Choosing Your Electric Rolling Tobacco Machine: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for electric rolling tobacco machine

In an increasingly competitive landscape, sourcing electric rolling tobacco machines presents unique challenges for international B2B buyers. The demand for efficient, cost-effective solutions is rising, particularly in emerging markets across Africa, South America, the Middle East, and Europe. This guide is designed to empower businesses by providing a comprehensive overview of electric rolling tobacco machines, covering various types, applications, and essential supplier vetting strategies.

As buyers navigate this global market, understanding the nuances of machine specifications, pricing structures, and regulatory considerations is crucial. We delve into the different styles available, from fully automatic models to semi-automatic options, and explore how these machines can enhance productivity and consistency in cigarette production. Additionally, we offer insights on cost factors, enabling businesses to make informed purchasing decisions that align with their operational needs and budget constraints.

By equipping B2B buyers with actionable insights and detailed guidance, this guide aims to facilitate successful sourcing experiences. Whether you are based in Nigeria, Vietnam, or any other location, our goal is to help you identify reliable suppliers and make confident investments in electric rolling tobacco machines that will ultimately drive profitability and growth in your business.

Understanding electric rolling tobacco machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Semi-Automatic Machines | Requires some manual input; lever-operated | Small businesses, retail shops | Pros: Cost-effective, easier to maintain. Cons: Slower production, requires user skill. |

| Fully Automatic Machines | Fully automated operation; push-button functionality | Large-scale manufacturers, wholesalers | Pros: High efficiency, consistent quality. Cons: Higher upfront investment, complex maintenance. |

| Portable Electric Machines | Compact design, battery-operated options available | On-the-go retailers, events | Pros: Easy to transport, versatile use. Cons: Limited capacity, may lack power of larger machines. |

| High-Capacity Machines | Designed for large volumes; robust construction | Factories, large distribution centers | Pros: Maximizes output, durable. Cons: Requires significant space, higher energy consumption. |

| Specialty Machines | Customizable for specific tobacco types or sizes | Niche markets, specialty retailers | Pros: Tailored production, unique offerings. Cons: Potentially higher costs, longer lead times. |

What Are the Characteristics of Semi-Automatic Electric Rolling Machines?

Semi-automatic electric rolling machines require the user to perform some manual tasks, such as inserting tobacco and placing cigarette tubes. These machines are ideal for small businesses and retail shops that want to offer fresh, rolled cigarettes without investing in fully automated systems. B2B buyers should consider the balance between cost and skill level required for operation, as these machines tend to be more affordable but may require trained staff for optimal use.

Why Choose Fully Automatic Electric Rolling Machines?

Fully automatic electric rolling machines operate with minimal user intervention, allowing for high-speed production and consistent quality. They are best suited for large-scale manufacturers and wholesalers looking to meet high demand efficiently. Buyers should weigh the higher upfront costs against the potential for increased output and reduced labor costs, ensuring that the investment aligns with their production goals.

How Do Portable Electric Rolling Machines Fit into the Market?

Portable electric rolling machines are designed for mobility, often featuring battery-operated options for convenience. They cater to on-the-go retailers and event vendors who require flexibility in production. While their compact size makes them easy to transport, B2B buyers should consider their limited capacity and whether they can meet demand during peak times.

What Advantages Do High-Capacity Electric Rolling Machines Offer?

High-capacity electric rolling machines are constructed for durability and designed to handle large volumes of production. These machines are suitable for factories and large distribution centers aiming to maximize output. However, they require significant space and may have higher energy consumption, which buyers must account for in their operational planning.

What Are the Benefits of Specialty Electric Rolling Machines?

Specialty electric rolling machines offer customizable features to accommodate specific tobacco types or sizes, appealing to niche markets and specialty retailers. They allow businesses to differentiate their product offerings. Buyers should consider the potential for higher costs and longer lead times associated with customization when evaluating these machines for their operations.

Key Industrial Applications of electric rolling tobacco machine

| Industry/Sector | Specific Application of electric rolling tobacco machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Tobacco Manufacturing | High-volume cigarette production | Increased efficiency and consistency in production | Machine capacity, speed, and compatibility with tobacco types |

| Retail Tobacco Outlets | In-store cigarette rolling services | Enhanced customer experience and potential revenue boost | Ease of use, maintenance requirements, and compact size |

| Custom Tobacco Blends | Personalized cigarette production | Ability to create tailored products for niche markets | Versatility in rolling different sizes and types |

| Export and Import Firms | Bulk cigarette production for international markets | Cost-effective production aligned with export demands | Compliance with local regulations and shipping logistics |

| Hospitality Industry | On-site cigarette rolling for bars and lounges | Unique offering that attracts clientele | Durability, aesthetic appeal, and user-friendliness |

How Are Electric Rolling Tobacco Machines Used in Tobacco Manufacturing?

Electric rolling tobacco machines are integral to tobacco manufacturing, where they facilitate high-volume production of cigarettes. These machines automate the rolling process, ensuring uniformity in size and density, which is crucial for maintaining product quality. For international buyers, especially in regions like Africa and South America, sourcing machines that can handle local tobacco varieties and comply with regulatory standards is essential. Additionally, the ability to produce at scale can significantly reduce costs, making it a vital investment for manufacturers aiming to compete in the global market.

In What Ways Do Retail Tobacco Outlets Benefit from Electric Rolling Machines?

Retail tobacco outlets are increasingly adopting electric rolling machines to offer in-store cigarette rolling services. This not only enhances the shopping experience by providing customers with freshly rolled cigarettes but also creates an additional revenue stream. For businesses in Europe and the Middle East, the compact design and ease of use are critical factors when sourcing these machines. Retailers must consider machine maintenance and the speed of operation to meet customer demand efficiently, ensuring that they can serve multiple customers in a timely manner.

How Do Electric Rolling Machines Support Custom Tobacco Blends?

Electric rolling tobacco machines are essential for businesses specializing in custom tobacco blends, allowing them to produce personalized cigarette offerings tailored to specific consumer preferences. This capability is particularly beneficial in niche markets where unique flavors and blends can command premium prices. Buyers from regions like Nigeria and Vietnam should focus on sourcing machines that offer versatility in rolling various sizes and types of tobacco, as this flexibility can significantly enhance product differentiation in a competitive market.

What Advantages Do Export and Import Firms Gain from Electric Rolling Tobacco Machines?

Export and import firms leverage electric rolling tobacco machines to produce bulk cigarettes that meet international market standards. By ensuring cost-effective production, these machines allow firms to remain competitive while adhering to the quality expectations of diverse markets. Buyers must prioritize compliance with local regulations regarding tobacco products, as well as efficient shipping logistics when sourcing these machines. The ability to scale production quickly can also help firms respond to fluctuating market demands, making this technology a strategic asset in the global tobacco trade.

How Can the Hospitality Industry Enhance Customer Experience with Electric Rolling Machines?

The hospitality industry, particularly bars and lounges, can enhance their customer experience by incorporating electric rolling tobacco machines for on-site cigarette rolling. This unique offering can attract a clientele looking for a personalized smoking experience. When sourcing these machines, businesses should consider their durability and aesthetic appeal, as well as user-friendliness for staff. Providing a distinctive service not only adds to the atmosphere but also positions the establishment as a premium destination for tobacco enthusiasts.

3 Common User Pain Points for ‘electric rolling tobacco machine’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Quality in Production

The Problem: Many B2B buyers in the tobacco industry struggle with the inconsistency in the quality of cigarettes produced by electric rolling tobacco machines. Variability in tobacco density, moisture content, and machine calibration can lead to under-filled or over-filled cigarettes, which not only affects the taste but can also impact customer satisfaction and loyalty. This inconsistency can be particularly challenging for businesses looking to maintain a reliable brand image in competitive markets across Africa, South America, and Europe.

The Solution: To overcome this challenge, buyers should prioritize sourcing machines equipped with adjustable settings for both compression and tobacco feed. It’s advisable to collaborate with suppliers who offer comprehensive training and support for machine calibration. Regular maintenance and periodic checks on tobacco quality are essential; utilizing moisture meters can help ensure optimal tobacco conditions. Implementing a quality control protocol that includes sampling and testing rolled products at various stages can help maintain consistency. By investing in equipment that allows for fine-tuning and establishing robust quality assurance practices, businesses can significantly reduce variability and enhance customer satisfaction.

Scenario 2: High Operational Costs and Maintenance Issues

The Problem: Another common pain point for B2B buyers is the high operational costs associated with electric rolling tobacco machines, which can include energy consumption, maintenance, and downtime due to repairs. These expenses can significantly cut into profit margins, especially for smaller operations that may not have the budget for frequent repairs or upgrades. Additionally, machines that require specialized parts or technical expertise for maintenance can lead to longer downtimes, adversely affecting production schedules.

The Solution: To mitigate operational costs, buyers should consider investing in energy-efficient models that are designed to reduce power consumption without compromising performance. Furthermore, it is beneficial to establish a relationship with suppliers who offer extended warranties and maintenance packages, ensuring that any repairs can be handled swiftly without incurring significant costs. Regular training for staff on proper machine operation and care can also prolong the life of the equipment and prevent unnecessary wear and tear. Conducting a thorough cost-benefit analysis of different machine models can help identify those that provide the best long-term value, balancing initial investment with operational efficiency.

Scenario 3: Navigating Regulatory Compliance and Quality Standards

The Problem: B2B buyers often face the challenge of navigating complex regulatory landscapes concerning tobacco production. Different countries in Africa, South America, the Middle East, and Europe have varying regulations regarding the production and sale of tobacco products. Ensuring compliance while also meeting quality standards can be overwhelming, especially for businesses looking to expand their operations internationally.

The Solution: To successfully navigate these regulatory hurdles, buyers should engage with industry consultants or legal advisors who specialize in tobacco regulations specific to their target markets. It’s crucial to stay updated on local laws regarding tobacco manufacturing, packaging, and marketing. Buyers should also look for electric rolling tobacco machines that meet international quality certifications, as this can ease the compliance process. Implementing an internal compliance team dedicated to monitoring regulatory changes and ensuring adherence to quality standards can provide an additional layer of security. By proactively addressing regulatory compliance and quality assurance, businesses can minimize risks and ensure smoother operations in various markets.

Strategic Material Selection Guide for electric rolling tobacco machine

When selecting materials for electric rolling tobacco machines, it is crucial to consider properties that directly impact performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the construction of these machines, focusing on their key properties, advantages and disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Aluminum in Electric Rolling Tobacco Machines?

Aluminum is a widely used material in electric rolling tobacco machines due to its lightweight nature and excellent corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for applications where heat is generated during operation. Aluminum also has good machinability, allowing for complex designs.

Pros: Aluminum is durable and lightweight, which facilitates easy handling and reduces shipping costs. Its resistance to corrosion enhances the longevity of the machines.

Cons: While aluminum is relatively affordable, it can be more expensive than some plastics, especially when considering high-grade alloys. Additionally, it may not be as strong as steel, which could limit its use in high-stress applications.

Impact on Application: Aluminum is compatible with various tobacco products and does not impart any flavors, making it an ideal choice for machines designed for rolling cigarettes.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Africa and South America should ensure that the aluminum used meets local regulations regarding material quality and safety.

How Does Stainless Steel Compare as a Material for Electric Rolling Tobacco Machines?

Stainless steel is another popular choice for electric rolling tobacco machines, known for its high strength, durability, and resistance to rust and corrosion. It can handle higher temperatures and pressures, making it suitable for machines that may experience significant wear and tear.

Pros: The strength of stainless steel contributes to the machine’s overall durability. It is also easy to clean, which is a significant advantage in maintaining hygiene standards.

Cons: Stainless steel tends to be more expensive than aluminum and can be heavier, which may increase shipping costs. Its manufacturing process is also more complex, potentially leading to longer lead times.

Impact on Application: Stainless steel is compatible with a wide range of tobacco products and is less likely to react with them, ensuring a consistent taste.

Considerations for International Buyers: Buyers should verify that the stainless steel used complies with international standards. In regions like the Middle East and Europe, certifications for food-grade materials are particularly important.

What Role Does Plastic Play in Electric Rolling Tobacco Machines?

Plastic components are often used in electric rolling tobacco machines for parts that do not require high strength or heat resistance. Common types include ABS and polycarbonate, which offer good durability and resistance to impact.

Pros: Plastics are generally less expensive than metals, making them an attractive option for cost-sensitive buyers. They are also lightweight, which reduces shipping costs.

Cons: While plastic is durable, it may not withstand high temperatures as effectively as metals. Over time, plastics can degrade, especially when exposed to UV light or certain chemicals.

Impact on Application: Plastic parts can be used in non-critical areas of the machine, such as housing or covers, where exposure to heat and stress is minimal.

Considerations for International Buyers: Buyers should ensure that the plastics used are compliant with local regulations regarding safety and environmental impact, especially in regions with strict waste management policies.

How Does Composite Material Enhance Electric Rolling Tobacco Machines?

Composite materials, which combine different materials to achieve superior properties, are increasingly being used in electric rolling tobacco machines. These materials can offer enhanced strength while being lightweight.

Pros: Composites can provide excellent resistance to corrosion and wear, making them suitable for long-term use. They can also be engineered to meet specific performance criteria.

Cons: The cost of composite materials can be high, and their manufacturing processes may be complex. This can lead to longer production times and higher initial investment costs.

Impact on Application: Composites can be tailored for specific applications, allowing for customization in machine design and performance.

Considerations for International Buyers: It is essential to ensure that composite materials meet international standards and certifications, particularly in regions where material quality is heavily regulated.

Summary Table of Material Selection for Electric Rolling Tobacco Machines

| Material | Typical Use Case for electric rolling tobacco machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body and structural components | Lightweight and corrosion-resistant | Less strong than steel | Medium |

| Stainless Steel | High-stress components and frames | High strength and easy to clean | Higher cost and heavier | High |

| Plastic | Non-critical parts like covers and housing | Cost-effective and lightweight | Limited heat resistance | Low |

| Composite | Custom components for performance optimization | Tailored properties and durability | High cost and complex manufacturing | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to enhance their electric rolling tobacco machine offerings, ensuring optimal performance while considering cost and compliance factors.

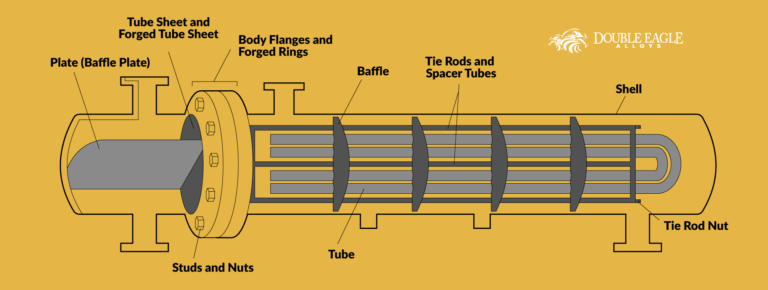

In-depth Look: Manufacturing Processes and Quality Assurance for electric rolling tobacco machine

What Are the Key Manufacturing Processes for Electric Rolling Tobacco Machines?

The manufacturing process of electric rolling tobacco machines involves several critical stages, each designed to ensure the final product meets quality and performance standards. Here’s an in-depth look at these stages:

How Is Material Prepared for Electric Rolling Tobacco Machines?

The first step in manufacturing electric rolling tobacco machines is material preparation. High-quality materials are essential for the durability and efficiency of the machines. Typically, manufacturers use metals like aluminum or stainless steel for the machine body and components due to their strength and resistance to corrosion.

Before production begins, raw materials undergo a thorough inspection to check for defects and to ensure they meet specified standards. This may include measuring thickness, checking for impurities, and ensuring the correct grade of metal is used. Suppliers often provide material certifications to affirm compliance with international standards.

What Techniques Are Used in Forming Electric Rolling Tobacco Machines?

Once materials are prepared, the next phase is forming. This stage typically involves various techniques such as:

-

Stamping and Cutting: Sheets of metal are stamped or cut into precise shapes that will form the chassis and internal components of the machine.

-

Molding: For plastic components, injection molding is commonly used to create parts like hoppers and casings. This technique allows for intricate designs and high-volume production.

-

Machining: CNC (Computer Numerical Control) machining is employed for parts requiring high precision. This technology allows for the accurate shaping of components that will fit together seamlessly.

-

Welding and Assembly: After forming, parts are welded or assembled using screws and fasteners. Automated assembly lines are often utilized to increase efficiency and reduce human error.

How Are Electric Rolling Tobacco Machines Finished?

The finishing process is crucial for both aesthetics and functionality. It typically includes:

- Surface Treatment: This may involve anodizing aluminum parts or applying powder coating to prevent corrosion and enhance appearance.

- Final Assembly: All components are assembled, including electrical parts, motors, and user interfaces. Attention to detail is vital here to ensure all parts fit correctly and function as intended.

What Quality Assurance Standards Are Relevant for Electric Rolling Tobacco Machines?

Quality assurance is an integral part of the manufacturing process for electric rolling tobacco machines. Manufacturers typically adhere to several international and industry-specific standards to ensure their products are reliable and safe.

Which International Standards Should B2B Buyers Look For?

-

ISO 9001: This standard outlines the criteria for a quality management system. It ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

-

CE Marking: For machines sold within Europe, CE marking indicates compliance with health, safety, and environmental protection standards. This is particularly relevant for electric rolling tobacco machines that involve electrical components.

-

API Standards: Depending on the specific components used, manufacturers may also comply with American Petroleum Institute (API) standards, particularly concerning machinery that involves moving parts and precision engineering.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is performed at several checkpoints throughout the manufacturing process. These include:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications. This step is crucial to prevent defects from entering the production line.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted at various stages, such as during forming and assembly. This helps identify and address issues early in the production process.

-

Final Quality Control (FQC): After assembly, the final product undergoes rigorous testing. This may include functional tests to ensure the machine operates correctly and safety tests to ensure compliance with international standards.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is vital. Here are several strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. During these audits, buyers can assess compliance with international standards and evaluate the overall production environment.

-

Requesting Quality Reports: Suppliers should be able to provide documentation detailing their quality control processes, including inspection reports and compliance certifications. This documentation can help buyers gauge the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection agencies can further validate a supplier’s claims regarding quality control. These agencies can conduct independent assessments of the manufacturing process and product quality.

What Are the Common Testing Methods for Electric Rolling Tobacco Machines?

Common testing methods utilized in the quality assurance of electric rolling tobacco machines include:

- Functional Testing: Ensures the machine operates as intended, including testing the electrical components and the rolling mechanism.

- Durability Testing: Machines are subjected to stress tests to assess their longevity and performance under typical usage conditions.

- Safety Testing: Checks for electrical safety, ensuring that components are insulated and that the machine complies with relevant safety standards.

What Nuances Should International Buyers Consider in Quality Control?

B2B buyers from various regions should be aware of specific nuances in quality control:

- Cultural Differences: Understanding the local manufacturing culture can help buyers appreciate different approaches to quality and compliance.

- Regulatory Requirements: Different countries have varying regulations governing the manufacturing and sale of tobacco-related products. Buyers should familiarize themselves with these regulations to ensure compliance.

- Logistical Considerations: Transportation and shipping can impact product quality. Buyers should discuss packaging and handling processes with suppliers to minimize potential damage during transit.

By considering these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when selecting suppliers for electric rolling tobacco machines. This ensures they acquire reliable, high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric rolling tobacco machine’

In today’s competitive market, selecting the right electric rolling tobacco machine is essential for maximizing efficiency and product quality. This guide serves as a practical checklist for B2B buyers looking to procure electric rolling tobacco machines, ensuring a streamlined purchasing process.

Step 1: Define Your Technical Specifications

Begin by outlining the specific technical requirements for your electric rolling tobacco machine. Consider the desired output capacity, types of tobacco that will be processed, and the sizes of cigarettes you intend to produce.

– Capacity Needs: Assess how many cigarettes you need to roll per hour to meet demand.

– Material Compatibility: Ensure the machine can handle the type of tobacco and rolling papers you plan to use.

Step 2: Research Market Options

Explore different brands and models available in the market. Look for electric rolling machines that have a proven track record in reliability and performance.

– Brand Reputation: Focus on well-established brands known for quality and customer service.

– User Reviews: Check online platforms and forums for feedback from existing users to gauge overall satisfaction.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, case studies, and references from buyers in similar industries or regions.

– Supplier Experience: Look for suppliers with a history of providing electric rolling machines to businesses like yours.

– After-Sales Support: Ensure they offer robust customer service and technical support post-purchase.

Step 4: Verify Certifications and Compliance

Confirm that the machines meet local regulations and industry standards. Check for certifications that reflect quality and safety compliance.

– Regulatory Standards: Different regions may have specific regulations regarding tobacco machinery; ensure compliance to avoid legal issues.

– Quality Certifications: Look for ISO or similar certifications that guarantee quality manufacturing processes.

Step 5: Request Samples or Demonstrations

Before making a final decision, ask suppliers for product demonstrations or samples. This step is crucial to assess the machine’s performance and ease of use.

– Hands-On Experience: Testing the machine allows you to evaluate its efficiency and quality firsthand.

– Training Needs: Determine if additional training will be necessary for your staff to operate the machine effectively.

Step 6: Compare Pricing and Payment Terms

Gather and compare pricing from multiple suppliers, but don’t focus solely on the lowest price. Consider the total cost of ownership, including warranty, maintenance, and operational costs.

– Cost Breakdown: Ensure you understand what is included in the price—installation, training, and spare parts.

– Payment Flexibility: Look for suppliers offering favorable payment terms, which can help manage cash flow.

Step 7: Finalize Purchase Agreement

Once you have selected a supplier, draft a detailed purchase agreement. This should outline all terms, including delivery schedules, warranty conditions, and maintenance support.

– Clear Terms: Ensure all expectations are documented to avoid disputes later.

– Legal Review: Consider having the agreement reviewed by legal counsel to protect your interests.

By following these steps, B2B buyers can confidently navigate the procurement process for electric rolling tobacco machines, ensuring they select a solution that meets their operational needs and budget.

Comprehensive Cost and Pricing Analysis for electric rolling tobacco machine Sourcing

What Are the Key Cost Components in Electric Rolling Tobacco Machine Manufacturing?

When sourcing electric rolling tobacco machines, understanding the cost structure is crucial for buyers. The main components that contribute to the total cost include:

-

Materials: The choice of materials significantly impacts the cost. High-quality metals and plastics are often used for durability, which can raise the price. Suppliers may offer different grades of materials, and opting for lower-grade materials can reduce costs but might compromise longevity.

-

Labor: Labor costs vary by region. In countries with higher wage standards, manufacturing costs will increase. However, outsourcing to regions with lower labor costs may present opportunities for savings.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and other indirect costs associated with production. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: Initial setup costs for machinery and molds can be significant, especially for custom designs. Buyers should consider whether standard machines meet their needs to avoid unnecessary tooling expenses.

-

Quality Control (QC): Implementing rigorous QC processes is essential to ensure product reliability and compliance with international standards. This can add to the overall cost but is crucial for maintaining product quality.

-

Logistics: Transportation and shipping costs can vary widely based on location and shipping terms. Buyers should be aware of these costs as they can greatly affect the total expenditure.

-

Margin: Suppliers will build a profit margin into their pricing. Understanding the typical margin in the industry can aid in negotiations.

How Do Price Influencers Affect Electric Rolling Tobacco Machine Costs?

Several factors influence the pricing of electric rolling tobacco machines, which are essential for international B2B buyers to consider:

-

Volume/MOQ: Ordering in larger quantities often allows buyers to negotiate better pricing. Suppliers frequently offer discounts for higher minimum order quantities (MOQs), which can lead to significant savings.

-

Specifications and Customization: Custom features or specific technical specifications can drive up costs. Buyers should carefully assess their needs to avoid over-specifying and incurring unnecessary expenses.

-

Materials and Quality Certifications: Machines made from superior materials or those that meet specific quality certifications (e.g., ISO standards) may command higher prices. Understanding the importance of these certifications in your market can guide purchasing decisions.

-

Supplier Factors: The reputation, reliability, and geographic location of suppliers play a role in pricing. Suppliers with a proven track record may charge more but can offer additional assurance in terms of product quality and after-sales support.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) influence the total landed cost. Buyers should clarify shipping responsibilities and costs associated with these terms to avoid unexpected charges.

What Buyer Tips Can Help Optimize Costs in Electric Rolling Tobacco Machine Sourcing?

B2B buyers can employ several strategies to enhance cost efficiency when sourcing electric rolling tobacco machines:

-

Negotiation Tactics: Establish clear criteria for negotiations, focusing on long-term partnerships. Suppliers may offer better terms for repeat business or larger orders.

-

Understanding Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also maintenance, operating costs, and potential resale value. A lower upfront cost may lead to higher TCO if the machine is less durable or efficient.

-

Pricing Nuances for International Buyers: Buyers in regions like Africa, South America, the Middle East, and Europe should consider currency fluctuations, import duties, and local taxes that may affect total costs. Being aware of these factors can prevent budget overruns.

-

Market Research: Conduct thorough market research to compare prices and features from various suppliers. Utilizing online platforms can provide insights into competitive pricing.

-

Seek Local Suppliers: Whenever feasible, sourcing from local suppliers can reduce shipping costs and lead times, enhancing overall supply chain efficiency.

Disclaimer on Indicative Prices

Prices for electric rolling tobacco machines can vary widely based on the factors discussed above. The figures referenced in various sources are subject to change and should be considered as indicative rather than fixed. It is advisable for buyers to obtain quotes from multiple suppliers to establish a comprehensive understanding of current market pricing.

Alternatives Analysis: Comparing electric rolling tobacco machine With Other Solutions

In the quest for an efficient and cost-effective way to produce rolled tobacco products, businesses often encounter various solutions. Among these, electric rolling tobacco machines have gained popularity due to their convenience and consistency. However, understanding the alternatives available can help B2B buyers make informed decisions that align with their operational needs and budget constraints.

| Comparison Aspect | Electric Rolling Tobacco Machine | Manual Rolling Machine | Cigarette Injection Machine |

|---|---|---|---|

| Performance | High speed and consistent quality | Moderate speed; quality varies | Very high speed and consistent quality |

| Cost | $70 – $300 (varies by model) | $5 – $50 | $100 – $500 |

| Ease of Implementation | Simple plug-and-play operation | Requires skill and practice | Easy to use with minimal training |

| Maintenance | Low; occasional cleaning needed | Moderate; requires more care | Low; regular cleaning needed |

| Best Use Case | Large-scale production | Small batches; personal use | Commercial production, high demand |

What Are the Pros and Cons of Manual Rolling Machines?

Manual rolling machines are a traditional alternative that offers simplicity and low initial costs. They are particularly suited for users who prefer a hands-on approach and enjoy the craft of rolling their own cigarettes. However, the main drawback lies in the learning curve; achieving a consistent quality requires practice. Additionally, production speed is significantly slower compared to electric machines, making them less ideal for businesses focusing on high volume.

How Do Cigarette Injection Machines Compare?

Cigarette injection machines represent a more advanced alternative, designed for commercial environments where speed is paramount. These machines can produce cigarettes much faster than both electric and manual rolling machines, making them a strong option for large-scale operations. However, they come with a higher price point and may require more extensive training to operate effectively. Maintenance is generally low, but the initial investment can be a barrier for smaller businesses.

Conclusion: Which Solution Should B2B Buyers Choose?

When evaluating the right solution for rolling tobacco products, B2B buyers should consider their specific operational needs, budget, and production volume. Electric rolling tobacco machines excel in efficiency and user-friendliness, making them ideal for businesses aiming for consistent quality with moderate investment. Manual rolling machines are best suited for smaller operations or those looking to minimize costs, while cigarette injection machines are the go-to choice for high-demand environments that prioritize speed. By aligning the chosen method with business goals, buyers can optimize their production processes and enhance profitability.

Essential Technical Properties and Trade Terminology for electric rolling tobacco machine

What Are the Key Technical Properties of Electric Rolling Tobacco Machines?

When considering the purchase of electric rolling tobacco machines, understanding their technical properties is crucial for B2B buyers. Here are some essential specifications that influence performance, durability, and cost-effectiveness:

-

Material Composition

Electric rolling machines are typically made from a combination of materials, including aluminum, plastic, and metal components. The choice of material affects the machine’s weight, durability, and overall lifespan. For instance, aluminum is lightweight and resistant to rust, making it ideal for portable machines, while metal parts may offer greater sturdiness for high-volume production. -

Production Capacity

This specification refers to the number of cigarettes a machine can produce in a given time frame, often measured in cigarettes per minute. Understanding the production capacity is vital for businesses that anticipate high demand. A machine with a higher capacity can lead to increased efficiency and lower operational costs, making it a better investment for larger enterprises. -

Power Source and Wattage

Electric rolling machines can vary in power requirements, typically ranging from 100 to 250 watts. A machine’s wattage affects its performance speed and efficiency. Higher wattage may indicate a more powerful motor, which can lead to quicker and more consistent rolling. Buyers should consider their power supply capabilities and the machine’s energy consumption. -

Tube Size Compatibility

Different electric rolling machines are designed to accommodate various tube sizes, such as king-size or 100mm tubes. Compatibility with multiple tube sizes allows businesses to cater to a broader customer base, offering flexibility in product offerings. It’s essential to ensure that the chosen machine aligns with the intended cigarette specifications. -

Ease of Operation and Maintenance

User-friendly designs and straightforward maintenance procedures are critical for minimizing downtime and ensuring consistent production. Features such as automatic feeding mechanisms and easy-to-clean components can enhance operational efficiency. For B2B buyers, considering the operational simplicity can lead to improved workforce productivity.

Which Trade Terms Should B2B Buyers Know When Purchasing Electric Rolling Tobacco Machines?

Navigating the procurement process involves understanding specific trade terminology that can impact negotiations and purchasing decisions. Here are key terms to be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of electric rolling machines, knowing the OEM can provide insights into the quality and reliability of the machine, as well as potential for customization. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of goods a supplier is willing to sell. Understanding the MOQ is essential for budgeting and inventory management, especially for businesses that may not require large volumes. It can also impact negotiation strategies when seeking bulk discounts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. For B2B buyers, issuing an RFQ can help compare prices, terms, and conditions from different suppliers, ensuring the best deal for electric rolling machines. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for understanding shipping costs, risk management, and delivery responsibilities, which are vital when importing machinery. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. Knowing the lead time is important for planning production schedules and managing inventory levels. Long lead times can affect cash flow and operational efficiency, making this a critical factor for decision-making.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when investing in electric rolling tobacco machines, ensuring they choose the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the electric rolling tobacco machine Sector

What Are the Key Market Dynamics and Trends Impacting the Electric Rolling Tobacco Machine Sector?

The electric rolling tobacco machine sector is witnessing significant growth driven by several global factors. One of the primary drivers is the rising demand for cost-effective and customizable smoking options, particularly in regions such as Africa, South America, the Middle East, and Europe. The shift towards rolling one’s own cigarettes is fueled by increasing tobacco taxes and the desire for personalized smoking experiences. B2B buyers are increasingly seeking electric machines that offer efficiency, consistency, and ease of use, which are essential for both small businesses and larger manufacturers.

Emerging technologies are also reshaping the market landscape. Innovations such as automated rolling machines equipped with smart technology are becoming more prevalent, allowing users to produce cigarettes with minimal effort while ensuring uniformity in size and quality. This technological advancement is particularly appealing to international B2B buyers who prioritize operational efficiency. Moreover, the trend towards online purchasing is gaining momentum, making it easier for buyers to compare products, check specifications, and evaluate supplier reputations from the comfort of their offices.

Additionally, regulatory changes regarding tobacco products are influencing sourcing trends. As various countries implement stricter regulations on tobacco sales and production, B2B buyers must navigate compliance challenges. Suppliers who can demonstrate adherence to these regulations while providing high-quality machines will gain a competitive edge in the market.

How Are Sustainability and Ethical Sourcing Shaping the Electric Rolling Tobacco Machine Industry?

Sustainability and ethical sourcing are becoming increasingly critical in the electric rolling tobacco machine sector. As environmental concerns grow, B2B buyers are more inclined to partner with suppliers who prioritize eco-friendly practices. This includes the use of sustainable materials, such as recycled plastics and metals, in the manufacturing of rolling machines. Suppliers that obtain ‘green’ certifications can significantly enhance their appeal to international buyers, as these certifications serve as tangible proof of their commitment to sustainable practices.

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing the sourcing of raw materials and the labor practices of suppliers. Ensuring that machines are produced in facilities that uphold fair labor practices and comply with local and international regulations is essential for maintaining a positive brand image and fostering customer loyalty. Suppliers that transparently communicate their sourcing practices and demonstrate a commitment to social responsibility are likely to attract more business in the long term.

The impact of these trends is not only limited to brand reputation; it also influences purchasing decisions. B2B buyers are often willing to pay a premium for machines that align with their sustainability goals, making it a vital consideration for suppliers looking to capture market share.

What Is the Evolution of Electric Rolling Tobacco Machines and Their Significance for B2B Buyers?

Electric rolling tobacco machines have evolved significantly since their inception, transitioning from basic manual devices to sophisticated automated systems. Initially, these machines were designed to meet the needs of individual smokers seeking convenience. However, as the market expanded, manufacturers began to focus on developing machines that catered to both individual consumers and commercial users.

In recent years, the introduction of advanced technologies, such as digital controls and automated filling processes, has transformed the functionality of electric rolling machines. These innovations not only enhance user experience but also increase production efficiency—crucial for B2B buyers looking to optimize their operations. As the market continues to mature, understanding the evolution of these machines can provide valuable insights into future trends and opportunities for investment in this sector.

Overall, the electric rolling tobacco machine sector presents a dynamic landscape rich with opportunities for B2B buyers, driven by technological advancements, sustainability considerations, and evolving consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of electric rolling tobacco machine

-

How do I solve issues with inconsistent cigarette rolling using electric machines?

Inconsistent rolling can often be attributed to improper machine setup or the quality of tobacco used. First, ensure that the machine is correctly calibrated according to the manufacturer’s instructions. Use high-quality, well-moistened tobacco that is free from excessive stems or debris. Regular maintenance, such as cleaning the feeding mechanism and rollers, also helps maintain consistency. If problems persist, consulting the supplier for troubleshooting guidance or potential machine upgrades may be beneficial. -

What is the best electric rolling tobacco machine for small businesses?

For small businesses, the Powermatic IV is often recommended due to its balance of affordability, efficiency, and ease of use. It provides semi-automatic functionality, allowing for quick production of consistent cigarettes. Additionally, consider the machine’s capacity and speed, as well as customer support from the supplier. Investing in a machine with a good warranty can also help mitigate risks associated with equipment failure. -

How can I vet suppliers of electric rolling tobacco machines internationally?

Vetting suppliers involves several steps: first, check their credentials, including business licenses and certifications. Look for reviews and testimonials from previous customers, and consider reaching out for references. Assess their production capabilities and quality control measures by requesting product samples. It’s also advisable to visit their facility if possible or conduct a virtual tour to observe their operations. Finally, ensure they comply with international trade regulations and standards relevant to your region. -

What are typical minimum order quantities (MOQs) for electric rolling tobacco machines?

MOQs can vary significantly among suppliers, often depending on the type of machine and manufacturer. Generally, you can expect MOQs to range from 5 to 20 units for electric rolling machines. Some manufacturers may offer flexibility for small businesses or first-time buyers, so it’s worth discussing your specific needs with suppliers. Always confirm the MOQ during negotiations to ensure it aligns with your business capabilities. -

What payment terms should I expect when purchasing electric rolling tobacco machines?

Payment terms can vary widely based on the supplier and the nature of the transaction. Common terms include a 30% deposit upfront with the balance due before shipping or upon delivery. Some suppliers may offer credit terms for established businesses. It’s crucial to clarify payment methods accepted (e.g., wire transfer, credit card) and any potential fees associated with international transactions. Always ensure that payment terms are documented in the purchase agreement to avoid misunderstandings. -

How do I ensure quality assurance (QA) for electric rolling tobacco machines?

To ensure quality assurance, request detailed specifications and quality control processes from the supplier. Look for certifications that indicate adherence to international standards, such as ISO. Before finalizing your order, consider conducting a factory audit or asking for a pre-shipment inspection. It’s beneficial to negotiate terms that allow for returns or exchanges in case the machines do not meet the agreed specifications upon delivery. -

What logistics considerations should I keep in mind when importing electric rolling tobacco machines?

When importing, consider shipping methods (air vs. sea), which will impact costs and delivery times. Ensure that the supplier provides necessary documentation for customs clearance, including invoices and packing lists. Familiarize yourself with import regulations specific to your country, including any tariffs or taxes. Additionally, working with a reliable freight forwarder can help streamline the logistics process and ensure compliance with international shipping standards. -

Can electric rolling tobacco machines be customized for my business needs?

Many manufacturers offer customization options for electric rolling machines to meet specific business needs. Customizations can include modifications in size, capacity, or even branding on the machine. Discuss your requirements with potential suppliers to understand the extent of customization available and any associated costs. Be sure to factor in lead times for customized products, as they may extend the delivery schedule compared to standard machines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Electric Rolling Tobacco Machine Manufacturers & Suppliers List

1. TED Tobacco – Gambler 100 Cigarette Machine

Domain: tedtobacco.com

Registered: 2012 (13 years)

Introduction: TED Tobacco offers a wide selection of rolling machines, including manual and electric designs. Key products include: 1. Gambler 100 Cigarette Machine – Special Price: $6.29 (Regular Price: $8.00) 2. Gambler King Size Cigarette Machine – Special Price: $6.29 (Regular Price: $8.00) 3. Mikromatic King Size Cigarette Machine – Special Price: $38.99 (Regular Price: $60.00) 4. Powermatic 1 Manual Cigar…

2. eBay – Electric Cigarette Rolling Injector Machine

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Electric Cigarette Rolling Injector Machine for sale on eBay. Popular models include Powermatic III+ and Top-O-Matic T2. Prices range from $8.79 for manual rollers to $234.44 for electric machines. Features include adjustable sizes (e.g., 110mm, 100mm), portability, and consistent tobacco filling. Customer reviews highlight ease of use and quality results. Related products include various rolling …

3. The Smoking Store – Electric Cigarette Rolling Machines

Domain: thesmokingstore.com

Registered: 2011 (14 years)

Introduction: Electric Cigarette Rolling Machine, Electric Cigarette Machine, Electric Cigarette Injector Machine, Free Shipping On Orders Over $129, Gift Certificate, Cigarette Rolling Machines, Electric Cigarette Rolling Machines, Cigarette Machines & Injectors, Cigarette Rollers (70mm, 79mm, 110mm), Cigarette Holders (Regular, Long, Meerschaum), Replacement Filters For Cigarette Holders, Cigarette Tubes (Kin…

4. Pipes Magazine – PowerMatic IV Cigarette Roller

Domain: pipesmagazine.com

Registered: 2008 (17 years)

Introduction: Power Matic IV cigarette roller, priced at $62 on sale, allows users to roll their own cigarettes quickly and efficiently. It is semi-automatic and can produce perfect cigarettes as fast as the user can lift the lever and place a tube on the spout. The machine is designed for use with loose tobacco, such as PS 400, which costs about $50 per pound and can roll up to 500 cigarettes. The cost per cig…

Strategic Sourcing Conclusion and Outlook for electric rolling tobacco machine

Electric rolling tobacco machines represent a pivotal opportunity for international B2B buyers seeking to optimize their tobacco product offerings. By strategically sourcing these machines, businesses can significantly enhance operational efficiency, reduce labor costs, and meet the growing demand for customizable smoking experiences. The diversity of available models—from manual to fully automated machines—allows buyers to tailor their investments according to market preferences and consumer behavior.

In regions like Africa, South America, the Middle East, and Europe, the appeal of electric rolling machines is underscored by their potential for cost savings and product quality improvement. As regulations around tobacco products tighten globally, companies that invest in reliable rolling machines can position themselves as leaders in compliance and customer satisfaction.

Looking forward, the landscape for electric rolling tobacco machines is poised for growth. Businesses are encouraged to leverage market insights and supplier relationships to stay ahead of trends. Engaging with reputable manufacturers and distributors can ensure access to cutting-edge technology and competitive pricing. Act now to capitalize on the advantages of electric rolling machines and drive your business towards success in a dynamic market.