Single Wall Corrugated Board: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for single wall corrugated board

In the fast-paced realm of global commerce, sourcing single wall corrugated board poses a significant challenge for B2B buyers, particularly those operating in emerging markets across Africa, South America, the Middle East, and Europe. With its versatility and cost-effectiveness, single wall corrugated board is an essential material for packaging, shipping, and product protection. However, navigating the complexities of supplier options, material specifications, and market fluctuations can be daunting. This guide aims to demystify the sourcing process by providing in-depth insights into various types of single wall corrugated board, their applications, and the critical factors to consider when selecting suppliers.

From understanding the different flute types and their specific uses to evaluating cost structures and sustainability practices, this comprehensive resource equips international buyers with the knowledge needed to make informed purchasing decisions. Additionally, we delve into supplier vetting processes, ensuring that you can establish reliable partnerships that align with your business needs. By addressing these key aspects, this guide empowers B2B buyers to streamline their procurement strategies, reduce costs, and enhance operational efficiency. Whether you are in Nigeria, Vietnam, or any other global market, you will find actionable insights tailored to your unique requirements, enabling you to harness the full potential of single wall corrugated board in your operations.

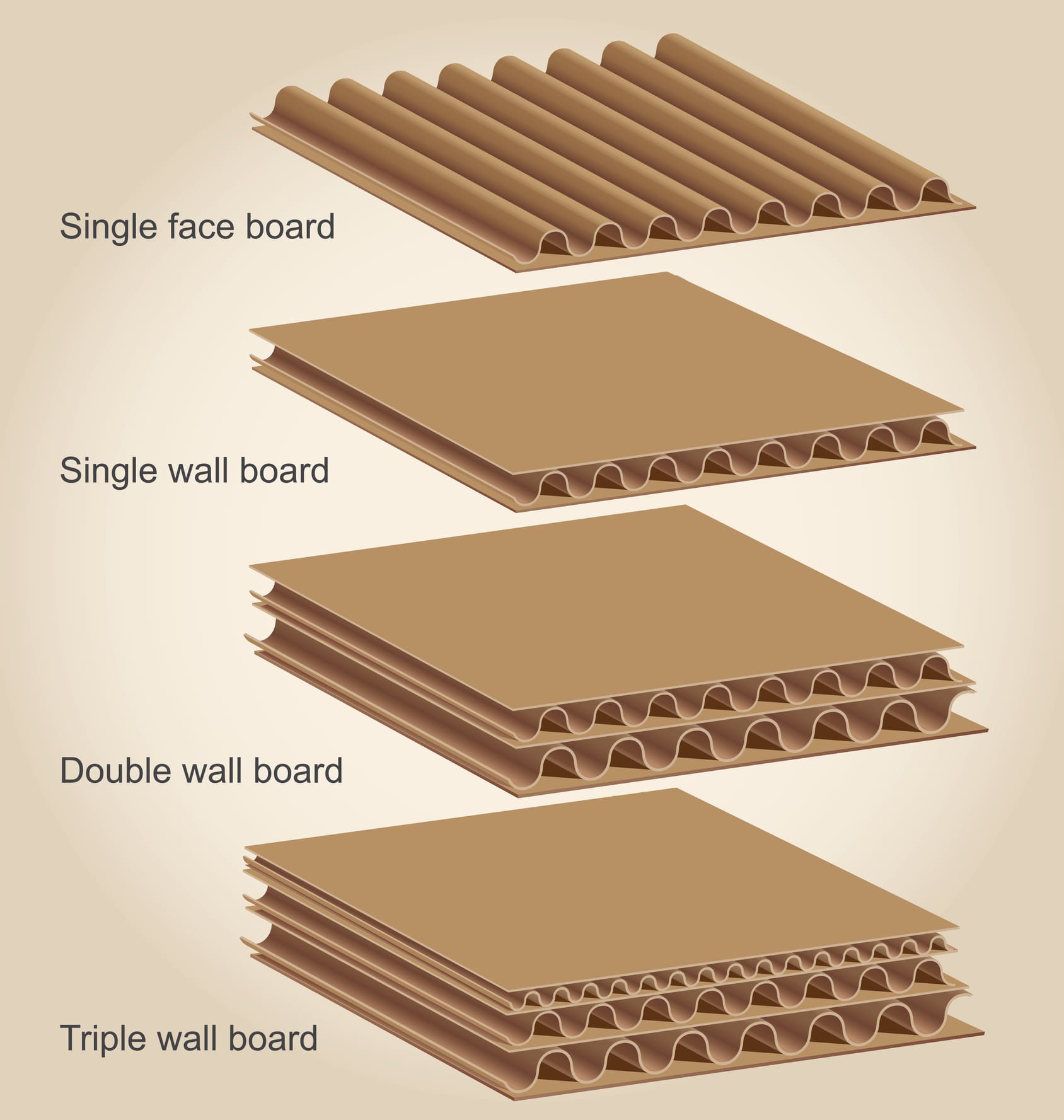

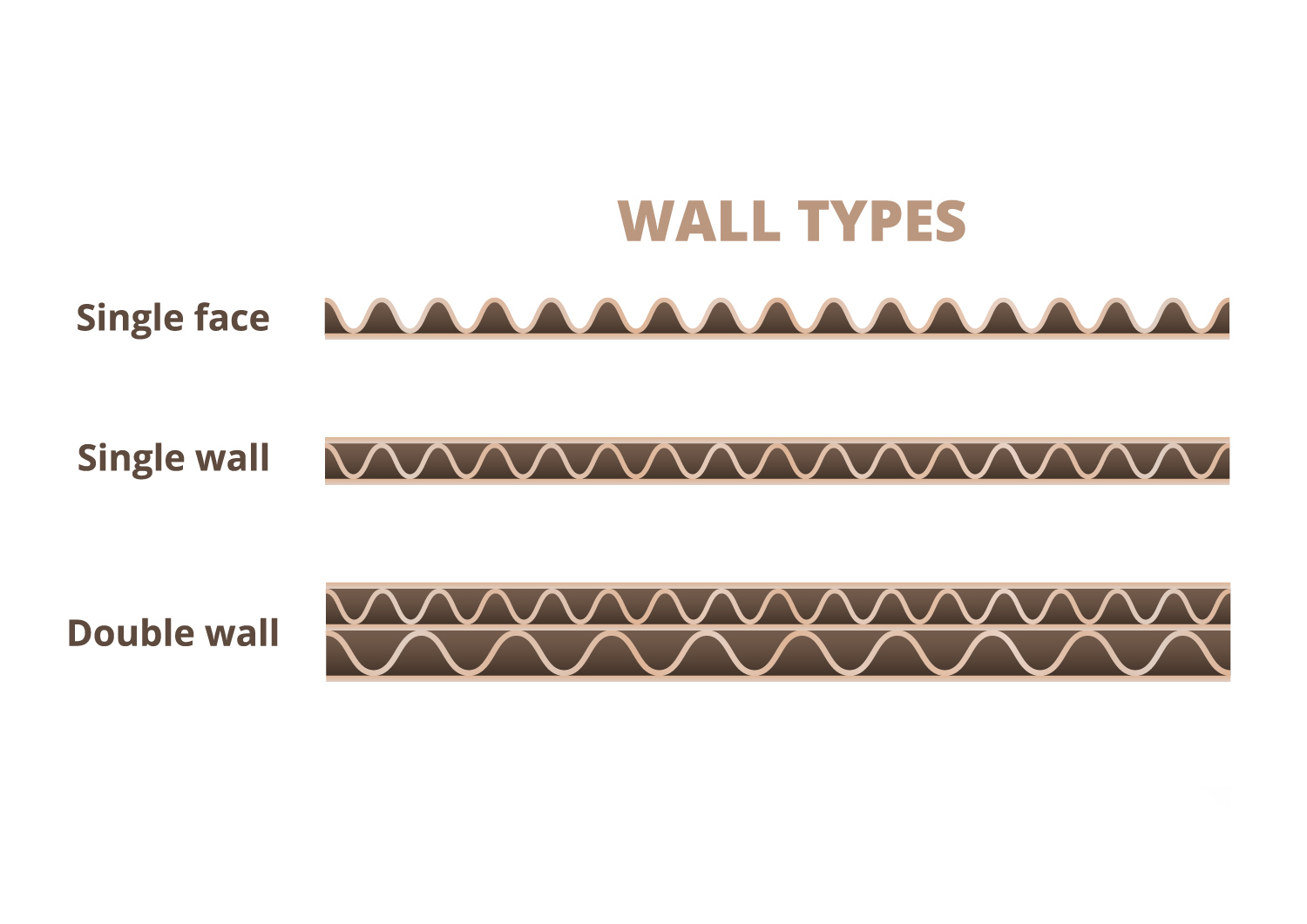

Understanding single wall corrugated board Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| B-Flute | Thinner flutes, smooth surface; lightweight | Retail packaging, display boxes | Pros: Cost-effective, easy to print. Cons: Less strength compared to thicker types. |

| E-Flute | Very thin, compact flutes; excellent printability | High-end packaging, fragile items | Pros: Lightweight, great for detailed graphics. Cons: Limited structural integrity. |

| C-Flute | Balanced thickness; versatile and durable | Shipping, storage, and protective boxes | Pros: Good strength-to-weight ratio. Cons: Heavier than E-flute, may increase shipping costs. |

| Heavy-Duty Single Wall | Enhanced strength; thicker liners | Heavy product shipping, industrial use | Pros: Superior durability, good for heavy loads. Cons: Higher cost, may not be necessary for lighter items. |

| Kraft Corrugated | Made from recycled material; eco-friendly | Sustainable packaging solutions | Pros: Environmentally friendly, cost-effective. Cons: May not provide the same durability as virgin fiber options. |

What are the Key Characteristics of B-Flute Corrugated Board?

B-Flute corrugated board features thinner flutes that create a smooth surface, making it an ideal choice for retail packaging and display boxes. Its lightweight nature allows for cost-effective shipping, and its print-friendly surface enhances branding opportunities. However, B-flute’s reduced thickness may compromise its strength, making it less suitable for heavier items.

How Does E-Flute Corrugated Board Stand Out?

E-Flute is characterized by very thin, compact flutes that provide excellent printability, making it popular for high-end packaging and fragile items. Its lightweight construction reduces shipping costs, but its limited structural integrity may not support heavier products. Buyers should consider the balance between aesthetics and functionality when selecting E-flute.

Why Choose C-Flute Corrugated Board for Versatile Applications?

C-Flute corrugated board offers a balanced thickness that provides versatility and durability, making it suitable for a wide range of applications, including shipping and storage. Its strength-to-weight ratio is favorable, allowing for effective protection of products during transit. However, it is heavier than E-flute, which may slightly increase shipping costs.

What are the Benefits of Heavy-Duty Single Wall Corrugated Board?

Heavy-duty single wall corrugated board is designed with enhanced strength, featuring thicker liners that make it ideal for shipping heavy products and industrial applications. Its superior durability ensures protection during transit, but the higher cost may deter some buyers, especially if they are packaging lighter items. It is essential for businesses to assess their specific needs before opting for this type.

How Does Kraft Corrugated Board Address Sustainability?

Kraft corrugated board is made from recycled materials, positioning it as an eco-friendly option for businesses looking to enhance their sustainability efforts. While it is generally cost-effective, it may not provide the same level of durability as boards made from virgin fibers. Buyers focused on green packaging solutions should weigh the trade-offs between environmental impact and product protection.

Key Industrial Applications of single wall corrugated board

| Industry/Sector | Specific Application of single wall corrugated board | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce & Retail | Packaging for shipping products | Cost-effective protection and branding during transit | Durability, weight capacity, and customization options |

| Food & Beverage | Food packaging and storage solutions | Compliance with safety standards and freshness retention | Food-grade materials, moisture resistance, and recyclability |

| Electronics | Protective packaging for components and devices | Minimizes damage during shipping and handling | ECT ratings, cushioning properties, and size specifications |

| Furniture & Home Goods | Shipping and display packaging for furniture items | Enhances visual appeal and protects against damage | Strength, size customization, and aesthetic options |

| Pharmaceuticals | Packaging for medical supplies and equipment | Ensures product integrity and compliance with regulations | Sterility, strength, and traceability features |

How is Single Wall Corrugated Board Used in E-commerce & Retail Packaging?

In the e-commerce and retail sector, single wall corrugated board serves as a primary packaging material for shipping a wide array of products. This board provides a lightweight yet sturdy solution that protects items during transit while also allowing for branding opportunities through custom printing. For international buyers, particularly from regions like Africa and South America, sourcing options should focus on durability and the ability to handle varying weights, ensuring that products arrive intact and in good condition.

What Role Does Single Wall Corrugated Board Play in Food & Beverage Packaging?

In the food and beverage industry, single wall corrugated board is crucial for packaging and storage solutions that comply with health and safety regulations. It is often used for boxes that transport perishable items, helping maintain freshness and prevent contamination. Buyers must prioritize food-grade materials that are moisture-resistant and recyclable, as sustainability is increasingly important in this sector, particularly in Europe and the Middle East.

How is Single Wall Corrugated Board Beneficial for Electronics Packaging?

Single wall corrugated board is widely utilized for packaging electronic components and devices due to its protective qualities. It minimizes the risk of damage during shipping and handling, which is vital for maintaining product integrity. B2B buyers in this sector should consider the Edge Crush Test (ECT) ratings to ensure the board can withstand the rigors of transport, especially when shipping internationally to markets like Vietnam and Nigeria.

Why is Single Wall Corrugated Board Important for Furniture & Home Goods?

In the furniture and home goods industry, single wall corrugated board is used for both shipping and display packaging. It not only protects items from damage but also enhances their visual appeal on retail floors. Buyers should focus on sourcing options that allow for strength and size customization to accommodate various furniture dimensions, particularly for international shipments that require robust packaging solutions.

How Does Single Wall Corrugated Board Ensure Compliance in Pharmaceuticals?

In the pharmaceutical sector, single wall corrugated board is essential for packaging medical supplies and equipment, ensuring product integrity and compliance with stringent regulations. It provides necessary strength while also being lightweight, making it suitable for various shipping conditions. When sourcing for this application, buyers must emphasize features such as sterility, traceability, and strength to meet regulatory standards, especially in highly regulated markets.

3 Common User Pain Points for ‘single wall corrugated board’ & Their Solutions

Scenario 1: Inconsistent Quality of Single Wall Corrugated Board

The Problem: A common challenge faced by B2B buyers is the inconsistency in the quality of single wall corrugated board. Variations in thickness, strength, and material quality can lead to significant issues such as product damage during shipping or inadequate protection for fragile items. This inconsistency not only affects operational efficiency but can also lead to increased costs due to returns and replacements, ultimately harming customer satisfaction and brand reputation.

The Solution: To mitigate quality inconsistencies, it is essential to establish strong relationships with reputable suppliers who specialize in single wall corrugated board. Begin by conducting a thorough supplier evaluation, focusing on their production processes, quality control measures, and material sourcing. Request samples to assess the board’s performance under various conditions, including weight-bearing tests and moisture resistance. Additionally, implement a quality assurance protocol upon receipt of the products, where each batch is inspected for compliance with your specifications. Regular feedback to suppliers about product performance can also foster improvements and ensure long-term consistency.

Illustrative image related to single wall corrugated board

Scenario 2: Misalignment with Packaging Needs

The Problem: Many B2B buyers encounter challenges when the specifications of single wall corrugated board do not align with their specific packaging needs. This misalignment can stem from inadequate understanding of the product’s properties or miscommunication with suppliers, leading to underperforming packaging solutions that do not adequately protect goods or are not cost-effective for the intended use.

The Solution: A proactive approach to understanding your packaging requirements is crucial. Begin by analyzing the types of products you are shipping and the conditions they will face during transit. Factors such as weight, fragility, and environmental exposure should dictate the choice of corrugated board. Collaborate with packaging engineers or consultants who can provide insights into the appropriate flute type and board grade that best suits your products. Additionally, consider engaging in discussions with suppliers about custom solutions, allowing them to suggest tailored options that meet your specific needs, thus improving overall packaging performance.

Scenario 3: High Costs of Packaging Materials

The Problem: As global supply chains fluctuate, many businesses experience rising costs associated with single wall corrugated board. Price increases can be attributed to raw material shortages, increased shipping costs, and supply chain disruptions. For B2B buyers, this can lead to budget constraints that limit their ability to maintain quality packaging, forcing them to make trade-offs that could compromise product integrity.

The Solution: To combat rising costs, consider implementing a strategic sourcing strategy that emphasizes long-term relationships with multiple suppliers. By diversifying your supplier base, you can negotiate better pricing and terms. Additionally, explore bulk purchasing options or long-term contracts that can lock in favorable rates and mitigate the impact of price fluctuations. Investigate alternative materials or packaging designs that may reduce costs without sacrificing quality. For example, experimenting with different flute sizes or switching to recycled materials can provide cost savings and enhance sustainability. Regularly review your packaging processes for efficiency improvements, such as optimizing box sizes to reduce material use and shipping expenses.

Strategic Material Selection Guide for single wall corrugated board

What Are the Key Materials for Single Wall Corrugated Board?

When selecting materials for single wall corrugated board, it is essential to understand the properties, advantages, and limitations of each option. Below are analyses of three common materials used in this application: Kraft paper, Virgin fiber, and Recycled paper. Each material has distinct characteristics that influence its performance and suitability for various applications.

How Does Kraft Paper Perform in Single Wall Corrugated Board?

Kraft paper is a widely used material in the production of single wall corrugated board. Its key properties include high tensile strength and durability, making it suitable for packaging applications that require resistance to tearing and puncturing. Kraft paper also has good moisture resistance, which is beneficial for products exposed to varying environmental conditions.

Pros: The primary advantage of Kraft paper is its strength-to-weight ratio, allowing for lightweight packaging that does not compromise durability. It is also relatively cost-effective, making it a popular choice for bulk orders.

Cons: However, Kraft paper can be less resistant to moisture compared to other materials, which may limit its application in humid environments. Additionally, its brown color may not meet aesthetic requirements for certain consumer-facing products.

For international buyers, particularly in regions like Africa and South America, compliance with local packaging regulations and standards (such as ASTM D5118 for shipping containers) is crucial. Kraft paper is generally accepted in most markets, but buyers should confirm specific requirements.

What Are the Advantages of Virgin Fiber in Corrugated Board?

Virgin fiber, derived from newly harvested wood pulp, offers exceptional strength and rigidity. This material is often used in applications requiring high structural integrity, such as heavy-duty packaging or protective containers for fragile items.

Pros: The key advantage of virgin fiber is its superior durability, which provides excellent protection during shipping and handling. It also has a clean, professional appearance that is suitable for high-end products.

Cons: The primary disadvantage is the higher cost associated with virgin fiber, as it is more expensive to produce than recycled alternatives. Additionally, sourcing virgin fiber raises sustainability concerns, particularly for environmentally conscious buyers.

Illustrative image related to single wall corrugated board

For B2B buyers in Europe and the Middle East, adherence to sustainability certifications (such as FSC or PEFC) may be critical. Virgin fiber products may need to meet specific environmental regulations, which can vary by country.

How Does Recycled Paper Compare in Terms of Performance?

Recycled paper is an increasingly popular choice for single wall corrugated board due to its environmental benefits and cost-effectiveness. The key properties of recycled paper include adequate strength and a lower environmental footprint.

Pros: The main advantage of recycled paper is its reduced cost, making it an economical option for businesses looking to minimize expenses. Additionally, using recycled materials can enhance a company’s sustainability profile, appealing to eco-conscious consumers.

Cons: However, recycled paper typically has lower tensile strength compared to virgin fiber, which may limit its use in heavy-duty applications. It can also exhibit variability in quality, depending on the source of the recycled material.

International buyers should be aware of the varying standards for recycled materials across regions. For instance, compliance with EN 13430 in Europe ensures that packaging meets recyclability criteria, which is essential for market acceptance.

Summary Table of Material Selection for Single Wall Corrugated Board

| Material | Typical Use Case for single wall corrugated board | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Kraft Paper | General packaging, shipping boxes | High strength-to-weight ratio | Lower moisture resistance | Medium |

| Virgin Fiber | Heavy-duty packaging, protective containers | Superior durability and professional look | Higher cost and sustainability concerns | High |

| Recycled Paper | Eco-friendly packaging, general shipping | Cost-effective and environmentally friendly | Lower strength and quality variability | Low |

This guide provides a comprehensive overview of the materials used in single wall corrugated board, enabling B2B buyers to make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for single wall corrugated board

What Are the Key Stages in the Manufacturing Process of Single Wall Corrugated Board?

The manufacturing of single wall corrugated board involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is vital for ensuring the quality and durability of the final product.

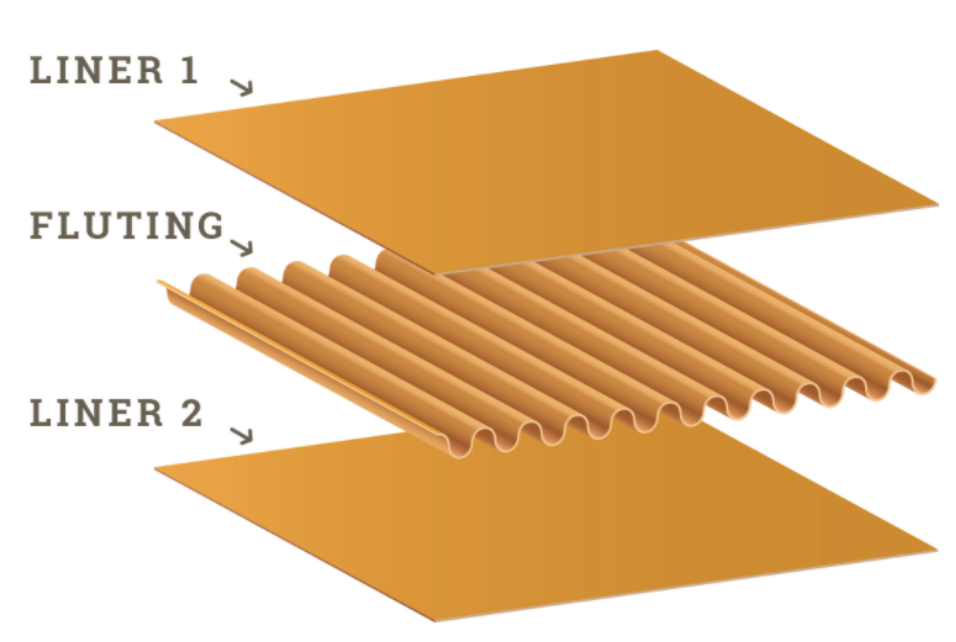

-

Material Preparation

The process begins with the selection of high-quality raw materials, typically comprising linerboard and medium. Linerboards are flat sheets that provide the outer layers, while the medium is a fluted layer that provides structural strength. Manufacturers often use virgin fibers for optimal performance, especially in applications requiring durability, such as packaging for fragile items. -

Forming

In this stage, the medium is passed through a corrugator, where it is heated and shaped into flutes. The fluting process involves pressing the medium between two flat plates to create the characteristic wave-like structure. This step is critical because the strength of the corrugated board depends on the flute’s geometry. -

Assembly

After forming, the fluted medium is sandwiched between two layers of linerboard. This assembly is adhered using a starch-based adhesive, which is eco-friendly and provides strong bonding. The assembly line often utilizes high-speed machinery to ensure efficiency, with automated systems that align and press the layers together. -

Finishing

The final stage includes cutting the assembled sheets to the required dimensions, applying any necessary coatings or treatments, and preparing the product for shipment. Quality control measures are often implemented at this stage to ensure that the board meets specifications.

How Is Quality Assurance Integrated Into the Manufacturing of Single Wall Corrugated Board?

Quality assurance (QA) is a crucial component of the manufacturing process for single wall corrugated board. This ensures that the products not only meet but exceed industry standards.

-

International and Industry-Specific Standards

Compliance with international standards, such as ISO 9001, is fundamental in the manufacturing process. This standard ensures that manufacturers have a quality management system in place that is effective and customer-focused. Additionally, industry-specific certifications such as CE marking in Europe or API standards in specific sectors provide further assurance of quality. -

Quality Control Checkpoints

Quality control is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the specified criteria. For instance, the quality of linerboard and medium is assessed for thickness, strength, and other attributes.

-

In-Process Quality Control (IPQC): During the manufacturing stages, continuous monitoring is conducted. This includes measuring the adhesive application, checking flute formation, and verifying the alignment of layers.

-

Final Quality Control (FQC): After assembly and finishing, the final product undergoes rigorous testing. This includes physical tests for strength, durability, and flexibility, as well as visual inspections for defects.

What Common Testing Methods Are Used to Ensure Quality in Single Wall Corrugated Board Production?

Several testing methods are employed to validate the quality of single wall corrugated board:

-

Bursting Strength Test: This test measures the board’s resistance to bursting under pressure, which is crucial for packaging applications.

-

Edge Crush Test (ECT): This evaluates the stacking strength of corrugated board by measuring how much weight it can bear before collapsing. It is essential for determining how the board will perform during shipping and storage.

-

Flat Crush Test (FCT): This assesses the flat compression strength of the board, which helps understand how the board will hold up under load.

-

Moisture Content Testing: Excessive moisture can weaken the integrity of the board, so manufacturers routinely check moisture levels to ensure they remain within acceptable limits.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to ensure the quality of their corrugated board suppliers should adopt several strategies:

-

Supplier Audits: Conducting on-site audits of suppliers is an effective way to assess their manufacturing processes and quality control measures. This can include reviewing production lines, quality control documentation, and compliance with industry standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their quality management systems. These reports should include results from various tests, compliance certificates, and any corrective actions taken for non-conformance.

-

Third-Party Inspections: Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These inspections typically cover raw material quality, manufacturing processes, and final product evaluations.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital:

-

Regulatory Compliance: Different regions have distinct regulatory requirements that may affect quality standards. Buyers should be familiar with local regulations and ensure that their suppliers comply with them.

-

Cultural Differences in Quality Standards: Expectations regarding quality can vary by region. Buyers must communicate their specific quality requirements clearly and ensure that suppliers understand and can meet these expectations.

-

Logistics and Shipping Considerations: Quality control does not end at production. Buyers should consider how products will be stored and transported, as environmental factors can impact the integrity of corrugated board.

By understanding the manufacturing processes and implementing robust quality assurance measures, B2B buyers can secure high-quality single wall corrugated board that meets their specific needs and withstands the rigors of international trade.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘single wall corrugated board’

Introduction

This practical sourcing guide serves as a comprehensive checklist for international B2B buyers seeking to procure single wall corrugated board. By following these steps, you can ensure that you select the best materials for your packaging needs, aligning quality with cost-effectiveness while also considering sustainability and supplier reliability.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your single wall corrugated board. Consider factors such as thickness, flute type, and strength ratings, which are critical for ensuring the board meets your packaging needs.

– Thickness: Generally, single wall boards range from 3mm to 5mm in thickness. Determine the optimal thickness based on the weight and fragility of your products.

– Flute Type: Different flute profiles (e.g., A-flute, B-flute) provide varying levels of cushioning and stacking strength. Choose based on the nature of the items you will be packaging.

Step 2: Identify Your Sustainability Goals

Incorporate sustainability into your sourcing strategy. Many buyers now prioritize eco-friendly materials, and opting for recyclable or biodegradable options can enhance your brand’s reputation.

– Material Source: Look for suppliers that use recycled content or sustainably sourced virgin fibers.

– Certifications: Check for certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification), which indicate responsible forestry practices.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to thoroughly vet potential suppliers. This not only safeguards your investment but also ensures you partner with reliable companies that can meet your demands.

– Company Profiles: Request detailed company profiles and product catalogs that showcase their offerings.

– References: Seek testimonials or case studies from other businesses within your industry to gauge the supplier’s reliability and service quality.

Illustrative image related to single wall corrugated board

Step 4: Request Samples

Always request samples before placing a bulk order. Testing samples in your actual packaging operations can reveal important insights about performance and compatibility.

– Performance Testing: Assess the sample boards for durability, weight capacity, and resistance to environmental factors such as moisture.

– Visual Inspection: Examine the quality of the printing and finishes, which can affect the overall presentation of your products.

Step 5: Compare Pricing Structures

Gather quotes from multiple suppliers to compare pricing structures effectively. Understanding the cost implications will help you make informed decisions that align with your budget.

– Bulk Discounts: Inquire about bulk pricing options, as many suppliers offer discounts for larger orders.

– Shipping Costs: Factor in shipping costs, which can significantly impact the total expenditure, especially for international deliveries.

Step 6: Verify Supplier Certifications

Ensure that your chosen supplier adheres to industry standards by verifying their certifications. This step is crucial for maintaining quality and compliance with regulations.

– Quality Standards: Look for certifications such as ISO 9001, which indicates a commitment to quality management systems.

– Environmental Compliance: Ensure the supplier meets local and international environmental regulations, particularly if you operate in regions with strict guidelines.

Step 7: Establish Clear Communication Channels

Finally, establish clear communication channels with your supplier. Effective communication is vital for resolving issues quickly and ensuring your needs are met throughout the procurement process.

– Contact Points: Designate specific contacts for order management, quality assurance, and logistics.

– Feedback Mechanism: Implement a feedback system to address any concerns and improve future orders based on performance evaluations.

By following this checklist, B2B buyers can navigate the complexities of sourcing single wall corrugated board with confidence, ensuring they select the best products for their packaging needs.

Comprehensive Cost and Pricing Analysis for single wall corrugated board Sourcing

What Are the Key Cost Components for Sourcing Single Wall Corrugated Board?

When considering the sourcing of single wall corrugated board, it is essential to understand the various cost components that contribute to the overall price. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The primary cost driver is the raw material used in production. High-quality virgin fibers, such as those used in acid-free boards, can be more expensive than recycled alternatives. The choice between different grades and specifications, such as ECT (Edge Crush Test) ratings, also significantly influences material costs.

-

Labor: Labor costs can vary widely based on location and manufacturing processes. In regions with higher labor costs, such as parts of Europe, these expenses can represent a larger share of total costs. Conversely, countries with lower labor costs may provide opportunities for savings.

-

Manufacturing Overhead: This includes expenses related to the factory operations, such as utilities, maintenance, and equipment depreciation. Efficient production processes can minimize overhead costs, impacting the final price.

-

Tooling: Custom tooling for unique box designs or sizes can lead to initial setup costs. However, once established, these costs can be amortized over larger production runs, making bulk orders more cost-effective.

-

Quality Control: Ensuring the quality of corrugated board through rigorous QC processes incurs additional costs. Buyers should consider the certifications and quality standards required for their specific applications, as higher standards can lead to increased pricing.

-

Logistics: Shipping costs, including freight and handling, are critical to consider, especially for international buyers. Factors such as distance, shipping method, and local tariffs can significantly affect the overall cost.

-

Margin: Suppliers will add a margin to cover their costs and ensure profitability. This margin can vary based on competition and the perceived value of the product.

How Do Price Influencers Affect the Cost of Single Wall Corrugated Board?

Several factors can influence the pricing of single wall corrugated board, including volume, specifications, materials, and supplier factors.

-

Volume/MOQ: Purchasing in larger volumes often leads to cost savings due to economies of scale. Suppliers may offer discounts for bulk orders, making it advantageous for buyers to consolidate their purchasing.

-

Specifications and Customization: Custom sizes, strengths, and finishes can lead to higher prices. Buyers should balance the need for customization with the benefits of standard products.

-

Quality and Certifications: Higher quality materials and certifications (e.g., eco-friendly or food-safe standards) may incur additional costs. Buyers should evaluate the necessity of these certifications based on their end-use requirements.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers with a history of quality may charge a premium, while newer or less-known suppliers may offer lower prices but with higher risk.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears the cost of shipping, insurance, and tariffs. This can significantly influence the total landed cost for international buyers.

What Tips Can Help Buyers Negotiate Better Prices for Single Wall Corrugated Board?

To achieve cost-efficiency when sourcing single wall corrugated board, buyers should consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing structures, potential discounts for bulk purchases, and flexibility on specifications. Building a rapport can lead to more favorable terms.

-

Total Cost of Ownership: Assess the total cost, including shipping, handling, and any potential waste or damage. This broader perspective can help identify the most cost-effective options.

-

Pricing Nuances for International Buyers: Buyers in Africa, South America, the Middle East, and Europe should be aware of local market conditions and the impact of currency fluctuations on pricing. Additionally, understanding regional demand can provide leverage in negotiations.

-

Long-Term Relationships: Cultivating long-term relationships with suppliers can lead to better pricing and service, as suppliers may be more willing to accommodate loyal customers.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult multiple suppliers to obtain accurate and competitive pricing tailored to your needs.

Alternatives Analysis: Comparing single wall corrugated board With Other Solutions

When evaluating packaging solutions, particularly for shipping and storage, it’s essential to consider alternatives to single wall corrugated board. While single wall corrugated board is widely utilized due to its balance of strength, weight, and cost, other options may better suit specific needs or applications. This section compares single wall corrugated board with two viable alternatives: rigid boxes and flexible packaging.

| Comparison Aspect | Single Wall Corrugated Board | Rigid Boxes | Flexible Packaging |

|---|---|---|---|

| Performance | Good protection for light to medium-weight items | Excellent protection; ideal for heavy items | Moderate protection; best for lightweight products |

| Cost | Cost-effective for bulk orders | Higher initial investment | Generally lower cost, especially for high-volume orders |

| Ease of Implementation | Easy to assemble and customize | Requires more space for storage and shipping | Simple to store, often pre-formed or rollable |

| Maintenance | Minimal maintenance required | Durable but can be bulky | Requires careful handling to avoid punctures |

| Best Use Case | Ideal for general shipping and storage | Best for high-value or fragile items | Suitable for food products and items requiring a seal |

What Are the Advantages and Disadvantages of Rigid Boxes Compared to Single Wall Corrugated Board?

Rigid boxes are constructed from thicker paperboard, providing superior strength and protection for high-value or fragile items. They are often used in luxury packaging, electronics, or high-end retail products. The primary advantage of rigid boxes is their sturdiness, which can significantly reduce the risk of damage during transit. However, they typically come with a higher cost and require more storage space, which could be a drawback for businesses focused on cost efficiency and space optimization.

How Does Flexible Packaging Compare to Single Wall Corrugated Board?

Flexible packaging, which includes materials like plastic films or pouches, is another alternative that offers unique benefits. This type of packaging is lightweight and can be produced in various sizes and shapes, making it versatile for different products, especially food items. Its lower cost for high-volume orders makes it appealing for businesses looking to reduce packaging expenses. However, flexible packaging may not provide the same level of protection as corrugated options, making it less suitable for fragile items. Additionally, it often requires careful handling to prevent punctures or tears.

Conclusion: How Can B2B Buyers Choose the Right Packaging Solution for Their Needs?

Choosing the right packaging solution involves assessing multiple factors, including the nature of the product, shipping conditions, and budget constraints. For general shipping needs, single wall corrugated board is often sufficient, offering a good balance of cost and protection. Rigid boxes may be the best option for high-value items requiring extra protection, while flexible packaging is ideal for lightweight products or those needing a sealed environment. By evaluating the specific requirements of their operations and considering the pros and cons of each option, B2B buyers can make informed decisions that enhance their packaging strategy and overall efficiency.

Essential Technical Properties and Trade Terminology for single wall corrugated board

What Are the Key Technical Properties of Single Wall Corrugated Board?

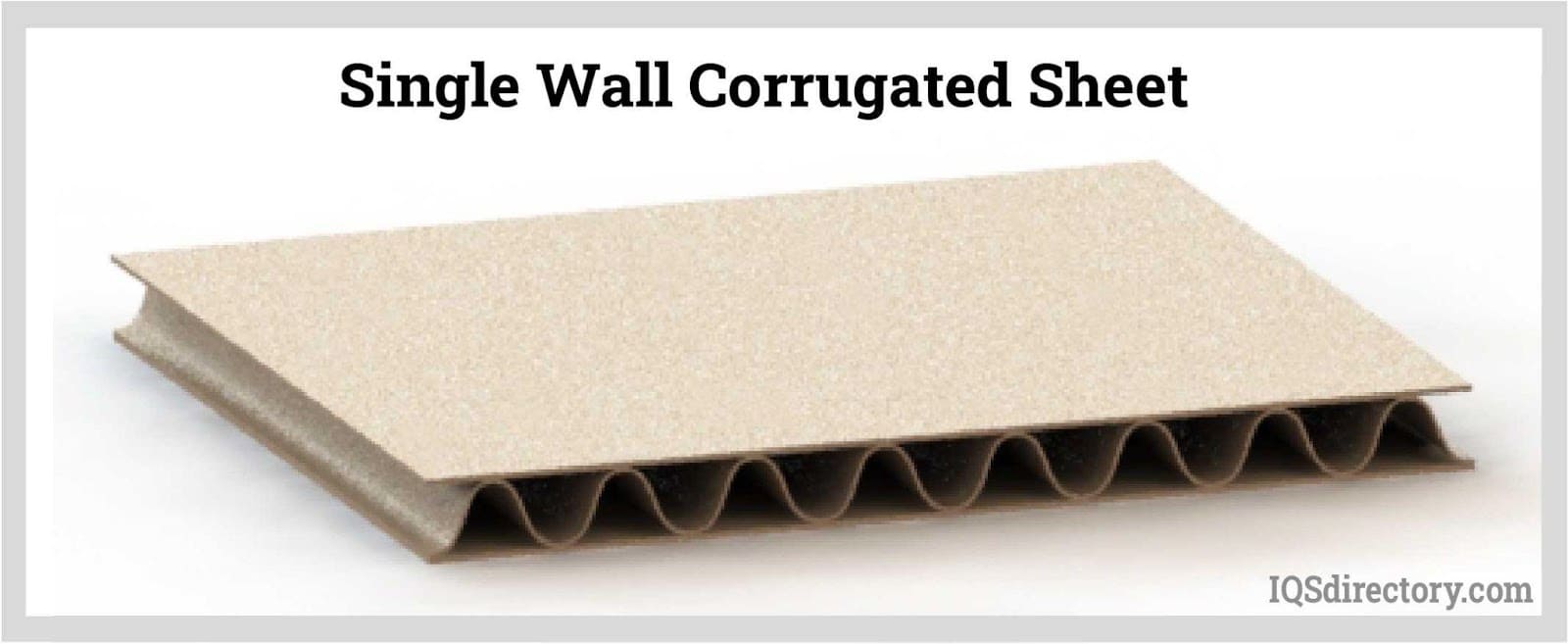

Single wall corrugated board is a widely used packaging material, known for its strength, lightweight nature, and versatility. Understanding its essential technical properties can help B2B buyers make informed decisions.

1. Material Grade

The material grade refers to the quality of the paper used in the production of the corrugated board. Commonly, grades like ECT (Edge Crush Test) and GSM (Grams per Square Meter) are used to determine strength and durability. For instance, a board with a higher ECT rating can withstand more weight, making it suitable for heavier products. B2B buyers should consider the material grade to ensure the packaging meets their specific requirements.

2. Flute Profile

Flute profiles, such as A, B, C, and E, define the thickness and spacing of the corrugated layers. Each profile offers different cushioning and stacking strength properties. For example, B-flute provides a balance between cushioning and structural integrity, making it ideal for shipping fragile items. Understanding flute profiles allows buyers to select the right board for their products.

3. Thickness

The thickness of single wall corrugated board typically ranges from 3/16″ to 1/4″. A thicker board generally offers more strength and better protection against impacts and compression during transport. Buyers should assess the thickness based on their product’s weight and fragility to avoid damage during shipping.

4. Weight Capacity

Weight capacity is crucial for determining how much load a corrugated box can safely carry without compromising its structure. This is often defined by the board’s ECT rating. A higher weight capacity ensures that the packaging can handle the demands of shipping and storage, reducing the risk of product damage.

5. Recyclability

With increasing emphasis on sustainability, the recyclability of packaging materials is a significant consideration. Single wall corrugated boards are typically made from recyclable materials, which can enhance a company’s eco-friendly profile. Buyers should prioritize suppliers that provide recyclable options to meet customer expectations and regulatory requirements.

6. Moisture Resistance

Moisture resistance is essential, especially for products sensitive to humidity or wet conditions. Some single wall corrugated boards come with treatments that enhance their moisture resistance. Understanding this property helps buyers select appropriate packaging for products that may encounter wet environments during transport or storage.

What Are Common Trade Terms Related to Single Wall Corrugated Board?

In the corrugated packaging industry, several trade terms are commonly used. Familiarizing yourself with these terms can enhance communication and streamline purchasing processes.

Illustrative image related to single wall corrugated board

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of corrugated board, an OEM might create custom packaging solutions tailored for specific products. Understanding OEM relationships can help buyers find specialized packaging solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost. Knowing the MOQ can help businesses plan their purchasing strategies and avoid overstocking.

3. RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on specific products or services. This process allows buyers to compare pricing, terms, and delivery options among different suppliers. Utilizing RFQs can lead to better pricing and terms for corrugated board purchases.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, particularly regarding shipping and delivery. Familiarity with these terms helps buyers understand shipping costs, insurance, and liability. This knowledge is essential for effective negotiation and contract management.

5. ECT (Edge Crush Test)

The Edge Crush Test measures the strength of corrugated board when subjected to pressure along its edge. This rating is critical for determining how much weight a box can support during stacking and shipping. Buyers should look for ECT ratings that match their shipping and storage needs.

6. GSM (Grams per Square Meter)

GSM measures the weight of the paper used in the board and is an indicator of quality and durability. A higher GSM typically implies a stronger board, which is essential for protecting products during transit. Understanding GSM helps buyers choose the appropriate packaging material for their specific applications.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding single wall corrugated board, ensuring they select the most suitable options for their packaging needs.

Navigating Market Dynamics and Sourcing Trends in the single wall corrugated board Sector

What Are the Current Market Dynamics for Single Wall Corrugated Board?

The single wall corrugated board sector is experiencing significant growth, driven by a surge in e-commerce and the increasing demand for sustainable packaging solutions. As global supply chains adapt to shifting consumer preferences, international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are looking for reliable sources of corrugated materials that balance cost-effectiveness and performance. Key trends include the integration of advanced technologies, such as automation in production and digital printing, which enhance customization options and reduce lead times.

Moreover, the rise of digital platforms for sourcing and procurement is changing how businesses interact with suppliers. Buyers are increasingly utilizing online marketplaces to streamline their purchasing processes, allowing for quick comparisons of prices and product specifications. In addition, the demand for heavier-duty single wall options, such as those with higher ECT ratings, is on the rise as companies seek to minimize damage during shipping and handling.

How Is Sustainability Influencing the Sourcing of Single Wall Corrugated Board?

Sustainability has become a cornerstone of the sourcing strategy for many B2B buyers. The environmental impact of packaging materials is under scrutiny, prompting buyers to seek out suppliers who prioritize ethical sourcing and offer eco-friendly products. Single wall corrugated boards made from recycled materials or those certified by recognized environmental standards, such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification), are increasingly favored.

Ethical supply chains are not just a trend; they are becoming a necessity as companies align their operations with global sustainability goals. Buyers are encouraged to evaluate the entire lifecycle of the corrugated board, from sourcing raw materials to production processes and end-of-life disposal. This focus on sustainability not only enhances brand reputation but also meets the growing consumer demand for responsible packaging solutions.

Illustrative image related to single wall corrugated board

What Has Been the Evolution of Single Wall Corrugated Board in the B2B Sector?

The evolution of single wall corrugated board has been marked by advancements in manufacturing processes and materials. Initially, corrugated board was primarily used for basic packaging needs; however, its applications have expanded significantly due to its lightweight yet robust nature. Over the years, innovations such as improved flute designs and the incorporation of moisture-resistant coatings have increased the board’s durability and versatility.

In recent years, the push towards sustainability has also influenced its evolution, with manufacturers increasingly using recycled materials and developing biodegradable options. This evolution is essential for B2B buyers who are not only looking for cost-effective solutions but also for products that align with their environmental commitments. As the market continues to evolve, keeping abreast of these changes will be crucial for businesses aiming to maintain a competitive edge in the packaging landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of single wall corrugated board

-

How do I ensure the quality of single wall corrugated board from suppliers?

To ensure quality, start by vetting suppliers through their certifications, such as ISO standards, which indicate adherence to quality management systems. Request samples to assess the board’s strength, thickness, and suitability for your specific application. Additionally, inquire about their quality control processes and ask for references from other businesses that have sourced from them. Establishing a solid communication channel can also help in addressing any concerns promptly. -

What is the best thickness of single wall corrugated board for shipping products?

The best thickness depends on the weight and fragility of your products. Generally, a thickness of 0.125 inches (approximately ECT-32) is suitable for lightweight items, while heavier or fragile products may require thicker boards for added protection. Always consider your product’s shipping distance and handling conditions; consulting with your supplier about specific requirements can help in selecting the appropriate thickness. -

What customization options are available for single wall corrugated board?

Customization options include various sizes, colors, and printing capabilities. Many suppliers offer tailored solutions such as die-cut shapes, branded printing, and moisture-resistant coatings. When discussing customization, consider your branding needs and whether the packaging will be used for retail display. Be sure to communicate your specific requirements early in the sourcing process to ensure compatibility with production timelines. -

What are the minimum order quantities (MOQ) for single wall corrugated board?

Minimum order quantities can vary significantly among suppliers, often ranging from 100 to 1,000 units or more, depending on the type of customization and board specifications. It’s essential to clarify MOQs during your initial discussions with suppliers. If you’re a smaller business, inquire about the possibility of ordering smaller batches or joining forces with other companies to meet MOQ requirements. -

What payment terms should I expect when sourcing single wall corrugated board internationally?

Payment terms typically include options like upfront payment, net 30, or letter of credit, depending on the supplier’s policies and your negotiation. For international orders, it’s common to use secure payment methods such as PayPal or escrow services to protect both parties. Discussing payment terms upfront can help prevent misunderstandings and ensure a smooth transaction process. -

How can I effectively manage logistics for international shipping of single wall corrugated board?

Effective logistics management involves selecting a reliable freight forwarder experienced in handling packaging materials. Consider factors such as shipping costs, delivery times, and customs regulations in your target regions. Collaborate closely with your supplier to ensure that the product is packaged appropriately for transit and that all necessary documentation is prepared in advance to avoid delays at customs. -

What are the environmental considerations when sourcing single wall corrugated board?

Sustainability is increasingly important in packaging. Look for suppliers who use recycled materials and offer recyclable or biodegradable options. Verify whether the boards are produced using environmentally friendly practices. Additionally, inquire about certifications like FSC (Forest Stewardship Council) that ensure responsible sourcing of materials, which can enhance your brand’s eco-friendly image. -

How do I handle unexpected price increases when sourcing single wall corrugated board?

To manage unexpected price increases, maintain open communication with your supplier about market trends and potential cost fluctuations. Consider establishing long-term contracts that lock in prices for a set period. Additionally, diversifying your supplier base can mitigate risks; this allows you to quickly switch suppliers if one increases prices significantly, ensuring you remain competitive in your market.

Top 4 Single Wall Corrugated Board Manufacturers & Suppliers List

1. Brown Packaging – Corrugated Board Solutions

Domain: brownpackaging.com

Registered: 1999 (26 years)

Introduction: Understanding Corrugated Board: Single Wall, Double Wall, Triple Wall. Key products include: Regular Slotted Containers (RSC), Half Slotted Containers (HSC), Full Overlap (FOL) Boxes, Custom Corrugated Mailers, Corrugated Tuck End Boxes, Corrugated Trays, Custom Corrugated Folders, Telescopic Corrugated Boxes, Corrugated Bin Boxes, Custom Gaylord Containers, Subscription Boxes, Bike Shipping Boxes…

2. Cable Ties and More – Single Wall Corrugated Sheets

Domain: cabletiesandmore.com

Registered: 2006 (19 years)

Introduction: This company, Cable Ties and More – Single Wall Corrugated Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Rocket Industrial – 48 x 96 Single Wall Corrugated Sheets

Domain: rocketindustrial.com

Registered: 2014 (11 years)

Introduction: 48″ x 96″ Single Wall Corrugated Sheets – 250 Pack

4. The Packaging Company – Heavy Duty Corrugated Boxes

Domain: thepackagingcompany.us

Registered: 2016 (9 years)

Introduction: Single Wall Heavy Duty Boxes | Corrugated Shipping Boxes | Available Sizes: 6x6x6″, 8x8x8″, 10x8x6″, 11 1/4×8 3/4×10″, 12x6x6″, 12x10x6″, 12x10x8″, 12x12x6″, 14x12x10″, 16x12x8″, 16x12x12″, 18x18x12″, 20x16x14″, 24x12x12″, 24x18x12″, 24x18x18″ | ECT Rating: 44 | Price Range: $0.86 – $5.67

Strategic Sourcing Conclusion and Outlook for single wall corrugated board

In today’s dynamic market, effective strategic sourcing of single wall corrugated board is paramount for businesses aiming to optimize their packaging solutions. By understanding the diverse grades and specifications of corrugated board, B2B buyers can select materials that not only meet their product protection needs but also align with sustainability goals. The lightweight yet robust nature of single wall corrugated board makes it an ideal choice for various applications, from shipping to storage, enhancing operational efficiency while minimizing costs.

Establishing strong relationships with reliable suppliers is essential for navigating fluctuations in material costs and ensuring consistent quality. By leveraging consumer feedback and prioritizing innovative designs, businesses can further enhance their packaging strategies, leading to increased customer satisfaction and loyalty.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe should remain proactive in sourcing high-quality single wall corrugated board. By adopting a strategic approach, companies can not only secure competitive pricing but also foster sustainable practices that resonate with today’s environmentally-conscious consumers. Now is the time to evaluate your sourcing strategies and embrace the opportunities presented by single wall corrugated board to drive growth and success in your packaging solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.