Top 4 Vertical Lift Conveyor Systems Suppliers (And How to Choose)

Introduction: Navigating the Global Market for vertical lift conveyor systems

In the fast-paced global market, sourcing vertical lift conveyor systems poses a significant challenge for B2B buyers looking to optimize material handling solutions. As industries evolve, the need for efficient, safe, and cost-effective vertical lifting solutions becomes paramount. This comprehensive guide aims to demystify the complexities of vertical lift conveyor systems, covering various types—from hydraulic to mechanical systems—and their diverse applications across sectors such as manufacturing, distribution, and warehousing.

International buyers, particularly from Africa, South America, the Middle East, and Europe, will find invaluable insights into supplier vetting processes, cost considerations, and compliance with regional safety standards. By understanding the nuances of vertical lift systems, decision-makers can make informed choices that align with their operational needs and budget constraints.

This guide empowers businesses to navigate the intricacies of sourcing vertical lift conveyor systems, ensuring they select solutions that enhance productivity while adhering to safety regulations. With expert analysis and practical advice, readers will be equipped to tackle their toughest material handling challenges effectively, driving efficiency and growth in their operations.

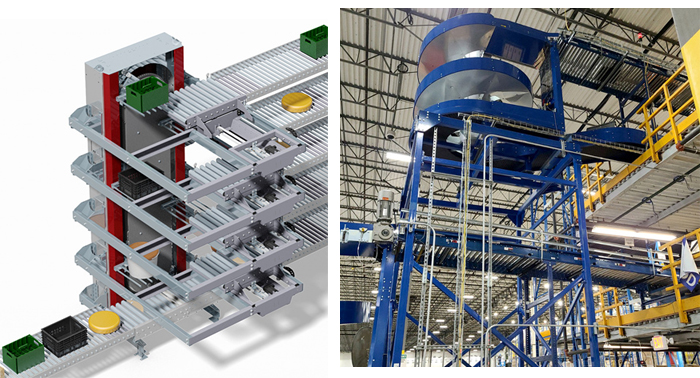

Understanding vertical lift conveyor systems Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical VRC | High load capacity, continuous cycle use, customizable sizes | Warehouses, manufacturing, heavy machinery handling | Pros: High efficiency, suitable for large loads. Cons: Higher initial cost. |

| Hydraulic VRC | Affordable, compact design, stable level movement | Two-level lifting, smaller facilities | Pros: Cost-effective, space-saving. Cons: Limited load capacity compared to mechanical. |

| Automated Vertical Lift | Integrated with conveyor systems, high-speed operation | Automated warehouses, distribution centers | Pros: Maximizes efficiency, reduces labor costs. Cons: Higher complexity, potentially higher maintenance. |

| Box Lift | Small package handling, compact size | E-commerce fulfillment centers, retail environments | Pros: Ideal for small loads, minimal footprint. Cons: Limited to lighter loads. |

| Custom VRC Solutions | Tailored designs for specific needs | Specialized industrial applications | Pros: Fully meets unique requirements. Cons: Longer lead times, potential higher costs. |

What Are the Characteristics of Mechanical Vertical Reciprocating Conveyors (VRCs)?

Mechanical VRCs are engineered for high load capacities, making them ideal for applications that require the movement of heavy materials or machinery. They operate continuously, allowing for efficient material handling in environments such as warehouses and manufacturing facilities. Buyers should consider factors like the expected load sizes, frequency of use, and available space, as these systems can require a more significant initial investment but offer substantial long-term efficiency.

How Do Hydraulic Vertical Reciprocating Conveyors Compare?

Hydraulic VRCs are characterized by their affordability and compact design. They provide a stable lifting solution, particularly for two-level applications. Their design is well-suited for smaller facilities where space is a premium. Buyers should evaluate their load requirements and consider that while hydraulic lifts are cost-effective, they may not handle as heavy loads as mechanical systems, which could impact operational efficiency in high-demand environments.

What Are the Advantages of Automated Vertical Lifts?

Automated vertical lifts integrate seamlessly with existing conveyor systems, providing high-speed operation for efficient material handling in automated warehouses and distribution centers. These systems significantly reduce the need for manual labor, leading to lower operational costs over time. However, businesses must weigh the benefits of increased efficiency against the complexity and potential maintenance requirements associated with automated systems.

In What Scenarios Are Box Lifts Most Effective?

Box lifts are designed specifically for handling small packages, making them an excellent choice for e-commerce fulfillment centers and retail environments. Their compact size allows for minimal space usage, which is a significant advantage in facilities with limited room. Buyers should note that while box lifts excel in handling lighter loads, they are not suitable for heavier materials, which could limit their application scope in certain businesses.

Why Consider Custom VRC Solutions?

Custom vertical reciprocating conveyors are tailored to meet specific operational needs, making them suitable for specialized industrial applications. These systems can be designed to handle unique load sizes and configurations, ensuring optimal performance. However, buyers should be prepared for longer lead times and potentially higher costs associated with custom designs, but the investment can pay off in enhanced operational efficiency and safety tailored to their specific requirements.

Key Industrial Applications of vertical lift conveyor systems

| Industry/Sector | Specific Application of vertical lift conveyor systems | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Lifting heavy machinery and components between floors | Increases operational efficiency and worker safety | Load capacity, speed, and customization options for specific needs |

| Warehousing & Logistics | Moving pallets and packages between storage levels | Optimizes space utilization and reduces manual labor | Footprint size, installation requirements, and safety features |

| Food Processing | Transporting bulk ingredients and finished products | Enhances hygiene and compliance with safety standards | Material compatibility, ease of cleaning, and regulatory compliance |

| Automotive | Handling vehicle parts in assembly lines | Streamlines production processes and minimizes downtime | Custom configurations, load capacity, and integration with existing systems |

| Pharmaceuticals | Vertical transport of sensitive drugs and materials | Ensures safe handling and meets strict regulatory standards | Compliance with industry regulations and specialized safety features |

How Are Vertical Lift Conveyor Systems Used in Manufacturing?

In the manufacturing sector, vertical lift conveyor systems are crucial for lifting heavy machinery and components between different floor levels. These systems address the challenge of moving bulky materials safely, reducing the risk of workplace injuries associated with manual handling. Buyers in this sector should prioritize load capacity and speed, ensuring the lift can handle specific operational demands, especially in high-cycle environments. Customization options are also important to fit unique manufacturing layouts.

What Role Do Vertical Lift Conveyor Systems Play in Warehousing & Logistics?

In warehousing and logistics, vertical lift conveyor systems facilitate the efficient movement of pallets and packages between storage levels. This application optimizes space utilization, allowing for more effective inventory management and reducing the reliance on manual labor, which can be costly and inefficient. International buyers should consider the footprint size and installation requirements, as well as safety features that comply with local regulations, particularly in regions with stringent safety standards.

How Are Vertical Lift Conveyor Systems Beneficial in Food Processing?

In the food processing industry, vertical lift conveyor systems are used to transport bulk ingredients and finished products, ensuring a hygienic and efficient workflow. These systems help meet safety standards and regulatory requirements, crucial for maintaining product quality. Buyers should focus on material compatibility and ease of cleaning to ensure compliance with health regulations. Additionally, features that enhance safety and minimize contamination risks are essential for food industry applications.

What Advantages Do Vertical Lift Conveyor Systems Offer in Automotive Applications?

The automotive industry utilizes vertical lift conveyor systems to handle vehicle parts efficiently within assembly lines. These systems streamline production processes by allowing quick access to components, which minimizes downtime and increases overall productivity. When sourcing for this application, businesses should consider custom configurations that fit existing assembly lines, as well as the load capacity required to support heavy automotive parts.

How Are Vertical Lift Conveyor Systems Used in Pharmaceuticals?

In the pharmaceutical sector, vertical lift conveyor systems are essential for the safe transport of sensitive drugs and materials. This application addresses the need for stringent handling protocols and compliance with industry regulations. Buyers should ensure that the systems they source are equipped with specialized safety features and comply with relevant regulatory standards, particularly in regions like Europe and the Middle East, where such regulations are strictly enforced.

Illustrative image related to vertical lift conveyor systems

3 Common User Pain Points for ‘vertical lift conveyor systems’ & Their Solutions

Scenario 1: Inefficient Material Handling Leading to Delays

The Problem: In many manufacturing and distribution facilities, time is of the essence. A common challenge faced by B2B buyers is the inefficiency of moving materials between different levels of operation. Traditional methods, such as forklifts or manual lifting, can lead to delays, increased labor costs, and potential safety hazards. This inefficiency not only impacts workflow but can also result in missed deadlines and unhappy customers.

The Solution: To address this issue, buyers should consider investing in customized vertical lift conveyor systems that are designed to meet specific operational needs. When sourcing a VRC, it’s crucial to assess the load capacity, height requirements, and frequency of use. For instance, mechanical VRCs are ideal for high-speed applications where multiple pallets or heavy machinery need to be moved efficiently. Collaborating with an experienced supplier can ensure that the chosen system integrates seamlessly into existing workflows, reducing bottlenecks and enhancing overall productivity. Furthermore, implementing automated systems can further streamline operations, allowing for continuous material flow without the need for manual intervention.

Scenario 2: Safety Concerns with Material Lifting

The Problem: Safety is a paramount concern in any industrial setting. B2B buyers often face the challenge of ensuring that their employees are not exposed to unnecessary risks when moving heavy materials. Traditional lifting methods, such as forklifts, can lead to accidents, injuries, and costly downtime, which may also result in regulatory penalties.

The Solution: To mitigate these safety risks, investing in vertical lift conveyor systems that adhere to stringent safety standards is essential. Buyers should prioritize systems that come with advanced safety features, such as the DeckLock Safety System or explosion-proof components. It’s also advisable to choose VRCs that comply with local and international safety codes, like the ASME B20.1. During the purchasing process, B2B buyers should engage with vendors who provide comprehensive training for operators and maintenance staff. This training should focus on safe operating procedures, routine maintenance checks, and emergency protocols to ensure that the equipment is used properly, minimizing the risk of accidents and injuries.

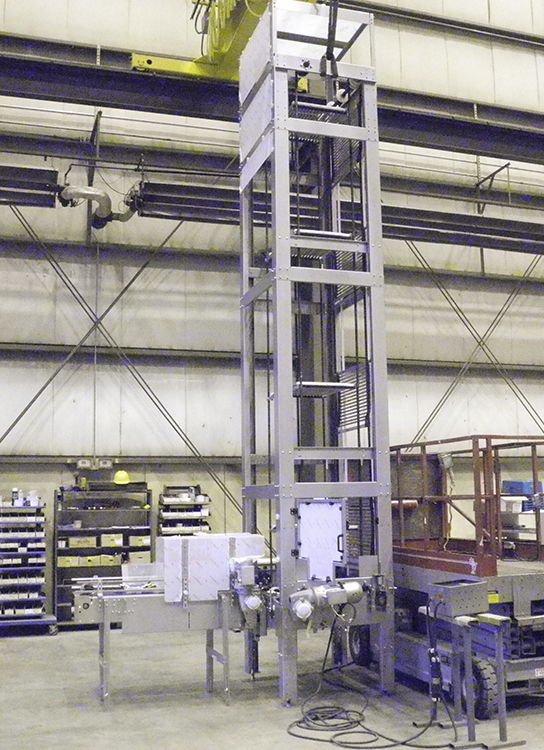

Scenario 3: Limited Space for Material Handling Solutions

The Problem: Many facilities, especially in urban areas, are constrained by limited space, making it difficult to implement traditional material handling solutions. B2B buyers may struggle with maximizing vertical space while ensuring efficient material movement between floors. This challenge can hinder operational efficiency and limit growth potential.

Illustrative image related to vertical lift conveyor systems

The Solution: To effectively utilize limited space, buyers should explore compact and customizable vertical lift conveyor systems. Hydraulic VRCs, for instance, are often more space-efficient than mechanical options, allowing for installation in tight areas without sacrificing performance. Buyers should work with suppliers who can provide tailored solutions that fit specific spatial constraints, including configurations that utilize existing shafts or can be integrated into new constructions. Additionally, conducting a thorough space analysis prior to installation can help identify the best locations for vertical lifts, ensuring that they enhance rather than obstruct workflow. By strategically planning the layout of the facility with vertical lifts in mind, companies can optimize their operations and make the most of their available space.

Strategic Material Selection Guide for vertical lift conveyor systems

What Materials Are Commonly Used in Vertical Lift Conveyor Systems?

When selecting materials for vertical lift conveyor systems, it’s essential to consider properties that affect performance, durability, and overall cost. Here, we analyze four common materials used in these systems: steel, aluminum, stainless steel, and composite materials.

How Does Steel Perform in Vertical Lift Conveyor Systems?

Steel is a widely used material in vertical lift conveyor systems due to its strength and durability. It typically has a high tensile strength, making it suitable for heavy loads and high-cycle applications. Steel can withstand significant pressure and is often treated to resist corrosion, although it may require additional coatings for enhanced protection in harsh environments.

Pros: Steel’s primary advantage is its robustness, allowing it to handle heavy loads without deforming. It is also relatively cost-effective compared to other materials, making it a popular choice for budget-conscious projects.

Cons: The main downside is its susceptibility to corrosion if not properly treated, which can lead to increased maintenance costs. Additionally, steel structures can be heavier, impacting installation and transportation logistics.

Illustrative image related to vertical lift conveyor systems

Impact on Application: Steel is ideal for environments where heavy loads are common, such as manufacturing and distribution facilities. However, buyers must ensure compliance with relevant standards, such as ASTM A36 for structural steel.

What Are the Benefits of Using Aluminum in Vertical Lift Conveyor Systems?

Aluminum is known for its lightweight properties and corrosion resistance, making it an attractive option for vertical lift conveyor systems. It is easier to handle and install due to its lower weight, which can reduce labor costs during installation.

Pros: The primary advantage of aluminum is its excellent corrosion resistance, especially in humid or corrosive environments. It also offers a good strength-to-weight ratio, making it suitable for applications where weight savings are crucial.

Cons: Aluminum is generally more expensive than steel and may not be suitable for extremely heavy loads. Its lower tensile strength means it may require additional support or reinforcement in certain applications.

Impact on Application: Aluminum is particularly beneficial in industries such as food processing or pharmaceuticals, where hygiene and corrosion resistance are paramount. International buyers should be aware of compliance with standards like ASTM B221 for aluminum extrusions.

Why Choose Stainless Steel for Vertical Lift Conveyor Systems?

Stainless steel offers exceptional corrosion resistance and is often used in environments where hygiene is critical, such as food and beverage processing. It maintains its strength and integrity even at high temperatures, making it suitable for a variety of applications.

Pros: The key advantage of stainless steel is its durability and resistance to corrosion, which minimizes maintenance costs over time. It also provides a clean aesthetic, which is important in industries where appearance matters.

Illustrative image related to vertical lift conveyor systems

Cons: The primary limitation is its higher cost compared to carbon steel and aluminum. Additionally, stainless steel can be more challenging to fabricate, which may lead to increased manufacturing complexity.

Impact on Application: Stainless steel is ideal for applications requiring high hygiene standards, such as in the food, pharmaceutical, and chemical industries. Buyers in regions with stringent regulations, such as Europe, should ensure compliance with standards like EN 10088 for stainless steel.

What Role Do Composite Materials Play in Vertical Lift Conveyor Systems?

Composite materials, often made from a combination of plastics and fibers, are increasingly being used in vertical lift conveyor systems. They offer unique properties such as lightweight, corrosion resistance, and flexibility in design.

Pros: Composites are lightweight and can be engineered for specific applications, providing excellent resistance to corrosion and chemicals. They are often easier to mold into complex shapes, allowing for innovative design solutions.

Cons: The main disadvantage is that composites may not have the same load-bearing capacity as metals, limiting their use in heavy-duty applications. Additionally, they can be more expensive to produce and may require specialized manufacturing techniques.

Impact on Application: Composites are suitable for applications in corrosive environments or where weight is a critical factor. Buyers should consider compliance with industry-specific standards, such as ASTM D638 for plastic materials.

Illustrative image related to vertical lift conveyor systems

Summary of Material Properties for Vertical Lift Conveyor Systems

| Material | Typical Use Case for vertical lift conveyor systems | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications in manufacturing | High strength and load capacity | Susceptible to corrosion | Low |

| Aluminum | Lightweight applications in food processing | Excellent corrosion resistance | Higher cost, lower load capacity | Medium |

| Stainless Steel | Hygienic applications in food and pharmaceutical | Durability and aesthetic appeal | Higher cost, complex fabrication | High |

| Composite | Corrosive environments and lightweight applications | Lightweight and design flexibility | Limited load capacity, higher production cost | Medium |

This material selection guide provides B2B buyers with insights into the properties, advantages, and limitations of various materials used in vertical lift conveyor systems. Understanding these factors will aid in making informed decisions that align with specific application requirements and compliance standards across different regions.

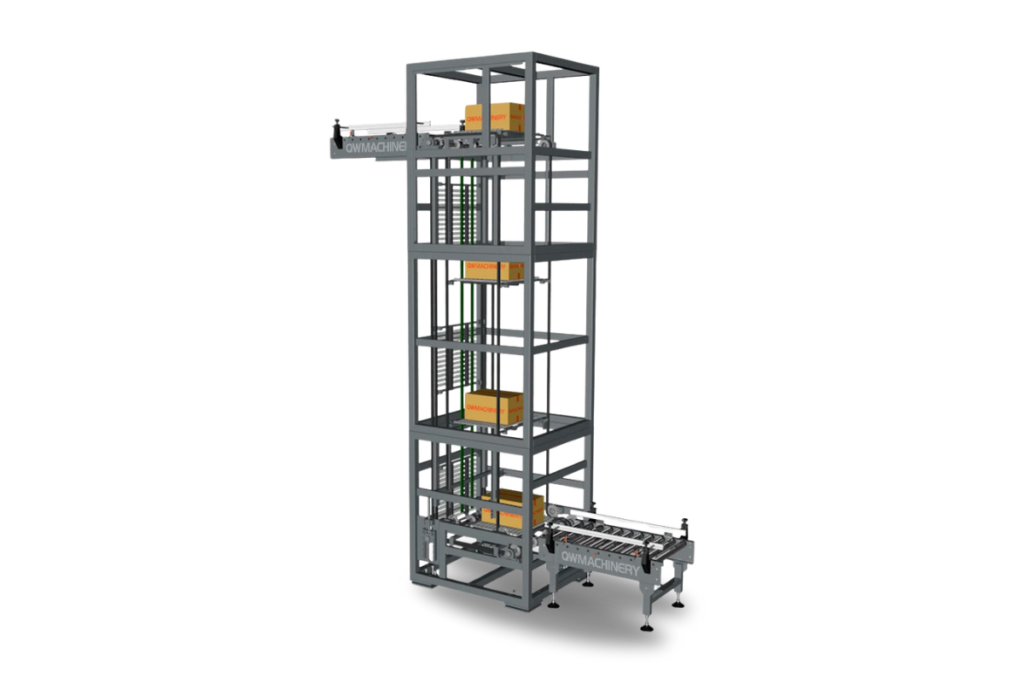

In-depth Look: Manufacturing Processes and Quality Assurance for vertical lift conveyor systems

What Are the Main Stages in the Manufacturing Process of Vertical Lift Conveyor Systems?

The manufacturing of vertical lift conveyor systems involves a series of well-defined stages that ensure the final product is safe, efficient, and tailored to meet specific operational needs. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Vertical Lift Conveyor Systems?

Material preparation is the foundational step in the manufacturing process. It involves selecting high-quality raw materials such as structural steel, aluminum, and specialized components like hydraulic cylinders and motors. Suppliers often conduct rigorous material inspections to ensure that the materials meet specific mechanical and chemical properties.

Once materials are sourced, they undergo processes such as cutting, machining, and surface treatment to prepare them for subsequent stages. For instance, steel components may be cut to size and then treated for corrosion resistance, especially for systems intended for outdoor use or in humid environments.

What Techniques Are Used in Forming Vertical Lift Conveyor Systems?

The forming stage employs techniques like welding, bending, and stamping to create structural components. Automated machinery often assists in these processes to enhance precision and reduce production time.

For example, robotic welding systems may be used to ensure consistent weld quality across all joints, while CNC machines can accurately bend metal components to required specifications. This level of automation not only increases efficiency but also helps in maintaining quality standards across batches.

How Are Vertical Lift Conveyor Systems Assembled?

Assembly is a critical phase where individual components are brought together to create the final product. This typically occurs in a clean, organized environment to minimize contamination and defects. During this stage, components such as the carriage, drive systems, and safety mechanisms are carefully installed.

Illustrative image related to vertical lift conveyor systems

Assembly teams often follow detailed engineering drawings and assembly instructions to ensure accuracy. This phase may also involve the integration of automated controls, which enhance the functionality and safety of the conveyor systems. Quality checkpoints during assembly ensure that any discrepancies are identified and rectified before moving forward.

What Finishing Processes Are Applied to Vertical Lift Conveyor Systems?

The finishing stage involves surface treatments, painting, and final inspections. Common practices include powder coating and galvanizing, which not only improve aesthetics but also provide additional protection against wear and corrosion.

Final inspections at this stage involve checking for alignment, functionality, and compliance with safety standards. These inspections are crucial, as they ensure that the systems are ready for deployment and meet all regulatory requirements.

What Quality Assurance Standards Should B2B Buyers Expect in Vertical Lift Conveyor Systems?

Quality assurance (QA) is paramount in the manufacturing of vertical lift conveyor systems. Buyers should look for suppliers that adhere to international standards such as ISO 9001, which outlines a framework for quality management systems, ensuring consistent product quality and customer satisfaction.

Which Industry-Specific Certifications Are Important for Vertical Lift Conveyors?

In addition to ISO 9001, several industry-specific certifications are crucial for vertical lift conveyor systems. For instance, the CE mark indicates compliance with European health, safety, and environmental protection standards. Similarly, the American Petroleum Institute (API) certification is vital for systems used in oil and gas applications, ensuring that they meet stringent safety and reliability standards.

Understanding these certifications can help B2B buyers assess the quality and safety of the systems they intend to purchase.

What Are the Key Quality Control Checkpoints in Vertical Lift Conveyor Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with several key checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to catch defects early. This may include tests on weld integrity, dimensional accuracy, and functionality.

- Final Quality Control (FQC): A thorough inspection of the completed system before it is shipped. This includes functional testing, load testing, and safety feature verification.

These checkpoints ensure that any deviations from quality standards are identified and addressed promptly.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are some effective strategies:

- Audits: Conducting on-site audits allows buyers to evaluate manufacturing facilities, processes, and quality control systems firsthand. This can provide insights into the supplier’s commitment to quality.

- Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s QC performance, including defect rates and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the quality control processes and product quality before purchase.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances when it comes to quality control:

- Regulatory Compliance: Different regions have varying regulations regarding safety and quality standards. Understanding local regulations is essential for compliance.

- Cultural Differences: Communication styles and business practices can vary significantly across regions. Building strong relationships with suppliers through regular communication can help mitigate misunderstandings.

- Logistical Considerations: International shipping introduces additional risks, such as damage during transport. Ensuring that suppliers have robust packaging and handling procedures can help minimize these risks.

By understanding the manufacturing processes and quality assurance practices associated with vertical lift conveyor systems, B2B buyers can make informed decisions that align with their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vertical lift conveyor systems’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring vertical lift conveyor systems, specifically tailored for various industrial applications. By following this checklist, you can ensure that you make informed decisions, prioritize safety and efficiency, and select the right solution that meets your operational requirements.

Illustrative image related to vertical lift conveyor systems

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for identifying the most suitable vertical lift conveyor system. Consider factors such as load capacity, height requirements, and the type of materials to be transported. Additionally, specify whether you need mechanical or hydraulic systems based on your operational needs and budget constraints.

- Load Capacity: Determine the maximum weight the lift must handle.

- Vertical Height: Assess the distance between levels to ensure the lift meets your height requirements.

Step 2: Assess Compliance with Safety Standards

Before finalizing any purchase, verify that the vertical lift conveyor system complies with relevant safety standards, such as ASME B20.1. Compliance not only ensures the safety of your workers but also minimizes legal risks and potential liability.

- Documentation: Request certificates and safety compliance documentation from suppliers.

- Safety Features: Look for advanced safety features like emergency stop buttons, safety guards, and maintenance pins.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they have the necessary expertise and a solid reputation in the industry. Request company profiles, case studies, and references from buyers in similar sectors or regions. This step is crucial to ensure you partner with a reliable supplier who can deliver quality products and services.

- Experience: Check how long the supplier has been in the vertical lift industry.

- Customer Feedback: Look for reviews or testimonials that speak to their reliability and service quality.

Step 4: Request Customization Options

Every operational environment is unique, so inquire about customization options that can tailor the vertical lift system to your specific needs. A supplier that offers custom solutions can help address unique challenges, such as space constraints or specialized material handling requirements.

- Design Flexibility: Ask about the ability to modify dimensions, weight capacities, and configurations.

- Integration Capabilities: Ensure that the lift can be seamlessly integrated into your existing systems.

Step 5: Analyze Total Cost of Ownership

Understanding the total cost of ownership (TCO) is critical for making a financially sound decision. This includes not just the initial purchase price, but also installation costs, maintenance, and operational expenses over the system’s lifespan.

- Installation Fees: Request detailed quotes that include installation costs.

- Maintenance Plans: Inquire about routine maintenance and repair services, as well as warranty options.

Step 6: Conduct a Risk Assessment

Before making a final decision, perform a risk assessment to identify any potential issues associated with the installation and operation of the vertical lift conveyor system. This proactive approach can help you mitigate future challenges and enhance safety.

- Site Evaluation: Assess your facility for any potential hazards that could impact lift performance.

- Operational Impact: Consider how the new system will affect existing workflows and employee safety.

Step 7: Finalize Contractual Agreements

Once you have selected a supplier and system, ensure that all terms and conditions are clearly documented in a contractual agreement. This should include delivery timelines, payment terms, warranties, and service agreements to protect your interests.

- Clarity on Deliverables: Ensure the contract specifies all technical specifications and customization requests.

- Service Support: Confirm the availability of after-sales support and maintenance services in the contract.

By following this checklist, B2B buyers can make well-informed decisions when sourcing vertical lift conveyor systems, ensuring they select the best fit for their operational needs while prioritizing safety and efficiency.

Comprehensive Cost and Pricing Analysis for vertical lift conveyor systems Sourcing

What Are the Key Cost Components of Vertical Lift Conveyor Systems?

When sourcing vertical lift conveyor systems, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. For example, high-grade steel used in mechanical lifts may be more expensive than standard materials, but it enhances durability and longevity. Additionally, options for corrosion-resistant coatings can further influence pricing.

-

Labor: Labor costs encompass both manufacturing and installation. Skilled labor is often required for assembly and installation, particularly for customized solutions, which can lead to higher labor costs.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help mitigate these overheads, but they will still factor into the final pricing.

-

Tooling: Custom tooling may be necessary for specialized designs, particularly for bespoke configurations. This upfront investment can lead to higher initial costs but may result in more effective and efficient production.

-

Quality Control (QC): Rigorous quality control processes are essential to ensure safety and reliability. These costs can vary based on the complexity of the systems and the quality standards required.

-

Logistics: Transportation and shipping costs can vary widely based on the destination. International shipping may include tariffs and customs duties, which should be factored into the total cost.

-

Margin: Suppliers typically include a profit margin that can range significantly based on market competition and the uniqueness of the offering.

What Influences Pricing for Vertical Lift Conveyor Systems?

Several factors can affect the pricing of vertical lift conveyor systems, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Suppliers often have MOQ requirements that can impact pricing.

-

Specifications and Customization: Custom solutions tailored to specific operational needs generally cost more than standard models. Buyers should weigh the benefits of customization against their budget constraints.

-

Material Quality and Certifications: Higher quality materials that meet international safety and environmental standards may come at a premium. Certifications can also add to the cost but may be necessary for regulatory compliance.

-

Supplier Factors: Established suppliers with a strong reputation may charge more due to their reliability and service quality. New entrants may offer lower prices to attract business but might lack the same level of service.

-

Incoterms: The chosen Incoterms can significantly affect the final price. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to accurately assess total costs.

How Can Buyers Negotiate for Better Pricing?

Effective negotiation strategies can help buyers achieve more favorable pricing and terms:

-

Leverage Volume Discounts: If planning to purchase multiple units, negotiate for bulk pricing. Suppliers are often willing to provide discounts for larger orders.

-

Understand Total Cost of Ownership (TCO): Assess the long-term costs associated with maintenance, operation, and potential downtime. A slightly higher upfront cost may lead to lower TCO if the system is more reliable or efficient.

-

Be Aware of Pricing Nuances in International Markets: Different regions may experience fluctuations in material costs, labor rates, and shipping expenses. Understanding these regional dynamics can provide leverage during negotiations.

-

Request Multiple Quotes: Engage with multiple suppliers to compare pricing and terms. This competitive approach can often yield better offers.

-

Consider Payment Terms: Flexible payment options may influence overall pricing. Suppliers may offer discounts for upfront payments or alternative financing options.

Conclusion

Sourcing vertical lift conveyor systems involves a multifaceted analysis of costs and pricing influencers. By understanding the key cost components and leveraging negotiation strategies, international buyers can make informed decisions that align with their operational needs and budget constraints. It’s essential to engage with suppliers early in the process to clarify specifications and explore customization options that may impact pricing. Remember, the indicative prices can vary widely based on numerous factors, so thorough research and planning are crucial for successful procurement.

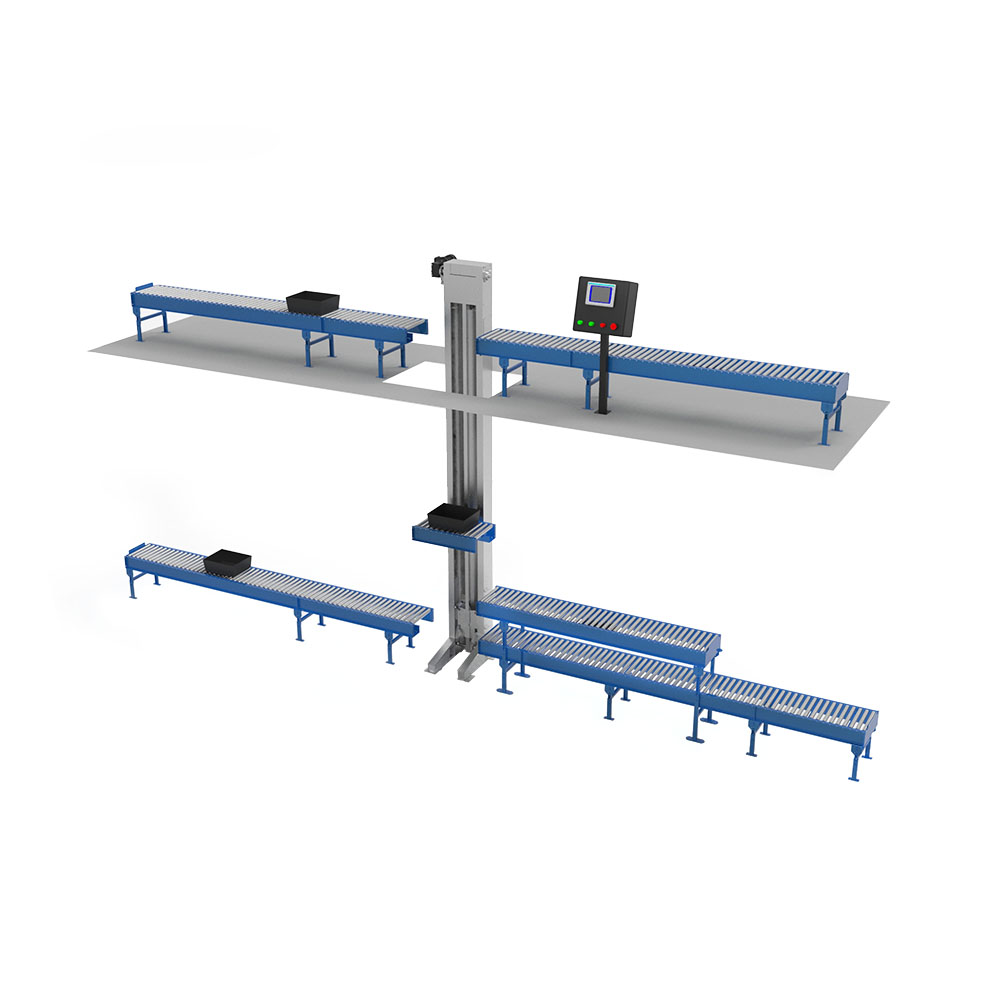

Alternatives Analysis: Comparing vertical lift conveyor systems With Other Solutions

Introduction to Alternative Solutions for Material Handling

In the realm of material handling, vertical lift conveyor systems (VLCs) provide a specialized solution for transporting goods between different levels within a facility. However, various alternative solutions exist that may suit specific operational needs or constraints. This analysis compares VLCs with two viable alternatives: Forklifts and Inclined Belt Conveyors, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table of Vertical Lift Conveyor Systems and Alternatives

| Comparison Aspect | Vertical Lift Conveyor Systems | Forklifts | Inclined Belt Conveyors |

|---|---|---|---|

| Performance | High efficiency for vertical transport; ideal for heavy loads | Versatile; suitable for various load types but limited to horizontal travel | Effective for continuous transport; best for lighter loads |

| Cost | Moderate initial investment; lower operational costs | High operational costs due to fuel and maintenance | Lower upfront cost; moderate operational costs |

| Ease of Implementation | Requires specific installation; adaptable to existing structures | Quick deployment; requires operator training and space for maneuvering | Straightforward installation; requires space for incline |

| Maintenance | Low maintenance; designed for heavy-duty use | High maintenance; mechanical wear and tear | Moderate maintenance; dependent on belt wear |

| Best Use Case | Multi-level warehouses and factories needing efficient material lifting | Versatile operations needing flexibility in transport | Facilities with continuous material flow on a slope |

Detailed Breakdown of Alternatives

Forklifts

Forklifts are a well-known solution for material handling, offering flexibility in transporting loads across various surfaces and heights. They can maneuver through tight spaces and are suitable for outdoor use, making them ideal for varied environments. However, their operational costs can be high due to fuel, maintenance, and the need for trained operators. Additionally, forklifts have limitations in vertical transport, making them less efficient than VLCs for multi-level applications.

Inclined Belt Conveyors

Inclined belt conveyors are designed to transport materials from one elevation to another at a slope. They are particularly effective for continuous movement of lighter loads, such as packaged goods or small parts. Their installation is generally straightforward and cost-effective, making them a popular choice for facilities with consistent material flow. However, they may not handle heavy loads as effectively as VLCs and require more space for the incline, which can be a limiting factor in tighter facilities.

Conclusion: Choosing the Right Solution for Your Business Needs

Selecting the appropriate material handling system depends on various factors, including the nature of the goods being transported, available space, and budget considerations. Vertical lift conveyor systems excel in environments requiring efficient vertical movement of heavy loads, while forklifts offer versatility for horizontal and vertical transport but at a higher operational cost. Inclined belt conveyors serve well in scenarios with continuous flow but may fall short for heavier materials. B2B buyers should evaluate their specific needs, facility layout, and budget to determine which solution aligns best with their operational goals. By carefully considering these alternatives, businesses can enhance their material handling efficiency and optimize their workflows.

Essential Technical Properties and Trade Terminology for vertical lift conveyor systems

What Are the Key Technical Properties of Vertical Lift Conveyor Systems?

When considering vertical lift conveyor systems, understanding the essential technical specifications is crucial for making informed purchasing decisions. Below are some critical specifications that B2B buyers should be familiar with:

1. Load Capacity

Load capacity refers to the maximum weight that a vertical lift conveyor can safely handle. This specification is vital as it directly impacts operational efficiency and safety. Systems are typically rated for capacities ranging from a few hundred to over 100,000 pounds. Choosing a system with the appropriate load capacity ensures that it can meet the demands of your specific application without risking damage to the equipment or materials.

2. Travel Speed

Travel speed indicates how quickly the lift can move materials between levels, usually measured in feet per minute (FPM). Typical speeds range from 17 to 25 FPM for hydraulic systems and can exceed 60 FPM for mechanical systems. Faster travel speeds can enhance productivity, particularly in high-cycle environments, making it a key consideration for businesses aiming to optimize workflow.

Illustrative image related to vertical lift conveyor systems

3. Vertical Rise

Vertical rise is the maximum height the lift can achieve, which is essential for determining whether it can effectively serve the intended application, such as multi-story facilities. Systems can accommodate rises from a few feet up to over 200 feet, allowing for flexibility in various building designs. Understanding vertical rise helps ensure that the system fits within the constraints of your facility’s architecture.

4. Configuration Type

Vertical lift conveyors come in various configurations, including straddle and cantilever designs. The configuration affects the installation footprint and load handling capabilities. Selecting the right configuration can optimize space usage and enhance the system’s effectiveness in moving materials, especially in constrained environments.

5. Safety Features

Safety features like the DeckLock Safety System and explosion-proof components are critical for ensuring safe operation. These features protect both the materials being moved and the personnel operating the equipment. Investing in systems with advanced safety features not only complies with regulatory standards but also minimizes the risk of accidents, thereby protecting your workforce.

Illustrative image related to vertical lift conveyor systems

What Are Common Trade Terms Used in Vertical Lift Conveyor Systems?

Familiarity with industry terminology can streamline communication and negotiations, making it easier to navigate the purchasing process for vertical lift conveyor systems.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is essential for buyers seeking to ensure quality and compatibility in their vertical lift systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. This term is crucial for buyers as it affects inventory management and procurement strategies. Knowing the MOQ can help businesses plan their purchases effectively to avoid excess stock or shortages.

Illustrative image related to vertical lift conveyor systems

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific goods or services. This process is essential for buyers to compare offers and negotiate favorable terms, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms is important for B2B buyers engaged in cross-border transactions, as they clarify shipping responsibilities, risk, and costs.

5. VRC (Vertical Reciprocating Conveyor)

VRC is a specific type of vertical lift conveyor designed to move materials between different levels safely and efficiently. Understanding this term helps buyers identify the right solutions tailored to their material handling needs.

Illustrative image related to vertical lift conveyor systems

By grasping these essential technical properties and industry terms, B2B buyers can make more informed decisions when selecting vertical lift conveyor systems, ultimately optimizing their material handling processes.

Navigating Market Dynamics and Sourcing Trends in the vertical lift conveyor systems Sector

What Are the Current Market Dynamics and Key Trends Affecting Vertical Lift Conveyor Systems?

The vertical lift conveyor systems market is experiencing robust growth driven by several global factors. Increasing urbanization, coupled with the surge in e-commerce, has heightened the need for efficient material handling solutions across various industries, including manufacturing, logistics, and warehousing. Regions such as Africa, South America, the Middle East, and Europe are witnessing significant investments in infrastructure, further fueling demand. Countries like Saudi Arabia are ramping up their industrial capabilities as part of their Vision 2030 initiatives, while Germany continues to innovate in manufacturing technologies, creating a fertile ground for the adoption of vertical lift systems.

In addition to traditional mechanical and hydraulic lifts, emerging technologies such as IoT-enabled systems are gaining traction. These advanced vertical lifts offer enhanced monitoring capabilities, predictive maintenance, and improved safety features. Furthermore, automation is becoming a pivotal trend, with businesses increasingly integrating vertical lifts into automated production lines to maximize efficiency and reduce labor costs. As a result, international B2B buyers must stay abreast of these technological advancements to ensure they are sourcing the most effective solutions for their operations.

How Are Sustainability and Ethical Sourcing Influencing the Vertical Lift Conveyor Systems Market?

Sustainability is becoming a critical focus for businesses across the globe, and the vertical lift conveyor systems sector is no exception. The environmental impact of manufacturing processes, along with increased regulatory scrutiny, is compelling manufacturers to adopt greener practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through the use of eco-friendly materials and energy-efficient technologies.

Ethical sourcing is also gaining importance in the supply chain. Businesses are now more aware of the social implications of their sourcing choices, and many are seeking suppliers who adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential criteria for B2B buyers when evaluating potential partners. By emphasizing sustainability and ethical sourcing, companies can not only meet regulatory requirements but also enhance their brand reputation and appeal to a growing segment of environmentally-conscious consumers.

Illustrative image related to vertical lift conveyor systems

How Have Vertical Lift Conveyor Systems Evolved Over Time?

The evolution of vertical lift conveyor systems can be traced back to the early 20th century when mechanical lifts were primarily used for moving heavy loads in industrial settings. Over the decades, advancements in hydraulic technology led to the development of more efficient and versatile vertical reciprocating conveyors (VRCs). These systems began to incorporate safety features and customizations, enabling them to handle a wider variety of materials and applications.

In recent years, the integration of smart technologies and automation has transformed the vertical lift conveyor landscape. Today’s systems are not only designed for maximum efficiency but also equipped with advanced monitoring and control capabilities, allowing businesses to optimize their operations further. As the industry continues to evolve, the focus on safety, sustainability, and technological integration will play a pivotal role in shaping the future of vertical lift conveyor systems.

Frequently Asked Questions (FAQs) for B2B Buyers of vertical lift conveyor systems

-

1. How do I solve the challenge of transporting heavy materials between different levels?

To effectively transport heavy materials between different levels, consider investing in vertical lift conveyor systems, specifically designed for such tasks. These systems can handle diverse loads and are engineered for safety and efficiency. Hydraulic and mechanical vertical reciprocating conveyors (VRCs) are popular options, allowing for customized solutions based on your specific lifting requirements. Engaging with a reputable supplier can help assess your needs and recommend the best system for your application, ensuring that it meets safety standards and operational efficiency. -

2. What is the best vertical lift conveyor system for my warehouse?

The best vertical lift conveyor system for your warehouse depends on several factors, including the weight and size of the materials to be lifted, the required lifting height, and the frequency of use. Hydraulic lifts are typically more cost-effective for two-level operations, while mechanical lifts are suited for larger loads and higher elevations. Consult with a supplier who can provide tailored recommendations based on your unique operational demands and facility layout, ensuring optimal performance and safety compliance. -

3. How can I ensure the quality and reliability of the vertical lift conveyor systems I purchase?

To ensure the quality and reliability of vertical lift conveyor systems, conduct thorough research on potential suppliers. Look for manufacturers with a strong reputation, proven track record, and positive customer reviews. Verify their adherence to international safety standards, such as ASME B20.1, and request documentation regarding their quality assurance processes. Additionally, consider seeking testimonials or case studies from similar industries to gauge the effectiveness of their systems in real-world applications. -

4. What customization options are available for vertical lift conveyor systems?

Customization options for vertical lift conveyor systems are extensive and can include varying carriage sizes, load capacities, and configurations (such as cantilever or straddle designs). Suppliers often work closely with clients to design systems that fit specific operational needs, such as integrating safety features or adapting to unique warehouse layouts. Discussing your requirements with the manufacturer will help you explore all available customization options to ensure the system optimally meets your material handling challenges. -

5. What are the minimum order quantities (MOQ) for vertical lift conveyor systems?

Minimum order quantities (MOQ) for vertical lift conveyor systems can vary significantly by supplier and the complexity of the systems being ordered. Some manufacturers may have a low MOQ for standard models, while custom systems may require larger orders. It’s advisable to discuss your needs with potential suppliers to understand their policies and negotiate terms that suit your purchasing capabilities, especially if you’re considering bulk orders or multiple systems. -

6. What payment terms should I expect when purchasing vertical lift conveyor systems?

Payment terms for purchasing vertical lift conveyor systems can differ by supplier and region. Common terms may include a percentage of the total cost upfront, with the balance due upon completion or delivery. Some suppliers may offer financing options or extended payment plans. Be sure to clarify all payment conditions, including any potential deposits, installment options, and accepted payment methods, before finalizing your order to avoid misunderstandings later in the process. -

7. How do I manage logistics and shipping for international purchases of vertical lift conveyor systems?

Managing logistics for international purchases requires careful planning. Coordinate with your supplier to understand shipping options and timelines. Consider working with a freight forwarder who specializes in heavy machinery to navigate customs regulations and ensure timely delivery. Additionally, clarify who is responsible for shipping costs, insurance, and potential tariffs, so you can factor these into your overall budget. It’s crucial to maintain open communication with both your supplier and logistics provider throughout the shipping process. -

8. What are the key safety features to look for in vertical lift conveyor systems?

When sourcing vertical lift conveyor systems, prioritize safety features that enhance operational security. Look for systems equipped with advanced safety mechanisms such as emergency stop buttons, safety gates, and overload protection. Additionally, consider optional features like DeckLock safety systems and maintenance pins, which can further mitigate risks during operation. Ensure that the systems comply with relevant safety codes and standards, providing peace of mind for both operators and management.

Top 4 Vertical Lift Conveyor Systems Manufacturers & Suppliers List

1. NERAK – Vertical Conveyors and Lifts

Domain: nerak-systems.com

Registered: 1998 (27 years)

Introduction: NERAK vertical conveyors and lifts are space-saving, quiet, durable, high-performance, cost-effective solutions for vertical transport. They utilize a unique Rubber Block Chain to transport loads up to 120 ft high and in temperatures ranging from -50 to 280 degrees F. The product range includes: 1. Continuous Vertical Conveyors (CVC) – designed for high capacity between two levels, maintaining hor…

2. IQS Directory – Vertical Conveyors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Vertical conveyors, also known as vertical reciprocating conveyors (VRCs), are mechanical systems designed for elevating items between various height levels. They enhance efficiency by saving time and minimizing physical effort in transporting materials. VRCs are classified as material handling equipment governed by ASME safety standards. Types include spiral vertical conveyors, which transfer mat…

3. PFI Conveyors – PURlift Positive Drive Vertical Lift Conveyor

Domain: pficonveyors.com

Introduction: PURlift Positive Drive Vertical Lift Conveyor features a dual “sandwich” lift design for vertical product elevation with minimal waste. It is suitable for various products including dough, peanut butter, and meat. Key features include:

– Positive drive, self-tracking belt system

– Pneumatic belt tensioning with quick release

– Automatic infeed for continuous operation

– Tool-less belt scrapers and…

4. Ryson – Spiral Vertical Conveyor

Domain: ryson.com

Registered: 1996 (29 years)

Introduction: Product Name: Spiral Vertical Conveyor

Manufacturer: Ryson International

Key Features:

– Small footprint with big throughput

– Commonly used in Industrial & Manufacturing, Consumer Packaged Goods, Food & Beverage, Warehousing & Logistics

– Slat Width options: 6″, 9″, 12″, 16″, 20″, 24″, 26″, 30″, 36″

– Total Weight Capacity: 1,800 – 3,600 lbs

– High throughput with continuous flow operation

– Spee…

Strategic Sourcing Conclusion and Outlook for vertical lift conveyor systems

In summary, strategic sourcing of vertical lift conveyor systems is essential for optimizing material handling processes across diverse industries. By investing in tailored solutions like hydraulic and mechanical vertical reciprocating conveyors (VRCs), businesses can enhance operational efficiency while ensuring safety and compliance with national regulations. The ability to customize these systems to meet specific load requirements and operational environments is a significant advantage, particularly for enterprises in Africa, South America, the Middle East, and Europe.

As international B2B buyers navigate the complexities of sourcing, understanding the unique advantages of vertical lift systems can drive better decision-making and long-term value. This is especially pertinent in regions where space optimization and cost-effectiveness are critical. By prioritizing partnerships with experienced manufacturers who offer comprehensive support and innovative engineering, companies can ensure that their investments yield substantial returns.

Looking ahead, the demand for efficient material handling solutions is set to grow, driven by advancements in technology and evolving industry standards. Now is the time to engage with suppliers and explore how vertical lift conveyor systems can elevate your operations to new heights. Act today to secure a competitive edge in your market.

Illustrative image related to vertical lift conveyor systems

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.