A Deep Dive into 3 Types Of Centrifugal Pumps Solution

Introduction: Navigating the Global Market for 3 types of centrifugal pumps

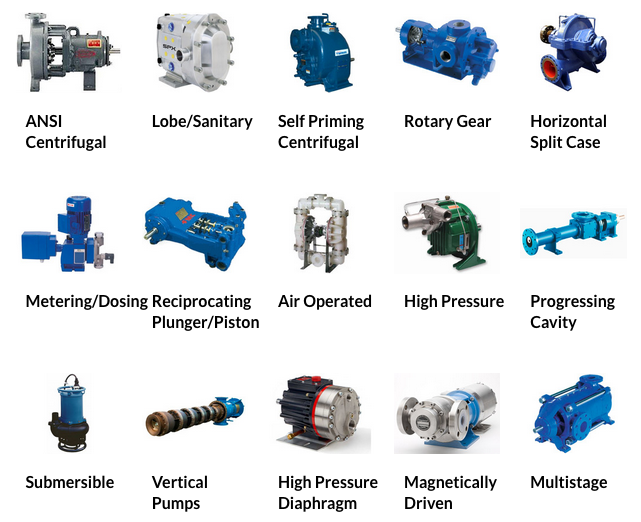

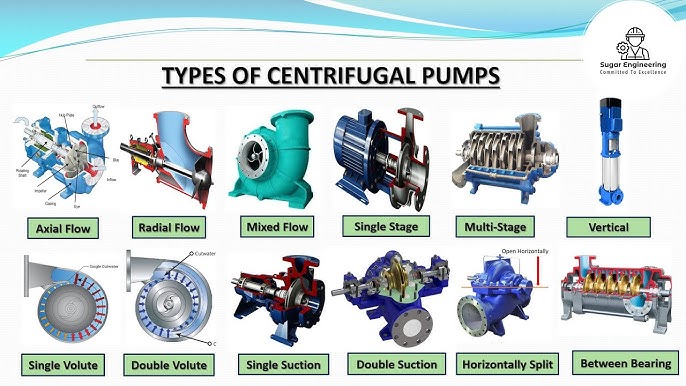

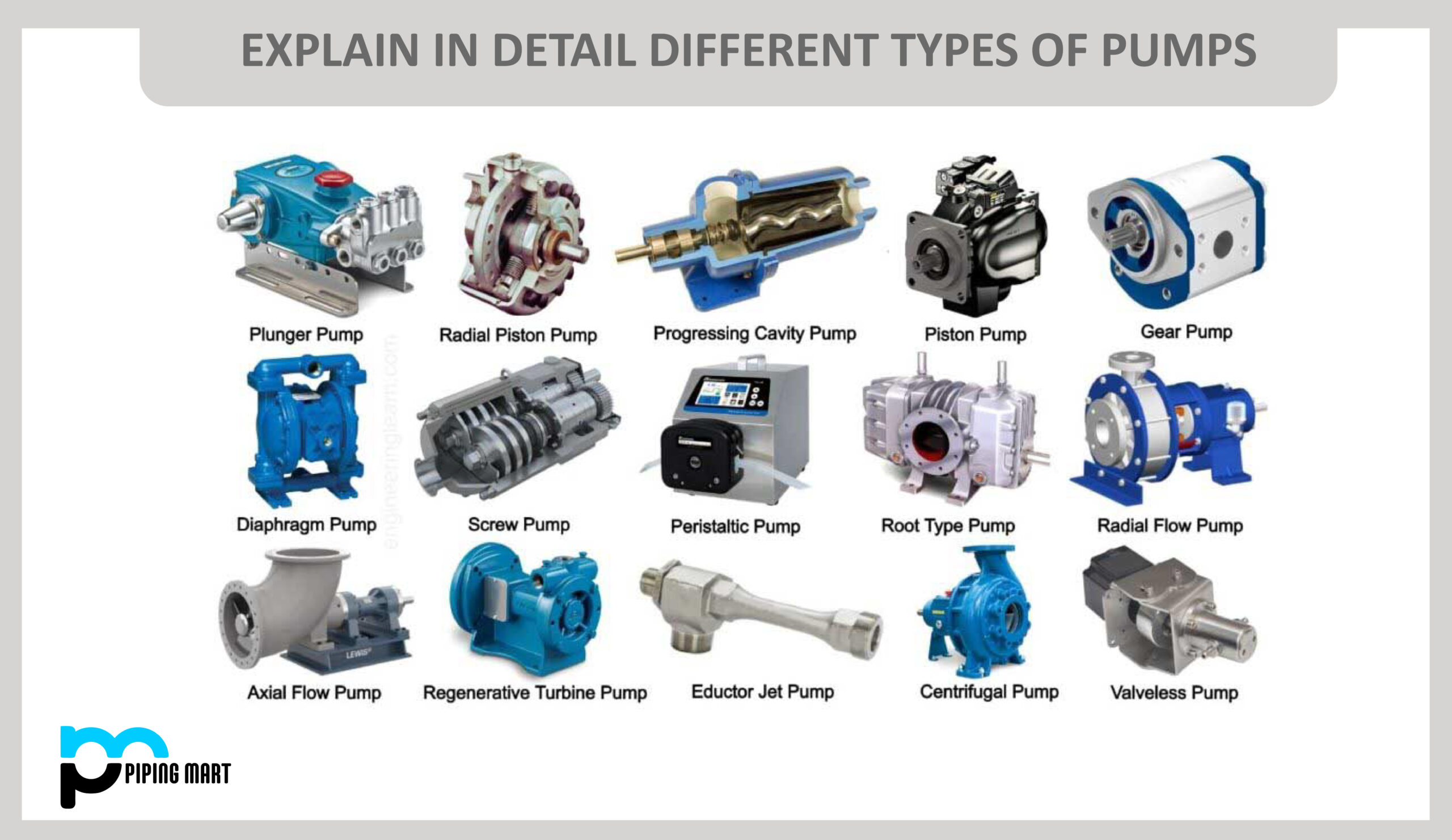

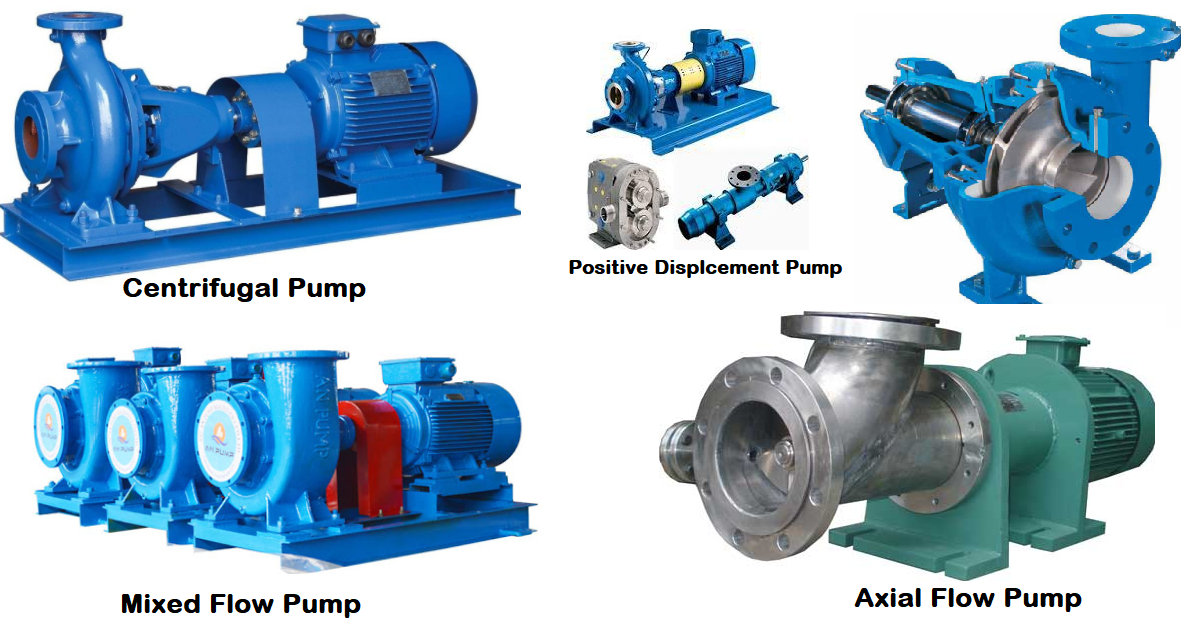

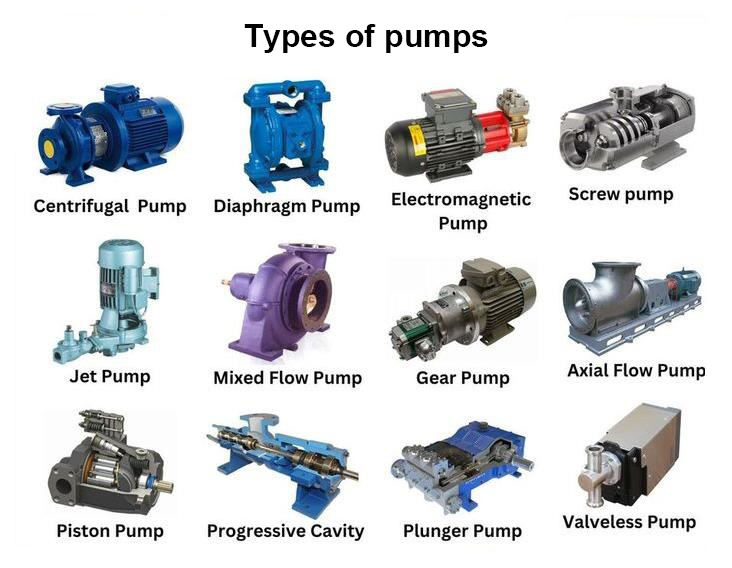

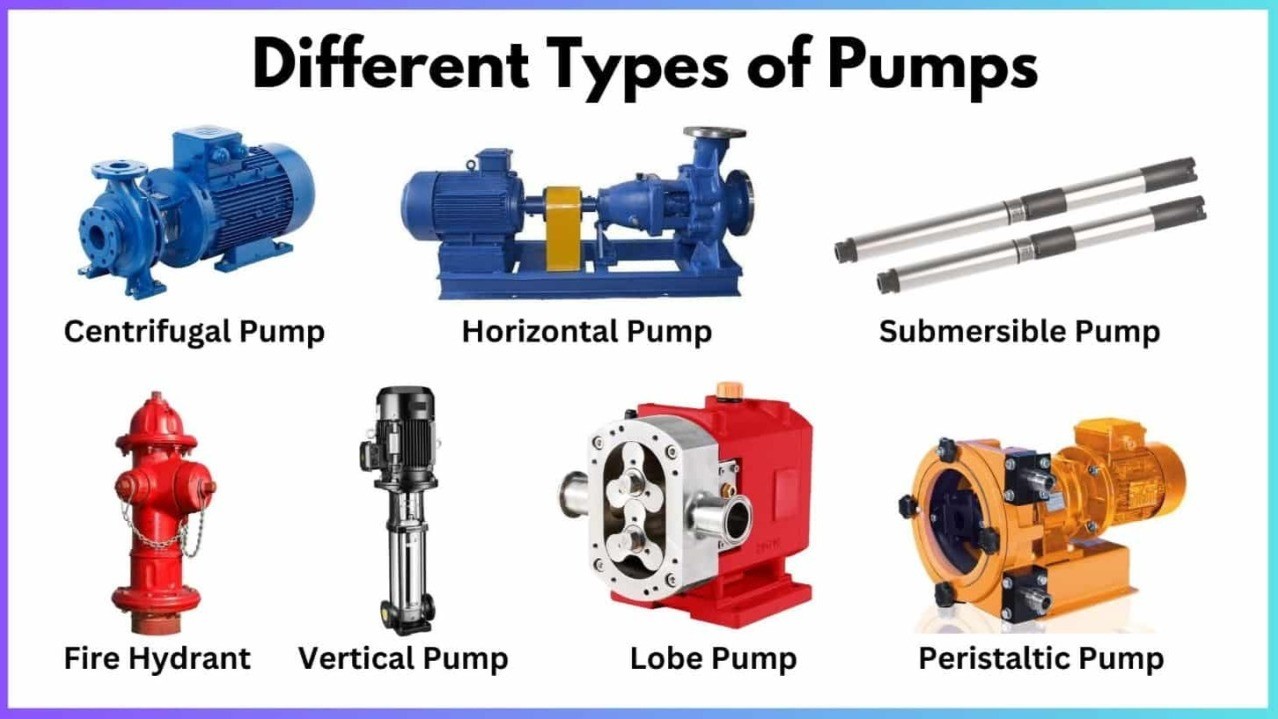

In the competitive landscape of industrial procurement, sourcing the right type of centrifugal pump can be a daunting task for B2B buyers, especially when navigating diverse market demands across Africa, South America, the Middle East, and Europe. This guide offers a comprehensive exploration of three essential types of centrifugal pumps: single-stage, multi-stage, and axial flow. Each type plays a pivotal role in various applications, from water supply and wastewater treatment to chemical processing and HVAC systems.

Understanding the unique characteristics, advantages, and limitations of these centrifugal pump types is crucial for making informed purchasing decisions. This guide delves into their specific applications, helping buyers assess which pumps align best with their operational needs. Additionally, we provide insights into supplier vetting, cost considerations, and maintenance requirements, ensuring that buyers are equipped with the knowledge necessary to optimize their procurement strategy.

By addressing key challenges and offering actionable insights, this guide empowers international B2B buyers to navigate the global market confidently. Whether you’re in Nigeria, Vietnam, or any other region, our goal is to facilitate informed decisions that enhance operational efficiency and drive business success.

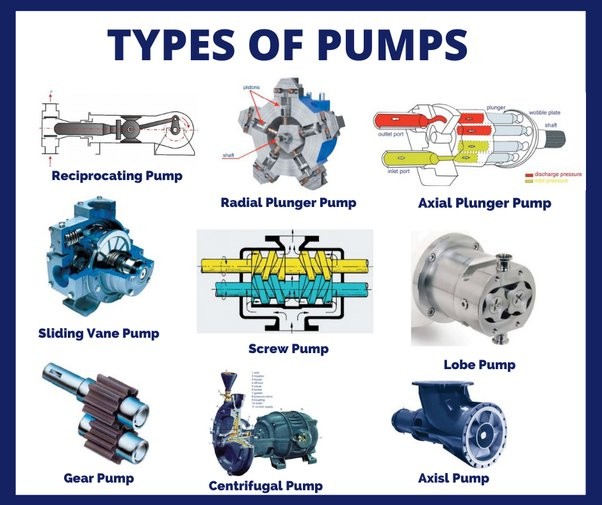

Understanding 3 types of centrifugal pumps Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-stage Centrifugal Pumps | One impeller, low to moderate pressure, simple design | Water supply, HVAC circulation | Pros: Cost-effective, easy maintenance. Cons: Limited pressure, not suitable for high-viscosity fluids. |

| Multi-stage Centrifugal Pumps | Multiple impellers for higher pressure generation | Boiler feed systems, water treatment plants | Pros: High pressure capability, efficient for viscous fluids. Cons: Higher cost, complex maintenance. |

| Axial Flow Centrifugal Pumps | Fluid moves parallel to shaft, high flow rates | Irrigation, flood control | Pros: Efficient for large volumes, compact design. Cons: Limited pressure generation, less effective at low flow rates. |

| Radial Flow Centrifugal Pumps | Fluid moves radially outward, versatile flow rates | Industrial processes, chemical processing | Pros: Good for moderate viscosity, wide application range. Cons: Susceptible to clogging, less efficient at low flow. |

| Self-priming Centrifugal Pumps | Automatically primes, designed for intermittent operation | Marine applications, drainage systems | Pros: No manual priming needed, prevents dry running. Cons: Lower efficiency, complex design. |

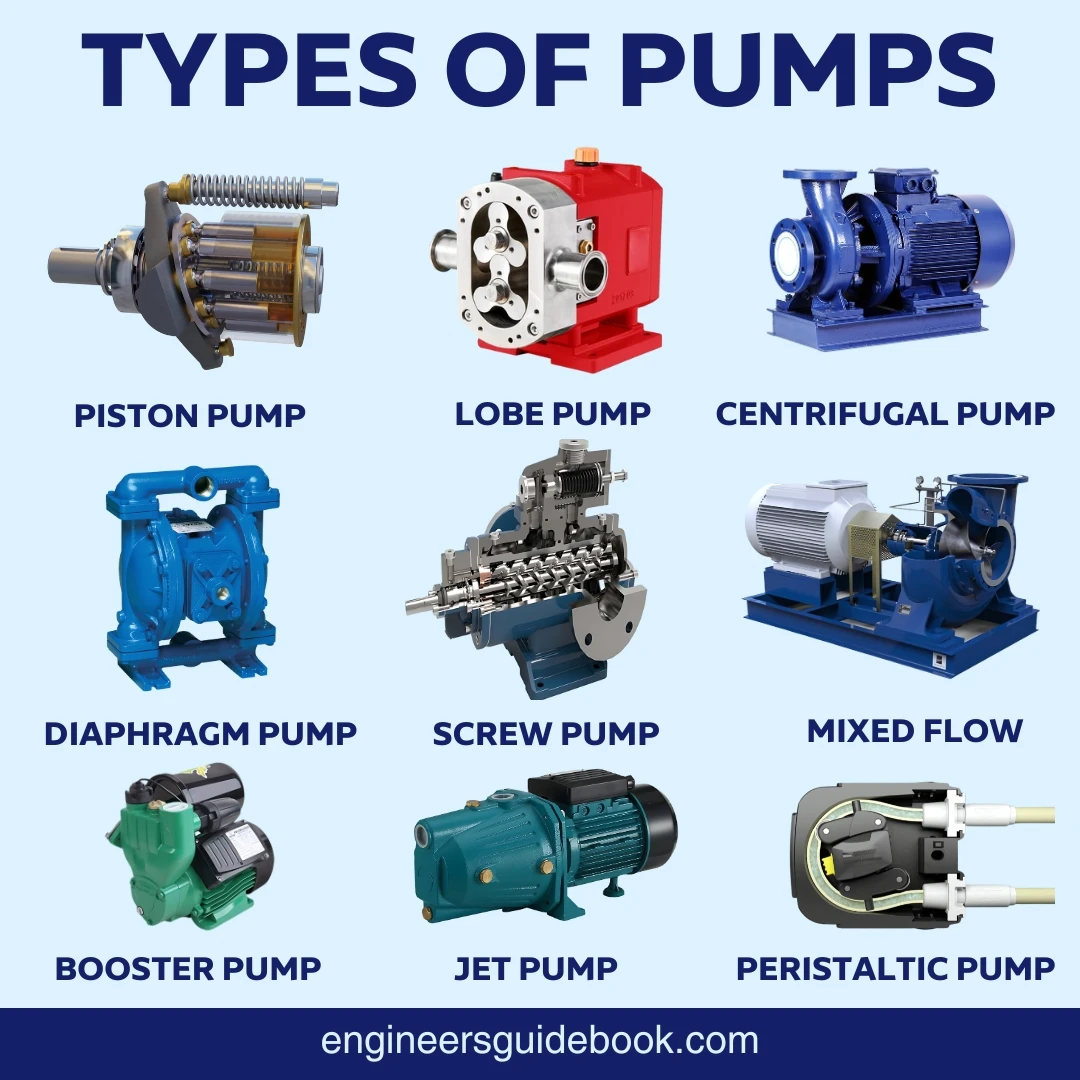

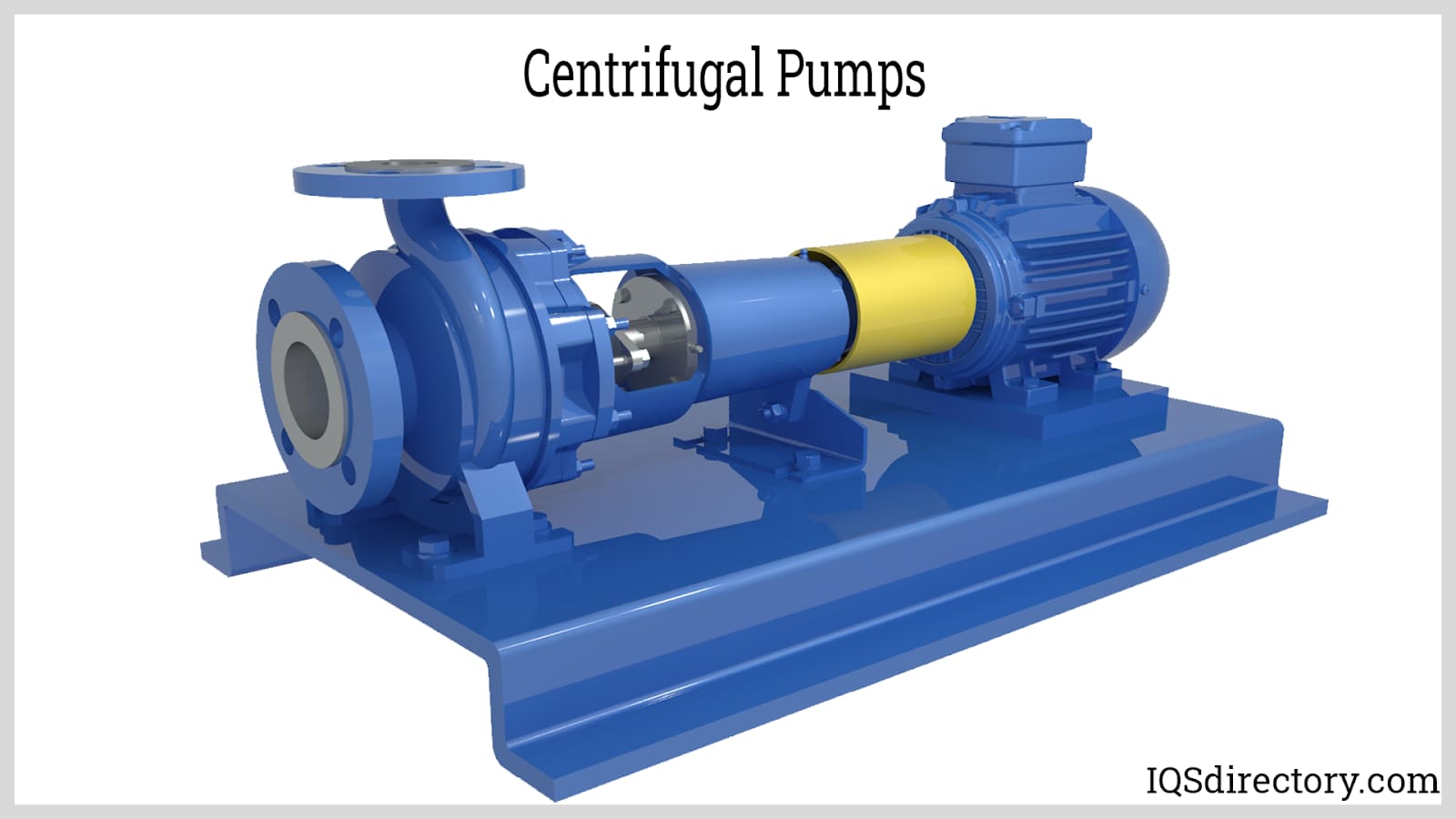

What Are the Characteristics of Single-stage Centrifugal Pumps?

Single-stage centrifugal pumps are characterized by their simple design, featuring a single impeller that efficiently handles low to moderate pressure applications. They are ideal for B2B buyers looking for cost-effective solutions in water supply systems, irrigation, and HVAC circulation. When considering a purchase, businesses should evaluate the fluid’s viscosity and the required pressure, as these pumps may not perform well in high-pressure or high-viscosity scenarios.

Illustrative image related to 3 types of centrifugal pumps

How Do Multi-stage Centrifugal Pumps Stand Out?

Multi-stage centrifugal pumps excel in applications requiring high pressure due to their multiple impellers arranged in series. This design allows them to generate significant pressure increases, making them suitable for boiler feed systems and water treatment plants. Buyers should weigh the initial investment against the efficiency and performance benefits, especially for fluids with higher viscosities. Maintenance considerations are also crucial, as these pumps require more complex servicing.

Why Choose Axial Flow Centrifugal Pumps for High Flow Rates?

Axial flow centrifugal pumps are designed to move fluid parallel to the pump shaft, making them highly efficient for applications with high flow rates, such as irrigation and flood control. Their compact design is advantageous in limited spaces. However, B2B buyers should note their limitations in pressure generation and efficiency at low flow rates, making them less suitable for applications that require high head.

What Makes Radial Flow Centrifugal Pumps Versatile?

Radial flow centrifugal pumps are versatile, moving fluid radially outward from the impeller’s center. They are well-suited for a variety of industrial processes, including chemical processing and water treatment. Buyers can benefit from their ability to handle moderate viscosity fluids and a wide range of flow rates. However, potential issues like clogging when handling solids should be considered, along with their efficiency at varying flow rates.

When to Consider Self-priming Centrifugal Pumps?

Self-priming centrifugal pumps are ideal for applications where manual priming is impractical, such as in marine environments or drainage systems. They feature built-in mechanisms that allow them to automatically remove air from the suction line. While they eliminate the need for manual intervention, buyers should consider their lower efficiency compared to traditional pumps and the complexity of their design, which may lead to higher maintenance requirements.

Key Industrial Applications of 3 types of centrifugal pumps

| Industry/Sector | Specific Application of 3 types of centrifugal pumps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Multi-stage pumps for pressure boosting in filtration systems | Ensures consistent water quality and supply under high demand | Efficiency ratings, durability in corrosive environments, and service support |

| Agriculture | Single-stage pumps for irrigation systems | Enhances crop yield through reliable water distribution | Energy efficiency, compatibility with local power sources, and ease of maintenance |

| Oil & Gas | Axial flow pumps for cooling and circulation in refineries | Improves operational efficiency and reduces downtime | Ability to handle high temperatures and viscosities, and compliance with safety standards |

| Construction | Self-priming pumps for dewatering applications | Prevents flooding and maintains site safety | Portability, ease of operation, and performance in varying water levels |

| HVAC | Radial flow pumps for chilled water circulation | Optimizes energy consumption and system reliability | Noise levels, energy efficiency, and compatibility with existing systems |

How Are Multi-Stage Pumps Used in Water Treatment Facilities?

Multi-stage centrifugal pumps are pivotal in water treatment plants, particularly for pressure boosting in filtration systems. These pumps enable the efficient movement of water through various treatment stages, ensuring consistent water quality despite fluctuating demand. For international buyers, especially from regions like Africa and South America, sourcing pumps that can withstand local water conditions and have robust service support is crucial. Moreover, the efficiency ratings of these pumps can directly impact operational costs, making it essential to consider energy-efficient models.

Illustrative image related to 3 types of centrifugal pumps

What Role Do Single-Stage Pumps Play in Agriculture?

In the agriculture sector, single-stage centrifugal pumps are commonly employed for irrigation systems. They provide a cost-effective solution for transporting water to crops, enhancing yield through reliable distribution. Buyers from regions such as Nigeria and Vietnam should prioritize pumps that offer energy efficiency and compatibility with local power sources to optimize operational costs. Additionally, ease of maintenance is vital to ensure minimal downtime during critical growing seasons.

How Are Axial Flow Pumps Beneficial in Oil & Gas Refineries?

Axial flow centrifugal pumps are utilized in oil and gas refineries for cooling and circulation processes. Their design allows for high flow rates at low pressure, making them ideal for moving large volumes of fluids efficiently. For B2B buyers in the Middle East, where temperatures can be extreme, sourcing pumps that can handle high temperatures and viscosities is essential. Compliance with industry safety standards is also a critical consideration to ensure operational integrity and worker safety.

Why Are Self-Priming Pumps Important in Construction?

Self-priming centrifugal pumps are crucial for dewatering applications in construction sites. They automatically remove air from the suction line, allowing for efficient operation without manual intervention. This capability is particularly beneficial in regions with unpredictable weather patterns, helping to prevent flooding and maintain site safety. Buyers should consider the portability and ease of operation of these pumps, as well as their performance in varying water levels, to ensure they meet the dynamic needs of construction projects.

Illustrative image related to 3 types of centrifugal pumps

How Do Radial Flow Pumps Enhance HVAC Systems?

Radial flow centrifugal pumps are integral to chilled water circulation in HVAC systems. They help optimize energy consumption and ensure reliable system performance, which is critical for maintaining comfortable indoor environments. For international buyers, especially in Europe, factors like noise levels and energy efficiency should be prioritized when sourcing these pumps. Compatibility with existing HVAC systems is also essential to facilitate seamless integration and minimize installation costs.

3 Common User Pain Points for ‘3 types of centrifugal pumps’ & Their Solutions

Scenario 1: Insufficient Pressure for High-Demand Applications

The Problem: A manufacturing facility in Nigeria relies on multi-stage centrifugal pumps to maintain the pressure required for their high-volume production lines. Recently, they have noticed a significant drop in output due to insufficient pressure, which is causing delays and increasing operational costs. The maintenance team suspects that the existing pumps are not adequately rated for the demands of the new processes they have implemented, leading to inefficiencies and potential downtime.

The Solution: To address this issue, it is crucial for the facility to conduct a thorough analysis of their current pump specifications and operational requirements. Begin by evaluating the flow rate and pressure needs of the production line to ensure that the selected multi-stage pumps can handle the increased demand. Consult with pump manufacturers to assess options that provide higher head capabilities and efficiency ratings. Additionally, consider integrating a variable frequency drive (VFD) to allow for dynamic adjustments to pump speed based on real-time demand, which can optimize performance while reducing energy consumption. Regular maintenance checks should also be instituted to ensure that the pumps are operating at peak performance, potentially including the replacement of worn components that could be impacting efficiency.

Scenario 2: Clogging Issues in Wastewater Treatment

The Problem: A wastewater treatment facility in Brazil is experiencing frequent clogging in their radial flow centrifugal pumps, which are critical for maintaining the flow of sewage through the treatment process. The clogs are often due to solids and debris that are not adequately managed, leading to increased maintenance costs and operational disruptions. This has resulted in a backlog of untreated waste, raising environmental compliance concerns.

The Solution: To mitigate clogging issues, the facility should first implement a pre-screening process to filter out larger solids before they enter the pump system. Upgrading to a pump with a larger diameter impeller can also help accommodate solids more effectively. Additionally, consider investing in a pump with a self-cleaning feature or a design specifically engineered to handle solids, such as a chopper pump. This would significantly reduce the frequency of clogs and maintenance interventions. Training operational staff on best practices for monitoring and managing incoming waste can further enhance system reliability and reduce operational downtime.

Illustrative image related to 3 types of centrifugal pumps

Scenario 3: Inefficient Energy Consumption in Industrial Circulation Systems

The Problem: A chemical processing plant in the Middle East has been facing escalating energy costs associated with their axial flow centrifugal pumps used for liquid circulation. The pumps are running at full capacity, leading to excessive energy consumption and higher-than-expected utility bills. Management is concerned that the inefficiencies may also shorten the lifespan of the pumps, leading to costly replacements.

The Solution: To combat this issue, the plant should perform an energy audit to identify inefficiencies in the current pumping system. It may be beneficial to replace existing pumps with more energy-efficient models designed to operate at lower energy levels while maintaining flow rates. Consideration should be given to implementing a system that includes real-time monitoring to analyze energy usage and performance metrics. This data can help in making informed decisions about pump operation schedules and maintenance needs. Additionally, training operators on optimizing pump operation, including adjusting for varying flow demands and ensuring that pumps are not oversized for the application, can lead to significant energy savings and extended equipment life.

Strategic Material Selection Guide for 3 types of centrifugal pumps

When selecting materials for centrifugal pumps, it is crucial to consider the specific requirements of the application, including fluid properties, operating conditions, and environmental factors. This analysis will focus on four common materials used in the construction of centrifugal pumps: cast iron, stainless steel, bronze, and thermoplastics. Each material offers unique advantages and limitations that impact performance and suitability for various applications.

What are the Key Properties of Cast Iron in Centrifugal Pumps?

Cast iron is a widely used material for centrifugal pumps, particularly in applications involving water and wastewater. Its key properties include excellent wear resistance, high strength, and good corrosion resistance when properly coated. Cast iron can typically withstand temperatures up to 200°C (392°F) and pressures of around 10 bar (145 psi).

Illustrative image related to 3 types of centrifugal pumps

Pros: Cast iron is durable and cost-effective, making it suitable for low to moderate pressure applications. Its ability to dampen vibrations also contributes to reduced noise levels during operation.

Cons: However, cast iron is susceptible to corrosion in aggressive environments, which may necessitate additional protective coatings. It can also be heavy, impacting installation and transportation costs.

Impact on Application: Cast iron is ideal for handling clean and slightly contaminated fluids, but its limitations in corrosive environments may restrict its use in certain industrial applications.

Illustrative image related to 3 types of centrifugal pumps

How Does Stainless Steel Perform in Centrifugal Pumps?

Stainless steel is favored for its superior corrosion resistance and strength, making it suitable for a wide range of fluids, including those that are corrosive or abrasive. It can withstand higher temperatures (up to 300°C or 572°F) and pressures (up to 20 bar or 290 psi) compared to cast iron.

Pros: The durability and aesthetic appeal of stainless steel make it an excellent choice for food processing and pharmaceutical applications. Its resistance to rust and staining enhances longevity.

Cons: The primary drawback is its higher cost compared to cast iron. Additionally, stainless steel can be more challenging to machine and fabricate, which may increase manufacturing complexity.

Illustrative image related to 3 types of centrifugal pumps

Impact on Application: Stainless steel is particularly effective for applications involving harsh chemicals, making it a preferred choice in industries such as oil and gas, chemical processing, and food and beverage.

What Advantages Does Bronze Offer for Centrifugal Pumps?

Bronze is another material option, known for its excellent corrosion resistance and ability to handle seawater and other aggressive media. It typically operates effectively at temperatures up to 150°C (302°F) and pressures around 10 bar (145 psi).

Pros: Bronze is lightweight and has good mechanical properties, making it easy to fabricate and install. Its resistance to corrosion and biofouling makes it suitable for marine applications.

Cons: The main limitation of bronze is its relatively high cost compared to cast iron. Additionally, it may not be as strong as stainless steel, limiting its use in high-pressure applications.

Illustrative image related to 3 types of centrifugal pumps

Impact on Application: Bronze is ideal for applications in marine environments, HVAC systems, and water treatment, where corrosion resistance is critical.

Why Consider Thermoplastics for Centrifugal Pumps?

Thermoplastics, such as polypropylene and PVC, are increasingly used in centrifugal pumps due to their lightweight nature and excellent chemical resistance. They can typically handle temperatures up to 60°C (140°F) and pressures around 5 bar (72 psi).

Pros: The primary advantage of thermoplastics is their resistance to a wide range of chemicals, making them suitable for corrosive fluids. They are also lightweight and easy to install, reducing overall system costs.

Cons: However, thermoplastics may not be suitable for high-temperature or high-pressure applications and can be less durable than metals, leading to potential wear issues over time.

Impact on Application: Thermoplastics are particularly effective for applications involving aggressive chemicals, such as in chemical processing and wastewater treatment.

Summary of Material Selection for Centrifugal Pumps

| Material | Typical Use Case for 3 types of centrifugal pumps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Water supply, irrigation, HVAC systems | Cost-effective and durable | Susceptible to corrosion | Low |

| Stainless Steel | Chemical processing, food and beverage applications | Superior corrosion resistance | Higher manufacturing complexity | High |

| Bronze | Marine applications, HVAC systems | Excellent corrosion resistance | Higher cost and lower strength | Med |

| Thermoplastics | Chemical processing, wastewater treatment | Lightweight and chemically resistant | Limited temperature and pressure range | Low |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their specific application requirements and operational conditions.

Illustrative image related to 3 types of centrifugal pumps

In-depth Look: Manufacturing Processes and Quality Assurance for 3 types of centrifugal pumps

What Are the Typical Manufacturing Processes for Centrifugal Pumps?

The manufacturing of centrifugal pumps involves a series of meticulously organized processes to ensure quality, efficiency, and reliability. Understanding these processes can help B2B buyers make informed decisions when selecting suppliers.

How Is Material Prepared for Centrifugal Pumps?

The first stage in manufacturing centrifugal pumps involves material preparation. Common materials include cast iron, stainless steel, and various polymers, selected based on application requirements such as corrosion resistance and strength. Material preparation includes:

-

Material Selection: Choosing the appropriate material is critical. For example, stainless steel is often used for food and chemical applications due to its resistance to corrosion, while cast iron is favored for its durability in general industrial uses.

-

Material Processing: This may involve cutting, melting, or molding the selected materials into usable forms. Techniques such as casting and forging are employed to create the pump’s components, including impellers, casings, and shafts.

-

Quality Inspection: Before moving to the next stage, materials undergo inspection for defects, ensuring that only high-quality materials are used in the pump assembly. This is typically done through visual inspections and non-destructive testing methods.

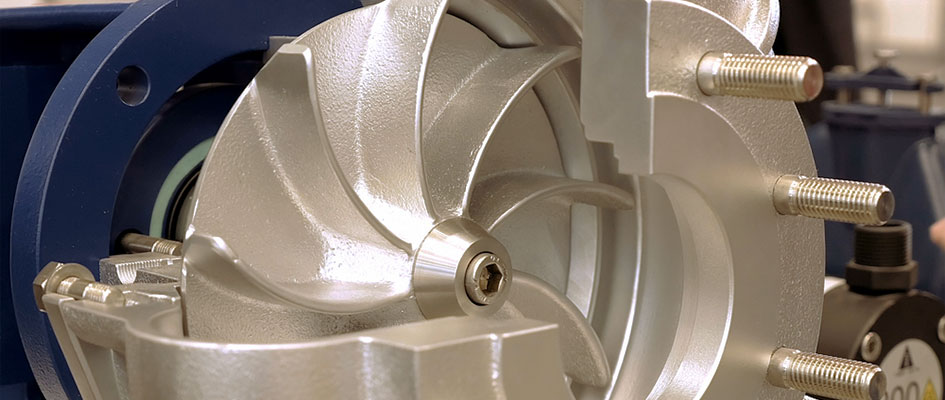

What Forming Techniques Are Used in Centrifugal Pump Manufacturing?

The forming stage is crucial, as it shapes the components that will make up the centrifugal pump. Key techniques include:

-

Casting: Most centrifugal pumps are produced using casting methods, where molten metal is poured into molds to create complex shapes. Sand casting and investment casting are common methods.

-

Machining: After casting, components often require machining to achieve precise dimensions and surface finishes. Techniques such as milling, turning, and grinding are used to ensure that parts fit together seamlessly.

-

Welding and Assembly: For multi-stage pumps, individual components are welded or bolted together. This stage may also involve the installation of seals and bearings, which are essential for the pump’s operation.

How Is the Assembly Process Conducted for Centrifugal Pumps?

The assembly process for centrifugal pumps involves integrating all components to create a functioning unit. This includes:

-

Sub-Assembly: Components like impellers and volutes are often assembled separately before final assembly. Each sub-assembly is tested for functionality.

-

Final Assembly: The sub-assemblies are brought together, and additional components such as motors and drive systems are installed. It’s essential to ensure alignment and fit during this stage to avoid operational issues.

-

Testing: After assembly, pumps undergo initial testing to verify that they meet design specifications. This includes checking for leaks and ensuring proper operation.

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance is paramount in the manufacturing of centrifugal pumps to ensure reliability and performance. International and industry-specific standards guide these processes.

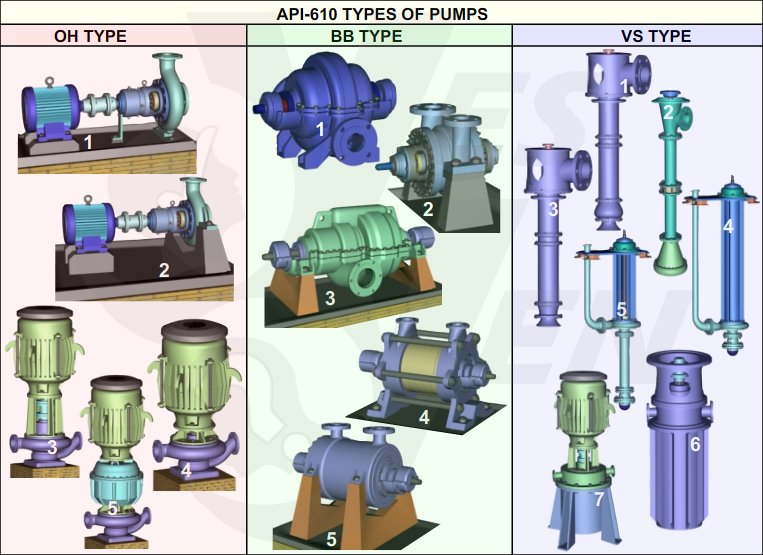

Which International Standards Are Relevant for Centrifugal Pumps?

Manufacturers typically adhere to various international standards, including:

- ISO 9001: This standard provides a framework for quality management systems, ensuring consistent quality in manufacturing processes.

- CE Marking: In Europe, this mark indicates compliance with health, safety, and environmental protection standards.

- API Standards: The American Petroleum Institute (API) provides guidelines specifically for pumps used in the oil and gas industry, ensuring they can handle the unique demands of this sector.

What Are the Key QC Checkpoints During the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival at the facility to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, inspections are conducted at various stages to catch defects early. This may include measuring dimensions and testing for material properties.

-

Final Quality Control (FQC): After assembly, pumps undergo rigorous testing to verify their performance. This includes pressure tests, flow tests, and vibration analysis to ensure they operate within specified parameters.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several strategies:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing practices and quality control measures. This includes reviewing documentation and observing processes firsthand.

-

Quality Assurance Reports: Requesting detailed reports on a supplier’s quality assurance processes can help buyers assess compliance with international standards and verify testing procedures.

-

Third-Party Inspections: Engaging third-party inspectors can add an additional layer of verification. These independent firms can conduct thorough inspections and testing, providing unbiased assessments of product quality.

What Are the Nuances of QC Certification for International Buyers?

For B2B buyers in diverse regions, understanding the nuances of QC certification is vital. Here are key considerations:

-

Cultural and Regulatory Differences: Different countries may have varying regulations and standards for quality assurance. Buyers should familiarize themselves with local requirements to ensure compliance.

-

Language Barriers: Documentation and communication may be hindered by language differences. Ensure that suppliers can provide materials in a language that is understood by the buyer’s team.

-

Supply Chain Transparency: Buyers should look for suppliers who maintain transparency in their supply chain, as this can significantly impact the quality of the final product. This includes knowing the sources of raw materials and the manufacturing processes used.

By understanding the manufacturing processes and quality assurance measures for centrifugal pumps, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 types of centrifugal pumps’

Introduction

This practical sourcing guide is designed to assist B2B buyers in effectively procuring three types of centrifugal pumps: single-stage, multi-stage, and self-priming. By following this checklist, buyers can ensure they select the right pump type for their specific applications while navigating supplier options with confidence.

Illustrative image related to 3 types of centrifugal pumps

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is critical to ensuring the selected pump meets operational demands. Consider factors such as flow rate, head pressure, fluid characteristics (viscosity, temperature), and the type of application (e.g., irrigation, industrial processes). This clarity will help you communicate effectively with suppliers and narrow down suitable options.

Step 2: Identify Your Application Needs

Understanding the specific application for which the pump will be used is essential. Different centrifugal pumps are optimized for varying scenarios—single-stage pumps are ideal for lower pressure, while multi-stage pumps excel in high-pressure situations. By identifying your needs, you can avoid overspending on unnecessary features or under-specifying your pump.

Step 3: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in centrifugal pumps. Look for companies with a proven track record in your region or industry, as they are more likely to understand local market conditions and regulatory requirements. Evaluate their online presence, customer reviews, and case studies to gauge reliability and performance.

Step 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that include pricing, lead times, and delivery options. A comprehensive quote should outline all costs associated with the procurement, including installation and maintenance services. This transparency will help you compare suppliers effectively and make informed decisions based on total cost of ownership.

Step 5: Verify Supplier Certifications and Compliance

Ensure that your chosen supplier meets industry certifications and regulatory compliance standards relevant to your application. Certifications like ISO 9001 or CE marking indicate adherence to quality and safety standards. This step not only mitigates risk but also assures you of the product’s quality and reliability.

Step 6: Evaluate After-Sales Support and Maintenance Services

Assess the level of after-sales support and maintenance services offered by suppliers. A good supplier should provide comprehensive service agreements, including troubleshooting, repairs, and regular maintenance schedules. This support is crucial for maximizing pump efficiency and extending its operational lifespan.

Step 7: Finalize the Purchase Agreement

Before finalizing the purchase, carefully review the terms and conditions of the sale. Pay attention to warranty provisions, return policies, and payment terms. Having clear and mutually agreed-upon terms protects both parties and fosters a positive working relationship moving forward.

Illustrative image related to 3 types of centrifugal pumps

By following these steps, B2B buyers can navigate the procurement process for centrifugal pumps with greater confidence and ensure they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for 3 types of centrifugal pumps Sourcing

What Are the Key Cost Components in Sourcing Centrifugal Pumps?

When sourcing centrifugal pumps, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials like stainless steel, cast iron, and thermoplastics vary in price and durability. Higher-grade materials often lead to increased longevity and efficiency.

-

Labor: Labor costs can fluctuate based on geographic location and the complexity of the manufacturing process. Skilled labor may be required for assembling specialized pumps, leading to higher labor costs.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can reduce overhead costs, positively impacting the pricing structure.

-

Tooling: Custom tooling for specific pump configurations can add to initial costs. However, investing in quality tooling can enhance manufacturing efficiency and product consistency over time.

-

Quality Control (QC): Implementing rigorous QC measures ensures product reliability, but it also adds to costs. Buyers should consider the balance between quality assurance and pricing.

-

Logistics: Shipping and handling costs can vary widely based on the destination and Incoterms. For international buyers, understanding logistics can help mitigate unexpected expenses.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition, demand, and the supplier’s brand reputation.

How Do Price Influencers Affect Centrifugal Pump Costs?

Several factors can influence the pricing of centrifugal pumps, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounted prices. Understanding the supplier’s MOQ can help in negotiating better rates.

-

Specifications and Customization: Custom-built pumps tailored to specific applications can significantly increase costs. Buyers should evaluate whether standard models could meet their needs to save on expenses.

-

Material Choices: Selecting different materials can alter both the pump’s performance and its price. Buyers should weigh the benefits of higher-cost materials against potential savings in maintenance and longevity.

-

Quality and Certifications: Pumps with recognized certifications (e.g., ISO, API) may carry a premium price. However, these certifications can ensure higher reliability and compliance with industry standards, which is crucial for many applications.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Established suppliers may command higher prices but offer better reliability and service.

-

Incoterms: Understanding Incoterms is essential for international transactions, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This can affect the total landed cost of the pumps.

What Buyer Tips Can Enhance Cost-Efficiency in Pump Sourcing?

To navigate the complexities of sourcing centrifugal pumps effectively, buyers should consider the following strategies:

-

Negotiation: Engage in discussions with suppliers to negotiate pricing based on volume, payment terms, or long-term contracts. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Total Cost of Ownership (TCO): Focus not just on the purchase price but also on the TCO, which includes installation, maintenance, and operational costs. A lower initial cost may result in higher long-term expenses if the pump requires frequent repairs or is less efficient.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and local regulations that may affect pricing. Conduct thorough research on the market conditions in your region to anticipate potential cost changes.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and access to the latest technologies. Consider establishing partnerships with reliable suppliers to ensure ongoing support.

-

Research and Due Diligence: Invest time in understanding the different types of centrifugal pumps and their applications. This knowledge will enable you to make better purchasing decisions and avoid over-specifying or under-specifying your needs.

In conclusion, a comprehensive understanding of the cost components, price influencers, and strategic purchasing tips can empower international B2B buyers to make informed decisions when sourcing centrifugal pumps. Always remember that pricing can fluctuate based on various factors, so staying informed is key to achieving the best value.

Illustrative image related to 3 types of centrifugal pumps

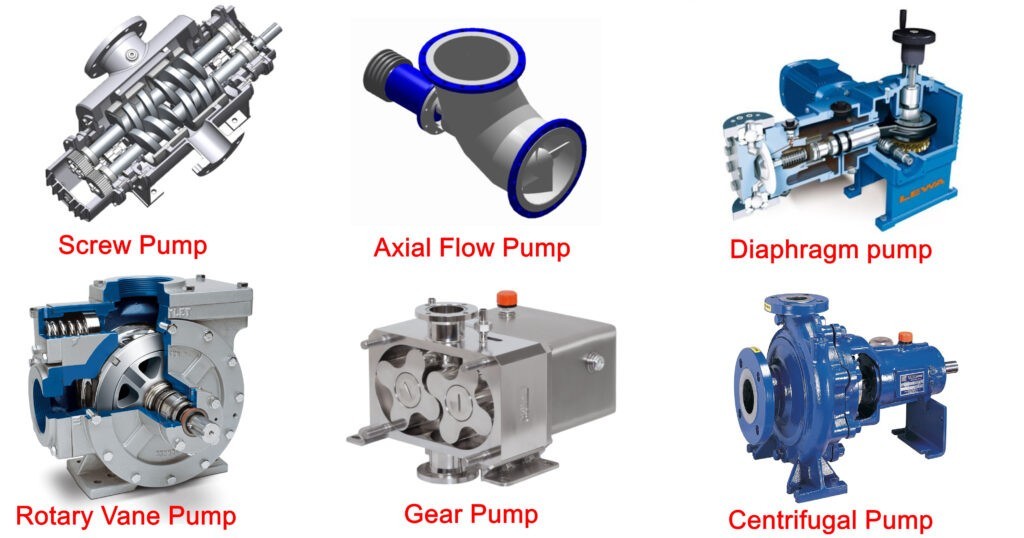

Alternatives Analysis: Comparing 3 types of centrifugal pumps With Other Solutions

Exploring Alternatives to Centrifugal Pumps: A Comparative Analysis

In the quest for effective fluid transfer solutions, businesses often weigh the advantages of centrifugal pumps against alternative technologies. Understanding these alternatives can guide B2B buyers in selecting the most suitable option for their specific operational needs. This analysis compares three types of centrifugal pumps—single-stage, multi-stage, and submersible—with two alternative solutions: positive displacement pumps and diaphragm pumps.

Comparison Table

| Comparison Aspect | 3 Types Of Centrifugal Pumps | Positive Displacement Pumps | Diaphragm Pumps |

|---|---|---|---|

| Performance | Efficient for various flow rates; suitable for low to moderate pressures | Excellent for high-viscosity fluids; generates high pressure | Ideal for precise flow control and handling slurries |

| Cost | Generally cost-effective; varies by type | Higher initial investment; cost-efficient for high-viscosity applications | Moderate cost; economical for small-scale operations |

| Ease of Implementation | Simple installation; varies by type | More complex; requires precise alignment | Straightforward installation; can be mounted in various orientations |

| Maintenance | Moderate; requires regular inspections and cleaning | Higher maintenance needs due to wear | Low maintenance; minimal parts subject to wear |

| Best Use Case | Water supply, HVAC systems, and industrial processes | Oil and gas, chemical processing | Food and beverage, pharmaceuticals, and wastewater treatment |

Detailed Breakdown of Alternatives

Positive Displacement Pumps

Positive displacement pumps operate by trapping a fixed volume of fluid and forcing it through the discharge pipe. They are particularly effective for high-viscosity fluids and applications requiring high pressure. The advantages include their ability to maintain a consistent flow rate regardless of pressure changes, making them ideal for oil and gas industries. However, they tend to be more expensive initially, and their maintenance can be more intensive due to wear and tear on moving parts.

Diaphragm Pumps

Diaphragm pumps utilize a flexible diaphragm that oscillates to create a pumping action. They excel in applications requiring precise flow control, such as in the food and beverage industry or pharmaceuticals. The major benefits include low maintenance needs and the ability to handle slurries or fluids with solids without clogging. While they are generally less costly than positive displacement pumps, their performance may not match that of centrifugal pumps in high-flow applications.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a fluid transfer solution, B2B buyers must consider the specific requirements of their applications. Centrifugal pumps offer versatility and efficiency for a wide range of uses, while positive displacement pumps provide superior pressure capabilities for high-viscosity fluids. Diaphragm pumps, on the other hand, are ideal for applications demanding precision and low maintenance. By evaluating performance, cost, ease of implementation, maintenance needs, and best use cases, buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for 3 types of centrifugal pumps

What Are the Essential Technical Properties of Centrifugal Pumps?

When selecting centrifugal pumps, understanding their technical properties is crucial for ensuring optimal performance and compatibility with specific applications. Here are several critical specifications to consider:

1. Material Grade

The material grade of a centrifugal pump refers to the type of materials used in its construction, which can include stainless steel, cast iron, and thermoplastics. The choice of material affects the pump’s durability, resistance to corrosion, and suitability for different fluids. For instance, pumps made from stainless steel are ideal for chemical processing due to their resistance to aggressive fluids, while cast iron is often used in water supply applications.

2. Flow Rate

Flow rate measures the volume of fluid the pump can move within a specified time, typically expressed in liters per minute (L/min) or gallons per minute (GPM). This specification is vital for ensuring that the pump meets the requirements of the application, whether it’s for irrigation, industrial processes, or wastewater management. Understanding flow rate helps buyers avoid underperformance or overcapacity situations.

3. Head (Pressure)

Head is a measure of the pressure generated by the pump, expressed in meters or feet. It indicates the height to which the pump can raise a fluid. Different applications require different head levels; for example, multi-stage pumps are suitable for high-pressure needs in oil refineries, while single-stage pumps are sufficient for low-pressure applications. Selecting a pump with the appropriate head ensures efficient fluid transfer.

Illustrative image related to 3 types of centrifugal pumps

4. Efficiency Rating

The efficiency rating of a centrifugal pump indicates how effectively it converts input energy into hydraulic energy. Higher efficiency ratings lead to lower operational costs and energy consumption. It is particularly important for B2B buyers focused on long-term operational efficiency and sustainability, as inefficient pumps can significantly increase energy expenditures over time.

5. Tolerance and Clearances

Tolerance refers to the allowable variations in dimensions and clearances between moving parts within the pump. Proper tolerances are critical for preventing wear and tear, ensuring smooth operation, and extending the pump’s lifespan. Understanding the tolerances required for specific applications helps buyers select pumps that will perform reliably under varying conditions.

What Are Common Trade Terms Used in the Centrifugal Pump Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the centrifugal pump market. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of centrifugal pumps, OEMs often provide pumps tailored to specific industrial requirements, ensuring compatibility and quality.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory costs effectively and assess the financial feasibility of a purchase.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific products or services. Providing detailed specifications in an RFQ can lead to more accurate pricing and better alignment with project requirements.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, risk transfer, and costs associated with freight, which is particularly important for international procurement.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. In the centrifugal pump industry, understanding lead times is vital for project planning and ensuring timely delivery, particularly in industries with strict operational deadlines.

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions, ensuring they select the right centrifugal pump for their specific needs and optimize their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the 3 types of centrifugal pumps Sector

What Are the Current Market Dynamics for Centrifugal Pumps Globally?

The centrifugal pump market is experiencing robust growth, driven by increasing industrialization, urbanization, and the expanding water and wastewater treatment sectors across Africa, South America, the Middle East, and Europe. Key trends include the integration of smart technologies, such as IoT-enabled monitoring systems, which enhance operational efficiency and predictive maintenance. As businesses aim to optimize their processes, the demand for energy-efficient and high-performance pumps has surged, particularly in sectors like oil and gas, chemical processing, and power generation.

Emerging sourcing trends highlight a shift toward local suppliers to mitigate risks associated with global supply chains. B2B buyers are increasingly seeking partnerships with manufacturers who can offer customized solutions tailored to specific applications. This trend is particularly pronounced in regions like Africa and South America, where local conditions necessitate unique pump configurations. Additionally, sustainability considerations are becoming paramount, with buyers actively seeking pumps designed for low energy consumption and minimal environmental impact.

International buyers must navigate these dynamics by staying informed about technological advancements and understanding regional market variations. Engaging with suppliers who are adaptable to shifting demands and who prioritize innovation can significantly enhance procurement strategies.

How Are Sustainability and Ethical Sourcing Influencing Centrifugal Pump Procurement?

Sustainability is a critical factor influencing the centrifugal pump sector, as companies increasingly recognize the environmental impact of their operations. The production and operation of pumps can contribute significantly to energy consumption and carbon emissions. Therefore, sourcing pumps that are energy-efficient and designed for longevity has become essential. B2B buyers should prioritize suppliers that adhere to sustainability standards and offer energy-efficient models that help reduce operational costs while minimizing environmental footprints.

Ethical sourcing also plays a pivotal role in the procurement process. Buyers are increasingly scrutinizing the supply chain for transparency and accountability, looking for manufacturers that demonstrate a commitment to ethical labor practices and environmentally responsible materials. Certifications such as ISO 14001 (Environmental Management) and Energy Star can serve as benchmarks for evaluating potential suppliers.

Moreover, the adoption of green materials in manufacturing processes is gaining traction. Pumps made from recyclable materials or designed for easy disassembly can contribute to a circular economy, further appealing to environmentally conscious buyers. By prioritizing sustainability and ethical sourcing, B2B buyers not only enhance their brand reputation but also align with global initiatives aimed at reducing environmental impact.

What Is the Historical Context of Centrifugal Pumps and Their Evolution?

The history of centrifugal pumps dates back to the 17th century, with early designs focusing on simple mechanical principles. Initially, these pumps were used primarily for irrigation and drainage in agricultural settings. The industrial revolution marked a significant turning point, as the demand for efficient fluid transfer systems grew in factories and processing plants.

Throughout the 20th century, advancements in materials science and engineering led to the development of more sophisticated designs, including multi-stage and self-priming pumps. These innovations expanded the applications of centrifugal pumps, making them integral to various industries, from water supply to chemical processing.

Illustrative image related to 3 types of centrifugal pumps

Today, the centrifugal pump sector continues to evolve with the incorporation of digital technologies, emphasizing the need for B2B buyers to remain agile and informed about historical trends and their implications for future procurement strategies. Understanding the evolution of centrifugal pumps allows buyers to make informed decisions, leveraging historical insights to guide contemporary sourcing practices.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 types of centrifugal pumps

-

1. How do I select the right centrifugal pump for my application?

Choosing the right centrifugal pump involves assessing your specific application requirements, including flow rate, head pressure, and fluid characteristics such as viscosity and temperature. For instance, a single-stage pump is suitable for low-pressure applications, while a multi-stage pump is ideal for high-pressure needs. Additionally, consider environmental factors and space constraints to determine the most fitting pump type. Consulting with manufacturers or suppliers can provide insights tailored to your operational needs. -

2. What are the advantages of multi-stage centrifugal pumps?

Multi-stage centrifugal pumps are designed for high-pressure applications, offering a series of impellers that incrementally increase fluid pressure. Their ability to handle higher viscosities makes them suitable for industries like oil and gas, water treatment, and industrial processing. Although they have a higher initial cost and more complex maintenance requirements, their efficiency in producing high pressure and flow rates can yield significant operational benefits over time. -

3. What factors should I consider when sourcing centrifugal pumps internationally?

When sourcing centrifugal pumps internationally, consider factors such as supplier reliability, product quality, compliance with local standards, and after-sales support. Verify the supplier’s reputation through customer reviews, certifications, and previous project experience. Additionally, understand the logistics involved, including shipping costs, delivery timelines, and customs regulations in your country. Ensuring clear communication about your specifications and expectations can prevent misunderstandings and delays. -

4. What is the minimum order quantity (MOQ) for centrifugal pumps?

Minimum order quantities for centrifugal pumps can vary significantly by manufacturer and pump type. Many suppliers may have a MOQ of 10 to 50 units, while others may offer flexibility for smaller orders, especially for custom or specialized pumps. It’s advisable to discuss your specific needs with the supplier to negotiate terms that suit your purchasing plans and inventory strategies. -

5. How can I ensure the quality of the centrifugal pumps I purchase?

To ensure quality, request product certifications and compliance documentation from suppliers, such as ISO standards. Consider conducting factory audits or quality assurance checks, especially for larger orders. Additionally, evaluate suppliers’ warranty policies and after-sales service offerings, which can provide insights into their commitment to product quality. Engaging with third-party inspection services can also be beneficial in validating product specifications before shipment. -

6. What payment terms should I expect when purchasing centrifugal pumps?

Payment terms can vary based on supplier policies and your negotiation. Common terms include a deposit upfront (typically 30-50%) with the balance due before shipment or upon delivery. Some suppliers may offer credit terms for established relationships. It’s essential to clarify payment methods accepted (e.g., bank transfer, letter of credit) and any potential fees associated with international transactions to avoid unexpected costs. -

7. How can I customize centrifugal pumps for my specific needs?

Customization options for centrifugal pumps often include adjustments to materials, sizes, and performance specifications such as flow rates and pressure limits. Discuss your requirements with the supplier during the initial inquiry phase to understand the available customization options. Some manufacturers may offer tailored solutions that can improve efficiency or compatibility with your existing systems, while others might have standard models with limited customization. -

8. What logistics considerations should I keep in mind when importing centrifugal pumps?

When importing centrifugal pumps, consider logistics aspects such as shipping methods, costs, and delivery timelines. Evaluate whether to use air or sea freight based on urgency and budget. Additionally, ensure that you understand import duties, taxes, and any special handling required for heavy machinery. Collaborating with a freight forwarder can help streamline the process, ensuring compliance with local regulations and smooth customs clearance.

Top 4 3 Types Of Centrifugal Pumps Manufacturers & Suppliers List

1. Rotech Pumps – Types of Centrifugal Pumps

Domain: rotechpumps.com

Registered: 2002 (23 years)

Introduction: Types of Centrifugal Pumps: 1. Single-stage Centrifugal Pumps: – One impeller, low to moderate-pressure applications. – Components: impeller, casing, volute, shaft, bearings, mechanical seals. – Advantages: simplicity, cost-effective, suitable for clean/slightly contaminated fluids. – Limitations: limited head generation, less efficient for high-viscosity fluids. – Common applications: water suppl…

2. DXPE – Centrifugal Pumps

Domain: dxpe.com

Registered: 1997 (28 years)

Introduction: Centrifugal pumps are used in various domestic and industrial processes, including water supply for residential buildings, food and beverage manufacturing, and chemical manufacturing. Key types include: 1. Radial Pumps: Outward motion of liquid, pressurized and exited through downstream piping. 2. Axial Pumps: Generate fluid motion via lifting effect of impeller vanes. 3. ANSI Pumps: High-quality,…

3. IQS Directory – Centrifugal Pumps

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Centrifugal pumps are hydraulic mechanisms that convert mechanical energy into hydraulic energy through centrifugal force. Key components include: 1. Shaft – connects to the prime mover and turns with the impeller. 2. Impeller – consists of backwards-curved vanes that impart velocity to the liquid. 3. Casing – a sealed passage that converts velocity into pressure energy; types include volute casin…

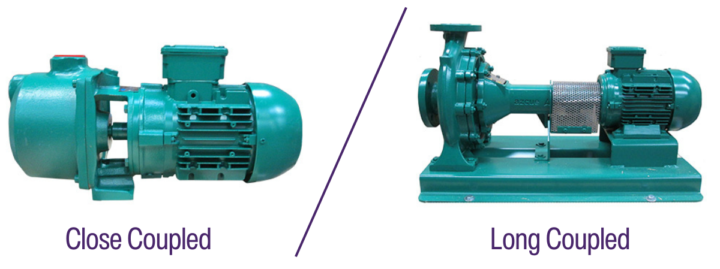

4. Castle Pumps – Types of Centrifugal Pumps

Domain: castlepumps.com

Registered: 2007 (18 years)

Introduction: Types of Centrifugal Pumps: Close Coupled Pumps, Long Coupled Pumps, Vertical Inline Pumps, Horizontal Pumps, Magnetic Drive Pumps, Mechanically Sealed Pumps. Applications: Industrial Pumps, Marine Pumps, Abrasive Fluid Pumps, Adhesive & Resin Pumps, Biogas Pumps, Brewery Pumps, Chemical Pumps, Cooling Pumps, Corrosive Liquid Pumps, Distillery Pumps, Dosing Pumps, Edible Oil Pumps, Food Grade Pump…

Strategic Sourcing Conclusion and Outlook for 3 types of centrifugal pumps

In the competitive landscape of industrial fluid management, understanding the diverse types of centrifugal pumps—single-stage, multi-stage, axial flow, radial flow, mixed flow, self-priming, and submersible—is essential for effective sourcing strategies. Each type serves unique applications, from high-pressure systems in oil refineries to efficient water circulation in HVAC setups. International buyers must prioritize factors such as flow rates, fluid properties, and operational requirements to ensure optimal selection and performance.

Strategic sourcing not only enhances procurement efficiency but also fosters partnerships with reliable manufacturers who prioritize quality and innovation. As markets in Africa, South America, the Middle East, and Europe continue to evolve, establishing robust supply chains will be crucial for sustaining operational success.

Looking ahead, B2B buyers are encouraged to leverage insights from this guide to make informed decisions that align with their specific needs. Embrace the opportunity to engage with suppliers who understand the local context and can offer tailored solutions. By doing so, you will not only optimize your pump selection but also drive long-term value for your organization in a rapidly changing global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.