A B2B Buyer’s Guide to Sonotube Footer: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for sonotube footer

In today’s rapidly evolving global construction landscape, sourcing reliable sonotube footers poses significant challenges for international B2B buyers. As businesses across Africa, South America, the Middle East, and Europe (including key markets like Germany and Brazil) seek innovative solutions for foundation support, understanding the nuances of sonotube footers becomes imperative. This guide offers a comprehensive overview of sonotube footers, detailing their various types, applications, and the critical factors to consider when selecting a supplier.

With a focus on practical insights, we delve into the essential aspects of sourcing, from material quality and cost considerations to supplier vetting processes and compliance with local regulations. By equipping decision-makers with the necessary knowledge, this guide empowers businesses to make informed purchasing decisions that align with their project requirements and budget constraints.

Whether you’re involved in residential construction, commercial projects, or infrastructure development, understanding the benefits and limitations of sonotube footers can significantly influence project success. This resource is designed to streamline your sourcing process, ensuring that you find the right products to meet your construction needs while navigating the complexities of the international marketplace.

Understanding sonotube footer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Sonotube | Cylindrical, cardboard construction; customizable sizes | Residential and commercial foundations | Pros: Cost-effective, easy to transport. Cons: Less durable in wet conditions. |

| TubeBase Plastic Form | Made from high-density polyethylene; reusable and durable | Concrete columns and piers | Pros: Resistant to moisture, reusable. Cons: Higher initial cost than cardboard. |

| Redi Base Footing | Pre-formed plastic footer with integrated Sonotube section | Quick installations for small structures | Pros: Saves time on setup, minimizes labor. Cons: Limited size options. |

| Heavy-Duty Sonotube | Reinforced cardboard or composite material for heavy loads | Industrial applications, large structures | Pros: Supports heavier loads, suitable for harsh conditions. Cons: Higher cost. |

| Custom Sonotube | Tailored dimensions and materials to specific project needs | Specialized construction projects | Pros: Exact fit for unique requirements. Cons: Longer lead times and costs. |

What Are the Characteristics of Standard Sonotubes for B2B Buyers?

Standard Sonotubes are cylindrical forms primarily made of cardboard, offering a range of diameters and heights. They are commonly used for creating footings in both residential and commercial construction. Their lightweight design facilitates easy transportation and installation, making them an attractive choice for contractors looking to minimize costs. However, their susceptibility to moisture can limit their durability in wet conditions, prompting buyers to consider their environmental factors before selection.

How Does the TubeBase Plastic Form Stand Out in the Market?

The TubeBase Plastic Form is a robust alternative made from high-density polyethylene. It is designed for reuse, making it a sustainable option for businesses aiming to reduce waste. This product excels in moisture resistance, which is crucial for maintaining structural integrity in damp environments. While the initial investment is higher compared to cardboard options, the long-term savings from reusability and reduced labor costs can be significant for B2B buyers.

Why Choose the Redi Base Footing for Quick Installations?

The Redi Base Footing features a pre-formed design that incorporates a Sonotube section, significantly speeding up the installation process for small structures. This product is particularly beneficial for contractors who need to complete projects quickly and efficiently. Despite its advantages, the limited size options might restrict its applicability for larger projects, which is an essential consideration for buyers planning diverse construction tasks.

In What Scenarios Are Heavy-Duty Sonotubes Necessary?

Heavy-Duty Sonotubes are constructed from reinforced materials, making them ideal for industrial applications that require support for heavier loads. These forms are suitable for large structures, ensuring stability in challenging conditions. While they provide enhanced durability and load-bearing capabilities, the higher cost may deter some buyers. However, for businesses in sectors like manufacturing or infrastructure, the investment can be justified by the long-term performance and reliability.

What Benefits Do Custom Sonotubes Offer for Specialized Projects?

Custom Sonotubes allow for tailored dimensions and materials to meet specific project requirements. This flexibility is particularly valuable for specialized construction projects where standard sizes may not suffice. While the lead times and costs associated with custom orders can be higher, the precise fit and performance can lead to better outcomes in unique applications. B2B buyers should weigh the benefits of customization against the potential for increased expense and time delays.

Key Industrial Applications of sonotube footer

| Industry/Sector | Specific Application of sonotube footer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Foundation for residential and commercial buildings | Provides stable and durable support for structures, reducing settlement risks | Ensure compliance with local building codes and frost line specifications |

| Renewable Energy | Base for wind turbine installations | Enhances stability and longevity of wind turbines, ensuring operational efficiency | Consider environmental factors and soil conditions for optimal performance |

| Agriculture | Support for agricultural structures like barns and silos | Facilitates safe and effective load distribution, minimizing risk of structural failure | Assess soil type and load requirements to determine appropriate sonotube dimensions |

| Infrastructure Development | Footings for bridges and elevated walkways | Promotes safety and durability in public infrastructure, decreasing maintenance costs | Evaluate local regulations and environmental impact assessments |

| Landscaping & Outdoor Structures | Bases for pergolas, gazebos, and fences | Improves aesthetics while ensuring structural integrity, enhancing customer satisfaction | Source materials that are weather-resistant and suited for local climates |

How is Sonotube Footer Used in Construction Projects?

In the construction industry, sonotube footers are widely used for laying foundations for both residential and commercial buildings. They create a reliable base that minimizes settlement and shifting, crucial in areas with unstable soil or where frost heave is a concern. Buyers must ensure that the sonotubes comply with local building codes, especially in regions with specific frost line requirements. This compliance not only enhances the structural integrity of the building but also mitigates future repair costs.

What Role Does Sonotube Footer Play in Renewable Energy Installations?

In renewable energy projects, particularly wind turbine installations, sonotube footers serve as essential bases that provide stability against high winds. These footers ensure that turbines remain upright and operational, which is vital for energy production efficiency. International buyers from regions with high wind speeds, such as parts of Europe and South America, should consider local environmental factors and soil conditions when sourcing sonotubes to ensure optimal performance and longevity.

How is Sonotube Footer Beneficial for Agricultural Structures?

Agricultural applications often require robust support for structures like barns and silos, where heavy loads and external pressures are common. Sonotube footers facilitate effective load distribution, minimizing the risk of structural failure. For buyers in agricultural sectors, especially in areas prone to heavy rainfall or shifting soil, it’s essential to assess soil type and load requirements to determine the appropriate sonotube dimensions and specifications.

Illustrative image related to sonotube footer

Why are Sonotube Footers Important in Infrastructure Development?

In infrastructure development, sonotube footers are critical for providing a solid foundation for bridges and elevated walkways. They promote safety and durability, which is essential for public infrastructure projects. Buyers involved in this sector should evaluate local regulations, as well as conduct environmental impact assessments to ensure that their projects comply with safety standards and minimize ecological disruption.

How Can Sonotube Footer Enhance Landscaping and Outdoor Structures?

In landscaping, sonotube footers are increasingly used for bases of outdoor structures such as pergolas, gazebos, and fences. They not only enhance the aesthetic appeal of outdoor spaces but also ensure structural integrity against weather elements. For buyers in this sector, sourcing weather-resistant materials that suit the local climate is crucial to achieving long-lasting installations that meet customer expectations.

3 Common User Pain Points for ‘sonotube footer’ & Their Solutions

Scenario 1: Inconsistent Quality of Sonotube Products

The Problem: B2B buyers often face challenges with inconsistent product quality when sourcing sonotubes. Variations in material strength, dimensions, and manufacturing defects can lead to structural integrity issues, resulting in costly project delays and potential safety hazards. For buyers from regions with less stringent quality control standards, this problem can be particularly pronounced, leading to frustrations in ensuring that the sonotubes will meet the necessary engineering specifications for their projects.

The Solution: To mitigate this risk, it’s crucial for buyers to establish strong relationships with reputable suppliers who can provide certified quality assurance documentation. When sourcing sonotubes, look for suppliers that offer detailed product specifications, including material certifications and adherence to international standards such as ASTM or ISO. Additionally, conducting quality checks upon delivery—such as measuring dimensions and inspecting for defects—can help ensure that the sonotubes meet required standards before installation. Investing in a supplier that prioritizes quality will not only enhance the reliability of your projects but also foster trust and long-term collaboration.

Scenario 2: Difficulties in Installation and Setup

The Problem: Many B2B buyers encounter challenges during the installation of sonotubes, especially if their team lacks experience with this specific type of footer. Issues such as improper alignment, inadequate depth, and insufficient backfill can compromise the stability of the structure being supported. This is particularly relevant in regions where soil conditions vary significantly, as improper installation can lead to additional costs for rework and potential structural failures.

The Solution: Providing comprehensive training for installation teams is essential. Buyers should consider organizing workshops or partnering with experienced contractors who can share best practices for sonotube installation. Furthermore, utilizing installation guides that include detailed diagrams and step-by-step instructions can enhance understanding. It’s also advisable to include a quality checklist that outlines critical steps, such as ensuring the sonotubes are level, verifying the depth of installation based on local frost lines, and confirming proper backfill techniques. This proactive approach not only minimizes installation errors but also boosts overall project efficiency.

Scenario 3: Misalignment with Local Building Codes

The Problem: B2B buyers often struggle with ensuring that sonotube footers comply with local building codes and regulations. This can be particularly challenging for international buyers who may not be familiar with the specific requirements in their regions. Non-compliance can lead to fines, delays, and the need for costly re-engineering of projects, which can jeopardize timelines and budgets.

The Solution: To address this issue, it is imperative for buyers to conduct thorough research on local building codes before finalizing their sonotube specifications. Engaging local engineers or consultants who are well-versed in regional requirements can provide invaluable insights. Additionally, buyers should ensure that their selected sonotubes are compatible with local standards, including load-bearing capacities and frost depth requirements. Creating a checklist that outlines all necessary compliance elements can streamline the process and provide clarity for all stakeholders involved in the project. This diligence not only enhances project reliability but also builds a reputation for compliance and professionalism in the market.

Strategic Material Selection Guide for sonotube footer

What are the Key Materials for Sonotube Footers?

When selecting materials for sonotube footers, it is essential to consider the specific properties, advantages, and limitations of each material. This analysis focuses on four common materials: concrete, plastic, metal, and composite materials. Each material has distinct characteristics that can influence the performance and suitability of sonotube footers in various applications.

How Does Concrete Perform as a Material for Sonotube Footers?

Concrete is the most traditional and widely used material for sonotube footers. It offers excellent compressive strength, making it ideal for supporting heavy loads. Concrete is resistant to temperature fluctuations and provides a durable solution that can withstand environmental stresses.

Pros: High durability, excellent load-bearing capacity, and resistance to weather conditions. Concrete footers can be easily molded into various shapes and sizes, allowing for customization based on project requirements.

Cons: Concrete can be heavy and may require specialized equipment for transportation and installation. Additionally, it can be susceptible to cracking under extreme temperature changes if not properly mixed and cured.

Impact on Application: Concrete is suitable for a wide range of applications, from residential buildings to industrial structures. However, it is crucial to ensure that the mix design complies with local standards such as ASTM or DIN.

What Advantages Do Plastic Materials Offer for Sonotube Footers?

Plastic materials, such as high-density polyethylene (HDPE) or polypropylene, are increasingly being used for sonotube footers due to their lightweight nature and corrosion resistance. These materials are particularly advantageous in environments where moisture or chemical exposure is a concern.

Pros: Lightweight, easy to handle, and resistant to corrosion and chemicals. Plastic forms can be manufactured in various sizes and shapes, making them versatile for different applications.

Cons: Plastic may not provide the same load-bearing capacity as concrete, and its long-term durability can be affected by UV exposure unless treated. Additionally, it may not be suitable for applications requiring significant structural support.

Impact on Application: Plastic sonotubes are ideal for temporary structures or in areas with high moisture levels. Buyers should consider local regulations regarding the use of plastic materials in construction.

How Do Metal Materials Compare for Sonotube Footers?

Metal materials, particularly steel, are sometimes used in sonotube footer applications, especially in heavy-duty construction projects. Steel offers high tensile strength and durability, making it suitable for supporting substantial loads.

Pros: Exceptional strength-to-weight ratio, high durability, and resistance to environmental factors. Steel can also be prefabricated to meet specific design requirements.

Cons: Metal can be prone to corrosion if not properly treated, and it may require additional insulation or protective coatings. Furthermore, the cost of steel can be significantly higher than other materials.

Impact on Application: Metal sonotubes are suitable for industrial applications where high strength is required. Compliance with international standards such as JIS or ASTM is essential for ensuring safety and performance.

Illustrative image related to sonotube footer

What Role Do Composite Materials Play in Sonotube Footer Applications?

Composite materials, which combine different materials to enhance performance, are gaining traction in sonotube footer applications. These materials can be engineered to provide specific properties, such as increased strength or reduced weight.

Pros: High strength, lightweight, and resistance to corrosion and environmental factors. Composites can be tailored to meet specific project requirements and can offer superior durability.

Cons: The manufacturing process for composites can be complex and may result in higher costs. Additionally, availability may be limited in certain regions, affecting supply chains.

Illustrative image related to sonotube footer

Impact on Application: Composites are suitable for specialized applications where performance is critical. Buyers should assess local market availability and compliance with relevant standards.

Summary Table of Material Selection for Sonotube Footers

| Material | Typical Use Case for sonotube footer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Concrete | Heavy-duty construction | High durability and load capacity | Heavy and requires special handling | High |

| Plastic | Temporary or moisture-prone structures | Lightweight and corrosion-resistant | Limited load-bearing capacity | Medium |

| Metal | Industrial applications | Exceptional strength | Prone to corrosion | High |

| Composite | Specialized high-performance needs | Tailored properties and durability | Complex manufacturing process | High |

This guide provides a comprehensive overview of the materials available for sonotube footers, enabling international B2B buyers to make informed decisions based on their specific project requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for sonotube footer

What Are the Main Stages of Manufacturing Sonotube Footers?

The manufacturing process of sonotube footers involves several critical stages, each designed to ensure the final product meets the required specifications for strength, durability, and functionality.

Material Preparation

The journey begins with the selection of raw materials, primarily high-density polyethylene (HDPE) or other plastic compounds known for their resistance to moisture and durability. These materials are sourced from reputable suppliers who adhere to international quality standards. Before proceeding, the materials undergo a rigorous quality inspection to verify their compliance with necessary specifications.

Forming

Once the raw materials are prepared, the next step is the forming process. This involves heating the plastic until it becomes pliable and then shaping it into the desired cylindrical form using molds. Advanced techniques such as blow molding or rotational molding may be utilized, depending on the specific design requirements. The forming process is critical, as it determines the structural integrity of the sonotube footer.

Illustrative image related to sonotube footer

Assembly

In the assembly stage, additional components, such as rebar supports or integrated footings, are added to enhance the strength and stability of the sonotubes. This stage often involves automated machinery, which ensures precision and consistency across all units produced. The assembly process is designed to accommodate various sizes and specifications, catering to diverse construction needs.

Finishing

The finishing stage includes several steps aimed at enhancing the product’s usability and appearance. This may involve trimming excess material, applying surface treatments to improve adhesion for concrete, and ensuring all sonotubes are free from defects. Each footer is labeled with important information, including dimensions and load ratings, to facilitate proper installation.

What Quality Control Measures Are Essential for Sonotube Footers?

Quality control (QC) is paramount in the manufacturing of sonotube footers, especially for B2B buyers who rely on these products for critical construction applications.

What Are the Relevant International Standards for Sonotube Footers?

Manufacturers often adhere to internationally recognized standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with this standard demonstrates a commitment to consistent quality and customer satisfaction. Additionally, depending on the region, certifications such as CE marking in Europe or API standards may apply, ensuring that products meet specific safety and performance criteria.

What QC Checkpoints Should Be Considered?

Quality control checkpoints during the manufacturing process typically include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for compliance with specifications before they enter the production line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are performed to ensure that the production methods and equipment are functioning correctly. This includes monitoring temperature during the forming process and verifying dimensions during assembly.

-

Final Quality Control (FQC): Once the sonotube footers are completed, a final inspection is conducted to assess the overall quality of the product. This may involve tests for structural integrity, dimensional accuracy, and surface finish.

What Common Testing Methods Are Used in Quality Assurance?

To ensure that sonotube footers meet the necessary standards, various testing methods are employed:

-

Load Testing: Assessing the load-bearing capacity of the footers to ensure they can support the intended structures without failure.

-

Impact Resistance Testing: Evaluating the material’s ability to withstand sudden forces, which is crucial for applications in regions prone to extreme weather conditions.

-

Dimensional Verification: Using precision measuring tools to confirm that the sonotube footers adhere to specified dimensions, ensuring compatibility with construction requirements.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating in international markets such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential.

Illustrative image related to sonotube footer

What Are Effective Verification Methods?

-

Supplier Audits: Conducting on-site audits of manufacturing facilities can provide insight into the supplier’s QC processes, equipment, and adherence to international standards. This is often a valuable step for buyers seeking long-term partnerships.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation of quality control processes and test results. This transparency can build trust and assure buyers of the product quality.

-

Third-Party Inspections: Engaging third-party inspection agencies to evaluate manufacturing processes and product quality can offer an unbiased assessment. This is particularly important when dealing with suppliers from regions where regulatory compliance may vary.

What Are the QC and Certification Nuances for International Buyers?

International buyers should be aware of specific nuances related to quality control and certification that may affect their purchasing decisions.

-

Understanding Local Regulations: Each region may have different regulations and standards that products must meet. Buyers should familiarize themselves with these requirements to avoid compliance issues.

-

Language and Documentation: Ensure that all quality assurance documentation is available in a language that is easily understandable to facilitate clear communication. Misunderstandings can lead to costly errors in construction.

-

Cultural Considerations: Recognizing cultural differences in business practices can enhance communication and negotiation. Establishing rapport and trust is crucial for successful international transactions.

In conclusion, understanding the manufacturing processes and quality assurance measures for sonotube footers is vital for B2B buyers. By focusing on these aspects, buyers can ensure they are sourcing reliable products that meet their specific needs and comply with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sonotube footer’

This guide serves as a practical checklist for B2B buyers looking to procure sonotube footers effectively. Ensuring a successful purchase involves several critical steps that will help you find the right products and suppliers to meet your construction needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to clearly outline your technical specifications. Determine the dimensions, weight capacity, and material requirements for the sonotube footers based on your project’s needs. This clarity will help you communicate effectively with potential suppliers and ensure they can meet your requirements.

- Consider local building codes: Make sure your specifications comply with regional regulations, which can vary significantly between countries and regions.

- Assess load-bearing requirements: Understand the weight and stress your structures will impose on the footers to avoid future structural issues.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in sonotube footers. Look for companies with a strong reputation in the industry, particularly those that have experience supplying to your geographic region.

- Check online reviews and testimonials: Pay attention to feedback from previous clients, especially those in similar industries or locations.

- Evaluate supplier experience: Consider how long the supplier has been in business and their track record with similar projects.

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier choice, verify their certifications and compliance with international standards. This step is crucial to ensure product quality and safety.

- Look for ISO certifications: Suppliers with ISO certifications demonstrate their commitment to quality management systems.

- Check for local compliance: Ensure that products meet the building standards and regulations specific to your region.

Step 4: Request Product Samples

Request samples of the sonotube footers to evaluate their quality and suitability for your project. This hands-on assessment can reveal critical information about the product that specifications may not cover.

Illustrative image related to sonotube footer

- Assess material quality: Check for durability, resistance to environmental factors, and overall construction quality.

- Test compatibility: Ensure the samples fit your intended application and work seamlessly with other materials you plan to use.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Understanding the total cost of ownership, including shipping and potential tariffs, is vital for accurate budgeting.

- Discuss bulk discounts: Inquire if there are price reductions for larger orders, which can significantly impact your project budget.

- Clarify warranty and return policies: Ensure you understand the supplier’s policies on defective products or unsatisfactory materials.

Step 6: Establish a Communication Plan

Set up a clear communication plan with your chosen supplier to facilitate ongoing discussions about order status, potential issues, and future needs.

- Assign a point of contact: Having a designated contact person can streamline communication and ensure accountability.

- Schedule regular check-ins: Regular updates can help address any concerns promptly and keep your project on track.

Step 7: Finalize Your Order and Confirm Delivery

Once all terms are agreed upon, finalize your order and confirm delivery schedules. It’s essential to ensure that the sonotube footers arrive on time to avoid project delays.

- Review delivery logistics: Understand how the products will be shipped and what to expect regarding arrival times.

- Prepare for receipt: Ensure your site is ready to receive the shipment, including necessary equipment for unloading and storage.

By following this checklist, B2B buyers can streamline the procurement process for sonotube footers, ensuring they secure high-quality products that meet their project specifications and budget constraints.

Comprehensive Cost and Pricing Analysis for sonotube footer Sourcing

What Are the Key Cost Components for Sonotube Footer Sourcing?

When sourcing sonotube footers, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials, such as plastic for sonotubes and concrete, significantly influences the overall price. Premium materials may enhance durability and performance but will also increase the initial investment.

-

Labor: Labor costs encompass the workforce required for manufacturing, assembly, and installation. Efficient labor practices can help control these costs, but fluctuations in local labor markets may affect pricing.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Manufacturers may pass these costs onto buyers, impacting the final price.

-

Tooling: The initial investment in specialized tools and molds for producing sonotubes can be substantial. These costs are typically amortized over production volumes, influencing the pricing structure.

-

Quality Control: Ensuring product quality requires investment in QC processes. Compliance with international standards may necessitate additional testing and certification, affecting overall costs.

-

Logistics: Transportation and warehousing costs can vary widely based on location and supply chain efficiency. Import duties and shipping fees are critical considerations for international buyers.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the typical margins in the industry can help buyers gauge whether they are receiving competitive pricing.

What Influences Pricing for Sonotube Footers?

Several factors can affect the pricing of sonotube footers, and being aware of these can help buyers negotiate better deals.

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Buyers should assess their project needs to leverage volume discounts effectively.

-

Specifications and Customization: Customized sonotubes designed to meet specific project requirements may incur additional costs. It’s essential to clarify specifications upfront to avoid unexpected charges.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can impact pricing. Buyers should consider the long-term value of investing in higher-quality products with certifications.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their proven track record and support services.

-

Incoterms: Understanding shipping terms is vital for international transactions. The choice of Incoterms can affect responsibilities for shipping costs, insurance, and customs clearance, impacting the total cost.

How Can International Buyers Optimize Their Sourcing Strategy for Sonotube Footers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, optimizing sourcing strategies is key to cost efficiency.

-

Negotiation: Engage suppliers in discussions about pricing, especially when committing to larger orders. Highlighting potential long-term relationships can incentivize better pricing.

-

Total Cost of Ownership: Consider not just the purchase price but also long-term operational costs, including maintenance, durability, and potential resale value. This holistic view can lead to more strategic purchasing decisions.

-

Pricing Nuances for Different Markets: Be aware of regional pricing variances due to local demand, competition, and economic conditions. Adjusting sourcing strategies based on regional factors can lead to significant savings.

-

Research and Compare Suppliers: Conduct thorough research to compare various suppliers, considering their pricing, reliability, and customer service. Utilizing platforms that aggregate supplier information can streamline this process.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements. Buyers should perform their due diligence to obtain the most accurate and current pricing.

Alternatives Analysis: Comparing sonotube footer With Other Solutions

When considering foundation solutions for construction projects, it’s essential to evaluate various options to determine the best fit for specific needs. Sonotube footers are a popular choice, but alternatives such as traditional concrete footings and precast concrete piers also offer viable solutions. This comparison highlights key aspects of each method to aid B2B buyers in making informed decisions.

| Comparison Aspect | Sonotube Footer | Traditional Concrete Footing | Precast Concrete Piers |

|---|---|---|---|

| Performance | Effective for load distribution, suitable for various soil types. | Very strong and stable, ideal for heavy structures. | Quick installation, stable, and reliable. |

| Cost | Moderate initial cost (approx. $120.99 each). | Typically higher due to labor and materials. | Higher upfront cost, but labor savings can offset. |

| Ease of Implementation | Easy to set up with minimal tools and labor. | Requires skilled labor and more extensive preparation. | Quick installation process, less labor-intensive. |

| Maintenance | Low maintenance if installed correctly. | Requires regular inspections and potential repairs. | Minimal maintenance needed; durable materials. |

| Best Use Case | Residential buildings, small structures, or temporary installations. | Large commercial buildings or structures in high-load scenarios. | Areas with challenging access or where speed is critical. |

What Are the Key Advantages and Disadvantages of Traditional Concrete Footings?

Traditional concrete footings are known for their strength and stability, making them suitable for heavy structures such as multi-story buildings. Their ability to withstand significant loads and resist lateral forces is unmatched. However, the installation process is labor-intensive and requires skilled workers, which can drive up costs. Additionally, curing time can delay project timelines. These footings are best used in scenarios where structural integrity is paramount, particularly in regions with unstable soil conditions or extreme weather.

How Do Precast Concrete Piers Compare to Sonotube Footers?

Precast concrete piers offer a faster installation process compared to sonotube footers, as they are delivered ready to use. This solution is particularly beneficial in projects where time is critical, as they can be placed quickly without the need for extensive on-site preparation. However, the initial cost of precast piers is generally higher, and they may not be as versatile in various soil conditions as sonotube footers. They excel in situations where speed is essential, such as in commercial developments or remote locations with limited access.

Conclusion: How Should B2B Buyers Choose the Right Foundation Solution?

Selecting the right foundation solution requires careful consideration of project specifics, including load requirements, soil conditions, budget constraints, and time constraints. Sonotube footers provide a balance of affordability and ease of use, making them ideal for smaller projects or those with lighter loads. Traditional concrete footings are best for heavy-duty applications, while precast concrete piers are suitable for time-sensitive projects. By assessing these factors, B2B buyers can make informed decisions that align with their project goals and operational requirements.

Essential Technical Properties and Trade Terminology for sonotube footer

What Are the Key Technical Properties of Sonotube Footers?

Understanding the technical specifications of sonotube footers is essential for B2B buyers to ensure they choose the right product for their construction needs. Here are some critical properties to consider:

-

Material Grade: Sonotubes are typically made from high-density polyethylene (HDPE) or concrete. The material grade affects durability and load-bearing capacity. For instance, HDPE is lightweight and resistant to moisture, making it ideal for environments prone to frost heave, while concrete offers superior compressive strength for heavy structures.

-

Tolerance: Tolerance refers to the allowable deviation from specified dimensions. For sonotubes, a standard tolerance might be ±1/8 inch. Understanding tolerance is crucial for ensuring that the footers fit perfectly with the columns or structures they support, minimizing the risk of structural failure.

-

Diameter and Depth: Common diameters for sonotubes range from 8 inches to 12 inches, with depths varying based on local frost lines and load requirements. Selecting the correct diameter and depth is vital to ensure adequate support for the intended structure and to mitigate issues related to ground movement.

-

Load Capacity: This specification indicates the maximum weight that the footer can support without failure. It is typically measured in pounds per square foot (psf). B2B buyers should assess load capacity based on the specific application and structural requirements, as exceeding this capacity can lead to catastrophic failure.

-

Frost Resistance: In regions susceptible to frost heave, sonotubes must be placed below the frost line to prevent movement due to freezing and thawing cycles. This property is particularly significant for B2B buyers in colder climates, as proper installation can extend the longevity of the structure.

-

Reinforcement Options: Many sonotube systems allow for reinforcement with rebar or other materials to enhance structural integrity. Understanding the reinforcement options available can help buyers customize footers to meet specific engineering requirements.

What Are Common Trade Terms Associated with Sonotube Footers?

Familiarity with trade terminology can streamline the purchasing process and facilitate clearer communication between buyers and suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components or products that are used in another company’s end product. In the context of sonotubes, an OEM may manufacture the forms or materials used for creating footers, which can impact quality and consistency.

-

MOQ (Minimum Order Quantity): This specification indicates the smallest number of units a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for budgeting and inventory management, especially when purchasing large quantities of sonotubes for construction projects.

-

RFQ (Request for Quotation): An RFQ is a standard business process used to invite suppliers to bid on specific products or services. For sonotube footers, submitting an RFQ can help buyers compare prices and specifications from different suppliers, ensuring they get the best value.

-

Incoterms (International Commercial Terms): These are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers involved in cross-border purchases of sonotubes, as they dictate shipping responsibilities, risk, and costs.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is vital for B2B buyers to plan construction schedules effectively and ensure that projects remain on track.

-

Compliance Standards: These are regulatory standards that products must meet to be deemed safe for use in construction. For sonotube footers, compliance with local building codes and international standards is essential to avoid legal issues and ensure structural integrity.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing sonotube footers, ultimately leading to successful construction projects.

Navigating Market Dynamics and Sourcing Trends in the sonotube footer Sector

What Are the Key Market Trends Influencing the Sonotube Footer Sector?

The sonotube footer sector is witnessing a transformative phase driven by several global factors. Firstly, the increasing demand for sustainable construction practices is shaping sourcing strategies, as companies prioritize eco-friendly materials. The construction industry’s shift towards modular and prefabricated solutions is also significant, as it reduces labor costs and construction time, making sonotubes a preferred option for quick foundations. Additionally, advancements in technology, such as the integration of Building Information Modeling (BIM) and 3D printing, are enhancing the precision and efficiency of sonotube applications.

Internationally, B2B buyers from regions such as Africa, South America, the Middle East, and Europe (particularly Germany and Brazil) are increasingly focused on sourcing products that comply with local building codes and environmental regulations. The rise of e-commerce platforms facilitates easier access to suppliers and comparative pricing, further influencing buyer behavior. Moreover, the fluctuation in raw material prices and supply chain disruptions necessitate a strategic approach to sourcing, where long-term partnerships with reliable suppliers become essential for ensuring consistent product availability and quality.

How Is Sustainability Shaping Ethical Sourcing in the Sonotube Footer Market?

Sustainability is becoming a critical concern in the construction industry, and ethical sourcing of materials for sonotube footers is at the forefront of this trend. The environmental impact of construction activities, including carbon emissions and waste generation, is prompting businesses to seek solutions that minimize their footprint. Buyers are increasingly looking for sonotubes made from recycled materials or those certified by recognized green standards, such as LEED (Leadership in Energy and Environmental Design) and FSC (Forest Stewardship Council).

Illustrative image related to sonotube footer

Incorporating sustainable practices not only helps in compliance with regulatory requirements but also enhances brand reputation among environmentally conscious consumers. Furthermore, businesses that prioritize ethical supply chains are better positioned to mitigate risks associated with resource scarcity and potential supply chain disruptions. Collaborating with suppliers who share these values can lead to innovative solutions that meet both market demands and environmental responsibilities, ultimately driving growth in the sonotube footer sector.

What Is the Historical Context of Sonotube Footers in B2B Construction?

The use of sonotubes in construction dates back several decades, evolving from simple wooden forms to the advanced plastic and composite materials used today. Initially, sonotubes were primarily utilized for residential projects, but their versatility has led to widespread adoption across various commercial applications. Over time, engineering advancements have improved their structural integrity and ease of use, making them a staple in foundation work.

The historical context of sonotubes also reflects changing construction methodologies. As building codes have become more stringent, the need for reliable footing solutions has increased, and sonotubes have adapted to meet these requirements. This evolution has positioned sonotubes as a vital component in modern construction, catering to the demands of a global marketplace that values efficiency, sustainability, and reliability.

In conclusion, navigating the sonotube footer sector involves understanding market dynamics, embracing sustainability, and recognizing historical trends that shape current practices. International B2B buyers must stay informed about these factors to make strategic sourcing decisions that align with their business goals and ethical standards.

Illustrative image related to sonotube footer

Frequently Asked Questions (FAQs) for B2B Buyers of sonotube footer

-

How do I ensure the quality of sonotube footers before purchase?

To ensure quality, request detailed product specifications and certifications from suppliers. Look for compliance with international standards and any relevant local codes. Consider asking for samples or references from previous clients to evaluate product performance. Additionally, inquire about the supplier’s quality assurance processes, including testing for durability and load-bearing capacity. Engaging a third-party inspection service can provide further assurance before placing bulk orders. -

What is the best sonotube size for my construction project?

The optimal sonotube size depends on the load-bearing requirements of your structure and local building codes. Generally, sonotubes range from 6 inches to 12 inches in diameter, with larger sizes used for heavier loads. Consulting with a structural engineer can provide insights into the appropriate dimensions based on soil conditions, frost depth, and anticipated loads. Always ensure that the selected size allows for sufficient concrete cover and reinforcement. -

What are the payment terms typically offered by sonotube suppliers?

Payment terms can vary widely among suppliers, but common options include upfront payment, net 30, or net 60 days. Some suppliers may offer discounts for early payment or bulk orders. It’s advisable to clarify payment conditions upfront to avoid misunderstandings. Additionally, consider establishing a Letter of Credit (LC) for larger transactions to protect both parties. Always review terms carefully and negotiate them based on your cash flow needs. -

How can I find reliable suppliers for sonotube footers in international markets?

Start by researching reputable suppliers through industry directories, trade shows, and online marketplaces. Utilize platforms like Alibaba or Global Sources, focusing on verified suppliers with positive reviews. Networking within industry associations can also yield referrals. Request detailed company profiles, including production capacity, lead times, and past performance. Conducting background checks and site visits can further ensure supplier reliability, especially for significant investments. -

What is the minimum order quantity (MOQ) for sonotube footers?

The MOQ for sonotube footers typically depends on the supplier and the specific product specifications. Many suppliers establish an MOQ based on production efficiency, often ranging from 100 to 500 units. However, some may accommodate smaller orders for new customers or specific projects. Always discuss your needs directly with the supplier to negotiate favorable terms, especially if you are a first-time buyer. -

What are the shipping options for international orders of sonotube footers?

Shipping options for international orders may include air freight, ocean freight, or land transportation, depending on your location and urgency. Ocean freight is usually the most cost-effective for large orders but may take longer. Ensure you discuss delivery timelines with suppliers, as well as customs clearance processes. It’s beneficial to work with logistics partners experienced in international trade to streamline shipping and reduce potential delays. -

How do I handle customs clearance for imported sonotube footers?

To handle customs clearance effectively, ensure that all documentation is complete and accurate, including invoices, packing lists, and certificates of origin. Familiarize yourself with local import regulations and tariffs specific to construction materials. Working with a customs broker can simplify the process, as they can assist with paperwork and compliance requirements. Always maintain communication with your supplier regarding any documentation they need to provide. -

Can I customize sonotube footers according to my project specifications?

Yes, many suppliers offer customization options for sonotube footers, including varying sizes, wall thicknesses, and materials. Discuss your specific requirements with the supplier, including any unique load or environmental considerations. Custom orders may require longer lead times and potential adjustments to pricing, so plan accordingly. Always obtain written confirmations of the specifications to ensure the final product meets your expectations.

Top 3 Sonotube Footer Manufacturers & Suppliers List

1. Reddit – 10 Diameter Sonotube Footings

2. Hansen Pole Buildings – Sonotubes

Domain: hansenpolebuildings.com

Registered: 2002 (23 years)

Introduction: Sonotubes are used in post frame buildings to reduce the amount of concrete needed in footings. They are designed to be placed in holes and backfilled around, providing support for pole barn columns. The effectiveness of sonotubes is influenced by factors such as frost heave and wind uplift. The Coulomb theory of earth pressures suggests that the friction between the earth and the post increases a…

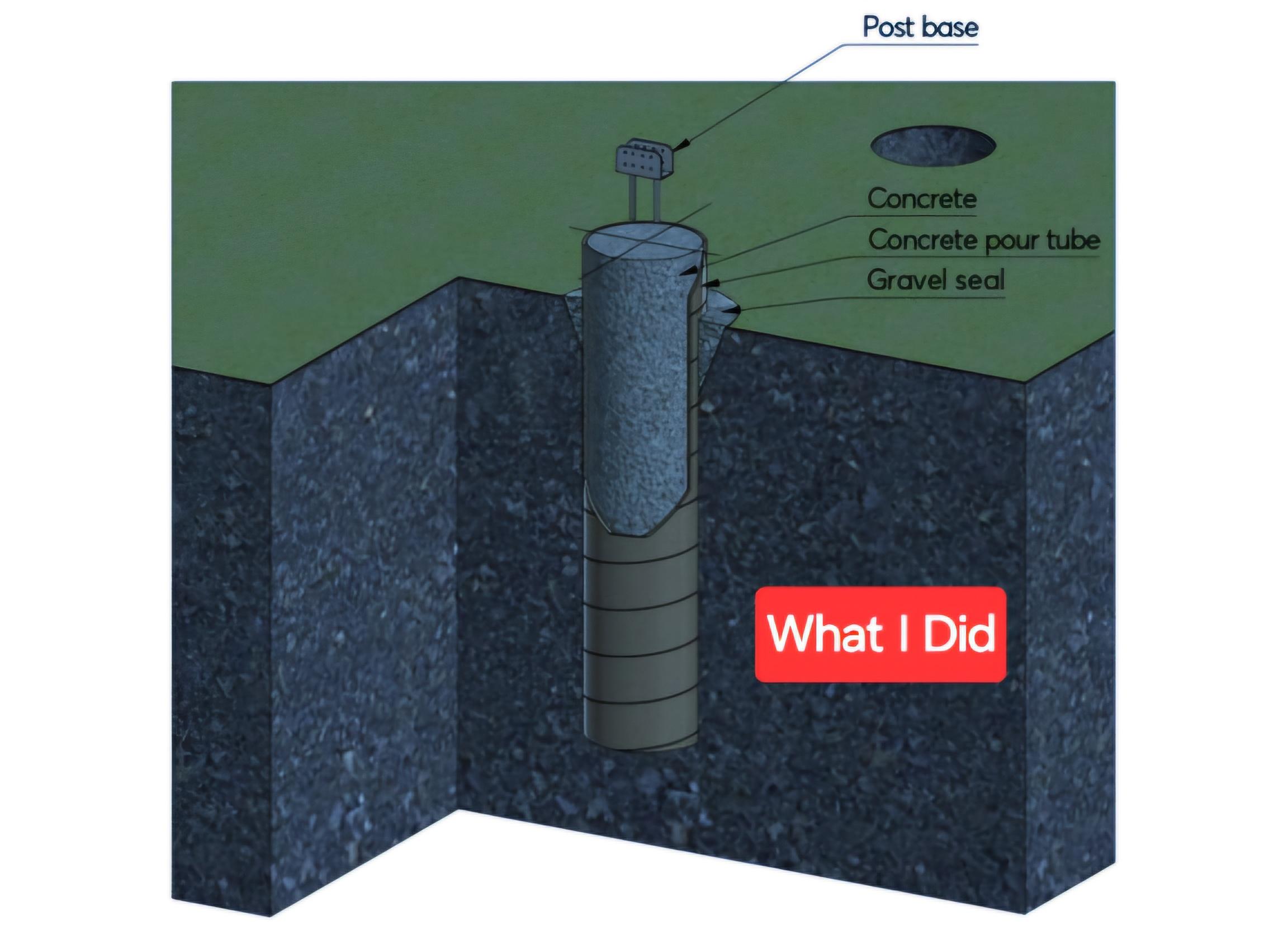

3. The Vanderveen House – Deck Supplies and Equipment

Domain: thevanderveenhouse.com

Registered: 2015 (10 years)

Introduction: 1. **Deck Supplies**: Ordered from Morrisburg Building Centre, including portland cement and gravel. 2. **Digging Holes**: Options include post hole auger or mini-excavator; mini-excavator was used due to rocky soil. 3. **Footing Frames**: Built using 2″ x 6″ pressure treated lumber, with frames measuring 2′ x 2′. Holes were over 4 feet deep to prevent frost under footings. 4. **Rebar**: Added to …

Strategic Sourcing Conclusion and Outlook for sonotube footer

The strategic sourcing of sonotube footers presents a significant opportunity for international B2B buyers to enhance the stability and longevity of construction projects. By leveraging high-quality sonotubes and associated components, businesses can ensure compliance with engineering standards and local building codes, particularly in regions with unique environmental challenges, such as frost heave or seismic activity. The ability to select the right dimensions and materials not only optimizes structural integrity but also reduces long-term maintenance costs.

Investing in sonotube solutions enables companies to streamline their supply chains, potentially lowering costs through bulk purchasing and long-term supplier partnerships. As the global construction market continues to expand, particularly in Africa, South America, the Middle East, and Europe, the demand for reliable and efficient footing solutions will only grow.

As you consider your sourcing strategies, prioritize suppliers that offer not only competitive pricing but also technical support and innovative products tailored to your specific regional requirements. Engage with manufacturers who understand the complexities of your market to ensure that your projects are both cost-effective and resilient. Embrace the future of construction by integrating sonotube footers into your building solutions and secure a competitive edge in a rapidly evolving industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.