جت پرینتر: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for جت پرینتر

In the competitive landscape of modern manufacturing, sourcing the right جت پرینتر can be a daunting challenge for international B2B buyers. With various models, technologies, and applications available, making an informed purchasing decision is crucial to ensure that your business operations run smoothly and efficiently. This comprehensive guide will navigate the complexities of the جت پرینتر market, covering essential topics such as types of printers, their diverse applications across industries, supplier vetting processes, and pricing strategies.

As businesses in Africa, South America, the Middle East, and Europe (including key markets like Brazil and Germany) increasingly rely on advanced printing technologies for labeling, coding, and compliance, understanding the nuances of جت پرینتر selection becomes imperative. This guide empowers buyers to evaluate their specific needs, understand the technical aspects of different printing technologies—including Continuous Inkjet (CIJ) and Drop-on-Demand (DOD)—and identify reputable suppliers who can provide the necessary support and service. By leveraging the insights presented here, you will be well-equipped to make strategic decisions that enhance your production capabilities and drive business growth in a global marketplace.

Understanding جت پرینتر Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Continuous Inkjet (CIJ) | High-speed printing, continuous ink flow, minimal clogging | Packaging, labeling, product marking | Pros: Fast, efficient for high-volume production. Cons: Higher initial investment. |

| Drop-on-Demand (DOD) | Prints droplets on demand, often uses thermal technology | Small batch printing, variable data printing | Pros: Cost-effective for lower volumes. Cons: Slower than CIJ, may require more maintenance. |

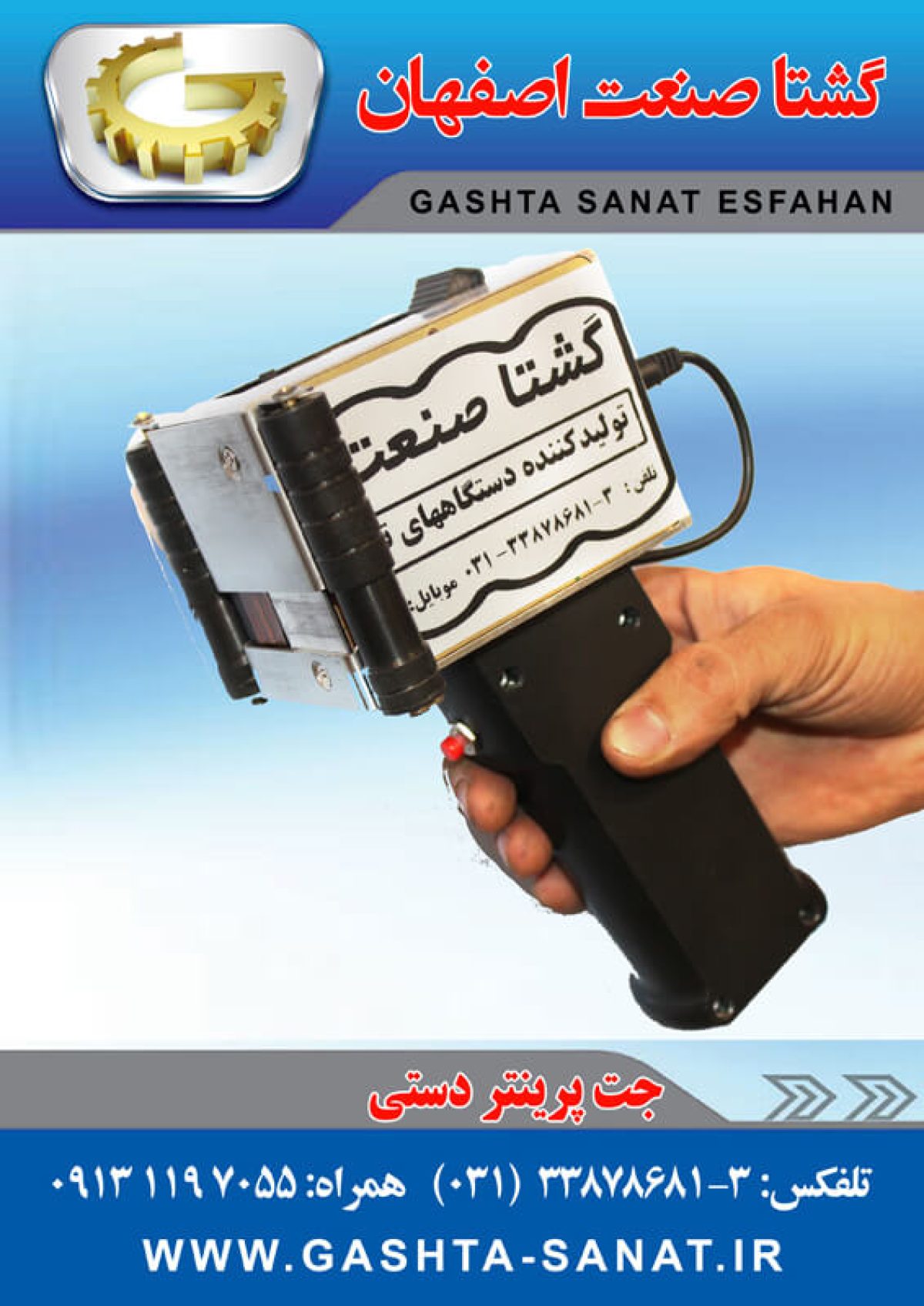

| Handheld Jet Printer | Portable, manual operation, easy to use | Field applications, small-scale printing | Pros: Versatile, easy to transport. Cons: Limited printing speed and volume. |

| Automatic Jet Printer | Fixed installation, integrates with production lines | Large-scale manufacturing, high-speed printing | Pros: High efficiency, automated operation. Cons: Requires space and setup investment. |

| Laser Jet Printer | Uses laser technology for permanent marking | Durable labeling, high-quality prints | Pros: High precision, no ink required. Cons: Higher operational costs, limited to certain materials. |

What Are the Characteristics of Continuous Inkjet (CIJ) Printers?

Continuous Inkjet (CIJ) printers are renowned for their ability to print at high speeds, making them ideal for large-scale production environments. They utilize a continuous flow of ink, which helps prevent clogging and ensures consistent print quality. CIJ is particularly suitable for packaging and labeling applications, where speed and efficiency are critical. B2B buyers should consider the initial investment, as CIJ printers can be more expensive upfront, but their efficiency often leads to lower operational costs over time.

How Do Drop-on-Demand (DOD) Printers Differ from CIJ?

Drop-on-Demand (DOD) printers operate by ejecting ink droplets only when needed, which can result in significant cost savings for businesses with lower printing volumes. This technology is commonly used for variable data printing, where each print may contain different information. While DOD printers can be more affordable than CIJ models, they tend to be slower and may require more frequent maintenance. Buyers should assess their printing needs and volume to determine the best fit.

What Advantages Do Handheld Jet Printers Offer?

Handheld jet printers are designed for portability and ease of use, making them ideal for field applications or environments where space is limited. Users can manually operate these printers to mark products on-site, which adds a layer of convenience for small-scale printing tasks. While they provide versatility, buyers should be aware that handheld printers typically have lower printing speeds and volumes compared to their stationary counterparts.

Why Consider Automatic Jet Printers for Production Lines?

Automatic jet printers are fixed installations that integrate seamlessly into production lines, allowing for high-speed printing without manual intervention. They are essential for large-scale manufacturing operations where efficiency and reliability are paramount. While they require a more significant initial investment and dedicated space, the automation and speed they offer can lead to significant long-term savings in labor and material costs.

What Are the Key Features of Laser Jet Printers?

Laser jet printers utilize laser technology to create permanent markings on products, offering high precision and quality. They are particularly effective for durable labeling and can print on a variety of materials. While they eliminate the need for ink, which can reduce operational costs, laser printers may have higher initial and maintenance costs. Buyers should evaluate the specific materials they intend to print on and their overall budget when considering this option.

Key Industrial Applications of جت پرینتر

| Industry/Sector | Specific Application of جت پرینتر | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Printing expiration dates and batch numbers | Ensures compliance with regulations and enhances product traceability | Look for printers that can handle various packaging materials and offer high-speed printing. |

| Pharmaceuticals | Labeling vials and packaging with variable data | Increases accuracy in tracking and reduces errors in medication distribution | Choose printers with high resolution for fine details and durability for sterile environments. |

| Cosmetics | Printing product information on containers | Enhances branding and provides essential product details to consumers | Consider printers that can print on different materials and offer customizable ink options. |

| Electronics | Marking serial numbers and manufacturing dates | Facilitates inventory management and enhances product security | Ensure compatibility with automated production lines and look for printers with quick changeover capabilities. |

| Automotive | Printing on parts and components for identification | Improves supply chain efficiency and reduces counterfeit risks | Select printers that can withstand harsh conditions and provide robust printing solutions for various substrates. |

How is جت پرینتر Used in the Food and Beverage Industry?

In the food and beverage sector, جت پرینتر is primarily utilized for printing essential information such as expiration dates, batch numbers, and nutritional facts directly onto packaging. This ensures compliance with food safety regulations and enhances traceability, which is critical for consumer safety. Buyers in this industry should consider printers that can handle diverse packaging materials, offer high-speed printing capabilities, and maintain consistent ink quality to prevent smudging or fading.

What Role Does جت پرینتر Play in Pharmaceuticals?

In pharmaceuticals, جت پرینتر is essential for labeling vials, ampoules, and packaging with variable data, including expiration dates and unique identifiers. This application enhances accuracy in tracking medications and reduces the risk of dispensing errors, which can have severe implications. Buyers should prioritize high-resolution printers that can operate in sterile environments and provide durability against chemicals, ensuring the integrity of the printed information.

How Do Cosmetics Benefit from جت پرینتر Technology?

The cosmetics industry leverages جت پرینتر to print vital product information on various containers, including ingredients, usage instructions, and branding elements. This not only enhances brand visibility but also provides consumers with critical information needed for safe usage. International buyers should look for printers capable of printing on multiple substrates, including glass and plastic, and those that offer customizable ink options to meet specific branding needs.

Why is جت پرینتر Important in Electronics Manufacturing?

In the electronics sector, جت پرینتر is used for marking serial numbers, manufacturing dates, and barcodes on components and assemblies. This practice is crucial for inventory management and helps prevent counterfeiting, ensuring that products can be traced back through the supply chain. Buyers should seek printers that are compatible with automated production lines and offer quick changeover capabilities to minimize downtime during production.

What Advantages Does جت پرینتر Provide in the Automotive Industry?

The automotive industry employs جت پرینتر to print identification marks, serial numbers, and manufacturing dates directly onto parts and components. This practice enhances supply chain efficiency and helps mitigate the risks of counterfeit parts. Buyers should consider printers that can withstand harsh manufacturing environments and provide robust solutions for printing on various substrates, ensuring long-lasting legibility of the printed information.

3 Common User Pain Points for ‘جت پرینتر’ & Their Solutions

Scenario 1: Challenges with Ink Quality and Consistency

The Problem: One of the most common frustrations for B2B buyers of جت پرینتر is dealing with inconsistent ink quality, which can lead to poor print results and affect product presentation. For manufacturers, especially in industries like food and beverage, cosmetics, or pharmaceuticals, the integrity of printed information (like expiration dates or batch codes) is critical. Inconsistent ink performance can result in smudging, fading, or even complete print failure, causing costly production delays and potential regulatory issues.

The Solution: To combat ink quality issues, buyers should prioritize sourcing جت پرینتر from reputable suppliers who offer high-quality inks specifically designed for their chosen printer model. It’s essential to review product specifications and consult with manufacturers to ensure compatibility and performance standards. Additionally, regular maintenance of the printer, including cleaning the print head and ensuring the ink supply is properly managed, can prevent many quality issues. Establishing a consistent inventory of high-quality ink can also help maintain print consistency, while investing in a printer with advanced ink management features can further enhance reliability.

Scenario 2: Difficulty in Integration with Existing Production Lines

The Problem: B2B buyers often face challenges when integrating جت پرینتر into existing production lines. Many businesses operate with legacy systems, making it difficult to seamlessly introduce new technology. This can lead to operational disruptions, compatibility issues, and delays in production schedules. The fear of high costs associated with downtime or system overhauls can make companies hesitant to adopt new printing solutions.

The Solution: To ensure smooth integration, businesses should conduct a comprehensive needs assessment prior to purchasing a جت پرینتر. This includes evaluating existing production workflows and identifying potential integration points. Collaborating with suppliers who offer technical support and customization options can facilitate a smoother transition. Additionally, investing in a جت پرینتر with flexible connectivity options—such as Ethernet, USB, or wireless capabilities—can enhance compatibility with existing systems. Providing training for staff on the new system can also minimize disruption and ensure that everyone is prepared to operate the new equipment effectively.

Scenario 3: High Operational Costs and Maintenance Requirements

The Problem: Another significant concern for B2B buyers is the ongoing operational costs associated with جت پرینتر, including maintenance, ink replacement, and potential repairs. Many companies underestimate the total cost of ownership, which can lead to budget overruns and financial strain. Additionally, frequent maintenance can disrupt production and reduce overall efficiency.

The Solution: To manage operational costs effectively, it’s crucial to perform a total cost analysis before making a purchase. This analysis should include not only the initial price of the جت پرینتر but also projected ink usage, maintenance requirements, and potential repair costs over time. Buyers should seek out models known for their durability and lower maintenance needs, as well as suppliers who provide comprehensive warranties and customer support. Implementing a preventive maintenance schedule can also help identify issues before they become costly repairs. Moreover, considering bulk ink purchasing agreements can reduce per-unit ink costs and improve overall budgeting accuracy.

Strategic Material Selection Guide for جت پرینتر

What Are the Key Materials Used in جت پرینتر Manufacturing?

When selecting materials for جت پرینتر (inkjet printers), it’s essential to consider their properties and suitability for various applications. The materials used can significantly affect the performance, durability, and cost of the printers. Below, we analyze four common materials utilized in the manufacturing of جت پرینتر, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand elevated temperatures and pressures. It is non-reactive, making it suitable for various ink formulations.

Pros & Cons:

The durability of stainless steel is a significant advantage, as it can endure harsh industrial environments. However, it is more expensive than other materials and can complicate manufacturing due to the need for specialized machining.

Impact on Application:

Stainless steel is particularly well-suited for components that come into contact with inks, ensuring that the integrity of the printed material is maintained. Its resistance to corrosion also extends the lifespan of the printer.

Considerations for International Buyers:

Buyers from regions like Europe may prefer stainless steel due to stringent compliance standards (e.g., DIN standards). In contrast, buyers in Africa or South America might weigh the cost against the benefits more critically.

2. Plastic (Polycarbonate and ABS)

Key Properties:

Plastics such as polycarbonate and ABS offer lightweight characteristics and good impact resistance. They can be molded into complex shapes, making them versatile for various components.

Pros & Cons:

While plastics are generally more affordable and easier to manufacture, they may not withstand high temperatures or aggressive chemicals as well as metals. This can limit their use in specific applications where durability is paramount.

Impact on Application:

Plastics can be used for housing and non-critical components of جت پرینتر. However, their limitations in temperature resistance may affect the printer’s performance in high-temperature environments.

Considerations for International Buyers:

For buyers in regions like the Middle East, where temperatures can soar, selecting high-temperature resistant plastics is crucial. Compliance with local regulations regarding material safety is also a consideration.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can be anodized for additional surface protection, enhancing its durability.

Pros & Cons:

Aluminum’s lightweight nature makes it easy to handle and install, while its corrosion resistance extends its usability in various environments. However, it can be more expensive than other metals and may require additional treatment for specific applications.

Impact on Application:

Aluminum is often used in structural components of جت پرینتر, providing a balance between strength and weight. Its thermal properties also help in managing heat during operation.

Considerations for International Buyers:

Buyers in Brazil and Germany may favor aluminum for its recyclability and compliance with environmental standards. Understanding local recycling regulations can also influence purchasing decisions.

4. Ceramics

Key Properties:

Ceramics are known for their hardness, wear resistance, and ability to withstand high temperatures. They are also chemically inert, making them suitable for various ink types.

Pros & Cons:

Ceramics provide excellent durability and resistance to wear, but they are brittle and can be challenging to manufacture. The cost of ceramics is generally higher than metals and plastics.

Illustrative image related to جت پرینتر

Impact on Application:

Ceramics are often used in the nozzles of جت پرینتر, where precision and durability are critical. Their ability to handle high temperatures makes them suitable for industrial applications.

Considerations for International Buyers:

In regions with stringent quality standards, such as Europe, ceramics may be preferred for high-end applications. However, buyers in developing markets may find the cost prohibitive.

Summary Table

| Material | Typical Use Case for جت پرینتر | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Components in contact with ink | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Plastic | Housing and non-critical parts | Lightweight, cost-effective | Limited temperature resistance | Low |

| Aluminum | Structural components | Lightweight, corrosion-resistant | Higher cost, requires treatment | Medium |

| Ceramics | Nozzles and precision parts | High durability and temperature resistance | Brittle, high manufacturing cost | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in جت پرینتر manufacturing, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for جت پرینتر

The manufacturing processes and quality assurance protocols for جت پرینتر (inkjet printers) are crucial for ensuring product reliability and performance. As international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe evaluate suppliers, understanding these processes can significantly influence purchasing decisions. This section outlines the key stages of manufacturing, quality control standards, and actionable insights for buyers.

What Are the Main Stages of Manufacturing جت پرینتر?

The manufacturing process of جت پرینتر involves several critical stages, each essential to delivering a high-quality product.

1. Material Preparation: What Materials Are Used in Manufacturing جت پرینتر?

The initial stage involves sourcing and preparing materials, which typically include:

- Metals and Plastics: Used for the printer’s chassis, casing, and internal components.

- Electronic Components: Such as circuit boards, sensors, and nozzles that facilitate the inkjet mechanism.

- Ink Formulation: The production of various types of ink, including water-based, solvent-based, and UV inks, tailored for specific printing requirements.

Quality sourcing of these materials is vital, as they directly impact the printer’s durability and printing quality.

2. Forming: How Are Components Shaped for جت پرینتر?

The forming stage involves shaping the prepared materials into the necessary components through various techniques:

- Injection Molding: Commonly used for creating plastic components, ensuring high precision and repeatability.

- CNC Machining: Employed for metal parts, allowing for intricate designs and tight tolerances.

- 3D Printing: Emerging as a technique for rapid prototyping and producing complex geometries that are difficult to achieve with traditional methods.

These techniques ensure that each part meets the specified design and functional requirements.

3. Assembly: What Is the Assembly Process for جت پرینتر?

In the assembly stage, the individual components are brought together. This involves:

- Sub-Assembly: Components like print heads and electronic boards are assembled separately before being integrated into the main unit.

- Integration: The final assembly combines all components, ensuring that mechanical and electrical connections are properly established.

- Testing During Assembly: Implementing in-process quality checks to verify that each assembly step meets specifications.

The assembly process is crucial as it determines the operational integrity of the final product.

4. Finishing: What Are the Final Touches on جت پرینتر?

The finishing stage involves:

- Surface Treatment: Applying coatings or treatments to enhance durability and aesthetics.

- Final Inspection: Conducting thorough inspections to ensure that the printer meets quality standards before packaging.

- Packaging: Ensuring that the product is securely packaged to prevent damage during transportation.

Finishing touches not only enhance the product’s appearance but also protect it during shipping.

How Is Quality Assurance Implemented in جت پرینتر Manufacturing?

Quality assurance is paramount in the manufacturing of جت پرینتر to ensure product reliability and customer satisfaction.

What International Standards Guide Quality Assurance for جت پرینتر?

Several international standards are relevant to the quality assurance of جت پرینتر:

- ISO 9001: This standard outlines criteria for a quality management system, focusing on consistent product quality and customer satisfaction.

- CE Marking: Indicates compliance with EU safety, health, and environmental protection standards, crucial for buyers in Europe.

- API Standards: Particularly relevant for industrial applications, ensuring performance and safety in demanding environments.

Adherence to these standards not only enhances product credibility but also facilitates market entry in different regions.

What Are the Key Quality Control Checkpoints in جت پرینتر Manufacturing?

Quality control checkpoints are integral to the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process at various stages to catch defects early.

- Final Quality Control (FQC): Conducting comprehensive tests on the finished product to verify functionality and performance.

Implementing these checkpoints minimizes defects and enhances overall product quality.

What Common Testing Methods Are Used for جت پرینتر Quality Assurance?

Testing methods employed in the quality assurance of جت پرینتر include:

- Performance Testing: Evaluating print quality, speed, and reliability under different conditions.

- Durability Testing: Assessing the longevity of components and overall printer performance over time.

- Safety Testing: Ensuring compliance with safety standards to protect users and the environment.

These testing methods help ensure that the final product meets both quality and safety expectations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Here are actionable steps:

Illustrative image related to جت پرینتر

1. Conduct Audits: How Can Buyers Perform Supplier Audits?

Buyers should consider conducting on-site audits of potential suppliers to evaluate their manufacturing processes and quality assurance practices. This includes reviewing:

- Documentation: Quality manuals, process flow charts, and previous audit reports.

- Facilities: Inspecting the manufacturing environment for cleanliness, organization, and adherence to safety protocols.

2. Request Quality Reports: What Documentation Should Buyers Request?

Buyers can request quality reports that detail:

- Test Results: Evidence of compliance with international standards and testing outcomes.

- Non-Conformance Reports: Documentation of any issues encountered during production and how they were addressed.

These reports provide insights into the supplier’s commitment to quality.

3. Engage Third-Party Inspections: How Can Buyers Utilize Third-Party Inspections?

Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These services can conduct:

- Random Sampling Inspections: Evaluating a selection of products to ensure they meet quality standards.

- Compliance Checks: Verifying adherence to international and industry-specific standards.

By engaging third-party inspectors, buyers can mitigate risks associated with supplier quality.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers should be aware of specific nuances in quality control and certification:

- Regional Standards: Different regions may have specific certifications that are mandatory for market entry, such as GS Mark in Germany or INMETRO in Brazil.

- Cultural Considerations: Understanding the business practices and quality expectations in different regions can enhance supplier relationships.

- Supply Chain Complexity: Buyers should consider the entire supply chain, from raw material sourcing to final product delivery, when assessing quality.

By understanding these nuances, B2B buyers can make more informed purchasing decisions and foster stronger supplier partnerships.

Conclusion

In conclusion, the manufacturing processes and quality assurance for جت پرینتر are critical elements that influence product quality and reliability. B2B buyers from Africa, South America, the Middle East, and Europe should prioritize understanding these processes to make informed decisions. By focusing on quality control standards, conducting thorough supplier evaluations, and being aware of regional nuances, buyers can ensure they select reliable partners for their printing needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘جت پرینتر’

Introduction

This practical sourcing guide is designed to assist B2B buyers in effectively procuring جت پرینتر (jet printers) suitable for their operational needs. With various models and technologies available, understanding the essential steps in the sourcing process will ensure that you select the right device that meets your production requirements and budget constraints.

Illustrative image related to جت پرینتر

Step 1: Define Your Technical Specifications

Identifying your specific printing needs is the first step toward selecting the right جت پرینتر. Consider factors such as print speed, resolution, and the types of materials you will be printing on.

– Key Considerations:

– What information do you need to print (e.g., barcodes, expiration dates)?

– Will you require a portable or stationary unit based on your production line setup?

Step 2: Assess Different Technologies

Understanding the various printing technologies available is crucial for making an informed decision. The two primary types are Continuous Inkjet (CIJ) and Drop-On-Demand (DOD).

– Technology Insights:

– CIJ printers are ideal for high-speed production with continuous operation, while DOD printers are often more cost-effective for lower volume printing.

– Evaluate the advantages of each technology in relation to your specific use case.

Step 3: Evaluate Potential Suppliers

Thoroughly vetting suppliers is essential to ensure reliability and quality. Look for established manufacturers with a good track record in the industry.

– Supplier Evaluation Criteria:

– Request company profiles and client testimonials to gauge their reputation.

– Inquire about warranties, service agreements, and the availability of spare parts.

Step 4: Compare Pricing Models

Pricing for جت پرینتر can vary significantly based on technology and features. It’s important to compare prices from multiple suppliers while considering the total cost of ownership.

– Pricing Factors to Consider:

– Are there additional costs for consumables, maintenance, or training?

– How does the pricing compare within the same technology category to ensure you’re getting a fair deal?

Step 5: Verify Compliance and Certifications

Ensure that the جت پرینتر meets industry standards and regulatory requirements for your region. This step is critical for avoiding potential legal issues and ensuring product quality.

– Certification Checks:

– Confirm certifications related to safety, environmental standards, and manufacturing practices.

– Check if the printer complies with local regulations, especially for food and pharmaceutical packaging.

Step 6: Test Before You Buy

If possible, request a demonstration or trial period for the جت پرینتر before finalizing the purchase. This allows you to evaluate its performance in your specific production environment.

– Testing Focus Areas:

– Assess print quality, speed, and ease of use.

– Evaluate the responsiveness of the supplier’s support during the testing phase.

Step 7: Plan for After-Sales Support

Consider the level of after-sales support that will be provided by the supplier. This is vital for maintaining the printer’s performance over time.

– Support Considerations:

– Inquire about available technical support and training for your staff.

– Understand the process for obtaining repairs and replacement parts in case of malfunction.

By following this checklist, B2B buyers can streamline their sourcing process for جت پرینتر, ensuring they select a device that meets their operational needs while fostering a productive relationship with their supplier.

Illustrative image related to جت پرینتر

Comprehensive Cost and Pricing Analysis for جت پرینتر Sourcing

When sourcing جت پرینتر, understanding the cost structure and pricing dynamics is essential for international B2B buyers. The cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins. Each of these elements plays a significant role in the final pricing of جت پرینتر units, and buyers should be aware of how they interconnect.

What Are the Key Cost Components in جت پرینتر Pricing?

-

Materials: The type and quality of materials used, such as printing heads, ink cartridges, and housing components, significantly influence the overall cost. Higher-quality materials often lead to improved durability and performance, but they also increase the base price.

-

Labor: Labor costs can vary depending on the manufacturing location. Regions with higher labor costs may see increased pricing, while lower-cost regions may offer more competitive pricing but could compromise quality.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance, and facility costs. Efficient manufacturing processes can reduce overhead, which may be passed on to buyers in the form of lower prices.

-

Tooling: Initial tooling costs can be significant, especially for customized جت پرینتر models. Buyers looking for specific features or customizations should account for these costs in their total procurement budget.

-

Quality Control: Rigorous QC processes ensure that each جت پرینتر meets industry standards, which can add to the cost. Certifications such as ISO can influence pricing, reflecting the manufacturer’s commitment to quality.

-

Logistics: Shipping costs, including freight and insurance, can vary widely based on the origin and destination. Buyers should consider the total logistics costs, including potential tariffs and customs duties, when sourcing internationally.

-

Supplier Margin: Different suppliers have varying markups based on their market positioning, brand reputation, and service offerings. Understanding a supplier’s margin can aid in negotiating better pricing.

What Influences the Pricing of جت پرینتر?

Several factors can influence the pricing of جت پرینتر beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes typically lead to lower per-unit costs due to economies of scale. Buyers should inquire about MOQs, as smaller orders may incur higher prices.

-

Specifications and Customization: Custom features or advanced specifications can significantly increase costs. Buyers should weigh the necessity of these features against their budget constraints.

-

Quality and Certifications: Products that meet specific international standards or certifications may be priced higher. This is particularly relevant for buyers in regions with strict compliance regulations.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: Understanding the terms of sale, such as FOB (Free on Board) or CIF (Cost, Insurance, Freight), can affect the total landed cost of the جت پرینتر. Buyers must clarify these terms to avoid unexpected costs.

How Can Buyers Optimize Their Sourcing Strategy for جت پرینتر?

-

Negotiation: Engage in price negotiations with suppliers, especially when placing large orders. Leverage your purchasing power to secure better terms.

-

Cost-Efficiency: Look beyond initial pricing. Calculate the Total Cost of Ownership (TCO), which includes maintenance, operational costs, and potential downtime. A cheaper جت پرینتر may not always be the best value if it leads to higher operational costs.

-

Understanding Pricing Nuances for International Buyers: Be aware of regional pricing differences due to local economic conditions and demand. For instance, buyers in Africa and South America may face different pricing challenges compared to their counterparts in Europe.

-

Research Supplier Backgrounds: Investigate potential suppliers for their production capabilities, quality assurance processes, and after-sales support. A supplier with robust support can save costs in the long run.

Conclusion

In summary, a comprehensive understanding of the cost structure, pricing influencers, and strategic sourcing tips can empower B2B buyers to make informed decisions when procuring جت پرینتر. By considering all aspects of the purchasing process, buyers can enhance their procurement strategy and ensure they obtain the best value for their investment.

Alternatives Analysis: Comparing جت پرینتر With Other Solutions

Exploring Alternatives to جت پرینتر: Effective Solutions for Your Printing Needs

In the ever-evolving landscape of industrial printing, various technologies provide solutions for marking and coding products. While جت پرینتر has established itself as a reliable option, understanding its alternatives can help businesses make informed decisions. This section compares جت پرینتر with two viable alternatives: Laser Marking Systems and Thermal Transfer Printers (TTP).

| Comparison Aspect | جت پرینتر | Laser Marking Systems | Thermal Transfer Printers (TTP) |

|---|---|---|---|

| Performance | High-speed, variable data printing | Exceptional precision, long-lasting markings | Good for high-quality graphics, moderate speed |

| Cost | Moderate initial investment, ongoing ink costs | Higher upfront costs, low operating costs | Affordable equipment, ribbon costs vary |

| Ease of Implementation | Requires calibration and setup | Requires technical expertise for installation | Simple setup, user-friendly |

| Maintenance | Regular cleaning needed, ink replenishment | Minimal, but lens cleaning required | Ribbon and thermal head replacement |

| Best Use Case | Packaging, food and beverage, pharmaceuticals | Permanent markings, high-value products | Labels, barcodes, and graphics on packaging |

What Are the Pros and Cons of Laser Marking Systems?

Laser Marking Systems utilize focused laser beams to engrave or mark surfaces. Their primary advantage lies in the precision and permanence of the markings they produce, making them ideal for applications requiring durability, such as serial numbers or logos on metal and plastic products. However, the initial investment can be significantly higher than جت پرینتر, which may deter smaller businesses. Additionally, while they require less frequent maintenance, laser systems often necessitate specialized training for operators to handle the technology effectively.

Illustrative image related to جت پرینتر

How Do Thermal Transfer Printers Compare?

Thermal Transfer Printers (TTP) use heat to transfer ink from a ribbon onto various substrates. They are well-regarded for producing high-quality graphics and barcodes, making them suitable for labeling applications. Their cost-effectiveness and straightforward operation make TTP an attractive choice for small to medium-sized enterprises. However, the need for regular ribbon replacements can lead to ongoing costs that may accumulate over time, contrasting with the ink replenishment required for جت پرینتر.

Making the Right Choice: Which Solution Fits Your Needs?

Selecting the right printing solution hinges on a thorough understanding of your business’s specific requirements. For high-speed, variable data printing, جت پرینتر remains a solid choice, especially in industries like food and pharmaceuticals where quick turnaround is vital. If your focus is on permanence and precision, particularly for high-value products, investing in Laser Marking Systems could pay off in the long run. Alternatively, for businesses seeking affordability and high-quality labeling, Thermal Transfer Printers offer a practical solution without extensive capital investment.

Ultimately, evaluating each alternative against your operational needs, budget constraints, and desired output quality will guide you in choosing the most effective printing technology for your business.

Essential Technical Properties and Trade Terminology for جت پرینتر

What Are the Essential Technical Properties of جت پرینتر?

When evaluating جت پرینتر (inkjet printers), understanding the technical specifications is crucial for making informed purchasing decisions. Below are some of the critical specifications that B2B buyers should consider:

-

Print Resolution (DPI)

The print resolution, measured in dots per inch (DPI), indicates the clarity and detail of the printed output. Higher DPI values result in sharper images and text, making them particularly important for applications that require precise information, such as barcodes and product labels. For businesses that prioritize quality, selecting a جت پرینتر with a DPI of at least 300 is advisable. -

Print Speed (m/min)

Print speed, often expressed in meters per minute (m/min), measures how quickly a جت پرینتر can produce output. For high-volume production lines, a faster print speed can significantly enhance operational efficiency and reduce bottlenecks. Buyers should assess their production needs to select a printer that can keep pace with their output requirements. -

Ink Type

Different جت پرینتر models use various ink types, such as solvent-based, water-based, or UV-curable inks. Each type has its advantages and suitability for specific materials and environments. For example, solvent inks are often used for outdoor applications due to their durability, while water-based inks are preferred for eco-friendly printing. Understanding ink types helps buyers choose a printer that aligns with their product specifications and environmental goals. -

Durability and Maintenance Requirements

The durability of a جت پرینتر affects its long-term operational costs. Printers that require frequent maintenance or have a high failure rate can lead to increased downtime and repair expenses. Buyers should inquire about the average lifespan of components, availability of replacement parts, and the manufacturer’s maintenance support to ensure a reliable investment. -

Connectivity Options

Modern جت پرینتر devices often come with various connectivity options, including USB, Ethernet, and wireless capabilities. These features facilitate integration into existing production lines and enable remote management. Businesses should consider their infrastructure and the ease of integrating new equipment into their systems.

What Common Trade Terms Should B2B Buyers Know for جت پرینتر?

Understanding industry-specific terminology is vital for effective communication and negotiation in the B2B landscape. Here are some common terms related to جت پرینتر transactions:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding whether they are purchasing from an OEM or a reseller can affect warranty, service, and pricing considerations. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest order size that a supplier is willing to accept. Buyers should be aware of MOQs to ensure they can meet the supplier’s requirements without overcommitting to inventory that may not be needed. -

RFQ (Request for Quotation)

An RFQ is a formal request from a buyer to suppliers to provide pricing and terms for specific products or services. Utilizing RFQs can help buyers obtain competitive pricing and better understand the market. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for understanding shipping costs, risk transfer, and delivery obligations. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is crucial for planning production schedules and managing inventory effectively.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting جت پرینتر solutions tailored to their operational needs.

Navigating Market Dynamics and Sourcing Trends in the جت پرینتر Sector

What Are the Current Market Dynamics and Key Trends in the جت پرینتر Sector?

The جت پرینتر market is experiencing significant growth driven by the increasing demand for efficient and versatile printing solutions across various industries. In regions like Africa, South America, the Middle East, and Europe, businesses are increasingly adopting automated and semi-automated systems to enhance their production efficiency. This shift is propelled by the need for real-time printing capabilities, particularly for variable data such as batch numbers, expiration dates, and barcodes, which are essential for compliance and traceability.

Emerging trends indicate a growing preference for eco-friendly and sustainable printing technologies. Buyers are gravitating towards جت پرینتر solutions that minimize waste and utilize environmentally friendly inks and materials. Furthermore, advancements in technology, such as the introduction of drop-on-demand (DOD) and continuous inkjet (CIJ) systems, are enhancing printing precision and speed. Companies are also focusing on smart integration, with IoT-enabled devices that allow for remote monitoring and maintenance, which is particularly beneficial for businesses operating in remote areas.

Illustrative image related to جت پرینتر

International buyers should be aware of regional variations in demand and pricing. For instance, while European markets may prioritize high-tech and automated solutions, emerging markets in Africa and South America might focus on cost-effective, versatile models that require less infrastructure. Understanding these dynamics will empower B2B buyers to make informed sourcing decisions that align with their operational needs.

How Does Sustainability and Ethical Sourcing Impact the جت پرینتر Sector?

Sustainability is becoming a core concern for businesses in the جت پرینتر sector, reflecting a broader trend towards environmental responsibility. The production and operation of جت پرینتر systems can have a significant environmental impact, particularly regarding ink waste and energy consumption. Therefore, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as utilizing low-VOC (volatile organic compounds) inks and energy-efficient machinery.

Ethical sourcing also plays a crucial role in the decision-making process. Buyers are looking for suppliers who adhere to fair labor practices and provide transparency in their supply chains. This is particularly important in regions where labor standards may vary significantly. Certifications such as ISO 14001 for environmental management systems and other green certifications can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Investing in جت پرینتر systems that align with sustainability goals not only reduces environmental impact but can also enhance brand reputation among consumers increasingly concerned about corporate responsibility. For businesses targeting markets in Europe or North America, aligning with these values can provide a competitive edge.

What Is the Brief Evolution and History of جت پرینتر Technology?

The evolution of جت پرینتر technology has been marked by significant advancements since its inception. Initially developed for commercial printing, the technology has diversified to meet the demands of various industries, including food and beverage, pharmaceuticals, and consumer goods. The introduction of continuous inkjet (CIJ) technology in the late 20th century revolutionized the market, allowing for high-speed printing on a variety of surfaces.

As businesses sought more efficient and flexible printing solutions, the drop-on-demand (DOD) technology emerged, enabling precise control over ink application. This shift not only improved print quality but also reduced ink consumption, aligning with the growing focus on sustainability. Today, جت پرینتر systems are integral to production lines, providing essential functionality for product labeling and compliance across global markets.

In summary, the جت پرینتر sector is evolving rapidly, influenced by technological advancements and shifting market demands. B2B buyers must navigate these dynamics, considering sustainability and ethical sourcing as crucial factors in their purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of جت پرینتر

-

How do I choose the right جت پرینتر for my business needs?

Choosing the right جت پرینتر depends on several factors, including the type of products you are printing on, the volume of production, and the specific information you need to print (e.g., dates, barcodes). Consider whether you need a handheld (manual) or automated printer, as automated models are more efficient for high-volume environments. Additionally, evaluate the technology (CIJ vs. DOD), print speed, and resolution requirements. Consulting with a supplier or a specialist can also help tailor the selection to your unique operational needs. -

What is the best جت پرینتر for small to medium-sized enterprises (SMEs)?

For SMEs, a semi-automatic جت پرینتر is often the best choice, offering a balance between cost and functionality. Models with drop-on-demand (DOD) technology are generally more affordable and user-friendly, making them suitable for businesses with moderate printing needs. Additionally, look for printers that allow for easy maintenance and have a good warranty and support system in place, ensuring that you can keep your operations running smoothly without excessive downtime. -

What are the common payment terms when purchasing جت پرینتر internationally?

Payment terms for international purchases can vary widely depending on the supplier and the buyer’s negotiation skills. Common options include advance payment, letters of credit, or payment upon delivery. It’s essential to clarify these terms before finalizing the purchase, as they can significantly impact cash flow. Additionally, consider using escrow services for large transactions to ensure both parties meet their obligations, providing security in the transaction process. -

How do I vet suppliers for جت پرینتر?

Vetting suppliers requires thorough research to ensure reliability and quality. Start by checking their credentials, such as business licenses and industry certifications. Look for customer reviews and testimonials to gauge their reputation. Additionally, request references and inquire about their after-sales support, warranty policies, and service capabilities. A visit to their manufacturing facility can also provide insights into their production processes and quality control measures. -

What is the minimum order quantity (MOQ) for جت پرینتر?

The MOQ for جت پرینتر can vary significantly by supplier and model. Some suppliers may offer flexibility for smaller orders, particularly for less specialized models, while others may have higher MOQs for advanced or customized options. Always communicate your requirements upfront and negotiate terms that align with your budget and inventory needs. Understanding the MOQ can help streamline your purchasing strategy and inventory management. -

What customization options are available for جت پرینتر?

Customization options for جت پرینتر may include specific printing configurations, ink types, and sizes tailored to your product specifications. Some suppliers may also offer software customization for unique printing requirements, such as variable data printing or integration with existing production systems. Discussing your needs with the supplier can lead to tailored solutions that enhance your operational efficiency and meet branding requirements. -

What are the logistics considerations when importing جت پرینتر?

Logistics for importing جت پرینتر involve several critical factors, including shipping methods, customs clearance, and local regulations. Choose a reliable freight forwarder experienced in handling industrial equipment to ensure smooth transport. Be aware of import duties and taxes that may apply, and ensure compliance with local laws regarding equipment standards. Proper planning can minimize delays and unexpected costs, ensuring timely delivery to your operational site. -

How can I ensure quality assurance (QA) for my جت پرینتر?

To ensure quality assurance for your جت پرینتر, establish clear quality control protocols with the supplier. This includes requesting samples before finalizing orders to evaluate print quality, reliability, and functionality. Inquire about the supplier’s QA processes and certifications, such as ISO standards. Additionally, consider setting up periodic inspections during production and shipping to verify that the products meet your specifications and industry standards before acceptance.

Top 7 جت پرینتر Manufacturers & Suppliers List

1. Torob – جت پرینتر دستی H2

Domain: torob.com

Registered: 2005 (20 years)

Introduction: {“product_name”:”جت پرینتر دستی H2″,”display”:”صفحه نمایش لمسی ۲.۸ اینچ مقاومتی”,”operating_system”:”GUI-PH2″,”availability”:”ناموجود”}

2. Dana Code Negar – Jet Printers

Domain: danacodenegar.com

Registered: 2017 (8 years)

Introduction: دستگاه جت پرینتر دستی، صنعتی و اتوماتیک با تکنولوژی های مختلف شامل CIJ و TIJ. قیمت ها از 8,900,000 تومان تا 399,000,000 تومان متغیر است. انواع جت پرینتر شامل: جت پرینتر دستی (12 مدل)، جت پرینتر نیمه اتوماتیک (2 مدل)، جت پرینتر صنعتی (10 مدل)، و جت پرینتر تخم مرغ (3 مدل). گارانتی محصولات از 1 ماه تا 36 ماه متفاوت است. مواد قابل بستهبندی شامل انواع ظروف با جنس بدنه آلومینیوم، آهنی، استیل و پلاستیک …

3. Codajet – Fixed Jet Printers

Domain: codajet.com

Registered: 2016 (9 years)

Introduction: جت پرینتر ثابت Codajet F12, جت پرینتر ثابت F12 Pro, جت پرینتر ثابت iKonMac E25, جت پرینتر ثابت iKonMac E50, جت پرینتر ثابت iKonMac E19, جت پرینتر ثابت iKonMac E18 plus, جت پرینتر ثابت iKonMac C18, جت پرینتر ثابت iKonMac E12, جت پرینتر ثابت Sauven Codajet 6000, جت پرینتر لیزری, جت پرینتر تخم مرغ, جت پرینتر دستی مینی Codajet B8, جت پرینتر دستی Codajet B110, جت پرینتر دستی Codajet B52, جت پرینتر دستی…

4. San Marking – Jet Printer

Domain: san-marking.com

Registered: 2012 (13 years)

Introduction: جت پرینتر یک دستگاه چاپ است که برای چاپ اطلاعات متغیر مانند تاریخ تولید، تاریخ انقضا، بارکد و شماره سریال بر روی محصولات و بسته بندی ها استفاده می شود. این دستگاه ها معمولاً در صنایع مختلف مانند مواد غذایی، دارویی و بسته بندی کاربرد دارند و قادر به چاپ بر روی سطوح مختلف از جمله پلاستیک، کاغذ و فلز هستند. جت پرینترها به دلیل سرعت بالا و کیفیت چاپ مناسب، گزینه ای ایده آل برای خطوط تولید هستند.

5. Kalasanat – جت پرینتر دستی و لیزری

Domain: kalasanat.ir

Introduction: لیست قیمت جت پرینتر دستی، اتومات و لیزری شامل: 1. جت پرینتر دستی KS-PLUS به همراه کارتریج – قیمت: 24,800,000 تومان 2. جت پرینتر S9 دستی پیشرفته اندروید تحت شبکه – قیمت: 68,000,000 تومان 3. تاریخ زن حرارتی دستی – قیمت: 9,990,000 تومان 4. لیزر جت فایبر 30w – قیمت: 258,000,000 تومان 5. جت پرینتر دستی KS-PRO با کارتریج دسته و شابلون – قیمت: 24,800,000 تومان 6. جت پرینتر دستی H12 با کارتریج جوهر – قیمت…

6. Sepand Afzar – Jet Printer Solutions

Domain: sepandafzar.com

Registered: 2005 (20 years)

Introduction: جت پرینتر، دستگاهی است که برای چاپ اطلاعات متغیر بر روی سطوح مختلف استفاده میشود. این دستگاه قابلیت چاپ تاریخ، بارکد، شماره سریال و اطلاعات دیگر را دارد. جت پرینترها معمولاً در صنایع بستهبندی، تولید و انبارداری به کار میروند. این دستگاهها به دلیل سرعت بالا و کیفیت چاپ مناسب، گزینهای ایدهآل برای خطوط تولید هستند.

7. آرین بهرنگ – جت پرینتر دستی

Domain: abjetprinter.com

Registered: 2015 (10 years)

Introduction: جت پرینتر دستی | جت پرینتر آرین بهرنگ

مدلها:

1. جت پرینتر دستی انکودر دار مدل LB100s – قیمت: ۱۵.۶۰۰.۰۰۰ تومان

2. جت پرینتر دستی AB-H8 – قیمت: ۱۱.۲۰۰.۰۰۰ تومان

3. جت پرینتر دستی مدل LB100s ارتفاع ۲.۵ سانت – قیمت: ۲۳.۱۰۰.۰۰۰ تومان

4. جت پرینتر دستی مدل LB100s ارتفاع چاپ ۵ سانت – قیمت: ۵۸.۰۰۰.۰۰۰ تومان

5. مینی جت پرینتر مدل LB100s – قیمت: ۸.۰۰۰.۰۰۰ تومان

6. جت پرینتر دستی مدل LB100 – قیمت: ۱۱.۶۰۰.۰…

Strategic Sourcing Conclusion and Outlook for جت پرینتر

In conclusion, the strategic sourcing of جت پرینتر presents a vital opportunity for businesses aiming to enhance their production efficiency and product compliance. By understanding the diverse technologies available—such as CIJ and DOD—buyers can make informed decisions that align with their specific operational needs. The importance of selecting a reputable supplier cannot be overstated, as the right partner will not only provide quality equipment but also essential support and maintenance services.

As international markets, particularly in Africa, South America, the Middle East, and Europe, continue to evolve, the demand for high-quality printing solutions will only increase. Buyers should prioritize sourcing from manufacturers that offer innovative features and reliable performance at competitive prices.

Looking ahead, businesses are encouraged to engage with suppliers proactively, exploring options that can enhance their branding and traceability efforts through advanced printing technologies. Embrace the future of packaging and product marking by investing in the right جت پرینتر solutions, ensuring your operations remain competitive and compliant in a rapidly changing global landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to جت پرینتر