How to Source Dot Peening Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for dot peening

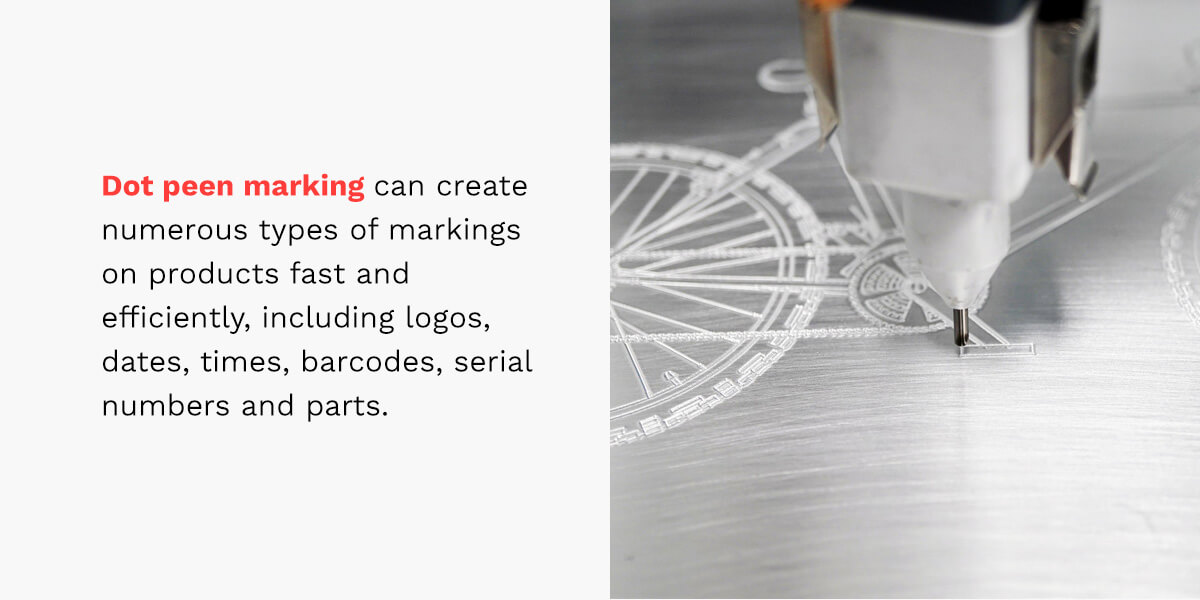

In the fast-paced world of manufacturing, ensuring accurate and reliable product identification is a critical challenge that many B2B buyers face. Dot peening, a versatile marking technology, has emerged as a solution that combines precision with efficiency, offering manufacturers the ability to automate their part marking processes effectively. This comprehensive guide delves into the various aspects of dot peening, including the different types of marking systems available, their applications across industries, and essential considerations for supplier vetting.

Whether you are operating in Africa, South America, the Middle East, or Europe, understanding the nuances of dot peening technology can significantly enhance your operational efficiency and traceability. From evaluating cost implications to integrating advanced marking solutions into your production line, this guide empowers international B2B buyers by providing actionable insights tailored to their specific needs.

By exploring the benefits of dot peening over traditional marking methods, you will be equipped to make informed purchasing decisions that can streamline your operations, reduce errors, and ultimately drive profitability. Join us as we navigate the global market for dot peening, ensuring you have all the information needed to invest wisely in your manufacturing processes.

Understanding dot peening Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Integrated Systems | Automated, in-line marking for production lines | High-volume manufacturing | Pros: Increases throughput; Cons: Higher initial investment. |

| Benchtop Markers | Stationary units for dedicated marking tasks | Small to medium production runs | Pros: Versatile; Cons: Limited mobility. |

| Portable Markers | Battery-operated, hand-held devices for on-the-go marking | Fieldwork, maintenance, and repairs | Pros: Flexibility; Cons: May have lower power. |

| Deep Marking Systems | Enhanced depth control for marking hard materials | Aerospace, automotive, and heavy machinery | Pros: Durable marks; Cons: Slower marking speed. |

| Tag Marking Machines | Specialized for metal tags and plates | Identification and inventory management | Pros: Efficient for tags; Cons: Limited to tag applications. |

What are Integrated Systems in Dot Peening?

Integrated systems are designed for seamless automation in high-volume production environments. These systems allow manufacturers to directly incorporate marking processes into their assembly lines, ensuring consistency and speed. They are particularly suitable for industries that require high traceability, such as automotive and electronics. When considering an integrated system, buyers should evaluate compatibility with existing machinery and the potential return on investment through increased efficiency.

How Do Benchtop Markers Function?

Benchtop markers serve as versatile solutions for businesses that need reliable marking in smaller production runs. These units are typically fixed in place and can handle a variety of materials and shapes, making them ideal for custom projects. Companies should consider their workspace constraints and the types of products they regularly mark when investing in benchtop solutions, as these can optimize production without the need for extensive floor space.

What Advantages Do Portable Markers Offer?

Portable dot peen markers are ideal for industries that require mobility, such as construction, maintenance, and field repairs. Their battery-operated design allows for marking in locations without electrical access, making them highly versatile. Buyers should assess the durability and battery life of these units, as well as their ability to produce high-quality marks on various surfaces, to ensure they meet operational needs.

What Are Deep Marking Systems Best Suited For?

Deep marking systems provide enhanced marking capabilities, particularly for hard materials found in sectors like aerospace and automotive. These systems allow for deeper engravings that are more resistant to wear and tear, ensuring that identification remains intact throughout the product lifecycle. Buyers should consider the specific material types they work with and the importance of mark durability when selecting deep marking solutions, as these can significantly impact long-term product identification.

How Do Tag Marking Machines Enhance Operations?

Tag marking machines are specialized tools designed for the efficient marking of metal tags and plates, commonly used for inventory management and product identification. They provide quick and precise engravings, which are essential for maintaining organized systems in warehouses and manufacturing plants. When evaluating tag marking machines, businesses should consider their tagging volume and the types of materials they typically work with to ensure optimal performance and efficiency.

Key Industrial Applications of dot peening

| Industry/Sector | Specific Application of dot peening | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Marking vehicle components with VINs and barcodes | Ensures traceability and compliance with regulations | Need for high-speed systems that integrate with production lines; consider durability against harsh environments. |

| Aerospace | Identification of parts and assemblies | Enhances safety through reliable traceability | Systems must accommodate various materials and ensure precision; international certification may be required. |

| Electronics | Marking circuit boards and electronic components | Facilitates inventory management and quality control | Machines should handle small, intricate designs; consider compatibility with automated assembly lines. |

| Construction & Heavy Machinery | Marking equipment parts for maintenance tracking | Reduces downtime and improves maintenance efficiency | Portable systems may be needed for large equipment; ensure ruggedness for outdoor use. |

| Medical Devices | Permanent marking on surgical instruments | Guarantees compliance with stringent health regulations | High precision and durability are essential; consider the ability to mark on various materials, including metals and plastics. |

How is Dot Peening Used in the Automotive Sector?

In the automotive industry, dot peening is extensively used for marking vehicle components, such as VINs and barcodes. This ensures traceability and compliance with safety regulations, which is crucial for manufacturers and suppliers. Dot peening systems can be integrated into high-speed production lines, allowing for quick and accurate marking without disrupting workflow. Buyers should prioritize systems that are durable and can withstand the harsh conditions often found in automotive manufacturing environments.

What Role Does Dot Peening Play in Aerospace Applications?

Dot peening technology is vital in the aerospace sector for marking parts and assemblies with unique identifiers. This practice enhances safety by ensuring that every component can be traced back to its manufacturing process, which is critical for compliance with strict industry regulations. Buyers in this sector must seek systems that can handle various materials and provide exceptional precision, as the integrity of aerospace components is paramount. Additionally, international certifications may be required for equipment to meet global standards.

How is Dot Peening Beneficial for Electronics Manufacturing?

In electronics, dot peening is employed to mark circuit boards and electronic components with identifying information. This facilitates inventory management and quality control, ensuring that each component can be traced throughout its lifecycle. Buyers should look for machines that can handle intricate designs and are compatible with automated assembly lines. Reliability and speed are essential, as electronic manufacturing often demands quick turnaround times and high accuracy.

What Applications Does Dot Peening Have in Construction and Heavy Machinery?

Dot peening is used in the construction and heavy machinery sector for marking equipment parts to track maintenance and service histories. This practice significantly reduces downtime and enhances maintenance efficiency, as operators can quickly identify parts that require servicing. Buyers may need portable marking systems that can be used on-site, and durability is crucial, given the outdoor and rugged environments in which this equipment operates.

How is Dot Peening Applied in Medical Device Manufacturing?

In the medical device industry, dot peening is essential for permanently marking surgical instruments and devices. This ensures compliance with stringent health regulations, as clear and indelible markings are necessary for traceability in the event of recalls or audits. Buyers should focus on systems that offer high precision and can mark on a variety of materials, including metals and plastics, to meet diverse product requirements.

3 Common User Pain Points for ‘dot peening’ & Their Solutions

Scenario 1: Challenges with Mark Quality on Rough Surfaces

The Problem: Many manufacturers struggle with achieving high-quality marks on rough or uneven surfaces. Traditional marking methods, such as laser marking or hand stamping, often fail to deliver clear and durable marks, leading to issues with product traceability and identification. This can result in costly errors, rework, and even product recalls if items cannot be accurately traced back to their origin.

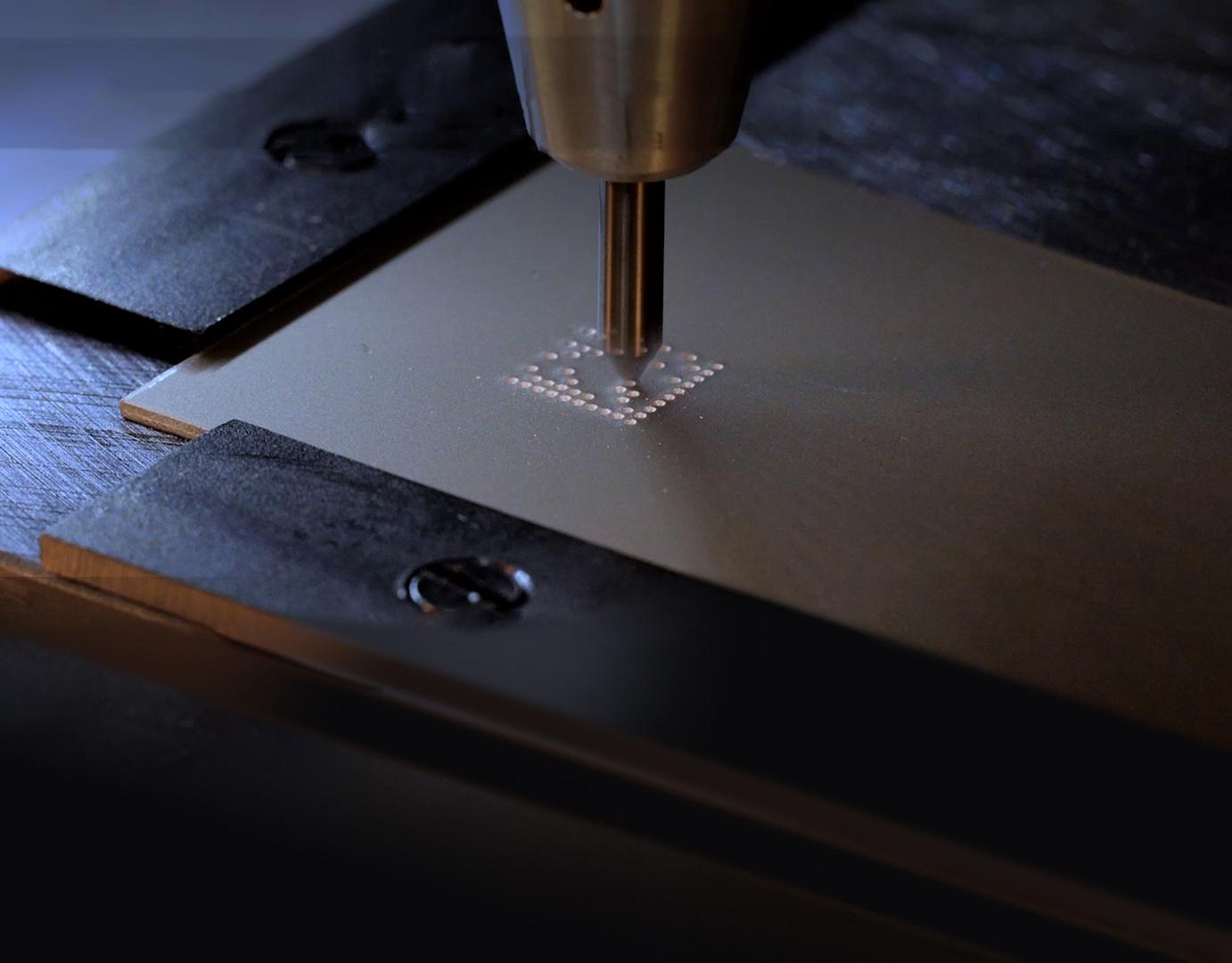

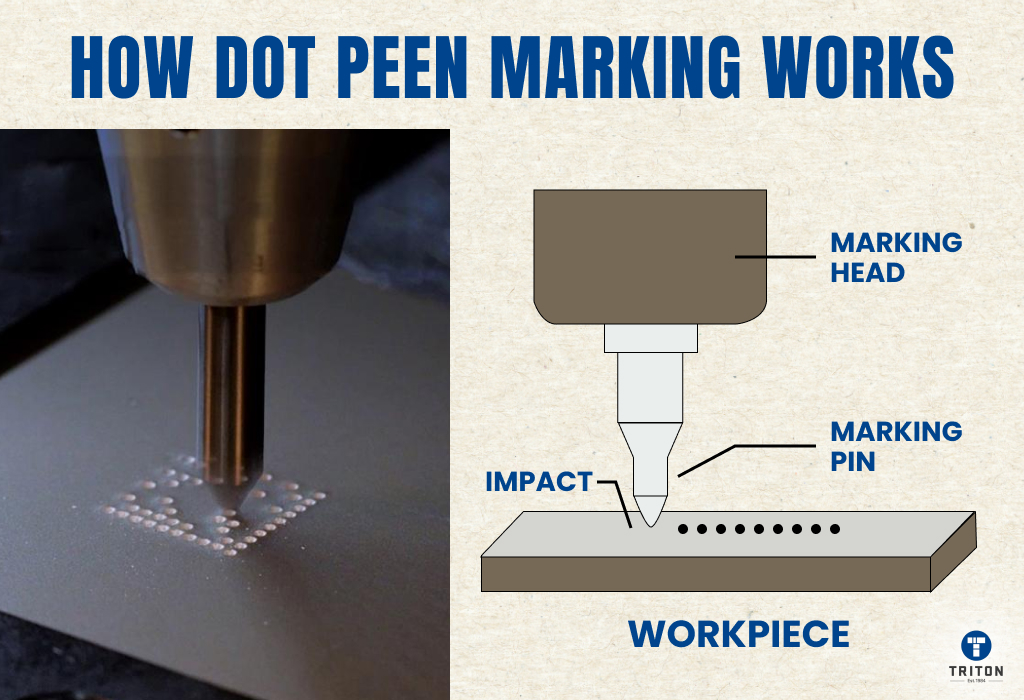

Illustrative image related to dot peening

The Solution: To overcome this challenge, B2B buyers should consider investing in advanced dot peen marking systems specifically designed for irregular surfaces. These machines utilize a pneumatically driven marking pin that creates precise indentations, ensuring that marks remain legible and permanent even on tough materials. When sourcing dot peening equipment, look for models that allow for adjustable marking depth and can effectively penetrate coatings or surface contaminants. Additionally, integrating these machines into your production line can enhance efficiency and accuracy, as they can be programmed to receive data automatically from existing systems like PLCs or barcode scanners. By making this upgrade, manufacturers can significantly reduce errors and enhance product traceability, ultimately improving operational reliability.

Scenario 2: High Operational Costs Due to Consumables

The Problem: Many companies face escalating operational costs due to the continuous need for consumables in traditional marking processes, such as inks for inkjet printers or gases for laser systems. These recurring expenses can eat into profit margins, especially for businesses operating in competitive markets where every cost must be justified.

The Solution: Dot peen marking technology presents a cost-effective alternative, as it does not require any consumables apart from the marking stylus itself. To maximize the cost-effectiveness of dot peening, buyers should select machines that are versatile and capable of handling a variety of materials without needing different consumable types. Additionally, consider battery-operated or portable models that can be used in diverse production environments, reducing the need for multiple machines. By performing a thorough cost-benefit analysis before purchasing, companies can evaluate the long-term savings associated with reduced consumable needs. Investing in reliable, durable dot peen machines can ultimately lead to significant savings and a more predictable budgeting process for manufacturing operations.

Scenario 3: Difficulty in Integrating Marking Systems into Existing Production Lines

The Problem: Many manufacturers find it challenging to integrate new marking technologies into their existing production processes. The complexity of compatibility with current systems, along with the potential for downtime during installation, can deter businesses from upgrading their marking methods. This hesitation can hinder productivity and prevent the realization of benefits associated with modern marking solutions.

The Solution: To address integration challenges, B2B buyers should seek dot peen marking systems that offer seamless compatibility with their current production setups. When evaluating options, look for machines that can easily interface with existing software systems, including PLCs and MES (Manufacturing Execution Systems). Suppliers should provide comprehensive support during the integration phase, including installation services and training for staff. Additionally, consider systems with flexible configurations, such as in-line, benchtop, or portable models, that can adapt to various production environments. Engaging with manufacturers who offer robust technical support and user-friendly interfaces can further ease the transition process. By prioritizing integration-friendly solutions, businesses can enhance productivity without significant disruptions, allowing them to take full advantage of the efficiency and accuracy benefits that dot peening technology offers.

Strategic Material Selection Guide for dot peening

What Materials Are Commonly Used in Dot Peening?

When selecting materials for dot peening, it is essential to consider their properties, advantages, and limitations. The following analysis covers four common materials used in dot peening applications: aluminum, stainless steel, carbon steel, and plastic. Each material presents unique characteristics that can significantly impact the marking process and end-product quality.

Aluminum: Lightweight and Versatile

Aluminum is a popular choice for dot peening due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating up to 600°F (316°C) and can withstand moderate pressure. The primary advantage of using aluminum is its durability, allowing for clear and long-lasting marks even in harsh environments. However, it can be more expensive than other metals and may require specialized equipment to achieve optimal marking depth.

For international B2B buyers, aluminum is often compliant with various standards such as ASTM and ISO, making it a suitable choice for global markets. However, the cost can be a limiting factor for buyers in developing regions, where budget constraints are more pronounced.

Stainless Steel: Strength and Corrosion Resistance

Stainless steel is renowned for its strength and exceptional corrosion resistance, making it ideal for demanding applications. With a temperature rating exceeding 1000°F (537°C) and high-pressure tolerance, it is suitable for industries like automotive and aerospace. The primary advantage of stainless steel is its ability to maintain mark integrity in corrosive environments, ensuring product traceability.

Illustrative image related to dot peening

However, the hardness of stainless steel can pose challenges during the dot peening process, potentially leading to increased wear on marking pins. For buyers in regions like Europe and the Middle East, where quality standards are stringent, stainless steel is often a preferred choice despite its higher cost compared to other materials.

Carbon Steel: Cost-Effective and Robust

Carbon steel is a widely used material for dot peening due to its cost-effectiveness and robustness. It typically has a temperature rating of around 500°F (260°C) and can handle moderate pressure. The advantages of carbon steel include its affordability and ease of machining, which can reduce manufacturing complexity. However, it is less corrosion-resistant than aluminum or stainless steel, making it less suitable for applications exposed to harsh environments.

International buyers should be aware of the varying grades of carbon steel and their compliance with standards like ASTM and JIS. In regions such as South America and Africa, where budget constraints are significant, carbon steel can be an attractive option, but buyers must consider the potential for corrosion and the need for protective coatings.

Plastic: Lightweight and Flexible

Plastic materials, particularly engineering plastics like polycarbonate and nylon, are increasingly used in dot peening applications. These materials are lightweight, flexible, and can be engineered to withstand a range of temperatures and pressures. The primary advantage of using plastic is its ability to produce clear, durable marks without the risk of damaging the substrate, making it ideal for delicate applications.

However, plastics generally have lower temperature and pressure ratings compared to metals, which may limit their use in high-stress environments. For international buyers, compliance with standards such as ISO can vary, and preferences may differ based on local regulations. In markets like Brazil and Vietnam, where lightweight materials are favored, plastics can be a viable option, provided that the application does not require extreme durability.

Illustrative image related to dot peening

Summary Table of Material Selection for Dot Peening

| Material | Typical Use Case for dot peening | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components | Excellent corrosion resistance | Higher cost compared to other metals | Medium |

| Stainless Steel | Automotive parts | High strength and durability | Increased wear on marking pins | High |

| Carbon Steel | Industrial machinery | Cost-effective and robust | Less corrosion resistance | Low |

| Plastic | Consumer goods | Lightweight and flexible | Limited temperature and pressure ratings | Medium |

This strategic material selection guide provides B2B buyers with essential insights into choosing the right materials for dot peening applications, ensuring optimal performance and compliance across diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for dot peening

The manufacturing process of dot peening involves several critical stages, each designed to ensure the production of high-quality marking systems that meet industry standards. This section provides an in-depth overview of typical manufacturing processes and quality assurance practices, tailored specifically for B2B buyers across diverse global markets.

What Are the Main Stages of the Dot Peening Manufacturing Process?

How Is Material Prepared for Dot Peening Marking Systems?

The initial stage in the manufacturing process involves careful material preparation. Key materials typically include steel, aluminum, and other metals that are durable enough to withstand the marking process. Manufacturers conduct a thorough analysis of these materials to ensure they meet the required specifications for hardness and surface finish. Surface cleaning is also crucial, as contaminants can affect the quality of the marks. Techniques like sandblasting or chemical cleaning may be employed to prepare surfaces, ensuring optimal adhesion and marking clarity.

Illustrative image related to dot peening

What Techniques Are Used in the Forming Stage of Dot Peening?

In the forming stage, components of the dot peening machines are produced using precision machining techniques. CNC (Computer Numerical Control) machines are commonly utilized to achieve the tight tolerances required for high-quality marking systems. This stage may involve milling, turning, and drilling operations to create parts such as the marking pin, housing, and other mechanical components. The use of high-quality materials and advanced manufacturing techniques ensures that the machines are robust and reliable.

How Is Assembly Conducted in Dot Peening Manufacturing?

Once the components are formed, they proceed to the assembly stage. This involves the integration of various parts, including the marking mechanism, control systems, and user interfaces. Skilled technicians meticulously assemble the machines, ensuring each component is correctly positioned and secured. During assembly, manufacturers often conduct preliminary checks to ensure that all parts fit together seamlessly, which is essential for the machine’s performance and longevity.

What Finishing Techniques Are Applied to Dot Peening Machines?

The finishing stage involves several processes designed to enhance the durability and aesthetics of the dot peening machines. This may include surface treatments such as anodizing or powder coating, which provide corrosion resistance and improve the machine’s appearance. Final adjustments are made during this stage to fine-tune operational settings and ensure that all systems are functioning correctly. A thorough cleaning process is also performed to remove any residues from manufacturing before the machines are packaged for delivery.

What Are the Key Quality Assurance Practices in Dot Peening Manufacturing?

How Do International Standards Impact Quality Control in Dot Peening?

Quality assurance in dot peening manufacturing is guided by relevant international standards, such as ISO 9001, which focuses on quality management systems. Compliance with these standards is essential for ensuring that manufacturers maintain consistent product quality and customer satisfaction. Additionally, industry-specific certifications, such as CE (Conformité Européenne) for products sold in the European market and API (American Petroleum Institute) for oil and gas applications, may be required, depending on the end-use of the marking systems.

What Are the Critical QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically integrated into the manufacturing process to ensure product integrity. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to confirm they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, allowing for immediate corrective action.

- Final Quality Control (FQC): Completed machines undergo rigorous testing to verify functionality, marking quality, and adherence to specifications before shipment.

These checkpoints help to minimize defects and ensure that only high-quality products reach the end-users.

What Common Testing Methods Are Used to Ensure Quality in Dot Peening?

Several testing methods are commonly employed to evaluate the performance and durability of dot peening machines. These may include:

- Mark Quality Tests: Assessing the clarity, depth, and permanence of the marks produced on various materials.

- Durability Tests: Subjecting machines to stress tests to evaluate their performance under different operational conditions.

- Functionality Tests: Ensuring that all components operate as intended, including the marking mechanism and control interfaces.

Such testing ensures that the machines not only meet operational requirements but also fulfill the specific needs of various industries.

How Can B2B Buyers Verify Supplier Quality Control?

What Steps Should Buyers Take to Audit Suppliers?

B2B buyers should conduct thorough audits of potential suppliers to verify their quality control processes. This can involve:

Illustrative image related to dot peening

- Requesting Documentation: Suppliers should provide ISO certifications, quality control reports, and details of their manufacturing processes.

- On-Site Visits: Whenever feasible, visiting the manufacturing facilities can provide insights into the supplier’s operations and adherence to quality standards.

- Third-Party Inspections: Engaging independent inspectors can offer an unbiased assessment of a supplier’s quality assurance practices.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Regulatory requirements may differ significantly across countries, affecting the acceptability of certain marking technologies or materials. Understanding local market standards, as well as international compliance requirements, is crucial for avoiding costly delays or compliance issues.

In conclusion, the manufacturing processes and quality assurance practices surrounding dot peening are integral to delivering reliable and efficient marking solutions. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dot peening’

In the competitive landscape of manufacturing, dot peening offers a reliable solution for part marking and traceability. This guide provides a step-by-step checklist for B2B buyers looking to procure dot peening systems, ensuring informed decision-making and optimal investment.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is essential before sourcing a dot peening system. Consider factors such as the types of materials you will be marking, the depth and clarity of markings needed, and whether you require integration with existing production lines. Documenting these specifications will help you communicate your needs effectively to potential suppliers.

Step 2: Research Available Technologies

Familiarize yourself with the various dot peening technologies available in the market. Different machines offer unique features such as programmable marking depths, integration capabilities, and adaptability to various surfaces. Knowing these details allows you to compare options and select a system that aligns with your operational goals.

Illustrative image related to dot peening

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Pay attention to the supplier’s reputation, warranty offerings, and customer support services, as these factors can significantly impact your long-term satisfaction.

Step 4: Assess Compliance and Certifications

Verify that the suppliers comply with relevant industry standards and regulations. Check for certifications such as ISO or CE, which demonstrate a commitment to quality and safety. Compliance ensures that the machines meet necessary operational and environmental standards, reducing potential risks.

Step 5: Request Demonstrations and Samples

Whenever possible, request product demonstrations or samples from potential suppliers. This hands-on experience allows you to assess the machine’s performance in real-world conditions, ensuring it meets your marking quality requirements. Look for clarity, durability, and ease of use during these evaluations.

Step 6: Consider Total Cost of Ownership (TCO)

Analyze the total cost of ownership, including not just the purchase price but also maintenance, operational costs, and potential downtime. Dot peening systems typically have low consumable costs and require minimal maintenance, making them a cost-effective choice in the long run. Ensure you account for all these factors when comparing suppliers.

Step 7: Negotiate Terms and Finalize the Agreement

Once you have chosen a supplier, engage in negotiations to secure favorable terms. Discuss payment options, delivery timelines, and after-sales support. A clear agreement protects both parties and helps establish a foundation for a successful partnership, ensuring you receive the best value for your investment.

By following this checklist, B2B buyers can streamline their sourcing process for dot peening systems, leading to informed decisions that enhance production efficiency and product traceability.

Comprehensive Cost and Pricing Analysis for dot peening Sourcing

What Are the Key Cost Components in Dot Peening Sourcing?

When sourcing dot peening solutions, several cost components must be considered to fully understand the pricing structure. These include:

-

Materials: The primary material involved in dot peening is the marking stylus or pin, typically made from durable materials like carbide. The quality and type of stylus can significantly impact the overall cost, especially if specialized pins for hard materials are required.

-

Labor: Labor costs include the expenses associated with operating the dot peening machines, maintenance, and programming. Automation can reduce labor requirements, but initial setup and training for staff to handle sophisticated marking systems may be necessary.

-

Manufacturing Overhead: This encompasses expenses related to the production environment, including utilities, rent, and indirect labor. The efficiency of the manufacturing process can greatly influence these costs.

-

Tooling: Tooling costs involve the expenses for specialized fixtures and setups required for specific applications. Investing in high-quality tooling can enhance precision and reduce waste.

-

Quality Control (QC): Ensuring that dot peening meets industry standards necessitates a robust QC process. This can involve testing for mark durability and readability, which adds to the overall cost.

-

Logistics: Shipping and handling costs are influenced by the location of suppliers and the final destination. Understanding Incoterms can help buyers manage these costs effectively.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on competition and market demand.

How Do Price Influencers Affect Dot Peening Costs?

Several factors influence the pricing of dot peening solutions, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to reduced pricing per unit due to economies of scale. Buyers should negotiate terms that favor larger orders whenever possible.

-

Specifications and Customization: Custom requirements for specific applications can increase costs. Standardized solutions are typically more cost-effective, while specialized markings (e.g., logos, unique codes) may require additional investment.

-

Materials and Quality Certifications: Higher-quality materials or specific certifications (ISO, CE) can drive up costs. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer competitive pricing to gain market share.

-

Incoterms: Understanding shipping terms can help buyers anticipate additional costs related to freight, insurance, and customs duties. Choosing the right Incoterm can result in significant savings.

What Are the Best Buyer Tips for Cost-Efficiency in Dot Peening?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Terms: Engage suppliers in discussions about pricing, delivery timelines, and payment terms. Establishing a good relationship can lead to better deals in the long run.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, operation, and potential downtime. A cheaper machine may lead to higher operational costs over time.

-

Understand Pricing Nuances for International Markets: Be aware of regional market conditions and currency fluctuations, which can impact pricing. Buyers in emerging markets should seek suppliers familiar with local challenges and regulations.

-

Request Sample Marks: Before committing to a large order, ask suppliers for sample marks to evaluate quality. This can prevent costly rework and ensure that the chosen solution meets your requirements.

Disclaimer on Indicative Prices

Prices for dot peening systems and services can vary significantly based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing and value for money.

Alternatives Analysis: Comparing dot peening With Other Solutions

Exploring Alternatives to Dot Peening: A Comparative Analysis

In the realm of industrial marking solutions, dot peening stands out for its precision and durability. However, various alternatives can cater to different operational needs and constraints. Understanding these alternatives allows B2B buyers to make informed decisions based on their specific requirements, including production volume, budget, and material types.

| Comparison Aspect | Dot Peening | Laser Marking | Hand Stamping |

|---|---|---|---|

| Performance | High precision; durable marks on various surfaces | Excellent for detailed designs; can mark quickly | Inconsistent; labor-intensive |

| Cost | Moderate initial investment; low ongoing costs | High upfront cost; requires consumables | Low initial cost; high labor costs |

| Ease of Implementation | Requires integration with systems; user-friendly | Complex setup; skilled operators needed | Simple setup; manual operation |

| Maintenance | Low; only stylus replacement needed | Moderate; lens cleaning and recalibration required | High; prone to wear and tear |

| Best Use Case | High-volume production with varied materials | High-detail applications; plastics and metals | Low-volume, custom marking |

Detailed Breakdown of Alternative Solutions

Laser Marking

Laser marking technology is renowned for its high precision and capability to produce intricate designs. It utilizes focused light to etch or engrave surfaces, making it ideal for detailed applications such as logos or barcodes. However, the initial investment is significant, and ongoing costs can arise from consumables like lenses and cleaning materials. Additionally, lasers can generate heat, which may damage heat-sensitive materials, and they require skilled operators to manage setup and operation effectively.

Hand Stamping

Hand stamping is one of the oldest marking methods, involving physical tools to imprint characters or designs manually. This method is simple to implement and does not require advanced technology or significant capital investment. However, it is labor-intensive and prone to human error, leading to inconsistent quality. It is best suited for low-volume production or custom marking needs, where flexibility is essential. The ongoing labor costs can outweigh the initial savings, particularly in high-throughput environments.

Conclusion: Choosing the Right Marking Solution for Your Needs

Selecting the appropriate marking technology requires careful consideration of your operational needs and constraints. Dot peening offers a balanced solution, providing durability, precision, and low maintenance costs, making it suitable for high-volume production across diverse materials. In contrast, laser marking excels in applications requiring intricate designs but comes with higher costs and complexity. Hand stamping, while cost-effective for low-volume projects, may not meet the efficiency demands of modern manufacturing. By assessing performance, cost, ease of implementation, and maintenance requirements, B2B buyers can identify the most suitable marking solution tailored to their unique operational landscape.

Essential Technical Properties and Trade Terminology for dot peening

What Are the Key Technical Properties of Dot Peening That B2B Buyers Should Know?

Understanding the essential technical properties of dot peening is critical for B2B buyers looking to enhance their manufacturing processes. Here are some key specifications that influence the effectiveness and efficiency of dot peening systems:

-

Material Compatibility

Dot peening machines are designed to work on a variety of materials, including metals, plastics, and composites. The ability to mark on both hard and soft surfaces ensures versatility in production. For manufacturers in sectors such as automotive or aerospace, selecting a marking solution that can handle different materials without compromising quality is vital for maintaining production efficiency. -

Marking Depth and Resolution

The depth of the marks produced can be adjusted, typically ranging from light to deep impressions. A standard resolution of 0.025mm is common, allowing for high precision in marking characters, logos, or Data Matrix codes. This adaptability is crucial for industries that require clear and permanent identification of parts, which aids in traceability and compliance with regulatory standards. -

Operating Speed

Dot peening systems are engineered for high-speed operations, significantly increasing throughput on production lines. The ability to quickly mark parts reduces cycle times and enhances overall productivity. For B2B buyers, investing in faster marking technology can lead to substantial cost savings and improved delivery timelines. -

Automation Capability

Many dot peening machines can be integrated with automated production lines, allowing for seamless data transfer from PLCs or host systems. This integration facilitates real-time marking, which minimizes human error and increases operational efficiency. For businesses scaling operations, the ability to automate marking processes is essential for maintaining competitive advantage. -

Durability of Marks

Dot peening creates permanent marks resistant to solvents, abrasion, and chemicals. This durability is particularly important for products exposed to harsh environments, ensuring that identification remains intact throughout the product lifecycle. B2B buyers should prioritize systems that guarantee long-lasting marks to reduce the need for rework or replacement.

What Are Common Trade Terms Associated with Dot Peening?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Below are some common terms related to dot peening:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help identify trusted suppliers of dot peening technology that meet specific quality standards. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory planning, especially for businesses looking to implement dot peening solutions across multiple production lines. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price proposals from suppliers for specific products or services. In the context of dot peening, sending an RFQ can help buyers compare offers and negotiate better terms with suppliers. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms is important for B2B buyers involved in cross-border transactions involving dot peening machinery, as they dictate shipping responsibilities, risk, and costs. -

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with acquiring and operating a product over its lifecycle. For dot peening systems, understanding TCO helps buyers evaluate the long-term financial implications, including maintenance, training, and consumables.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the dot peening Sector

What Are the Key Market Drivers Influencing Dot Peening Technology?

The dot peening sector is experiencing robust growth driven by several global factors. As industries increasingly prioritize automation and efficiency, dot peening marking technology has emerged as a reliable solution for precise, high-speed product identification. This technology is particularly advantageous for manufacturers in Africa, South America, the Middle East, and Europe, where increasing production demands require scalable solutions. Moreover, the need for stringent traceability and compliance in sectors like automotive, aerospace, and electronics is propelling the adoption of dot peening systems that can integrate seamlessly into existing production lines.

Illustrative image related to dot peening

Emerging B2B technology trends, such as the integration of IoT and Industry 4.0 principles, are transforming the landscape. Manufacturers are seeking machines that can not only mark but also collect data for real-time monitoring and analytics, enhancing operational efficiency. The rise of portable and battery-operated dot peening machines further caters to diverse operational environments, from large-scale factories to on-site installations in remote locations. Additionally, the growing emphasis on customization and flexibility in product marking is pushing suppliers to innovate and offer more versatile machines that can handle various materials and surfaces.

How Does Sustainability and Ethical Sourcing Influence Dot Peening Practices?

The environmental impact of industrial processes is increasingly scrutinized, making sustainability a critical consideration for businesses sourcing dot peening solutions. Dot peening technology inherently supports sustainable practices by eliminating the need for consumables like inks or hazardous chemicals, which reduces waste and lowers operational costs. Manufacturers are now focusing on sourcing equipment that not only meets production needs but also aligns with their sustainability goals.

Ethical sourcing in the dot peening sector involves selecting suppliers committed to responsible manufacturing practices. This includes ensuring the sustainability of raw materials used in machines and the longevity of products. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications are becoming vital in supplier evaluations. Buyers should prioritize suppliers who demonstrate transparency in their supply chains and have clear policies on reducing their carbon footprint. By fostering ethical partnerships, businesses not only enhance their brand reputation but also contribute positively to the environment and society.

What Is the Historical Context Behind Dot Peening Technology?

The evolution of dot peening technology can be traced back to the early 1990s when manufacturers sought more efficient and reliable methods for marking parts. Initially, traditional marking methods like hand stamping and chemical etching dominated the landscape, but these approaches were fraught with inefficiencies and potential errors. The advent of dot peening marked a significant shift, as it provided a programmable, automated solution that could adapt to various materials and surface conditions.

Over the years, advancements in pneumatic systems and electronic controls have enhanced the precision and speed of dot peening machines. Today, the technology is recognized for its ability to deliver high-quality, permanent marks on a wide range of substrates, including metals and plastics. As industries evolve and the demand for traceability and automation grows, dot peening technology continues to adapt, positioning itself as a vital tool in modern manufacturing processes.

Frequently Asked Questions (FAQs) for B2B Buyers of dot peening

-

How can I ensure the quality of dot peening equipment before purchasing?

To ensure the quality of dot peening equipment, request samples of markings from potential suppliers. Evaluate the clarity, depth, and durability of the marks on various materials. Additionally, check for certifications and compliance with international standards, such as ISO. Engaging with existing customers for testimonials or case studies can also provide insights into the supplier’s reliability and product performance. -

What are the key features to look for in a dot peening machine?

When selecting a dot peening machine, prioritize features such as marking speed, depth adjustment, and versatility in marking different surfaces. Look for systems with programmable capabilities for automation, as well as options for marking 2D Data Matrix codes for traceability. Ensure the machine is compatible with your existing production line and can handle the materials you work with, including those with coatings or irregular shapes. -

What are the common applications for dot peening technology?

Dot peening technology is widely used in industries such as automotive, aerospace, electronics, and metalworking for permanent product identification. Applications include marking serial numbers, logos, and barcodes on components and finished products. Its ability to mark on various surfaces, including rough or coated materials, makes it an ideal choice for enhancing traceability and compliance with industry regulations. -

What customization options are typically available for dot peening machines?

Most manufacturers offer customization options for dot peening machines, including specific marking sizes, depths, and configurations tailored to your products. You can also request software customization for program management or integration with existing production systems. Discuss your unique requirements with suppliers to find solutions that best fit your operational needs. -

What are the minimum order quantities (MOQs) for dot peening machines?

Minimum order quantities can vary significantly by supplier, typically ranging from one machine for smaller companies to bulk orders for larger manufacturers. It’s essential to communicate your needs and production volume with suppliers to negotiate favorable terms. Some suppliers may offer flexible MOQs for first-time buyers or during promotional periods, so inquire about these options. -

What payment terms should I expect when sourcing dot peening machines internationally?

Payment terms can differ based on the supplier’s policies and your negotiation. Common terms include a deposit upfront with the balance due upon shipment or delivery. For larger orders, suppliers may offer financing options or letter of credit arrangements to mitigate risk. Always clarify payment methods accepted and any currency fluctuations that might impact pricing. -

How can I vet suppliers for dot peening technology?

To vet suppliers, research their reputation through online reviews, industry forums, and trade associations. Request references and case studies to understand their experience with similar projects. Attend industry trade shows or exhibitions to meet suppliers in person and assess their capabilities. Verifying certifications and compliance with international quality standards is also crucial for ensuring product reliability. -

What logistics considerations should I keep in mind when importing dot peening machines?

When importing dot peening machines, consider shipping methods, import duties, and local regulations that may impact delivery times and costs. Coordinate with suppliers for shipping schedules and ensure proper documentation is provided for customs clearance. Engaging a reliable freight forwarder can help navigate complexities and ensure that your equipment arrives safely and on time.

Top 5 Dot Peening Manufacturers & Suppliers List

1. Pannier – Dot Peen Marking Systems

Domain: pannier.com

Registered: 1995 (30 years)

Introduction: Dot peen marking technology automates direct part marking for reliable traceability. Pannier’s dot peen marking systems provide high-quality, fast, and error-free marks on rough or uneven surfaces. They can mark 2D Data Matrix codes for enhanced traceability and use carbide marking pins for permanent marks on hard metals. Integration with PLCs, host systems, barcode scanners, or spreadsheets is st…

2. Technomark – Dot Peen Marking Solutions

Domain: technomark-inc.com

Registered: 2018 (7 years)

Introduction: Dot Peen marking is a part-marking technology that uses electromagnetic or pneumatic force to rapidly oscillate a carbide or diamond-tip stylus, creating indents on the surface of parts. It is a low-stress marking method that displaces material rather than removing it, making it suitable for materials with hardness up to 63 HRC. Dot Peen marking machines are versatile, allowing for both manual and…

3. Gravotech – LS100 Laser Engraver

Domain: gravotech.us

Registered: 2007 (18 years)

Introduction: Dot Peen Marking Technology by Gravotech offers a range of marking solutions suitable for various materials and applications. Key products include:

1. **Laser Tables**:

– **LS100**: Small CO2 laser engraver, marking area 460 x 305 mm, suitable for plastics, wood, glass, and painted surfaces.

– **LS100EX**: Medium CO2 or Fiber laser, marking area 610 x 305 mm, for plastics, wood, glass, meta…

4. Rocklin Manufacturing – FlyMarker® Handheld Marking Systems

Domain: rocklinmanufacturing.com

Registered: 2012 (13 years)

Introduction: FlyMarker® is a handheld, battery-operated dot peen marking system offered by Rocklin Manufacturing. Key models include the FlyMarker mini 65/30, mini 85/45 plus, and mini 120/45 plus. The FlyMarker mini 65/30 is lightweight, portable, and weighs 5 lbs, designed for marking various materials including plastics, aluminum, and hardened steel (up to 63 HRC). It eliminates the need for electrical or p…

5. HeatSign – Dot Peen Marking Solutions

Domain: heatsign.com

Registered: 2015 (10 years)

Introduction: Dot peen marking is a technique that creates permanent marks (numbers, text, logos) on various materials by indenting dots. It is suitable for a wide range of materials including metals (hardness less than HRC60) and plastics. The marks produced are durable and long-lasting, able to withstand harsh conditions without losing legibility, which is essential for product traceability and compliance. Do…

Strategic Sourcing Conclusion and Outlook for dot peening

In the evolving landscape of industrial manufacturing, dot peening emerges as a critical technology for ensuring product traceability and quality. As highlighted, the advantages of dot peen marking—such as its ability to deliver permanent, high-quality marks on various surfaces without the need for consumables—underscore its value in enhancing operational efficiency. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, investing in dot peening technology can lead to substantial cost savings and improved production throughput.

Strategic sourcing of dot peen marking systems not only streamlines the marking process but also minimizes errors, reducing the risk of rework and waste. As manufacturers increasingly prioritize automation and precision, the adoption of dot peen technology will become essential for maintaining competitive advantage.

Looking ahead, businesses must remain vigilant in evaluating suppliers who offer innovative, reliable solutions tailored to specific industrial needs. By embracing dot peening, companies can enhance their product identification capabilities while ensuring compliance with industry standards. As you consider your next procurement decisions, prioritize partners who align with these technological advancements to drive your operations forward.

Illustrative image related to dot peening

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.