Plunger Lock Key: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for plunger lock key

Navigating the complex landscape of sourcing plunger lock keys can be a daunting task for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying the right type of plunger lock key that fits specific applications but also in ensuring that the suppliers meet rigorous quality and compliance standards. This guide serves as a comprehensive resource, providing insights into various types of plunger lock keys, their applications across different industries, and critical factors for vetting suppliers effectively.

From understanding the nuances of barrel lock plunger keys to exploring options for securing sliding doors and cabinets, this guide covers a wide array of products tailored to meet the unique needs of global buyers. It delves into the cost implications associated with different types of keys and offers strategies for negotiating favorable terms with suppliers. By equipping B2B buyers with actionable insights and practical tools, this guide empowers them to make informed purchasing decisions that enhance security measures within their operations.

As you navigate the global market for plunger lock keys, our goal is to simplify the process, ensuring that you can procure high-quality products while fostering reliable supplier relationships. Whether you’re based in Vietnam, Brazil, or elsewhere, this guide is designed to facilitate your sourcing journey, ultimately helping you secure the best solutions for your business needs.

Understanding plunger lock key Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Barrel Lock Plunger Key | Designed for specific barrel locks, high carbon alloy steel | CATV systems, telecommunications | Pros: Durable, tamper-resistant. Cons: Limited compatibility. |

| Olympus Plunger Lock Key | Compatible with various pin tumbler locks, rekeyable options | Residential and commercial sliding doors | Pros: Versatile, secure. Cons: May require specific installation knowledge. |

| Tubular Plunger Lock Key | Tubular design, often used in trailer and cabinet locks | Trailers, storage solutions | Pros: Easy to duplicate, high security. Cons: May be less common in some regions. |

| Cam Lock Plunger Key | Used for cam locks, typically smaller and lighter | Office furniture, cabinets, lockers | Pros: Compact size, affordable. Cons: Limited security compared to other types. |

| High-Security Plunger Lock Key | Features advanced locking mechanisms, often resistant to picking | High-security facilities, safes | Pros: Enhanced security features. Cons: Higher cost, may require specialized keys. |

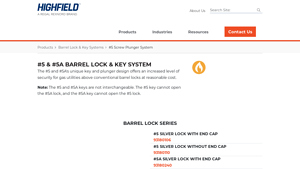

What are the characteristics of Barrel Lock Plunger Keys?

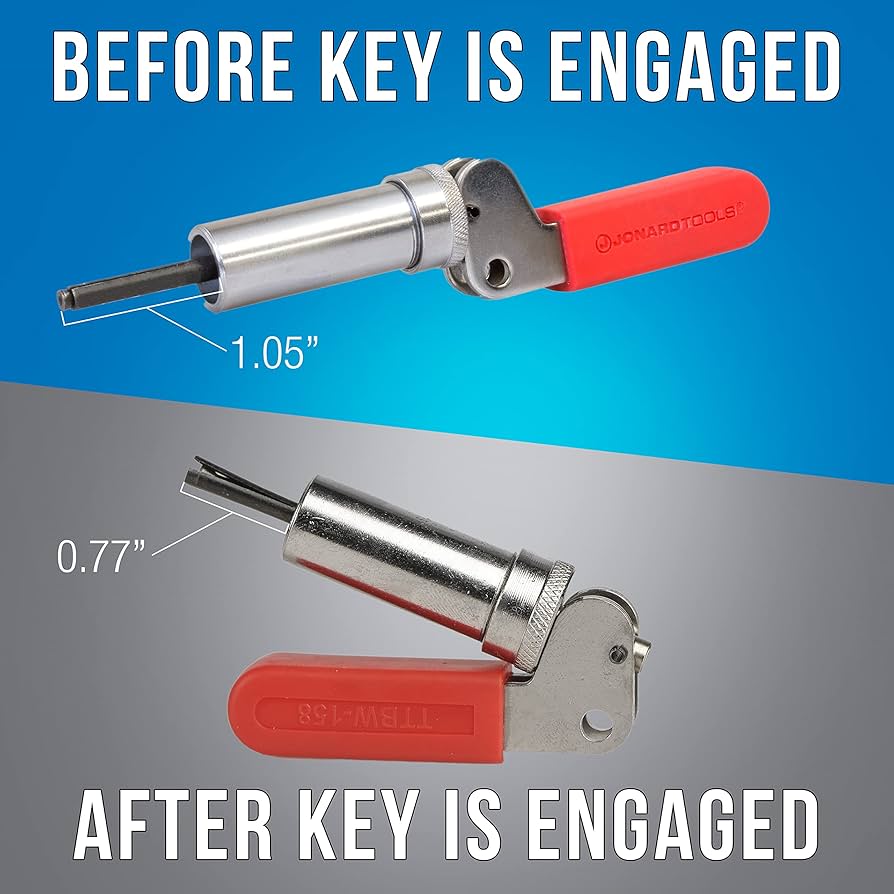

Barrel lock plunger keys are specifically engineered for use with certain barrel locks, such as the Channell LK03029817 and Highfield 93180775-S. Made from high carbon alloy steel, these keys offer robust durability and tamper resistance, making them ideal for environments requiring frequent access, such as CATV systems. When purchasing, B2B buyers should consider the compatibility with specific lock brands and the potential need for multiple keys for different locks.

Illustrative image related to plunger lock key

How do Olympus Plunger Lock Keys differ from other types?

Olympus plunger lock keys are designed for pin tumbler sliding door locks, available in keyed alike or keyed different configurations. Their rekeyable feature allows businesses to maintain security without needing to replace entire locking systems. This flexibility makes them suitable for both residential and commercial applications. Buyers should evaluate the security level required for their specific use case, as well as the installation requirements.

Why are Tubular Plunger Lock Keys popular in B2B applications?

The tubular design of plunger lock keys is particularly advantageous for applications in trailers and storage solutions. Their design facilitates easier duplication, which can be beneficial for businesses needing multiple access points. However, buyers should be aware of regional availability, as these keys may not be as common in every market, potentially complicating replacement or duplication efforts.

What makes Cam Lock Plunger Keys suitable for office environments?

Cam lock plunger keys are smaller and lighter, making them a practical choice for office furniture, cabinets, and lockers. Their affordability and compact design are appealing for businesses looking to secure various items without significant investment. However, the security level may not match that of heavier-duty options, so buyers should assess the security needs of the items being locked.

How do High-Security Plunger Lock Keys enhance security?

High-security plunger lock keys incorporate advanced locking mechanisms that resist picking and unauthorized access. These keys are ideal for high-security facilities and safes, where the protection of sensitive materials is paramount. While they offer superior security, the higher cost and potential need for specialized keys may deter some businesses. Buyers must weigh the importance of security against budget constraints when considering these options.

Key Industrial Applications of plunger lock key

| Industry/Sector | Specific Application of plunger lock key | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Unlocking CATV barrel locks for maintenance and access | Enhances operational efficiency and reduces downtime | Ensure compatibility with specific lock types and durability for outdoor conditions |

| Construction | Securing sliding doors and gates in commercial buildings | Increases security and safety on job sites | Look for weather-resistant materials and ease of installation |

| Transportation and Logistics | Locking cargo containers and trailers | Protects valuable goods during transit | Prioritize corrosion resistance and key duplication options |

| Retail and Warehousing | Securing storage units and display cases | Prevents theft and unauthorized access, boosting inventory control | Evaluate ease of rekeying and availability of replacement keys |

| Automotive | Locking mechanisms for vehicle doors and compartments | Enhances vehicle security and customer trust | Consider key compatibility with various vehicle models and potential for bulk orders |

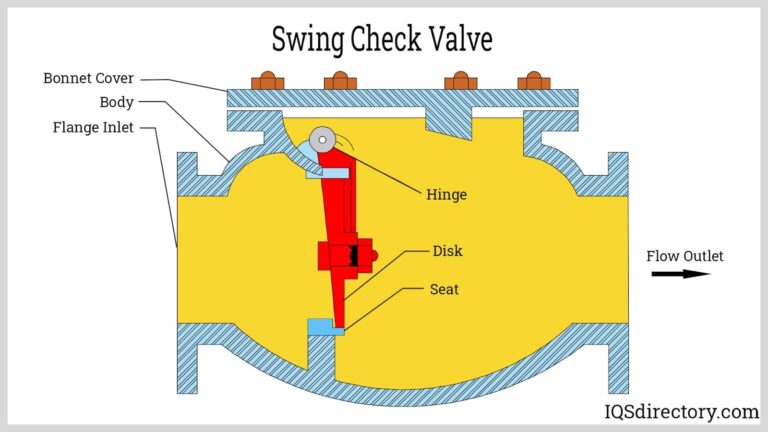

How is the plunger lock key utilized in telecommunications?

In the telecommunications industry, plunger lock keys are essential for unlocking CATV (cable television) barrel locks, which secure access to critical infrastructure. These locks are commonly found in outdoor environments, requiring keys made from durable materials to withstand weather conditions. The ability to quickly access these locks minimizes service interruptions, thereby enhancing operational efficiency. For international buyers, particularly in regions like Africa and South America, sourcing keys that are specifically designed for certain lock types is crucial to ensure reliability and performance.

What role does the plunger lock key play in construction?

In the construction sector, plunger lock keys are frequently used to secure sliding doors and gates, ensuring that only authorized personnel have access to job sites. This enhances safety and security, preventing unauthorized entry and potential theft of tools and materials. Buyers in Europe and the Middle East should focus on sourcing keys that are both easy to install and made from weather-resistant materials, as job sites often face diverse environmental conditions. The durability of the lock mechanism is also a significant consideration to ensure long-term functionality.

How does the plunger lock key contribute to transportation and logistics?

In transportation and logistics, plunger lock keys are vital for locking cargo containers and trailers, providing an added layer of security during transit. This is particularly important for businesses that transport high-value goods, as it helps prevent theft and loss. When sourcing plunger lock keys for this application, it is essential to consider features such as corrosion resistance and the ability to duplicate keys easily, especially for companies operating in regions with varying climates like Brazil and the Middle East.

Why are plunger lock keys important for retail and warehousing?

In retail and warehousing, plunger lock keys are used to secure storage units and display cases, which helps in preventing theft and unauthorized access. This is crucial for maintaining inventory control and ensuring that products are safe from potential loss. International buyers should evaluate the ease of rekeying these locks and the availability of replacement keys, as this can streamline security management processes. A reliable locking system can significantly enhance customer trust and satisfaction.

How is the plunger lock key utilized in the automotive industry?

In the automotive sector, plunger lock keys are integral to locking mechanisms found in vehicle doors and compartments. These keys enhance vehicle security, which is a critical concern for both manufacturers and consumers. Buyers should consider sourcing keys that are compatible with a wide range of vehicle models to ensure versatility. Additionally, the option for bulk orders can be advantageous for automotive companies looking to maintain a steady supply of replacement keys, particularly in markets across Europe and the Middle East.

3 Common User Pain Points for ‘plunger lock key’ & Their Solutions

Scenario 1: Difficulty in Finding Compatible Plunger Lock Keys

The Problem: Many B2B buyers, particularly those in the telecommunications and utilities sectors, often encounter challenges when trying to find compatible plunger lock keys for specific applications. With various lock types on the market, such as those used in CATV systems (e.g., Channell and Highfield locks), it can be frustrating to determine which key will work effectively. This leads to wasted time and resources, as purchasing incompatible keys can result in additional costs for replacements or extended downtime in operations.

The Solution: To mitigate this issue, buyers should prioritize a thorough specification process when sourcing plunger lock keys. Begin by identifying the precise lock types in use, including any brand or model numbers, and cross-reference these with manufacturers’ specifications. For instance, the Jonard TTB-6 is specifically designed for Channell LK03029817 and Highfield 93180775-S locks. Buyers should also establish relationships with reputable suppliers who can provide guidance and ensure that the correct keys are sourced based on the specifications provided. Utilizing a detailed inventory management system can aid in tracking the types of locks in use, making it easier to order compatible keys in the future.

Scenario 2: Concerns About Durability and Tamper Resistance

The Problem: Security is a paramount concern for businesses utilizing plunger locks in their operations, especially in regions with higher theft rates. B2B buyers may struggle with selecting keys that not only function effectively but also offer durability and resistance to tampering. A key that fails under stress or can be easily compromised may lead to significant security breaches, resulting in financial loss and damage to reputation.

The Solution: Buyers should focus on sourcing plunger lock keys made from high-quality materials, such as high carbon alloy steel, which provides superior tamper resistance and longevity. When evaluating suppliers, look for those who provide detailed information about the materials and construction of their products. It’s beneficial to request samples or conduct stress tests to assess the performance of the keys under various conditions. Additionally, investing in serialized or customized keys can enhance security by limiting unauthorized duplication, thus providing a more robust solution for protecting valuable assets.

Illustrative image related to plunger lock key

Scenario 3: Challenges in Key Duplication and Replacement

The Problem: In operations where multiple keys are required, the duplication and replacement of plunger lock keys can become a logistical challenge. B2B buyers may find that keys are lost or damaged frequently, leading to delays and increased operational costs. Furthermore, if the keys are proprietary or specially designed, sourcing replacements can be time-consuming and complicated.

The Solution: To streamline the process of key duplication and replacement, businesses should establish a standardized key management system. This can include keeping a detailed log of all keys in circulation and their specific applications. When ordering plunger lock keys, it is advisable to work with suppliers who offer bulk purchasing options or discounts for repeated orders. Additionally, consider investing in key management software that allows for easy tracking and reordering of keys as needed. This proactive approach can significantly reduce downtime and operational disruptions, ensuring that critical areas remain secured and accessible when necessary.

Strategic Material Selection Guide for plunger lock key

What Are the Key Materials Used for Plunger Lock Keys?

Plunger lock keys are essential tools in various industrial applications, and the choice of material significantly influences their performance, durability, and overall effectiveness. Here, we analyze four common materials used in the manufacture of plunger lock keys, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. High Carbon Alloy Steel

Key Properties: High carbon alloy steel is known for its high tensile strength and excellent wear resistance. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros & Cons: This material offers superior durability and tamper resistance, which is crucial for security applications. However, it can be more expensive than other materials and may require complex manufacturing processes like heat treatment.

Impact on Application: High carbon alloy steel is particularly effective in environments where keys are subject to frequent use and potential abuse, such as in industrial locks and security systems.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM for material properties. The availability of high carbon alloy steel can vary, impacting lead times and costs.

2. Die Cast Zinc

Key Properties: Die cast zinc is lightweight and offers good corrosion resistance, making it suitable for outdoor applications.

Pros & Cons: The manufacturing process is relatively simple and cost-effective, allowing for mass production. However, die cast zinc is less durable than steel and may not withstand extreme conditions.

Impact on Application: This material is ideal for applications where weight is a concern, such as portable locks used in shipping and logistics.

Considerations for International Buyers: Buyers should be aware of regional preferences for materials, as some markets may favor more robust options. Compliance with corrosion resistance standards is also essential.

3. Brass

Key Properties: Brass is known for its excellent corrosion resistance and good machinability. It performs well in various environmental conditions, including humid and saline environments.

Pros & Cons: Brass offers a balance of durability and aesthetic appeal, making it suitable for decorative applications. However, it can be more expensive than steel and may not be as strong under heavy loads.

Impact on Application: Brass is commonly used in residential and commercial locks, where appearance and corrosion resistance are essential.

Considerations for International Buyers: Compliance with JIS and DIN standards is crucial for buyers in Europe and Asia. Additionally, the aesthetic qualities of brass can be a selling point in markets that value design.

4. Stainless Steel

Key Properties: Stainless steel is renowned for its corrosion resistance and high strength-to-weight ratio. It can endure extreme temperatures and is often used in harsh environments.

Pros & Cons: While stainless steel is highly durable and resistant to rust, it is generally more expensive than other materials and may require specialized manufacturing techniques.

Impact on Application: This material is ideal for applications in marine environments or areas with high humidity, where corrosion could be a significant issue.

Considerations for International Buyers: Buyers from the Middle East and Europe should ensure compliance with international standards for stainless steel grades, such as ASTM and EN standards. The availability of specific grades can affect procurement strategies.

Summary Table of Material Selection for Plunger Lock Keys

| Material | Typical Use Case for plunger lock key | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High Carbon Alloy Steel | Industrial locks and security systems | Superior durability and tamper resistance | Higher cost and complex manufacturing | High |

| Die Cast Zinc | Portable locks in shipping and logistics | Lightweight and cost-effective | Less durable under extreme conditions | Medium |

| Brass | Residential and commercial locks | Corrosion resistance and aesthetic appeal | More expensive and less strong | Medium |

| Stainless Steel | Marine and harsh environment applications | High durability and corrosion resistance | Higher cost and specialized manufacturing | High |

This comprehensive analysis provides B2B buyers with essential insights into material selection for plunger lock keys, enabling informed decisions that align with their operational needs and regional standards.

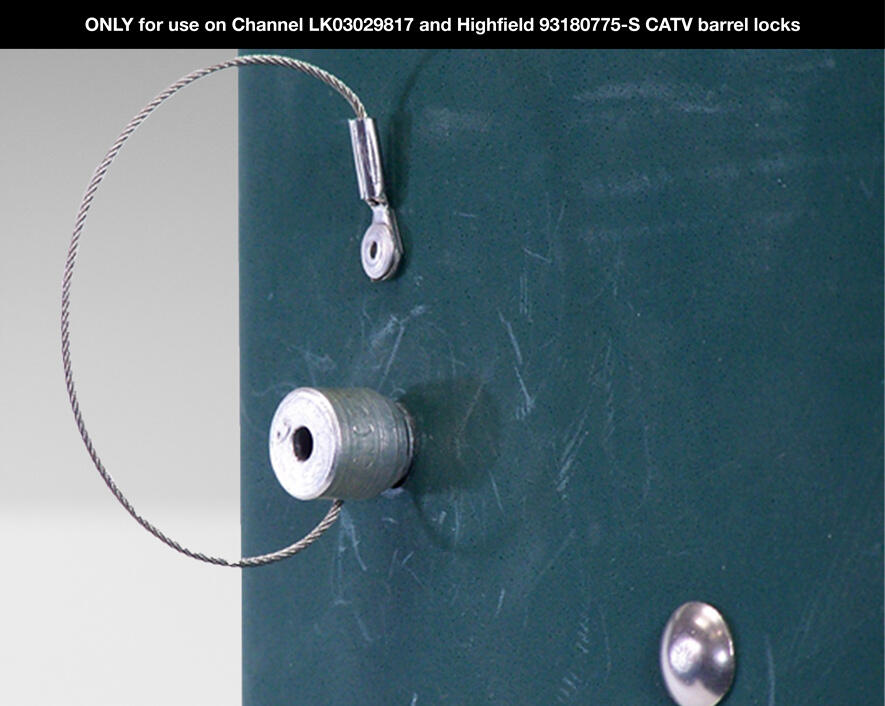

In-depth Look: Manufacturing Processes and Quality Assurance for plunger lock key

What Are the Key Stages in the Manufacturing Process of Plunger Lock Keys?

The manufacturing process of plunger lock keys is a multi-stage endeavor that ensures precision, durability, and reliability. Here are the main stages involved:

-

Material Preparation: The primary material used in the production of plunger lock keys is high-carbon alloy steel, known for its strength and resistance to wear. The first step involves sourcing high-quality raw materials that meet international standards. This material is then cut into manageable sizes for further processing.

-

Forming Techniques: The forming process typically involves techniques such as forging or machining. For plunger lock keys, precision machining is crucial to achieve the correct dimensions and tolerances. CNC (Computer Numerical Control) machines are often employed to ensure accuracy and repeatability, shaping the key to match specific lock designs.

-

Assembly: After forming, the components of the plunger lock key, including the barrel and the plunger, are assembled. This process may require manual labor or automated assembly lines, depending on production scale. The assembly must ensure that all parts fit perfectly to maintain the functionality of the lock mechanism.

-

Finishing: The final stage involves surface treatments such as polishing or coating. These processes not only enhance the aesthetic appeal of the plunger lock keys but also provide additional protection against corrosion and wear. A common finish is polished steel, which offers both durability and a professional appearance.

How Is Quality Assurance Implemented in Plunger Lock Key Manufacturing?

Quality assurance (QA) is critical in ensuring that plunger lock keys meet both customer expectations and regulatory standards. Here’s how QA is typically integrated into the manufacturing process:

-

Adhering to International Standards: Compliance with international standards such as ISO 9001 is essential. This standard outlines the requirements for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) standards may also apply, depending on the application of the lock keys.

-

Quality Control Checkpoints: Implementing various quality control (QC) checkpoints throughout the manufacturing process is vital. These checkpoints include:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, reducing waste and rework.

– Final Quality Control (FQC): At this stage, finished plunger lock keys undergo rigorous testing and inspection to verify their functionality, durability, and compliance with specifications. -

Common Testing Methods: Various testing methods are employed to assess the quality of plunger lock keys. These may include:

– Dimensional Inspection: Verifying that the keys meet specified dimensions using calipers and other measuring tools.

– Functional Testing: Testing the keys in their corresponding locks to ensure they operate smoothly without jamming or failure.

– Durability Testing: Subjecting the keys to stress and wear tests to evaluate their longevity and resistance to tampering.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are actionable steps to undertake:

-

Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. These audits can be performed in-person or through third-party organizations that specialize in quality assessments.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports from suppliers, which should outline the QC processes, results from testing, and compliance with relevant standards. These reports can provide transparency and assurance regarding the supplier’s capabilities.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of confidence. These services can perform independent evaluations of the manufacturing processes and final products, ensuring they meet specified quality standards.

-

Understanding Certification Nuances: Different regions may have varying certification requirements. Buyers should familiarize themselves with the specific certifications that apply to their market and ensure that their suppliers have the necessary documentation. This is particularly important when dealing with international suppliers who may be subject to different regulatory frameworks.

What Challenges Do International Buyers Face in Quality Assurance?

International B2B buyers must navigate several challenges related to quality assurance when sourcing plunger lock keys. These include:

-

Cultural Differences: Variations in business practices and communication styles can lead to misunderstandings about quality expectations. Establishing clear lines of communication and mutual understanding is crucial.

-

Logistical Issues: Importing products can introduce complexities related to customs, tariffs, and shipping delays, which may affect the timely delivery of quality products. Buyers should work closely with logistics partners to mitigate these risks.

-

Regulatory Compliance: Different regions have different regulatory requirements. Buyers must ensure that suppliers comply with local standards, which may differ from those in their home country. This is particularly relevant for industries such as telecommunications, where specific certifications are mandatory.

-

Market Variability: Fluctuations in demand and supply chain disruptions can impact the availability and pricing of plunger lock keys. Buyers should consider establishing relationships with multiple suppliers to enhance their purchasing power and reduce reliance on any single source.

By understanding the manufacturing processes, quality assurance protocols, and verification methods, B2B buyers can make informed decisions when sourcing plunger lock keys. Adopting a proactive approach to quality assurance will not only enhance product reliability but also foster long-term partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plunger lock key’

When sourcing plunger lock keys for your business, it’s essential to follow a structured approach to ensure quality, compatibility, and supplier reliability. This guide outlines a practical checklist to help you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline the technical requirements for the plunger lock keys you need. This includes identifying the specific lock models (e.g., Channell LK03029817, Highfield 93180775-S) and their dimensions, such as inside diameter and material specifications. Understanding these details ensures that you procure the right product that meets your operational needs.

Step 2: Research Potential Suppliers

Invest time in researching suppliers that specialize in plunger lock keys. Look for manufacturers or distributors with a solid reputation in your region, especially those familiar with the specific requirements of your market. Online directories, trade shows, and industry forums can provide valuable insights into potential suppliers.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with industry standards. This step is crucial for ensuring product quality and safety. Look for certifications such as ISO 9001, which indicates a commitment to quality management systems, and any relevant local certifications that may apply in your region.

Step 4: Request Samples and Technical Data Sheets

Always request samples of the plunger lock keys along with technical data sheets. Testing samples allows you to assess compatibility and quality firsthand. Technical data sheets provide essential information regarding material properties, dimensions, and usage instructions, which are vital for making informed decisions.

Illustrative image related to plunger lock key

Step 5: Review Pricing and Terms of Sale

Once you have shortlisted potential suppliers, compare their pricing structures and terms of sale. Ensure that you consider not only the unit price but also shipping costs, payment terms, and any bulk discounts. Understanding the total cost of procurement helps you budget effectively and negotiate better deals.

Step 6: Check Customer References and Reviews

Reach out to previous clients or check online reviews to gauge the supplier’s reliability and customer service. Feedback from other businesses can provide insights into the supplier’s responsiveness, product quality, and after-sales support. This information is crucial for building a trustworthy supplier relationship.

Step 7: Establish a Long-term Relationship

Once you’ve selected a supplier, focus on building a long-term relationship. Regular communication and feedback will help you address any issues promptly and ensure that your supplier is aligned with your evolving needs. A strong partnership can lead to better pricing, priority service, and collaborative product development in the future.

By following this checklist, you can enhance your sourcing strategy for plunger lock keys, ensuring that you procure high-quality products that meet your specific business requirements.

Comprehensive Cost and Pricing Analysis for plunger lock key Sourcing

Understanding the cost structure and pricing dynamics of plunger lock keys is crucial for international B2B buyers, especially when sourcing from diverse regions such as Africa, South America, the Middle East, and Europe. This analysis provides insights into cost components, pricing influencers, and strategic buying tips tailored for these markets.

Illustrative image related to plunger lock key

What Are the Key Cost Components for Plunger Lock Keys?

When assessing the cost of plunger lock keys, several components come into play:

-

Materials: The primary raw materials used in plunger lock keys include high carbon alloy steel and die-cast metals. The choice of material significantly impacts durability and tamper resistance, thus influencing the overall cost. Premium materials may increase the unit price but can offer better performance.

-

Labor: Labor costs vary by region and manufacturing processes. In countries with lower labor costs, such as certain South American and African nations, buyers can benefit from lower prices. However, skilled labor is essential for precision manufacturing, which may raise costs in regions where expertise is limited.

-

Manufacturing Overhead: This encompasses expenses related to utilities, facility maintenance, and indirect labor. Efficient manufacturing processes can help reduce overhead, which is particularly important for bulk orders.

-

Tooling: The initial investment in tooling for custom designs can be significant. For buyers requiring unique specifications, understanding these costs upfront can aid in budgeting effectively.

-

Quality Control (QC): Rigorous QC processes ensure that products meet the desired specifications and safety standards. Suppliers with robust QC practices may charge higher prices, but this often results in fewer defects and returns.

-

Logistics: Shipping costs are influenced by the weight, volume, and destination of the products. International buyers should consider logistics partners that offer competitive rates to minimize total expenses.

-

Margin: Finally, suppliers will factor in their profit margins, which can vary based on competition and market demand. Understanding market rates can help buyers negotiate better deals.

How Do Pricing Influencers Affect Plunger Lock Key Costs?

Several factors can influence the pricing of plunger lock keys:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically qualify for volume discounts, reducing per-unit costs. Buyers should evaluate their needs to optimize order sizes.

-

Specifications and Customization: Custom-designed keys or those with specific features will incur higher costs. Buyers should assess whether standard options meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Keys that meet industry-specific certifications may be priced higher due to the assurance of quality. Buyers should weigh the benefits of certified products against their budget constraints.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers may charge more due to their track record, while emerging suppliers might offer competitive pricing to gain market share.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. Incoterms dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk. Choosing the right terms can significantly influence the total cost of ownership.

What Negotiation Tips Can Help B2B Buyers Achieve Cost-Efficiency?

For international B2B buyers, especially from regions like Africa, South America, and the Middle East, effective negotiation strategies can lead to cost savings:

-

Research and Benchmarking: Before negotiations, conduct market research to understand standard pricing. Use this data to leverage better deals.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also long-term factors such as durability, maintenance, and replacement costs. Highlighting TCO can justify higher initial prices for superior quality.

-

Consider Long-Term Partnerships: Establishing a long-term relationship with suppliers can lead to better pricing and service. Suppliers may offer favorable terms to repeat customers.

-

Be Open to Alternative Suppliers: Exploring different suppliers can yield better pricing. Emerging suppliers may offer competitive rates as they seek to establish themselves in the market.

Conclusion

Navigating the cost and pricing landscape for plunger lock keys requires a comprehensive understanding of various influencing factors. By considering materials, labor, and logistics, along with strategic negotiation techniques, international B2B buyers can optimize their sourcing strategies and achieve cost-efficient outcomes. Always remember that indicative prices may vary, and thorough research is essential for informed decision-making.

Alternatives Analysis: Comparing plunger lock key With Other Solutions

When evaluating security solutions, it’s essential to consider various alternatives to the plunger lock key. This comparison will highlight the strengths and weaknesses of the plunger lock key against other viable methods, enabling B2B buyers to make informed decisions based on their specific operational requirements and security needs.

| Comparison Aspect | Plunger Lock Key | Barrel Lock Key | Electronic Locking System |

|---|---|---|---|

| Performance | High security for specific applications | Reliable for cable and utility locks | Offers advanced security features like access logs and remote access |

| Cost | Moderate initial cost, low maintenance | Generally lower cost for basic locks | Higher upfront costs, potential ongoing subscription fees for advanced features |

| Ease of Implementation | Simple installation process | Easy to use but limited to specific lock types | More complex installation, may require professional setup |

| Maintenance | Low maintenance requirements | Minimal upkeep, replaceable keys | Requires software updates, battery replacements, and potential troubleshooting |

| Best Use Case | Specific industrial applications | Ideal for utility and cable management | Suitable for high-security environments needing flexible access control |

What Are the Advantages and Disadvantages of Using a Barrel Lock Key?

The barrel lock key, such as the Jonard TTB-6, is designed specifically for certain types of locks, making it a reliable choice for users in industries like telecommunications. Its performance is solid, particularly for CATV applications, where it provides a secure solution for accessing locked enclosures. The cost is typically lower than that of an electronic locking system, and the ease of use is commendable. However, its main drawback lies in its limited compatibility; it can only unlock specific lock types, which may not suit businesses requiring a more versatile solution.

How Does an Electronic Locking System Compare to a Plunger Lock Key?

Electronic locking systems offer a modern approach to security, featuring advanced functionalities such as remote access, user management, and activity logging. These systems are particularly beneficial for environments where security protocols must adapt rapidly, such as in corporate settings or high-value asset storage. However, the initial setup can be complex, and ongoing costs may arise from software subscriptions and maintenance. While they provide a high level of security, businesses must weigh these costs against their budget and security needs.

Illustrative image related to plunger lock key

Conclusion: How Can B2B Buyers Choose the Right Locking Solution?

When selecting a locking solution, B2B buyers must assess their specific needs, including the level of security required, budget constraints, and the type of environment in which the locks will be used. The plunger lock key serves as a robust option for certain applications, while barrel lock keys provide a cost-effective solution for utility management. For those requiring advanced security features and flexibility, electronic locking systems may be worth the investment. Ultimately, the choice should align with the operational demands and security objectives of the organization.

Essential Technical Properties and Trade Terminology for plunger lock key

What are the Key Technical Properties of a Plunger Lock Key?

Understanding the essential technical properties of plunger lock keys is crucial for B2B buyers, particularly those involved in security, manufacturing, and distribution sectors. Here are some critical specifications to consider:

-

Material Grade

Plunger lock keys are commonly made from high carbon alloy steel or die-cast materials, which offer superior strength and durability. High carbon steel is particularly valued for its resistance to wear and tear, making it suitable for heavy-duty applications. Selecting the right material is vital as it directly influences the longevity and reliability of the lock key, impacting overall security. -

Inside Diameter Tolerance

The inside diameter of the lock key must match the specifications of the lock it is intended to operate. For instance, a common range is 0.176″ to 0.196″ (4.47 mm to 4.98 mm). Tolerance in this context refers to the acceptable range of deviation in the diameter measurement. This precision ensures that the key fits snugly into the lock, preventing unauthorized access and minimizing the risk of key malfunction. -

Weight

The weight of a plunger lock key, typically around 0.22 lb (99.88 g), can influence usability and handling. A lightweight key is easier to manage, especially in high-volume operations. However, it should not compromise the sturdiness required for effective locking mechanisms. Buyers should consider the balance between weight and durability when sourcing keys for their operations. -

Finish

The finish of a plunger lock key, such as polished steel or satin chrome, affects not only aesthetics but also resistance to corrosion and wear. A high-quality finish can enhance the key’s lifespan by protecting it from environmental factors. For international buyers, especially those in humid or coastal regions, selecting a key with an appropriate finish is crucial for maintenance and longevity. -

Serialization

Some plunger lock keys come serialized, which adds an extra layer of security by allowing for tracking and inventory management. Serialized keys help in maintaining records of key distribution and usage, thus facilitating better control over access points in a facility. This feature is particularly important for businesses that require strict security measures.

What are Common Trade Terms Used in the Plunger Lock Key Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation processes in B2B transactions. Here are several key terms:

Illustrative image related to plunger lock key

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers looking to procure plunger lock keys that fit specific locking systems. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. For plunger lock keys, MOQs can impact inventory management and purchasing strategies, especially for businesses aiming to optimize their supply chain. -

RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to invite suppliers to submit price proposals for specific products. This is a critical step for B2B buyers seeking competitive pricing for plunger lock keys, allowing them to evaluate different suppliers based on cost and quality. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding Incoterms is vital for B2B transactions involving plunger lock keys, as they govern shipping, insurance, and risk management during transportation. -

Lead Time

This term refers to the amount of time from placing an order to receiving the goods. For plunger lock keys, knowing the lead time can help businesses plan their inventory needs effectively, ensuring that they maintain security without interruption.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing plunger lock keys, ensuring they meet their operational needs while maintaining security standards.

Navigating Market Dynamics and Sourcing Trends in the plunger lock key Sector

What Are the Current Market Dynamics and Key Trends in the Plunger Lock Key Sector?

The global plunger lock key market is currently experiencing significant growth driven by increased demand for security solutions across various sectors, including telecommunications, automotive, and commercial facilities. As businesses prioritize security, the need for reliable locking mechanisms has surged, particularly in emerging markets in Africa, South America, and the Middle East, where rapid urbanization and industrialization are taking place. Additionally, advancements in manufacturing technology, such as precision machining and automation, are enhancing the production efficiency and quality of plunger lock keys.

Sourcing trends are evolving, with a notable shift towards digital procurement platforms that streamline the purchasing process. B2B buyers are increasingly leveraging online marketplaces and supplier directories to identify and engage with manufacturers globally, particularly in regions like Europe and Southeast Asia. Furthermore, the integration of Industry 4.0 technologies, such as IoT and AI in supply chain management, is enabling better inventory control and predictive analytics, allowing businesses to optimize their sourcing strategies.

Moreover, the rise of customization is a key trend in the plunger lock key market. Buyers are looking for suppliers that can provide tailored solutions that meet specific security requirements, including varying keyway designs and locking mechanisms. This demand for customization is prompting manufacturers to adopt flexible production techniques that can accommodate small batch sizes without compromising quality or delivery times.

Illustrative image related to plunger lock key

How Is Sustainability Shaping the Sourcing of Plunger Lock Keys?

Sustainability has emerged as a critical factor in the sourcing of plunger lock keys, reflecting the growing awareness of environmental impact among B2B buyers. Companies are increasingly scrutinizing their supply chains for sustainability, seeking suppliers that demonstrate a commitment to reducing their carbon footprint and employing eco-friendly manufacturing processes. The use of recycled materials in the production of plunger lock keys is gaining traction, as buyers prioritize products that minimize resource depletion.

Furthermore, ethical sourcing practices are becoming non-negotiable for businesses looking to enhance their brand reputation. Transparency in the supply chain, including the ethical sourcing of raw materials and fair labor practices, is essential for building trust with consumers and stakeholders. Certifications such as ISO 14001 for environmental management and Fair Trade certification are increasingly sought after by buyers as indicators of a supplier’s commitment to sustainable practices.

Incorporating sustainable materials, such as bioplastics or recycled metals, into the production of plunger lock keys not only reduces environmental impact but also aligns with the values of consumers in developed markets. As sustainability continues to shape purchasing decisions, suppliers that prioritize ethical practices and environmental stewardship will be better positioned to attract and retain B2B clients.

Illustrative image related to plunger lock key

How Has the Plunger Lock Key Market Evolved Over Time?

The evolution of the plunger lock key market reflects broader technological advancements and changing security needs. Initially designed for basic locking functions, plunger locks have transformed significantly with the introduction of more sophisticated locking mechanisms and materials. Early models were primarily constructed from basic metals, which provided limited security. Over time, the integration of high-carbon alloy steels and advanced locking designs has enhanced durability and tamper resistance.

The market has also adapted to the increasing demand for customization, with manufacturers now offering a variety of keyway designs and locking solutions tailored to specific applications. This evolution has been further accelerated by the digital transformation in manufacturing, allowing for rapid prototyping and customization to meet the diverse needs of international B2B buyers. As security concerns continue to evolve, the plunger lock key sector is likely to witness ongoing innovation, driven by technological advancements and shifting market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of plunger lock key

-

How do I ensure the quality of plunger lock keys when sourcing internationally?

To ensure quality when sourcing plunger lock keys, conduct thorough supplier vetting. Look for manufacturers with ISO certifications, positive reviews, and a solid track record in the industry. Request samples to assess the product quality firsthand. Additionally, consider third-party quality assurance inspections before shipment to verify that the keys meet your specifications and standards. Establishing clear quality expectations in your purchase agreement can also help mitigate risks. -

What is the best material for plunger lock keys?

The best materials for plunger lock keys are typically high carbon alloy steel or similar durable metals. These materials offer superior tamper resistance and durability, making them ideal for heavy-duty applications. When sourcing, confirm that the supplier uses high-quality materials that align with your operational needs, especially in environments that experience harsh conditions or heavy usage. -

What customization options are available for plunger lock keys?

Customization options for plunger lock keys can include variations in size, shape, and keyway configurations. Many manufacturers offer tailored solutions based on specific security requirements or operational needs. It’s advisable to discuss your customization needs upfront with potential suppliers to understand the possibilities and any associated costs or lead times. -

What are the typical minimum order quantities (MOQs) for plunger lock keys?

Minimum order quantities for plunger lock keys can vary significantly between manufacturers. Generally, MOQs can range from as low as 50 to several hundred units, depending on the supplier’s production capabilities and the complexity of the order. It’s essential to clarify MOQs during negotiations to align your purchasing strategy with supplier capabilities, especially if you are sourcing for a larger project. -

What payment terms should I expect when sourcing plunger lock keys internationally?

Payment terms for international orders can vary widely but often include options such as advance payment, letter of credit, or payment upon delivery. Commonly, suppliers may request a deposit (e.g., 30% upfront) with the balance due before shipment. Discussing and agreeing on payment terms early in negotiations can help establish trust and ensure a smooth transaction. -

How can I handle logistics and shipping for plunger lock keys?

Managing logistics for international shipments of plunger lock keys involves selecting reliable shipping partners who understand customs regulations in your destination country. Consider factors such as shipping costs, delivery times, and insurance options. It’s also wise to stay informed about any import duties or tariffs that may apply, as these can impact the total cost of your order. -

What are the common certifications for plunger lock keys and why are they important?

Common certifications for plunger lock keys include ISO 9001 (Quality Management Systems) and ISO 14001 (Environmental Management). These certifications indicate that a supplier adheres to recognized quality and environmental standards, which can be crucial for ensuring product reliability and compliance with international regulations. Certifications also enhance supplier credibility, making them a key consideration during the sourcing process. -

How do I assess the reliability of a supplier for plunger lock keys?

To assess the reliability of a supplier, conduct background checks, review their financial stability, and seek references from previous clients. Evaluating their production capacity, delivery timelines, and customer service responsiveness is also critical. Consider starting with a smaller order to gauge their reliability before committing to larger purchases. Additionally, using platforms that provide supplier ratings and reviews can help in making informed decisions.

Top 4 Plunger Lock Key Manufacturers & Suppliers List

1. Jonard – TTB-6 Barrel Lock Plunger Key

Domain: jonard.com

Registered: 1998 (27 years)

Introduction: This company, Jonard – TTB-6 Barrel Lock Plunger Key, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Highfield – Utility Barrel Lock & Plunger Key System

Domain: highfield-mfg.com

Registered: 1996 (29 years)

Introduction: Product Name: Utility Barrel Lock & Plunger Key System #5 & #5A

Key Features:

– Increased security for gas utilities compared to conventional barrel locks

– Unique key and plunger design

– Non-interchangeable keys: #5 key cannot open #5A lock and vice versa

– Dimensionally interchangeable with other barrel locks

– Designed for strength and durability

– Plated and case hardened steel components fo…

3. Medeco – Plunger Lock

Domain: medeco.com

Registered: 1996 (29 years)

Introduction: Sliding door hardware is only as good as its lock. Get the best plunger lock for the job.

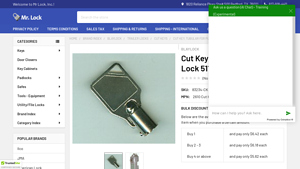

4. BlayLock – Cut Key for Plunger Lock 51134

Domain: mrlock.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “Cut Key, Tubular for Plunger Lock 51134”, “brand”: “BlayLock”, “sku”: “83234-CK”, “upc”: “”, “mpn”: “2610”, “bulk_discount_rates”: [{“quantity”: “1”, “price”: “$6.42”}, {“quantity”: “2 – 3”, “price”: “$6.18”}, {“quantity”: “4 or above”, “price”: “$5.62”}], “current_stock”: 45, “msrp”: “”, “current_price”: “$6.42”}

Strategic Sourcing Conclusion and Outlook for plunger lock key

In the evolving landscape of security solutions, strategic sourcing for plunger lock keys remains a critical focus for international B2B buyers. Understanding the nuances of different lock types, such as barrel locks and their corresponding keys, is essential for optimizing supply chains and ensuring product compatibility. High-quality materials, like high carbon alloy steel, enhance durability and tamper resistance, providing added value for businesses seeking reliable security solutions.

As markets in Africa, South America, the Middle East, and Europe expand, the demand for specialized locking mechanisms will continue to rise. Buyers should prioritize partnerships with manufacturers who offer not only superior products but also tailored solutions that meet regional compliance and security needs. This proactive approach will not only secure assets but also enhance operational efficiency.

Illustrative image related to plunger lock key

Looking ahead, it is crucial for businesses to stay informed about industry trends and technological advancements in locking systems. Engaging with reputable suppliers and investing in innovative security measures will position companies to capitalize on emerging opportunities. By prioritizing strategic sourcing, businesses can safeguard their interests and foster long-term growth in a competitive global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to plunger lock key

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.