Industrial Dust Collection System Design: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for industrial dust collection system design

In today’s industrial landscape, sourcing effective industrial dust collection systems poses a significant challenge for businesses aiming to enhance air quality and comply with stringent regulations. Dust collection systems are not merely operational necessities; they are critical for maintaining workplace safety and efficiency. As industries across Africa, South America, the Middle East, and Europe (including markets like Vietnam and Saudi Arabia) continue to expand, understanding the nuances of dust collection system design becomes imperative for international B2B buyers.

This comprehensive guide addresses the essential aspects of industrial dust collection system design, encompassing various types of systems—from cartridge collectors to baghouses and wet scrubbers. It outlines their applications across diverse sectors, ensuring that buyers can identify the most suitable solutions for their specific needs. Additionally, we delve into key factors such as supplier vetting processes, cost considerations, and maintenance requirements, empowering decision-makers with actionable insights.

By offering a thorough understanding of the intricacies involved in dust collection system design, this guide equips international B2B buyers with the knowledge necessary to make informed purchasing decisions. As you navigate the global market, our insights will help you not only select the right dust collection systems but also enhance operational efficiency, safety, and compliance with environmental standards.

Understanding industrial dust collection system design Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cartridge Dust Collectors | Compact design, pleated filter media, pulse-cleaning | Welding, woodworking, food processing | Pros: Space-efficient, versatile; Cons: Limited for high dust loads. |

| Baghouses | Fabric bags, suitable for high dust volumes, pulse-cleaning | Cement, chemical processing, metal fabrication | Pros: High efficiency, robust; Cons: Larger footprint, higher initial cost. |

| Wet Scrubbers | Uses liquid to capture dust, effective for certain pollutants | Mining, metal finishing, chemical processing | Pros: Efficient for sticky or heavy dust; Cons: Requires more maintenance and water supply. |

| Portable Dust Collectors | Mobile units, easy to relocate, ideal for small operations | Construction, small workshops, maintenance tasks | Pros: Flexible, cost-effective; Cons: Limited capacity, not for large-scale operations. |

| Cyclone Dust Collectors | Uses centrifugal force to separate dust from air | Woodworking, grain handling, food processing | Pros: Low maintenance, effective for coarse dust; Cons: Less effective for fine dust. |

What Are Cartridge Dust Collectors and Their Applications?

Cartridge dust collectors are designed with pleated filter media that provides a large surface area for capturing dust and fumes. They are ideal for applications such as welding, woodworking, and food manufacturing, where space is often limited. When considering a cartridge collector, B2B buyers should evaluate the specific dust characteristics and airflow requirements, as these systems are generally more effective for moderate dust loads rather than extremely high volumes.

How Do Baghouses Operate and Where Are They Used?

Baghouses utilize long fabric bags to filter dust from high volumes of air, making them suitable for industries like cement production and metal fabrication. They operate using a pulse-cleaning system, which ensures efficient dust removal. Buyers should consider the initial investment and space requirements, as baghouses tend to have a larger footprint and higher upfront costs, but they offer long-term operational efficiency for high dust-generating processes.

What Makes Wet Scrubbers a Unique Choice for Dust Collection?

Wet scrubbers utilize liquid to capture dust and are particularly effective for sticky or heavy pollutants. Commonly used in mining and chemical processing, they can handle a variety of particulate types. While they provide efficient dust control, buyers should factor in the maintenance needs and water supply requirements, which can add to operational costs.

Why Choose Portable Dust Collectors for Smaller Operations?

Portable dust collectors are mobile units that can be easily relocated, making them ideal for construction sites and small workshops. These systems are cost-effective and flexible, allowing businesses to maintain cleanliness without a significant investment in permanent infrastructure. However, their capacity is limited, making them unsuitable for larger, more dust-intensive operations.

How Do Cyclone Dust Collectors Work and What Are Their Benefits?

Cyclone dust collectors leverage centrifugal force to separate dust from air, making them effective for coarse dust applications in woodworking and grain handling. They are low-maintenance and can handle high volumes of dust efficiently. B2B buyers should consider their specific dust types, as cyclones are less effective for fine particulates.

Key Industrial Applications of industrial dust collection system design

| Industry/Sector | Specific Application of industrial dust collection system design | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Capture dust from machining operations | Improved air quality, compliance with safety regulations | System size, filter efficiency, and maintenance needs |

| Food Processing | Control flour dust in milling processes | Enhanced worker safety, reduced fire hazards | Material compatibility, explosion-proof features |

| Pharmaceuticals | Collect dust from tablet press operations | Ensured product purity, compliance with health standards | Containment level, filter types, and regulatory compliance |

| Woodworking | Manage wood dust from cutting and sanding | Increased operational efficiency, reduced health risks | Ductwork design, system scalability, and energy efficiency |

| Metal Fabrication | Capture welding fumes and metal dust | Enhanced worker safety, improved product quality | Type of collector, airflow requirements, and installation costs |

How is Industrial Dust Collection System Design Used in Manufacturing?

In the manufacturing sector, dust collection systems are essential for capturing dust generated during machining operations. These systems help improve air quality, ensuring compliance with safety regulations like OSHA. For international buyers, understanding the specific air volume and velocity requirements is crucial to avoid installation failures. Additionally, the choice of filters and maintenance protocols can significantly impact operational efficiency and cost.

What Role Does Dust Collection Play in Food Processing?

In food processing, particularly in flour milling, effective dust collection systems are vital for controlling airborne particles. This not only enhances worker safety but also mitigates fire hazards associated with combustible dust. Buyers must consider the compatibility of materials used in the dust collection system to prevent contamination. Furthermore, features like explosion-proof designs are critical for compliance with local regulations, especially in regions with strict safety standards.

Why is Dust Collection Important in Pharmaceuticals?

In pharmaceutical manufacturing, dust collection systems are critical for maintaining product purity by collecting dust from tablet press operations. These systems ensure compliance with stringent health standards and prevent cross-contamination. Buyers should focus on containment levels and filter types to meet specific regulatory requirements. Additionally, the ability of the system to handle various dust types without compromising performance is a key consideration for international procurement.

How is Dust Collection Beneficial in Woodworking?

Woodworking operations generate significant amounts of dust from cutting and sanding processes. An efficient dust collection system improves operational efficiency and reduces health risks for workers. International buyers should evaluate ductwork design and system scalability to accommodate varying production volumes. Energy efficiency is another important factor, as it directly impacts operating costs, making it a critical consideration in sourcing decisions.

What is the Importance of Dust Collection in Metal Fabrication?

In the metal fabrication industry, capturing welding fumes and metal dust is crucial for worker safety and product quality. Dust collection systems help maintain a clean working environment, which is essential for compliance with health regulations. Buyers should assess the type of collector required based on the specific types of dust generated and the airflow requirements. Installation costs and maintenance needs also play a significant role in the sourcing process, particularly for international buyers looking to optimize their investments.

3 Common User Pain Points for ‘industrial dust collection system design’ & Their Solutions

Scenario 1: Inadequate Dust Capture Leading to Compliance Risks

The Problem: Many industrial facilities struggle with inadequate dust capture due to poorly designed collection hoods or insufficient airflow. This not only leads to operational inefficiencies but also poses significant compliance risks with regulatory bodies such as OSHA and EPA. B2B buyers often find that their existing systems fail to capture dust effectively, resulting in excess dust accumulation that can harm employee health and increase the likelihood of regulatory fines. This scenario is particularly concerning for businesses operating in industries with stringent air quality standards, such as woodworking or chemical manufacturing.

The Solution: To address inadequate dust capture, it is essential to conduct a thorough assessment of the dust generation points within the facility. Begin by mapping out all processes that emit dust and consider the required capture velocity at each point. Utilize the formula Q = V x A to calculate the necessary airflow (CFM) needed for each hood, ensuring you account for surrounding air currents that may interfere with dust capture. When sourcing equipment, prioritize systems that offer adjustable capture hoods to accommodate varying dust generation rates. Additionally, consider investing in high-efficiency dust collectors, such as cartridge collectors with advanced filter media, which are designed to maintain optimal performance in challenging conditions. Regular maintenance, including filter replacement and system inspections, will further enhance dust capture efficiency, ensuring compliance with health and safety regulations.

Scenario 2: High Operational Costs Due to Inefficient Dust Collection Systems

The Problem: B2B buyers often face escalating operational costs stemming from inefficient dust collection systems. These inefficiencies can arise from overly complex ductwork, inappropriate fan selection, or outdated technology that consumes excessive energy. For facilities with high dust loads, such as those in metal fabrication or food processing, the financial impact can be significant, affecting both the bottom line and the ability to reinvest in other areas of the business.

The Solution: To mitigate high operational costs, start by evaluating the entire dust collection system design, focusing on the airflow dynamics and resistance within the ductwork. Simplifying duct layouts by minimizing bends and transitions can significantly reduce air resistance and improve system efficiency. When selecting fans, ensure they are appropriately sized for the specific application and consider models that are designed for energy efficiency. Implementing a variable frequency drive (VFD) on the fan motor can also optimize energy consumption based on real-time operational needs. Furthermore, regularly reviewing and upgrading filter technology can lead to longer service life and reduced energy usage. By investing in modern, efficient dust collection solutions, buyers can achieve substantial cost savings while maintaining a safe and compliant working environment.

Scenario 3: Difficulty in Selecting the Right Dust Collector for Specific Applications

The Problem: One of the most common challenges B2B buyers encounter is the selection of the right dust collector for their specific application. With various types of systems available, including baghouses, cartridge collectors, and wet scrubbers, it can be overwhelming to determine which solution best meets their operational needs. This complexity can lead to incorrect selections that fail to perform adequately, resulting in operational disruptions and increased maintenance requirements.

The Solution: To simplify the selection process, buyers should begin by conducting a thorough analysis of the dust characteristics, including particle size, composition, and moisture content. Understanding the specific application is critical; for example, woodworking operations may benefit from cartridge collectors due to their compact size and high efficiency, while industries handling heavier dust loads might require robust baghouses. Engage with manufacturers or industry experts to gain insights into the advantages and limitations of different systems based on real-world performance data. Additionally, consider pilot testing equipment in a controlled environment to assess performance before full-scale implementation. Finally, ensure that the chosen system is adaptable to future changes in production processes or regulatory requirements, providing flexibility and long-term value. By following these steps, B2B buyers can confidently select a dust collection system that meets their unique operational challenges and enhances overall productivity.

Strategic Material Selection Guide for industrial dust collection system design

What Are the Key Properties of Common Materials Used in Dust Collection Systems?

When designing an industrial dust collection system, the selection of materials is crucial for ensuring optimal performance and compliance with international standards. Here, we analyze four common materials used in dust collection systems: polyester, polypropylene, metal, and fiberglass. Each material has unique properties, advantages, and limitations that impact their suitability for various applications.

How Does Polyester Perform in Dust Collection Systems?

Polyester is a widely used material in dust collection systems, particularly for filter media. It offers excellent filtration efficiency and is resistant to many chemicals, making it suitable for diverse applications.

Illustrative image related to industrial dust collection system design

Key Properties: Polyester can withstand temperatures up to 190°C (374°F) and has good tensile strength. It is also resistant to moisture and has low absorbency, which helps maintain its performance in humid environments.

Pros & Cons: The advantages of polyester include its durability, cost-effectiveness, and ease of manufacturing. However, it may not perform well in high-temperature applications beyond its rating, and its chemical resistance can vary based on the specific blend used.

Impact on Application: Polyester is compatible with a wide range of dust types, including non-combustible and fibrous materials. However, it may not be suitable for highly abrasive or corrosive dusts.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that polyester filters comply with local environmental standards and certifications, such as ASTM or ISO.

What Are the Benefits of Using Polypropylene in Dust Collection Systems?

Polypropylene is another popular choice for dust collection systems, especially in environments where chemical resistance is a priority.

Key Properties: Polypropylene can handle temperatures up to 80°C (176°F) and is highly resistant to a variety of acids and bases. Its lightweight nature also makes it easy to handle and install.

Pros & Cons: The primary advantage of polypropylene is its exceptional chemical resistance, which makes it ideal for industries such as chemical processing. However, its lower temperature tolerance can be a limitation in high-heat applications.

Impact on Application: This material is well-suited for applications involving corrosive dusts, such as those found in the chemical and pharmaceutical industries.

Illustrative image related to industrial dust collection system design

Considerations for International Buyers: Buyers should verify compliance with standards like DIN for material specifications, especially in regions like Europe where regulatory adherence is critical.

How Do Metal Components Enhance Dust Collection Systems?

Metal components, particularly stainless steel, are often used in the construction of dust collection systems due to their strength and durability.

Key Properties: Stainless steel can withstand high temperatures (up to 800°C or 1472°F) and offers excellent corrosion resistance, making it suitable for harsh environments.

Pros & Cons: The durability and longevity of metal components are significant advantages. However, the cost of stainless steel is higher than that of synthetic materials, and manufacturing complexity can increase installation times.

Impact on Application: Metal is ideal for applications involving high-temperature processes or where mechanical wear is a concern, such as in the metalworking industry.

Illustrative image related to industrial dust collection system design

Considerations for International Buyers: Buyers should consider local availability and compliance with standards like JIS in Japan or ASTM in the U.S., which may affect procurement strategies.

What Role Does Fiberglass Play in Dust Collection Systems?

Fiberglass is commonly used in ductwork and housing for dust collection systems, particularly in corrosive environments.

Key Properties: Fiberglass can handle temperatures up to 200°C (392°F) and is resistant to many corrosive substances, making it suitable for a variety of industrial applications.

Pros & Cons: The main advantage of fiberglass is its lightweight nature and resistance to corrosion. However, it can be more expensive than other materials and may require specialized handling during installation.

Impact on Application: Fiberglass is particularly effective in applications involving aggressive chemicals or high humidity, making it suitable for industries like wastewater treatment.

Considerations for International Buyers: Buyers from South America and Africa should assess the availability of fiberglass materials and ensure they meet local compliance standards.

Summary Table of Material Properties for Dust Collection Systems

| Material | Typical Use Case for industrial dust collection system design | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General-purpose filter media in dust collectors | Cost-effective and durable | Limited high-temperature performance | Low |

| Polypropylene | Chemical processing applications | Excellent chemical resistance | Lower temperature tolerance | Medium |

| Metal | High-temperature and high-wear environments | Exceptional durability and strength | Higher cost and complexity of installation | High |

| Fiberglass | Corrosive environments and wastewater treatment | Lightweight and corrosion-resistant | Higher cost and specialized handling | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in dust collection systems, enabling informed decision-making for their specific industrial applications.

In-depth Look: Manufacturing Processes and Quality Assurance for industrial dust collection system design

What Are the Main Manufacturing Processes for Industrial Dust Collection Systems?

The design and manufacturing of industrial dust collection systems involve several critical stages to ensure efficiency and compliance with industry standards. Understanding these processes allows B2B buyers to make informed decisions when selecting suppliers.

How Is Material Prepared for Dust Collection System Components?

Material preparation is the initial stage where raw materials are sourced and processed. The primary materials used in dust collection systems include steel, aluminum, and specialized filter media.

-

Material Selection: Buyers should consider the durability and compatibility of materials with the dust types they will handle. For example, materials that resist corrosion are vital for systems dealing with chemical dust.

-

Cutting and Shaping: Raw materials are cut and shaped using CNC machines or laser cutting technology. Precision in this stage is crucial as it ensures that components fit together seamlessly during assembly.

-

Surface Treatment: After shaping, components often undergo surface treatment processes such as galvanization or powder coating. These treatments enhance corrosion resistance, especially important in humid or chemical-laden environments.

What Techniques Are Used in Forming Dust Collection Components?

Forming techniques include bending, welding, and assembling components into a cohesive system.

-

Welding: For steel components, welding is a common technique to join parts. Skilled welders ensure strong joints, which are essential for maintaining structural integrity under operational stress.

-

Bending: Ductwork and housing components often require bending to achieve the desired shapes. This is typically done using hydraulic presses or specialized bending machines.

-

Assembly: The assembly process involves integrating various components, including hoppers, fans, and filters. Quality assembly techniques ensure that the system operates as designed without air leaks that could compromise efficiency.

How Is Finishing Done on Dust Collection Systems?

Finishing processes are critical for both aesthetic and functional purposes.

-

Final Inspection: Each assembled unit undergoes a thorough inspection to check for defects or inconsistencies. This step is crucial to ensure that the system meets operational specifications.

-

Testing: Systems are often tested for airflow, pressure drop, and noise levels. These tests validate that the system meets performance criteria before shipping.

-

Documentation: Providing documentation detailing the materials used, testing results, and compliance with standards is essential for B2B buyers who may require this information for regulatory compliance.

What Are the Quality Control Measures for Dust Collection System Manufacturing?

Quality control (QC) is paramount in ensuring that industrial dust collection systems perform efficiently and safely.

Which International Standards Should Buyers Be Aware Of?

International standards, such as ISO 9001, provide a framework for quality management systems. Compliance with these standards indicates that a manufacturer follows best practices in quality assurance.

-

ISO 9001: This standard emphasizes a process-oriented approach to quality management, ensuring that products meet customer expectations consistently.

-

CE Marking: For products sold in Europe, CE marking signifies compliance with health, safety, and environmental protection standards.

-

API Standards: For manufacturers dealing with oil and gas industries, API standards ensure that dust collection systems meet the rigorous demands of these sectors.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integral to the manufacturing process, ensuring that each stage meets specified standards.

-

Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials upon arrival to ensure they meet predefined specifications. Non-conforming materials are rejected or flagged for further evaluation.

-

In-Process Quality Control (IPQC): During production, ongoing checks are conducted to monitor the manufacturing process. This includes evaluating weld quality, fit of components, and adherence to design specifications.

-

Final Quality Control (FQC): Once the system is fully assembled, FQC entails a comprehensive inspection and testing phase. Here, airflow, filter efficiency, and overall system performance are assessed.

What Testing Methods Are Commonly Used for Dust Collection Systems?

Various testing methods are employed to verify the performance and safety of dust collection systems:

-

Airflow Testing: Measuring airflow rates ensures that the system can handle the required volume of dust-laden air.

-

Pressure Drop Testing: This test assesses the system’s resistance to airflow, helping to identify potential inefficiencies.

-

Filter Efficiency Testing: Evaluating the filter media’s ability to capture particles of various sizes ensures compliance with industry standards for air quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control measures is essential to ensure reliability and compliance with standards.

What Steps Can Buyers Take to Audit Suppliers?

-

Supplier Audits: Conducting on-site audits of suppliers can provide insight into their manufacturing processes, QC measures, and adherence to international standards. This is particularly important for buyers in regions with varying compliance levels.

-

Requesting Reports: Buyers should request quality assurance reports that detail testing results, compliance certifications, and any corrective actions taken in response to non-conformities.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s capabilities and compliance with industry standards.

What QC and Certification Nuances Should International Buyers Consider?

-

Local Regulations: Buyers must be aware of local regulations and standards, which may differ significantly from international ones. Understanding these nuances can prevent compliance issues upon installation.

-

Cultural and Regional Factors: In regions such as Africa and South America, it’s crucial to assess the supplier’s understanding of local market needs and environmental conditions.

-

Language and Communication: Clear communication regarding quality expectations and compliance requirements is vital, especially when dealing with suppliers from diverse linguistic backgrounds.

By understanding the manufacturing processes and quality assurance practices for industrial dust collection systems, B2B buyers can make informed decisions that align with their operational needs and regulatory requirements. This comprehensive approach helps ensure the long-term success and efficiency of dust collection systems in various industrial applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘industrial dust collection system design’

Introduction

Designing an effective industrial dust collection system is essential for maintaining a safe and compliant working environment. This checklist serves as a practical guide for B2B buyers looking to procure and implement a dust collection system tailored to their specific needs. By following these steps, you can ensure a thorough evaluation of your requirements, potential suppliers, and the overall effectiveness of the system you choose.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the right dust collection system. Consider factors such as the type of dust generated, particle size, airflow requirements, and the volume of dust to be collected. By having these parameters defined, you can ensure that the system you design or purchase meets the operational needs of your facility.

Illustrative image related to industrial dust collection system design

- Dust Type: Identify whether the dust is combustible, toxic, or non-hazardous.

- Airflow Needs: Calculate the required cubic feet per minute (CFM) based on your facility layout and processes.

Step 2: Assess Regulatory Compliance Requirements

Understanding the regulations that apply to your industry and region is essential for ensuring safety and compliance. Familiarize yourself with standards set by OSHA, EPA, and other relevant bodies, especially regarding air quality and worker safety. Non-compliance can lead to hefty fines and operational shutdowns.

- Research Local Regulations: Regulations may vary significantly between countries and regions.

- Documentation: Ensure that the selected system includes necessary certifications and compliance documentation.

Step 3: Evaluate Potential Suppliers

Before finalizing your choice, it’s vital to thoroughly evaluate potential suppliers. Request detailed company profiles, case studies, and references from clients in similar industries or regions. A supplier’s experience and reputation can significantly impact the performance and reliability of your dust collection system.

- Check References: Look for testimonials from previous clients to gauge satisfaction and reliability.

- Supplier Stability: Choose suppliers with a proven track record and financial stability.

Step 4: Analyze System Design Options

Different dust collection systems offer varying advantages based on your specific needs. Explore options such as cartridge collectors, baghouses, and wet scrubbers to determine which design aligns best with your operational requirements. Each type has unique characteristics that can affect efficiency and maintenance.

- Consider Application Needs: Assess which system is best suited for your specific dust-generating processes.

- Maintenance Requirements: Evaluate the ease of maintenance and operational costs associated with each design.

Step 5: Conduct a Cost-Benefit Analysis

A comprehensive cost-benefit analysis will help you understand the financial implications of your dust collection system investment. Consider not just the initial purchase price, but also installation, maintenance, and operational costs over time. This holistic view can help you make an informed decision that maximizes ROI.

- Long-term Costs: Include energy consumption and potential downtime in your analysis.

- Financing Options: Explore leasing versus purchasing options to find the best financial fit.

Step 6: Plan for Installation and Integration

Effective installation is vital for the performance of your dust collection system. Develop a detailed plan that includes timelines, personnel training, and integration with existing processes. Proper installation ensures that the system operates at optimal efficiency from day one.

- Training Needs: Ensure that your team is adequately trained on system operation and safety protocols.

- Integration Challenges: Identify any potential challenges in integrating the new system with existing equipment.

Step 7: Establish a Maintenance Schedule

Post-installation, maintaining your dust collection system is key to its longevity and effectiveness. Create a routine maintenance schedule that includes regular inspections, filter changes, and performance evaluations. Proactive maintenance can prevent costly downtimes and ensure compliance with safety regulations.

- Document Maintenance Activities: Keep records of all maintenance performed to track system performance over time.

- Adjust for Performance: Be prepared to adjust your maintenance schedule based on system performance data.

Following this checklist will empower you to make informed decisions when designing and procuring an industrial dust collection system that meets your operational needs while ensuring compliance and safety.

Comprehensive Cost and Pricing Analysis for industrial dust collection system design Sourcing

What Are the Key Cost Components in Industrial Dust Collection System Design?

The cost structure of industrial dust collection systems encompasses several essential components. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The selection of materials significantly impacts costs. High-quality filters, ductwork, and fan components may come at a premium, but they often yield better performance and longer service life. For instance, using advanced filter media, such as those treated with proprietary technologies like HemiPleat, can enhance dust capture efficiency and extend filter life.

-

Labor: Labor costs can vary based on the complexity of the installation and the expertise required. Skilled labor may command higher wages, but their proficiency can reduce installation time and potential errors, ultimately leading to cost savings.

-

Manufacturing Overhead: This includes costs related to the facilities, utilities, and administrative expenses incurred in producing dust collection systems. Efficient production processes can lower these overhead costs, impacting the final price.

-

Tooling: Custom tooling may be necessary for specific designs, which adds to initial costs. However, investing in specialized tools can enhance production efficiency and quality in the long run.

-

Quality Control (QC): Rigorous QC processes ensure that the systems meet regulatory and performance standards. While these processes add to upfront costs, they help prevent costly failures and downtime in the future.

-

Logistics: Transportation and shipping costs can fluctuate based on the destination, especially for international buyers. Understanding the logistics involved can help buyers anticipate additional expenses that may not be included in the base price.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary significantly depending on market demand, competition, and the supplier’s strategic positioning.

How Do Price Influencers Affect Dust Collection System Costs?

Several factors influence the pricing of industrial dust collection systems.

-

Volume/MOQ: Purchasing in larger volumes typically results in lower per-unit costs. Buyers should consider minimum order quantities (MOQ) and negotiate bulk purchasing agreements to achieve better pricing.

-

Specifications and Customization: Customized systems to meet specific operational needs can increase costs. Buyers should evaluate whether off-the-shelf solutions could suffice to avoid unnecessary expenses.

-

Materials: The choice of materials impacts not only the initial costs but also the long-term operational efficiency and maintenance requirements. Investing in durable materials can lead to lower total ownership costs.

-

Quality and Certifications: Systems that meet international quality standards and certifications (like ISO or OSHA compliance) may carry a higher price tag but ensure reliability and regulatory compliance.

-

Supplier Factors: The supplier’s reputation, experience, and customer service can all affect pricing. Established suppliers may charge more but often provide added value in terms of support and reliability.

-

Incoterms: Understanding international trade terms is crucial. Pricing can vary significantly based on the chosen Incoterms, which dictate responsibility for shipping costs, risks, and insurance.

What Buyer Tips Can Help Optimize Costs in Sourcing Dust Collection Systems?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can leverage several strategies to optimize costs.

-

Negotiation: Engage in negotiations to secure better pricing and terms. Suppliers may be willing to offer discounts for larger orders or longer-term contracts.

-

Cost-Efficiency: Focus on the total cost of ownership (TCO) rather than just the initial purchase price. This includes installation, maintenance, energy consumption, and potential downtime costs.

-

Understanding Pricing Nuances: Be aware of regional pricing differences. Prices may vary based on local market conditions, so conducting market research can provide insights into competitive pricing.

-

Supplier Relationships: Build strong relationships with suppliers. A reliable partner can offer insights into cost-saving opportunities, such as alternative materials or designs that do not compromise performance.

-

Thorough Research: Investigate multiple suppliers to compare offerings, prices, and customer reviews. This will empower buyers to make informed decisions and negotiate from a position of strength.

Conclusion

While the costs associated with industrial dust collection systems can vary widely, understanding the components and influencers can help international buyers make informed purchasing decisions. By focusing on total cost, effective negotiation, and strategic supplier relationships, buyers can optimize their investments in dust collection systems.

Alternatives Analysis: Comparing industrial dust collection system design With Other Solutions

Introduction to Alternative Solutions for Dust Control

In the realm of industrial dust management, selecting the right solution is crucial for maintaining air quality, ensuring worker safety, and achieving compliance with environmental regulations. While industrial dust collection system design is a popular choice, several alternatives exist that may better suit specific operational needs. This analysis compares the traditional dust collection systems against other viable options, including industrial vacuum systems and wet scrubbers, allowing B2B buyers to make informed decisions tailored to their unique requirements.

Comparison Table of Dust Management Solutions

| Comparison Aspect | Industrial Dust Collection System Design | Industrial Vacuum Systems | Wet Scrubbers |

|---|---|---|---|

| Performance | High efficiency for large volumes | Effective for targeted cleaning | Excellent for fine particles and gases |

| Cost | Higher initial investment | Lower initial costs | Moderate initial investment with ongoing costs |

| Ease of Implementation | Complex installation process | Simple setup | Requires skilled personnel for setup |

| Maintenance | Regular filter changes required | Minimal maintenance | Requires regular water supply and maintenance |

| Best Use Case | Manufacturing facilities with continuous dust generation | Spot cleaning in specific areas | Chemical processing and industries with hazardous dust |

Detailed Breakdown of Alternatives

Industrial Vacuum Systems

Industrial vacuum systems are designed for targeted cleaning applications, making them ideal for environments where dust generation is sporadic or localized. They offer a lower initial cost compared to dust collection systems and are easier to implement, requiring minimal setup and training. However, their performance may not match that of dedicated dust collection systems when it comes to handling large volumes of dust, which could lead to inefficiencies in high-output manufacturing environments. Additionally, while maintenance is relatively low, reliance on manual operation can lead to inconsistent dust control.

Wet Scrubbers

Wet scrubbers are another alternative, particularly effective for capturing fine particles and gaseous pollutants. They utilize a liquid medium to remove contaminants from the air, making them suitable for industries dealing with hazardous or combustible dust. Their performance is commendable, especially in chemical processing where dust is often accompanied by fumes. However, the initial investment can be moderate, and ongoing costs include water supply and maintenance. The complexity of installation may require specialized personnel, which could slow down deployment in facilities looking for quick solutions.

Conclusion: Choosing the Right Dust Management Solution

When selecting a dust management solution, B2B buyers must consider multiple factors including performance, cost, implementation ease, and maintenance requirements. Industrial dust collection systems excel in high-volume applications but come with higher costs and installation complexity. In contrast, industrial vacuum systems are better suited for localized cleaning needs, while wet scrubbers offer robust performance for specific industries dealing with hazardous dust. By carefully evaluating the unique operational needs and constraints, buyers can choose a solution that not only meets regulatory standards but also enhances workplace safety and productivity.

Essential Technical Properties and Trade Terminology for industrial dust collection system design

What Are the Key Technical Properties in Industrial Dust Collection System Design?

When designing an industrial dust collection system, several critical specifications must be considered to ensure optimal performance and compliance with safety regulations. Understanding these properties can significantly influence purchasing decisions and system efficiency.

1. Airflow Rate (CFM)

Airflow rate, measured in cubic feet per minute (CFM), indicates the volume of air the dust collection system can effectively filter. A properly calculated CFM is crucial because insufficient airflow can lead to poor dust capture, resulting in a hazardous working environment. For B2B buyers, understanding airflow requirements helps in selecting systems that align with their operational needs, ensuring worker safety and regulatory compliance.

2. Static Pressure (Inches of Water Column)

Static pressure measures the resistance within the dust collection system, including ductwork and filters. It’s essential for determining the required fan power to maintain airflow. Higher static pressure may indicate a need for a more powerful fan or larger ductwork. Buyers should understand static pressure to evaluate the efficiency and longevity of the system, as excessive resistance can increase energy costs and reduce equipment lifespan.

3. Dust Particle Size and Type (Microns)

Different dust types and particle sizes affect the choice of dust collector. For instance, fine particles (below 10 microns) require high-efficiency filters, while coarser particles may be managed with less complex systems. Buyers need to specify dust characteristics to ensure the selected system meets filtration standards and maintains air quality.

4. Filter Media Material

The choice of filter media impacts the dust collector’s efficiency and maintenance requirements. Common materials include polyester, cellulose, and spunbond fabric, each offering different levels of durability and filtration efficiency. Understanding filter media properties aids buyers in selecting a system that minimizes operational costs and maximizes performance.

5. Collection Efficiency (% Removal Rate)

Collection efficiency refers to the percentage of dust particles removed from the airstream. Higher efficiency rates indicate better performance and compliance with environmental regulations. B2B buyers should prioritize systems with high collection efficiency to ensure they meet industry standards and protect worker health.

What Are Common Terms Used in Industrial Dust Collection System Design?

Familiarity with industry jargon is vital for effective communication and negotiation in the procurement process. Here are several key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In dust collection systems, buyers often work with OEMs to ensure compatibility and quality. Understanding OEM relationships can aid in sourcing reliable products that meet specific operational needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of a product that a supplier is willing to sell. This term is crucial for buyers as it affects inventory management and cost-effectiveness. Understanding MOQ can help businesses negotiate better terms and avoid overstocking.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for a specific product or service. For B2B buyers, issuing an RFQ is an essential step in the procurement process, enabling them to compare offers and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms can help buyers understand shipping costs, risks, and logistics, ensuring smooth transactions across borders.

5. Ductwork Configuration

This term refers to the layout and design of duct systems that transport dust-laden air to the collector. Proper configuration minimizes resistance and maximizes efficiency. Buyers should consider ductwork design when planning installations to ensure optimal system performance.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure compliance with safety standards in their dust collection systems.

Navigating Market Dynamics and Sourcing Trends in the industrial dust collection system design Sector

What are the Key Market Drivers and Trends in Industrial Dust Collection System Design?

The industrial dust collection system design sector is currently influenced by several global drivers and emerging trends that international B2B buyers should consider. Increased regulatory scrutiny regarding air quality and worker safety across regions, particularly in Africa, South America, the Middle East, and Europe, is a primary motivator for investing in advanced dust collection solutions. Compliance with standards set by organizations such as OSHA, EPA, and NFPA is critical, leading manufacturers to prioritize effective dust management systems.

Technological advancements are shaping the market, with innovations in smart dust collection systems that integrate IoT capabilities for real-time monitoring and predictive maintenance. These systems can significantly reduce operational downtime and enhance efficiency. Furthermore, the growing emphasis on automation and data analytics is allowing companies to optimize their dust collection processes, thus improving both productivity and compliance.

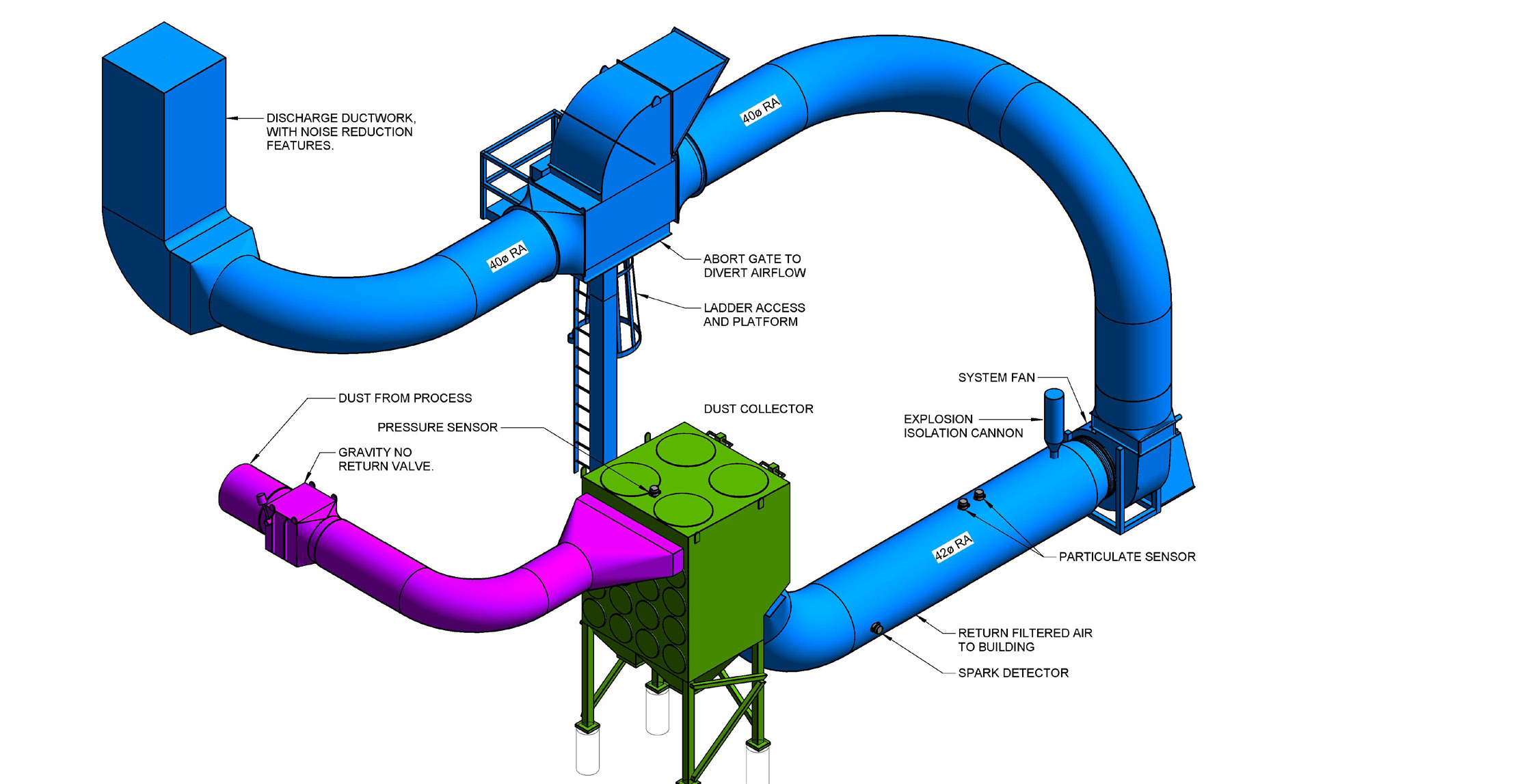

Illustrative image related to industrial dust collection system design

Additionally, there is a noticeable shift towards modular and scalable dust collection solutions. This trend is particularly relevant for businesses in developing regions, where flexibility in system design can accommodate varying operational scales and budgets. The move towards portable and versatile systems is also gaining traction, enabling companies to adapt quickly to changing production requirements without heavy investments in fixed infrastructure.

How Can B2B Buyers Embrace Sustainability and Ethical Sourcing in Dust Collection Systems?

Sustainability is becoming a non-negotiable aspect of industrial operations, and the dust collection system design sector is no exception. B2B buyers are increasingly recognizing the environmental impact of their sourcing decisions, leading to a heightened focus on ethical supply chains. Selecting suppliers that prioritize sustainable practices—such as using recyclable materials and energy-efficient manufacturing processes—can significantly reduce the overall carbon footprint of dust collection systems.

Furthermore, certifications such as ISO 14001 for environmental management and LEED for green building can guide buyers in identifying suppliers committed to sustainability. These certifications not only ensure compliance with environmental regulations but also enhance the company’s reputation in the marketplace.

Incorporating ‘green’ materials into the design of dust collection systems is essential for companies aiming to minimize their environmental impact. For instance, using filter media that is made from biodegradable or recycled materials can contribute to a more sustainable product lifecycle. Additionally, systems designed to optimize energy consumption, such as those utilizing variable frequency drives (VFDs), can further align with sustainability goals while also reducing operational costs.

What is the Historical Context of Industrial Dust Collection System Design?

The evolution of industrial dust collection systems dates back to the early 20th century when the first baghouses were introduced as a means of controlling airborne particulates in manufacturing environments. Initially, these systems relied heavily on manual maintenance and rudimentary filtration methods, leading to inefficiencies and high operational costs.

As industries grew and environmental awareness increased, the demand for more efficient and effective dust collection solutions rose. The introduction of advanced materials and technologies in the late 20th century, such as pleated filter media and pulse-jet cleaning mechanisms, revolutionized the sector. These innovations enabled higher filtration efficiency and longer filter life, addressing the dual challenges of compliance and cost-effectiveness.

Today, the industry continues to evolve with the integration of digital technologies and a stronger focus on sustainability. The ongoing developments reflect a market that is increasingly responsive to the needs of global B2B buyers, particularly in emerging markets that prioritize both efficiency and environmental responsibility.

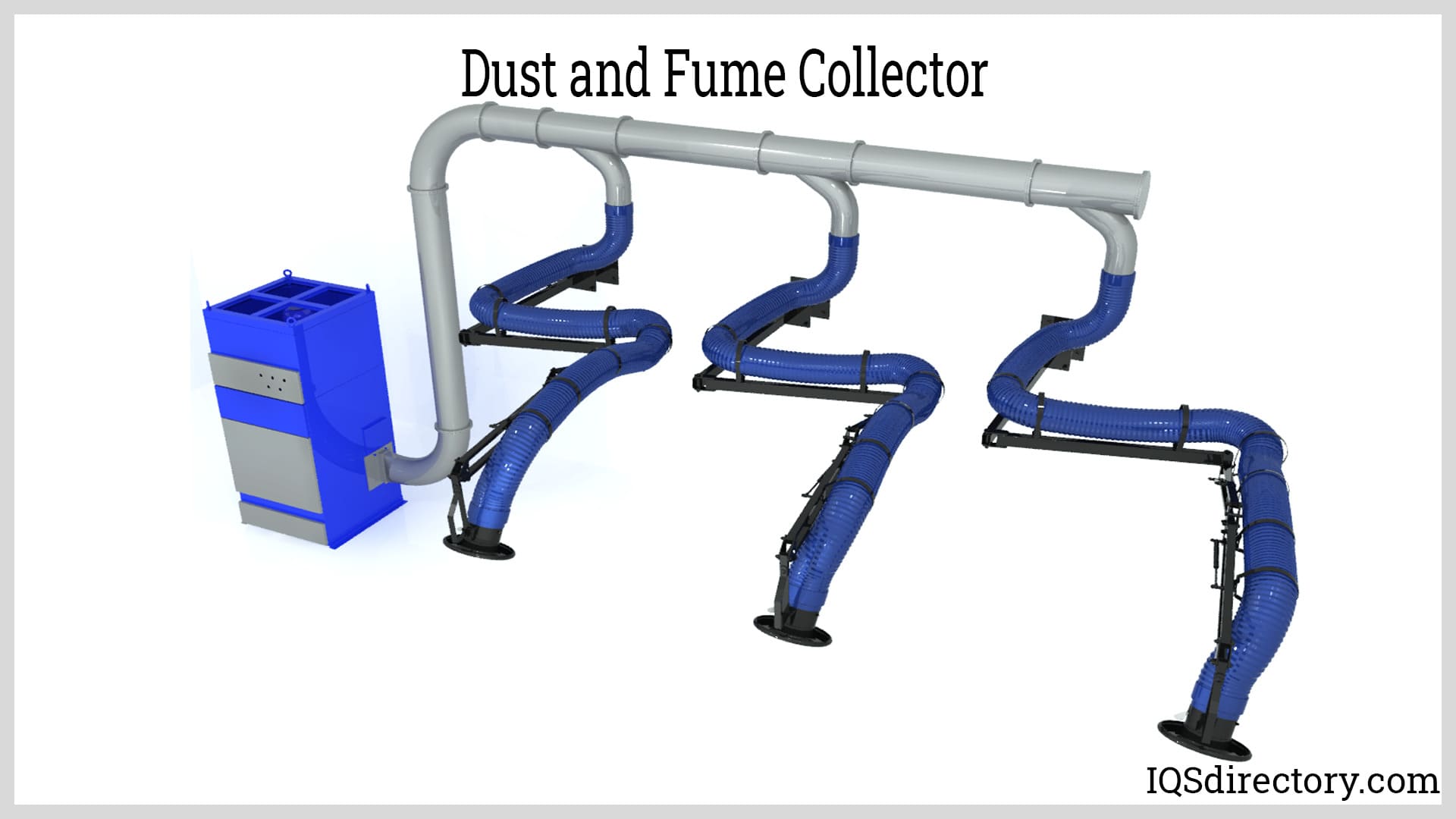

Illustrative image related to industrial dust collection system design

Frequently Asked Questions (FAQs) for B2B Buyers of industrial dust collection system design

-

How do I solve dust collection challenges in my facility?

To effectively address dust collection challenges, start by conducting a thorough assessment of your facility’s dust-generating processes. Identify key areas where dust is produced and determine the appropriate collection methods, such as using hoods or enclosures. Ensure that your system is designed to maintain sufficient capture velocity to overcome surrounding air currents. Additionally, calculate the necessary air volume and static pressure to select the right dust collector for your needs. Regular maintenance and inspections are also critical to sustaining system performance. -

What is the best type of dust collector for my manufacturing process?

The best type of dust collector depends on your specific manufacturing process and the characteristics of the dust generated. For general-purpose applications, cartridge dust collectors are often effective due to their versatility and compact design. For facilities with high dust volumes, baghouses are preferred. If your operation involves combustible dust, consider wet scrubbers for added safety. Evaluate factors such as dust particle size, chemical composition, and air flow requirements to make an informed choice. -

How can I customize a dust collection system for my unique needs?

Customization of a dust collection system involves tailoring the design to fit your specific operational requirements. Work closely with your supplier to outline your dust characteristics, volume, and collection points. Options may include different filter media, duct sizes, and configurations. Additionally, consider modular designs that allow for future scalability. Ensure that your supplier has experience in your industry to provide relevant insights and recommendations for a custom solution. -

What are the minimum order quantities (MOQ) for dust collection systems?

Minimum order quantities (MOQ) for dust collection systems can vary significantly based on the supplier and the complexity of the system. Generally, suppliers may require a MOQ for standard models, while custom systems could have different terms based on the design and components involved. It’s advisable to discuss your requirements with multiple suppliers to find flexible terms that align with your budget and operational needs. -

What payment terms should I expect when sourcing dust collection systems internationally?

When sourcing dust collection systems internationally, payment terms can vary widely. Common practices include upfront deposits (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or payment upon inspection. It’s crucial to clarify payment terms during negotiations and to ensure they align with your financial capabilities. Additionally, consider currency fluctuations and transaction fees that may apply to international payments. -

How do I vet suppliers for industrial dust collection systems?

To effectively vet suppliers, start by reviewing their industry experience, customer testimonials, and case studies. Request references from previous clients and assess their track record in delivering quality systems and services. Additionally, check for certifications related to safety and environmental compliance, such as ISO or OSHA standards. Engaging in direct conversations with potential suppliers can also provide insights into their reliability, technical expertise, and commitment to customer service. -

What quality assurance processes should I expect from suppliers?

Quality assurance processes vary by supplier, but reputable manufacturers typically implement rigorous testing and inspection protocols. Look for suppliers who follow standardized testing procedures for their dust collection systems, including performance evaluations and compliance with international standards. Additionally, inquire about their warranty and service policies, as these can be indicators of their commitment to quality and customer satisfaction. -

What logistics considerations should I be aware of when importing dust collection systems?

When importing dust collection systems, consider logistics factors such as shipping methods, lead times, and customs regulations. Ensure that your supplier can provide detailed shipping documentation to facilitate customs clearance. Additionally, factor in potential tariffs, taxes, and duties that may apply to your order. It’s advisable to work with a freight forwarder experienced in industrial equipment to navigate these complexities and ensure timely delivery to your facility.

Top 4 Industrial Dust Collection System Design Manufacturers & Suppliers List

1. Nordfab – Dust Collection Ductwork

Domain: blog.ductingsystems.com

Registered: 2003 (22 years)

Introduction: Nordfab® dust collection ductwork provides a reliable and versatile solution for controlling airborne particles. Product range includes fittings and pipes from 3″ to 24″ in diameter. Features double-rolled connecting edges for secure clamping, eliminating the need for additional fasteners. Designed for durability and ease of use, minimizing air resistance and reducing static pressure loss. Ideal f…

2. Spiral MFG – High Pressure Galvanized Pipe

Domain: spiralmfg.com

Registered: 1996 (29 years)

Introduction: HIGH PRESSURE GALVANIZED PIPE: Elbows, Tees, 90° Laterals, 30°/45°, Multi Branch Pant Wyes, Reducers, Fittings, Plugs, Caps & Couplings, Pickup Hoods, Weather Hoods, Rectangular & Round Transitions, Rectangular Duct, Single Wall Insulated Spiral Pipe, Dual Wall Insulated Spiral Pipe, Angle Rings & Flanges, Duct Sealants & Tapes, Hangers, Accessories, Clean Outs & Access Doors, Blast Gates & Contro…

3. JOA – Custom Industrial Dust Collection Solutions

Domain: joaairsolutions.com

Registered: 2020 (5 years)

Introduction: JOA offers custom industrial dust collection systems designed to improve safety and efficiency by managing harmful dust particles. Key features include: validated performance through air technical modeling and CFD, tailored solutions for specific requirements, and potential savings on energy costs and filter replacements. The systems include various types of filters such as Baghouse Filters, Packe…

4. Nederman – FlexPAK

Domain: nederman.com

Registered: 1996 (29 years)

Introduction: Nederman offers a wide range of industrial dust collection products and systems designed for various applications, particularly in woodworking and other industries generating combustible dust. Key products include:

1. **FlexPAK**: A small, central high vacuum dust collector for hand tool dust extraction, featuring frequency inverter and PLC control for energy efficiency, automatic on/off capabil…

Strategic Sourcing Conclusion and Outlook for industrial dust collection system design

How Can Strategic Sourcing Enhance Your Dust Collection System Design?

In conclusion, the successful design of an industrial dust collection system hinges on a strategic sourcing approach that emphasizes thorough understanding and precise execution. Key takeaways include the necessity of accurately mapping dust generation points, calculating air volumes for optimal system performance, and selecting the right dust collector type tailored to specific operational needs. By investing in quality components and leveraging advanced technologies such as pulse-cleaning and HemiPleat technology, businesses can significantly enhance efficiency and compliance with health and safety regulations.

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, the importance of strategic sourcing cannot be overstated. It not only ensures the reliability and effectiveness of dust collection systems but also fosters long-term partnerships with suppliers who understand the unique challenges of diverse markets. As industries evolve, the demand for innovative and sustainable dust collection solutions will continue to grow.

Now is the time to take action. Evaluate your current dust collection strategies and explore opportunities for improvement through strategic sourcing. Together, we can create safer work environments while driving operational excellence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to industrial dust collection system design

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.