOQ can help companies plan their procurement strategy, especially when budgeting for new machinery or components.

3. RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. For PVC extruders, submitting an RFQ allows buyers to receive detailed pricing and specifications from multiple suppliers, facilitating informed decision-making. A well-crafted RFQ can lead to better pricing and quality options.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk, and insurance responsibilities, thereby aiding in clearer negotiations and contracts.

5. Co-Extrusion

Co-extrusion is a process that allows two or more materials to be extruded simultaneously to create products with distinct layers. This technique is especially useful for producing PVC products that require varied physical properties, such as enhanced durability or improved aesthetics. Understanding co-extrusion can aid buyers in selecting the right machinery for specialized applications.

Illustrative image related to pvc extruder

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing PVC extruders, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the pvc extruder Sector

What Are the Current Market Dynamics and Key Trends in the PVC Extruder Sector?

The global PVC extruder market is being driven by several key factors, including the growing demand for PVC products in various industries such as construction, automotive, and packaging. The increasing focus on lightweight materials has further propelled the use of PVC, thanks to its cost-effectiveness, durability, and versatility. In regions like Africa, South America, the Middle East, and Europe, there is a noticeable trend towards modernization and expansion of infrastructure, which boosts the demand for PVC pipes, profiles, and sheets.

Emerging technologies such as Industry 4.0 are influencing sourcing trends, leading to the adoption of smart extruders equipped with advanced monitoring and control systems. These innovations enhance production efficiency and product quality while reducing energy consumption. Additionally, the trend of customization is gaining traction, with manufacturers offering tailored solutions that meet specific client needs, thereby fostering closer supplier-buyer relationships.

International B2B buyers are increasingly leveraging digital platforms to source PVC extruders, making it easier to compare products and suppliers. This shift not only streamlines procurement but also opens avenues for collaboration across borders. As sustainability becomes a pivotal concern, buyers are also prioritizing suppliers who demonstrate a commitment to environmental responsibility, paving the way for a more conscientious market landscape.

How Can Sustainability and Ethical Sourcing Impact the PVC Extruder Sector?

In today’s market, sustainability is not just a trend but a necessity. The PVC extruder sector faces significant scrutiny regarding its environmental impact, particularly concerning the lifecycle of PVC products. Buyers are increasingly aware of the implications of their sourcing decisions and are seeking manufacturers who adhere to ethical supply chain practices. This includes ensuring that raw materials are sourced responsibly and that production processes minimize waste and energy consumption.

A growing number of manufacturers are adopting ‘green’ certifications and materials, such as recycled PVC, to appeal to environmentally conscious buyers. Innovations in recycling technologies, such as the development of recycling extruders, are paving the way for a more sustainable production cycle. By focusing on sustainable sourcing, companies can reduce their carbon footprint while also enhancing their brand reputation among eco-conscious consumers.

For B2B buyers, engaging with suppliers who prioritize sustainability can lead to long-term partnerships that not only fulfill immediate needs but also align with broader corporate social responsibility goals. This alignment is increasingly becoming a critical factor in supplier selection, as companies recognize the value of integrating sustainability into their operations.

How Has the PVC Extruder Sector Evolved Over Time?

The PVC extruder sector has undergone significant evolution since its inception in the mid-20th century. Initially dominated by basic single-screw extruders, the industry has transitioned to more sophisticated technologies, including twin-screw extruders that offer enhanced processing capabilities and efficiency. This evolution has been driven by the increasing complexity of PVC applications and the demand for higher quality products.

Over the decades, advancements in materials science have also played a crucial role in shaping the sector. Innovations in screw design, barrel materials, and processing techniques have allowed manufacturers to optimize production processes, improve product quality, and reduce operational costs. As a result, today’s PVC extruders are not only more efficient but also more adaptable to various applications, from construction materials to consumer goods.

The continuous push towards automation and digitalization further marks the sector’s evolution, as companies strive to meet the demands of a competitive global market. This history of innovation and adaptation positions the PVC extruder sector as a vital component of the broader plastics industry, with a promising future driven by technological advancements and sustainability initiatives.

Frequently Asked Questions (FAQs) for B2B Buyers of pvc extruder

-

How do I select the right PVC extruder for my production needs?

Selecting the appropriate PVC extruder involves evaluating several factors including the type of PVC (rigid or flexible), the desired output capacity, and the specific application (e.g., pipes, profiles, or sheets). Consider the extruder design, such as single or twin-screw configurations, which can influence the material’s processing characteristics. Additionally, assess the supplier’s experience and technological advancements in their machinery, as well as their ability to customize equipment for unique production requirements. -

What are the common applications for PVC extruders in various industries?

PVC extruders are widely utilized in industries such as construction (for pipes and profiles), automotive (for interior components), medical (for tubing), and consumer goods (for packaging). The versatility of PVC allows it to be tailored for both rigid and flexible applications, making it suitable for a range of products from window frames to electrical conduits. Understanding the specific requirements of your industry can help in selecting an extruder that meets those needs efficiently. -

What factors influence the cost of a PVC extruder?

The cost of a PVC extruder varies based on several factors, including the type (single or twin-screw), size, output capacity, and the technology used in its design. Customization options and additional features, such as enhanced energy efficiency and automation capabilities, can also affect pricing. When budgeting, consider not just the initial purchase price, but also long-term operational costs, including energy consumption and maintenance. -

What is the typical lead time for ordering and receiving a PVC extruder?

Lead times for PVC extruders can range from several weeks to a few months, depending on the complexity of the machine and the manufacturer’s production schedule. Custom orders may take longer, particularly if specialized features are requested. It’s advisable to communicate clearly with suppliers about your timeline and any urgency in your production schedule, as this can help them prioritize your order. -

How can I ensure the quality of the PVC extruder I am purchasing?

To ensure quality, conduct thorough due diligence on potential suppliers. Request certifications and quality assurance documentation, such as ISO certifications. Visiting the manufacturer’s facility, if possible, can provide insight into their production processes and equipment. Additionally, seeking references from other customers and reviewing case studies can help assess the supplier’s reliability and product performance. -

What are the typical payment terms for international purchases of PVC extruders?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (often 30-50%) followed by the balance upon completion or prior to shipping. For international transactions, letters of credit or escrow services may be utilized to protect both parties. Always clarify payment terms before placing an order to avoid any misunderstandings that could delay the transaction. -

What logistics considerations should I keep in mind when importing a PVC extruder?

When importing a PVC extruder, consider shipping methods, customs regulations, and any applicable tariffs. Collaborating with a logistics provider experienced in handling industrial machinery can facilitate smoother transportation. Ensure that you have all necessary documentation, such as import permits and customs declarations, to avoid delays at the border. Additionally, factor in the potential for additional costs related to installation and setup upon arrival. -

How can customization of PVC extruders benefit my production process?

Customization allows you to tailor the extruder to specific materials, product shapes, and production speeds that align with your operational goals. This can enhance efficiency, reduce waste, and improve product quality. Many manufacturers offer bespoke solutions, so discussing your unique requirements upfront can lead to a machine that optimally fits your production needs, ultimately resulting in better throughput and profitability.

Top 4 Pvc Extruder Manufacturers & Suppliers List

1. Bausano – Custom Plastic Extruders

Domain: bausano.com

Registered: 2000 (25 years)

Introduction: Bausano offers a range of high-quality custom plastic extruders, including: 1. **Single Screw Extruders** – E-GO series for pipes and profiles, customizable with Digital Extruder Control 4.0. 2. **Twin-Screw Extruders** – MD Nextmover series, known for durability, performance, and energy savings. 3. **Co-Extruders** – Designed for processing various thermoplastics with synchronized drive capacity….

2. Preferred Plastics – Custom PVC Extrusion

Domain: preferredplastics.com

Registered: 2002 (23 years)

Introduction: Preferred Plastics is a leading custom PVC extrusion manufacturer specializing in high-performance extruded PVC components and other extrusion products. They offer a wide range of materials including flexible and rigid PVC, and serve various industries such as automotive, construction, plumbing, marine, furniture, RV, window & door, and agriculture. Common custom PVC extrusion products include tub…

3. KraussMaffei – 36D Series Twin-Screw Extruders

Domain: kraussmaffei.com

Registered: 1996 (29 years)

Introduction: Powerful machine technology, flexible application; Parallel twin-screw extruders of the 36D series designed for PVC processing; Goals: maximum economic efficiency through high output and best product quality; Broad product range with modular concept for economical and high-performance production solutions tailored to pipe extrusion; Low maintenance; Safe degassing; Wide processing spectrum; Increa…

4. Precious Plastic – CE Certified Extruder Machine

Domain: bazar.preciousplastic.com

Registered: 2012 (13 years)

Introduction: Product Name: Plastic Extruder

Categories: Machines, Parts & Kits

Key Products:

1. CE Certified – Extruder Machine – €2,288.00

2. Extruder Basic – €2,650.00

3. Extruder Mini – Hand Cranked KIT – €1,100.00

4. Combo Set (Shredder + Injection + Extruder) – €4,599.00

5. Extrusion Machine Made in the USA – €2,950.00

6. V3 EXTRUDER (COMPACT & ROBUST) – €2,100.00

7. Extruder Machine – €1,699.00

8. 3D Fil…

Strategic Sourcing Conclusion and Outlook for pvc extruder

In today’s competitive landscape, strategic sourcing of PVC extruders is essential for businesses aiming to optimize production efficiency and product quality. By selecting the right extruder technology—whether single-screw, twin-screw, or co-extruders—companies can significantly enhance their manufacturing processes. The emphasis on energy efficiency, customization, and sustainability in extrusion technology further underscores the importance of aligning with innovative suppliers who can meet specific operational needs.

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, the ability to source advanced PVC extruders can lead to substantial cost savings and improved product offerings. Engaging with manufacturers that prioritize technological advancements and after-sales support not only fosters a strong partnership but also ensures long-term operational success.

Looking ahead, the demand for PVC products is expected to grow, driven by diverse applications across industries such as construction, automotive, and healthcare. Now is the time to capitalize on this momentum by partnering with reputable extruder manufacturers. By doing so, businesses can secure a competitive edge and contribute to sustainable development in their respective markets. Explore your options today and position your company for future growth in the PVC extrusion sector.

Illustrative image related to pvc extruder

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.