Everything You Need to Know About Chamfer Screw Sourcing in 2025

Introduction: Navigating the Global Market for chamfer screw

In an increasingly interconnected world, sourcing high-quality chamfer screws can present significant challenges for international B2B buyers. The need for precision-engineered fasteners that enhance assembly efficiency and reduce the risk of cross-threading is paramount across various industries, from automotive to aerospace. This comprehensive guide delves into the multifaceted realm of chamfer screws, offering insights into their diverse types, applications, and specifications. By understanding the nuances of chamfer design—such as the benefits of plug and flat chamfer styles—buyers can make informed decisions that align with their operational requirements.

As the global market for chamfer screws expands, so does the complexity of supplier vetting and cost analysis. This guide equips B2B buyers from Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil, with the knowledge needed to navigate these intricacies. From assessing product quality to understanding pricing structures and shipping logistics, we provide actionable insights that empower buyers to optimize their procurement processes. By leveraging this guide, businesses can enhance their supply chain efficiency, ensuring they source the right chamfer screws that meet their technical and budgetary needs, ultimately driving operational success in their respective markets.

Understanding chamfer screw Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plug Chamfer Screw | Beveled edge aids in alignment, typically ANSI sizes | General manufacturing, assembly lines | Pros: Reduces cross-threading risk, enhances durability. Cons: May require precise machining for optimal fit. |

| Flat Chamfer Screw | Flat head with a chamfer for flush surface finish | Aerospace, automotive, electronics | Pros: Provides a clean aesthetic, easy installation. Cons: Limited to specific applications where flush fit is necessary. |

| Captive Chamfer Screw | Designed to remain attached to the assembly | Electronics, military equipment | Pros: Prevents loss of screws, improves assembly speed. Cons: Higher cost due to specialized design. |

| Socket Head Chamfer Screw | Hexagonal socket for increased torque application | Heavy machinery, construction | Pros: Allows for higher torque, reduces stripping risk. Cons: Requires specialized tools for installation. |

| Countersunk Chamfer Screw | Angled head for a flush finish with the surface | Furniture, cabinetry, and fixtures | Pros: Aesthetic appeal, minimizes snagging. Cons: Requires accurate hole size for proper fit. |

What Are the Characteristics of Plug Chamfer Screws?

Plug chamfer screws feature a beveled edge that facilitates smooth engagement and alignment during assembly. These screws are commonly available in ANSI sizes and are widely used in general manufacturing and assembly lines. The chamfer’s design reduces the risk of cross-threading, making it easier to start threading components. However, buyers must consider the precision required in machining for optimal fit, which can influence production costs.

How Do Flat Chamfer Screws Stand Out?

Flat chamfer screws are characterized by their flat heads and chamfered edges, allowing them to sit flush against surfaces. This design is particularly valuable in aerospace, automotive, and electronics applications, where aesthetics and functionality are paramount. While they provide a clean finish and ease of installation, they may be limited in use to specific applications that demand a flush fit. Buyers should assess their specific needs when considering this type.

What Are the Benefits of Captive Chamfer Screws?

Captive chamfer screws are engineered to remain attached to the assembly, preventing loss during installation or maintenance. This feature is especially beneficial in industries like electronics and military equipment, where components need to be assembled quickly and reliably. Although they can be more expensive due to their specialized design, the benefits of improved assembly speed and reduced loss can justify the investment for many B2B buyers.

Why Choose Socket Head Chamfer Screws?

Socket head chamfer screws feature a hexagonal socket that allows for increased torque during installation, making them ideal for heavy machinery and construction applications. Their design minimizes the risk of stripping, enhancing reliability in demanding environments. However, buyers must consider the need for specialized tools to install these screws, which can add to the overall cost of procurement.

What Makes Countersunk Chamfer Screws Ideal for Certain Applications?

Countersunk chamfer screws have an angled head that enables them to sit flush with the surface, making them a popular choice for furniture, cabinetry, and fixtures. Their aesthetic appeal and reduced snagging potential are significant advantages. However, accurate hole sizing is crucial for ensuring a proper fit, which may require additional machining. Buyers should weigh these factors against their project requirements when selecting this screw type.

Key Industrial Applications of chamfer screw

| Industry/Sector | Specific Application of chamfer screw | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Assembly of engine components and chassis | Enhances assembly speed and reduces risk of cross-threading | Ensure compatibility with specific engine designs and materials |

| Aerospace | Fastening of structural components in aircraft | Improves safety and reliability in critical applications | Adhere to strict aerospace standards and certifications |

| Construction | Joining of structural steel and framing systems | Provides robust connections in load-bearing applications | Focus on corrosion resistance and material specifications |

| Electronics | Mounting of circuit boards and electronic enclosures | Facilitates precise assembly and minimizes component damage | Consider thermal properties and electrical conductivity |

| Machinery Manufacturing | Assembly of machinery parts and equipment | Streamlines production processes and enhances durability | Evaluate tolerances and compatibility with existing machinery |

How are chamfer screws utilized in the automotive industry?

In the automotive sector, chamfer screws are crucial for the assembly of engine components and chassis. Their beveled edges allow for smoother engagement during installation, minimizing the risk of cross-threading, which can lead to costly repairs. For international buyers, it’s essential to ensure that the screws meet specific automotive standards and materials compatible with various engine designs, particularly in regions like Europe and South America where regulations may differ.

What role do chamfer screws play in aerospace applications?

In aerospace, chamfer screws are used to secure structural components of aircraft, where safety and reliability are paramount. The chamfer facilitates easier alignment and engagement, crucial in high-stakes environments. Buyers in this sector must prioritize sourcing screws that comply with stringent aerospace certifications and standards, ensuring that they can withstand extreme conditions while maintaining structural integrity.

How are chamfer screws applied in construction?

In construction, chamfer screws are integral for joining structural steel and framing systems. Their design allows for stronger connections in load-bearing applications, which is vital for the safety and longevity of buildings. For B2B buyers, sourcing considerations should include the screws’ corrosion resistance, especially in regions with high humidity or exposure to the elements, ensuring long-term durability.

Why are chamfer screws important in electronics manufacturing?

Chamfer screws are commonly used in the electronics industry for mounting circuit boards and securing electronic enclosures. The chamfered edges help prevent damage to sensitive components during assembly, facilitating a more precise fit. Buyers must consider the thermal properties and electrical conductivity of the screws, as these factors can significantly affect the performance and reliability of electronic devices.

What is the significance of chamfer screws in machinery manufacturing?

In machinery manufacturing, chamfer screws are essential for the assembly of various machine parts and equipment. Their design allows for streamlined production processes, improving efficiency and enhancing the durability of the assembled machinery. Buyers should evaluate the screws’ tolerances and compatibility with existing machinery to ensure optimal performance and longevity in demanding industrial environments.

3 Common User Pain Points for ‘chamfer screw’ & Their Solutions

Scenario 1: Difficulty in Achieving Proper Alignment During Assembly

The Problem: B2B buyers often encounter challenges when assembling components using chamfer screws, particularly in industries like automotive and machinery manufacturing. Misalignment during the assembly process can lead to cross-threading, damaged components, and increased labor costs due to rework. This issue is especially prevalent when working with materials that have tighter tolerances or when using automated assembly systems where precision is critical. Buyers may also struggle with ensuring that their team is trained to properly align screws without damaging the threads.

The Solution: To address these alignment challenges, it is essential to select chamfer screws with the appropriate chamfer angle tailored to the specific application. For instance, using screws with a 45-degree chamfer can facilitate easier engagement of the threads, reducing the risk of cross-threading. Additionally, investing in specialized tools such as thread alignment jigs or guides can significantly improve assembly accuracy. These tools help technicians achieve the correct alignment before tightening screws, thereby minimizing the risk of damage. Training sessions focused on assembly techniques, including proper handling and insertion of chamfer screws, can also enhance workforce efficiency and reduce error rates.

Scenario 2: Inconsistency in Thread Engagement Leading to Structural Weakness

The Problem: Another common pain point for B2B buyers is the inconsistency in thread engagement when using chamfer screws, which can compromise the structural integrity of the assembled components. This inconsistency often arises from variations in screw manufacturing or the materials used, leading to uneven pressure distribution and potential failure points. In high-stakes environments like aerospace or construction, such weaknesses can result in catastrophic failures, making this issue particularly pressing for buyers who prioritize safety and reliability.

The Solution: To mitigate the risks associated with inconsistent thread engagement, buyers should prioritize sourcing chamfer screws from reputable manufacturers known for their quality control processes. It’s beneficial to request samples and conduct thorough testing, including torque tests, to ensure that the screws perform reliably under expected load conditions. Furthermore, specifying screws with precise tolerances and utilizing advanced materials such as stainless steel or titanium can enhance durability and performance. Establishing a consistent supplier relationship can also facilitate better quality assurance and allow for more straightforward resolution of issues related to screw performance.

Scenario 3: High Costs Due to Excessive Waste from Improper Use

The Problem: Excessive waste generated from improperly used chamfer screws can lead to significant cost implications for B2B buyers. This issue often arises in production environments where workers may not be adequately trained on the correct usage of these fasteners, leading to high rejection rates due to defects or failures. Buyers may find that they are frequently replacing screws or entire assemblies, resulting in inflated material costs and longer lead times, impacting overall project budgets and timelines.

The Solution: To minimize waste and associated costs, implementing comprehensive training programs that focus on the correct use of chamfer screws is crucial. This training should cover proper handling techniques, the importance of selecting the right screw for the application, and best practices for installation. Additionally, employing a just-in-time inventory system can help manage screw supply more efficiently, ensuring that the right quantity of screws is available when needed without overstocking. Partnering with suppliers who offer flexible order quantities and rapid delivery can also reduce waste by ensuring that production lines are not halted due to supply shortages. Regular audits of the assembly process can further help identify areas where improvements can be made to reduce waste and enhance efficiency.

Strategic Material Selection Guide for chamfer screw

What Are the Key Properties of Common Materials Used for Chamfer Screws?

When selecting materials for chamfer screws, it is crucial to consider properties such as strength, corrosion resistance, and temperature ratings. The most commonly used materials include carbon steel, stainless steel, brass, and plastic. Each material offers unique advantages and disadvantages that can significantly impact the performance and suitability of the screws in various applications.

How Does Carbon Steel Perform as a Material for Chamfer Screws?

Carbon steel is widely used in manufacturing chamfer screws due to its excellent strength and hardness. It typically exhibits high tensile strength, making it suitable for applications requiring robust fastening solutions. However, carbon steel is prone to corrosion, especially in humid or chemically aggressive environments. This necessitates protective coatings or treatments, which can increase manufacturing complexity and cost. For international buyers, compliance with standards such as ASTM A307 is essential, particularly in regions like Europe and the Middle East, where corrosion resistance is often mandated.

What Are the Advantages of Using Stainless Steel for Chamfer Screws?

Stainless steel is another popular choice for chamfer screws, known for its superior corrosion resistance and durability. This material can withstand harsh environments and high temperatures, making it ideal for applications in the automotive and aerospace industries. While stainless steel screws tend to be more expensive than carbon steel, their longevity can offset initial costs by reducing replacement frequency. Buyers from Africa and South America should consider local availability and compliance with standards such as ASTM A193 or DIN 1.4401, ensuring the screws meet specific industry requirements.

How Does Brass Compare to Other Materials for Chamfer Screws?

Brass is favored for its excellent machinability and aesthetic appeal, often used in decorative applications or where electrical conductivity is required. It offers good corrosion resistance, particularly in non-aggressive environments. However, brass screws are generally less strong than steel counterparts and may not be suitable for high-stress applications. The cost of brass can be higher than carbon steel, but its unique properties make it a valuable choice for specific applications. International buyers should be aware of the varying standards for brass fasteners, such as JIS H3250 in Japan, to ensure compatibility.

What Role Does Plastic Play in the Selection of Chamfer Screws?

Plastic screws are becoming increasingly popular due to their lightweight nature and resistance to corrosion and chemicals. They are ideal for applications where electrical insulation is necessary or where weight reduction is critical. However, plastic screws may have lower tensile strength compared to metal screws, limiting their use in high-load applications. The cost of plastic screws is generally lower, making them an attractive option for bulk purchases. Buyers should consider the specific type of plastic used, such as nylon or polycarbonate, and ensure compliance with relevant standards, particularly in regions with stringent regulations.

Summary Table of Material Selection for Chamfer Screws

| Material | Typical Use Case for chamfer screw | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General fastening applications | High tensile strength | Prone to corrosion | Medium |

| Stainless Steel | Automotive and aerospace industries | Superior corrosion resistance | Higher cost | High |

| Brass | Decorative and electrical applications | Good machinability and aesthetics | Lower strength | Medium |

| Plastic | Electrical insulation applications | Lightweight and corrosion-resistant | Lower tensile strength | Low |

In conclusion, the selection of material for chamfer screws should align with the specific requirements of the application, considering factors such as environmental conditions, mechanical loads, and compliance with international standards. By understanding the properties, advantages, and limitations of each material, B2B buyers can make informed decisions that enhance the performance and reliability of their products.

In-depth Look: Manufacturing Processes and Quality Assurance for chamfer screw

What Are the Main Stages of Manufacturing Chamfer Screws?

Manufacturing chamfer screws involves several critical stages, each essential for ensuring the final product meets industry standards and customer specifications. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Chamfer Screws?

The manufacturing process begins with the selection of appropriate raw materials, typically high-quality steel, stainless steel, or alloys that provide the necessary strength and corrosion resistance. Material preparation includes cutting the raw stock to size and subjecting it to processes such as heat treatment to enhance mechanical properties. This step is crucial as it lays the foundation for the performance and durability of the chamfer screws.

What Forming Techniques Are Used in Chamfer Screw Production?

Once the material is prepared, the forming process takes place. This can involve various techniques such as machining, forging, or cold heading. For chamfer screws, precision machining is often preferred, allowing for the accurate creation of threads and chamfer angles. CNC (Computer Numerical Control) machines are commonly used to ensure consistency and precision in the shaping of the screws, including the critical chamfer that facilitates easier assembly and alignment.

How Are Chamfer Screws Assembled and Finished?

After forming, the assembly stage may not be as pronounced for individual screws but is significant when screws are part of a larger assembly. If integrated into mechanical systems, chamfer screws may be paired with nuts or other components during this phase. Finishing processes include surface treatments such as plating, anodizing, or passivation, which enhance corrosion resistance and improve aesthetics. These finishing touches are vital, particularly for applications in harsh environments, ensuring longevity and reliability.

What Quality Control Measures Are Relevant for Chamfer Screws?

Quality assurance is a fundamental aspect of chamfer screw manufacturing, ensuring that each product meets both international standards and customer expectations. Adhering to recognized quality management systems such as ISO 9001 is critical. This certification demonstrates a commitment to maintaining quality throughout the production process.

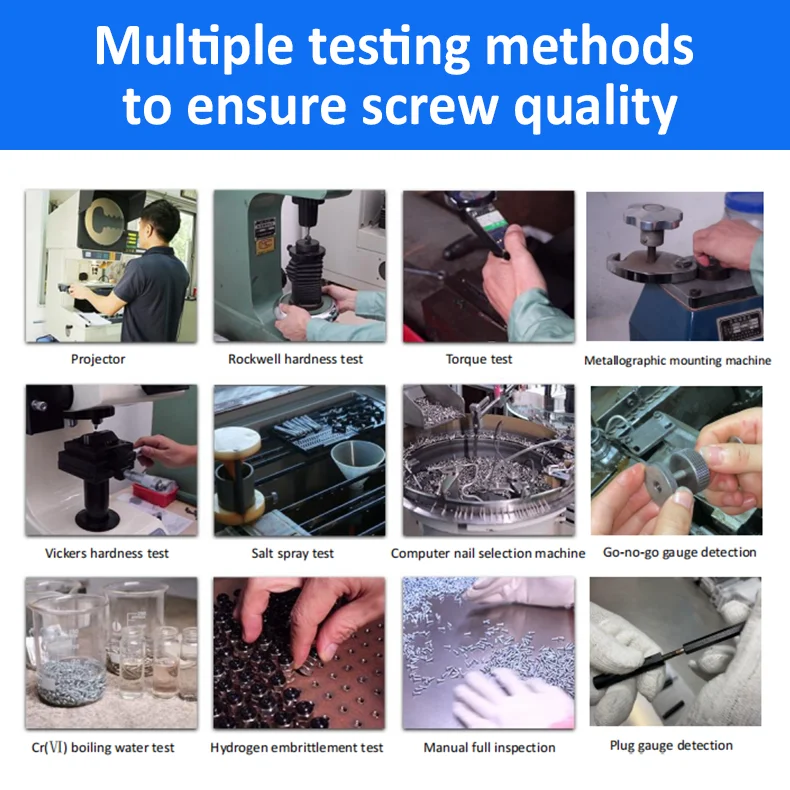

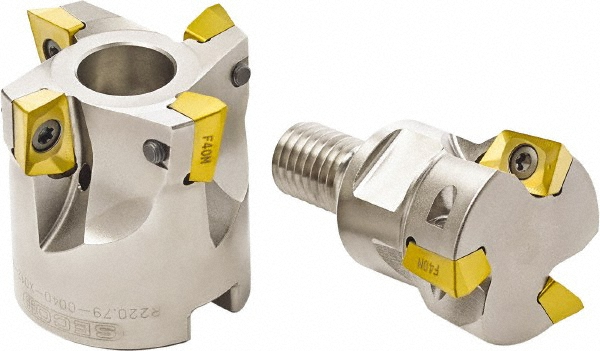

Illustrative image related to chamfer screw

What Are the Key International Standards for Chamfer Screws?

International standards such as ISO 9001 provide a framework for quality management, ensuring systematic processes and continuous improvement. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in the European market or API (American Petroleum Institute) standards for oil and gas applications are crucial. These certifications assure buyers that the screws conform to safety and performance requirements relevant to their industry.

What Are the Checkpoints in Quality Control?

Quality control in chamfer screw manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial stage assesses the quality of raw materials before they enter the production process. Suppliers are often required to provide certificates of compliance to verify material quality.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that processes remain within specified tolerances. This can include measuring thread depth, chamfer angles, and overall dimensions using precision instruments.

-

Final Quality Control (FQC): After production, a thorough inspection is conducted to ensure that each batch meets all specifications and standards. This includes visual inspections, dimensional checks, and functional testing, where applicable.

What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are employed to verify the quality and performance of chamfer screws:

-

Dimensional Inspection: Using tools such as calipers and micrometers, manufacturers measure the screws’ dimensions, ensuring they conform to specified tolerances.

-

Tensile Testing: This test evaluates the strength of the screws by applying force until failure, determining the maximum load they can withstand.

-

Corrosion Resistance Testing: For screws intended for harsh environments, salt spray tests or other corrosion tests are performed to evaluate the longevity of protective coatings.

-

Torque Testing: This method assesses how well screws perform under load, ensuring they meet the required torque specifications for their intended applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps buyers can take:

-

Conduct Supplier Audits: Regular audits of manufacturing facilities can provide insights into quality management practices. Buyers should assess whether suppliers adhere to international standards and maintain robust quality control processes.

-

Request Quality Reports: Suppliers should be willing to provide documentation detailing their quality control measures, inspection results, and any certifications they hold. This transparency helps buyers assess potential risks.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the quality control processes in place. This is particularly beneficial when dealing with suppliers in different regions, ensuring compliance with local and international standards.

What Are the Quality Control Nuances for International B2B Buyers?

When purchasing chamfer screws internationally, buyers should be aware of potential nuances in quality control. Different regions may have varying standards and regulations, which can affect product quality. For instance, European buyers may prioritize CE marking, while buyers in the Middle East may require compliance with local standards.

Additionally, language barriers and differences in business practices can complicate communication regarding quality expectations. Establishing clear specifications and maintaining open lines of communication with suppliers is essential to mitigate these challenges.

In conclusion, understanding the manufacturing processes and quality assurance measures for chamfer screws is crucial for B2B buyers. By familiarizing themselves with the stages of production, relevant standards, and quality control practices, buyers can make informed decisions that ensure the reliability and performance of the fasteners they procure.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chamfer screw’

To effectively procure chamfer screws, a structured approach is essential to ensure that the components meet your specific requirements and that you are working with reliable suppliers. This checklist will guide you through the critical steps in the sourcing process, enhancing your chances of making informed decisions.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the chamfer screws you need. This includes dimensions, materials, thread specifications, and chamfer angles. Accurate specifications help prevent miscommunications with suppliers and ensure that the products will fit your application without complications.

- Thread Types: Specify whether you require UNC or UNF threads.

- Material Selection: Decide between materials such as stainless steel or carbon steel based on environmental conditions and load requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in chamfer screws. Look for companies with a strong reputation in your target market, especially in regions like Africa, South America, the Middle East, and Europe.

- Industry Experience: Prefer suppliers with proven experience in manufacturing chamfer screws.

- Customer Reviews: Check online reviews and testimonials to gauge the reliability and quality of the supplier’s products.

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier, verify their certifications and compliance with international standards. This step is crucial for ensuring that the screws meet quality and safety regulations.

- Quality Management Systems: Look for ISO certifications or other relevant quality assurance certifications.

- Material Certifications: Ensure that the supplier can provide material test reports to confirm the integrity of their products.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the chamfer screws. Testing samples allows you to assess the quality and suitability of the screws for your specific application.

- Quality Control: Inspect the samples for dimensional accuracy, material quality, and chamfer integrity.

- Performance Testing: If applicable, conduct tests in real-world conditions to confirm that the screws perform as required.

Step 5: Negotiate Pricing and Terms

Engage in discussions with suppliers to negotiate pricing, payment terms, and delivery schedules. Clear communication during this phase can lead to better deals and long-term partnerships.

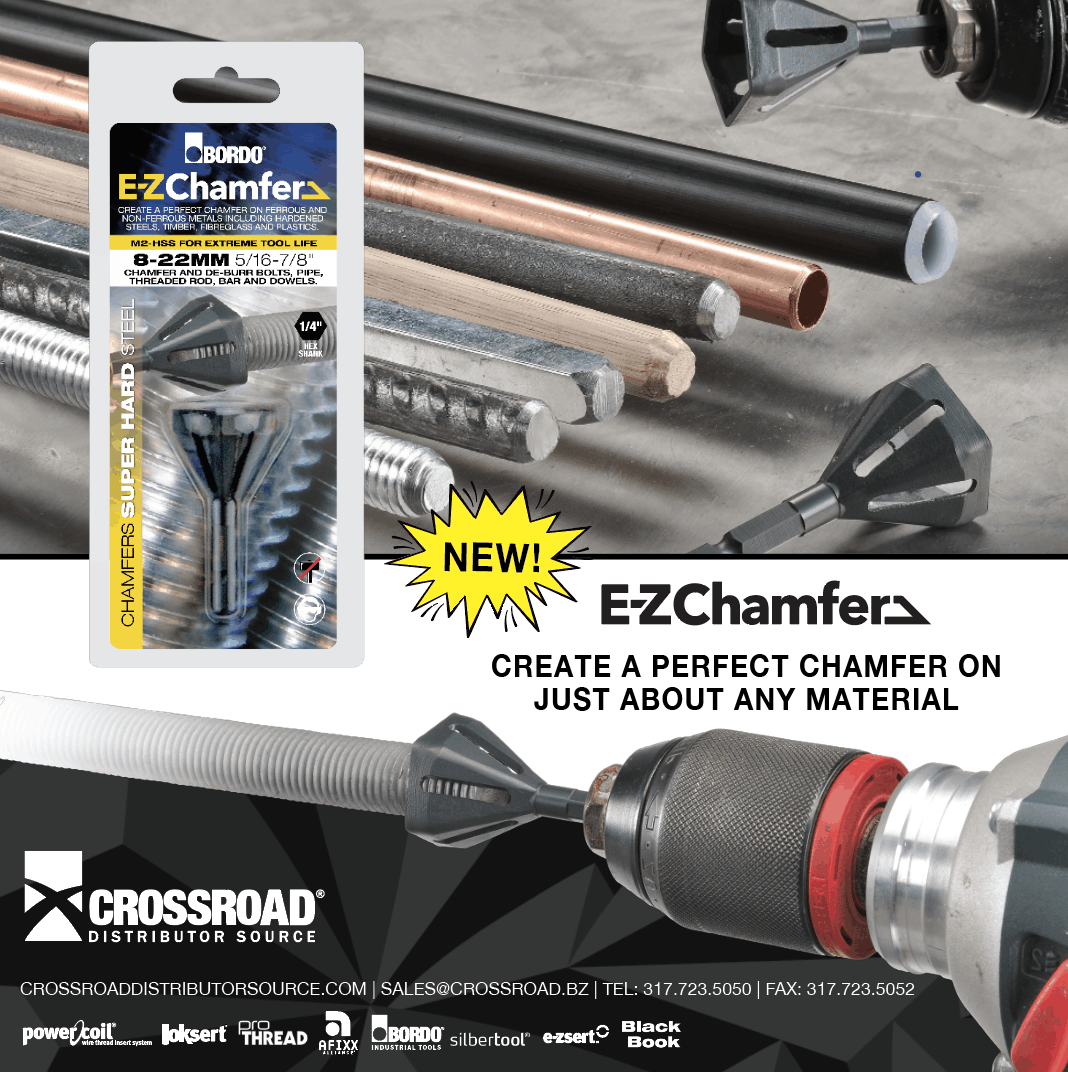

Illustrative image related to chamfer screw

- Bulk Discounts: Inquire about pricing structures for large orders or long-term contracts.

- Payment Flexibility: Discuss payment terms that align with your budget cycles and cash flow.

Step 6: Confirm Logistics and Delivery

Once terms are agreed upon, clarify the logistics of shipping and delivery. Ensure that the supplier can meet your timeline and that they have a reliable shipping process in place.

- Shipping Options: Evaluate different shipping methods and their costs to find the most efficient solution.

- Lead Times: Confirm lead times to align your production schedules with the delivery of the screws.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process for incoming shipments of chamfer screws. This step ensures that you consistently receive high-quality products that meet your specifications.

- Inspection Protocols: Develop an inspection checklist for incoming shipments to verify that the screws meet your quality standards.

- Feedback Loop: Establish a process for providing feedback to suppliers based on the quality of received products to foster continuous improvement.

By following this comprehensive checklist, B2B buyers can effectively navigate the complexities of sourcing chamfer screws, ensuring they find the right products from reliable suppliers while minimizing risks.

Comprehensive Cost and Pricing Analysis for chamfer screw Sourcing

What Are the Key Cost Components of Chamfer Screw Sourcing?

When sourcing chamfer screws, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of materials significantly impacts the cost. Common materials for chamfer screws include steel, stainless steel, and specialized alloys. Prices fluctuate based on market demand and global supply chain conditions. For instance, high-quality stainless steel may come with a premium, reflecting its durability and resistance to corrosion.

-

Labor: Labor costs can vary widely depending on the region of production. Countries with lower labor costs can provide significant savings, but this must be balanced against potential quality issues. Skilled labor is often required for precision manufacturing, especially when producing customized or high-specification screws.

-

Manufacturing Overhead: This encompasses the indirect costs of production, such as utilities, factory rent, and maintenance. Efficient manufacturing processes can help minimize overhead, making it a crucial area for cost management.

-

Tooling: The initial investment in tooling, including dies and molds, can be substantial. However, these costs are spread over production runs, making them less impactful per unit in large orders. Custom tooling may be necessary for specific designs, which can further increase costs.

-

Quality Control (QC): Ensuring the quality of chamfer screws is vital, particularly in industries such as aerospace and automotive. The costs associated with QC processes—testing, inspections, and certifications—should be factored into the overall pricing.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and volume. International buyers, particularly from regions like Africa and South America, should be aware of potential tariffs and import duties that can increase overall costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can be influenced by market competition and the supplier’s position within the supply chain.

How Do Price Influencers Affect Chamfer Screw Costs?

Several factors can influence the pricing of chamfer screws, particularly for international B2B buyers.

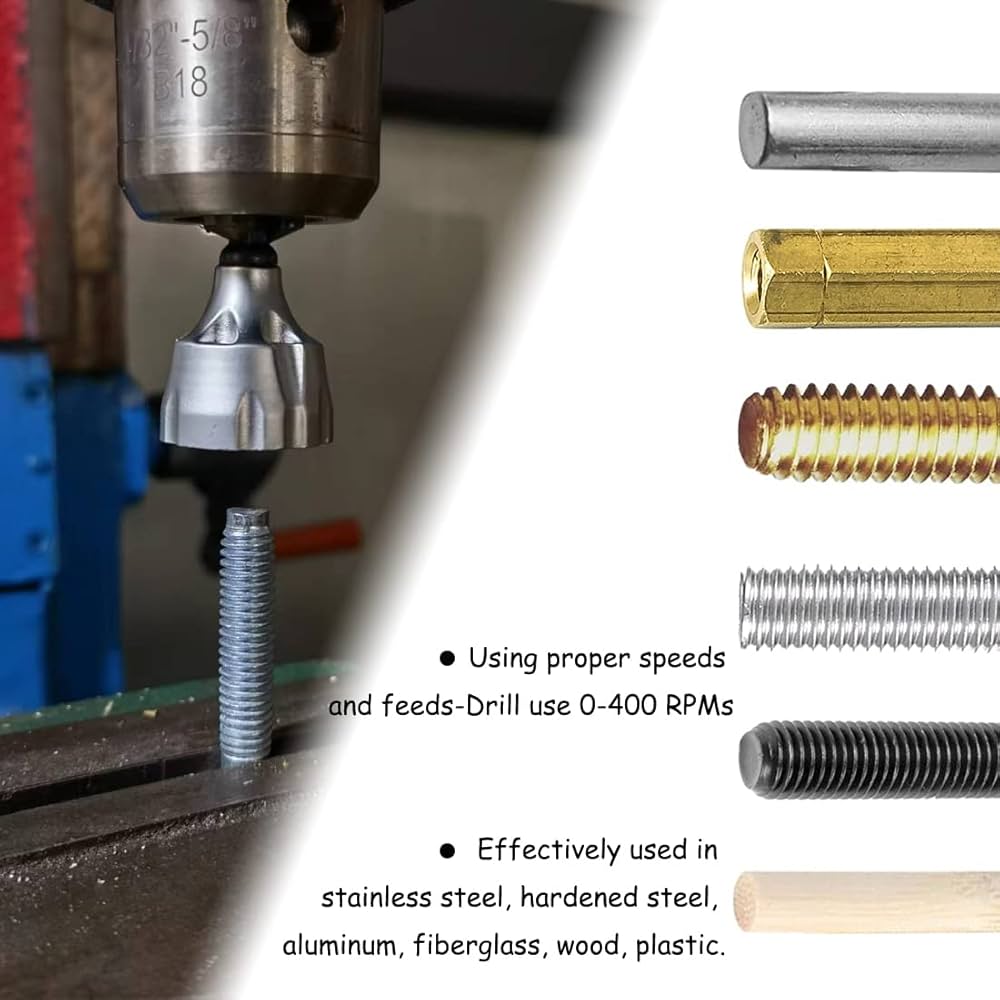

Illustrative image related to chamfer screw

-

Volume/MOQ: Minimum order quantities (MOQ) often apply, and larger orders typically reduce per-unit costs. Negotiating MOQs can lead to significant savings.

-

Specifications and Customization: Custom specifications, such as thread size, length, and material type, can affect pricing. Standardized products usually come at a lower cost compared to bespoke solutions.

-

Quality and Certifications: Products with industry-specific certifications (e.g., ISO) may command higher prices due to the assurance of quality and compliance with safety standards.

-

Supplier Factors: The reputation and reliability of the supplier can impact price. Established suppliers may charge more due to their proven track record, but they often provide better quality assurance and customer support.

-

Incoterms: The terms of delivery (e.g., FOB, CIF) can significantly affect costs. Understanding these terms is crucial for budgeting logistics expenses.

What Buyer Tips Should International B2B Buyers Consider?

For B2B buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe, effective negotiation and strategic sourcing are paramount.

-

Negotiation: Always negotiate prices and terms. Suppliers are often willing to provide discounts for larger orders or long-term partnerships. Building a strong relationship with suppliers can lead to better pricing and service.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes not just the purchase price but also maintenance, logistics, and potential downtime costs associated with inferior products.

-

Pricing Nuances: Be aware of regional pricing differences. For example, European suppliers might offer higher quality but at a premium, while suppliers from regions with lower labor costs may provide more competitive pricing.

-

Market Research: Conduct thorough market research to understand pricing trends and identify potential suppliers. This knowledge can empower buyers during negotiations and sourcing decisions.

-

Disclaimer for Indicative Prices: Prices can fluctuate based on market conditions, and it is essential to seek updated quotes from suppliers. Always consider potential changes in tariffs, material costs, and currency fluctuations when budgeting for chamfer screws.

By understanding these elements, B2B buyers can make informed sourcing decisions that optimize cost and quality for their chamfer screw needs.

Alternatives Analysis: Comparing chamfer screw With Other Solutions

In the competitive landscape of manufacturing and assembly, selecting the right fastening solution is crucial for operational efficiency and product integrity. While chamfer screws offer distinct advantages, it’s beneficial for B2B buyers to consider alternative fastening solutions that may better suit their specific applications or operational needs.

| Comparison Aspect | Chamfer Screw | Flat Head Screw | Socket Head Cap Screw |

|---|---|---|---|

| Performance | Excellent alignment; reduces cross-threading risks | Good for flush surfaces; moderate alignment | High torque capacity; excellent for tight spaces |

| Cost | Generally higher due to specialized design | Typically lower; widely available | Moderate to high; depends on material and finish |

| Ease of Implementation | Requires precision in installation | Easy to install, versatile | Requires Allen wrench for installation |

| Maintenance | Low maintenance; durable design | Low maintenance; prone to stripping if over-torqued | Low maintenance; can wear if not used properly |

| Best Use Case | High-precision applications, aerospace, automotive | General-purpose applications, electronics | High-stress applications, machinery, automotive |

What Are the Advantages and Disadvantages of Flat Head Screws Compared to Chamfer Screws?

Flat head screws are a popular alternative due to their ability to sit flush with the surface of the material, providing a neat finish. They are easy to install and suitable for various applications, particularly in electronics where aesthetics matter. However, they may not provide the same level of alignment and cross-threading protection as chamfer screws, which could lead to complications during assembly. Additionally, if over-torqued, flat head screws can strip, reducing their effectiveness over time.

How Do Socket Head Cap Screws Compare to Chamfer Screws in Performance?

Socket head cap screws are known for their high torque capacity and ability to withstand significant stress, making them ideal for heavy machinery and automotive applications. Their design allows for easier access in tight spaces, improving installation efficiency. However, they require an Allen wrench for installation, which may not be as straightforward as the installation of chamfer screws. Moreover, while they are durable, they can wear over time if not utilized properly, which could lead to performance issues.

Conclusion: How Can B2B Buyers Choose the Right Fastening Solution?

When choosing a fastening solution, B2B buyers should carefully evaluate their specific application requirements, including performance needs, cost constraints, and ease of installation. Chamfer screws excel in high-precision environments where alignment is critical, while flat head screws offer versatility and aesthetic appeal for general applications. Socket head cap screws provide strength and torque capacity for demanding conditions. By analyzing these aspects, buyers can make informed decisions that enhance operational efficiency and product quality, ultimately leading to better business outcomes.

Essential Technical Properties and Trade Terminology for chamfer screw

What Are the Key Technical Properties of Chamfer Screws?

Chamfer screws are specialized fasteners designed to facilitate easier assembly and enhance the durability of threaded connections. Understanding their technical properties is crucial for international B2B buyers looking to optimize their procurement processes. Here are some essential specifications to consider:

1. Material Grade

The material grade of a chamfer screw significantly impacts its strength, corrosion resistance, and suitability for various applications. Common materials include stainless steel, carbon steel, and alloy steels. For example, stainless steel offers excellent corrosion resistance, making it ideal for outdoor or marine applications. Selecting the right material ensures the longevity and reliability of the fasteners in specific environments.

2. Thread Type and Size

Chamfer screws come with various thread types, including UNC (Unified National Coarse) and UNF (Unified National Fine). The choice between these thread types affects the screw’s load-bearing capacity and ease of assembly. It’s crucial for buyers to specify the thread size and type when placing orders to ensure compatibility with existing components.

Illustrative image related to chamfer screw

3. Tolerance Levels

Tolerance levels indicate the allowable deviation from specified dimensions. For chamfer screws, tolerances are critical to ensure a precise fit with mating parts, which reduces the risk of cross-threading and mechanical failure. Tolerances are usually specified in both imperial and metric units, so international buyers should be aware of the standards relevant to their region.

4. Chamfer Angle

The chamfer angle, typically ranging from 45° to 82°, affects how easily the screw engages with a corresponding nut or threaded hole. A properly designed chamfer angle aids in the alignment of threads, facilitating smoother assembly. Understanding the required chamfer angle for specific applications can help in selecting the appropriate screw type.

5. Length and Head Style

The length of the chamfer screw and the style of its head (e.g., flat, round, or hex) play essential roles in its functionality. Different applications may require specific head styles to accommodate tools or aesthetic considerations. Buyers should ensure that the length and head style match their project requirements to avoid assembly issues.

6. Finish and Coating

The finish or coating of a chamfer screw can influence its performance in various environments. Common finishes include zinc plating, black oxide, and anodizing, which provide different levels of protection against corrosion and wear. Selecting the right finish is vital for ensuring that the screws perform optimally in their intended applications.

What Are Common Trade Terms Related to Chamfer Screws?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms that buyers should know:

Illustrative image related to chamfer screw

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are used as components in the products of another company. For chamfer screws, knowing whether a supplier is an OEM can help buyers assess quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of a product that a supplier is willing to sell. Understanding the MOQ helps buyers plan their purchases and manage inventory effectively, especially when sourcing specialized items like chamfer screws.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. Buyers should prepare detailed RFQs that specify all technical properties of chamfer screws required, which facilitates accurate and competitive pricing from multiple vendors.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps in understanding shipping costs, risk transfer, and delivery timelines associated with chamfer screws.

5. Lead Time

Lead time refers to the time between placing an order and receiving the products. For chamfer screws, understanding lead times is critical for project scheduling and ensuring that production timelines are met.

6. Certification

Certification indicates that a product meets specific standards or regulations. For chamfer screws, certifications such as ISO or ASTM can assure buyers of quality and reliability, particularly in critical applications.

By understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions, ensuring that their procurement processes are efficient and effective.

Navigating Market Dynamics and Sourcing Trends in the chamfer screw Sector

What Are the Current Market Dynamics and Key Trends Affecting the Chamfer Screw Sector?

The chamfer screw market is experiencing significant transformation driven by globalization, advancements in manufacturing technologies, and evolving buyer preferences. The increasing demand for precision-engineered components across various sectors, including automotive, aerospace, and construction, is propelling the growth of chamfer screws. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of key market dynamics such as the rising adoption of automation in manufacturing processes, which enhances productivity and reduces costs. This trend is particularly pronounced in Germany and Brazil, where industries are integrating smart technologies for improved operational efficiency.

Illustrative image related to chamfer screw

Additionally, sourcing trends are shifting toward a preference for customizable solutions. Buyers are seeking suppliers that can provide tailored products that meet specific application requirements. The emergence of digital platforms for sourcing chamfer screws is also notable, facilitating easier comparison of prices and specifications across suppliers. Buyers are encouraged to leverage these platforms to ensure they are obtaining the best value for their investments.

As the industry evolves, there is a growing emphasis on quality assurance and traceability in the supply chain. Buyers should prioritize suppliers that adhere to international quality standards, as this not only guarantees product reliability but also fosters long-term partnerships.

How Is Sustainability and Ethical Sourcing Impacting the Chamfer Screw Industry?

Sustainability and ethical sourcing are increasingly pivotal in the chamfer screw sector, aligning with global initiatives to reduce environmental impact and promote responsible manufacturing practices. The production of chamfer screws often involves significant energy consumption and material waste. Consequently, manufacturers are investing in ‘green’ technologies and processes that minimize these impacts, including energy-efficient machinery and waste recycling programs.

B2B buyers are encouraged to consider the environmental footprint of their sourcing decisions. This includes evaluating suppliers based on their commitment to sustainability, such as the use of recycled materials or adherence to certifications like ISO 14001, which indicates a robust environmental management system. The rise of eco-friendly materials, including biodegradable plastics and sustainably sourced metals, is also reshaping the landscape of chamfer screw manufacturing.

Moreover, buyers should be vigilant about ethical supply chains, ensuring that their suppliers uphold fair labor practices and contribute positively to their communities. Engaging with suppliers that demonstrate a commitment to corporate social responsibility can enhance brand reputation and foster customer loyalty.

What Is the Historical Context of Chamfer Screws in B2B Sourcing?

The concept of chamfering in screw design dates back to the early days of mechanical engineering, where the need for precise alignment in assembly processes became evident. Historically, chamfers were introduced to facilitate smoother engagement between threaded components, thereby reducing wear and enhancing durability. As industries evolved, the application of chamfer screws expanded beyond traditional manufacturing to include advanced sectors such as aerospace and automotive, where precision and reliability are paramount.

In recent decades, the evolution of materials science and manufacturing technology has further refined the design and production of chamfer screws. Today, modern chamfer screws are often engineered using advanced alloys and cutting-edge manufacturing techniques, enabling them to meet the rigorous demands of various applications. This historical progression underscores the importance of innovation in driving the chamfer screw market, providing B2B buyers with an understanding of the product’s development and its current relevance in diverse industries.

Frequently Asked Questions (FAQs) for B2B Buyers of chamfer screw

-

How do I choose the right chamfer screw for my application?

Selecting the appropriate chamfer screw involves considering several factors, including the screw’s material, thread type, and length. Determine the specific requirements of your application, such as load capacity and environmental conditions (e.g., corrosion resistance). Additionally, assess the compatibility with existing components to ensure optimal fit and performance. Engaging with suppliers who offer detailed technical data and samples can also facilitate informed decision-making. -

What are the advantages of using chamfer screws in assembly processes?

Chamfer screws provide significant benefits during assembly, including easier alignment and reduced risk of cross-threading. The beveled edges guide the screw into the corresponding threads, allowing for smoother engagement. This design minimizes wear and tear on both the screw and the mating part, enhancing overall durability. In high-volume production environments, chamfer screws can improve assembly speed and efficiency, translating to cost savings. -

What customization options are available for chamfer screws?

Most manufacturers offer customization options for chamfer screws, including variations in material, size, thread pitch, and coating. Customization can enhance performance characteristics, such as corrosion resistance or strength. It’s advisable to communicate your specific requirements to suppliers early in the sourcing process. This ensures that the final product meets your operational needs while adhering to industry standards. -

What is the typical minimum order quantity (MOQ) for chamfer screws?

The MOQ for chamfer screws can vary significantly based on the manufacturer and the specific product type. Generally, MOQs range from 100 to 1,000 units, but some suppliers may accommodate smaller orders for specialized applications. When negotiating with suppliers, clarify your requirements and explore options for bulk purchasing or long-term contracts, which may offer more favorable terms. -

How can I vet suppliers when sourcing chamfer screws internationally?

To effectively vet suppliers, start by researching their industry reputation and customer reviews. Request certifications and quality assurance documentation to ensure compliance with international standards. Engaging in direct communication is essential; inquire about their production capabilities, lead times, and experience in your specific market. Additionally, consider visiting their facilities or utilizing third-party inspection services to verify quality before placing large orders. -

What payment terms should I expect when purchasing chamfer screws?

Payment terms for chamfer screws can vary widely among suppliers. Common terms include upfront payment, partial payment before shipment, or payment upon delivery. For large orders, negotiating credit terms may be possible. It’s crucial to discuss payment options upfront to avoid misunderstandings later. Ensure that all terms are documented in the purchase agreement to protect both parties. -

What quality assurance measures should be in place for chamfer screws?

Quality assurance measures should encompass both the manufacturing process and final product testing. Suppliers should adhere to ISO standards and conduct routine inspections at various production stages. Request documentation of quality control protocols, such as material certifications and test results for strength and durability. Establishing clear quality expectations upfront can help ensure that the chamfer screws meet your specifications and performance standards. -

How can I manage logistics when sourcing chamfer screws internationally?

Effective logistics management is crucial when sourcing chamfer screws globally. Consider factors such as shipping methods, lead times, and customs regulations in your country. Partnering with suppliers who have experience in international shipping can streamline the process. Additionally, utilize freight forwarders to handle shipping logistics and ensure compliance with local import regulations. Proper planning and communication can help mitigate delays and unexpected costs.

Top 6 Chamfer Screw Manufacturers & Suppliers List

1. Reddit – Chamfer Guidelines

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Chamfers are the bevels or slanted entryways for thread starts or tool entry, usually at 45 degrees or shallower. Chamfer diameter should be slightly larger than the screw’s outer diameter. For flush mount socket head screws, an 82-degree chamfer is used. A general guideline is to make the chamfer on the minor diameter larger than the thread’s major diameter, often around .010″ larger.

2. Kennametal – T820 Form B Plug Chamfer

Domain: kennametal.com

Registered: 1995 (30 years)

Introduction: {“model”:”T820″,”type”:”Form B Plug Chamfer”,”application”:”Machine Screw and Fractional”,”length”:”4 inch”,”standard”:”ANSI”}

3. Military Fasteners – Flat Chamfer Fasteners

Domain: military-fasteners.com

Registered: 2013 (12 years)

Introduction: Flat Chamfer Fasteners available in various specifications including thread sizes (#1 to #24, 1/4″ to 7/8″), thread quantities (TPI from 10 to 72), overall lengths (ranging from 5/16″ to 8-7/8″), materials (Aluminum, Iron, Nickel, Stainless Steel, Steel, Titanium), surface treatments (Anodized, Black Oxide, Cadmium, Passivate, Zinc Oxide), and drive styles (Cross, Slotted, Square, Hexagon, Hexagon…

4. Practical Machinist – 45 Degree Chamfer Tool

Domain: practicalmachinist.com

Introduction: Chamfer for flat head screws, 0.490 diameter, 3 flute 45 degree chamfer tool, HAAS VF2 mill, aluminum material, suggested feeds and speeds include 3 ipm at 2500 rpm, single flute countersink recommended, 82 degree included angle for inch screws, 90 degree for metric screws up to M24, then 60 degree for larger metric screws, Lakeshore Carbide tools mentioned, G82 cycle for efficiency.

5. M3 – 304 SS Flat Head Hex Socket Screws

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “M3 304 SS Flat Head Hex Socket Screw Chamfer Furniture Screws”, “Condition”: “New – Open box”, “Material”: “304 Stainless Steel”, “Type”: “Machine Screws”, “System of Measurement”: “Metric”, “Thread Diameter”: “M3–PITCH 0.5”, “Available Lengths (exclude head)”: [“4mm”, “5mm”, “6mm”, “8mm”, “10mm”, “12mm”, “14mm”, “16mm”, “20mm”, “25mm”, “30mm”], “Package Options”: [“20 Pcs”, “30…

6. Keneng Hardware – Cross Flat Chamfered Head Screw

Domain: kenenghardware.com

Registered: 2020 (5 years)

Introduction: {‘name’: ‘Cross Flat Chamfered Head Screw’, ‘sizes’: ‘M4-M8’, ‘material’: ‘stainless steel’, ‘color’: ‘Natural’, ‘application’: ‘widely used in the furniture, decoration, electrical machinery industry’, ‘advantages’: ‘deep thread, uniform tooth distance, good fastening strength, smooth without burrs, exquisite workmanship, durable, strict control of raw materials, high hardness’, ‘customization’: …

Strategic Sourcing Conclusion and Outlook for chamfer screw

In the competitive landscape of manufacturing and assembly, strategic sourcing of chamfer screws presents a unique opportunity for international B2B buyers. By prioritizing quality and compatibility, businesses can enhance assembly efficiency and reduce operational risks associated with thread misalignment and cross-threading. Chamfer screws, with their beveled edges, facilitate smoother engagement and improve the longevity of threaded components, making them invaluable in various applications across industries.

Illustrative image related to chamfer screw

As global markets continue to evolve, sourcing chamfer screws from reputable suppliers is essential. Buyers from regions such as Africa, South America, the Middle East, and Europe should leverage digital tools to identify and collaborate with manufacturers that meet their specific requirements. Additionally, understanding regional regulations and tariffs can further optimize procurement strategies, ensuring cost-effective solutions.

Looking ahead, the demand for innovative fastening solutions will only grow. By investing in strategic sourcing practices now, companies can position themselves to capitalize on future market opportunities. Take the initiative to explore diverse suppliers and consider integrating advanced materials and designs in your sourcing strategy to stay ahead of the competition.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.