Aerogel For Sale: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for aerogel for sale

In the quest for sourcing aerogel for sale, international B2B buyers often face the challenge of navigating a complex market filled with diverse suppliers and product variations. Aerogels, celebrated for their exceptional insulation properties and lightweight nature, are increasingly sought after across various industries, including construction, energy, and aerospace. This comprehensive guide aims to demystify the global aerogel market by providing actionable insights into the different types of aerogels available, their applications, and key factors to consider when evaluating suppliers.

Throughout this guide, you will discover detailed information on the myriad forms of aerogels—ranging from silica and carbon aerogels to specialized aerogel blankets—and their specific applications in thermal insulation, catalysis, and even artistic endeavors. Additionally, we will explore essential criteria for vetting suppliers, ensuring that you make informed decisions that align with your organization’s goals and standards.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Brazil, understanding these dynamics is crucial. This guide empowers you to navigate the intricacies of the aerogel market, enabling you to identify reliable suppliers, assess cost implications, and ultimately enhance your procurement strategy with confidence. Embrace the potential of aerogels and unlock innovative solutions for your business needs.

Understanding aerogel for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Silica Aerogel | High thermal insulation, lightweight, fragile | Insulation in construction, aerospace | Pros: Excellent thermal performance; Cons: Brittle, requires careful handling. |

| Hydrophobic Silica Aerogel | Water-resistant, maintains insulation properties in damp conditions | Oil and gas applications, construction | Pros: Suitable for moisture-prone environments; Cons: Higher cost than standard silica. |

| Carbon Aerogel | High electrical conductivity, lightweight | Supercapacitors, batteries, electronics | Pros: Versatile for energy applications; Cons: Limited structural integrity. |

| Aerogel Blankets | Flexible, lightweight, and available in various thicknesses | Thermal insulation in industrial applications | Pros: Easy to install; Cons: May not offer the same insulation as rigid forms. |

| Precision Aerogel Particles | Nano-sized particles for enhanced surface area and reactivity | Research, catalysis, and experimentation | Pros: High reactivity and customization; Cons: Handling and storage challenges. |

What Are the Key Characteristics of Classic Silica Aerogel?

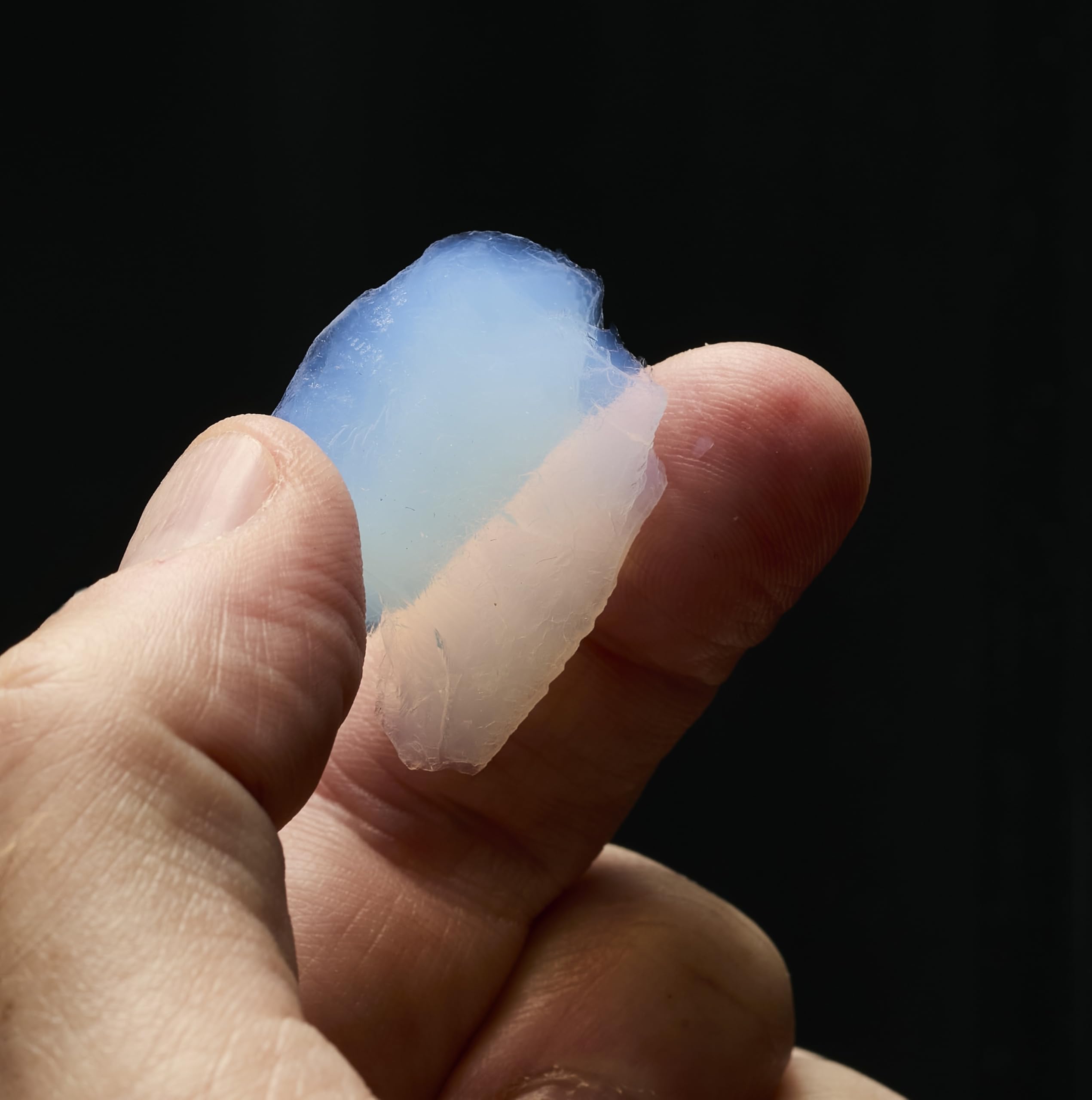

Classic Silica Aerogel is known for its exceptional thermal insulation properties, being composed of up to 99% air. This lightweight material is often used in applications requiring effective thermal barriers, such as aerospace and construction. However, its fragility necessitates careful handling during installation and transport. B2B buyers should consider the specific thermal performance requirements of their projects when selecting this aerogel type, keeping in mind the necessity for protective measures during use.

How Does Hydrophobic Silica Aerogel Differ from Other Types?

Hydrophobic Silica Aerogel is specifically designed to repel water, making it ideal for applications in environments where moisture exposure is a concern, such as oil and gas sectors. This type retains its insulation properties even when subjected to damp conditions. While it offers unique advantages, the cost is generally higher than that of standard silica aerogels, which may influence purchasing decisions for budget-conscious buyers. It’s essential for B2B clients to evaluate the long-term benefits versus initial costs.

What Are the Advantages of Using Carbon Aerogel?

Carbon Aerogel stands out due to its excellent electrical conductivity, making it a prime candidate for energy storage applications such as supercapacitors and batteries. Its lightweight nature and high surface area contribute to its effectiveness in electronic components. However, potential buyers should be aware of its limited structural integrity compared to silica-based aerogels. When considering Carbon Aerogel, B2B buyers should assess the specific electrical performance needs of their applications.

Why Choose Aerogel Blankets for Thermal Insulation?

Aerogel Blankets offer a flexible and lightweight solution for thermal insulation across various industrial applications. Available in different thicknesses, these blankets can be easily installed, providing a practical option for retrofitting existing systems. However, while they are convenient, they may not achieve the same level of insulation as more rigid aerogel forms. B2B buyers should analyze the insulation requirements of their projects and the ease of installation when selecting aerogel blankets.

What Are the Applications of Precision Aerogel Particles?

Precision Aerogel Particles are characterized by their nanoscale size, which enhances their reactivity and surface area, making them suitable for research and catalysis. Their customization potential allows for tailored applications, which can be particularly beneficial in scientific experimentation. However, handling and storage can pose challenges due to their fine nature. B2B buyers interested in these particles should consider the specific experimental needs and ensure proper handling protocols are in place.

Key Industrial Applications of aerogel for sale

| Industry/Sector | Specific Application of aerogel for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Insulation for pipelines and storage tanks | Reduces energy costs and enhances safety in extreme environments | Ensure compliance with local regulations and safety standards |

| Construction | Thermal insulation in buildings | Increases energy efficiency and reduces HVAC costs | Look for customized solutions to meet specific building codes |

| Aerospace | Lightweight insulation for spacecraft | Minimizes weight while maximizing thermal protection | Seek suppliers with aerospace-grade certifications |

| Electronics | Components in batteries and supercapacitors | Improves energy density and overall performance | Verify material purity and compatibility with existing systems |

| Environmental Technology | Filtration systems for air and water purification | Enhances efficiency in pollutant removal | Assess the effectiveness of aerogel in specific environmental conditions |

How is Aerogel Used in the Oil & Gas Industry?

In the oil and gas sector, aerogel serves as an advanced insulation material for pipelines and storage tanks. Its unique properties allow it to withstand extreme temperatures while significantly reducing energy costs associated with heating and cooling. For international buyers in regions like Nigeria and Brazil, sourcing aerogel requires attention to local regulations governing safety and environmental impact. Buyers should also consider suppliers that can provide technical support and installation guidance to optimize performance.

What Role Does Aerogel Play in Construction Projects?

Aerogel is increasingly utilized in construction for thermal insulation, helping to create energy-efficient buildings. Its lightweight nature and superior insulating properties allow architects and builders to design structures that require less energy for heating and cooling, thereby lowering operational costs. Buyers from Europe and the Middle East should focus on sourcing aerogel products that comply with local building codes and standards, ensuring that the materials meet specific thermal performance requirements.

How is Aerogel Beneficial for Aerospace Applications?

In aerospace, aerogel is used as lightweight insulation for spacecraft and satellite components, providing exceptional thermal protection without adding significant weight. This is crucial for mission success, as every gram counts in aerospace engineering. International buyers should seek suppliers with aerospace-grade certifications to guarantee that the aerogel meets rigorous industry standards. Additionally, understanding the specific thermal and mechanical requirements of their applications will aid in selecting the right type of aerogel.

What Advantages Does Aerogel Offer in Electronics?

Aerogel is increasingly incorporated into electronic devices, particularly in batteries and supercapacitors, where it enhances energy density and overall performance. Its lightweight and conductive properties make it an ideal material for next-generation electronic applications. Businesses in South America and Africa should prioritize sourcing high-purity aerogel to ensure compatibility with existing systems, as well as to maximize energy efficiency in their products.

How Can Aerogel Improve Environmental Technology Solutions?

Aerogel’s unique structure makes it an excellent choice for filtration systems in air and water purification applications. Its high surface area allows for effective pollutant removal, enhancing the efficiency of environmental technologies. Buyers looking to implement aerogel in these applications should evaluate the effectiveness of the material under specific environmental conditions, and ensure that suppliers can provide the necessary technical data to support their claims.

3 Common User Pain Points for ‘aerogel for sale’ & Their Solutions

Scenario 1: Fragility Concerns with Aerogel Products

The Problem: B2B buyers often face significant challenges regarding the fragility of aerogel materials. When purchasing aerogel, especially for industrial applications, the risk of damage during shipping or handling is a major concern. Buyers may worry about receiving products that are chipped or broken, which can lead to wasted resources and delays in project timelines. These issues are exacerbated in regions with less reliable shipping infrastructures, where the risk of mishandling increases.

The Solution: To mitigate the risk of fragility, buyers should prioritize sourcing from suppliers that offer robust packaging solutions specifically designed for aerogel products. When placing an order, communicate your concerns about handling and shipping. Request suppliers to use reinforced materials or cushioning that can withstand rough transit conditions. Additionally, consider ordering samples before committing to larger quantities to assess the product’s durability firsthand. It is also advisable to establish a clear return policy with the supplier in case the product does arrive damaged. This proactive approach can help ensure that you receive high-quality aerogel that meets your project needs without unexpected setbacks.

Scenario 2: Difficulty in Selecting the Right Aerogel Type

The Problem: Many B2B buyers struggle with the complexity of choosing the right type of aerogel for their specific applications. Aerogels come in various forms, such as monoliths, particles, and blankets, each tailored for different uses, from thermal insulation to lightweight structural components. This can lead to confusion and potentially costly mistakes if the wrong type is selected, especially for projects in sectors like construction or aerospace, where material properties are critical.

The Solution: Buyers should invest time in understanding the unique properties of the various aerogel types and how they align with their application requirements. Utilize resources like product comparison guides and technical datasheets provided by suppliers. Engaging with technical support teams or engineers from the aerogel manufacturer can also provide valuable insights. When in doubt, consider customizing your order; many suppliers offer tailored solutions that can optimize material properties for your specific needs. By being informed and leveraging supplier expertise, you can confidently select the appropriate aerogel product to enhance your project’s success.

Scenario 3: Limited Knowledge About Aerogel Applications

The Problem: A common pain point for B2B buyers is the limited understanding of aerogel’s potential applications. Many companies may recognize aerogel as a cutting-edge material but lack comprehensive knowledge about its diverse uses in industries such as energy, construction, and aerospace. This lack of awareness can lead to missed opportunities for innovation and efficiency improvements in their operations.

The Solution: To expand your knowledge of aerogel applications, invest in educational resources such as webinars, whitepapers, and case studies offered by aerogel manufacturers and industry experts. Additionally, attending industry conferences and networking events can provide insights into the latest trends and innovations involving aerogel. Collaborating with R&D teams can also be beneficial; they can experiment with aerogel in pilot projects to uncover its potential benefits in your specific context. By actively seeking knowledge and fostering a culture of innovation within your organization, you can effectively leverage aerogel technologies to improve product performance and operational efficiency.

Strategic Material Selection Guide for aerogel for sale

What Are the Key Properties of Common Aerogel Materials for B2B Buyers?

When selecting aerogel materials for specific applications, understanding their properties is crucial. Here, we analyze several common types of aerogels available in the market, focusing on their performance characteristics, advantages, disadvantages, and implications for international B2B buyers.

1. Silica Aerogel

Key Properties:

Silica aerogel is renowned for its exceptional thermal insulation properties, with a temperature resistance of up to 1,200°C. It is lightweight, with a density of approximately 3-15 kg/m³, and exhibits low thermal conductivity, making it ideal for thermal insulation applications.

Pros & Cons:

The primary advantage of silica aerogel is its outstanding insulation performance, which can significantly reduce energy costs in industrial applications. However, it is brittle and can be prone to chipping, which may affect its durability in harsh environments. Additionally, the manufacturing process can be complex, leading to higher costs.

Impact on Application:

Silica aerogel is compatible with various media, including gases and liquids, making it suitable for applications in the oil and gas industry, construction, and aerospace. Its fragility may limit its use in applications requiring mechanical strength.

Considerations for International Buyers:

B2B buyers from regions like Africa and South America should consider local availability and compliance with international standards such as ASTM or DIN. Understanding the specific insulation requirements of local climates can also influence material choice.

2. Carbon Aerogel

Key Properties:

Carbon aerogel is characterized by its high surface area and electrical conductivity, making it suitable for applications in energy storage and supercapacitors. It can withstand temperatures up to 1,000°C and has excellent mechanical properties.

Pros & Cons:

The key advantage of carbon aerogel is its versatility in energy applications, particularly in batteries and supercapacitors. However, it tends to be more expensive than silica aerogel, and its production can be less environmentally friendly due to the use of toxic solvents.

Impact on Application:

Carbon aerogel’s properties make it ideal for applications in renewable energy sectors, particularly in energy storage systems. Its compatibility with various electrolytes enhances its functionality in supercapacitors.

Considerations for International Buyers:

Buyers in regions with emerging energy markets, such as the Middle East, should evaluate the environmental regulations surrounding carbon aerogel production. Compliance with local standards for energy efficiency can also impact purchasing decisions.

3. Hydrophobic Aerogel

Key Properties:

Hydrophobic aerogels are designed to repel water, making them suitable for applications in humid environments. They maintain thermal insulation properties while being resistant to moisture, with a temperature rating similar to silica aerogels.

Pros & Cons:

The main advantage is their ability to perform in wet conditions without compromising insulation efficiency. However, they can be more expensive due to additional processing steps to achieve hydrophobicity, and their mechanical strength may still be a concern.

Impact on Application:

Hydrophobic aerogels are particularly useful in applications involving moisture-laden environments, such as construction in tropical regions or oil drilling in wet conditions.

Considerations for International Buyers:

B2B buyers in humid climates, such as Nigeria and Brazil, should prioritize hydrophobic aerogels to ensure long-term performance. Understanding local building codes and standards for moisture resistance is essential for compliance.

Summary Table of Aerogel Materials

| Material | Typical Use Case for aerogel for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silica Aerogel | Thermal insulation in construction | Exceptional thermal insulation properties | Brittle and prone to chipping | High |

| Carbon Aerogel | Energy storage in batteries | High surface area and electrical conductivity | More expensive and less environmentally friendly | High |

| Hydrophobic Aerogel | Moisture-resistant insulation | Performs well in humid environments | Higher cost due to additional processing | Medium |

This strategic material selection guide provides B2B buyers with essential insights into aerogel materials, enabling informed decisions tailored to specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for aerogel for sale

What Are the Main Stages in the Manufacturing Process of Aerogel?

The manufacturing of aerogel involves several critical stages that ensure the production of high-quality materials suitable for various applications.

Material Preparation

The first step in aerogel production is material preparation, which typically involves the selection and processing of silica or other precursor materials. Silica is often preferred due to its favorable properties, including high thermal stability and low density. The materials are subjected to a series of chemical reactions to produce a gel. This stage may include the use of solvents and catalysts, which are crucial for controlling the properties of the final product.

Forming

Once the gel is prepared, the next stage is forming. This involves shaping the gel into the desired configuration, which can be in the form of monoliths, particles, or blankets. Techniques such as sol-gel processing are commonly employed, where the gel undergoes a transition from a liquid to a solid state. This is a delicate process, as the gel must maintain its structure while transitioning into a solid form.

Assembly

After forming, the aerogel pieces may require assembly, especially when producing larger components or composite materials. This step can involve the combination of aerogel with other materials to enhance its properties, such as mechanical strength or thermal resistance. Adhesives or bonding agents may be used, and care must be taken to ensure compatibility between materials.

Finishing

The final stage is finishing, which includes drying and any necessary surface treatments. Supercritical drying is a common method, where the gel is dried in a manner that avoids collapsing its structure. This method preserves the unique properties of aerogel, such as its low density and high porosity. Additional finishing processes may involve coating or texturing the aerogel to enhance its performance for specific applications.

How Is Quality Assurance Implemented in Aerogel Manufacturing?

Quality assurance (QA) is paramount in ensuring that aerogel products meet the high standards required by various industries, such as aerospace, construction, and energy.

What International Standards Are Relevant for Aerogel Quality Assurance?

Manufacturers often adhere to international standards like ISO 9001, which focuses on quality management systems. Compliance with these standards indicates a commitment to consistent quality and continuous improvement. Industry-specific certifications, such as CE marking for European markets and API standards for oil and gas applications, are also crucial. These certifications ensure that the products meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in Aerogel Production?

Quality control (QC) is integrated throughout the manufacturing process, with several key checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for consistency and compliance with specifications. Suppliers should provide certification for the materials used, which can help in verifying their quality.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular checks are conducted to monitor the processes and ensure that they are within specified parameters. This includes monitoring temperature, pressure, and chemical concentrations to ensure optimal conditions for aerogel formation.

-

Final Quality Control (FQC): Once the aerogels are formed and finished, they undergo thorough testing to verify their properties. This includes density measurements, thermal conductivity tests, and mechanical strength assessments. Products that do not meet the established criteria are rejected or reworked.

What Testing Methods Are Commonly Used in Aerogel Quality Control?

Aerogel manufacturers utilize a variety of testing methods to ensure product performance:

-

Thermal Conductivity Testing: This assesses how well the aerogel insulates. The lower the thermal conductivity, the better the material performs in insulation applications.

-

Mechanical Testing: This includes evaluating the compressive strength and flexibility of aerogel, which are critical for applications where structural integrity is essential.

-

Porosity Analysis: Understanding the pore size and distribution helps determine the aerogel’s effectiveness for specific applications, such as filtration or catalysis.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for ensuring that the aerogel products will meet their needs.

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is one of the most effective ways to verify quality control practices. Buyers should request access to the supplier’s quality management documentation, including ISO certifications and internal quality control procedures.

How Important Are Reports and Third-Party Inspections?

In addition to audits, requesting detailed quality assurance reports can provide insights into the supplier’s manufacturing processes and QC results. Engaging third-party inspection services can also add an additional layer of verification, ensuring that the products meet international standards before shipment.

What Are the QC/CERT Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances in quality assurance and certification when sourcing aerogel products. Different countries may have unique regulations regarding material safety and environmental standards. For instance, products sold in the European market must comply with REACH regulations, which govern chemical safety.

Additionally, language barriers and differences in certification processes can pose challenges. Buyers should ensure that their suppliers can provide documentation in an understandable format and that they are familiar with the regulatory landscape in their respective markets.

Conclusion

Understanding the manufacturing processes and quality assurance measures in aerogel production is crucial for B2B buyers seeking reliable suppliers. By familiarizing themselves with the stages of production, quality control checkpoints, testing methods, and the intricacies of international standards, buyers can make informed decisions that ensure the procurement of high-quality aerogel products tailored to their specific needs. This proactive approach not only mitigates risk but also fosters long-term partnerships with suppliers committed to excellence in aerogel manufacturing.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aerogel for sale’

In this practical sourcing guide, we provide a detailed checklist for B2B buyers interested in procuring aerogel. This lightweight, highly insulating material has applications across various industries, from construction to aerospace. Following this checklist will ensure a smooth procurement process while maximizing value and minimizing risks.

Step 1: Define Your Technical Specifications

Before you begin sourcing aerogel, it is essential to clearly define your technical requirements. This includes understanding the specific type of aerogel you need, such as silica, carbon, or hydrophobic aerogel, and its intended application, whether for insulation, lightweight materials, or scientific experimentation.

– Key Considerations:

– Thermal conductivity and insulation properties.

– Mechanical strength and durability based on usage conditions.

Step 2: Research Potential Suppliers

Start by compiling a list of potential suppliers who specialize in aerogel products. Utilize industry directories, trade shows, and online platforms to identify reputable vendors.

– What to Look For:

– Supplier experience in the aerogel market.

– Range of products offered to ensure they can meet your specific needs.

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is crucial for ensuring product quality and compliance with international standards. Check for certifications such as ISO 9001, which indicates a commitment to quality management systems.

– Important Certifications:

– Environmental certifications (e.g., ISO 14001) for sustainability.

– Safety standards relevant to your region or industry.

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the aerogel products you are considering. Testing samples allows you to evaluate the material’s performance against your specifications.

– Evaluation Criteria:

– Conduct thermal and mechanical tests to assess insulation properties.

– Check for any fragility or handling issues based on the supplier’s handling instructions.

Step 5: Inquire About Custom Solutions

If standard products do not meet your needs, ask suppliers about custom solutions. Many aerogel manufacturers offer tailored products designed to specific requirements, which can enhance your application.

– Questions to Ask:

– What customization options are available?

– What is the lead time for custom orders?

Step 6: Compare Pricing and Payment Terms

Once you have shortlisted suppliers, compare their pricing and payment terms. Ensure that you consider the total cost of ownership, including shipping, taxes, and potential tariffs, especially for international transactions.

– Factors to Consider:

– Discounts for bulk purchases.

– Payment terms that align with your cash flow requirements.

Step 7: Review Delivery and After-Sales Support

Confirm the delivery timelines and after-sales support provided by the supplier. Reliable delivery schedules and robust support systems are vital for maintaining operational efficiency.

– Key Support Aspects:

– Warranty and return policies.

– Technical support availability for installation or application challenges.

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for aerogel and ensure they make informed purchasing decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for aerogel for sale Sourcing

What Are the Key Cost Components in Aerogel Sourcing?

When considering the sourcing of aerogel, understanding the cost structure is essential for B2B buyers. The main cost components include:

-

Materials: The primary raw materials for aerogel production are silica and specialized chemicals. The quality and source of these materials can significantly influence the final price. High-purity silica, for example, tends to be more expensive but offers better performance.

-

Labor: The manufacturing process of aerogel is labor-intensive, requiring skilled technicians for handling and processing. Labor costs can vary widely by region, impacting overall pricing, especially in countries with higher wage standards.

-

Manufacturing Overhead: This includes costs related to the facility, utilities, and equipment maintenance. Aerogel production often involves advanced technology, which can lead to higher overhead costs.

-

Tooling: Custom molds and tools for aerogel manufacturing can add to the initial costs. If specific shapes or sizes are required, these tooling expenses can be significant.

-

Quality Control (QC): Ensuring that aerogel meets industry standards necessitates rigorous testing and quality assurance processes. This adds to the overall cost but is crucial for maintaining product integrity and reliability.

-

Logistics: Transporting aerogel, particularly in bulk, requires careful handling due to its fragile nature. Shipping costs can escalate, especially for international buyers, due to packaging requirements and potential tariffs.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. This can vary based on market demand and competition.

How Do Price Influencers Affect Aerogel Costs?

Several factors can influence the pricing of aerogel:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often come with discounts, making it advantageous for buyers to consolidate purchases. However, new buyers may face higher unit costs if they cannot meet MOQ.

-

Specifications and Customization: Customized aerogel products tailored to specific applications can incur additional costs. Buyers should be prepared to negotiate based on their unique requirements.

-

Material Quality and Certifications: Higher-grade materials and products with recognized certifications (ISO, ASTM) command premium prices. For industries requiring stringent compliance, investing in certified products can yield long-term benefits.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their brand value and quality assurance processes.

-

Incoterms: The terms of shipping and delivery (Incoterms) can significantly impact the final cost. Buyers should understand which costs they are responsible for, including insurance, duties, and taxes.

What Tips Can Help Buyers Negotiate Better Pricing for Aerogel?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the following tips can enhance negotiation strategies:

-

Conduct Thorough Market Research: Understanding the average market rates for aerogel can empower buyers during negotiations. This knowledge can help in assessing whether a quote is fair.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider logistics, handling, and potential waste due to fragility. A lower upfront cost may lead to higher TCO if not managed properly.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Suppliers are often more willing to negotiate with repeat customers.

-

Be Clear About Requirements: Clearly articulate specifications and needs upfront. This can help avoid misunderstandings that could lead to increased costs later in the process.

-

Explore Multiple Suppliers: Don’t settle on the first supplier. Comparing multiple quotes can reveal a range of pricing and terms, enabling better decision-making.

Are There Any Pricing Nuances International Buyers Should Be Aware Of?

International buyers should be particularly mindful of currency fluctuations and their impact on pricing. Additionally, understanding local market conditions, including tariffs and import regulations, is crucial. These factors can significantly influence the final cost of aerogel, making it essential to account for them during the budgeting process.

Disclaimer: The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek updated quotes from suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing aerogel for sale With Other Solutions

Understanding Alternative Solutions to Aerogel for Sale

When considering materials for insulation and other industrial applications, aerogel is often a leading choice due to its unique properties. However, there are alternative solutions that may fit specific business needs. This analysis compares aerogel with two viable alternatives: polyurethane foam and fiberglass insulation. Each option has distinct advantages and drawbacks, making it crucial for B2B buyers to evaluate them based on performance, cost, and ease of implementation.

| Comparison Aspect | Aerogel For Sale | Polyurethane Foam | Fiberglass Insulation |

|---|---|---|---|

| Performance | Exceptional insulation, lightweight, high thermal efficiency | Good thermal insulation, moderate weight | Moderate thermal insulation, heavier than aerogel |

| Cost | Higher initial cost, but potential long-term savings | Moderate cost, widely available | Lower upfront cost, but variable long-term performance |

| Ease of Implementation | Requires careful handling, custom solutions available | Easy to install, versatile | Requires professional installation, can be cumbersome |

| Maintenance | Low maintenance, durable under proper conditions | Moderate maintenance, can degrade over time | Moderate maintenance, susceptible to moisture |

| Best Use Case | High-performance applications (e.g., aerospace, oil & gas) | General insulation (e.g., buildings, refrigeration) | Affordable insulation for residential and commercial buildings |

Detailed Breakdown of Alternatives

Polyurethane Foam

Polyurethane foam is a popular insulation material known for its good thermal performance and versatility. It is easier to implement than aerogel, often requiring minimal professional skills for installation. The material is commonly used in both residential and commercial applications, making it widely available and cost-effective. However, it may not provide the same level of insulation efficiency as aerogel, especially in extreme temperatures. Additionally, polyurethane can degrade over time, necessitating periodic maintenance or replacement.

Fiberglass Insulation

Fiberglass insulation is one of the most traditional insulation materials on the market. It is cost-effective, with a lower upfront price than both aerogel and polyurethane foam. Its moderate thermal insulation properties make it suitable for a variety of applications, particularly in residential construction. However, fiberglass can be cumbersome to install and often requires professional assistance. Furthermore, it is more susceptible to moisture, which can lead to mold and reduced insulation effectiveness over time.

Making the Right Choice for Your Business Needs

When selecting the right insulation solution, B2B buyers must consider the specific requirements of their applications. Aerogel offers unparalleled performance in high-demand environments, making it ideal for industries like aerospace and oil and gas. Conversely, polyurethane foam and fiberglass insulation are more suitable for general applications where cost and ease of installation are higher priorities.

By thoroughly evaluating the performance, cost, maintenance, and ease of implementation, businesses can make informed decisions that align with their operational needs and financial constraints. Ultimately, the best choice will depend on balancing initial investments with long-term benefits, ensuring that the selected material meets both current and future demands.

Essential Technical Properties and Trade Terminology for aerogel for sale

What Are the Key Technical Properties of Aerogel for Sale?

Aerogel is a highly specialized material known for its remarkable properties, making it a preferred choice in various industries. Understanding its essential technical specifications can help B2B buyers make informed purchasing decisions.

-

Material Grade

– Material grade refers to the quality classification of aerogel, often determined by its composition and intended application. Common grades include silica aerogel, carbon aerogel, and polymer-based aerogels. Choosing the correct material grade is crucial for ensuring optimal performance in insulation, structural applications, or specific chemical interactions. -

Density

– Aerogel’s density is a critical parameter that affects its thermal and mechanical properties. Typically, silica aerogels have densities ranging from 0.003 to 0.5 g/cm³. Lower density aerogels provide superior insulation but may sacrifice structural integrity. Understanding the density is essential for applications requiring lightweight materials without compromising strength. -

Thermal Conductivity

– This property measures how well heat passes through the aerogel. Aerogels are renowned for their low thermal conductivity, often less than 0.020 W/m·K. In industries like construction and aerospace, low thermal conductivity is vital for energy efficiency and insulation solutions. -

Porosity

– The porosity of aerogel indicates the volume fraction of voids in the material, directly influencing its insulating capabilities and mechanical strength. High porosity allows for excellent thermal insulation, but excessive porosity can lead to fragility. B2B buyers must consider the balance between porosity and required structural performance in their applications. -

Hydrophobicity

– Hydrophobic aerogels repel water, making them suitable for applications in humid environments or where moisture resistance is critical. Hydrophobicity is essential for ensuring the longevity and performance of aerogels in industrial settings, particularly in oil and gas, construction, and electronics. -

Mechanical Strength

– Mechanical strength refers to the material’s ability to withstand external forces without failure. Aerogels typically exhibit low compressive strength, making them fragile under certain conditions. Understanding the mechanical properties is essential for applications where the aerogel will be subjected to physical stress.

What Are Common Trade Terms in the Aerogel Industry?

Familiarity with industry terminology can enhance communication and negotiation in the aerogel marketplace. Here are some common trade terms relevant to B2B buyers:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of aerogels, OEMs may create specialized aerogel products tailored to specific industry needs, making it essential for buyers to know their suppliers’ capabilities. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. For aerogel products, MOQs can vary significantly based on the type and grade of aerogel. Understanding MOQ is crucial for budget management and inventory planning. -

RFQ (Request for Quotation)

– An RFQ is a formal request from a buyer to suppliers to provide pricing and terms for specific products or services. For aerogel purchases, submitting an RFQ allows buyers to compare offers from different suppliers, ensuring competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

– Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which is vital when sourcing aerogel from international suppliers, especially in regions like Africa, South America, and the Middle East. -

Lead Time

– Lead time is the amount of time from placing an order to receiving the product. Aerogel lead times can vary based on production schedules and supply chain logistics. Understanding lead times is essential for project planning and timely product availability. -

Custom Solutions

– Many suppliers offer custom aerogel solutions tailored to specific industry applications. This term indicates the ability to modify properties, shapes, or formulations to meet unique client requirements, providing flexibility for B2B buyers in diverse sectors.

By grasping these technical specifications and trade terms, B2B buyers can navigate the aerogel market more effectively, ensuring they select the right products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the aerogel for sale Sector

What Are the Current Market Dynamics and Key Trends in the Aerogel Sector?

The global aerogel market is experiencing robust growth driven by increasing demand across various sectors, including construction, aerospace, and energy. As a highly versatile material, aerogels are sought for their exceptional thermal insulation properties, lightweight nature, and unique structural characteristics. B2B buyers from Africa, South America, the Middle East, and Europe, particularly in regions like Nigeria and Brazil, are increasingly leveraging these attributes to enhance product offerings and operational efficiencies.

Emerging trends highlight a shift towards customized aerogel solutions tailored to specific applications, such as thermal barriers in building insulation and lightweight components in automotive manufacturing. Additionally, advancements in nanotechnology are enabling the production of aerogels with improved performance metrics, further expanding their applicability. The rise of e-commerce platforms dedicated to aerogel sales also facilitates easier access to these materials for international buyers, streamlining the sourcing process.

Another significant trend is the growing integration of aerogels into renewable energy applications, such as solar panels and energy-efficient buildings. This shift is aligned with global sustainability goals and presents an opportunity for businesses to innovate and differentiate their products in a competitive market.

How Does Sustainability and Ethical Sourcing Impact the Aerogel Market?

Sustainability is becoming a focal point for B2B buyers in the aerogel market. As environmental concerns gain prominence, companies are increasingly seeking materials that not only perform well but also have a minimal ecological footprint. The production of aerogels often involves processes that can be energy-intensive; thus, sourcing from manufacturers committed to sustainable practices is crucial.

Ethical supply chains are also gaining traction, with buyers prioritizing suppliers who adhere to environmental regulations and labor standards. Certifications such as ISO 14001 for environmental management systems and other green certifications can serve as indicators of a supplier’s commitment to sustainable practices.

Moreover, the development of bio-based aerogels presents an exciting opportunity for companies looking to enhance their sustainability profile. These materials utilize renewable resources, reducing reliance on fossil fuels and potentially lowering overall production emissions. By prioritizing sustainability and ethical sourcing, B2B buyers can not only meet regulatory requirements but also appeal to an increasingly eco-conscious market.

What Is the Evolution of the Aerogel Industry and Its Relevance to B2B Buyers?

The history of aerogels dates back to the 1930s when they were first developed by scientists at the University of California, Berkeley. Initially, their use was limited to niche applications, primarily in aerospace due to their remarkable thermal insulation properties. However, as technology has progressed, the versatility of aerogels has been recognized across various industries, including construction, automotive, and electronics.

Today, the aerogel market is characterized by continuous innovation and research aimed at enhancing the material’s properties and expanding its applications. This evolution is particularly relevant for B2B buyers, as it signifies a broader acceptance and understanding of aerogels beyond traditional uses. With ongoing advancements, businesses now have access to a wider range of products, from superinsulating blankets to lightweight structural components, allowing them to leverage aerogel technology to meet specific operational needs and competitive challenges.

By staying informed about the evolution of aerogels and their applications, international B2B buyers can make strategic sourcing decisions that align with market demands and technological advancements, ensuring they remain at the forefront of innovation in their respective industries.

Frequently Asked Questions (FAQs) for B2B Buyers of aerogel for sale

-

How do I determine the right type of aerogel for my application?

To select the appropriate aerogel, consider the specific requirements of your application, such as thermal insulation, mechanical strength, or hydrophobicity. Evaluate the different types available, including silica, carbon, and specialized aerogels, each designed for unique properties and uses. Consult with suppliers who can provide technical data sheets and expert recommendations based on your project needs, and don’t hesitate to request samples for testing to ensure compatibility. -

What are the minimum order quantities (MOQs) for aerogel purchases?

Minimum order quantities can vary significantly based on the supplier and the specific type of aerogel. Some suppliers may have MOQs as low as a few units for specialty items, while bulk orders might require a minimum of several kilograms or more. It’s essential to discuss your requirements directly with suppliers to negotiate terms that suit your purchasing capacity and ensure you meet your project deadlines. -

What are the typical payment terms for international aerogel transactions?

Payment terms can differ based on the supplier and the buyer’s location. Common terms include payment upfront, net 30, or letter of credit arrangements for larger orders. When sourcing from international suppliers, ensure that you understand the implications of currency exchange rates and transaction fees. Discussing payment options upfront can help streamline the procurement process and build a trustworthy supplier relationship. -

How can I ensure the quality of the aerogel I am purchasing?

To guarantee the quality of your aerogel, request detailed product specifications, certifications, and quality assurance (QA) documentation from suppliers. Look for suppliers who adhere to international standards such as ISO 9001. Additionally, consider asking for samples to perform your own quality tests or relying on third-party laboratories for independent verification of the material properties. -

What logistics considerations should I be aware of when importing aerogel?

When importing aerogel, consider factors such as shipping methods, customs regulations, and potential tariffs that may apply based on your country. Aerogels are often lightweight, but their fragility requires careful handling during transport. Work closely with suppliers who can provide guidance on packaging and logistics to minimize damage risk. Additionally, ensure you have a reliable freight forwarder experienced in handling sensitive materials. -

Can I customize aerogel products to meet my specific needs?

Yes, many suppliers offer customization options for aerogel products, allowing you to specify dimensions, shapes, and material properties tailored to your application. When discussing customization, provide detailed specifications and intended uses to help suppliers understand your requirements. Be prepared for longer lead times for custom orders, and confirm any additional costs associated with the customization process. -

What industries commonly utilize aerogel, and how can it benefit my business?

Aerogel is widely used in industries such as construction, aerospace, oil and gas, and electronics due to its exceptional thermal insulation and lightweight properties. Incorporating aerogel into your products can enhance energy efficiency, reduce weight, and improve performance. Understanding the specific applications within your industry can help you leverage aerogel’s benefits effectively and differentiate your offerings in the market. -

How do I vet potential aerogel suppliers for reliability and expertise?

To assess the reliability of potential aerogel suppliers, conduct thorough research by checking their business credentials, customer reviews, and industry reputation. Request references from previous clients and inquire about their experience with product quality and customer service. Additionally, evaluate their technical expertise by asking about their product development capabilities and willingness to provide support throughout the purchasing process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Aerogel For Sale Manufacturers & Suppliers List

1. TeacherSource – Silica Aerogel

Domain: teachersource.com

Registered: 1997 (28 years)

Introduction: Silica Aerogel, also known as Frozen Smoke, is available for purchase at Teachersource.com. It is suitable for density lab experiments and homeschool lesson plans. The product qualifies for FREE Economy Ground SHIPPING on orders over $99 (prepaid orders only, restrictions apply). Custom kits can also be built.

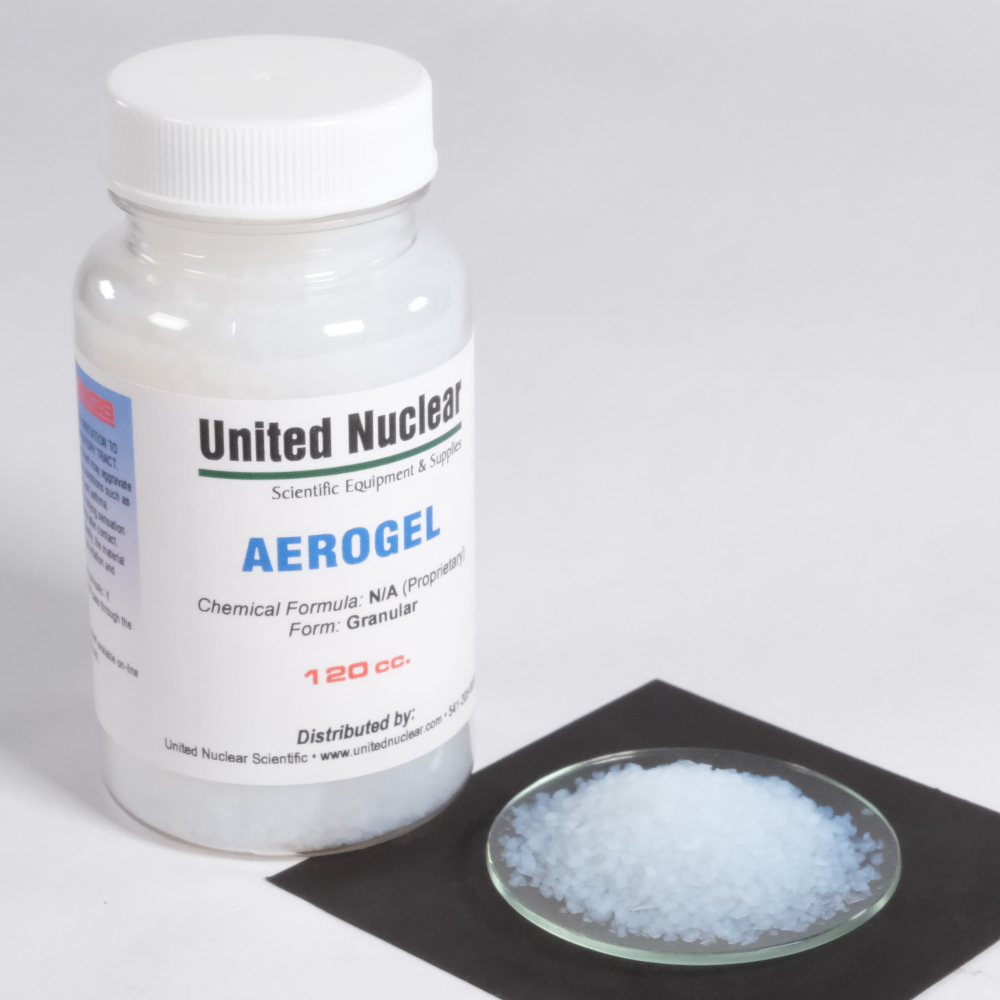

2. Aerogel – Affordable Options

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Aerogel is being sold at prices ranging from $40-50 per cubic cm for small amounts, which are targeted at novelty buyers. The user is looking for cheaper options, ideally around $1-2 per cubic cm as suggested by Google. They need a small amount, with a maximum requirement of 40 cubic cm. One suggestion includes fiberglass reinforced aerogel sheets from McMaster Carr priced at $22 for a sheet measu…

3. eBay – Silica Aerogel Products

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Silica aerogel products available for sale on eBay include various forms such as aerogel cubes, balls, and blocks. Key features include high permeability, high porosity, and hydrophobic properties. Products are categorized by material (e.g., ceramic fiber, polyethylene), suitable applications (e.g., acoustic insulation, high temperature), and various conditions (new or used). Prices range from und…

4. Flinn Scientific – Aerogel

Domain: flinnsci.com

Registered: 1997 (28 years)

Introduction: Aerogel Item #: AP7776 Price: $56.95 In Stock. Aerogel is a low-density porous material that is used for insulation, oil remediation, and it even went into space with the NASA probe Stardust. Aerogels are a diverse class of the world’s lightest solid material, composed of up to 99% air by volume. This low-density, porous material is already used for insulation, high-energy radiation detectors, and…

5. StemCell – Aerogel

Domain: stemcell.eco

Registered: 2021 (4 years)

Introduction: This company, StemCell – Aerogel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Etsy – Silica Aerogel Samples and Custom Chunks

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Aerogel – Silica Aerogel – Light solid – Available in 8.50 fl oz or 17.00 fl oz. Price: $61.14. World’s lightest solid, silica aerogel sample (frozen smoke) from NASA, hydrophobic. Price: $14.99 with free shipping. Custom Made Aerogel Chunks in a 20 ML Bottle. Price: $49.99 with free shipping. Silica Aerogel 5ml Sample (World’s Lightest Solid, Frozen Smoke). Price: $17.99 with free shipping.

Strategic Sourcing Conclusion and Outlook for aerogel for sale

Strategic sourcing of aerogel presents a unique opportunity for international B2B buyers, especially those in emerging markets across Africa, South America, the Middle East, and Europe. The versatility of aerogel—ranging from thermal insulation to lightweight materials for industrial applications—makes it an invaluable asset in various sectors including construction, aerospace, and energy. Buyers should prioritize sourcing from reputable suppliers that offer custom solutions, ensuring they receive products that meet specific application needs while maintaining quality and performance standards.

As the demand for energy-efficient materials grows, strategic sourcing becomes crucial for companies looking to innovate and remain competitive. By leveraging the unique properties of aerogels, businesses can enhance their product offerings and improve sustainability metrics.

Looking forward, the aerogel market is expected to expand significantly, driven by technological advancements and an increasing focus on energy efficiency. Now is the time for international buyers to explore partnerships with leading aerogel manufacturers. Take proactive steps to integrate aerogel into your supply chain and position your business at the forefront of this innovative material’s potential. Engage with suppliers today to discover the myriad applications of aerogel that can propel your business forward.