Top 5 Pipe Expansion Joints Suppliers (And How to Choose)

Introduction: Navigating the Global Market for pipe expansion joints

In today’s interconnected global market, sourcing high-quality pipe expansion joints can pose a significant challenge for international B2B buyers. With increasing demands for durability and flexibility across various industries, understanding the nuances of different types of expansion joints is crucial. This guide aims to demystify the complexities of pipe expansion joints, offering insights into the diverse range of products available, their specific applications, and the factors that influence pricing.

From metal bellows expansion joints to rubber variants, each type serves distinct functions in accommodating thermal movements and pressure variations within piping systems. Additionally, we will explore the importance of supplier vetting, ensuring that buyers can confidently select partners who meet international quality standards and regulatory requirements.

By providing comprehensive information on product specifications, applications, and best practices for procurement, this guide empowers B2B buyers from Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—to make informed purchasing decisions. With a focus on actionable insights, our goal is to facilitate seamless sourcing processes and enhance operational efficiency in your projects.

Whether you are looking to optimize your supply chain or enhance the reliability of your piping systems, this guide is your essential resource for navigating the global market for pipe expansion joints.

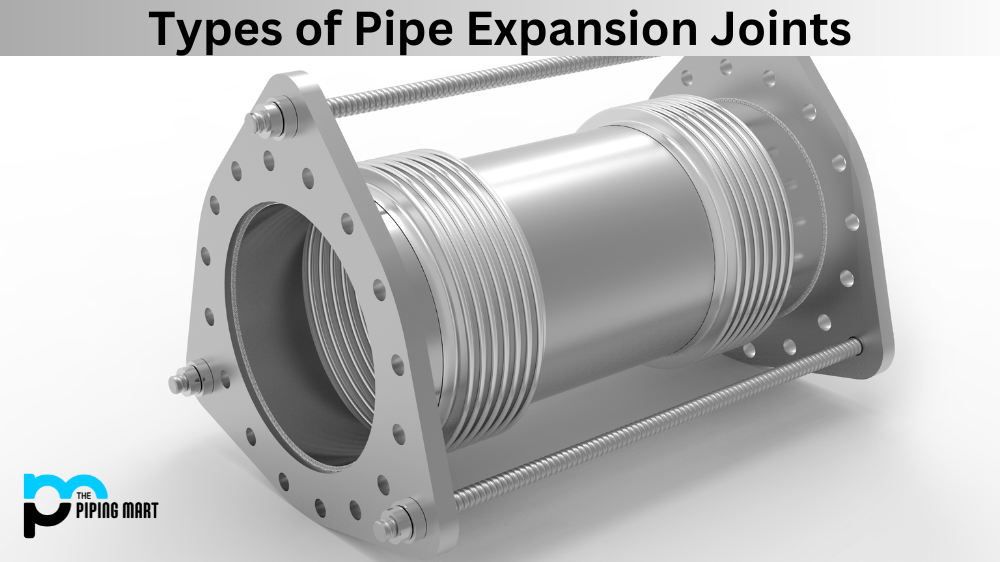

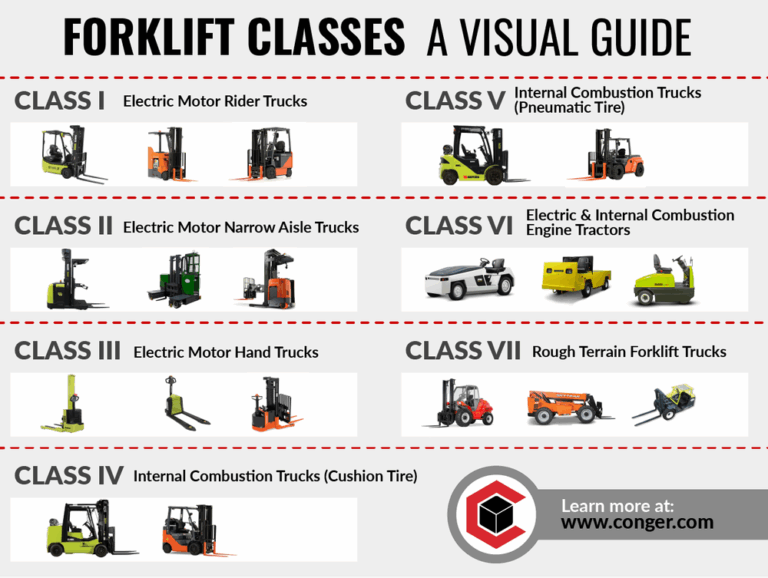

Understanding pipe expansion joints Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Expansion Joints | Durable stainless steel construction; high pressure ratings | HVAC, industrial piping systems | Pros: High durability, suitable for extreme temperatures; Cons: Higher initial cost. |

| Rubber Expansion Joints | Flexible rubber material; good vibration absorption | Water treatment, chemical processing | Pros: Cost-effective, excellent for low-pressure applications; Cons: Limited lifespan. |

| Externally Pressurized Joints | Designed to handle greater movements; rugged design | Seismic applications, building joints | Pros: Accommodates large expansions; Cons: Requires careful installation and support. |

| Bellows Expansion Joints | Corrugated design allows for axial, lateral, and angular movement | Power generation, oil & gas industries | Pros: Versatile movement capabilities; Cons: Sensitive to improper anchoring. |

| Fabric Expansion Joints | Lightweight, flexible fabric; ideal for low-pressure systems | Ventilation, exhaust systems | Pros: Easy to install, low weight; Cons: Not suitable for high temperature or pressure. |

What are the Key Characteristics of Metal Expansion Joints?

Metal expansion joints are primarily constructed from stainless steel, providing excellent durability and resistance to high temperatures and pressures. They are typically used in HVAC systems and industrial piping applications where robust performance is required. Buyers should consider the specific pressure ratings and temperature limits, as well as the need for custom sizes, when selecting metal expansion joints. They are a long-term investment, offering reliability in demanding environments.

How Do Rubber Expansion Joints Benefit B2B Applications?

Rubber expansion joints are designed for flexibility and vibration absorption, making them ideal for water treatment facilities and chemical processing plants. Their cost-effectiveness and ease of installation are significant advantages for buyers looking for budget-friendly solutions. However, they have a limited lifespan compared to metal options, so it’s essential for buyers to evaluate the expected operational conditions and replacement schedules.

When Should Externally Pressurized Joints Be Used?

Externally pressurized joints are engineered to handle significant movements, making them suitable for seismic applications and building joints. Their rugged design allows them to accommodate thermal expansions without compromising structural integrity. Buyers must ensure proper installation and anchoring to prevent potential failures, as these joints require a higher level of engineering consideration.

What Makes Bellows Expansion Joints Versatile?

Bellows expansion joints feature a corrugated design that permits axial, lateral, and angular movements, making them versatile for use in power generation and oil & gas industries. Their adaptability is a key selling point for buyers, but they are sensitive to improper anchoring, which can lead to premature failure. Understanding the installation requirements is crucial for maximizing their lifespan and performance.

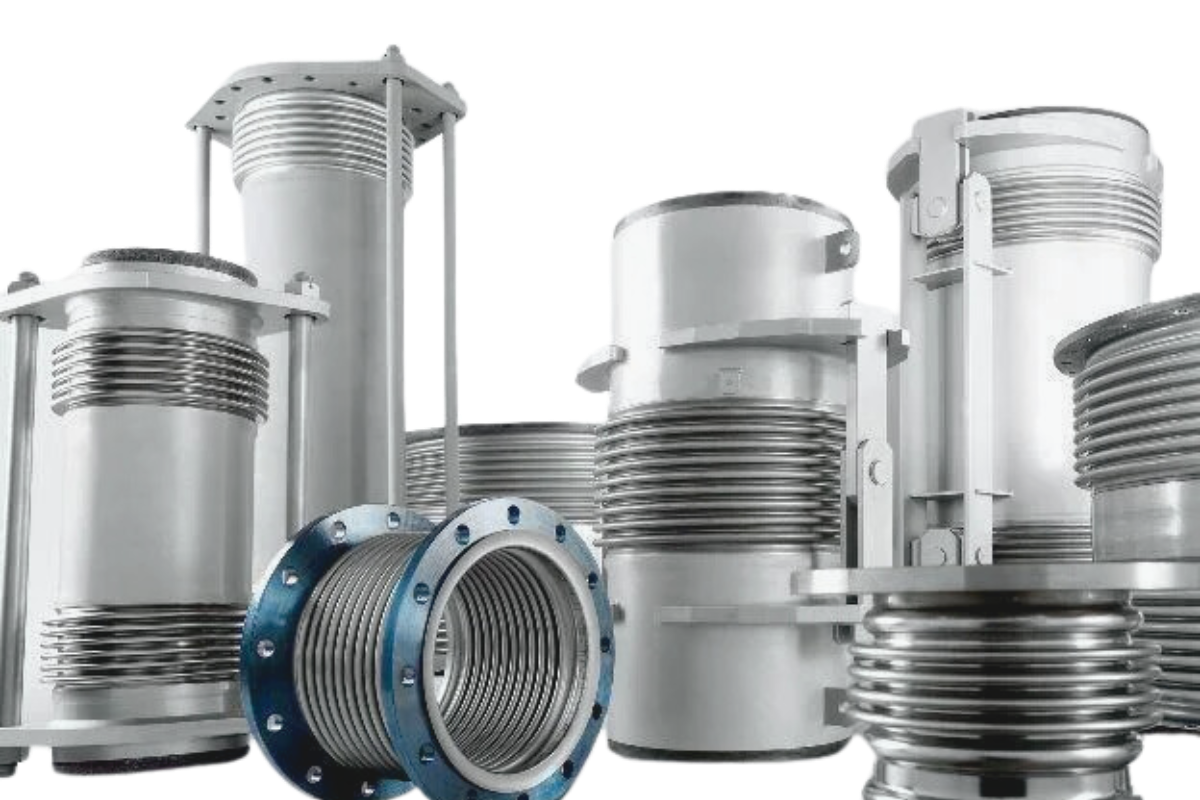

Illustrative image related to pipe expansion joints

Why Choose Fabric Expansion Joints for Specific Applications?

Fabric expansion joints are lightweight and flexible, making them suitable for low-pressure systems in ventilation and exhaust applications. They are easy to install and can be a cost-effective solution for specific needs. However, their limitations in high-temperature and pressure applications mean that buyers should carefully assess their requirements to ensure that fabric joints are appropriate for their intended use.

Key Industrial Applications of pipe expansion joints

| Industry/Sector | Specific Application of Pipe Expansion Joints | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Integration in pipeline systems for transporting oil and gas | Reduces stress on pipes, preventing leaks and failures | Ensure compatibility with high pressure and temperature; consider corrosion resistance materials. |

| Chemical Processing | Used in chemical reactors and transport pipelines | Enhances safety by accommodating thermal expansion, reducing risk of rupture | Look for joints that can handle aggressive chemicals and high temperatures; check for certifications. |

| HVAC Systems | Installed in ductwork and piping for heating and cooling systems | Improves efficiency and longevity of HVAC systems by allowing for thermal movement | Verify joint flexibility and pressure ratings; consider ease of installation and maintenance. |

| Power Generation | Applied in steam and cooling water systems | Prevents system failures due to thermal expansion, ensuring continuous operation | Assess thermal and pressure ratings; consider sourcing from reputable manufacturers with industry certifications. |

| Water & Wastewater Management | Utilized in sewage and water treatment plants | Prevents pipe damage from thermal and pressure fluctuations, maintaining system integrity | Ensure compliance with local regulations; focus on durability and resistance to environmental factors. |

How Are Pipe Expansion Joints Used in the Oil & Gas Industry?

In the oil and gas sector, pipe expansion joints are crucial for integration into pipeline systems that transport crude oil and natural gas. These joints alleviate the stress caused by thermal expansion and contraction, which can lead to leaks or catastrophic failures if not managed properly. Buyers in this industry must prioritize sourcing materials that can withstand high pressures and temperatures, as well as corrosive environments typical of oil and gas applications.

What Role Do Pipe Expansion Joints Play in Chemical Processing?

Within chemical processing, pipe expansion joints are vital components in reactors and transport pipelines. They accommodate thermal expansion and contraction, which is essential for maintaining safety and preventing ruptures in high-pressure systems. For international buyers, it is important to ensure that the expansion joints can handle aggressive chemicals and meet industry-specific certifications, which can vary by region.

Why Are Pipe Expansion Joints Important in HVAC Systems?

In HVAC systems, pipe expansion joints are employed in both ductwork and piping to facilitate heating and cooling. These joints allow for the necessary movement due to thermal expansion, thereby improving the efficiency and longevity of HVAC systems. B2B buyers should focus on the flexibility and pressure ratings of the joints, as well as their installation and maintenance requirements, to ensure optimal performance.

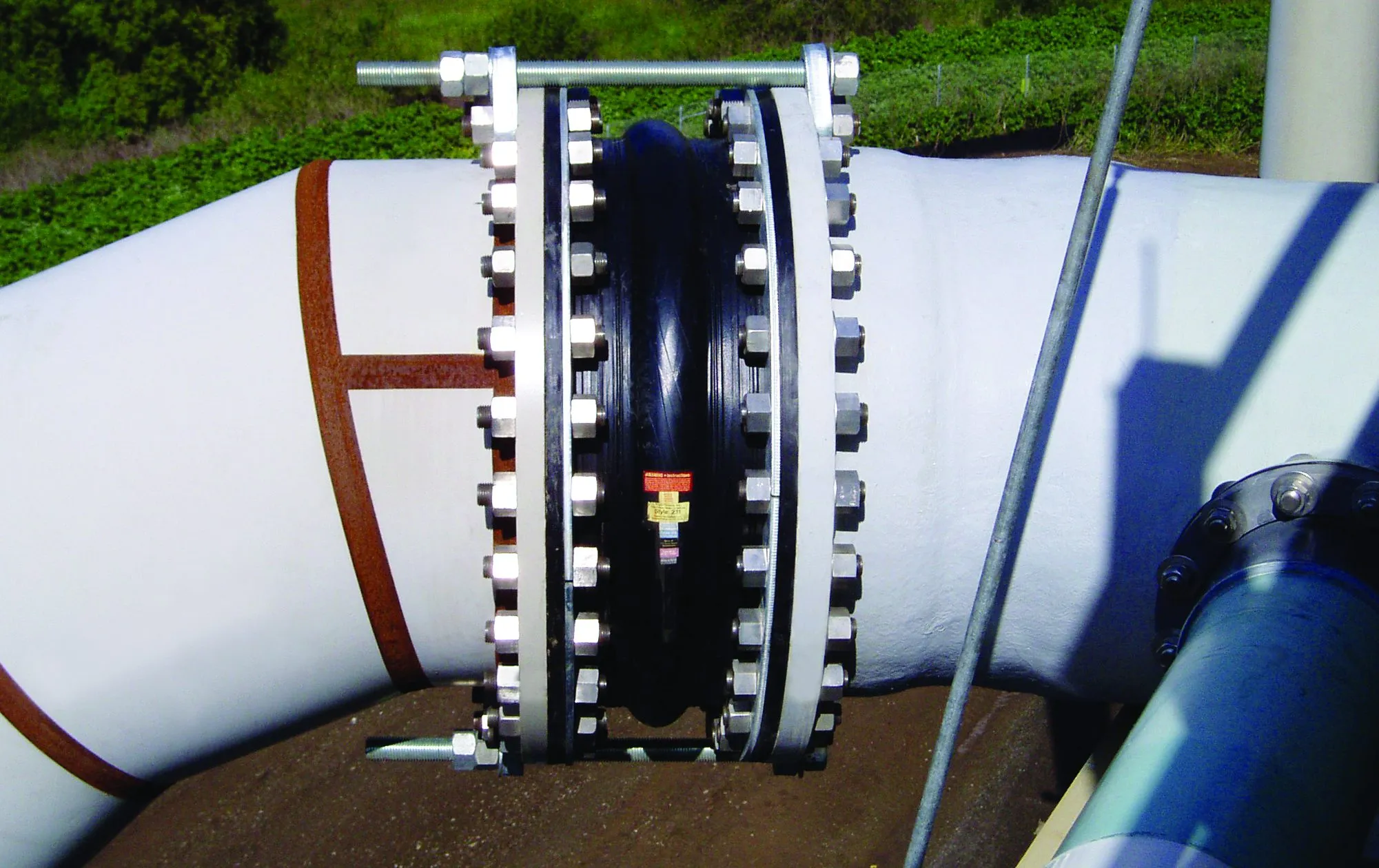

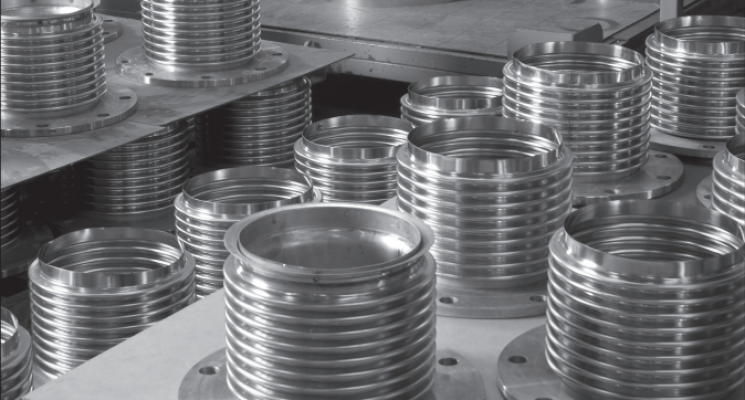

Illustrative image related to pipe expansion joints

How Do Pipe Expansion Joints Benefit Power Generation Facilities?

In power generation, pipe expansion joints are used in steam and cooling water systems to prevent failures caused by thermal expansion. By accommodating movement, these joints ensure the continuous operation of critical systems, which is essential for energy production. Buyers should consider the thermal and pressure ratings of the joints and opt for products from manufacturers with industry certifications to guarantee reliability.

What Are the Applications of Pipe Expansion Joints in Water & Wastewater Management?

In water and wastewater management, pipe expansion joints are utilized to prevent damage from thermal and pressure fluctuations in sewage and treatment plants. These joints help maintain system integrity, which is crucial for efficient operation. Buyers should ensure that the joints comply with local regulations and focus on durability and resistance to environmental factors, as these are key considerations in sourcing for this sector.

3 Common User Pain Points for ‘pipe expansion joints’ & Their Solutions

Scenario 1: Challenges with Thermal Expansion and Contraction in Piping Systems

The Problem: B2B buyers often struggle with the thermal expansion and contraction of piping systems, especially in environments with significant temperature fluctuations. For instance, a manufacturing facility may experience extreme temperature variations throughout the day, leading to excessive stress on rigid piping. This can result in leaks or even catastrophic failures, causing costly downtime and potential safety hazards. The challenge lies in accurately predicting these movements and choosing the right expansion joints that can effectively accommodate these changes without compromising system integrity.

The Solution: To address this issue, it is crucial to invest in high-quality pipe expansion joints specifically designed for thermal movement. Buyers should conduct a thorough analysis of the temperature variations their systems face and choose expansion joints with appropriate movement capabilities. For instance, metal expansion joints, like those with low corrugation stainless steel bellows, can handle substantial thermal expansion due to their flexibility. Furthermore, buyers should consider pre-compressing the expansion joints during installation to ensure they can extend properly when the pipes contract. Collaborating with reputable suppliers who offer technical support can also help in selecting the right specifications and ensuring proper installation practices.

Scenario 2: Managing Pressure Thrust in High-Pressure Applications

The Problem: In high-pressure piping systems, such as those found in oil and gas industries, managing pressure thrust is a common concern for B2B buyers. Pressure thrust occurs when the internal pressure of the fluid pushes against the expansion joint, potentially leading to misalignment, system failure, or excessive wear. Many buyers underestimate the forces involved, resulting in insufficient anchoring and support for the expansion joints, which can lead to premature failure and costly repairs.

The Solution: To effectively manage pressure thrust, buyers should take a proactive approach by calculating the potential anchor loads generated by the expansion joints. This involves assessing the pressure exerted on the joint and determining the effective area of the bellows. By integrating this data into the design phase, buyers can specify the appropriate anchors and supports that will accommodate the calculated loads. Additionally, opting for expansion joints with double braided construction can enhance tensile strength and pressure ratings, providing extra safety. Engaging with manufacturers to understand the specific requirements of their products will enable buyers to create robust systems that can withstand high-pressure conditions without compromising performance.

Scenario 3: Difficulties in Sourcing the Right Expansion Joint for Unique Applications

The Problem: B2B buyers often face difficulties when sourcing pipe expansion joints tailored to their unique applications, particularly in industries with specialized requirements, such as pharmaceuticals or food processing. Standard expansion joints may not suffice due to stringent regulatory standards or the need for specific material compatibility. This can lead to prolonged procurement cycles, increased costs, and potential project delays.

The Solution: To mitigate these challenges, buyers should prioritize collaboration with manufacturers who offer customizable expansion joints. Engaging with suppliers that provide tailored solutions can streamline the sourcing process significantly. Buyers should communicate their specific application needs, including material specifications, size requirements, and compliance with industry standards. Additionally, leveraging technology such as 3D modeling can aid in visualizing how the expansion joints will fit within existing systems. Conducting a thorough supplier evaluation to ensure they have experience in producing specialized joints will also enhance the chances of timely and successful procurement. Establishing long-term partnerships with reliable manufacturers can provide ongoing support and insight into future needs, ensuring that buyers are always equipped with the right products for their applications.

Strategic Material Selection Guide for pipe expansion joints

What are the Key Properties of Common Materials for Pipe Expansion Joints?

When selecting materials for pipe expansion joints, it is essential to consider their unique properties and how they align with specific application requirements. Here, we analyze four common materials: stainless steel, rubber, PTFE (Polytetrafluoroethylene), and carbon steel.

How Does Stainless Steel Perform in Pipe Expansion Joints?

Stainless steel is a popular choice for pipe expansion joints due to its excellent strength and corrosion resistance. Key properties include high-temperature tolerance (up to 875°F) and the ability to withstand high pressures (up to 500 PSI). Its durability makes it suitable for a wide range of applications, including those involving steam, gas, and chemical transport.

Pros: Stainless steel offers exceptional longevity and can handle extreme conditions without degrading. It is also relatively easy to manufacture, allowing for custom designs.

Cons: The primary drawback is its cost, which can be higher than other materials. Additionally, while it resists corrosion, it can still be susceptible to certain aggressive chemicals.

For international buyers, compliance with standards such as ASTM F-1120 or ASTM F-2934 is crucial. Countries in Europe, the Middle East, and South America often have stringent regulations regarding material specifications, making stainless steel a reliable choice.

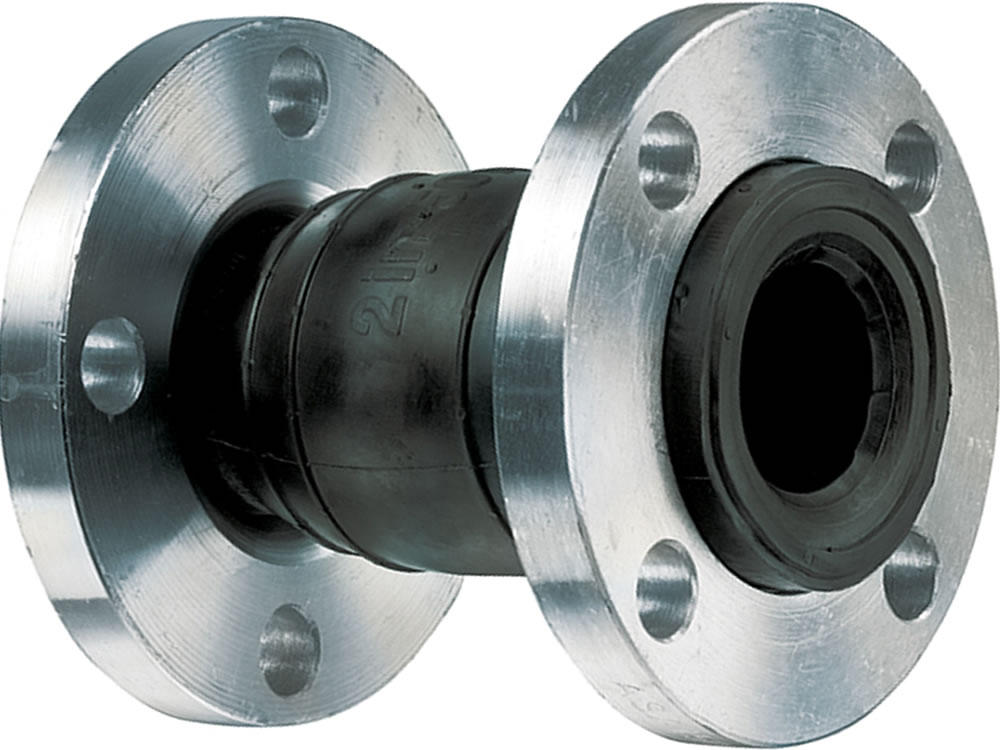

What Advantages Does Rubber Provide for Pipe Expansion Joints?

Rubber expansion joints are primarily used in applications where flexibility and vibration absorption are critical. They can handle moderate temperatures and pressures, typically up to 250°F and 150 PSI, respectively. Rubber is particularly effective for handling thermal expansion and contraction in piping systems.

Pros: Rubber joints are cost-effective and provide excellent shock absorption, making them suitable for dynamic applications. They are also lightweight, which simplifies installation.

Illustrative image related to pipe expansion joints

Cons: Rubber has a limited lifespan compared to metals and can degrade when exposed to certain chemicals or extreme temperatures. This limitation makes them less suitable for high-pressure or high-temperature applications.

International buyers should be aware of the need for compliance with various standards, including JIS for Japanese markets and DIN for European applications. Buyers from regions with high humidity or temperature fluctuations should also consider the rubber’s performance in those environments.

How Does PTFE Enhance Pipe Expansion Joint Performance?

PTFE is known for its outstanding chemical resistance and low friction properties. It is often used in applications involving aggressive chemicals and high temperatures, with a maximum operating temperature of around 500°F. PTFE expansion joints are particularly effective in corrosive environments.

Pros: The primary advantage of PTFE is its chemical inertness, making it suitable for a wide range of applications, including pharmaceuticals and food processing. Its ability to withstand extreme temperatures adds to its versatility.

Cons: PTFE joints can be more expensive than rubber or even stainless steel options. Additionally, they may require more complex manufacturing processes, which can lead to longer lead times.

Illustrative image related to pipe expansion joints

Buyers in Africa and South America should ensure that PTFE products meet local compliance standards, which may vary significantly. Understanding the specific chemical compatibility is also vital for successful applications.

What Role Does Carbon Steel Play in Pipe Expansion Joints?

Carbon steel is often used in applications where cost is a significant concern and where the operating conditions are less extreme. It typically has a lower temperature and pressure rating compared to stainless steel, making it suitable for less demanding environments.

Pros: Carbon steel is generally more affordable than stainless steel and offers good mechanical properties. It is widely available and can be easily welded or fabricated.

Cons: Its susceptibility to corrosion limits its use in harsh environments, and it often requires protective coatings to enhance durability. Additionally, its lower temperature and pressure ratings restrict its application scope.

For B2B buyers, understanding local market conditions is essential. In regions where corrosion is a concern, such as coastal areas in South America or humid climates in Africa, carbon steel may not be the best choice without additional protective measures.

Summary Table of Material Properties

| Material | Typical Use Case for pipe expansion joints | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure gas and chemical transport | Excellent durability and corrosion resistance | Higher cost and chemical susceptibility | High |

| Rubber | Vibration absorption in HVAC systems | Cost-effective and flexible | Limited lifespan and chemical degradation | Low |

| PTFE | Corrosive chemical applications | Outstanding chemical resistance | Higher cost and complex manufacturing | High |

| Carbon Steel | Low-pressure applications | Affordable and widely available | Susceptible to corrosion and lower ratings | Med |

This strategic material selection guide provides a comprehensive overview of common materials used in pipe expansion joints, helping international B2B buyers make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pipe expansion joints

What Are the Main Stages of the Manufacturing Process for Pipe Expansion Joints?

The manufacturing process of pipe expansion joints is intricate and involves several stages that ensure high-quality products. Understanding these stages is crucial for B2B buyers looking to procure reliable solutions.

Material Preparation: What Materials Are Used?

The first stage in manufacturing pipe expansion joints is material preparation. Typically, high-grade stainless steel, such as 304 or 316, is used due to its corrosion resistance and strength. For specialized applications, other materials like Inconel or Monel may be employed. The material is sourced from trusted suppliers and undergoes initial inspections to ensure it meets the required specifications. This step is critical, as subpar materials can compromise the integrity of the expansion joints.

How Is the Forming Process Conducted?

Following material preparation, the forming process begins. This involves cutting the metal sheets into appropriate sizes and shapes, followed by processes such as deep drawing or hydroforming to create the bellows. Hydroforming, in particular, allows for precise shaping while maintaining material integrity, which is essential for high-pressure applications. Advanced techniques like computer numerical control (CNC) machining may also be employed to achieve exact tolerances.

Illustrative image related to pipe expansion joints

What Does the Assembly Stage Involve?

The assembly stage is where various components of the expansion joint are brought together. This includes attaching the bellows to end fittings, which may be flanged, welded, or grooved, depending on the application requirements. Control rods may also be integrated at this stage to enhance stability and control movement. The assembly process must adhere to strict guidelines to ensure that all parts fit correctly and function as intended.

How Is the Finishing Process Executed?

The final stage of the manufacturing process is finishing. This includes surface treatments such as polishing or passivation to enhance corrosion resistance and aesthetic appeal. Additionally, protective coatings may be applied to ensure durability in harsh environments. This step is particularly important for expansion joints used in industries such as oil and gas, where exposure to corrosive substances is a concern.

What Quality Assurance Practices Are Essential for Pipe Expansion Joints?

Quality assurance (QA) is a critical aspect of manufacturing pipe expansion joints, ensuring that the final products meet international standards and customer expectations. For B2B buyers, understanding these practices can provide confidence in their purchasing decisions.

Which International Standards Are Relevant for Quality Assurance?

Manufacturers of pipe expansion joints often adhere to international quality standards such as ISO 9001, which outlines the criteria for a quality management system. Additionally, industry-specific standards like CE marking for European markets and API standards for the oil and gas sector are essential for ensuring compliance. These standards help guarantee that products are manufactured consistently and safely.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous checks are performed during manufacturing to monitor processes and detect defects early.

- Final Quality Control (FQC): The finished products undergo rigorous testing to ensure they meet all specifications and performance standards before shipment.

These checkpoints help mitigate risks and enhance product reliability.

What Common Testing Methods Are Employed?

To validate the quality and performance of pipe expansion joints, several testing methods are commonly employed:

- Hydrostatic Testing: This method involves filling the expansion joint with water and applying pressure to check for leaks and structural integrity.

- Dimensional Inspection: Ensuring that all dimensions meet specifications is critical, and this is often done using precision measurement tools.

- Material Testing: Techniques like tensile testing and hardness testing are performed to assess the material properties and ensure they align with industry standards.

B2B buyers should inquire about these testing methods when evaluating suppliers.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing pipe expansion joints, B2B buyers must ensure that their suppliers maintain high-quality standards. Here are some ways to verify supplier QC:

What Role Do Audits and Reports Play?

Conducting supplier audits is an effective way to assess the quality management systems and processes of potential manufacturers. During an audit, buyers can review documentation related to ISO certifications, quality control procedures, and testing protocols. Requesting quality assurance reports and certificates of compliance can also provide insights into a supplier’s commitment to quality.

Why Is Third-Party Inspection Important?

Utilizing third-party inspection services can add an extra layer of assurance for B2B buyers. Independent inspectors can evaluate the manufacturing processes, conduct tests, and provide unbiased reports on the quality of the products. This practice is particularly beneficial for international buyers who may not have the capability to conduct on-site inspections.

What Are the Quality Control and Certification Nuances for International Buyers?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential.

How Do Regional Standards Affect Quality?

Different regions may have varying standards and regulations for pipe expansion joints. For instance, European buyers might prioritize CE certification, while buyers in the Middle East may focus on compliance with local standards. Understanding these regional requirements can help buyers make informed decisions and avoid regulatory pitfalls.

What Should Buyers Know About Import Regulations?

When importing pipe expansion joints, B2B buyers must be aware of customs regulations and import duties that may apply. Ensuring that products comply with the destination country’s standards can prevent delays and additional costs during the import process. It is advisable to work with suppliers who are experienced in international trade and can provide necessary documentation for compliance.

Conclusion

For B2B buyers in the market for pipe expansion joints, a thorough understanding of the manufacturing processes and quality assurance practices is essential. By focusing on material preparation, forming, assembly, and finishing, buyers can appreciate the complexity involved in producing high-quality products. Furthermore, being well-versed in international standards, QC checkpoints, and testing methods enables buyers to make informed purchasing decisions and ensure the reliability and performance of their investments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pipe expansion joints’

In the competitive landscape of industrial procurement, sourcing pipe expansion joints requires a systematic approach to ensure that you select the right products for your specific applications. This checklist will guide you through the essential steps in your sourcing process, helping you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly define the technical requirements for your pipe expansion joints. Consider factors such as pressure ratings, temperature tolerances, and the specific materials needed for your application. Accurate specifications will help you narrow down your options and ensure compatibility with existing systems.

- Pressure Ratings: Identify the maximum pressure the expansion joints will encounter to avoid failures.

- Material Selection: Choose materials that resist corrosion and suit the media being transported, such as stainless steel or rubber.

Step 2: Research Regulatory Compliance

Ensure that the expansion joints you consider meet relevant industry standards and certifications. Compliance with international standards such as ASTM or ISO can indicate product reliability and safety.

- Documentation: Request certification documents from suppliers to verify compliance.

- Regional Standards: Be aware of any local regulations that may apply in your region, particularly in markets like Africa or South America.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they have a proven track record in providing high-quality pipe expansion joints. Reliable suppliers should offer transparency regarding their production processes and quality control measures.

- Company Profiles: Review supplier profiles and product portfolios.

- References: Ask for case studies or references from other clients in similar industries to gauge supplier performance.

Step 4: Request Samples and Perform Testing

Before finalizing your order, request samples of the pipe expansion joints for testing. This step allows you to verify that the products meet your technical specifications and quality expectations.

- Functionality Tests: Conduct tests for flexibility, pressure handling, and temperature resilience.

- Compatibility Checks: Ensure that the samples integrate seamlessly with your existing piping systems.

Step 5: Review Pricing and Terms

Once you’ve identified suitable products and suppliers, review pricing structures and contractual terms. Understanding the total cost of ownership, including shipping and installation, is crucial for effective budgeting.

- Volume Discounts: Inquire about pricing breaks for bulk orders.

- Payment Terms: Clarify payment conditions and any warranties offered by the supplier.

Step 6: Negotiate Delivery and Lead Times

Timely delivery is critical for maintaining project schedules. Negotiate lead times with your suppliers to ensure that they align with your operational timelines.

- Delivery Guarantees: Confirm that suppliers can meet your delivery requirements.

- Contingency Plans: Discuss potential delays and how they will be managed to minimize disruptions.

Step 7: Finalize Your Order and Establish a Relationship

Once you are satisfied with all aspects of the sourcing process, finalize your order. Establishing a solid relationship with your supplier can lead to better support and future collaborations.

- Long-term Partnerships: Consider the potential for long-term contracts or partnerships that can benefit both parties.

- Feedback Loop: Maintain open communication for feedback and improvements in future orders.

By following this checklist, you can streamline your procurement process for pipe expansion joints, ensuring that you select the best products for your needs while fostering strong supplier relationships.

Illustrative image related to pipe expansion joints

Comprehensive Cost and Pricing Analysis for pipe expansion joints Sourcing

What Are the Key Cost Components in Pipe Expansion Joints?

When sourcing pipe expansion joints, it’s crucial to understand the various cost components that contribute to the final pricing. These components typically include:

-

Materials: The choice of materials significantly impacts cost. Stainless steel, for instance, is often more expensive than rubber or plastic but offers enhanced durability and temperature resistance. The specific grade of stainless steel used also affects pricing, as higher grades can withstand more extreme conditions.

-

Labor: Labor costs vary based on the complexity of the manufacturing process. Customization or unique specifications may require specialized skills, leading to higher labor costs. Additionally, labor rates differ by region, affecting the overall price for international buyers.

-

Manufacturing Overhead: This includes costs related to the facility, utilities, and general administration. Suppliers with advanced manufacturing capabilities or higher automation levels may have lower overhead costs, which can be reflected in their pricing.

-

Tooling: Custom tooling for specific designs or sizes can be a significant upfront investment. This cost is often amortized over the volume of units produced, making it essential to consider order size when evaluating pricing.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. The cost of these processes is often factored into the overall pricing, with suppliers who emphasize quality potentially commanding higher prices.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, shipping method, and import duties can significantly influence the final landed cost.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand, competition, and perceived value. Understanding this can help buyers negotiate more effectively.

How Do Price Influencers Impact Your Sourcing Strategy?

Several factors can influence the pricing of pipe expansion joints, particularly for international buyers:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders often lead to economies of scale, resulting in lower per-unit costs. Buyers should assess their needs carefully to optimize order sizes.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs. Buyers should clearly define their needs upfront to avoid unexpected price hikes during production.

-

Materials and Quality Certifications: The quality and type of materials used directly impact price. Moreover, certifications (e.g., ISO, ASTM) may come with additional costs but provide assurance of quality and compliance, which can be critical in regulated markets.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may charge more due to their track record and the trust they have built with customers.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the overall cost structure.

What Negotiation Tips Can Help You Achieve Cost Efficiency?

To ensure a cost-effective sourcing process for pipe expansion joints, consider the following negotiation strategies:

-

Establish Clear Requirements: Clearly outline your specifications and expectations. This minimizes misunderstandings and helps suppliers provide accurate quotes.

-

Leverage Volume Discounts: If possible, consolidate orders to negotiate better pricing based on volume. Suppliers are often willing to offer discounts for larger orders.

-

Analyze Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime associated with the product. A higher upfront cost may lead to lower TCO if the quality is superior.

-

Be Aware of Regional Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, labor costs, and regulations. Understanding these nuances can provide leverage in negotiations.

-

Seek Long-term Partnerships: Building a relationship with suppliers can lead to better terms over time, as trust and reliability often translate to more favorable pricing and service.

Conclusion: What Should International Buyers Keep in Mind?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, it is essential to approach the sourcing of pipe expansion joints with a comprehensive understanding of cost structures and pricing influencers. By leveraging negotiation strategies and being aware of regional nuances, buyers can secure favorable terms that align with their operational needs. Always remember to account for the total cost of ownership to make informed purchasing decisions. Pricing is subject to change, and it’s advisable to consult suppliers for the most accurate and up-to-date quotes.

Alternatives Analysis: Comparing pipe expansion joints With Other Solutions

In the industrial landscape, selecting the right solution for accommodating pipe movements is crucial for maintaining system integrity and operational efficiency. While pipe expansion joints are a well-established choice, there are alternative solutions that can also meet specific needs. This analysis compares pipe expansion joints against two viable alternatives: flexible couplings and slip joints, highlighting key performance metrics, costs, implementation ease, maintenance requirements, and ideal use cases.

| Comparison Aspect | Pipe Expansion Joints | Flexible Couplings | Slip Joints |

|---|---|---|---|

| Performance | High flexibility, accommodates thermal expansion and contraction | Moderate flexibility, suitable for misalignment | Limited movement, primarily for axial displacement |

| Cost | Generally higher initial investment, but long-term durability can justify cost | Lower initial cost, but may require more frequent replacements | Moderate cost, but installation can be complex |

| Ease of Implementation | Requires precise installation and anchoring | Easier to install, fewer components | Installation complexity can vary based on design |

| Maintenance | Requires periodic inspections; low maintenance if installed correctly | Minimal maintenance; may need replacement over time | Low maintenance; regular checks recommended |

| Best Use Case | High-temperature or high-pressure applications; systems with significant movement | Systems with minor misalignment; quick repairs | Applications with limited movement, such as short runs |

What are the Pros and Cons of Flexible Couplings as an Alternative?

Flexible couplings are designed to connect two pipe segments while allowing for some degree of misalignment and vibration absorption. They are typically less expensive upfront, making them an attractive option for budget-conscious projects. However, their lifespan may be shorter than that of pipe expansion joints, particularly in high-pressure or high-temperature environments. Additionally, while installation is generally straightforward, they may not provide the same level of flexibility and movement accommodation as expansion joints, which can lead to potential system failures if not monitored closely.

What Makes Slip Joints a Viable Alternative?

Slip joints are another alternative that allows for axial movement in piping systems. They are typically used where there is a need for linear expansion or contraction, making them suitable for applications with limited displacement requirements. The installation of slip joints can be more complex than that of flexible couplings, and they may require precise alignment to function properly. While they are generally low maintenance, regular inspections are essential to ensure they are functioning as intended. Slip joints, however, do not accommodate lateral or angular movements as effectively as pipe expansion joints, which can be a critical drawback in dynamic environments.

How to Choose the Right Solution for Your Needs?

When choosing between pipe expansion joints and alternatives like flexible couplings or slip joints, consider the specific requirements of your application. For high-temperature or high-pressure systems with significant movement, pipe expansion joints are often the best choice due to their durability and flexibility. If budget constraints are a priority and the application involves minor misalignments, flexible couplings may be suitable. In cases where axial movement is the primary concern, slip joints can be effective. Ultimately, a thorough assessment of your system’s operational conditions, maintenance capabilities, and budget will guide you to the most appropriate solution for your needs.

Essential Technical Properties and Trade Terminology for pipe expansion joints

What Are the Key Technical Properties of Pipe Expansion Joints?

Understanding the essential technical properties of pipe expansion joints is crucial for B2B buyers looking to optimize their piping systems. Here are some critical specifications to consider:

Illustrative image related to pipe expansion joints

1. Material Grade

The material used for expansion joints typically includes stainless steel, rubber, or other alloys. Stainless steel is favored for its corrosion resistance and strength, while rubber provides flexibility and vibration absorption. The choice of material affects the joint’s durability, pressure rating, and compatibility with different media. Selecting the right material grade ensures longevity and reliability in various environments.

2. Pressure Rating

This specification indicates the maximum internal pressure that the expansion joint can withstand without failure. Measured in PSI (pounds per square inch), pressure ratings are essential for ensuring safety and performance in high-pressure applications. Buyers must match the pressure rating of the expansion joint to the operational conditions of their systems to prevent leaks or catastrophic failures.

3. Temperature Tolerance

Temperature tolerance defines the range of temperatures within which the expansion joint can operate effectively. Some joints can handle extreme temperatures, while others are suitable for moderate conditions. This specification is vital for applications involving hot fluids or gases, as exceeding temperature limits can lead to material degradation and joint failure.

4. Movement Capability

This property describes the joint’s ability to accommodate thermal expansion and contraction, as well as lateral and angular movements. Understanding the movement capability helps in selecting the appropriate joint for specific applications, ensuring that the piping system remains flexible and functional without causing stress or damage to the infrastructure.

5. End Connection Type

The end connection of an expansion joint can be flanged, grooved, or welded, and this affects how the joint integrates with existing piping systems. Selecting the right end connection is critical for ensuring a leak-proof seal and compatibility with other components in the system.

Illustrative image related to pipe expansion joints

6. Size and Dimensions

The size of the expansion joint must match the diameter of the piping system. Standard and custom sizes are available, and accurate sizing is essential to maintain system integrity and performance. Misalignment can lead to increased stress and potential failure.

What Are Common Trade Terms Related to Pipe Expansion Joints?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common trade terms you should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEMs is important for buyers seeking reliable components that meet specific quality standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. This is crucial for buyers to understand as it can impact inventory levels and cash flow. Knowing the MOQ helps in planning purchases and managing supply chain logistics.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. This process allows buyers to compare prices and terms, ensuring they receive competitive offers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Understanding these terms helps buyers manage logistics and costs associated with shipping and delivery.

5. Lead Time

Lead time is the duration between placing an order and receiving it. This term is crucial for project planning and inventory management, as delays can significantly impact operations.

6. BOM (Bill of Materials)

A BOM is a comprehensive list of materials, components, and assemblies needed to manufacture a product. Having an accurate BOM is essential for ensuring that all necessary parts, including expansion joints, are sourced efficiently.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance the efficiency and reliability of their piping systems.

Navigating Market Dynamics and Sourcing Trends in the pipe expansion joints Sector

What Are the Key Trends Shaping the Global Pipe Expansion Joints Market?

The pipe expansion joints market is experiencing significant transformation driven by several global factors. As industries across Africa, South America, the Middle East, and Europe expand, the demand for durable, flexible, and efficient piping solutions is surging. Key trends include the increasing adoption of automation and smart technologies in manufacturing processes, which enhance precision and reduce costs. Furthermore, the rise in infrastructure projects, particularly in emerging economies, is leading to a heightened need for reliable piping systems that can withstand thermal expansion and contraction.

International buyers are also witnessing a shift towards customized solutions. Manufacturers are increasingly offering bespoke designs that cater to specific industry requirements, such as varying pressure ratings and sizes. Additionally, the focus on energy efficiency is influencing sourcing decisions, with companies prioritizing products that contribute to reduced operational costs over their lifecycle.

Sustainability is becoming a pivotal concern, prompting buyers to seek suppliers who adhere to eco-friendly practices. This trend is compounded by growing regulatory pressures regarding emissions and waste management, pushing the industry towards greener technologies and materials. As a result, companies are now evaluating the total cost of ownership rather than just initial procurement costs, further shaping sourcing strategies.

How Are Sustainability and Ethical Sourcing Impacting the Pipe Expansion Joints Market?

Sustainability and ethical sourcing have become crucial considerations for B2B buyers in the pipe expansion joints sector. The environmental impact of manufacturing processes, particularly regarding resource consumption and waste generation, has led many companies to reassess their supply chains. Buyers are increasingly favoring suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing energy usage during production.

Certifications like ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are gaining importance as they provide a framework for evaluating a supplier’s environmental performance. Moreover, the use of ‘green’ materials, such as low-emission alloys and eco-friendly coatings, is becoming a differentiator in the market. These materials not only reduce the carbon footprint but also enhance the longevity and reliability of pipe expansion joints.

The push for ethical sourcing is also reflected in the demand for transparency throughout the supply chain. Buyers are increasingly looking for suppliers who can trace their materials back to responsible sources, ensuring that their products do not contribute to environmental degradation or unethical labor practices. This shift is transforming procurement strategies, making sustainability and ethics key factors in supplier selection.

What Is the Historical Context Behind the Development of Pipe Expansion Joints?

The evolution of pipe expansion joints can be traced back to the early 20th century when industries began to recognize the need for flexibility in piping systems. Initially, these joints were rudimentary, constructed from basic materials without the advanced engineering techniques we see today. However, as industrial processes became more complex and the demand for durability increased, manufacturers began to innovate.

By the mid-20th century, the introduction of metal bellows expansion joints revolutionized the industry. These joints provided greater flexibility and resistance to extreme conditions, making them suitable for a wider range of applications. Over the decades, advancements in materials science and engineering have led to the development of high-performance joints capable of withstanding intense pressures and temperatures, further solidifying their role in modern piping systems.

Today, the industry is at a crossroads, where technology and sustainability are driving the next wave of innovations in pipe expansion joints. As international buyers navigate this evolving landscape, understanding the historical context can provide valuable insights into current market dynamics and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of pipe expansion joints

-

1. How do I solve issues related to thermal expansion in piping systems?

To address thermal expansion in piping systems, it’s crucial to select the right type of expansion joint. Metal bellows expansion joints are highly effective for handling thermal movements due to their flexibility. Ensure that the expansion joint is pre-compressed during manufacturing to accommodate thermal contraction, allowing it to extend when pipes heat up. Additionally, consider using slide guides to manage thermal movement effectively, particularly in installations crossing building joints or in environments with significant temperature fluctuations. -

2. What is the best expansion joint for high-pressure applications?

For high-pressure applications, metal expansion joints designed with double braided construction are ideal. This design enhances tensile strength, enabling the joint to withstand pressures exceeding standard ratings. When sourcing these products, ensure that the manufacturer can provide detailed specifications and test data to validate the pressure ratings. Also, confirm that the joint complies with industry standards such as ASTM F-1120 or ASTM F-2934, which are essential for ensuring safety and reliability in high-pressure environments. -

3. How can I ensure the quality of expansion joints from international suppliers?

To ensure quality when sourcing expansion joints internationally, start by vetting suppliers through their certifications and compliance with industry standards. Request documentation like ISO certifications, material test reports, and quality assurance protocols. Additionally, consider visiting manufacturing facilities or using third-party inspection services to validate product quality before shipment. Engaging in regular communication throughout the production process can also help maintain quality control and address any concerns early. -

4. What are the minimum order quantities (MOQ) for pipe expansion joints?

Minimum order quantities (MOQ) for pipe expansion joints can vary significantly between manufacturers. Typically, MOQs may range from a few units to several hundred, depending on the joint type, customization, and supplier capabilities. When negotiating with suppliers, clarify MOQs upfront and explore possibilities for smaller orders, especially if you are testing new products. Additionally, consider bulk purchasing to reduce unit costs if you anticipate ongoing requirements. -

5. What payment terms are commonly accepted for international transactions?

Payment terms for international transactions often include options like advance payment, letters of credit, or open account terms. Many suppliers may request a deposit upfront, with the balance due upon shipment or delivery. It’s essential to establish clear payment terms in your contract to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, such as escrow services, especially when dealing with new suppliers. -

6. How do I calculate the required size of an expansion joint for my application?

Calculating the required size of an expansion joint involves assessing the total thermal movement, pressure ratings, and specific application conditions. Start by determining the expected thermal expansion based on material properties and temperature ranges. Next, consult the manufacturer’s guidelines to find the appropriate joint size that can accommodate the calculated movement. Always consider environmental factors, such as pressure and vibration, which may influence the selection of the right joint for your piping system. -

7. What logistics considerations should I keep in mind when sourcing expansion joints internationally?

When sourcing expansion joints internationally, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable shipping partner experienced in handling industrial components to ensure timely delivery. Be aware of potential delays at customs and prepare necessary documentation to avoid complications. Additionally, factor in shipping costs, which can vary based on weight and destination, when budgeting for your purchase. -

8. Can I customize expansion joints to meet specific project requirements?

Yes, many manufacturers offer customization options for expansion joints to meet specific project needs. Customizations may include variations in size, material type, pressure ratings, and design features. When discussing customization with suppliers, provide detailed specifications and any relevant application data to ensure the final product meets your requirements. Be prepared for potential lead time increases for customized orders, and verify that the supplier has experience in producing bespoke solutions.

Top 5 Pipe Expansion Joints Manufacturers & Suppliers List

1. Garlock – Expansion Joints

Domain: garlock.com

Registered: 1995 (30 years)

Introduction: This company, Garlock – Expansion Joints, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Flexonics – Piping Expansion Joints

Domain: flexonics.com

Registered: 1996 (29 years)

Introduction: Flexonics offers a range of piping expansion joints designed to accommodate thermal expansion and contraction in piping systems. Key product details include:

– Sizes available: 2″ to 144″ in various increments (e.g., 2″, 2.5″, 3″, 3.5″, up to 108″ to 144″).

– Types of expansion joints: Metal bellows expansion joints, fabric expansion joints, and options for cryogenics and compressed gas.

– Move…

3. Proco Products – Expansion Joints

Domain: procoproducts.com

Registered: 1998 (27 years)

Introduction: Proco Products is a leading manufacturer of expansion joints for piping and ducting systems, offering a variety of designs in rubber, stainless steel, and PTFE. Their expansion joints are designed to protect equipment from thermal expansion, vibration, and ground movement, ensuring safe and reliable operations. Key features include:

– Rubber expansion joints: Used in HVAC systems, plumbing, power…

4. Mason – Custom Expansion Joints

Domain: mason-ind.com

Registered: 1996 (29 years)

Introduction: Expansion joints custom manufactured to diameters as large as 8 feet (2.4m). Construction varies based on operating pressure and required movements. Stock expansion joints available in 2″ to 16″ diameters with 2″ axial and 1/4″ transverse capability. Can build to specific product descriptions or provide recommendations based on movement and pressure requirements.

5. PD Blowers – Pipe Expansion Joints

Domain: pdblowers.com

Registered: 1998 (27 years)

Introduction: Pipe Expansion Joints isolate the blower or vacuum pump from other system components to allow for thermal expansion and misalignment of the piping. Common flanged rubber expansion joints feature single or double arched bellows constructed of molded elastomers, specifically EPDM elastomer. Functions include reducing flange loading on the blower, allowing thermal expansion of the blower casing, prov…

Strategic Sourcing Conclusion and Outlook for pipe expansion joints

As the demand for efficient and reliable piping systems grows globally, the strategic sourcing of pipe expansion joints becomes increasingly vital for businesses across Africa, South America, the Middle East, and Europe. By prioritizing high-quality materials and innovative designs, companies can enhance the durability and performance of their piping systems, ultimately reducing downtime and maintenance costs. Understanding the specific requirements for various applications, such as thermal expansion and seismic considerations, is crucial for selecting the right expansion joints.

Furthermore, engaging with trusted suppliers who provide comprehensive technical support and customized solutions can significantly streamline the procurement process. This not only ensures compliance with international standards but also enhances overall system efficiency.

Looking ahead, businesses should leverage advancements in technology and materials to optimize their piping systems. By fostering strategic partnerships with leading manufacturers, buyers can stay ahead of market trends and achieve sustainable growth. Take the initiative today to explore the vast array of options available in pipe expansion joints, ensuring your operations are prepared to meet future challenges with confidence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.