Unlocking Value: A Strategic Analysis of the 4 X 8 Expanded Metal Sheet Market

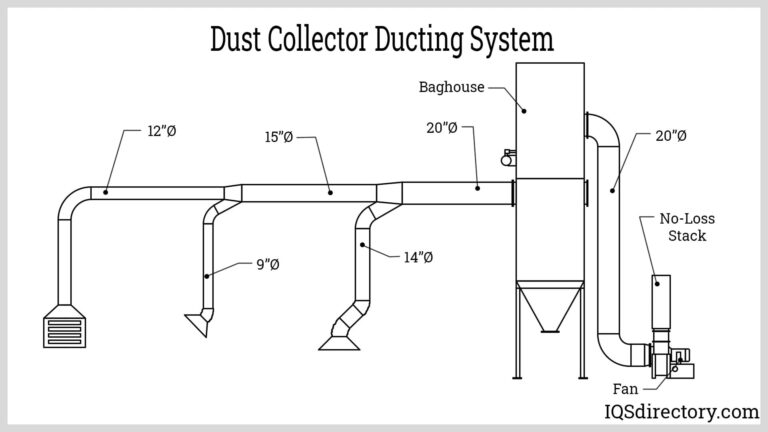

Introduction: Navigating the Global Market for 4 x 8 expanded metal sheet

In the competitive landscape of global manufacturing, sourcing high-quality 4 x 8 expanded metal sheets presents a significant challenge for B2B buyers. With diverse applications ranging from architectural design to industrial security, understanding the nuances of this versatile material is crucial. This guide is designed to navigate the complexities of the expanded metal market, addressing key factors such as types, applications, supplier vetting, and cost considerations.

International buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe—including major markets like Germany and Saudi Arabia—will find actionable insights tailored to their specific needs. By exploring various materials—including mild steel, stainless steel, and aluminum—and their respective applications, this guide empowers buyers to make informed purchasing decisions.

Furthermore, we delve into essential aspects such as supplier credibility, pricing strategies, and logistical considerations to ensure a seamless procurement process. Whether you are looking for decorative solutions or functional components, this comprehensive resource equips you with the knowledge to navigate the global market effectively, helping you secure the best deals while minimizing risks. With the right information at your fingertips, you can confidently approach your next sourcing decision in the dynamic world of expanded metal sheets.

Understanding 4 x 8 expanded metal sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Expanded Metal | Diamond-shaped openings, lightweight, versatile | Grating, fencing, security screens | Pros: Cost-effective, good airflow; Cons: Limited strength for heavy loads. |

| Flattened Expanded Metal | Cold-rolled to a smooth surface, offers a flat finish | Decorative applications, architectural designs | Pros: Aesthetic appeal, easy to clean; Cons: Slightly heavier than standard. |

| Heavy Duty Expanded Metal | Thicker gauge, larger openings for increased load capacity | Industrial flooring, heavy-duty applications | Pros: High strength, durable; Cons: Higher cost, less flexibility in design. |

| Aluminum Expanded Metal | Lightweight, corrosion-resistant, non-magnetic | Architectural facades, ventilation systems | Pros: Lightweight, rust-resistant; Cons: Higher price compared to steel. |

| Stainless Steel Expanded Metal | Enhanced corrosion resistance, aesthetic finish | Food processing, medical applications | Pros: Hygiene, durability; Cons: Costly, heavier than aluminum. |

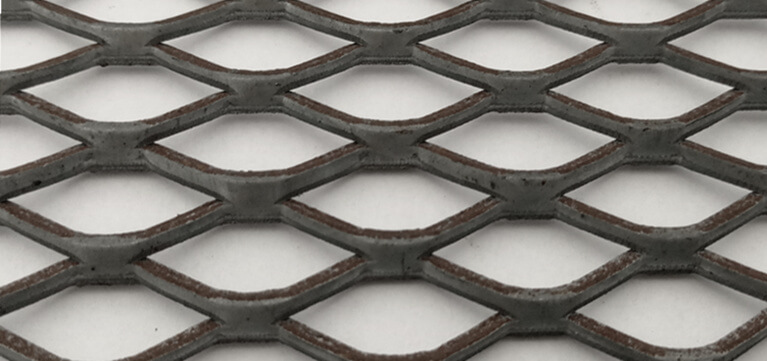

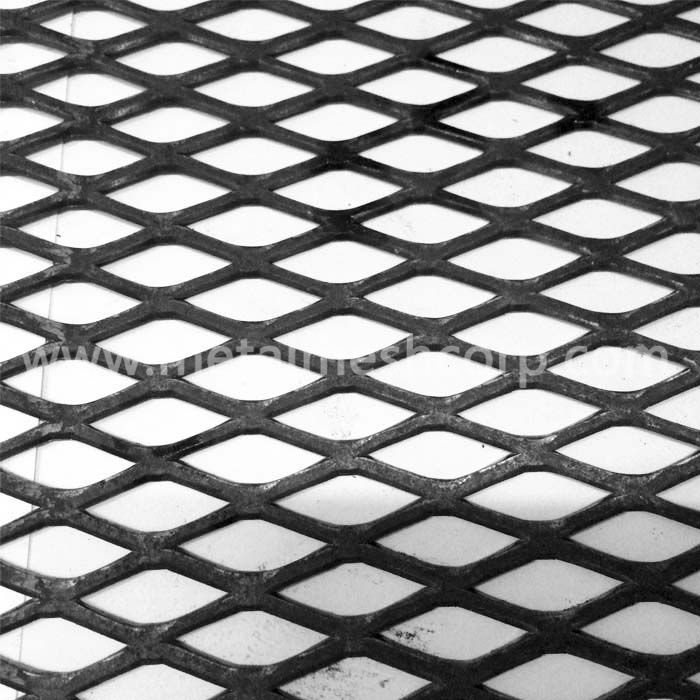

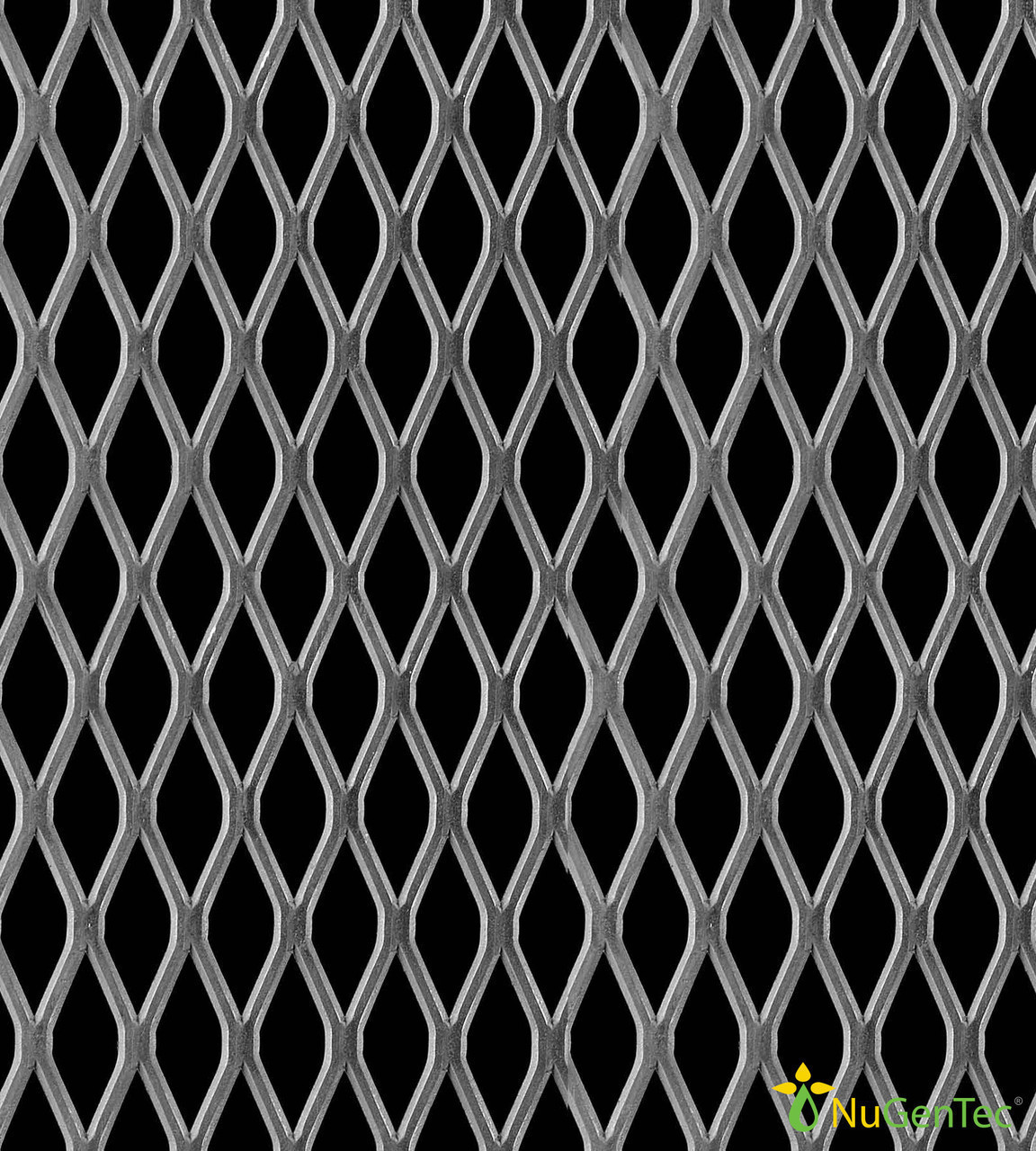

What Are the Characteristics of Standard Expanded Metal Sheets?

Standard expanded metal sheets are characterized by their diamond-shaped openings formed from slitting and stretching the metal. This type is lightweight, making it ideal for applications that require good airflow, such as grating and security fencing. When purchasing, B2B buyers should consider factors like thickness and material type, as these will influence the sheet’s strength and suitability for specific applications.

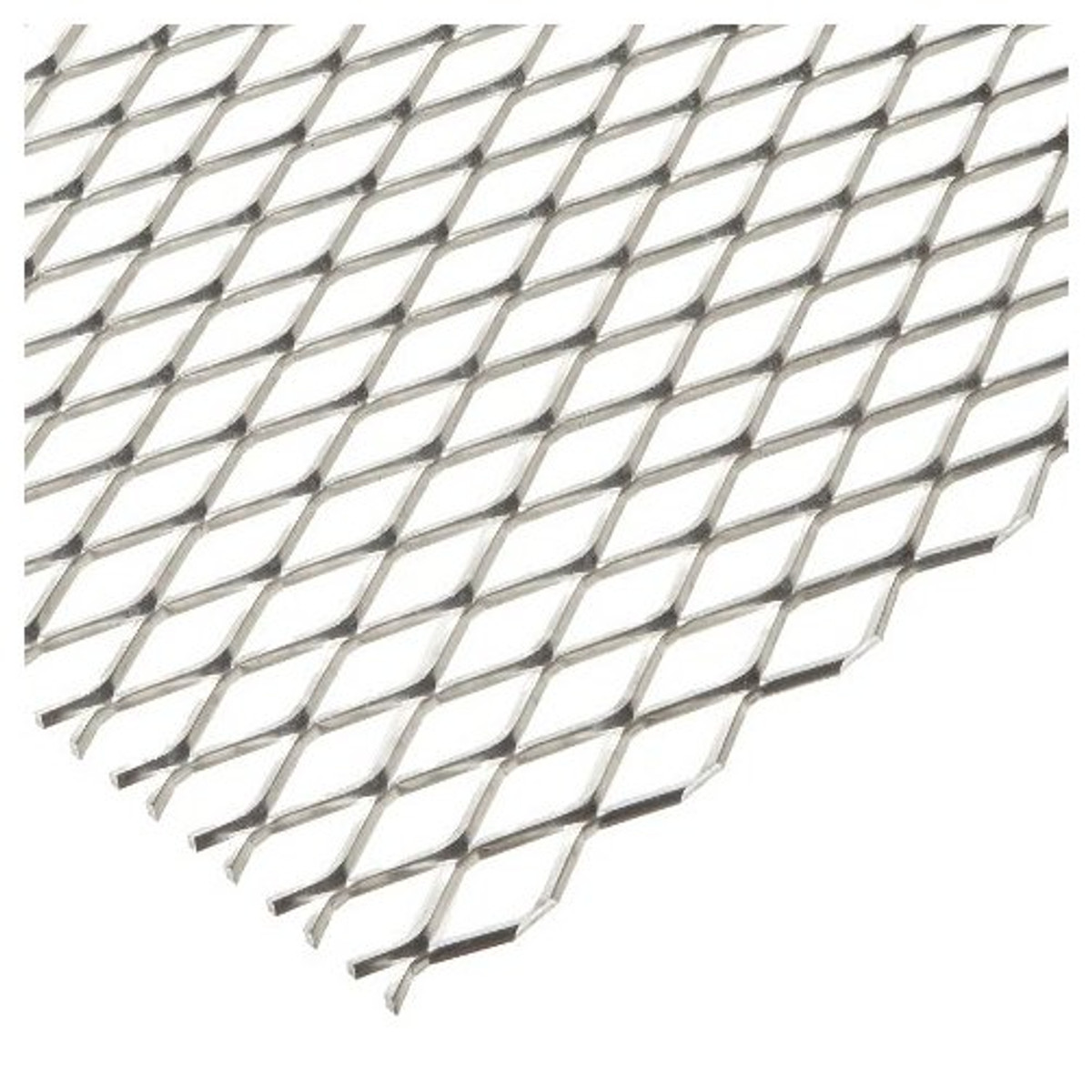

How Does Flattened Expanded Metal Differ from Other Types?

Flattened expanded metal is cold-rolled to create a smooth surface, distinguishing it from standard expanded metal. This smooth finish makes it particularly suitable for decorative applications, such as architectural designs and furniture. Buyers should evaluate the aesthetic requirements of their projects and consider the ease of cleaning, as flattened sheets can be easier to maintain. However, they may be slightly heavier than standard expanded options.

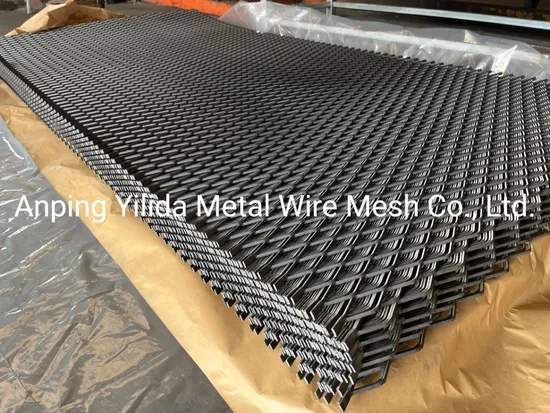

Illustrative image related to 4 x 8 expanded metal sheet

What Are the Advantages of Heavy Duty Expanded Metal?

Heavy-duty expanded metal sheets are produced from thicker gauge materials, providing increased load capacity for industrial applications. Their larger openings allow for enhanced drainage and airflow, making them suitable for flooring in industrial settings. B2B buyers should assess the specific load requirements of their projects, as the higher cost may be justified by the durability and strength of these sheets.

Why Choose Aluminum Expanded Metal for Your Projects?

Aluminum expanded metal offers unique advantages, such as being lightweight, corrosion-resistant, and non-magnetic. This makes it an excellent choice for architectural facades and ventilation systems where weight is a concern. Buyers should weigh the benefits of rust resistance and aesthetics against the higher cost compared to steel options, especially for long-term installations.

What Makes Stainless Steel Expanded Metal a Preferred Choice?

Stainless steel expanded metal is favored for its high corrosion resistance and durability, making it ideal for food processing and medical applications. Its aesthetic finish also appeals to designers looking for both functionality and style. However, B2B buyers should note that while it offers superior hygiene and strength, the initial investment is higher than other materials like aluminum or mild steel.

Key Industrial Applications of 4 x 8 expanded metal sheet

| Industry/Sector | Specific Application of 4 x 8 expanded metal sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Curtain wall cladding and facade design | Enhances aesthetic appeal while providing structural integrity | Ensure compliance with local building codes and regulations |

| Manufacturing & Industrial | Grating for walkways and platforms | Provides safety and durability in high-traffic areas | Consider load-bearing capacity and corrosion resistance |

| Agriculture & Horticulture | Greenhouse benches and ventilation systems | Facilitates air circulation and light penetration for plants | Sourcing materials that are resistant to environmental factors |

| Security & Safety | Window guards and fencing | Enhances security without obstructing visibility | Evaluate thickness and mesh pattern for specific security needs |

| Mining & Heavy Industry | Screening and sorting applications | Improves efficiency in material handling and processing | Assess material strength and custom sizing options |

How is 4 x 8 Expanded Metal Sheet Used in Construction and Architecture?

In the construction and architecture sector, 4 x 8 expanded metal sheets are often used for curtain wall cladding and facade designs. Their unique diamond-shaped openings allow for aesthetic versatility while maintaining structural integrity. For international buyers, especially in regions like Europe and the Middle East, it’s crucial to source materials that comply with local building codes. Additionally, buyers should consider the surface treatment options available, such as powder coating, to enhance durability against environmental factors.

What Role Does 4 x 8 Expanded Metal Play in Manufacturing and Industrial Settings?

In manufacturing and industrial environments, 4 x 8 expanded metal sheets are commonly utilized for grating in walkways and platforms. This application offers safety by preventing slips while allowing for drainage and airflow. B2B buyers in Africa and South America should prioritize sourcing expanded metal that meets specific load-bearing requirements and corrosion resistance, especially in humid or corrosive environments. Custom sizing may also be necessary to fit unique industrial layouts.

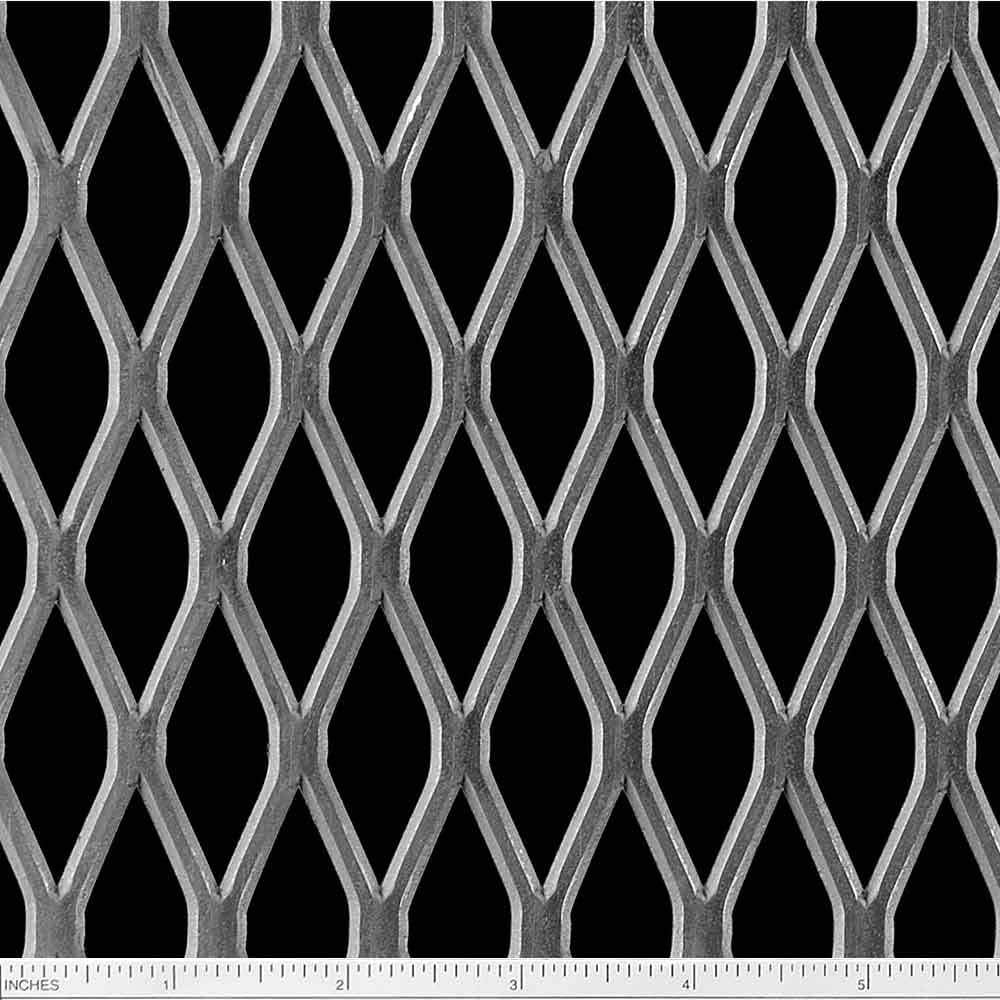

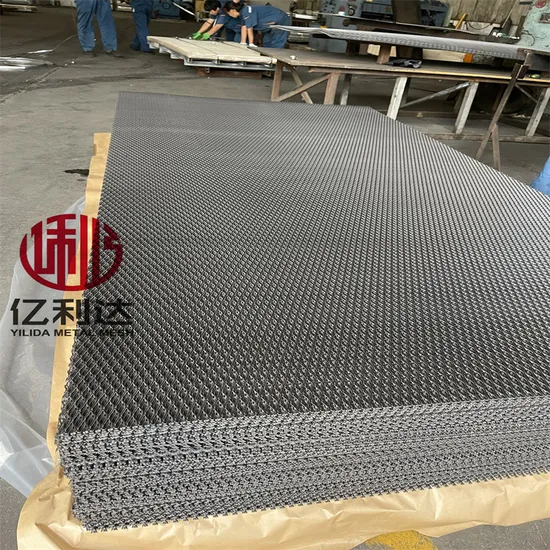

Illustrative image related to 4 x 8 expanded metal sheet

How Does Expanded Metal Benefit Agriculture and Horticulture?

In agriculture, 4 x 8 expanded metal sheets are frequently employed for greenhouse benches and ventilation systems. These sheets facilitate air circulation and light penetration, essential for healthy plant growth. International buyers should look for materials that can withstand varying climatic conditions, ensuring longevity and functionality. Additionally, sourcing options that offer custom shapes can optimize space and efficiency in greenhouse designs.

Why is 4 x 8 Expanded Metal Important for Security Applications?

For security and safety applications, 4 x 8 expanded metal sheets are utilized in window guards and fencing solutions. They provide enhanced security without obstructing visibility, making them ideal for both residential and commercial settings. Buyers in the Middle East and Europe should evaluate the thickness and mesh pattern to ensure they meet specific security requirements. It’s also advisable to consider surface treatments that provide additional protection against weathering.

How is 4 x 8 Expanded Metal Used in Mining and Heavy Industry?

In the mining and heavy industry, 4 x 8 expanded metal sheets are essential for screening and sorting applications. Their design improves efficiency in material handling and processing by allowing for the quick separation of materials. B2B buyers should assess the strength of the materials used and consider custom sizing options to fit specific equipment and operational needs. This is particularly important in regions with demanding mining conditions, where durability is paramount.

3 Common User Pain Points for ‘4 x 8 expanded metal sheet’ & Their Solutions

Scenario 1: Challenges with Customization and Specifications

The Problem: Many B2B buyers encounter difficulties when trying to obtain customized specifications for 4 x 8 expanded metal sheets. This often arises from a lack of clear communication with suppliers regarding specific requirements such as thickness, strand size, and surface treatment. Inadequate customization can lead to product mismatches, project delays, and increased costs, particularly when buyers need sheets that meet unique project specifications for applications like security screens or architectural features.

The Solution: To effectively overcome these customization challenges, it is crucial for buyers to engage in detailed discussions with suppliers before placing orders. Clearly outline project requirements and expectations regarding dimensions, material type (such as mild steel, aluminum, or stainless steel), and surface finishes. Providing drawings or examples can significantly enhance communication. Additionally, buyers should consider suppliers that offer flexibility in production and have a robust capability for custom cutting and shaping. Requesting samples can also help ensure that the final product aligns with the buyer’s vision, minimizing the risk of errors and enhancing project efficiency.

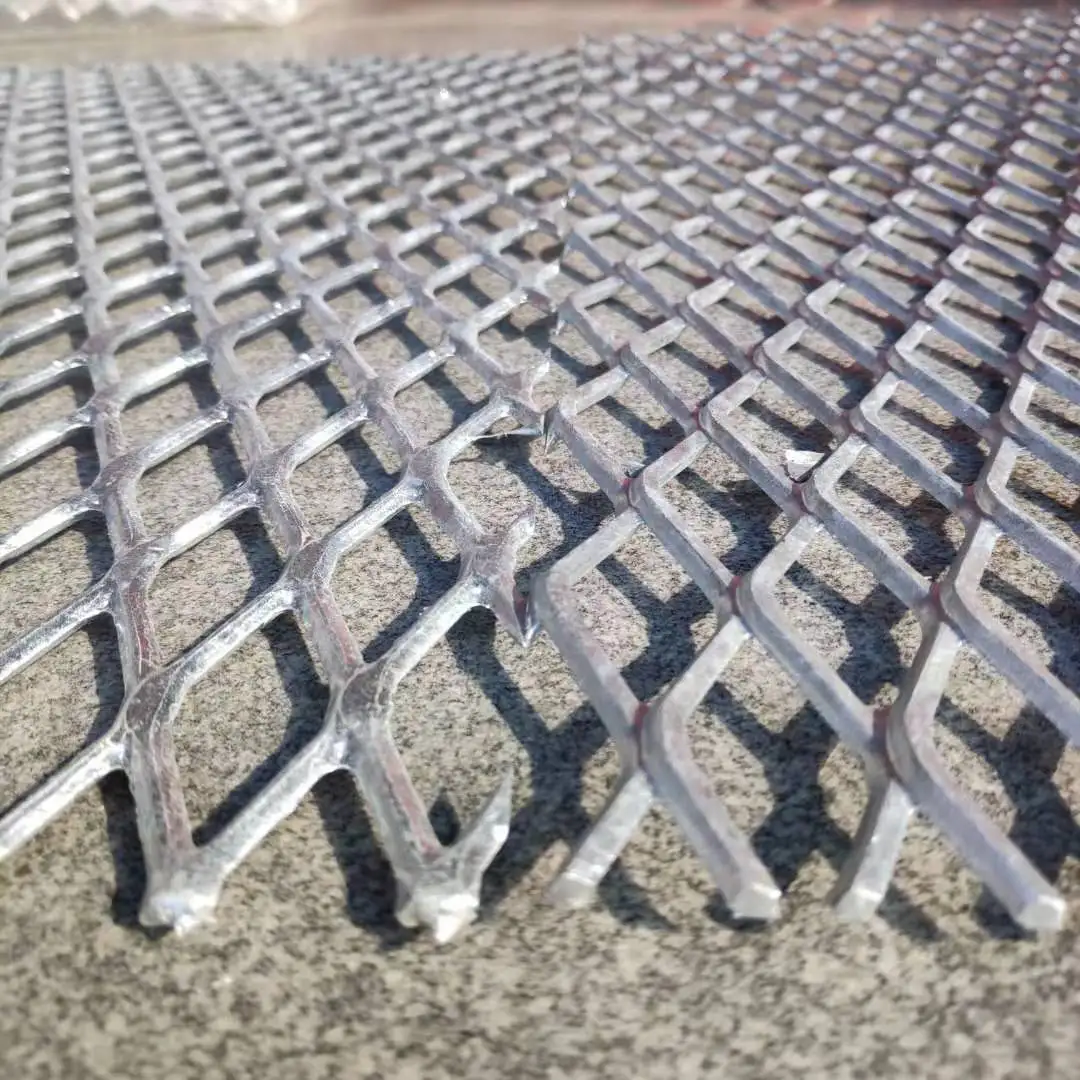

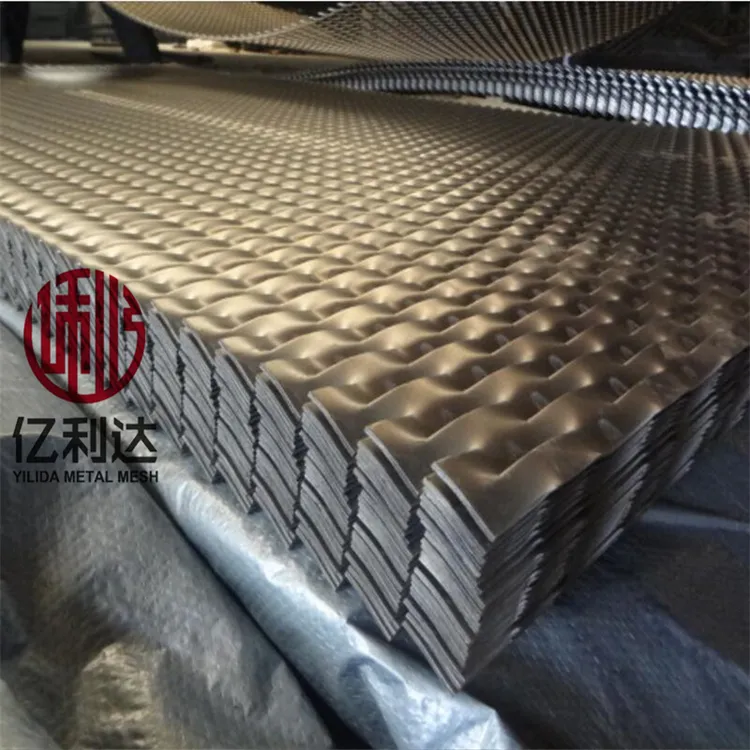

Illustrative image related to 4 x 8 expanded metal sheet

Scenario 2: Understanding Pricing Structures and Additional Costs

The Problem: B2B buyers often face confusion regarding the pricing structures associated with 4 x 8 expanded metal sheets. Factors such as material type, thickness, and additional processing (like cutting or surface treatments) can lead to unexpected costs. This lack of transparency in pricing can complicate budgeting and financial planning, especially for projects with tight margins.

The Solution: To navigate pricing complexities, buyers should proactively request detailed quotes from multiple suppliers. These quotes should itemize all costs, including base price per sheet, cutting fees, and any additional charges for customizations. By comparing these quotes, buyers can identify the most cost-effective options while ensuring they are not sacrificing quality. It’s also beneficial to establish long-term relationships with suppliers who offer loyalty discounts or bulk pricing, which can reduce costs significantly over time. Lastly, understanding the full lifecycle cost of the expanded metal sheets, including maintenance and durability, can help in making informed financial decisions.

Scenario 3: Ensuring Timely Delivery and Lead Times

The Problem: Timely delivery of 4 x 8 expanded metal sheets is often a significant concern for B2B buyers, particularly when they are working under tight project timelines. Delays in production or shipping can lead to disruptions, causing project stalls and potential financial losses. This is particularly critical for buyers in regions like Africa and South America, where logistics can be more challenging.

The Solution: To mitigate delivery-related issues, buyers should establish clear timelines and communicate these expectations to suppliers during the order process. It’s essential to inquire about lead times for different types of expanded metal sheets, especially for custom orders. Additionally, leveraging suppliers who have a proven track record of on-time delivery and robust logistical capabilities can be advantageous. Buyers may also consider placing orders well in advance of project deadlines and maintaining a buffer stock of essential materials, thereby reducing the risk of last-minute shortages or delays. Finally, utilizing tracking services offered by suppliers can provide transparency throughout the shipping process, allowing buyers to plan accordingly.

Strategic Material Selection Guide for 4 x 8 expanded metal sheet

What Are the Key Properties of Mild Steel for 4 x 8 Expanded Metal Sheets?

Mild steel is one of the most commonly used materials for 4 x 8 expanded metal sheets due to its balance of strength, ductility, and cost-effectiveness. It typically has a tensile strength of around 400-550 MPa and can withstand moderate temperatures and pressures. However, it offers limited corrosion resistance unless treated with a protective coating. This makes it suitable for applications in construction and manufacturing where exposure to harsh environments is minimal.

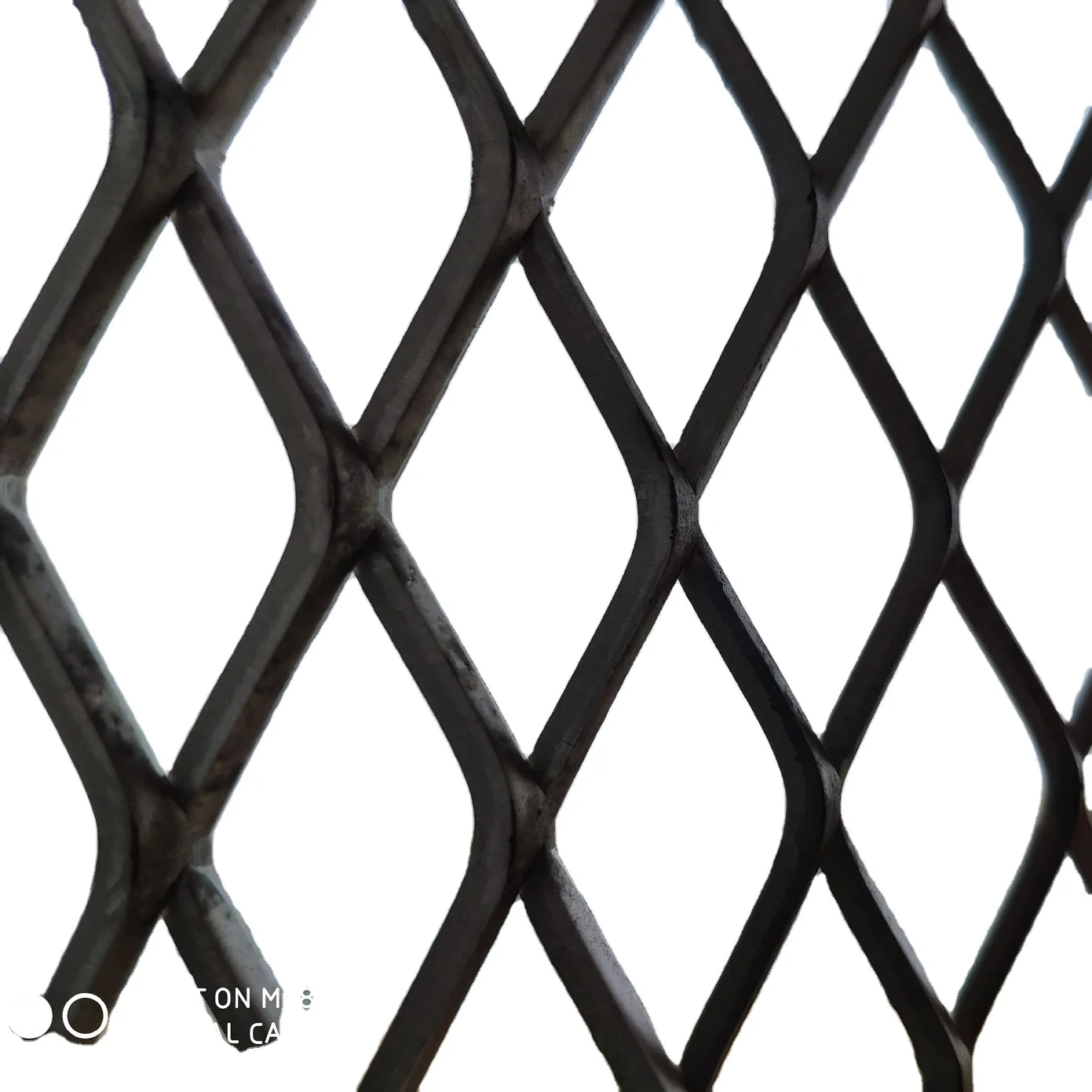

Illustrative image related to 4 x 8 expanded metal sheet

Pros and Cons: The advantages of mild steel include its affordability and ease of fabrication, making it suitable for a wide range of applications. However, its susceptibility to rust without proper treatment can be a significant drawback, particularly in humid or corrosive environments. Buyers should consider the long-term maintenance costs associated with corrosion protection.

Impact on Application: Mild steel expanded metal is ideal for structural applications, such as flooring and grating, where strength is paramount. However, in environments where moisture or chemicals are present, its use may be limited unless adequately protected.

How Does Aluminum Perform in 4 x 8 Expanded Metal Sheets?

Aluminum expanded metal sheets are lightweight and offer excellent corrosion resistance, making them a popular choice for various applications, particularly in architectural and decorative contexts. Aluminum typically has a tensile strength of around 70-700 MPa, depending on the alloy, and can withstand moderate temperatures.

Pros and Cons: The key advantages of aluminum include its lightweight nature, which reduces shipping costs, and its inherent resistance to corrosion, making it suitable for outdoor applications. However, aluminum can be more expensive than mild steel, and its lower strength compared to some steel grades may limit its use in heavy-load applications.

Illustrative image related to 4 x 8 expanded metal sheet

Impact on Application: Aluminum expanded metal is often used in applications requiring aesthetic appeal, such as facades and interior designs, where weight and corrosion resistance are critical factors.

What Are the Advantages of Stainless Steel for 4 x 8 Expanded Metal Sheets?

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it an excellent choice for 4 x 8 expanded metal sheets in harsh environments. With a tensile strength ranging from 520 to 750 MPa, stainless steel can withstand high temperatures and pressures, making it suitable for a variety of industrial applications.

Pros and Cons: The main advantage of stainless steel is its longevity and resistance to rust and staining, which reduces maintenance costs over time. However, it is generally more expensive than both mild and aluminum options, which may deter cost-sensitive buyers.

Impact on Application: Stainless steel expanded metal is ideal for applications in food processing, chemical manufacturing, and marine environments where hygiene and corrosion resistance are critical.

What Should International Buyers Consider When Selecting Expanded Metal Materials?

International buyers from regions like Africa, South America, the Middle East, and Europe should consider compliance with local and international standards such as ASTM, DIN, and JIS. These standards ensure the materials meet safety and performance criteria. Additionally, preferences for specific materials may vary by region; for instance, buyers in Europe may favor stainless steel for its durability, while those in Africa may prioritize cost-effectiveness with mild steel.

Summary Table of Material Selection for 4 x 8 Expanded Metal Sheets

| Material | Typical Use Case for 4 x 8 Expanded Metal Sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | Structural applications, flooring, grating | Cost-effective and easy to fabricate | Prone to rust without treatment | Low |

| Aluminum | Architectural features, decorative applications | Lightweight and corrosion-resistant | Higher cost and lower strength | Med |

| Stainless Steel | Food processing, chemical manufacturing, marine | Exceptional corrosion resistance | Higher initial cost | High |

This strategic material selection guide provides a comprehensive overview of the most common materials used for 4 x 8 expanded metal sheets, equipping international B2B buyers with the insights needed to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for 4 x 8 expanded metal sheet

What Are the Key Stages in the Manufacturing Process of 4 x 8 Expanded Metal Sheets?

The manufacturing of 4 x 8 expanded metal sheets involves several critical stages that ensure the final product meets quality and performance specifications. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting the appropriate raw materials, typically coils or sheets of mild steel, stainless steel, aluminum, or galvanized steel. The choice of material depends on the intended application and the desired properties such as corrosion resistance and weight. The selected material is then cleaned and inspected to remove any surface contaminants that may affect the subsequent processes.

-

Forming: The heart of expanded metal production lies in the forming stage. The metal sheets undergo a unique process where slits are cut into the material and then stretched. This is often accomplished using hydraulic or mechanical presses that create the characteristic diamond-shaped openings. The process is efficient, as it generates minimal waste by utilizing the entire sheet of metal, enhancing the product’s strength while reducing its weight.

-

Assembly: For applications that require custom dimensions, the formed sheets may need to be cut to size. This step is crucial for ensuring that the final product fits specific requirements. Techniques such as laser cutting or shearing are commonly employed to achieve precise dimensions. Additionally, if the expanded metal is intended for decorative purposes, various patterns can be created during this stage.

-

Finishing: The final stage involves applying surface treatments to enhance durability and aesthetic appeal. Options include powder coating, anodizing, or galvanizing, which not only protect against corrosion but also add color and texture. The choice of finishing process can be tailored to meet specific customer requirements, further increasing the product’s versatility.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing of expanded metal sheets, ensuring that each product meets international standards and customer specifications. Various quality control checkpoints are implemented throughout the process.

-

International Standards Compliance: Manufacturers often adhere to internationally recognized standards such as ISO 9001, which sets criteria for a quality management system. Compliance with these standards demonstrates a commitment to quality and continuous improvement. In certain regions, additional certifications such as CE marking for products sold in Europe or API standards for industrial applications may also be required.

-

Quality Control Checkpoints: The QA process typically includes several critical checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon delivery to ensure they meet specified standards for dimensions and material properties.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes such as forming and cutting. This helps identify any deviations from quality standards early in the production cycle.

– Final Quality Control (FQC): Once the product is completed, a final inspection is performed to verify that the expanded metal sheets meet all specifications, including dimensions, surface finish, and structural integrity. -

Common Testing Methods: Various testing methods are employed to assess the quality of expanded metal sheets. These may include visual inspections, dimensional checks, tensile strength tests, and corrosion resistance tests. Each of these tests ensures that the product can withstand the demands of its intended application.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential to ensure product reliability and compliance with standards.

-

Supplier Audits: Conducting supplier audits can provide valuable insights into the manufacturing processes and quality control systems in place. Buyers can request to see the facilities and review the QA protocols followed by the supplier. This firsthand observation can help assess the supplier’s capability and commitment to quality.

-

Quality Assurance Reports: Suppliers should provide detailed QA reports that outline their processes, testing methods, and results. These reports should include data on compliance with international standards and any certifications held by the manufacturer. Buyers should scrutinize these documents to ensure they align with their quality expectations.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality assurance practices. These agencies can conduct independent inspections and testing, providing buyers with an additional layer of confidence in the quality of the products they are purchasing.

What Are the Nuances of Quality Certification for International B2B Transactions?

Understanding the nuances of quality certification is crucial for B2B buyers, especially when dealing with international suppliers. Different regions may have specific requirements that affect the procurement process.

-

Regional Compliance: Buyers must be aware of the regulatory landscape in their respective regions. For example, European buyers may require CE marking for compliance with EU regulations, while buyers in the Middle East might need to consider local certifications that reflect regional standards.

-

Documentation and Traceability: It is essential for buyers to request documentation that verifies the origin of materials and the production processes. Traceability ensures that the products can be traced back to their source, which is vital in industries where quality and safety are paramount.

-

Cultural and Communication Barriers: International transactions can also present challenges related to cultural differences and communication barriers. Establishing clear lines of communication and understanding cultural norms can facilitate smoother negotiations and ensure that both parties have aligned expectations regarding quality and delivery.

Conclusion

The manufacturing processes and quality assurance measures for 4 x 8 expanded metal sheets are complex yet crucial for ensuring the product’s reliability and performance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to successful procurement outcomes. Emphasizing quality throughout the manufacturing cycle and verifying supplier capabilities will help mitigate risks and foster long-term business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘4 x 8 expanded metal sheet’

To effectively procure a 4 x 8 expanded metal sheet, it’s essential to follow a structured approach that ensures quality, compliance, and value. This checklist serves as a practical guide for B2B buyers navigating the sourcing process, particularly in diverse international markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Specifications should include material type (e.g., mild steel, aluminum, stainless steel), thickness, and desired patterns (standard or flattened). Understanding these details helps in obtaining accurate quotes and ensures that the product meets your application needs, whether for industrial, architectural, or decorative uses.

Illustrative image related to 4 x 8 expanded metal sheet

Step 2: Identify Reputable Suppliers

Research potential suppliers through industry directories, trade shows, and online platforms. Look for companies with a strong reputation in the expanded metal market and positive customer reviews. A reputable supplier not only assures product quality but also provides reliable service and support throughout the purchasing process.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. This due diligence will help you ascertain the supplier’s reliability and ability to meet your specific needs effectively.

- Check for Certifications: Verify if the supplier has relevant industry certifications, such as ISO 9001, which indicates adherence to quality management standards.

- Assess Production Capacity: Ensure the supplier can handle your order volume and has the capability for custom processing if needed.

Step 4: Request Samples and Quotes

Once you have shortlisted suppliers, request samples to evaluate the quality of the expanded metal sheets. This step allows you to assess the material’s finish, strength, and design. Along with samples, obtain detailed quotes that include pricing, lead times, and shipping costs.

- Compare Pricing Structures: Look for transparency in pricing and potential hidden costs, such as freight charges or processing fees.

- Negotiate Terms: Don’t hesitate to negotiate terms, especially for bulk orders, to secure the best possible deal.

Step 5: Understand Shipping and Logistics

Given the international nature of your procurement, it’s vital to understand the logistics involved. Discuss shipping options, delivery timelines, and customs requirements with your supplier.

Illustrative image related to 4 x 8 expanded metal sheet

- Choose Reliable Shipping Partners: Ensure that the supplier collaborates with reputable shipping companies to minimize delays.

- Plan for Customs Clearance: Familiarize yourself with import regulations in your country to avoid unexpected complications.

Step 6: Finalize Payment Terms

Establish clear payment terms before placing your order. Common options include upfront payments, deposits, or payment upon delivery. Ensure that the payment methods are secure and that you have documented agreements in place.

Step 7: Conduct Quality Control Upon Delivery

Upon receiving your order, perform a thorough inspection to confirm that the delivered goods meet the agreed specifications. Check for any damages or discrepancies and address them immediately with the supplier to ensure resolution.

By following these steps, B2B buyers can navigate the complexities of sourcing 4 x 8 expanded metal sheets with confidence, ensuring a smooth procurement process and satisfactory outcomes.

Comprehensive Cost and Pricing Analysis for 4 x 8 expanded metal sheet Sourcing

What Are the Key Cost Components in Sourcing 4 x 8 Expanded Metal Sheets?

When sourcing 4 x 8 expanded metal sheets, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type of metal (mild steel, aluminum, stainless steel, etc.) significantly influences the base price. For example, aluminum is generally more expensive than mild steel but offers advantages in weight and corrosion resistance.

-

Labor: Labor costs encompass the wages of workers involved in cutting, forming, and finishing the expanded metal sheets. This can vary based on geographic location and labor market conditions.

-

Manufacturing Overhead: This includes costs related to the factory, such as utilities, equipment depreciation, and maintenance. Efficient manufacturing processes can reduce these overhead costs.

-

Tooling: Custom tooling for specific patterns or sizes can incur additional costs. Buyers should consider whether standardized products meet their needs to avoid these extra charges.

-

Quality Control (QC): Ensuring that the products meet specified standards can add to costs, particularly if third-party inspections or certifications are required.

-

Logistics: Shipping costs can vary widely based on the shipping method, distance, and weight of the materials. International buyers should be particularly mindful of customs duties and tariffs.

-

Margin: Suppliers will add a markup to cover their costs and profit. This margin can vary based on competition and the supplier’s pricing strategy.

How Do Price Influencers Affect Sourcing Decisions for Expanded Metal Sheets?

Several factors influence the pricing of 4 x 8 expanded metal sheets that international buyers should consider:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower unit prices. Suppliers may offer discounts for minimum order quantities (MOQs), which can be advantageous for larger projects.

-

Specifications and Customization: Customized sheets or specific thicknesses may incur additional costs. Buyers should evaluate whether standard products could suffice to keep expenses down.

-

Materials and Quality Certifications: Higher-quality materials or certifications (e.g., ISO, ASTM) can increase costs. Buyers should balance the need for quality with budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and production capacity can all affect pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) will determine who bears the costs and risks associated with shipping. This can significantly impact the total cost of ownership.

What Are Essential Negotiation Tips for International Buyers Sourcing Expanded Metal Sheets?

For international buyers, effective negotiation can lead to cost savings and better terms. Here are some actionable tips:

-

Research Market Prices: Understanding the average market price for 4 x 8 expanded metal sheets can provide leverage during negotiations. Use multiple suppliers to gauge competitive pricing.

-

Discuss Volume Discounts: If planning to place a large order, discuss potential discounts upfront. Suppliers are often willing to negotiate based on volume.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also shipping, duties, and any potential costs associated with quality issues or returns.

-

Communicate Clearly: Establish clear communication regarding specifications, delivery timelines, and payment terms. Misunderstandings can lead to unexpected costs or delays.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Regular orders can also establish trust, prompting suppliers to offer more favorable terms.

What Should Buyers Keep in Mind Regarding Pricing Nuances in Different Regions?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, must consider regional pricing nuances:

-

Currency Fluctuations: Exchange rates can affect pricing. It’s advisable to negotiate prices in a stable currency or establish a clear agreement on how currency fluctuations will be handled.

-

Regional Demand and Supply: Local market conditions can influence pricing. For example, high demand in a particular region may lead to increased prices.

-

Regulatory Compliance: Different regions may have varying regulations that affect pricing, especially concerning quality standards and environmental regulations.

-

Cultural Differences: Understanding cultural negotiation styles can enhance communication and lead to more successful outcomes.

In conclusion, a comprehensive understanding of the cost structure, price influencers, negotiation strategies, and regional nuances can empower international B2B buyers to make informed decisions when sourcing 4 x 8 expanded metal sheets. Always consider obtaining multiple quotes and thoroughly vetting suppliers to ensure the best value for your investment.

Alternatives Analysis: Comparing 4 x 8 expanded metal sheet With Other Solutions

Understanding Alternatives to the 4 x 8 Expanded Metal Sheet

When considering the procurement of metal sheets for various applications, it is essential to evaluate alternatives to the 4 x 8 expanded metal sheet. This analysis will help international B2B buyers make informed decisions based on performance, cost, and suitability for specific projects. Alternatives such as perforated metal sheets and welded wire mesh offer different attributes that may align better with your business needs.

Comparison Table

| Comparison Aspect | 4 x 8 Expanded Metal Sheet | Perforated Metal Sheet | Welded Wire Mesh |

|---|---|---|---|

| Performance | High strength-to-weight ratio, allows airflow and light | Customizable hole sizes for varied applications | High tensile strength, excellent for fencing and enclosures |

| Cost | Moderate cost, economical due to minimal waste | Varies widely based on hole size and thickness | Generally lower cost, especially for large quantities |

| Ease of Implementation | Requires cutting and installation; can be heavy | Easy to customize; can be lightweight | Simple installation; often pre-fabricated |

| Maintenance | Low maintenance; durable against corrosion | Moderate maintenance; depends on finish | Low maintenance; rust-resistant options available |

| Best Use Case | Ideal for decorative and functional applications | Suitable for filtration, ventilation, and aesthetic purposes | Best for security fencing and animal enclosures |

Detailed Breakdown of Alternatives

1. Perforated Metal Sheet

Perforated metal sheets are made from solid metal that has been punched with holes to create a pattern. This allows for various applications where airflow or visibility is required, such as in sound dampening panels or decorative facades. The primary advantage of perforated sheets lies in their customization; buyers can select hole sizes, shapes, and patterns to meet specific requirements. However, costs can escalate significantly based on these customizations. Additionally, while they provide excellent aesthetic appeal and functionality, they may not offer the same structural integrity as expanded metal sheets in high-load applications.

Illustrative image related to 4 x 8 expanded metal sheet

2. Welded Wire Mesh

Welded wire mesh consists of intersecting wires that are welded together to form a grid. This alternative is particularly advantageous for security applications, such as fencing or cages, due to its robustness. It is generally less expensive than both expanded metal and perforated sheets, making it a cost-effective solution for large-scale projects. However, welded wire mesh may not provide the same aesthetic appeal or versatility in decorative applications as expanded metal or perforated sheets. Its installation is straightforward, often requiring minimal tools and labor.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between the 4 x 8 expanded metal sheet and its alternatives, B2B buyers must consider their specific application requirements, budget constraints, and desired aesthetics. Expanded metal offers a balance of strength and versatility, making it ideal for both structural and decorative uses. In contrast, perforated metal sheets allow for customization but may come at a higher price, while welded wire mesh provides an economical solution for security and fencing needs. Ultimately, assessing the unique demands of your project will guide you toward the most suitable choice.

Essential Technical Properties and Trade Terminology for 4 x 8 expanded metal sheet

What Are the Key Technical Properties of 4 x 8 Expanded Metal Sheets?

When considering the purchase of 4 x 8 expanded metal sheets, understanding the following technical properties is essential for making informed decisions that align with your project requirements and budget constraints.

1. Material Grade

The most common materials for expanded metal sheets include mild steel, galvanized steel, aluminum, and stainless steel. Each material offers distinct advantages: mild steel is cost-effective, galvanized steel provides corrosion resistance, aluminum is lightweight and corrosion-resistant, while stainless steel offers exceptional durability and aesthetic appeal. Selecting the appropriate material grade is crucial for ensuring the longevity and suitability of the sheet for specific applications.

Illustrative image related to 4 x 8 expanded metal sheet

2. Thickness

The thickness of expanded metal sheets typically ranges from 0.3 mm to 10.0 mm. Thicker sheets provide increased strength and durability, making them ideal for heavy-duty applications such as flooring or industrial grating, while thinner sheets are often used for decorative purposes or lightweight installations. Understanding the required thickness for your specific application can help prevent premature failure and ensure performance.

3. Strand Width and Opening Size

Strand width refers to the width of the metal strands that form the mesh, while opening size (SWD – Short Way of Diamond and LWD – Long Way of Diamond) defines the dimensions of the diamond-shaped openings. Common configurations might include dimensions like 2″ x 4″ or 3″ x 5″. These specifications influence airflow, visibility, and load-bearing capabilities. Thus, selecting the right strand and opening size is essential for achieving the desired functionality.

4. Surface Treatment Options

Surface treatments can enhance the performance and aesthetic appeal of expanded metal sheets. Options include powder coating, anodizing, and PVDF painting, which add protective layers against corrosion and wear while providing a variety of color finishes. This is particularly important for applications exposed to harsh environments or for decorative projects where appearance is a priority.

5. Tolerance Levels

Tolerance levels define the acceptable deviation from specified dimensions during manufacturing. This is critical in applications requiring precise fits and assembly. High tolerance levels ensure that sheets will integrate seamlessly with other components, reducing the risk of defects or failures during installation.

What Are Common Trade Terms Related to Expanded Metal Sheets?

Navigating the purchase process for expanded metal sheets requires familiarity with specific industry terminology. Here are some key terms that B2B buyers should know:

Illustrative image related to 4 x 8 expanded metal sheet

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for ensuring the quality and compatibility of the expanded metal sheets with existing machinery or structures.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For expanded metal sheets, this can affect budgeting and inventory management, especially for smaller businesses or projects with limited scope.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. Submitting an RFQ for 4 x 8 expanded metal sheets can facilitate competitive bidding and help buyers secure the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for understanding shipping costs, risk transfer, and delivery obligations when sourcing expanded metal sheets from global suppliers.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This is an important consideration for project timelines and planning, particularly if custom processing or cutting is required for the expanded metal sheets.

Illustrative image related to 4 x 8 expanded metal sheet

Understanding these technical properties and trade terms will empower B2B buyers to make well-informed decisions, ensuring that their investment in 4 x 8 expanded metal sheets aligns with their operational needs and project goals.

Navigating Market Dynamics and Sourcing Trends in the 4 x 8 expanded metal sheet Sector

What Are the Current Market Dynamics and Key Trends in the 4 x 8 Expanded Metal Sheet Sector?

The global market for 4 x 8 expanded metal sheets is experiencing significant growth, driven by increasing demand across various sectors, including construction, automotive, and manufacturing. As industries worldwide focus on lightweight materials that offer strength without compromising durability, expanded metal sheets have become a preferred choice. In regions like Africa and South America, infrastructure projects are on the rise, creating a robust demand for these materials. Meanwhile, the Middle East is seeing increased investment in commercial and residential developments, further propelling market growth.

Emerging trends in B2B sourcing include digital procurement platforms that facilitate easier access to suppliers and streamlined order processes. The integration of AI-driven analytics allows buyers to predict market fluctuations and optimize inventory management. Additionally, customization options are becoming a key selling point, as businesses seek tailored solutions to meet specific project requirements. International buyers are increasingly prioritizing suppliers that offer flexible delivery options and reduced lead times, especially in regions with evolving market demands.

How Is Sustainability Influencing the Sourcing of 4 x 8 Expanded Metal Sheets?

Sustainability is becoming a central theme in the sourcing of 4 x 8 expanded metal sheets, with buyers increasingly aware of the environmental impact of their purchasing decisions. The production of expanded metal sheets typically involves minimal waste, as the manufacturing process allows for efficient use of raw materials. This attribute aligns well with sustainability goals, making these products attractive to environmentally conscious businesses.

Ethical sourcing practices are also gaining traction, with B2B buyers seeking suppliers who adhere to responsible manufacturing standards. Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) can enhance a supplier’s credibility. Furthermore, the use of recycled materials in the production of expanded metal sheets is on the rise, allowing businesses to reduce their carbon footprint while maintaining high-quality standards. As companies strive to meet their sustainability objectives, sourcing from suppliers who prioritize environmentally friendly practices will become increasingly important.

How Has the Expanded Metal Sheet Industry Evolved Over Time?

The expanded metal sheet industry has a rich history that dates back to the late 19th century when the technique of expanding metal was first developed. Initially used for functional purposes, such as grating and ventilation, the versatility of expanded metal sheets soon caught the attention of architects and designers. By the mid-20th century, the aesthetic potential of these materials began to be recognized, leading to their incorporation in various architectural applications.

Today, the evolution of technology has led to enhanced production techniques, allowing for a wider range of patterns, thicknesses, and finishes. The introduction of advanced cutting methods, such as laser cutting, has further improved customization options for international B2B buyers. As the industry continues to innovate, the future looks promising for expanded metal sheets, particularly in applications that prioritize both functionality and design aesthetics.

Illustrative image related to 4 x 8 expanded metal sheet

Frequently Asked Questions (FAQs) for B2B Buyers of 4 x 8 expanded metal sheet

-

How do I choose the right type of 4 x 8 expanded metal sheet for my project?

Choosing the right type of expanded metal sheet involves considering the intended application, required strength, and environmental factors. For structural applications, mild steel is a cost-effective choice, while aluminum and stainless steel offer corrosion resistance for outdoor or industrial settings. Evaluate the thickness and opening size based on your needs—larger openings reduce weight but may not provide the same strength. Consulting with suppliers about customization options can help ensure you select the best product for your specific requirements. -

What are the common applications for 4 x 8 expanded metal sheets?

4 x 8 expanded metal sheets are versatile and used in various applications, including architectural features, security screens, flooring, and grating. They allow air, light, and water to pass through while providing structural integrity. Common uses include ventilation systems, decorative wall panels, and protective guards in industrial settings. Understanding the specific demands of your project will help you determine the most suitable type and pattern of expanded metal. -

How can I ensure the quality of the 4 x 8 expanded metal sheets I purchase?

To ensure quality, choose suppliers that adhere to recognized industry standards and certifications, such as ISO 9001. Request samples or conduct quality checks on the materials before placing a bulk order. Inquire about the manufacturing processes and materials used, and consider suppliers that offer warranties or guarantees. Additionally, seeking references or reviews from previous clients can provide insight into the reliability and quality of the supplier’s products. -

What is the minimum order quantity (MOQ) for 4 x 8 expanded metal sheets?

Minimum order quantities can vary significantly among suppliers. While some may allow orders for a single sheet, others might require a minimum of several sheets or a specific weight. When sourcing internationally, consider the MOQ in relation to shipping costs and your project requirements. It’s advisable to discuss your needs with suppliers upfront to find a solution that aligns with your budget and project timeline. -

What payment terms should I expect when purchasing 4 x 8 expanded metal sheets internationally?

Payment terms can vary widely based on the supplier and the buyer’s location. Common terms include advance payment, letters of credit, or payment upon delivery. For international transactions, it’s crucial to clarify these terms before finalizing orders. Always ensure that payment methods are secure and consider using escrow services for larger transactions to mitigate risks. -

How do I vet suppliers for 4 x 8 expanded metal sheets?

Vetting suppliers involves researching their reputation, checking certifications, and reviewing client testimonials. Utilize platforms like LinkedIn or industry-specific forums to gather feedback. Request references and contact previous clients to assess their experiences. Additionally, consider suppliers that have been in business for several years, as established companies tend to have proven reliability and quality. -

What logistics should I consider when sourcing 4 x 8 expanded metal sheets?

When sourcing internationally, consider shipping costs, lead times, and customs regulations specific to your country. Ensure that the supplier provides detailed information about shipping methods and delivery timelines. Discuss packaging options to prevent damage during transit. Additionally, it may be beneficial to work with a freight forwarder who can facilitate the import process and handle logistics efficiently. -

Can I customize the specifications of my 4 x 8 expanded metal sheets?

Yes, most manufacturers offer customization options for expanded metal sheets, including thickness, strand size, and surface treatment. You can also request specific patterns or dimensions to meet your project’s requirements. When discussing customization, provide detailed specifications and discuss any additional costs or lead times associated with your requests. This ensures you receive a product tailored to your exact needs.

Top 7 4 X 8 Expanded Metal Sheet Manufacturers & Suppliers List

1. MetalsDepot® – Expanded Steel Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: MetalsDepot® – Buy Expanded Steel Sheet Online! Steel Expanded Metal is a sheet product that has been slit and stretched to a wide array of diamond shaped openings. It offers savings in weight and metal, free passage of light, liquid, sound and air, while providing a decorative or ornamental effect. Specifications: MIL-M-17194D, ASTM F1267-91, Type I Standard (Raised) & Type II Flattened (smooth) …

2. Wheeler Metals – Exp Metal Solutions

Domain: wheelermetals.com

Registered: 1999 (26 years)

Introduction: [{‘size’: ‘4 X 8’, ‘weight’: ‘Heavy’, ‘type’: ‘Exp Metal’, ‘price’: ‘$119.00’}, {‘size’: ‘4 X 8’, ‘thickness’: ‘1/2’, ‘type’: ‘#13 Exp Metal Flt’, ‘price’: ‘$56.00’}, {‘size’: ‘4 X 8’, ‘thickness’: ‘1/2’, ‘type’: ‘#13 Exp Metal Std’, ‘price’: ‘$56.00’}, {‘size’: ‘4 X 8’, ‘thickness’: ‘3/4’, ‘type’: ‘#9 Exp Metal Flt’, ‘price’: ‘$58.80’}, {‘size’: ‘4 X 8’, ‘thickness’: ‘3/4’, ‘type’: ‘#9 Exp Metal …

3. Midwest Steel Supply – Steel Flattened Expanded Metal

Domain: midweststeelsupply.com

Registered: 2005 (20 years)

Introduction: {“Product Name”: “Steel Flattened Expanded Metal (4ft x 8ft)”, “Sizes Available”: [“1/4″ x #18”, “1/2″ x #18”, “1/2″ x #16”, “1/2″ x #13”, “3/4″ x #16”, “3/4″ x #13”, “3/4″ x #9”, “1-1/2″ x #13”, “1-1/2″ x #9”], “Dimensions”: “48×96 inches”, “Material”: “Steel”, “Features”: [“Lightweight”, “Allows passage of air, light, or liquid”, “Cold rolled to flatten into one plane”], “Uses”: [“Decorative”, “…

4. Metal Supermarkets – Expanded Sheet Metal

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Expanded sheet (or expanded metal) is a piece of metal with slits cut and stretched into a mesh with diamond-shaped spaces. Available metal types include Aluminum and Mild Steel. It is designed to reduce weight while providing strength and an ornamental appearance, allowing water, light, or air to pass through. Customers can purchase it online or at any Metal Supermarkets location, cut to exact sp…

5. Hole Metals – 4×8 Sheet Expanded Metal

Domain: holemetals.com

Registered: 2016 (9 years)

Introduction: Product Name: 4×8 Sheet Expanded Metal

Description: Versatile and economical expanded metal mesh made from sheets or coils of mild steel, galvanized steel, stainless steel, and aluminum, uniformly slit and stretched to form a diamond pattern. Available in various patterns and can be sheared or formed to specifications.

Materials: Mild Steel, Galvanized Steel, Aluminum (1060, Alloy 3003, 5005), Sta…

6. McNICHOLS – Standard Expanded Metal

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: Standard Expanded Metal, also known as Raised Expanded Metal, features diamond-shaped openings that are slightly raised. Available materials include Aluminum, Carbon Steel, Galvanized Steel, and Stainless Steel. Key specifications include various opening sizes (e.g., 3/16″, 1/4″, 1/2″, 3/4″, 1-1/2″, 2″), gauges (e.g., No. 9, No. 13, No. 16, No. 20, No. 22), and percent open areas ranging from 30% …

7. DDM Buildings – #9 x 3/4′ Expanded Metal Sheet

Domain: store.ddmbuildings.com

Registered: 2013 (12 years)

Introduction: {“Product Name”: “#9 x 3/4′ Expanded Metal – 4′ x 8′ Rough Steel Sheet”, “Price”: “$45.00”, “SKU”: “9X.75EXPMETAL4ZX8R”, “Size”: “4′ x 8′”, “Material”: “Steel”, “Pattern Type”: “0.75 inch”, “Characteristics”: “Rough”, “In Stock”: “Yes”}

Strategic Sourcing Conclusion and Outlook for 4 x 8 expanded metal sheet

In today’s competitive landscape, strategic sourcing of 4 x 8 expanded metal sheets is essential for optimizing supply chains and enhancing operational efficiency. By leveraging diverse materials such as mild steel, aluminum, and stainless steel, businesses can cater to various applications ranging from architectural designs to industrial uses. The availability of customizable options in thickness and surface treatment allows companies to meet specific project requirements effectively, providing both functional and aesthetic value.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should focus on building relationships with reliable suppliers who offer flexibility in order quantities and delivery timelines. As market dynamics evolve, embracing innovative sourcing strategies will not only reduce costs but also improve product quality and sustainability.

Looking ahead, the demand for 4 x 8 expanded metal sheets is poised to grow, driven by increasing construction activities and industrial applications. Engage with suppliers who understand your unique needs and can provide tailored solutions. Now is the time to act—optimize your sourcing strategy to capitalize on the opportunities presented by this versatile product.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to 4 x 8 expanded metal sheet

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.