A Deep Dive into Keyway Connector Solution

Introduction: Navigating the Global Market for keyway connector

In the fast-evolving landscape of global commerce, sourcing keyway connectors presents unique challenges for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With a myriad of options available, businesses often struggle to identify reliable suppliers that offer high-quality products tailored to specific applications. This comprehensive guide aims to demystify the keyway connector market by providing detailed insights into various types, their applications across industries, and strategies for effective supplier vetting.

From understanding the technical specifications of connectors to navigating pricing structures and shipping logistics, this guide serves as an essential resource for international buyers. It addresses critical questions such as: What are the different types of keyway connectors available? How do I assess the quality and reliability of potential suppliers? What factors should I consider when evaluating costs? By equipping buyers with actionable information and expert recommendations, this guide empowers decision-makers to make informed purchasing choices that align with their operational needs.

Whether you’re a procurement officer in Vietnam looking for durable connectors for industrial machinery or a project manager in Germany seeking reliable components for automotive applications, this guide will help you navigate the complexities of the global keyway connector market. Embrace the opportunity to enhance your sourcing strategy and ensure that your business remains competitive in an increasingly interconnected world.

Understanding keyway connector Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| M12 Connectors | Compact design, robust housing | Industrial automation, sensors | Pros: Versatile, easy to install; Cons: Limited to specific applications. |

| DT Series Connectors | High durability, multiple keyway options | Automotive, heavy machinery | Pros: High reliability; Cons: Higher cost than standard connectors. |

| Superseal Connectors | Weatherproof, multi-way configurations | Marine, outdoor equipment | Pros: Excellent sealing; Cons: Bulkier than other options. |

| Sumitomo HX Series | Low keyway design, lightweight | Automotive, consumer electronics | Pros: Lightweight, cost-effective; Cons: Limited current capacity. |

| AMP Connectors | Wide range of configurations, custom options | Telecommunications, electronics | Pros: Highly customizable; Cons: Longer lead times for custom orders. |

What are M12 Connectors and Their Key Applications?

M12 connectors are designed for industrial applications, particularly in automation and sensor technologies. Their compact design allows for easy integration into tight spaces, while their robust housing ensures durability in harsh environments. When purchasing M12 connectors, buyers should consider the specific pin configuration and environmental ratings to ensure compatibility with their systems.

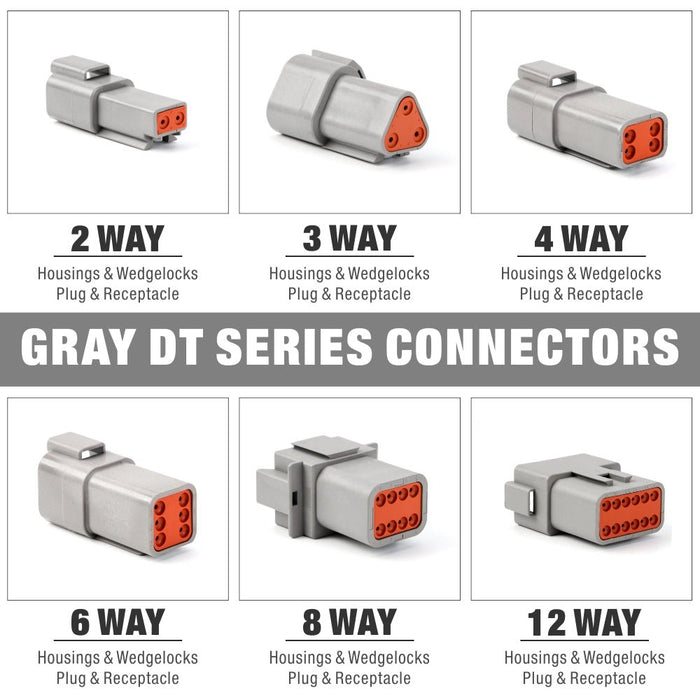

What Makes DT Series Connectors Ideal for Heavy Machinery?

The DT series connectors are known for their high durability and multiple keyway options, making them suitable for heavy machinery and automotive applications. These connectors are built to withstand extreme conditions, ensuring reliable performance. Buyers should evaluate the specific requirements of their applications, such as voltage and environmental exposure, when selecting DT connectors.

How Do Superseal Connectors Provide Weatherproofing?

Superseal connectors are designed with a focus on weatherproofing, making them ideal for marine and outdoor applications. Their multi-way configurations allow for flexible wiring solutions while maintaining excellent sealing against moisture and dust. B2B buyers should assess the sealing capabilities and environmental ratings to ensure they meet the demands of their specific applications.

What Are the Advantages of Using Sumitomo HX Series Connectors?

Sumitomo HX series connectors feature a low keyway design and are lightweight, which makes them cost-effective for automotive and consumer electronics applications. Their design allows for efficient space utilization while maintaining a reliable connection. Buyers should consider the current capacity and application requirements when choosing these connectors to ensure optimal performance.

Why Choose AMP Connectors for Custom Solutions?

AMP connectors offer a wide range of configurations and customization options, making them suitable for telecommunications and electronics industries. Their flexibility allows businesses to tailor solutions to their specific needs. However, buyers should be mindful of longer lead times associated with custom orders and ensure that they plan their procurement accordingly to avoid delays in production.

Key Industrial Applications of keyway connector

| Industry/Sector | Specific Application of keyway connector | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Wiring harnesses in vehicles | Ensures reliable connections in harsh environments | Compatibility with various vehicle systems and standards |

| Industrial Automation | Sensor and actuator connections | Facilitates seamless communication between components | Durability and resistance to environmental factors |

| Telecommunications | Data transmission in communication systems | Enhances signal integrity and reduces downtime | Compliance with international data standards |

| Renewable Energy | Connections in solar panel and wind turbine systems | Maximizes energy efficiency and reliability | Weather resistance and ease of installation |

| Aerospace | Electrical connections in aircraft systems | Ensures safety and operational reliability | Compliance with strict aerospace regulations |

How Are Keyway Connectors Used in the Automotive Industry?

In the automotive sector, keyway connectors are vital for wiring harnesses, which connect various electrical components in vehicles. These connectors ensure reliable connections that withstand the rigors of automotive environments, such as vibration, temperature fluctuations, and moisture. For international B2B buyers, sourcing connectors that meet specific automotive standards and compatibility with different vehicle systems is crucial to ensure seamless integration and performance.

What Role Do Keyway Connectors Play in Industrial Automation?

In industrial automation, keyway connectors are used to link sensors and actuators, enabling efficient communication between machinery. They help maintain consistent operational performance, especially in environments that require high reliability. Businesses must consider the durability and resistance of these connectors to environmental factors, such as dust and moisture, when sourcing products, particularly in regions with challenging climates.

How Are Keyway Connectors Essential in Telecommunications?

Keyway connectors are integral to telecommunications systems, where they facilitate data transmission between network components. Their design helps maintain signal integrity, reducing the risk of downtime and service interruptions. For buyers in the telecommunications sector, it’s essential to ensure that connectors comply with international data transmission standards to guarantee compatibility and performance across different regions.

Why Are Keyway Connectors Critical in Renewable Energy Applications?

In renewable energy, particularly in solar and wind systems, keyway connectors are essential for establishing reliable connections between various components. They contribute to maximizing energy efficiency and ensuring the reliability of power generation systems. Buyers should prioritize connectors that are weather-resistant and easy to install, especially when deploying systems in diverse geographical locations, including remote areas in Africa and South America.

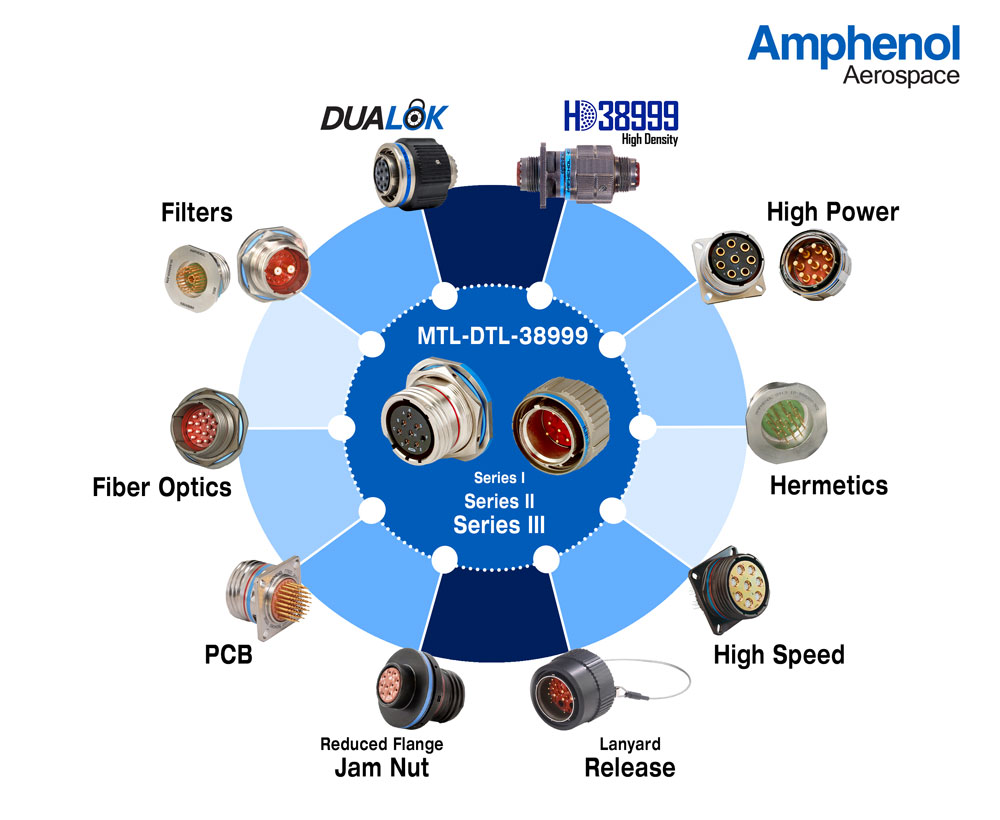

What Is the Importance of Keyway Connectors in Aerospace Applications?

In the aerospace industry, keyway connectors serve as critical electrical connections within aircraft systems, ensuring safety and operational reliability. Given the stringent regulations governing aerospace components, international buyers must source connectors that comply with these standards while offering robust performance under extreme conditions. The focus should be on connectors that provide high reliability and can withstand the unique challenges of aerospace environments.

3 Common User Pain Points for ‘keyway connector’ & Their Solutions

Scenario 1: Misalignment Issues in High-Volume Production

The Problem: In high-volume manufacturing environments, misalignment of keyway connectors can lead to significant delays and increased costs. B2B buyers often encounter situations where connectors fail to align correctly, causing assembly line slowdowns and even product failures. This issue not only hampers productivity but can also affect product quality and reliability, leading to potential customer dissatisfaction.

The Solution: To mitigate misalignment challenges, it is crucial for buyers to invest in precision-engineered keyway connectors that feature clear alignment indicators. When sourcing connectors, buyers should prioritize manufacturers who provide detailed specifications, including dimensional tolerances and alignment features. Additionally, implementing a standardized assembly protocol, which includes training for assembly line workers on proper connector handling and installation, can further reduce the risk of misalignment. Regular quality checks and the use of jigs or fixtures designed to maintain connector alignment during assembly can also enhance efficiency and accuracy.

Scenario 2: Incompatibility with Existing Systems

The Problem: Many B2B buyers face compatibility issues when integrating new keyway connectors with existing systems or equipment. These incompatibilities can arise from differences in connector design, pin configuration, or even material composition, which can lead to costly rework or system failures. This problem is particularly prevalent in industries such as automotive and industrial machinery, where legacy systems are common.

The Solution: To avoid compatibility issues, buyers should conduct a thorough compatibility analysis before purchasing keyway connectors. This involves reviewing the specifications of both existing connectors and the new options being considered. Consulting with manufacturers for custom solutions can also be beneficial. Buyers should seek connectors that offer modular designs or adaptable features, allowing for easier integration with various systems. Additionally, engaging with suppliers who can provide samples for testing before bulk orders ensures that the connectors meet the necessary compatibility requirements, thus minimizing the risk of operational disruptions.

Scenario 3: Supply Chain Disruptions and Delays

The Problem: Supply chain disruptions are a significant concern for B2B buyers of keyway connectors, particularly in regions affected by logistical challenges or geopolitical issues. Delays in receiving essential components can halt production lines and lead to missed deadlines, which can have severe financial implications. Buyers often struggle with finding reliable suppliers who can consistently meet their demands in a timely manner.

The Solution: To combat supply chain disruptions, B2B buyers should establish relationships with multiple suppliers and diversify their sourcing strategies. This approach reduces dependency on a single source and mitigates risks associated with potential supply chain failures. Implementing just-in-time inventory practices can also help maintain flexibility and responsiveness to market demands. Additionally, investing in supply chain management tools that offer real-time tracking and forecasting can enhance visibility into order statuses and potential delays. Buyers should also consider negotiating agreements with suppliers that include contingency plans for unexpected disruptions, ensuring that production can continue smoothly despite unforeseen challenges.

Strategic Material Selection Guide for keyway connector

What Are the Key Properties of Common Materials Used in Keyway Connectors?

When selecting materials for keyway connectors, understanding their properties is crucial for ensuring product performance and longevity. Here, we analyze four common materials: thermoplastic, thermoset, aluminum, and stainless steel.

How Does Thermoplastic Material Perform in Keyway Connectors?

Thermoplastic materials, such as polyamide (nylon) and polycarbonate, are widely used in keyway connectors due to their excellent electrical insulation properties and resistance to impact. These materials can typically withstand temperatures ranging from -40°C to 120°C, making them suitable for various environments.

Pros: Thermoplastics are lightweight, cost-effective, and can be molded into complex shapes, which simplifies manufacturing. They also exhibit good chemical resistance, particularly against oils and fuels.

Cons: However, they may not perform well under extreme temperatures or heavy mechanical loads. Additionally, their susceptibility to UV degradation can be a concern in outdoor applications.

Impact on Application: Thermoplastics are ideal for applications requiring lightweight connectors, such as automotive or consumer electronics. However, international buyers should ensure compliance with standards like UL94 for flammability and ISO 9001 for quality management.

What Benefits Do Thermoset Materials Offer for Keyway Connectors?

Thermoset materials, such as epoxy and phenolic resins, provide superior heat resistance and mechanical strength compared to thermoplastics. These materials can withstand temperatures up to 200°C, making them suitable for high-temperature applications.

Pros: Thermosets are highly durable and resistant to deformation under stress, which is essential for connectors exposed to harsh environments. Their chemical resistance is also superior, making them ideal for applications in the chemical and oil industries.

Cons: The main drawback is their higher manufacturing complexity and cost, as thermosets require curing processes that can increase production time. Additionally, once set, they cannot be remolded or recycled.

Illustrative image related to keyway connector

Impact on Application: Thermoset connectors are suitable for applications in aerospace and industrial machinery, where high performance is critical. Buyers from regions with strict environmental regulations should consider compliance with standards such as ASTM D638 for tensile properties.

Why Choose Aluminum for Keyway Connectors?

Aluminum is a popular choice for keyway connectors due to its lightweight nature and excellent electrical conductivity. It typically has a temperature rating of up to 150°C and is resistant to corrosion when anodized.

Pros: The primary advantages of aluminum include its strength-to-weight ratio and cost-effectiveness, especially for large-scale production. Aluminum connectors can be easily machined and assembled, which simplifies the manufacturing process.

Cons: However, aluminum can be prone to galvanic corrosion when in contact with dissimilar metals, which may limit its use in certain environments. Additionally, it may not be suitable for applications requiring high-temperature resistance.

Impact on Application: Aluminum connectors are commonly used in automotive and aerospace applications. International buyers should ensure that their products meet standards such as ISO 9001 and ASTM B117 for corrosion resistance.

What Are the Advantages of Stainless Steel in Keyway Connectors?

Stainless steel is renowned for its strength and corrosion resistance, making it an ideal material for keyway connectors in harsh environments. It can withstand temperatures exceeding 200°C and is resistant to a wide range of chemicals.

Pros: The durability and longevity of stainless steel connectors make them suitable for critical applications in industries such as oil and gas, marine, and food processing. They also offer excellent mechanical properties, ensuring reliable performance.

Cons: The primary disadvantage is the higher cost compared to other materials, which can impact budget-sensitive projects. Additionally, stainless steel connectors may require specialized tools for assembly, increasing manufacturing complexity.

Impact on Application: Stainless steel connectors are essential in applications requiring high durability and corrosion resistance. Buyers in regions with stringent quality standards, such as Europe, should ensure compliance with EN standards for materials.

Summary Table of Material Selection for Keyway Connectors

| Material | Typical Use Case for keyway connector | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Automotive, consumer electronics | Lightweight and cost-effective | Limited high-temperature performance | Low |

| Thermoset | Aerospace, industrial machinery | Superior heat resistance and durability | Higher manufacturing complexity | High |

| Aluminum | Automotive, aerospace | Excellent strength-to-weight ratio | Prone to galvanic corrosion | Med |

| Stainless Steel | Oil & gas, marine, food processing | High durability and corrosion resistance | Higher cost and assembly complexity | High |

This analysis provides B2B buyers with actionable insights into material selection for keyway connectors, ensuring informed decisions that align with their specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for keyway connector

What Are the Key Manufacturing Processes for Keyway Connectors?

The manufacturing of keyway connectors involves several critical stages, each contributing to the overall quality and functionality of the final product. Understanding these processes can help B2B buyers ensure they are sourcing connectors that meet their operational needs.

How is Material Prepared for Keyway Connectors?

The first step in the manufacturing process is material preparation. Keyway connectors are typically made from high-grade plastics and metals, such as polyamide or copper alloys. The selection of materials is crucial, as it affects durability, conductivity, and resistance to environmental factors.

Manufacturers often use advanced techniques like injection molding for plastic components, ensuring precise dimensions and complex shapes. Metal parts may undergo processes such as stamping or machining to achieve the required specifications. Quality control during this stage includes verifying material properties and checking for any defects that could compromise the connector’s performance.

Illustrative image related to keyway connector

What Techniques Are Used in Forming Keyway Connectors?

Once materials are prepared, the forming stage begins. This involves shaping the components into their final design. Techniques such as injection molding, extrusion, and die casting are commonly used.

For instance, injection molding allows for high-volume production of plastic parts, ensuring consistency and reducing waste. In contrast, metal components may be formed using stamping or forging processes, which can handle high-stress applications.

Precision is paramount in this stage; therefore, manufacturers often employ CNC (Computer Numerical Control) machines to guarantee accuracy. Quality checks are implemented at this point to ensure that the dimensions of the formed parts meet strict tolerances.

How Are Keyway Connectors Assembled?

The assembly process is where the various components of keyway connectors come together. This stage typically involves both manual and automated assembly techniques.

Automated assembly systems may use robotics for tasks such as inserting pins and securing housings, while manual assembly may be employed for more complex configurations. Each assembly line is designed to optimize efficiency while maintaining stringent quality standards.

Post-assembly, manufacturers conduct visual inspections and functional tests to ensure that the connectors operate as intended. This includes checking for proper alignment of keyways, ensuring a snug fit, and verifying electrical continuity.

What Finishing Processes Are Applied to Keyway Connectors?

Finishing processes enhance the performance and aesthetic appeal of keyway connectors. Techniques such as surface treatment, plating, and coating are employed to improve corrosion resistance and electrical conductivity.

For instance, connectors that will be exposed to harsh environments may undergo treatments such as anodizing or powder coating. These processes not only protect the connectors but also improve their lifespan. Quality control during finishing includes checking for uniformity in coatings and verifying that surface treatments meet industry standards.

How is Quality Assurance Implemented in Keyway Connector Manufacturing?

Quality assurance (QA) is a critical aspect of manufacturing keyway connectors, ensuring that products meet both international and industry-specific standards.

What International Standards Should B2B Buyers Be Aware Of?

For keyway connectors, compliance with international standards such as ISO 9001 is essential. This standard outlines requirements for a quality management system, emphasizing a process-based approach to improving customer satisfaction and ensuring product quality.

Illustrative image related to keyway connector

Additionally, industry-specific certifications like CE marking for European markets or API standards for the oil and gas sector may also apply, depending on the intended use of the connectors. Buyers should verify that their suppliers hold these certifications, as they reflect a commitment to quality and safety.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to maintaining high standards throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial stage checks the quality of raw materials before production begins. Suppliers must provide documentation proving compliance with specified standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, ongoing inspections ensure that components are being produced within tolerances. This may include dimensional checks and functional testing.

-

Final Quality Control (FQC): Before shipment, a comprehensive review is conducted to verify that the finished connectors meet all specifications and quality standards. This typically involves stress tests and environmental simulations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct thorough due diligence to ensure that suppliers adhere to stringent quality control practices. Here are several strategies for verification:

-

Supplier Audits: Regular audits of supplier facilities can provide insights into their manufacturing processes and quality assurance protocols. Buyers should inquire about the frequency and scope of these audits.

-

Quality Reports: Requesting quality assurance reports, including defect rates and corrective actions taken, can help buyers assess a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures. This is particularly important when sourcing from regions where local standards may vary.

What Nuances Should International Buyers Consider Regarding QC?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of potential nuances in quality assurance practices across different regions. Understanding local manufacturing standards, customs regulations, and logistical challenges is essential for ensuring that keyway connectors meet their specific needs.

Additionally, buyers should be prepared for variations in lead times and communication barriers that may affect the quality control process. Establishing clear expectations and maintaining open lines of communication with suppliers can mitigate these risks.

Conclusion

Understanding the manufacturing processes and quality assurance measures for keyway connectors is vital for B2B buyers seeking reliable, high-quality products. By familiarizing themselves with material preparation, forming, assembly, and finishing techniques, as well as the relevant quality standards and checkpoints, buyers can make informed decisions when sourcing connectors for their operations. Prioritizing quality assurance practices will not only enhance product reliability but also foster long-term partnerships with suppliers across diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘keyway connector’

In the world of B2B procurement, sourcing the right keyway connector is essential for ensuring the reliability and efficiency of your operations. This step-by-step guide will help you navigate the complexities of purchasing keyway connectors, enabling you to make informed decisions that meet your business needs.

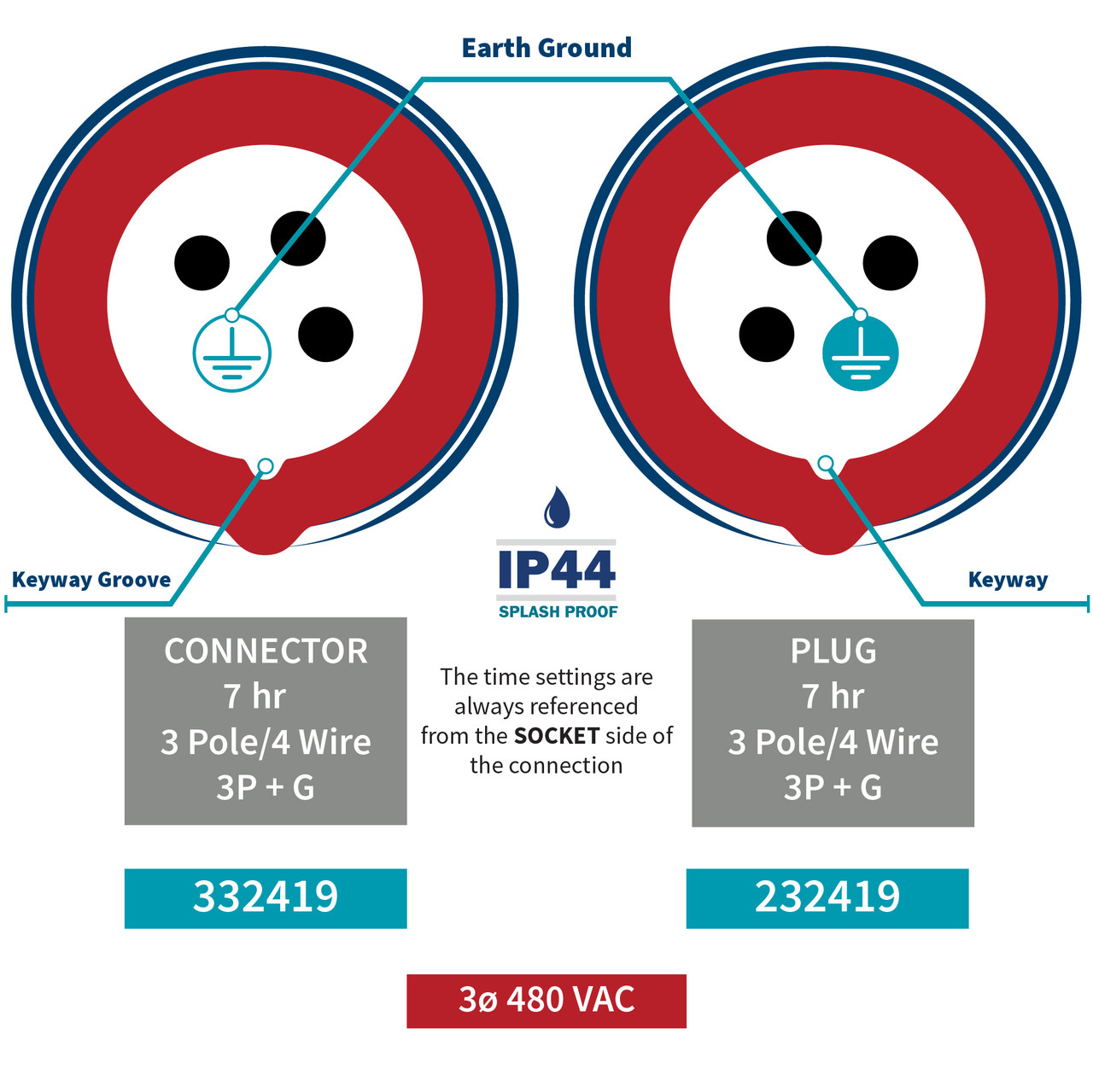

Step 1: Define Your Technical Specifications

Start by clearly outlining your technical requirements for the keyway connector. This includes factors such as the number of ways (e.g., 3-way, 8-way), material compatibility, voltage ratings, and environmental conditions (e.g., humidity, temperature). Defining these specifications will prevent miscommunications with suppliers and ensure that the connectors you procure will function correctly in your applications.

Step 2: Research Market Options

Conduct thorough research on the available keyway connector options in the market. Explore various manufacturers and their product lines to identify connectors that meet your specifications. Focus on features such as durability, ease of installation, and compatibility with existing systems. Using platforms like industry-specific catalogs and supplier databases can streamline this process.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to assess their credibility and reliability. Request detailed company profiles, including their manufacturing processes, quality control measures, and client testimonials. Look for suppliers with relevant certifications (e.g., ISO 9001) that demonstrate their commitment to quality and customer satisfaction.

- Check Reviews and References: Seek feedback from other businesses in your industry or region that have previously worked with the supplier.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of the keyway connectors. This step is vital to verify the quality and compatibility of the connectors with your systems. Examine the samples for any defects and test them under actual working conditions to ensure they meet your performance expectations.

Step 5: Compare Pricing and Payment Terms

Gather detailed quotations from your shortlisted suppliers, ensuring you compare not only the pricing but also the terms of payment. Look for potential discounts on bulk orders and inquire about shipping costs, lead times, and payment flexibility. Understanding the total cost of ownership will help you make a financially sound decision.

- Consider Long-Term Value: While the lowest price might be appealing, consider the durability and reliability of the connectors, as these factors will affect your total cost over time.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, enter negotiations to finalize the terms of your purchase. Discuss warranties, return policies, and after-sales support to ensure that you have recourse in case of defects or issues. Clear communication during this stage can prevent misunderstandings and build a strong relationship with your supplier.

Step 7: Place Your Order and Monitor Delivery

After agreeing on the terms, place your order and establish a timeline for delivery. Keep in touch with your supplier to monitor the progress of your shipment. Having a clear understanding of the delivery schedule will help you plan your operations accordingly and avoid potential disruptions.

By following this checklist, B2B buyers can streamline the sourcing process for keyway connectors, ensuring that they find the right products and suppliers to support their business operations effectively.

Illustrative image related to keyway connector

Comprehensive Cost and Pricing Analysis for keyway connector Sourcing

What Are the Key Cost Components for Sourcing Keyway Connectors?

Understanding the cost structure of keyway connectors is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. High-quality plastics or metals used in connectors can raise prices but also enhance durability and performance.

-

Labor: Labor costs vary by region and can be influenced by local wage standards. In regions like Europe, labor costs may be higher compared to South America or Africa, affecting the overall pricing.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and indirect labor. Efficient manufacturing processes can reduce overhead costs, which can be passed on to the buyer.

-

Tooling: Initial tooling costs for custom connectors can be substantial. However, these costs can be amortized over large production runs, making it crucial to consider volume when negotiating prices.

-

Quality Control (QC): Rigorous QC processes ensure product reliability but can add to costs. Certification requirements, such as ISO standards, also influence pricing.

-

Logistics: Shipping costs depend on the distance, shipping method, and Incoterms. Buyers need to account for these costs when evaluating supplier quotes.

-

Margin: Suppliers typically include a margin that reflects their overhead and profit expectations. Understanding a supplier’s margin can help in negotiations.

How Do Pricing Influencers Affect Keyway Connector Costs?

Several factors influence the pricing of keyway connectors:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Suppliers are generally more willing to negotiate prices for larger orders, which can significantly reduce per-unit costs.

-

Specifications and Customization: Custom connectors designed for specific applications may incur additional costs. Standardized products are often less expensive than custom solutions due to reduced tooling and production complexity.

-

Material Quality and Certifications: Higher-quality materials and certifications increase costs but can lead to better performance and longevity. International buyers should weigh the benefits of premium products against their budgets.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can impact pricing. Established suppliers may charge more due to their reliability, while new entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms define the responsibilities of buyers and sellers in shipping. This can affect total costs, particularly in terms of who bears shipping and insurance costs.

What Are the Best Practices for Negotiating Keyway Connector Prices?

For international buyers, effective negotiation can lead to cost savings:

-

Research and Benchmarking: Understand market prices and compare quotes from different suppliers. This information empowers buyers during negotiations.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors like shipping, maintenance, and potential downtime. A lower upfront cost may not always equate to better value.

-

Leverage Volume: If possible, commit to larger orders or long-term contracts for better pricing. Suppliers often provide significant discounts for guaranteed future sales.

-

Be Clear on Specifications: Clearly define your requirements to avoid misunderstandings and potential additional costs. This clarity can also help suppliers provide accurate quotes.

-

Build Relationships: Establishing a good relationship with suppliers can facilitate better pricing and terms over time. Trust can lead to more favorable negotiations in the long run.

What Pricing Nuances Should International Buyers Consider?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Changes in currency exchange rates can impact pricing. It may be beneficial to negotiate prices in a stable currency or set fixed rates to mitigate risks.

-

Import Tariffs and Duties: Understand the import regulations and tariffs in your country, as these can significantly affect the total cost.

-

Shipping Times and Costs: International shipping can be unpredictable. Ensure that delivery timelines are clearly defined and consider potential delays in your planning.

-

Cultural Differences in Negotiation: Different regions may have varied negotiation styles. Understanding local customs can enhance communication and foster better deals.

Disclaimer on Indicative Prices

The prices referenced in this analysis are indicative and subject to change based on market conditions, supplier pricing strategies, and other economic factors. Buyers are encouraged to conduct their own research and obtain updated quotes from suppliers for accurate pricing.

Alternatives Analysis: Comparing keyway connector With Other Solutions

Understanding Alternatives to Keyway Connectors in B2B Applications

In the realm of industrial connectivity, selecting the right connector is crucial for ensuring reliable performance and operational efficiency. Keyway connectors are a popular choice due to their unique design that helps prevent incorrect connections. However, other solutions exist that can fulfill similar roles in various applications. This analysis aims to compare keyway connectors with alternative options to help B2B buyers make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Keyway Connector | Circular Connector | Rectangular Connector |

|---|---|---|---|

| Performance | High, with secure fit | Moderate, varies by type | High, versatile for many uses |

| Cost | Moderate | Generally higher | Variable, can be cost-effective |

| Ease of Implementation | Simple, user-friendly | Moderate, requires careful alignment | Relatively easy, but depends on application |

| Maintenance | Low, durable materials | Moderate, can require regular checks | Low, generally robust |

| Best Use Case | Automotive, industrial machinery | Aerospace, military, robotics | Consumer electronics, industrial |

Analyzing Alternative Solutions for Keyway Connectors

What are the Advantages and Disadvantages of Circular Connectors?

Circular connectors, such as the M12 series, are often used in environments where space is constrained. They provide a robust connection and can withstand harsher conditions, making them suitable for applications in the aerospace and military sectors. However, their alignment can be more complex compared to keyway connectors, which can lead to installation errors if not managed properly. Furthermore, circular connectors tend to be more expensive, which may not align with budget-conscious projects.

How Do Rectangular Connectors Compare to Keyway Connectors?

Rectangular connectors are highly versatile, accommodating a wide range of pin configurations and applications. They are commonly found in consumer electronics and industrial applications due to their adaptability. Their ease of use is a significant advantage, as they often allow for quick connections. However, while they can be cost-effective, their performance may not be as reliable in demanding environments compared to keyway connectors, which are specifically designed to prevent misalignment.

Conclusion: How Can B2B Buyers Choose the Right Connector Solution?

When deciding between keyway connectors and their alternatives, B2B buyers should evaluate their specific application requirements, including environmental conditions, budget constraints, and the desired level of performance. Keyway connectors excel in preventing incorrect connections, making them a reliable choice for critical applications. In contrast, circular and rectangular connectors offer flexibility and adaptability for various use cases. Ultimately, the best solution will depend on a careful assessment of the operational context and the long-term goals of the project. By prioritizing these factors, buyers can select the most effective connector for their needs, ensuring both performance and cost efficiency in their operations.

Essential Technical Properties and Trade Terminology for keyway connector

What Are the Key Technical Properties of Keyway Connectors?

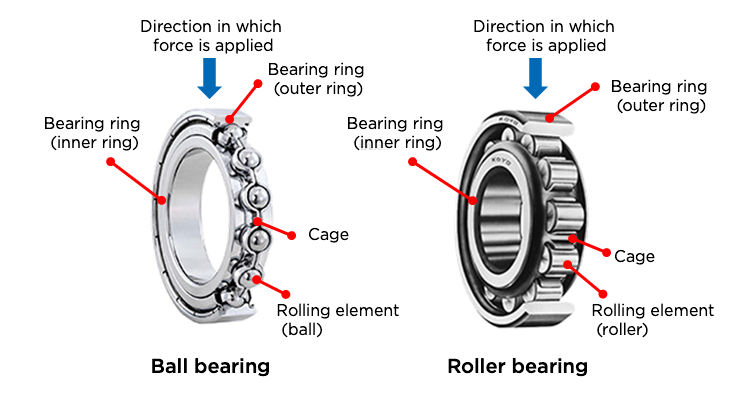

When selecting keyway connectors for industrial applications, understanding their technical specifications is crucial for ensuring compatibility, performance, and longevity. Here are the essential properties to consider:

-

Material Grade

Keyway connectors are typically made from various materials such as thermoplastic, thermoset, or metal alloys. The material grade affects durability, resistance to environmental factors, and overall performance. For instance, connectors made from high-grade thermoplastics are often lightweight and resistant to chemical exposure, making them suitable for harsh environments. -

Current Rating

The current rating specifies the maximum current that a connector can safely carry without overheating. This is critical in ensuring that the connector can handle the electrical load of the application without failure. Selecting a connector with an appropriate current rating helps prevent electrical fires and equipment damage. -

Contact Resistance

Contact resistance refers to the resistance to current flow at the interface between the connector and the wires. Low contact resistance is essential for efficient energy transfer and minimizing heat generation. High contact resistance can lead to increased power loss and reduced system efficiency, impacting overall operational costs. -

Temperature Range

The operating temperature range indicates the temperatures within which the connector can function effectively. It is vital to choose connectors that can withstand the ambient conditions of their application, whether in extreme heat, cold, or fluctuating environments. This ensures reliability and reduces the risk of failure. -

Ingress Protection (IP) Rating

The IP rating defines the level of protection against dust and moisture. For applications in challenging environments, such as outdoor installations or in industries like agriculture and mining, a higher IP rating is essential. This specification helps buyers ensure that the connectors will maintain performance despite exposure to contaminants. -

Tolerance Levels

Tolerance levels indicate how much variance is acceptable in dimensions of the connector parts. High tolerance levels are crucial for ensuring that connectors fit together securely and function as intended. Proper tolerances can prevent issues like misalignment and ensure consistent performance across multiple units.

Which Trade Terms Are Commonly Used in Keyway Connector Transactions?

Understanding industry terminology is vital for effective communication and negotiation in the B2B marketplace. Here are some commonly used terms relevant to keyway connectors:

Illustrative image related to keyway connector

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Buyers often seek OEM connectors to ensure compatibility with existing systems and to maintain quality standards in their products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory costs and ensure they are purchasing a sufficient quantity to meet their needs without overstocking. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for a specific quantity of connectors. This is a standard practice in procurement, allowing buyers to compare offers and select the best supplier based on price, quality, and delivery terms. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding Incoterms is crucial for international transactions to clarify who bears the risk and costs during shipping. -

Lead Time

Lead time is the amount of time from placing an order to receiving the goods. This metric is critical for supply chain management, as it affects project timelines and inventory levels. Buyers should inquire about lead times when planning their procurement strategies. -

Certification Standards

Certification standards refer to industry benchmarks that connectors must meet, such as ISO or UL certifications. These standards ensure that the products adhere to safety and quality requirements, which is particularly important for sectors like automotive and aerospace.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing keyway connectors, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the keyway connector Sector

Market Overview & Key Trends in the Keyway Connector Sector

The global keyway connector market is undergoing significant transformation, driven by the increasing demand for reliable and efficient connectivity solutions across various industries. The rise of automation and IoT technologies is a pivotal factor, as industries such as manufacturing, automotive, and telecommunications require robust connectors that ensure seamless data transfer and device interoperability. International B2B buyers, particularly from emerging markets in Africa and South America, are increasingly seeking high-quality keyway connectors that offer durability and performance under demanding conditions.

Current trends indicate a growing preference for modular connector designs that allow for easy customization and scalability. This shift is particularly relevant for sectors undergoing rapid technological advancements, such as renewable energy and electric vehicles, where the need for adaptable solutions is paramount. Furthermore, with a heightened focus on global supply chains, buyers are prioritizing suppliers who can provide real-time inventory visibility and expedited shipping options, enhancing operational efficiency.

Emerging technologies such as 3D printing and advanced manufacturing processes are also influencing sourcing decisions, enabling buyers to access innovative connector designs with reduced lead times. In regions like Europe, particularly Germany, there is a marked emphasis on engineering excellence and precision, which drives the demand for high-performance keyway connectors that meet stringent regulatory standards.

How is Sustainability and Ethical Sourcing Impacting Keyway Connectors?

Sustainability is becoming a critical consideration for B2B buyers in the keyway connector sector. The environmental impact of electronic waste and the need for responsible sourcing practices are prompting companies to seek suppliers who prioritize sustainable materials and manufacturing processes. Keyway connectors made from recycled or environmentally friendly materials are gaining traction, as buyers increasingly recognize the importance of reducing their carbon footprint.

Ethical sourcing is not just a trend but a necessity for businesses looking to maintain their competitive edge. Suppliers that adhere to ethical practices, including fair labor standards and transparent supply chains, are more likely to build long-term partnerships with international buyers. Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances are becoming essential benchmarks for evaluating potential suppliers.

Moreover, the demand for “green” certifications in the keyway connector market is on the rise, as buyers aim to align their procurement strategies with corporate social responsibility (CSR) goals. By investing in sustainable and ethically sourced connectors, businesses not only enhance their brand reputation but also contribute to a more sustainable future.

What is the Brief Evolution of Keyway Connectors in B2B?

The evolution of keyway connectors can be traced back to the early days of electrical engineering when the need for reliable connections became apparent. Initially, connectors were simple, mechanical devices used primarily in industrial applications. However, as technology advanced, the design and functionality of keyway connectors evolved to meet the demands of increasingly complex electrical systems.

Illustrative image related to keyway connector

The introduction of new materials and manufacturing techniques in the late 20th century allowed for the development of connectors that were more durable and efficient. The rise of digital technologies in the 21st century further accelerated this evolution, leading to the creation of specialized connectors that cater to specific applications, such as automotive and telecommunications.

Today, keyway connectors are integral to the functionality of various electronic systems, providing the necessary reliability and performance that modern industries require. This evolution reflects not only technological advancements but also the growing importance of quality and sustainability in the sourcing of these critical components.

Frequently Asked Questions (FAQs) for B2B Buyers of keyway connector

-

How do I choose the right keyway connector for my application?

Selecting the appropriate keyway connector involves understanding your specific application needs, including environmental conditions, voltage requirements, and compatibility with existing systems. Evaluate the number of pins required, the connector’s durability against mechanical stress, and its resistance to environmental factors like moisture or dust. Additionally, consider the ease of installation and maintenance. Consulting with suppliers about your technical specifications can help narrow down options and ensure you select the most suitable connector for your application. -

What factors should I consider when vetting suppliers for keyway connectors?

When vetting suppliers, assess their industry reputation, quality certifications (like ISO), and experience in manufacturing keyway connectors. Request samples to evaluate product quality and ensure compliance with international standards. Review customer testimonials and case studies to gauge reliability and service level. Additionally, consider their ability to provide customization options and timely delivery, especially if you’re operating in regions with specific regulations or logistical challenges. -

Can keyway connectors be customized for specific projects?

Yes, many manufacturers offer customization options for keyway connectors. Customizations can include variations in size, pin configuration, and material selection to meet unique project requirements. When seeking customization, communicate your specifications clearly and discuss lead times, as custom orders may require longer production periods. Ensure you receive prototypes for testing before finalizing large orders to confirm that the modifications meet your needs. -

What are the typical minimum order quantities (MOQs) for keyway connectors?

Minimum order quantities for keyway connectors vary by supplier and product type. Generally, MOQs can range from as low as 10 units to several hundred, depending on the complexity and customization of the connectors. It’s important to confirm MOQs with your supplier during the negotiation phase to ensure they align with your project scale and budget. Some suppliers may offer flexible terms for first-time orders or bulk purchases. -

What payment terms should I expect when sourcing keyway connectors internationally?

Payment terms vary by supplier but typically include options such as upfront payment, net 30/60 days, or letters of credit for larger orders. When negotiating terms, consider your cash flow and the supplier’s payment policies. Ensure that any agreed-upon terms are documented in your purchase agreement to avoid misunderstandings. Be aware of additional costs like customs duties or taxes that may apply when importing connectors into your country. -

How do I ensure quality assurance for keyway connectors?

To ensure quality assurance, request certifications and compliance documentation from your supplier. Many manufacturers will provide quality control processes and testing protocols they follow. Consider establishing a quality assurance agreement that outlines the inspection criteria and testing methods prior to shipment. Additionally, if possible, conduct an on-site visit or request third-party inspections for large orders to verify that production meets your standards. -

What logistics considerations should I keep in mind when importing keyway connectors?

When importing keyway connectors, consider shipping methods, costs, and delivery times. Ensure that your supplier can provide adequate packaging to protect the connectors during transit. Familiarize yourself with customs regulations in your country to avoid delays. It may also be beneficial to work with a freight forwarder who can assist with logistics management and ensure compliance with international shipping standards. -

How can I track the status of my keyway connector order?

Most reputable suppliers will provide tracking information once your order has shipped. This can include tracking numbers for freight carriers or updates via email or a customer portal. If you have not received tracking information, proactively contact your supplier for updates. Establishing a clear communication channel with your supplier can help ensure you are informed about any potential delays or issues during transit.

Top 3 Keyway Connector Manufacturers & Suppliers List

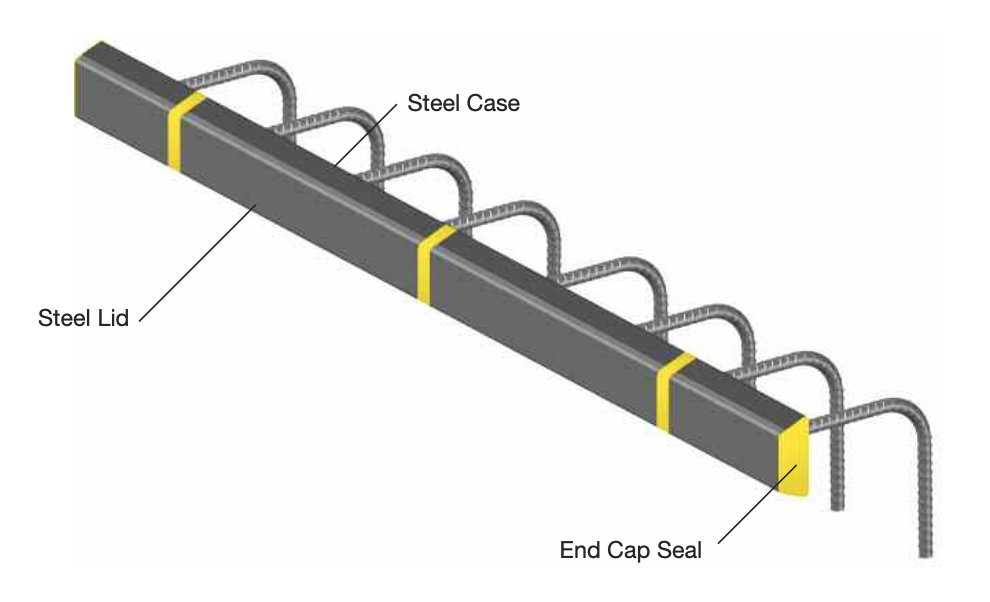

1. ProWire USA – 34 Way Connector Kit Keyway 2

Domain: prowireusa.com

Registered: 2005 (20 years)

Introduction: {“product_name”: “34 Way Connector Kit Keyway 2”, “item_number”: “68110”, “price_per_unit”: “$16.728”, “availability”: “253 Each In Stock”, “pricing_breaks”: [{“quantity”: 1, “unit_price”: “$16.728”, “ext_price”: “$16.73”}, {“quantity”: 5, “unit_price”: “$16.250”, “ext_price”: “$81.25”}, {“quantity”: 10, “unit_price”: “$15.294”, “ext_price”: “$152.94”}, {“quantity”: 25, “unit_price”: “$14.338”, “e…

2. Sumitomo – 3 Way HX 040 Low Keyway Connector Kit

Domain: bmotorsports.com

Registered: 2004 (21 years)

Introduction: {“product_name”: “3 Way Sumitomo HX 040 Low Keyway Grey Plug Connector Kit”, “sale_info”: “10% Sale on LinkECU Wire-In ECUs 8/22 – 9/5 – Coupon code WIRED25”, “category”: “Connectors / Harnesses”, “manufacturer”: “Sumitomo”}

3. Reddit – Connector Identification Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Ribbon cable connectors; Pin 1 identification; Keyway standards; Red marker indicates Pin 1; Arrow indicators on connectors; Variability in assembly standards; Use of multimeter for pin identification; Staggered metal stabbers in connectors.

Strategic Sourcing Conclusion and Outlook for keyway connector

As international B2B buyers consider the strategic sourcing of keyway connectors, it is essential to recognize the multifaceted advantages these components offer. Keyway connectors play a critical role in ensuring reliable connections across various applications, from automotive to industrial sectors. Their design features, such as dual-keyway options and multiple configurations, enhance compatibility and ease of installation, which can significantly reduce operational downtime.

Strategic sourcing not only optimizes procurement costs but also fosters long-term partnerships with suppliers that can deliver quality and innovation. By focusing on suppliers that adhere to robust quality management systems, businesses can enhance their supply chain resilience and adaptability in a competitive market.

Looking ahead, it is crucial for buyers in regions such as Africa, South America, the Middle East, and Europe to leverage emerging technologies and trends within the keyway connector market. Engaging with suppliers who prioritize sustainability and efficiency will not only align with global standards but also position companies for future growth. As the demand for reliable connectivity solutions continues to rise, now is the time to secure the right partnerships and invest in quality keyway connectors to drive success in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.